Structure adjustment and properties of carbon nanotube film interlaminar modified carbon fiber/bismaleimide composites

-

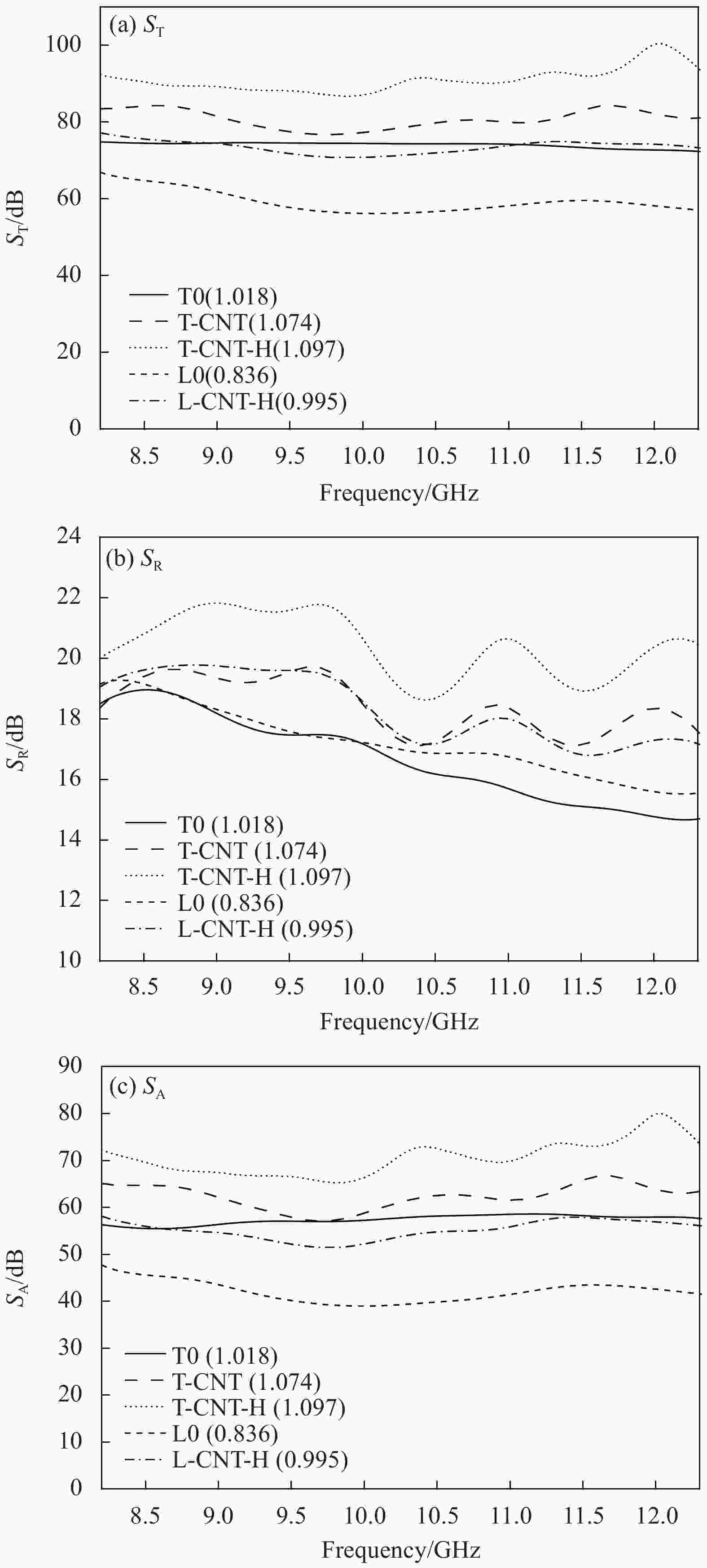

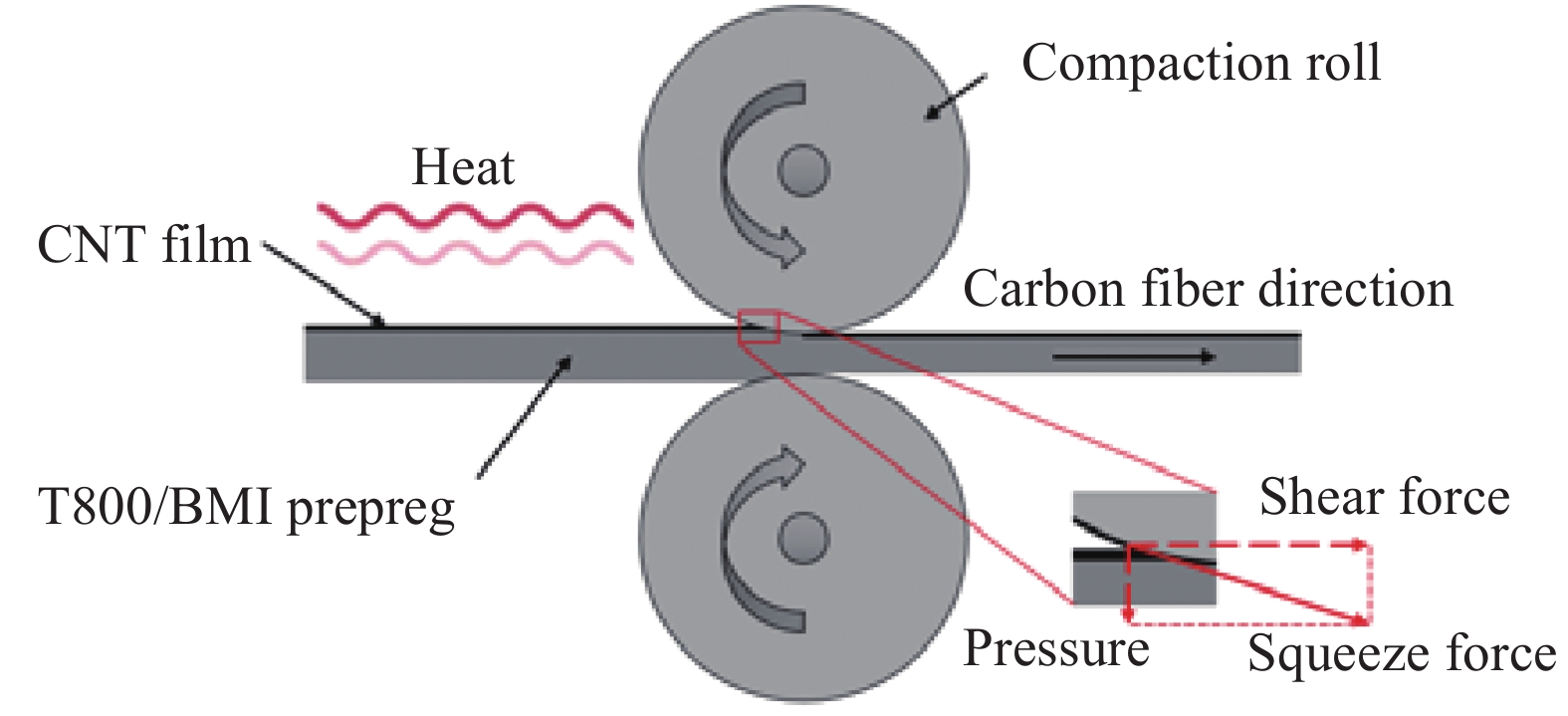

摘要: 对比研究了热塑性层间增韧和碳纳米管(CNT)膜层间混杂碳纤维(CF)/双马来酰亚胺复合材料不同层间结构调控方法,分析了其复合材料的压缩、动态力学、导电和电磁屏蔽等性能的变化。结果表明,热密实可显著降低层间CNT膜的厚度,抑制其局部富树脂程度,CNT膜-CF混杂复合材料的压缩强度得以提升,其压缩断口形貌明显不同于初始的CF复合材料。对比而言,热塑性树脂层间增韧CF复合材料的压缩强度明显低于CNT膜/CF混杂复合材料。CNT膜的加入贯通了混杂复合材料的层间导电通路,其厚度方向电导率提高了3个数量级,然而不同复合材料的体积电导率则表现出明显的“木桶效应”。值得关注的是,CNT膜层间混杂对提高CF复合材料的电磁屏蔽特性作用显著,其中致密CNT膜混杂复合材料的电磁屏蔽效能可达到90 dB。Abstract: The interlayer structure adjusting methods were studied on carbon fiber (CF)/bismaleimide composite materials, conducted respectively by thermoplastic interlaminar toughening and carbon nanotube (CNT) film hybridizing in contrast. The changes of compression properties, dynamic mechanical properties, electrical conductivities and electromagnetic shielding properties of the modified CF composites were analyzed. The results show that thermal compaction processing reduces the thickness of the CNT film significantly, suppressing the local resin-rich of the interlayer CNT region. The compressive strengths of the CNT film-CF hybrid composites are improved, with the fracture morphologies obviously different from that of the CF composites. In comparison, the thermoplastic interlaminar toughened CF composites show much lower compression strengths than the CNT film/CF hybrid composites. Additionally, the interlaminar electrical conductive paths are penetrated by the CNT networks of the hybrid composites, hence the thickness direction conductivities are increased by 3 orders of magnitude. However, the volumetric electrical conductivities of the diverse hybrid composites exhibit an evident “Cannikin Law”. It is noteworthy that the CNT film interlaminar hybrid can dramatically improve the electromagnetic shielding properties of the CF composite, reaching up to 90 dB for the dense CNT film hybrid composite.

-

表 1 不同复合材料试样的标号、组成及密实复合工艺

Table 1. List of different composite samples including the main constituents, the combination and compaction process

Label Material Compaction method T0 Toughened prepreg No T-CNT Toughened prepreg+CNT film No T-CNT-C Toughened prepreg+CNT film Cold compaction T-CNT-H Toughened prepreg+CNT film Heat compaction L0 Normal prepreg No L-CNT-H Normal prepreg+CNT film Heat compaction -

[1] AHMAD F, YUVARAJ N, BAJPAI P K. Effect of reinforcement architecture on the macroscopic mechanical properties of fiberous polymer composites: A review[J]. Polymer Composites,2020,41(6):2518-2534. doi: 10.1002/pc.25666 [2] CHOI D, KIL H S, LEE S. Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies[J]. Carbon,2019,142:610-649. doi: 10.1016/j.carbon.2018.10.028 [3] LI Z, HAIGH A, SOUTIS C, et al. Principles and applications of microwave testing for woven and non-noven carbon fibre-reinforced polymer composites: A topical review[J]. Applied Composite Materials,2018,25(4):965-982. doi: 10.1007/s10443-018-9733-x [4] LIU L, JIA C, HE J, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites[J]. Composites Science and Technology,2015,121:56-72. doi: 10.1016/j.compscitech.2015.08.002 [5] WANG B, MA S, YAN S, et al. Readily recyclable carbon fiber reinforced composites based on degradable thermosets: A review[J]. Green Chemistry,2019,21(21):5781-5796. doi: 10.1039/C9GC01760G [6] WANG J, MA C, CHEN G, et al. Interlaminar fracture toughness and conductivity of carbon fiber/epoxy resin compo-site laminate modified by carbon black-loaded polypropylene non-woven fabric interleaves[J]. Composite Structures,2020,234:111649. doi: 10.1016/j.compstruct.2019.111649 [7] SHRIVASTAVA R, SINGH K K. Interlaminar fracture toughness characterization of laminated composites: A review[J]. Polymer Reviews,2019:1-52. [8] CHENG C, CHEN Z, HUANG Z, et al. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs[J]. Composites Part A: Applied Science and Manufacturing,2020,129:105696. doi: 10.1016/j.compositesa.2019.105696 [9] RAMANATHAN T, ABDALA A A, STANKOVICH S, et al. Functionalized graphene sheets for polymer nanocompo-sites[J]. Nature Nanotechnology,2008,3(6):327-331. doi: 10.1038/nnano.2008.96 [10] MACOSKO C. Graphene/polymer nanocomposites[J]. Macromolecules,2015,43(16):6515-6530. [11] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature,1991,354(6348):56-58. doi: 10.1038/354056a0 [12] THOSTENSON E T, LI W Z, WANG D Z, et al. Carbon nano-tube/carbon fiber hybrid multiscale composites[J]. Journal of Applied Physics,2002,91(9):6034. doi: 10.1063/1.1466880 [13] SHIN Y C, LEE W I, KIM H S. Mode II interlaminar fracture toughness of carbon nanotubes/epoxy film-interleaved carbon fiber composites[J]. Composite Structures,2020,236:111808. doi: 10.1016/j.compstruct.2019.111808 [14] NI X, FURTADO C, KALFON-COHEN E, et al. Static and fatigue interlaminar shear reinforcement in aligned carbon nanotube-reinforced hierarchical advanced compo-sites[J]. Composites Part A: Applied Science and Manufacturing,2019,120:106-115. doi: 10.1016/j.compositesa.2019.02.023 [15] ZENG Y, CI L, CAREY B J, et al. Design and reinforcement: Vertically aligned carbon nanotube-based sandwich composites[J]. ACS Nano,2010,4(11):6798-6804. doi: 10.1021/nn101650p [16] WANG S, DOWNES R, YOUNG C, et al. Carbon fiber/carbon nanotube buckypaper interply hybrid composites: Manufacturing process and tensile properties[J]. Advanced Engineering Materials,2015,17(10):1442-1453. doi: 10.1002/adem.201500034 [17] GARCIA E J, WARDLE B L, HART A J. Joining prepreg composite interfaces with aligned carbon nanotubes[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1065-1070. [18] GARCIA E J, WARDLE B L, HART A J, et al. Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown In Situ[J]. Composites Science and Technology,2008,68(9):2034-2041. doi: 10.1016/j.compscitech.2008.02.028 [19] XU H, TONG X, ZHANG Y, et al. Mechanical and electrical properties of laminated composites containing continuous carbon nanotube film interleaves[J]. Composites Science and Technology,2016,127(28):113-118. [20] 刘刚, 胡晓兰, 张朋, 等. 碳纳米管膜层间改性碳纤维/环氧树脂复合材料[J]. 高分子学报, 2013, 10:109-115.LIU G, HU X L, ZHANG P, et al. Carbon nanotube film interlayer toughened carbon fiber reinforced epoxy resin hybrid composites[J]. Acta Polymerica Sinica,2013,10:109-115(in Chinese). [21] 刘玲, 杨乔馨. 碳纳米管网格对碳纤维复合材料层间剪切性能的影响[J]. 固体力学学报, 2015, s1:80-84.LIU L, YANG Q X. Effect of carbon nanotube networks on the interlaminar shear performance of carbon fiber reinforced laminates[J]. Chinese Journel of Solid Mechanics,2015,s1:80-84(in Chinese). [22] 邓火英, 王立敏, 冯奕钰, 等. 碳纳米管膜层间增韧对碳纤维复合材料力学性能的影响[J]. 宇航材料工艺, 2015, 5:31-35. doi: 10.3969/j.issn.1007-2330.2015.04.007DENG H Y, WANG L M, FENG Y Y, et al. Effect of carbon nanotube film interlayer toughening on mechanical properties of carbon fiber reinforced composite[J]. Aerospace Materials & Technology,2015,5:31-35(in Chinese). doi: 10.3969/j.issn.1007-2330.2015.04.007 [23] PAN J, LI M, WANG S, et al. Hybrid effect of carbon nano-tube film and ultrathin carbon fiber prepreg composites[J]. Journal of Reinforced Plastics and Compo-sites,2017,36(6):452-463. doi: 10.1177/0731684416684020 [24] MIKHALCHAN A, RIDHA M, TAY T E. Carbon nanotube fibres for CFRP-hybrids with enhanced in-plane fracture behaviour[J]. Materials & Design,2018,143:112-119. [25] LEE J, STEIN I Y, KESSLER S S, et al. Aligned carbon nano-tube film enables thermally induced state transformations in layered polymeric materials[J]. ACS Applied Materials & Interfaces,2015,7(16):8900-8905. [26] VILLORIA R G D, YAMAMOTO N, MIRAVETE A, et al. Multi-physics damage sensing in nano-engineered structural composites[J]. Nanotechnology,2011,22(18):185502. doi: 10.1088/0957-4484/22/18/185502 [27] RAWAL S, BRANTLEY J, KARABUDAK N. Development of carbon nanotube-based composite for spacecraft components[C]. 2013 6th International Conference on Recent Advances in Space Technologies (RAST), IEEE, 2013. [28] LIU Y N, LI M, GU Y, et al. Ultrastrong carbon nanotube/bismaleimide composite film with super-aligned and tightly packing structure[J]. Composites Science and Technology,2015,117:176-182. doi: 10.1016/j.compscitech.2015.06.014 [29] LI T, LI M, GU Y, et al. Mechanical enhancement effect of the interlayer hybrid CNT film/carbon fiber/epoxy composite[J]. Composites Science and Technology,2018,166:176-182. doi: 10.1016/j.compscitech.2018.02.007 [30] ZOU J, ZHANG X, ZHAO J, et al. Strengthening and toughening effects by strapping carbon nanotube cross-links with polymer molecules[J]. Composites Science and Technology,2016,135:123-127. doi: 10.1016/j.compscitech.2016.09.019 -

下载:

下载: