Fabrication and compression performance of continuous fiber Octet-truss lattice sandwich structure

-

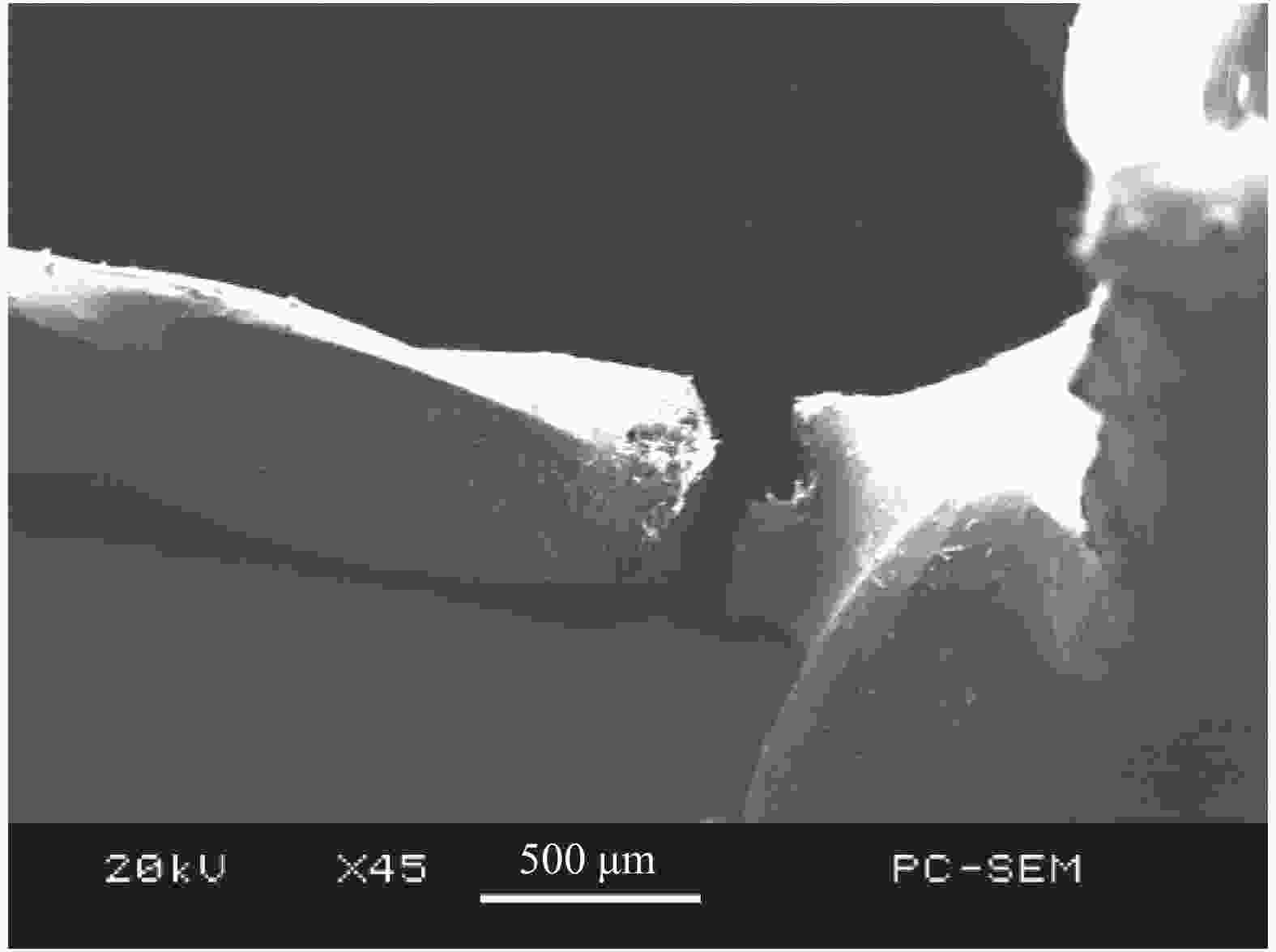

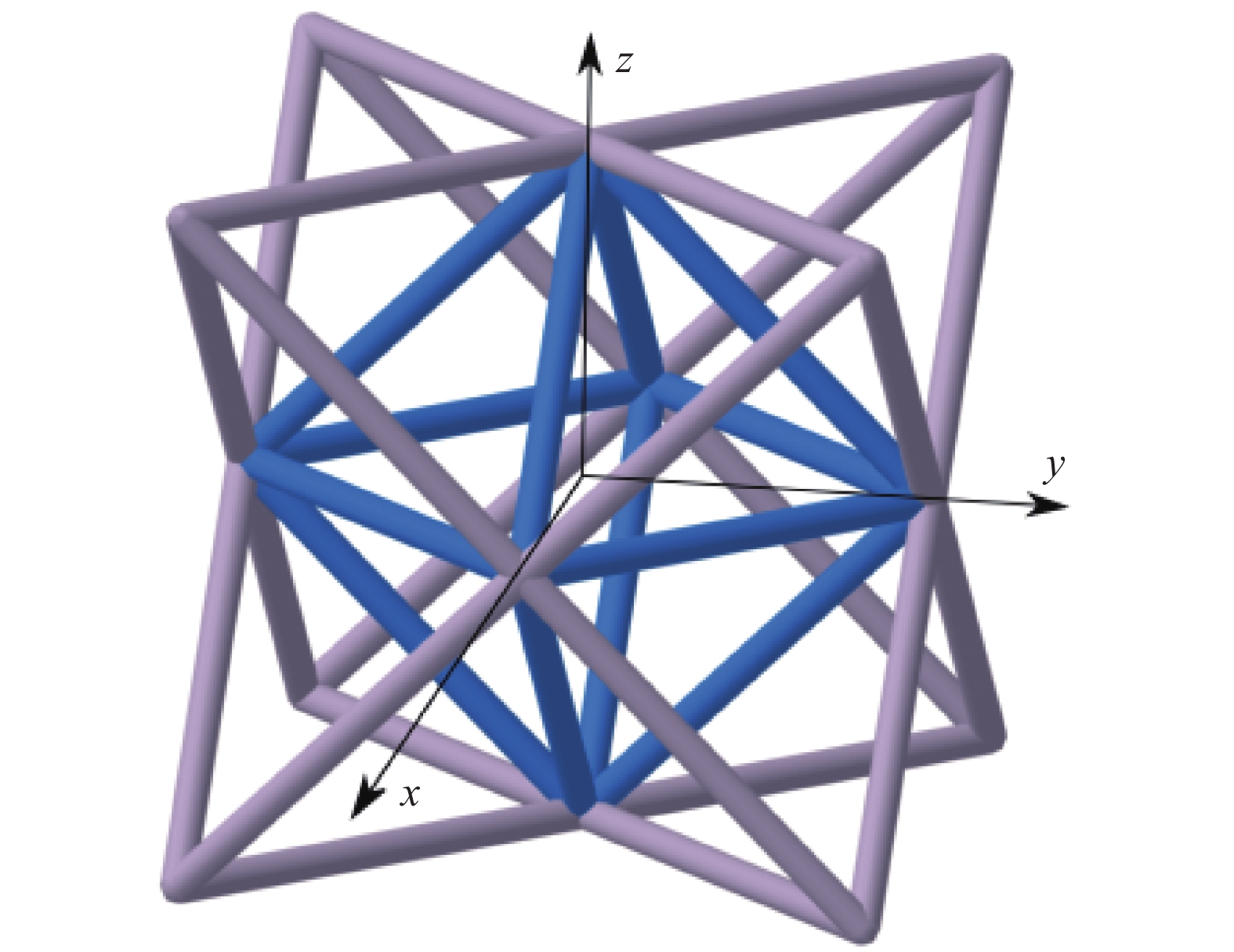

摘要: Octet-truss是一种兼具轻质构型和多功能特点的三维点阵结构,为分析和验证其抗压缩性能,提出了一种采用连续纤维制备Octet-truss点阵夹芯板的方法,该方法设计了一套Octet-truss结构成型工装,采用该工装,运用空间编织法及树脂固化工艺制备了不同类型的玻璃纤维和凯夫拉纤维试件,并对试件进行了轴压测试,实验结果表明该方法制备的不同材质、不同尺寸的夹芯板力学性能稳定,验证了其制备工艺的可靠性,结合实验过程与SEM图像分析了玻璃纤维试件主要失效模式为节点附近纤维杆因纤维微屈曲出现断裂,凯夫拉纤维试件主要失效模式为纤维杆欧拉屈曲而出现弯曲破坏。

-

关键词:

- Octet-truss /

- 点阵夹芯结构 /

- 制备工艺 /

- 成型工装 /

- 压缩性能

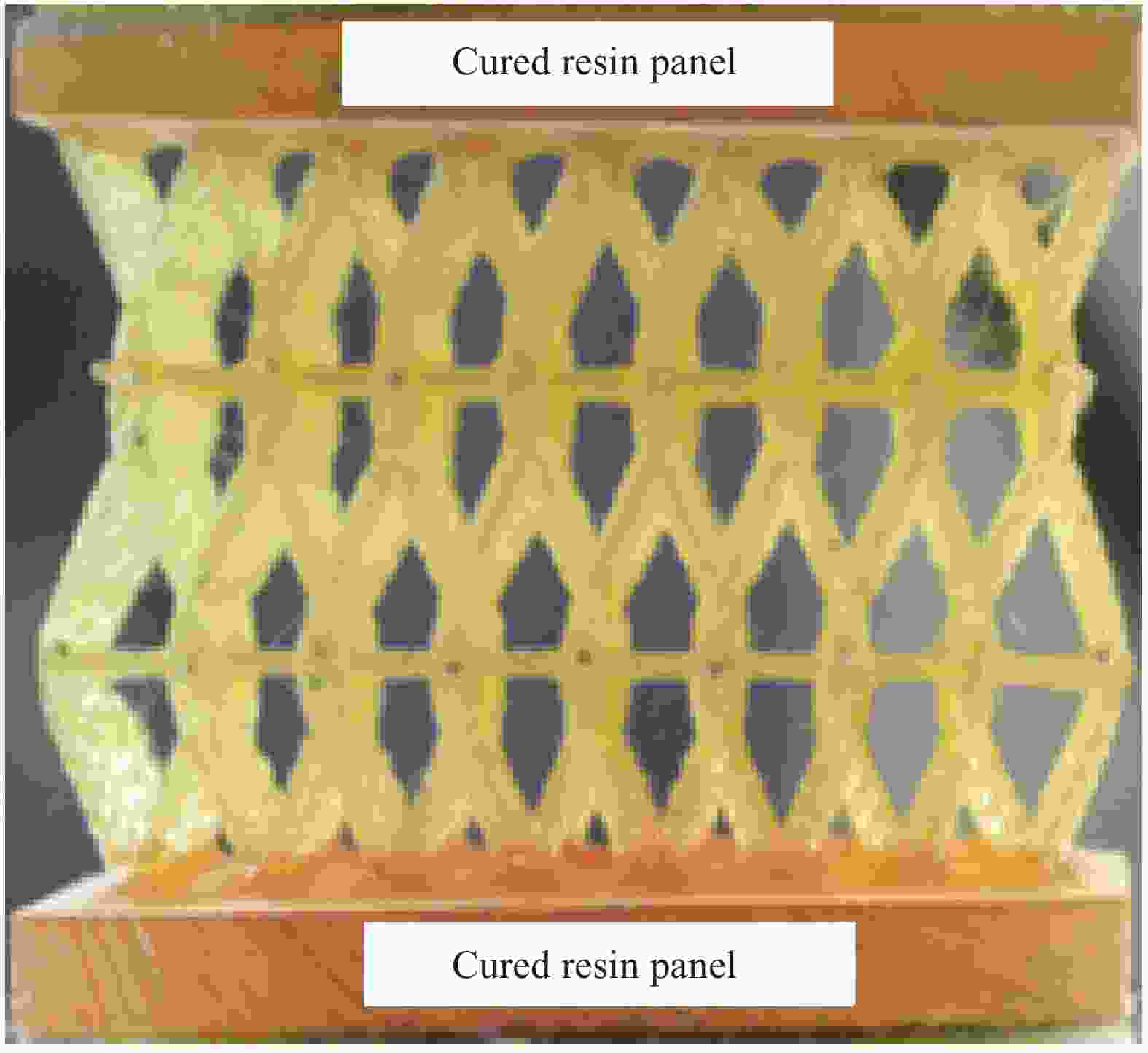

Abstract: Octet-truss is a three-dimensional lattice structure with light configuration and multi-function characteristics. In order to analyze and verify its compression resistance, a method of preparing Octet-truss lattice sandwich panel with continuous fiber was proposed. A set of Octet-truss structure molding tools was designed by this method. Different types of glass fiber and Kevlar fiber specimens were prepared by spatial weaving method and resin curing process, and the axial compression test was carried out. The experimental results show that the mechanical properties of different materials and different sizes of sandwich panels prepared by this method are stable, and the reliability of the preparation process is verified, Combined with the experimental process and electron microscope images, the main failure mode of glass fiber samples is fracture of the struts near the nodes induced by fiber microbuckling, while the Kevlar fiber samples failed by the Euler buckling of the struts.-

Key words:

- Octet-truss /

- lattice sandwich structure /

- preparation process /

- molding tool /

- compression performance

-

表 1 Octet-truss点阵夹芯结构试件相关数据

Table 1. Octet-truss lattice sandwich structure specimen related data

Sample number Strut length/mm Average diameter/mm Inclination angle/(°) Raw material Note 1 4 0.4 60 Glass fibre - 2 4 0.4 60 Glass fibre With panel K1 8 0.68 60 Kevlar fiber - K2 8 0.68 60 Kevlar fiber With panel -

[1] 熊健, 杜昀桐, 杨雯. 轻质复合材料夹芯结构设计及力学性能最新进展[J]. 宇航学报, 2020, 41(6):749-760.XIONG Jian, DU Yuntong, YANG Wen, et al. Research progress on design and mechanical properties of lightweight composite sandwich structures[J]. Journal of Astronautics,2020,41(6):749-760(in Chinese). [2] 韦兴宇, 熊健, 王杰, 等. 纤维增强复合材料蜂窝结构的研究进展[J]. 中国科学: 技术科学, 2020, 63(8):1348-1370. doi: 10.1007/s11431-020-1650-9WEI Xingyu, XIONG Jian, WANG Jie, et al. New advances in fiber-reinforced composite honeycomb materials[J]. Scientia Sinica (Technologica),2020,63(8):1348-1370(in Chinese). doi: 10.1007/s11431-020-1650-9 [3] 李华东, 周振龙, 陈国涛. 基于高阶剪切理论的复合材料格栅夹层板弯曲特性[J]. 复合材料学报, 2019, 36(12):2745-2755.LI Huadong, ZHOU Zhenlong, CHEN Guotao. Bending characteristic of composite grid of sandwich plate based on high-order shear theory[J]. Acta Materiae Compositae Sinaca,2019,36(12):2745-2755(in Chinese). [4] 邓云飞, 曾宪智, 周翔, 等. 复合材料褶皱夹芯结构研究进展[J]. 复合材料学报, 2020, 37(12):2966-2983.DENG Yunfei, ZENG Xianzhi, ZHOU Xiang, et al. Research progress for the compositae sandwich structure with foldcore[J]. Acta Materiae Composite Sinica,2020,37(12):2966-2983(in Chinese). [5] GEORGE T, DESHPANDE V S, WADLEY H N G. Hybrid carbon fiber composite lattice truss structures[J]. Compo-sites Part A: Applied Science and Manufacturing,2014,65:135-147. doi: 10.1016/j.compositesa.2014.06.011 [6] WANG B, WU Linzhi, MA Li, et al. Mechanical behavior of the sandwich structures with carbon fiber-reinforced pyramidal lattice truss core[J]. Materials & Design (1980-2015),2010,31(5):2659-2663. [7] DONG L, WADLEY H. Mechanical properties of carbon fiber composite octet-truss lattice structures[J]. Compo-sites Science and Technology,2015,119(23):26-33. [8] COMPTON B G, LEWIS J A. 3D-printing of lightweight cellular composites[J]. Advanced Materials,2015,26(34):5930-5935. [9] XU Z, HA C S, KADAM R, et al. Additive manufacturing of two-phase lightweight, stiff and high damping carbon fiber reinforced polymer microlattices[J]. Additive Manufacturing,2020,32:101106. doi: 10.1016/j.addma.2020.101106 [10] JENETT B, GREGG C, CELLCCI D, et al. Design of multifunctional hierarchical space structures[C]// IEEE Aero-space Conference. IEEE, 2017. [11] GREGG C E, KIM J H, CHEUNG K C. Ultra-light and scalable composite lattice materials[J]. Advanced Engineering Materials,2018,20(9):1800213. doi: 10.1002/adem.201800213 [12] 李静雯, 张博明, 孙义亮, 等. 不同铺层方式下连续玻璃纤维/聚丙烯复合材料波纹夹芯板的力学性能[J]. 复合材料学报, 2019, 36(5):18-26.LI Jingwen, ZHANG Boming, SUN Yiliang, et al. Mechanical properties of continuous glass fiber/polypropylene corrugated sandwich boards under different laminates[J]. Acta Materiae Compositae Sinaca,2019,36(5):18-26(in Chinese). [13] 袁文昊, 李凤莲, 吕梅. 不同边界条件下波纹夹芯板的自由振动特性[J]. 复合材料学报, 2020, 37(12):3149-3159.YUAN Wenhao, LI Fenglian, LV Mei. Free vibration characteristics of corrugated sandwich plates under different boundary conditions[J]. Acta Materiae Compositae Sinaca,2020,37(12):3149-3159(in Chinese). [14] 郑权, 冀宾, 李昊, 等. 基于增材制造的多层金字塔点阵夹芯板抗压缩性能[J]. 航空材料学报, 2018, 38(3):77-82.ZHENG Quan, JI Bin, LI Hao, et al. Compressive behavior of sandwich panels with multilayer pyramidal truss cores by additive manufacturing[J]. Journal of Aeronautical Materials,2018,38(3):77-82(in Chinese). [15] 张成利, 樊峻江, 许兰兰, 等. 新型混合芯材复合材料夹芯板受弯性能试验研究[J]. 新型建筑材料, 2019, 46(3):93-97.ZHANG Chengli, FAN Junjiang, XU Lanlan, etal. Experimental study on bending performance of a new hybrid core composite sandwich panel[J]. New Building Materials,2019,46(3):93-97(in Chinese). [16] LIU Gang, KANG Kiju, et al. A weaving machine for three-dimensional Kagome reinforcements[J]. Textile Research Journal,2018,88(3):322-332. [17] LIANG Dong, VIKRAM Deshpande, HAYDN Wadley. Mechanical response of Ti–6Al–4V octet-truss lattice structures[J]. International Journal of Solids and Structures, 2015, 60-61: 107-124. [18] DESHPANDE V S, FLECK N A, ASHBY M F. Effective properties of the octet-truss lattice material[J]. Journal of the Mechanics & Physics of Solids,2001,49(8):1747-1769. [19] 赖长亮, 刘闯, 王俊彪. IsoTruss超轻复合材料结构制造及力学性能测试[J]. 复合材料学报, 2014, 31(2):365-382.LAI Changliang, LIU Chuang, WANG Junbiao. Fabrication and mechanical property test of IsoTruss ultra-lightweight composite structures[J]. Acta Materiae Compositae Sinaca,2014,31(2):365-382(in Chinese). [20] 黄发荣, 周燕. 先进树脂基复合材料[M]. 北京: 化学工业出版社, 2008: 294-299.HUANG Farong, ZHOU Yan. Advanced polymer compo-site[M]. Beijing: Chemical Industry Press, 2008: 294-299(in Chinese). [21] ASTM. Standard test method for flatwise compressive properties of sandwich cores: ASTM C 365M—2005[S]. Philadelphia: ASTM, 2005. [22] 吴林志, 熊健, 马力. 复合材料点阵结构力学性能表征[M]. 北京: 科学出版社, 2015: 20-35.WU Linzhi, XIONG Jian, MA Li. Characterization of the mechanical properties of composite lattice structures[M]. Beijing: Science Press, 2015: 20-35(in Chinese). [23] 黄英杰. 三维Al基点阵材料设计, 制备及力学性能研究[D]. 合肥: 中国科学技术大学, 2017.HUANG Yingjie. Study on the design, preparation and mechanical properties of Al based lattice materials[D]. Hefei: University of Science and Technology of China, 2017(in Chinese). [24] 熊健. 轻质复合材料新型点阵结构设计及其力学行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2012.XIONG Jian. Design and mechanical behavior of lightweight composite innovative lattice truss structures[D]. Harbin: Harbin Institute of Technology, 2012(in Chinese). [25] 熊健, 马力, 杨金水, 等. 碳纤维复合材料金字塔点阵结构制备工艺及力学性能研究[J]. 固体力学学报, 2011(S1):8-13.XIONG Jian, MA Li, YANG Jinshui, etal. Fabrication and mechanical response of carbon fiber sandwich panels wich pyramidal truss cores[J]. Chinese Journal of Solid Mechanics,2011(S1):8-13(in Chinese). [26] 王兵, 吴林志, 杜善义, 等. 碳纤维增强金字塔点阵夹芯结构的抗压缩性能[J]. 复合材料学报, 2010, 27(1):133-138.WANG Bing, WU Linzhi, DU Shanyi, et al. Compressive behavior of sandwich structures with carbon fiber reinforced pyramidal lattice truss cores[J]. Acta Materiae Compositae Sinaca,2010,27(1):133-138(in Chinese). [27] 冀宾, 韩涵, 宋林郁, 等. 面内压缩超轻质点阵夹芯板的优化, 试验与仿真[J]. 复合材料学报, 2019, 36(4):281-287.JI Bin, HAN Han, SONG Linyu, et al. Optimization, experiment and simulation of lightweight lattice sandwich plates under in-plane compression load[J]. Acta Materiae Compositae Sinaca,2019,36(4):281-287(in Chinese). [28] 钟翔屿, 包建文, 张代军, 等. 国产芳纶纤维增强环氧复合材料的压缩性能[J]. 固体火箭技术, 2017, 40(2):244-249.ZHONG Xiangyu, BAO Jianwen, ZHANG Daijun, etal. Compression performance of epoxy matrix composite reinforced by domestic aramid fiber[J]. Journal of Solid Rocket Technology,2017,40(2):244-249(in Chinese). -

下载:

下载: