Effect of polyethersulfone on the properties of continuous carbon fiber/polyetheretherketone composites

-

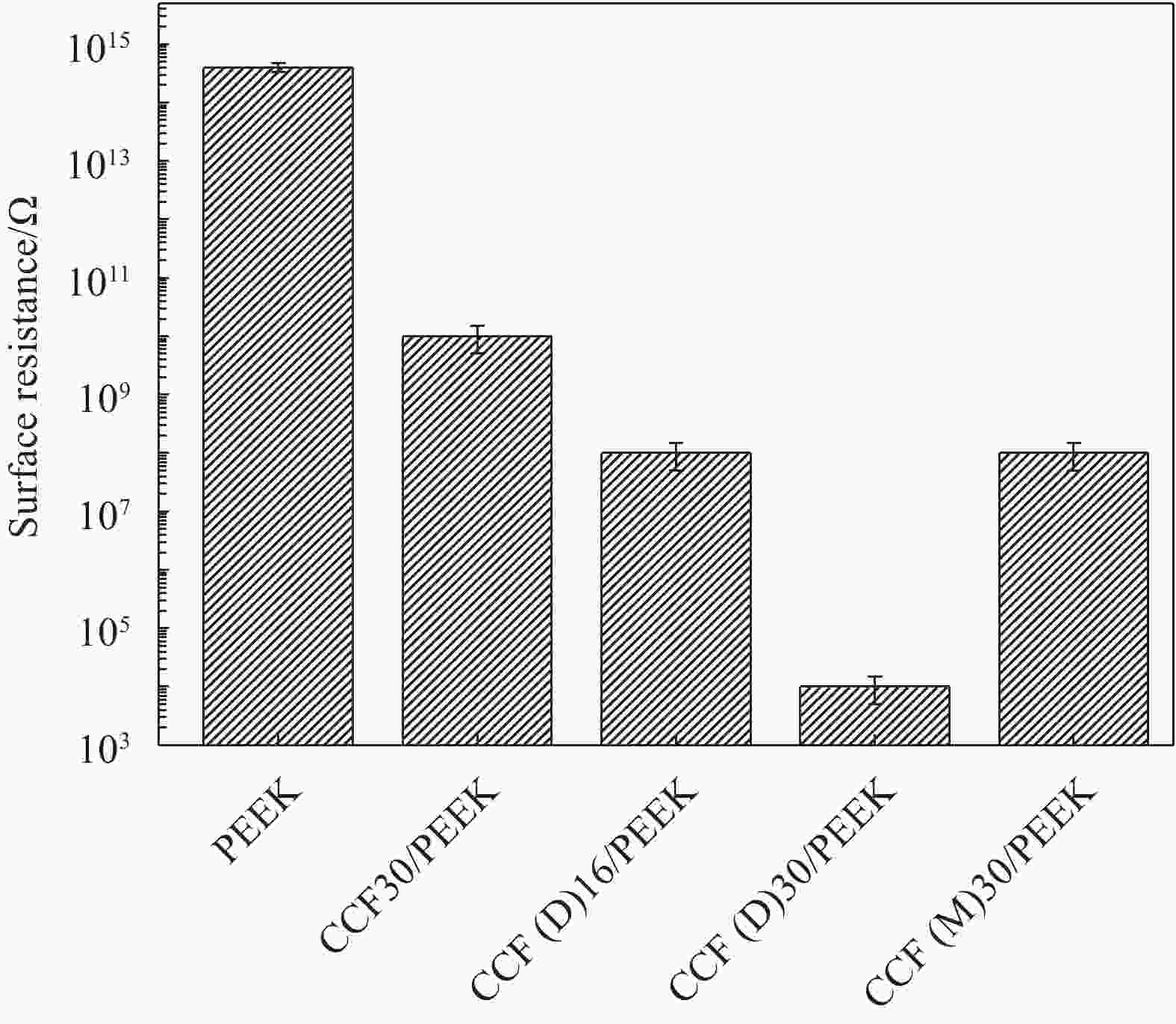

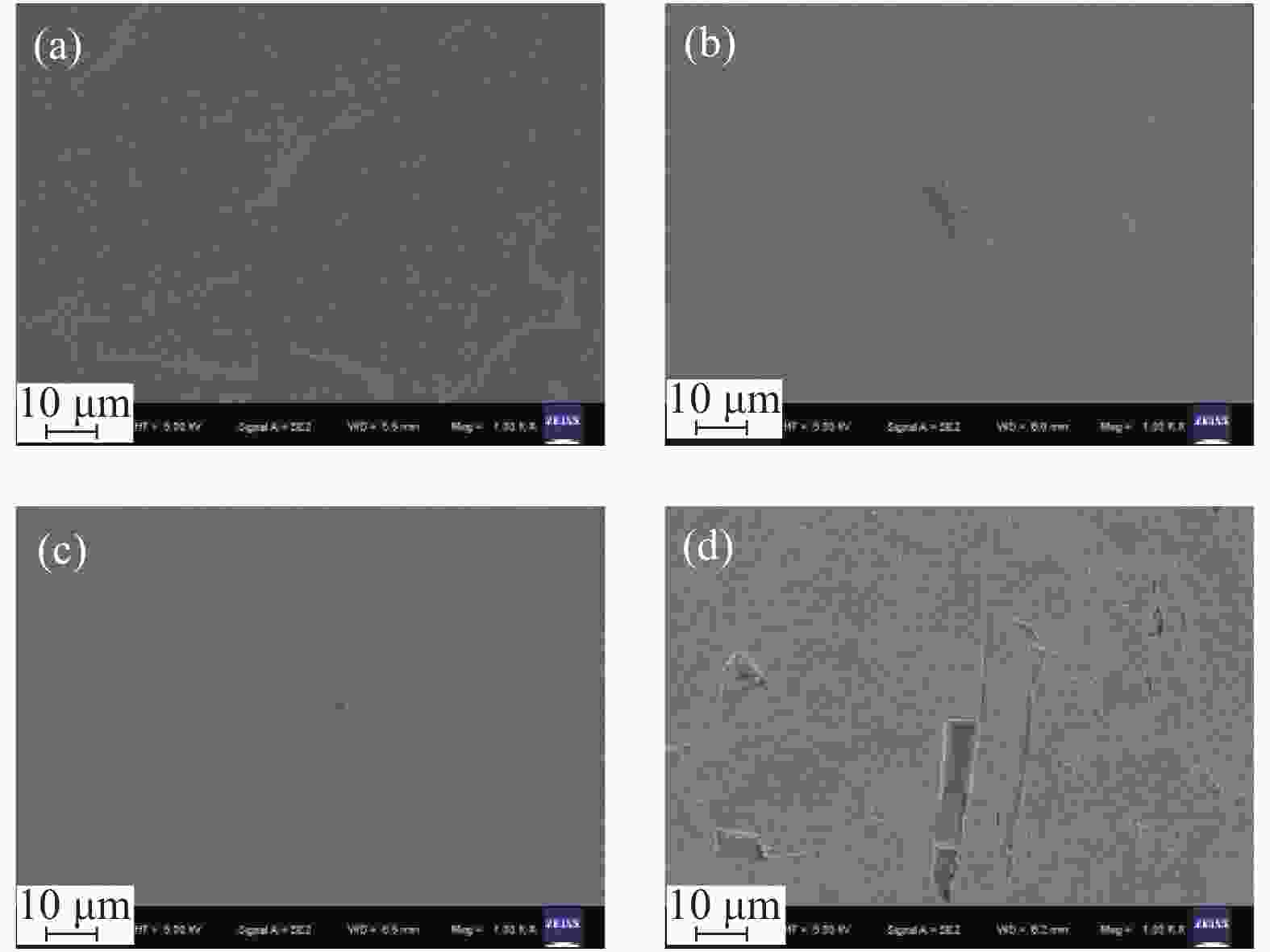

摘要: 以聚醚砜(PES)作为第三组分及活化PES作为连续碳纤维(CCF)的表面改性剂制备CCF/聚醚醚酮(PEEK)复合材料,重点研究CCF/PEEK复合材料的制备工艺方法对其性能的影响。结果表明:PES作为第三组分制备的CCF/PEEK复合材料,当填充16wt%的CCF时,复合材料表面电阻降低到107~109 Ω,出现导电逾渗状态,此时摩擦系数降到最低(0.2430)。活化PES作为表面改性剂制备的CCF/PEEK复合材料,当填充30wt%的CCF时,复合材料的拉伸强度、弯曲强度、冲击强度分别提高到236.2 MPa、345.1 MPa、12.3 kJ/m2,相比无PES改性的CCF30/PEEK复合材料分别提高了13.69%,21.70%,36.97%,其中PES起到显著的均匀分散CCF与界面粘结作用。摩擦学研究结果表明,复合材料的摩擦性能不仅取决于润滑材料CCF在基体中的分布还取决于CCF与基体的界面作用力。Abstract: In this work, continuous carbon fiber (CCF)/polyetheretherketone (PEEK) composites were prepared by using polyethersulfone (PES) as tertiary component and activated PES as surface modifier for CCF respectively. The research focuses on the effects of the preparation process on the properties of the CCF/PEEK composites. The results show that for the CCF/PEEK composites prepared with PES as tertiary component, when 16wt% of CCF is filled, the surface resistance decreases to 107-109 Ω, appearing conductive percolation state, and the friction coefficient reduces to the lowest value of 0.2430. The tensile strength, bending strength and impact strength of CCF/PEEK composites filled with 30wt% of CCF with surface modifier by activated PES are increased to 236.2 MPa, 345.1 MPa and 12.3 kJ/m2 respectively, which are increased by 13.69%, 21.70% and 36.97% respectively, compared with the CCF30/PEEK composites without PES modification, with the good dispersion of CCF and better interface adhesion between PEEK and CCF surface modified by PES. The tribological results indicate that the friction properties of the composites depend not only on the distribution of CCF in the matrix, but also on the interface force between CCF and the matrix.

-

表 1 PEEK及CCF/PEEK复合材料的摩擦性能

Table 1. Friction properties of PEEK and CCF/PEEK composites

Material Friction coefficient Wear mass loss/mg Wear width/mm Wear rate 10−9cm3/(N·m) PEEK 0.4240 8.1 4.92 8.302 CCF30/PEEK 0.2982 1.0 2.24 1.078 CCF(D)16/PEEK 0.2430 1.7 3.58 1.828 CCF(D)30/PEEK 0.3196 0.7 2.08 0.7856 CCF(M)30/PEEK 0.3845 0.4 2.19 0.4332 -

[1] CHEN J, GUO Q, ZHAO Z, et al. Thermal, crystalline, and tribological properties of PEEK/PEI/PES plastics alloys[J]. Journal of Applied Polymer Science,2013,127(3):2220-2226. doi: 10.1002/app.37923 [2] ZHENG B, GAO X P, LI M Y, et al. Formability and failure mechanisms of woven CF/PEEK composite sheet in solid-state thermoforming[J]. Polymers,2019,11(6):966. doi: 10.3390/polym11060966 [3] LV Y, WANG W, XIE G, et al. Self-lubricating PTFE-based composites with black phosphorus nanosheets[J]. Tribology Letters,2018,66(2):61. doi: 10.1007/s11249-018-1010-5 [4] WANG Q, WANG Y, WANG H, et al. Comparative study of the effects of nano-sized and micro-sized CF and PTFE on the thermal and tribological properties of PEEK composites[J]. Polymers for Advanced Technologies,2018,29(2):896-905. doi: 10.1002/pat.4200 [5] MA N, LIN G M, XIE G Y, et al. Tribological behavior of polyetheretherketone composites containing short carbon fibers and potassium titanate whiskers in dry sliding against steel[J]. Journal of Applied Polymer Science,2012,123(2):740-748. doi: 10.1002/app.34502 [6] RODRIGUEZ V, SUKUMARAN J, SCHLARB A K, et al. Reciprocating sliding wear behaviour of PEEK-based hybrid composites[J]. Wear,2016,362:161-169. [7] WANG P, MA R X, WANG Y M, et al. Comparative study of fullerenes and graphene nanoplatelets on the mechanical and thermomechanical properties of poly (ether ether ketone)[J]. Materials Letters,2019,249:180-184. doi: 10.1016/j.matlet.2019.04.092 [8] WANG B, ZHANG K, ZHOU C H, et al. Engineering the mechanical properties of CNT/PEEK nanocomposites[J]. RSC Advances,2019,9(23):12836-12845. doi: 10.1039/C9RA01212E [9] PAPAGEORGIOU D G, LIU M F, LI Z L et al. Hybrid poly(ether ether ketone) composites reinforced with a combination of carbon fibres and graphene nanoplatelets[J]. Composites Science and Technology,2019,175:60-68. doi: 10.1016/j.compscitech.2019.03.006 [10] KALIN M, ZALAZNIK M, NOVAK S. Wear and friction behaviour of poly-ether-ether-ketone (PEEK) filled with graphene, WS2 and CNT nanoparticles[J]. Wear,2015,332-333:855-862. doi: 10.1016/j.wear.2014.12.036 [11] CHUNG D D L. Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials[J]. Carbon,2001,39(8):1119-1130. doi: 10.1016/S0008-6223(00)00314-6 [12] YAO S S, JIN F L, RHEE K Y, et al. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review[J]. Composites Part B: Engineering,2018,142:241-300. doi: 10.1016/j.compositesb.2017.12.007 [13] HASSAN E A M, ELAGIB T H H, MEMON H, et al. Surface modification of carbon fibers by grafting PEEK-NH2 for improving interfacial adhesion with polyetheretherketone[J]. Materials,2019,12(5):778. doi: 10.3390/ma12050778 [14] LU C R, QIU S, LU X, et al. Enhancing the interfacial strength of carbon fiber/poly (ether ether ketone) hybrid composites by plasma treatments[J]. Polymers,2019,11(5):753. doi: 10.3390/polym11050753 [15] CHEN J, ZHANG T, WANG K, et al. Multiscale enhancement behavior of nano-silica modified CF/PEEK composites prepared by wet powder impregnation[J]. Polymer Composites,2019,40(3):1187-1197. doi: 10.1002/pc.24830 [16] GAO X P, HUANG Z G, ZHOU H M, et al. Higher mechanical performances of CF/PEEK composite laminates via reducing interlayer porosity based on the affinity of functional s-PEEK[J]. Polymer Composites,2019,40(9):3749-3757. doi: 10.1002/pc.25236 [17] HASSAN E A M, YANG L L, ELAGIB T H H, et al. Synergistic effect of hydrogen bonding and pi-pi stacking in interface of CF/PEEK composites[J]. Composites Part B: Engineering,2019,171:70-77. doi: 10.1016/j.compositesb.2019.04.015 [18] LI S, JIN Y, WANG Z Y, et al. Preparation and characterisation of nickel-plated carbon fibre/polyether ether ketone composites with high electromagnetic shielding and high thermal conductivity[J]. Colloid and Polymer Science,2019,297(7-8):967-977. doi: 10.1007/s00396-019-04522-5 [19] LIN G M, XIE G Y, SUI G X, et al. Hybrid effect of nanoparticles with carbon fibers on the mechanical and wear properties of polymer composites[J]. Composites Part B: Engineering,2012,43(1):44-49. doi: 10.1016/j.compositesb.2011.04.029 [20] LIU L, XIAO L H, ZHANG X P, et al. Improvement of the thermal conductivity and friction performance of poly(ether ether ketone)/carbon fiber laminates by addition of graphene[J]. RSC Advances,2015,5(71):57853-57859. doi: 10.1039/C5RA10722A [21] MANDAL S, ALAM S. Studies on the mechanical, thermal, and morphological properties of poly (ether ether ketone)/poly (ether sulfone)/barium titanate nanocomposites: Correlation of experimental results with theoretical predictive models[J]. Journal of Applied Polymer Science,2012,126(2):724-733. doi: 10.1002/app.36735 [22] NANDAN B, KANDPAL L D, MATHUR G N. Poly (ether ether ketone)/poly (aryl ether sulfone) blends: Relationships between morphology and mechanical properties[J]. Journal of Applied Polymer Science,2003,90(11):2887-2905. doi: 10.1002/app.13009 [23] ZHANG S L, WANG H S, WANG G B, et al. Material with high dielectric constant, low dielectric loss, and good mechanical and thermal propertiesproduced using multi-wall carbon nanotubes wrapped with poly (ether sulphone) in a poly (ether etherketone) matrix[J]. Applied Physics Letters,2012,101(1):012904. doi: 10.1063/1.4733723 [24] JIANG W, JIN X, ZHANG H, et al. Poly (ether ether ketone)/wrapped graphite nanosheets with poly (ether sulfone) composites: Preparation, mechanical properties, and tribological behavior[J]. Journal of Applied Polymer Science,2015,132(14):41728. [25] HU Y, HOU X C, HU X Y, et al. Improvement in the mechanical and friction performance of poly (ether ether ketone) composites by addition of modificatory short carbon fibers and zinc oxide[J]. High Performance Polymers,2017,30(6):643-656. [26] 中华人民共和国国家质量监督检验检疫总局. 固体绝缘材料体积电阻率和表面电阻率试验方法: GB/T 1410—2006[S]. 北京: 中国标准出版社, 2006.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Methods of test for volume resistivity and surface resistivity of solid electrical insulating materials: GB/T 1410—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [27] 中国石油和化学工业协会. 塑料拉伸性能试验方法: GB/T 1040—1992[S]. 北京: 中国标准出版社, 1992.China Petroleum and Chemical Industry Association. Plastics: Determination of tensile properties: GB/T 1040—1992[S]. Beijing: China Standards Press, 1992(in Chinese). [28] 中华人民共和国国家质量监督检验检疫总局. 塑料弯曲性能试验方法: GB/T 9341—2000[S]. 北京: 中国标准出版社, 2000.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Plastics: Determination of flexural properties GB/T 9341—2000 [S]. Beijing: China Standards Press, 2000 (in Chinese) [29] WANG Q, WANG H, WANG Y, et al. The influences of several carbon additions on the fretting wear behaviors of UHMWPE composites[J]. Tribology International,2015,93:390-398. [30] ZHANG X, PEI X, WANG Q. Friction and wear properties of combined surface modified carbon fabric reinforced phenolic composites[J]. European Polymer Journal,2008,44(8):3051-3057. [31] VISHKAEI M S, SALLEH M A M, YUNUS R, et al. Effect of short carbon fiber surface treatment on composite properties[J]. Journal of Composite Materials,2011,45(18):1885-1891. doi: 10.1177/0021998310389090 [32] DEY M, DEITZEL J M, GILLESPIE J W, et al. Influence of sizing formulations on glass/epoxy interphase properties[J]. Composites Part A: Applied Science and Manufacturing,2014,63(18):59-67. [33] LAN D N U, BAKAR A A, AZAHARI B, et al. Effect of interlocking between porous epoxy microparticles and elastomer on mechanical properties and deformation modes[J]. Polymer Testing,2012,31(7):931-937. doi: 10.1016/j.polymertesting.2012.06.004 [34] CHEN Z B, LIU X J, LV R G, et al. Friction and wear mechanisms of PA66/PPS blend reinforced with carbon fiber[J]. Journal of Applied Polymer Science,2007,105(2):602-608. doi: 10.1002/app.25999 [35] SU F H, ZHANG Z Z, WANG K, et al. Tribological and mechanical properties of the composites made of carbon fabrics modified with various methods[J]. Composites Part A: Applied Science and Manufacturing,2005,36(12):1601-1607. doi: 10.1016/j.compositesa.2005.04.012 -

下载:

下载: