Microstructure and mechanical properties of micro/nano B4C particle reinforced 6061Al matrix composites

-

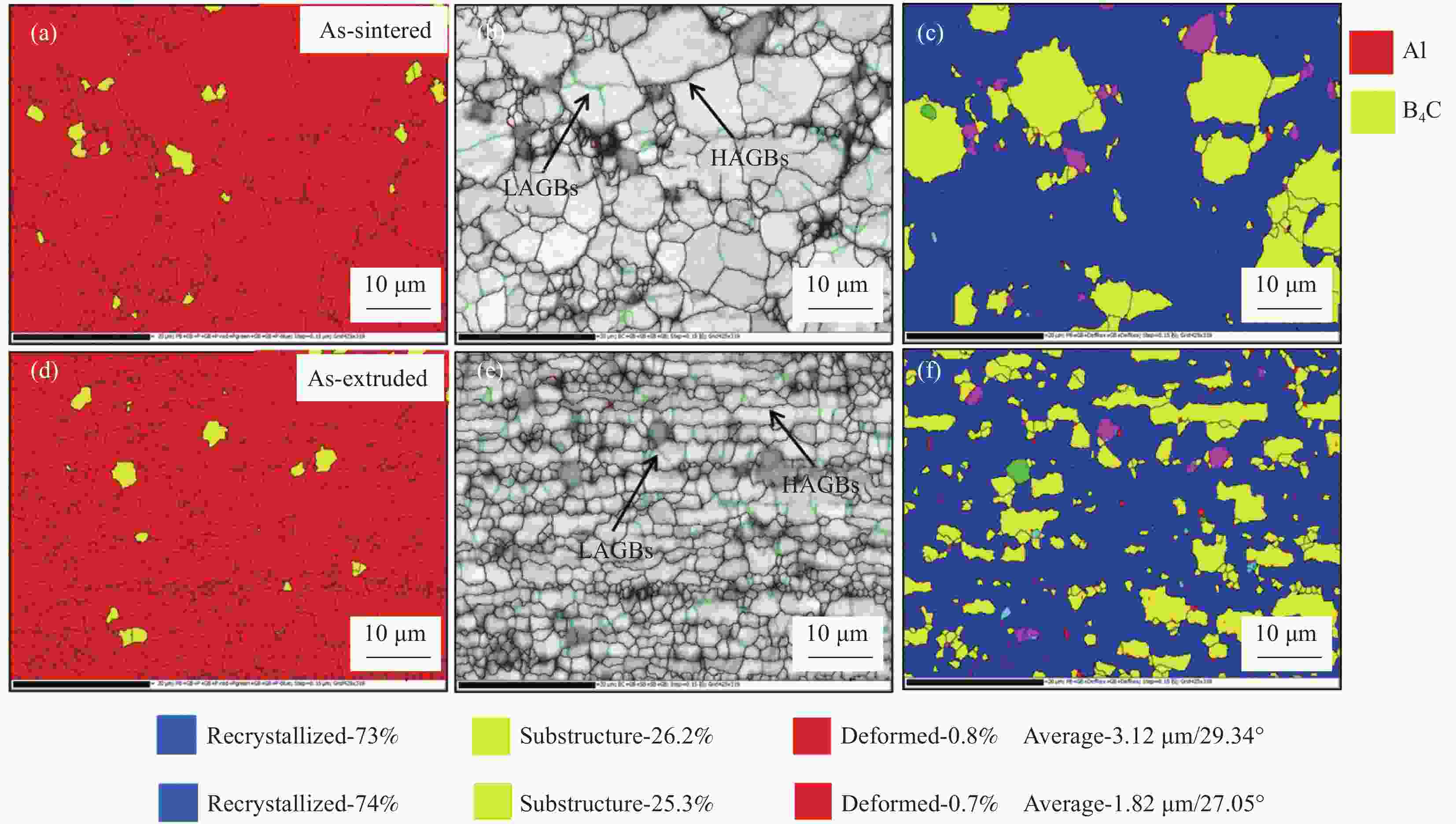

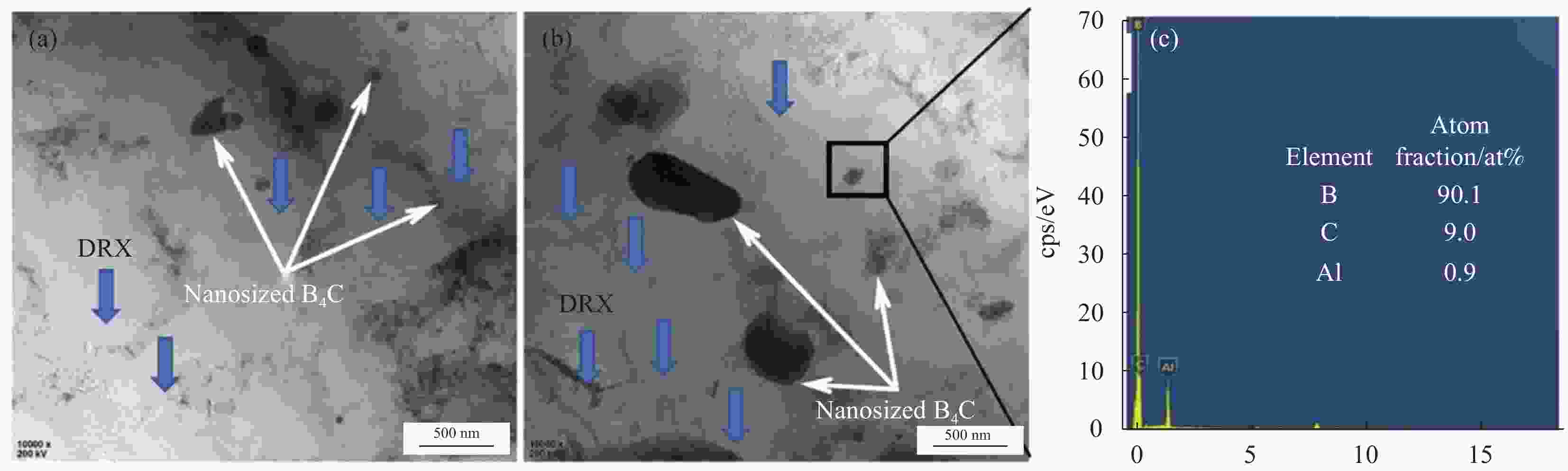

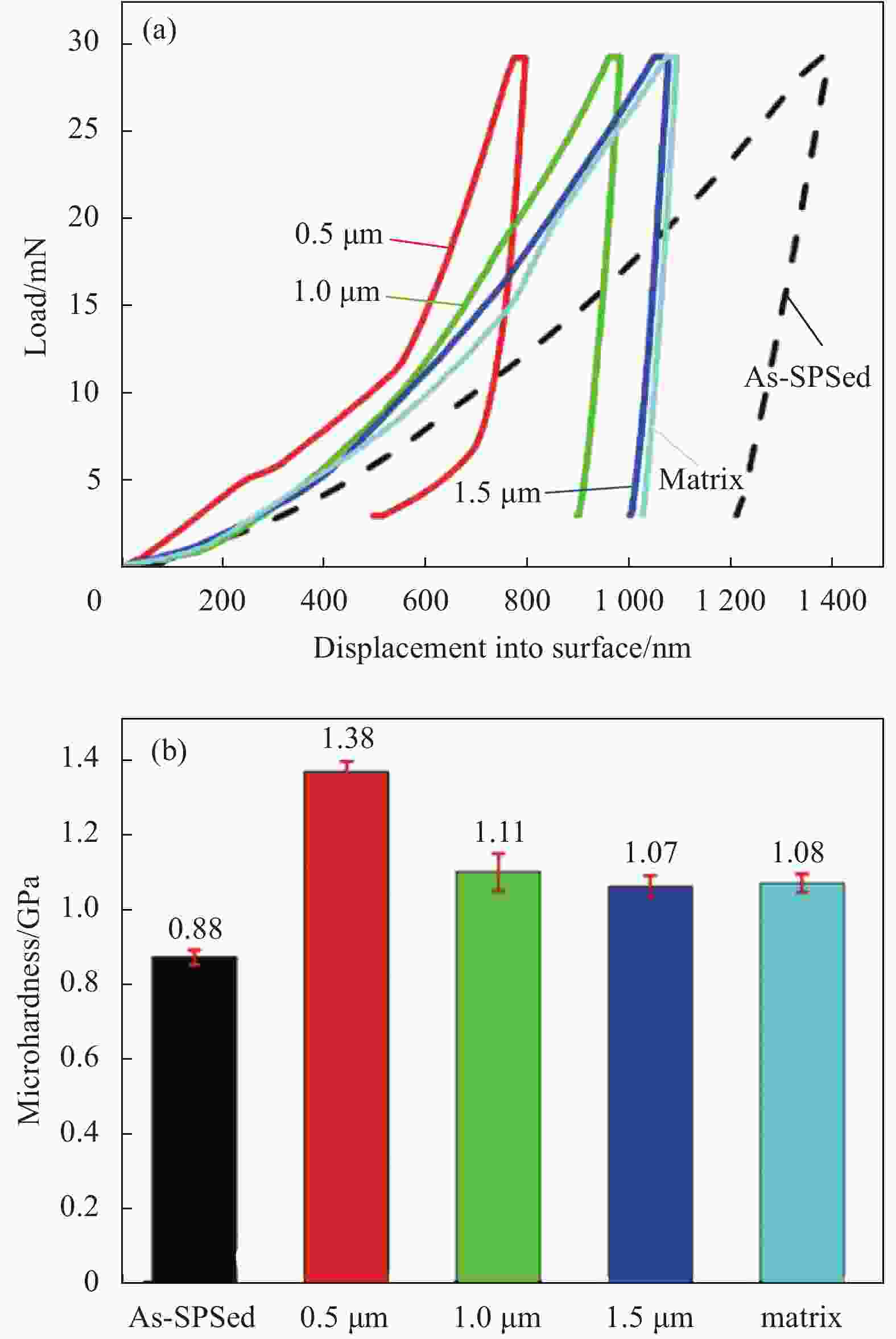

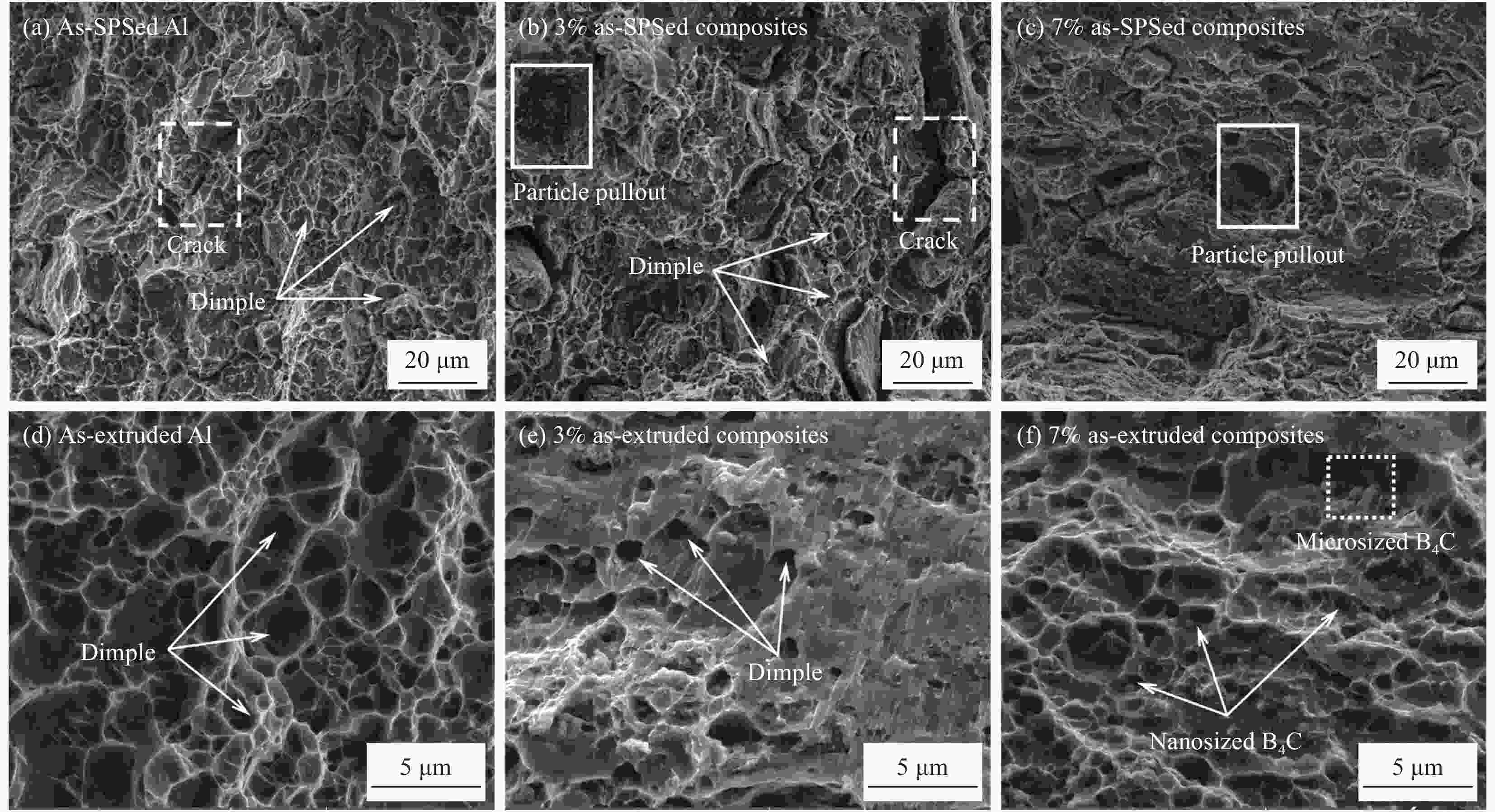

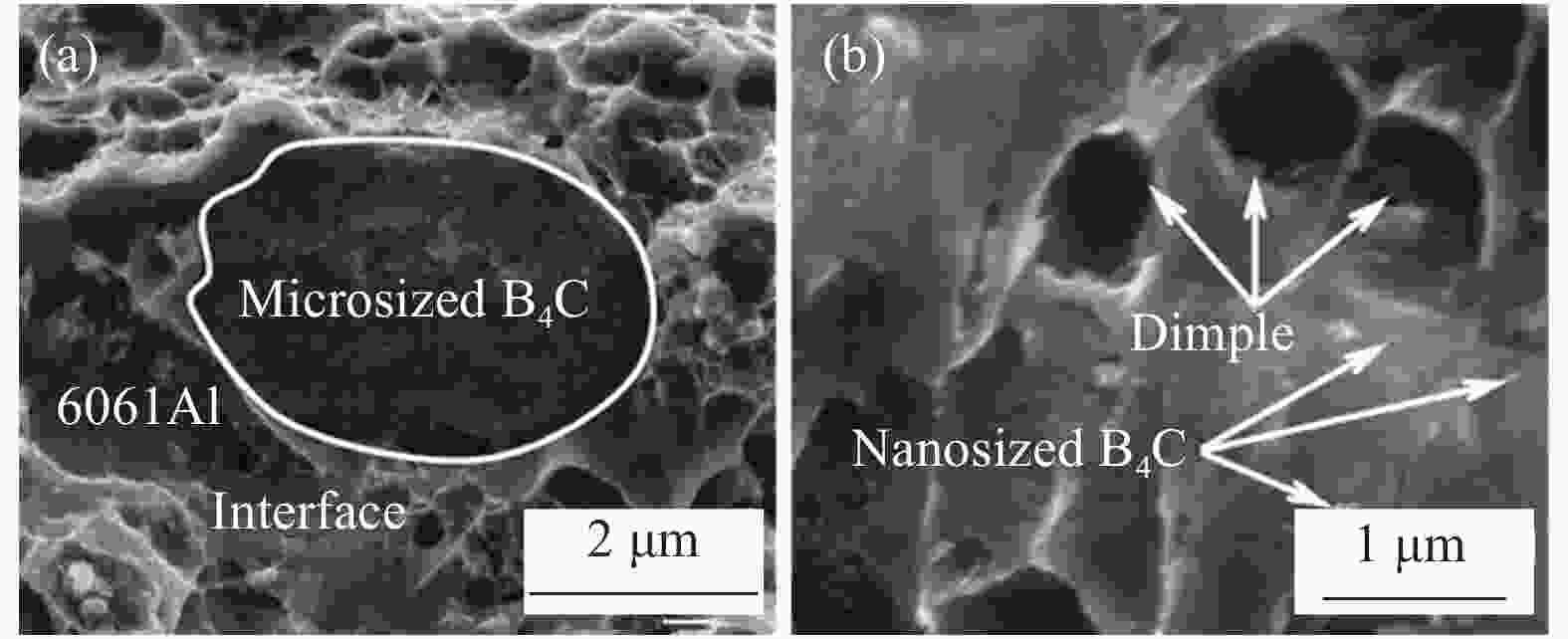

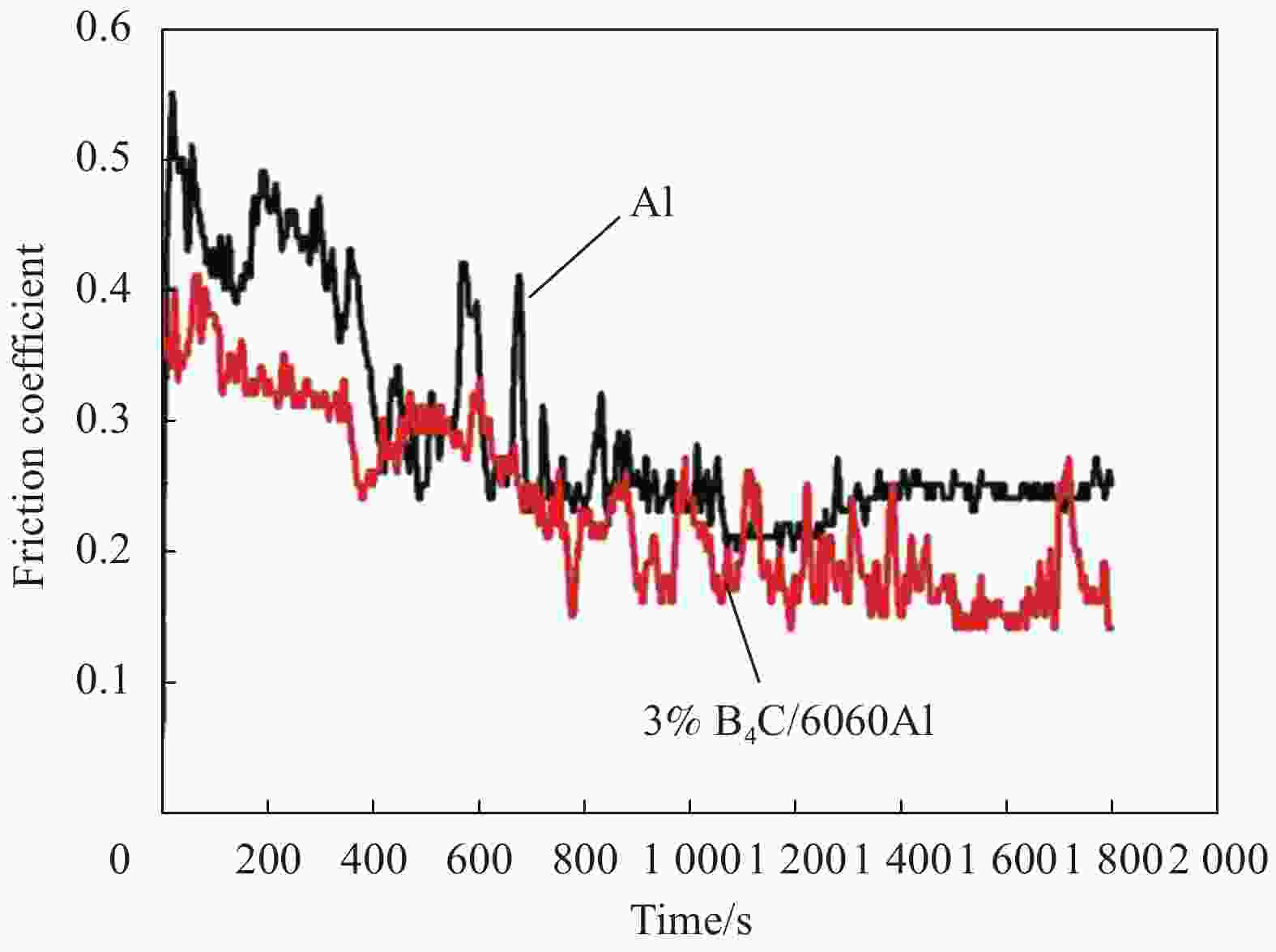

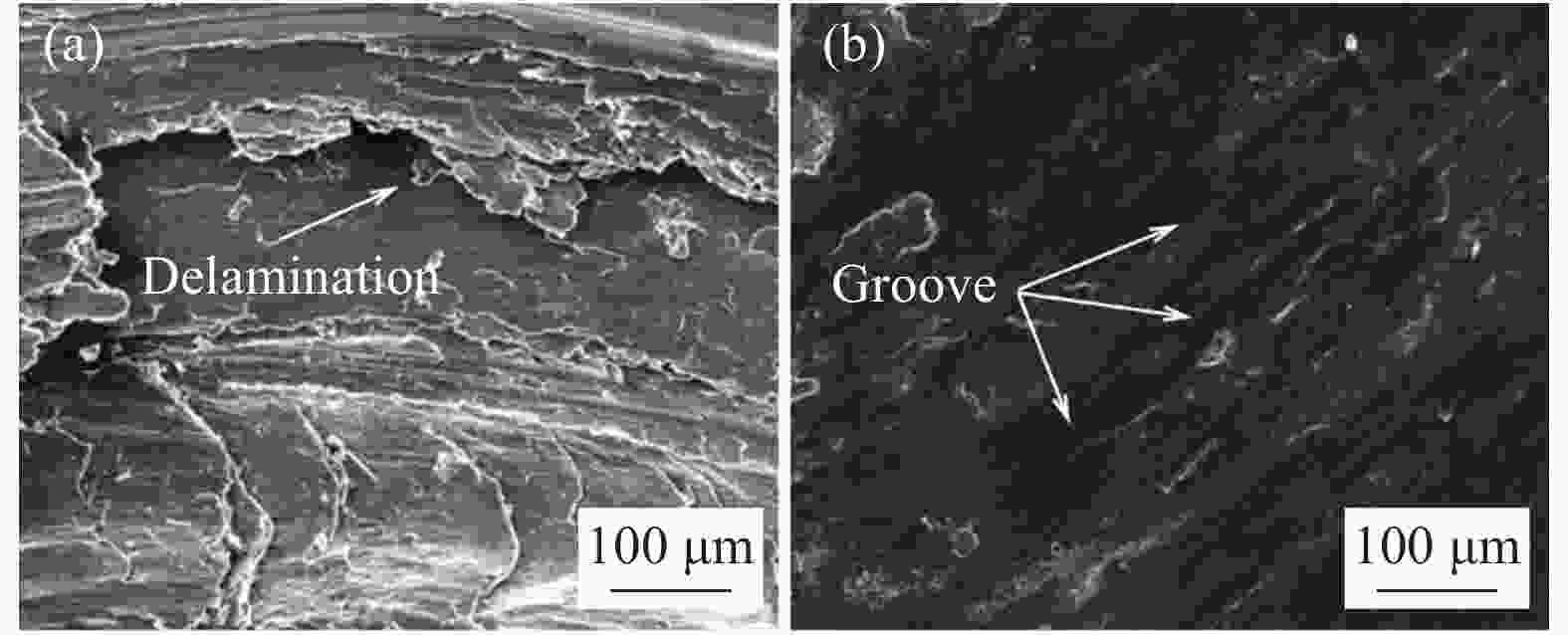

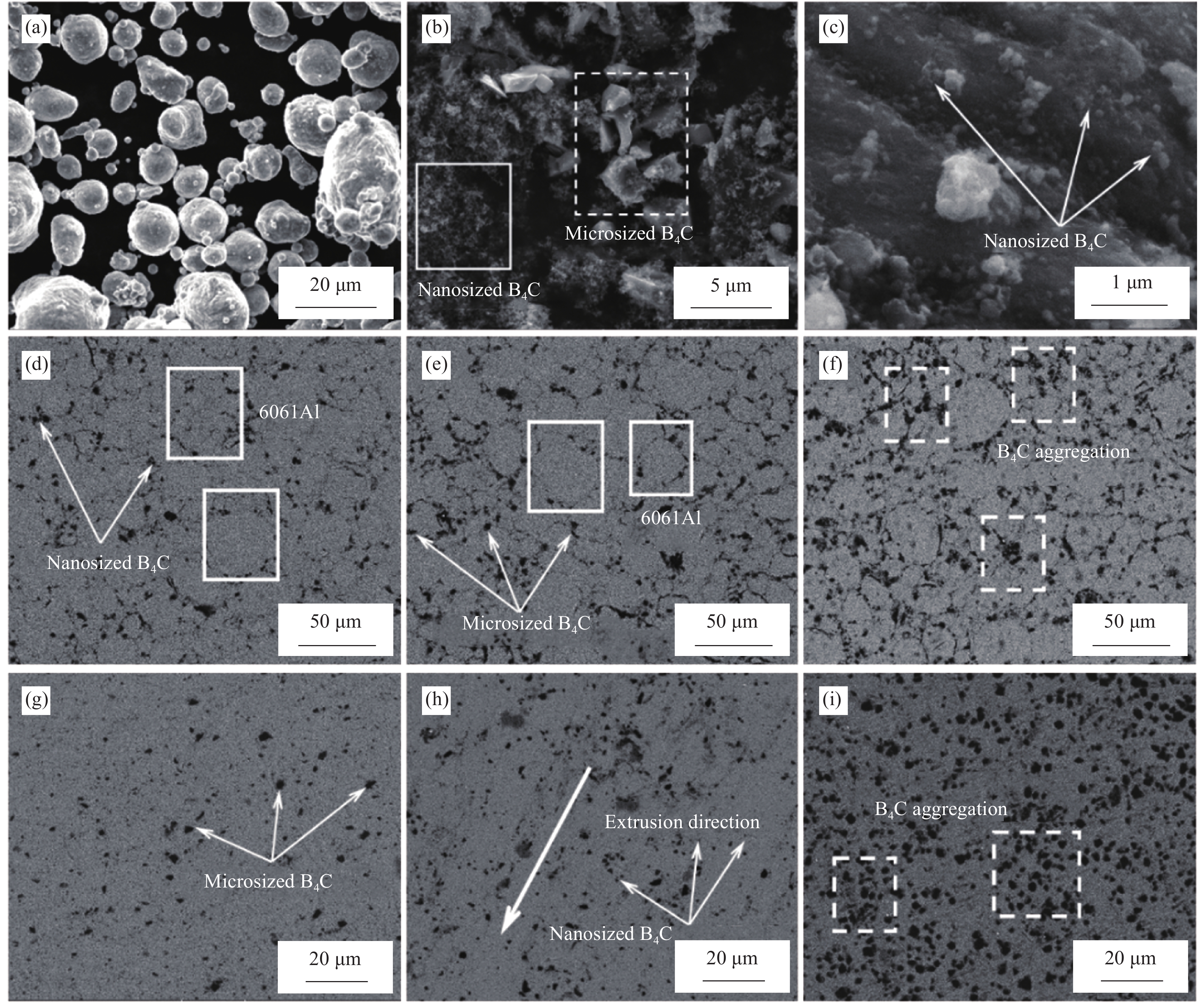

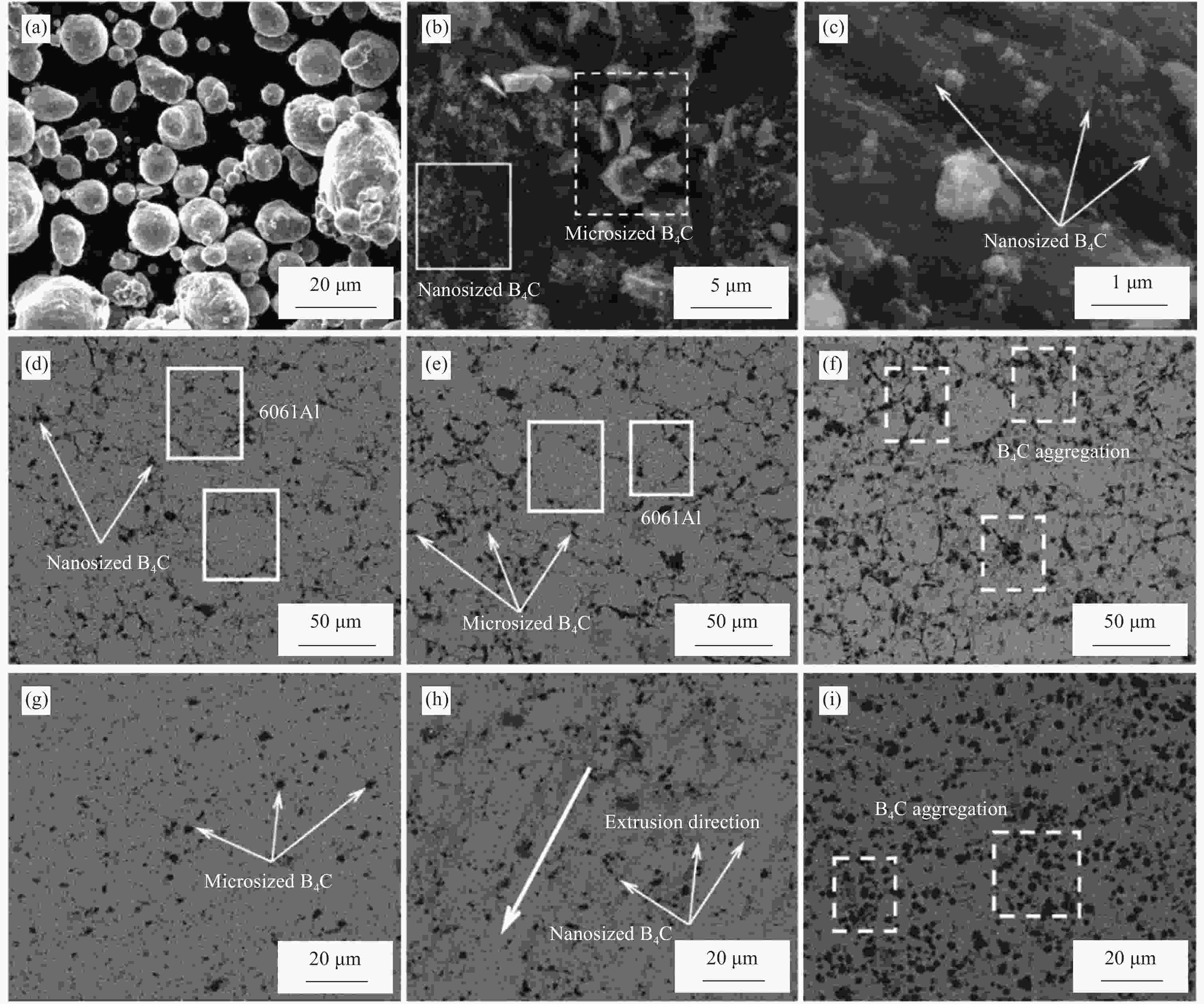

摘要: 采用先进粉末冶金技术(放电等离子烧结+热挤压)制备了三种体积分数(3vol%、5vol%、7vol%)的微/纳B4C增强6061Al复合材料,对不同制备阶段复合材料的微观组织(SEM、TEM、EBSD)进行观察分析,对复合材料的纳米压痕行为及拉伸性能进行测试。结果表明:烧结后B4C颗粒在基体中呈“网状”分布;挤压变形后B4C颗粒在基体实现弥散均匀分布。挤压变形后,纳米B4C在晶内及晶界均有分布,纳米B4C对位错的钉扎作用使得基体积累大量位错,提供驱动力并越过动态回复,使内部再结晶比例高达74%。当B4C体积分数为3vol%时,挤压态B4C/6061Al复合材料的抗拉强度、屈服强度及延伸率为219 MPa、88 MPa和22.5%,断裂形貌中呈现大量韧窝。Abstract: Micro/nano B4C particle reinforced 6061Al composites with three volume fractions (3vol%, 5vol%, 7vol%) were prepared by advanced powder metallurgy technology (spark plasma sintering +hot extrusion). The microstructure evolution at different stages was observed by SEM, TEM and EBSD. The nano-indentation behavior, tensile properties and friction and wear properties were also tested. Results show that B4C particles distribute in a network structure after sintering, and the B4C particles are dispersed uniformly after extrusion. The nano-B4C particles are distributed in the grains and grain boundaries. The pinning effect of nano-B4C on the dislocation accumulates a large number of dislocations in the matrix, which provides driving force and overrides the dynamic recovery. Finally, the recrystallization ratio reaches 74%. When the volume fraction of B4C is 3vol%, the tensile strength, yield strength and elongation of as-extruded B4C/6061Al composites are 219 MPa, 88 MPa and 22.5%, and a large number of dimples appear in the fracture morphology.

-

Key words:

- micro/nano B4C /

- composites /

- interface /

- fracture mechanism /

- friction-wear

-

表 1 烧结态、挤压态B4C/6061Al复合材料的极限拉伸强度、屈服强度和延伸率

Table 1. Ultimate tensile strength (UTS), yield strength (YS) and elongation of as-sintered and as-extruded B4C/6061Al composites

B4C/vol% UTS/MPa YS/MPa Elongation/% As-SPSed 0 138 65 18 3 178 78 13 5 150 92 7 7 158 117 6 As-extruded 0 190 77 25 3 219 88 22.5 5 209 95 20 7 190 114 7.5 -

[1] 王国峰, 王海洋. 烧结助剂对反应热压烧结B4C基复合材料性能的影响[J]. 复合材料学报, 2009, 26(4):102-106. doi: 10.3321/j.issn:1000-3851.2009.04.018WANG Guofeng, WANG Haiyang. Influence of sintering additive on the performance of B4C based composites sintered by reaction hot-pressing[J]. Acta Materiae Compositae Sinca,2009,26(4):102-106(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.04.018 [2] 刘瑞峰, 王文先, 陈洪胜, 等. 基于SPS法B4C/6061Al中子吸收复合材料组织及性能[J]. 复合材料学报, 2018, 35(2):364-370.LIU Ruifeng, WANG Wenxian, CHEN Hongsheng, et al. Microstructure and mechanical properties of B4C/6061Al neutron absorber composites prepared by SPS[J]. Acta Materiae Compositae Sinca,2018,35(2):364-370(in Chinese). [3] DOU Y H, LIU Y, LIU Y B, et al. Friction and wear behaviors of B4C/6061Al Composite[J]. Materials & Design,2014,60:669-677. [4] VINTILA R, CHAREST A, DREW R A L, et al. Synthesis and consolidation via spark plasma sintering of nanostructured Al-5356/B4C composite[J]. Materials Science and Engineering: A,2011,528(13-14):4395-4407. doi: 10.1016/j.msea.2011.02.079 [5] WU C D, MA K K, WU J L, et al. Influence of particle size and spatial distribution of B4C reinforcement on the microstructure and mechanical behavior of precipitation strengthened Al alloy matrix composites[J]. Materials Science and Engineering: A,2016,675:421-430. doi: 10.1016/j.msea.2016.08.062 [6] SHIN J H, CHOI H J, BAE D H. The structure and properties of 2024 aluminum composites reinforced with TiO2 nanoparticles[J]. Materials Science & Engineering A,2014,607:605-610. [7] DASH K, CHAIRA D, RAY B C. Synthesis and characterization of aluminium-alumina micro-and nano-composites by spark plasma sintering[J]. Materials Research Bulletin,2013,48:2535-2542. doi: 10.1016/j.materresbull.2013.03.014 [8] ZHANG Y, LI J W, ZHAO L L, et al. Effect of metalloid silicon addition on densification, microstructure and thermal-physical properties of Al/diamond composites consolidated by spark plasma sintering[J]. Materials & Design,2014,63:838-847. [9] BATHULA S, ANANDANI R C, DHAR A, et al. Microstructural features and mechanical properties of Al 5083/SiCp metal matrix nanocomposites produced by high energy ball milling and spark plasma sintering[J]. Materials Science & Engineering A,2014,545:97-102. [10] CHEN H S, WANG W X, LI Y L, et al. The design, microstructure and mechanical properties of B4C/6061Al neutron absorber composites fabricated by SPS[J]. Materials & Design,2016,94:360-367. [11] DEND K K, WU K, WU Y W. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites[J]. Journal of Alloys and Compounds,2010,504:542-547. doi: 10.1016/j.jallcom.2010.05.159 [12] KHODABAKHSHI F, SIMCHI A. The role of microstructural features on the electrical resistivity and mechanical properties of powder metallurgy Al-SiC-Al2O3 nano composites[J]. Materials & Design,2017,130:26-36. [13] SUN Y P, YAN H G, SU B, et al. Microstructure and mechanical properties of spray deposition Al/SiCp composite after hot extrusion[J]. Journal of Materials Engineering and Performance,2011,20:1697-1702. doi: 10.1007/s11665-011-9859-6 [14] CHEN H S, WANG W X, NIE H H, et al. Microstructure and mechanical properties of B4C/6061Al laminar composites fabricated by power metallurgy[J]. Vacuum,2017,143:363-370. doi: 10.1016/j.vacuum.2017.06.009 [15] JAFARIAN H, HABIBI-LIVAR J, RAZAVI S H, et al. Microstructure evolution and mechanical properties in ultrafine grained Al/TiC composite fabricated by accumulative roll bonding[J]. Composites Part B: Engineering,2015,77:84-92. doi: 10.1016/j.compositesb.2015.03.009 [16] KASPAR K, BADU N K, ALOGAB K A, et al. Microstructure and mechanical properties of near net shaped aluminium/alumina nanocomposites fabricated by powder metallurgy[J]. Journal of Alloys and Compounds,2017,714:133-143. doi: 10.1016/j.jallcom.2017.04.233 [17] YUAN Y C, MA A B, JIANG J H, et al. Mechanical properties and precipitate behavior of Mg-9Al-1Zn alloy processed by equal channel angular pressing and aging[J]. Journal of Alloys and Compounds,2014,594:182-188. doi: 10.1016/j.jallcom.2014.01.140 [18] WANG Z W, SONG M, SUN C, et al. Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al-Cu alloy composites[J]. Materials Science and Engineering: A,2010,527(24-25):6537-6542. doi: 10.1016/j.msea.2010.07.017 [19] WANG Z W, SONG M, SUN C, et al. Effect of particle size and distribution on the mechanical properties of SiC reinforced Al-Cu alloy composites[J]. Materials Science and Engineering: A,2011,528(3):1131-1137. doi: 10.1016/j.msea.2010.11.028 [20] AKBARPOURA M R, MIRABADA H M, ALIPOURB S. Microstructural and mechanical characteristics of hybrid SiC/Cu composites with nano- and micro-sized SiC particles[J]. Ceramics International,2019,45:3276-3283. doi: 10.1016/j.ceramint.2018.10.235 -

下载:

下载: