Effect of steel fiber-nano carbon black/concrete smart layer on crack self-monitoring performance

-

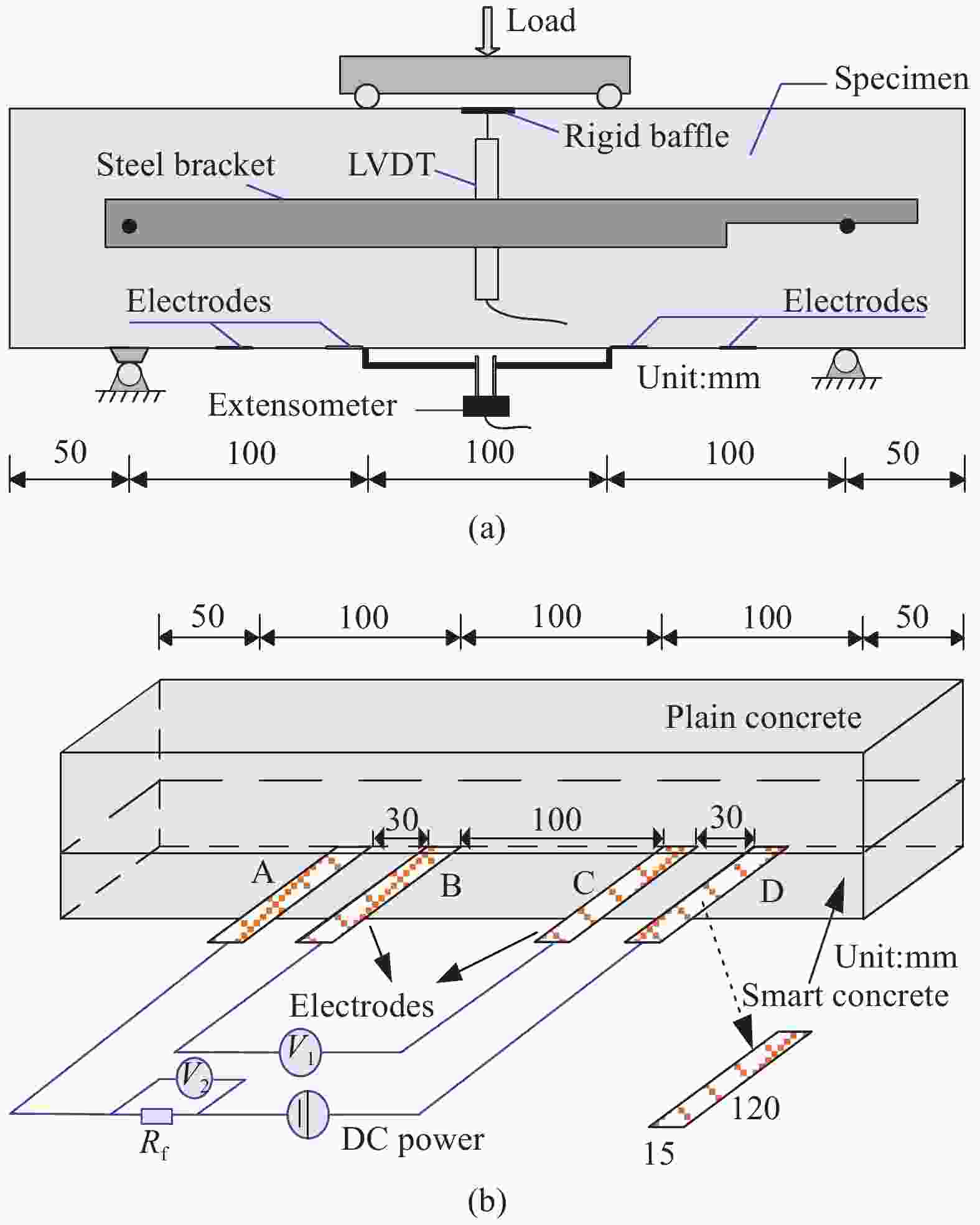

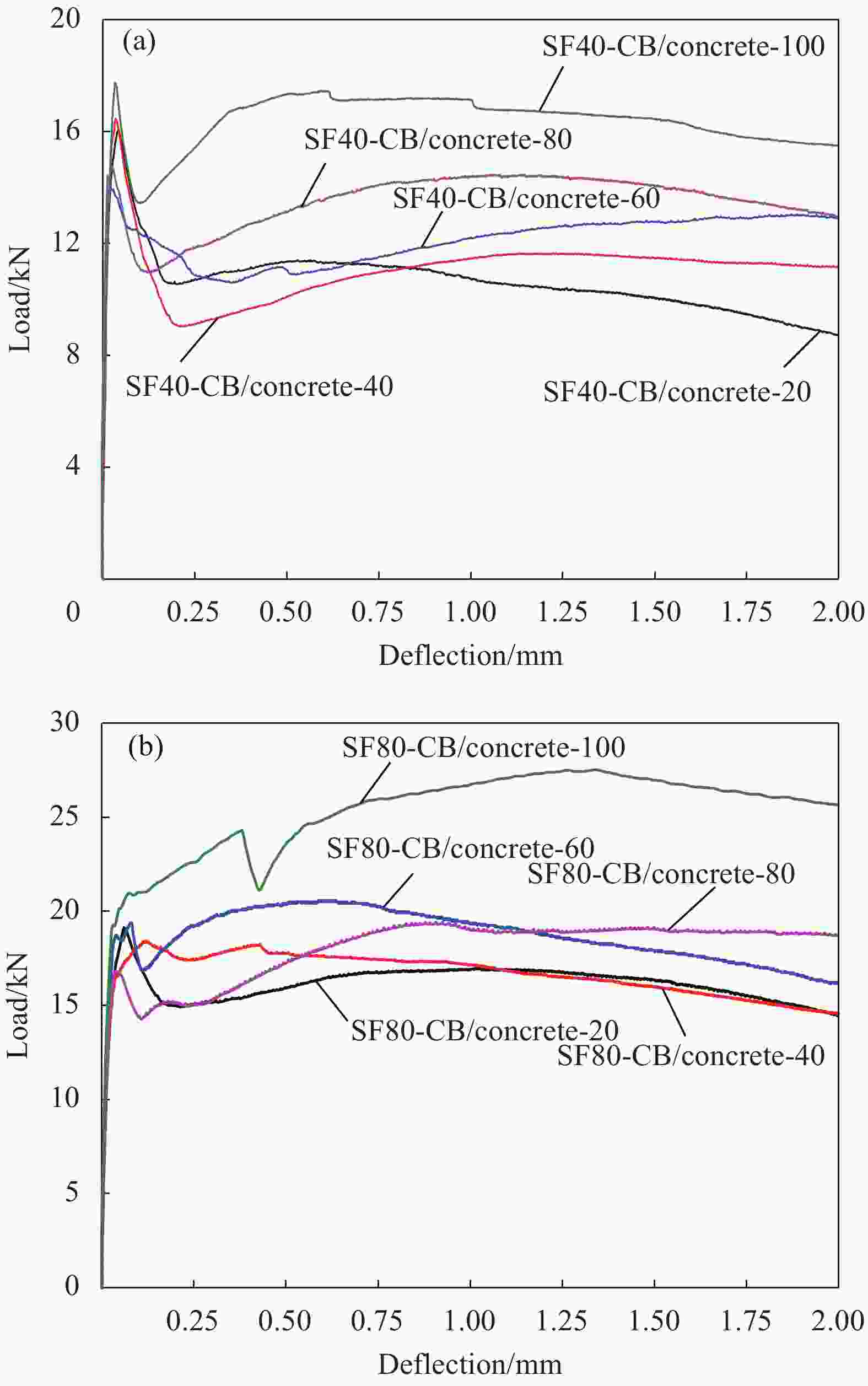

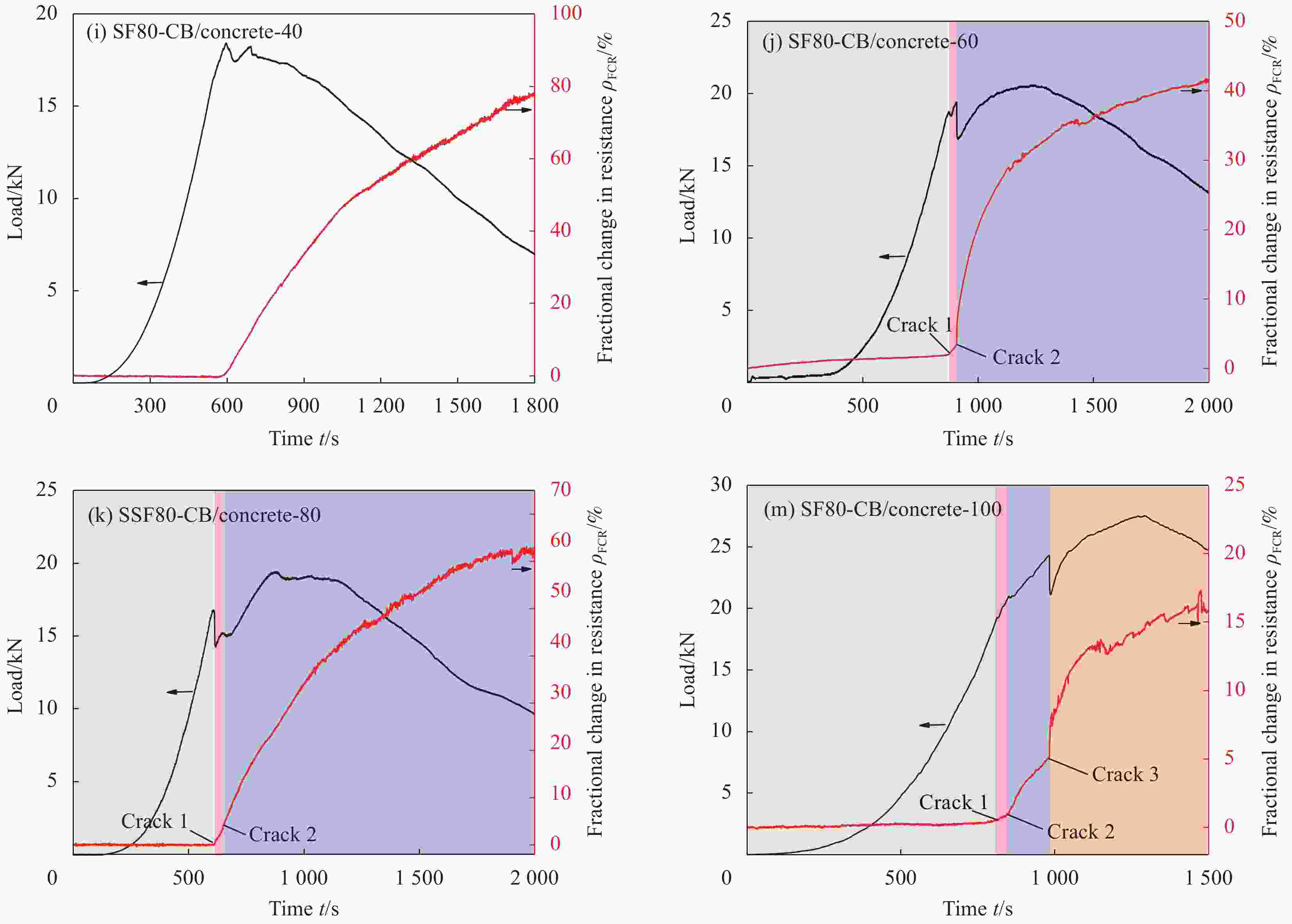

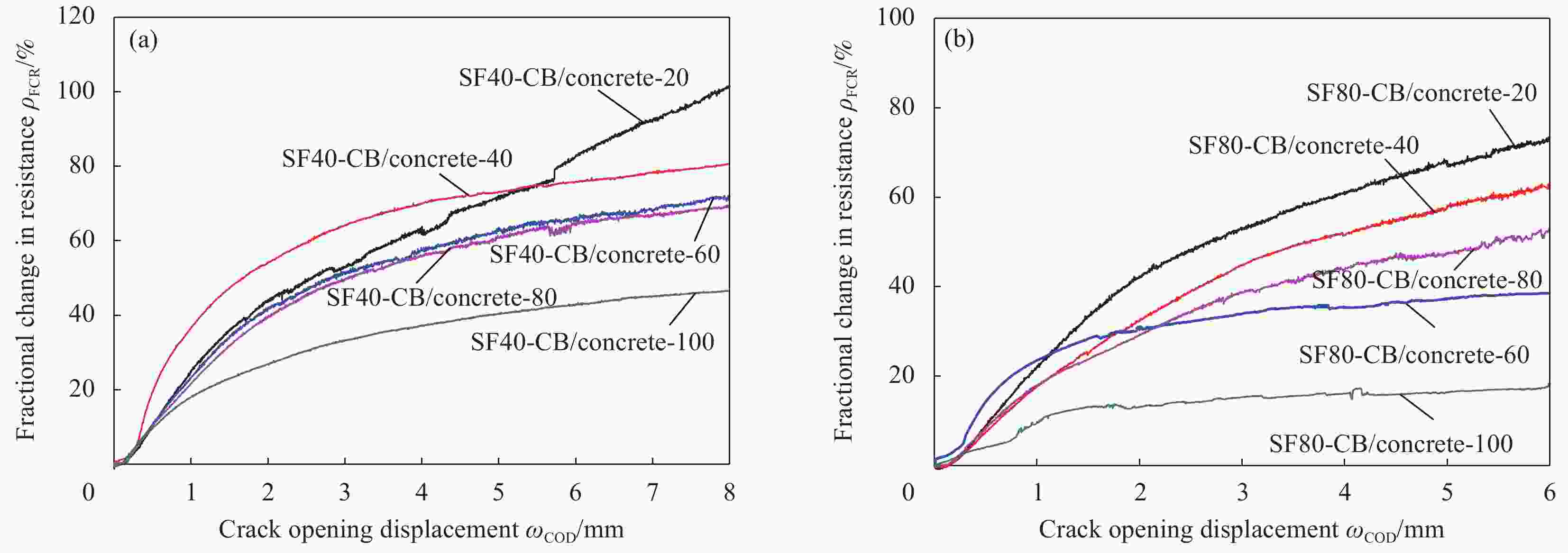

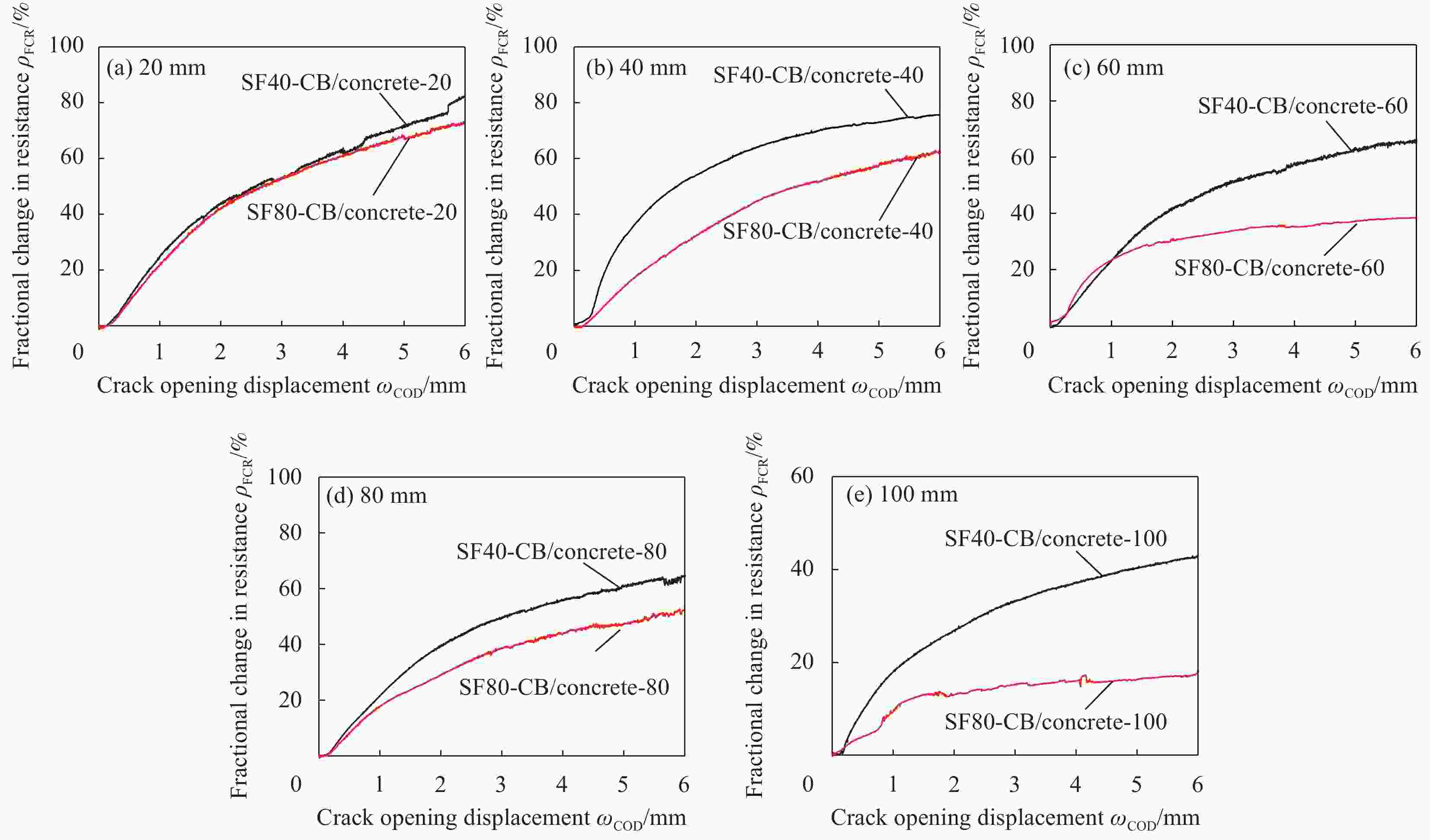

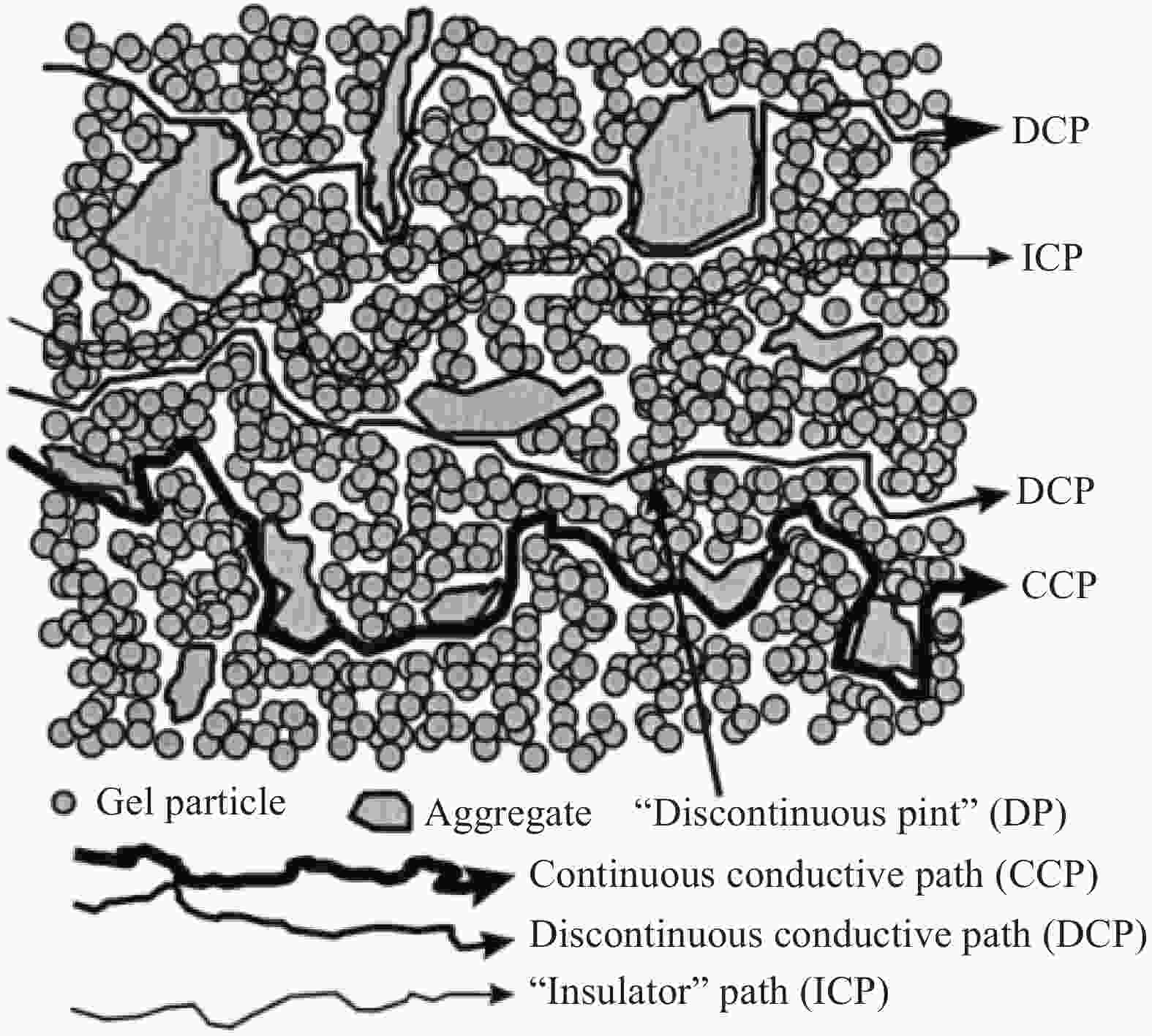

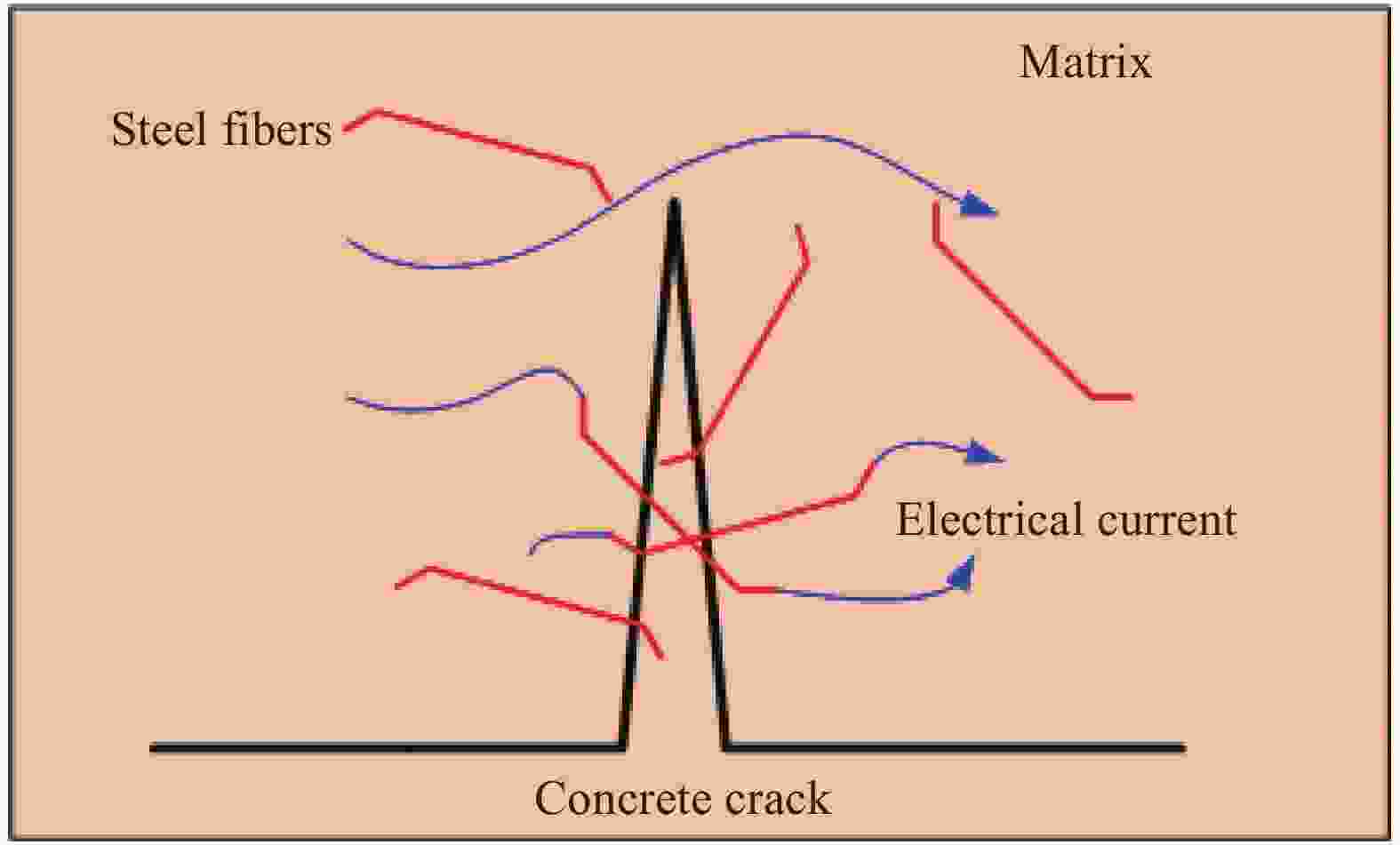

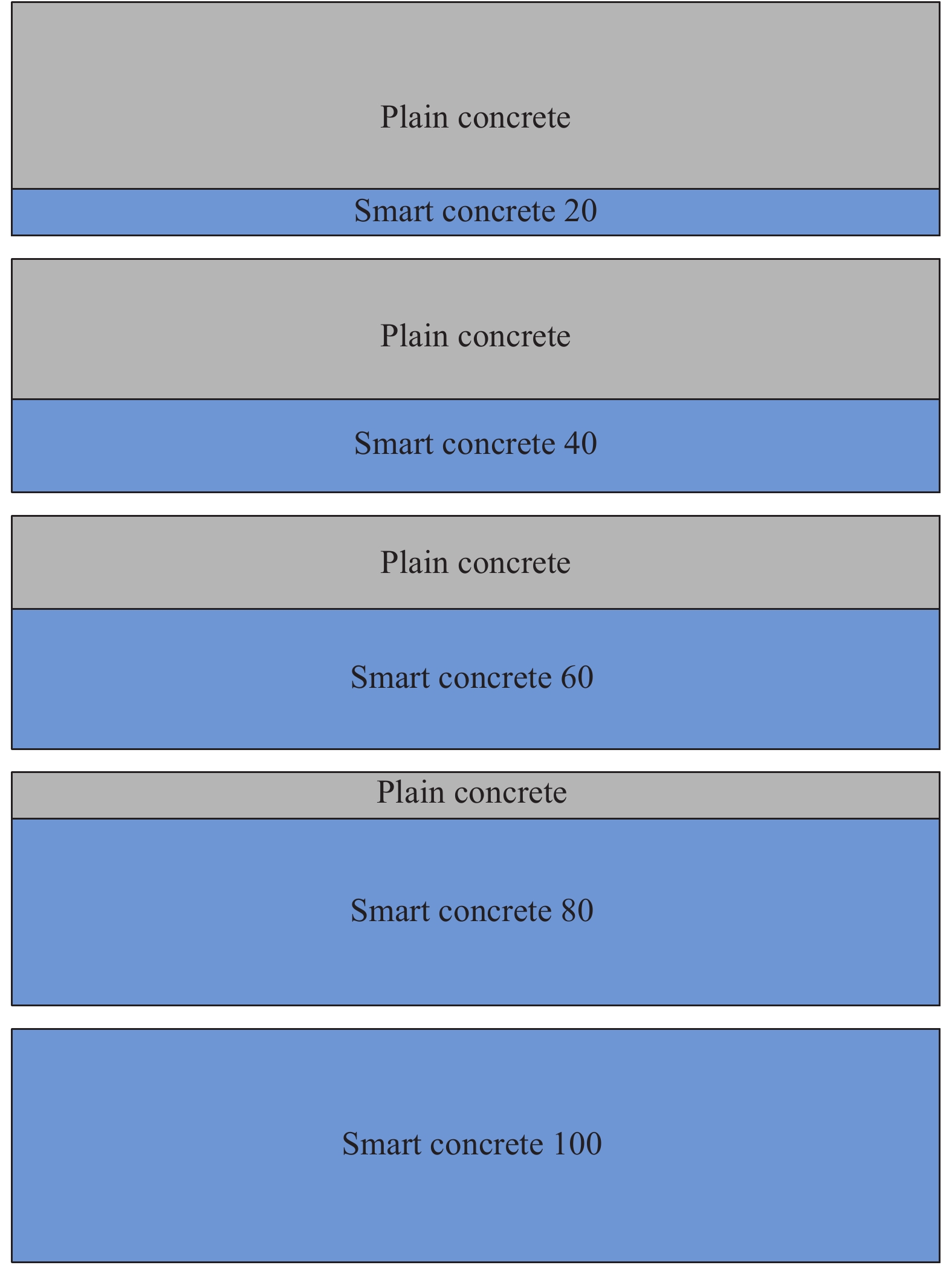

摘要: 将结构型钢纤维及纳米炭黑作为导电材料加入混凝土形成智能混凝土,并将智能混凝土和素混凝土一起浇筑形成双层混凝土梁。在四点弯曲加载下,采用四电极法对混凝土试件的电阻进行测量,对比研究了复掺钢纤维-纳米炭黑/混凝土层中钢纤维掺量及智能层厚度对混凝土梁的弯曲性能及裂缝自监测性能的影响。结果表明:混凝土智能层内结构型钢纤维的掺量和智能层厚度的增加能够显著提高混凝土梁的弯曲性能;依据电阻变化率-时间(ρFCR-t)曲线的变化特征可对混凝土的裂缝出现时刻进行监测,裂缝出现前,ρFCR-t曲线基本维持在零点附近,智能混凝土梁出现裂缝时,ρFCR-t曲线开始急剧上升,出现新裂缝后,ρFCR-t曲线出现新的转折点,斜率发生明显变化;裂缝出现时,试件的ρFCR增长较迅速,后期ρFCR增长变缓,ρFCR-裂缝扩展宽度(ωCOD)曲线呈负衰减函数特征;对于双层混凝土梁,增加混凝土智能层钢纤维掺量和智能层厚度,减小了相同裂缝宽度下裂缝自监测信号ρFCR的数值;本文提出的一阶指数衰减函数模型拟合ρFCR-ωCOD曲线效果较好。Abstract: The macro steel fiber and nano carbon black as conductive materials were added into the concrete to make smart concrete. A new type of concrete beam with double layers combined with the smart concrete and plain concrete was produced. In addition, the effect of the steel fiber content and the depth of the steel fiber-nano carbon black/concrete smart layer on the post-crack toughness and self-monitoring performance were studied in this paper. In order to monitor the concrete crack, four-probe method was used to measure the electrical resistance of the specimens. The results show that the toughness of the concrete beams is increased with the increasing of fiber content and the depth of the smart concrete layer. The crack self-monitoring of the concrete can be realized by analyzing the characteristics of the fraction change in resistance-time (ρFCR-t) curve. Furthermore, the ρFCR value is nearby zero before cracking, then a significant increase of ρFCR can be found after the crack appearing. If more than one crack happens on the smart concrete beam due to the deflection hardening behavior, new turning points where the slope of ρFCR-t curve changes can be observed. Additionally, the self sensing behavior decreases with the increasing of the steel fiber content and the depth of the smart concrete layer. The ρFCR value of the specimen increases rapidly after crack happening, after that it increases slowly gradually. However, the fractional change in resistance value at a certain crack width (ωCOD) decreases with the increasing of the fiber content and the height of the smart concrete layer. The proposed first order exponential decay function fits well with the ρFCR-ωCOD curves.

-

Key words:

- steel fiber /

- carbon black /

- smart concrete /

- fraction change in resistance /

- crack self-monitoring

-

表 1 混凝土基准配合比

Table 1. Mix proportions of concrete

kg·m−3 Cement Fly ash Water Fine aggregate (0–5 mm) Coarse aggregate (5–10 mm) SP 390 155 272.5 848 822 5.5 Note: SP—Superplasticizer. 表 2 双层混凝土梁试件的导电相纤维掺量和智能层厚度

Table 2. Fiber content and depth of different layers of concrete specimens with double layers

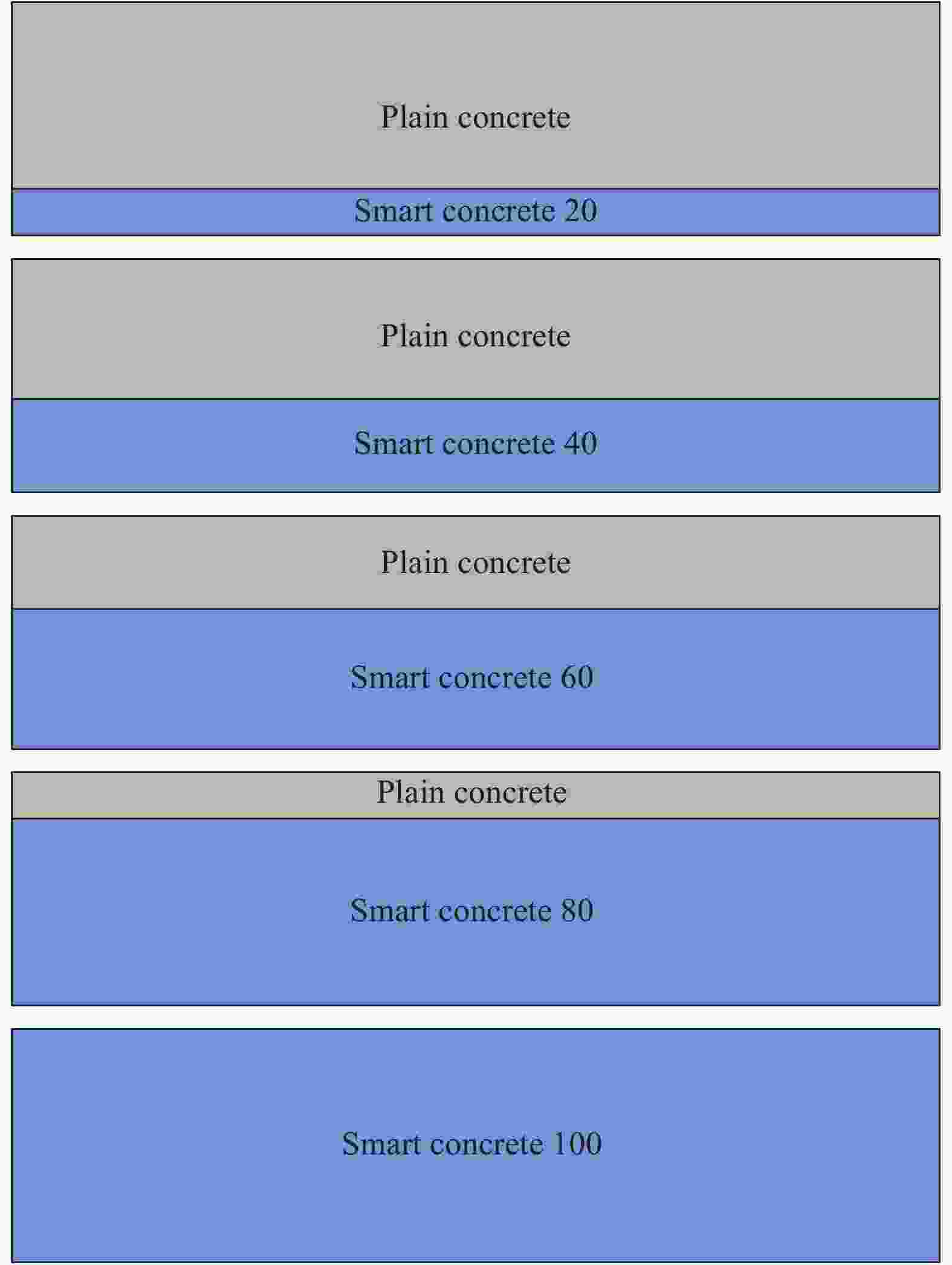

Specimen Content of SF/(kg·m−3) Smart layer depth/mm PC layer depth/mm SF40-CB/concrete-20 40 20 80 SF40-CB/concrete-40 40 40 60 SF40-CB/concrete-60 40 60 40 SF40-CB/concrete-80 40 80 20 SF40-CB/concrete-100 40 100 0 SF80-CB/concrete-20 80 20 80 SF80-CB/concrete-40 80 40 60 SF80-CB/concrete-60 80 60 40 SF80-CB/concrete-80 80 80 20 SF80-CB/concrete-100 80 100 0 Notes: SF—Steel fiber; PC—Plain concrete; CB—Carbon black. 表 3 双层混凝土试件受弯性能

Table 3. Flexure performance of concrete specimens with double layers

Specimen ${P_1}$/kN ${P_{\rm{P}}}$/kN $P_{{\rm{600}}}^{\rm{D}}$/kN $f_{{\rm{600}}}^{\rm{D}}$/MPa $P_{{\rm{150}}}^{\rm{D}}$/kN $f_{{\rm{150}}}^{\rm{D}}$/MPa $T_{{\rm{150}}}^{\rm{D}}$/(N·m) SF40-CB/concrete-20 16.1 16.1 11.3 3.4 8.7 2.6 21.3 SF40-CB/concrete-40 16.5 16.5 10.1 3.0 11.2 3.4 22.1 SF40-CB/concrete-60 14.0 14.0 11.0 3.3 12.9 3.9 24.2 SF40-CB/concrete-80 14.7 14.7 13.1 3.9 13.0 3.9 27.0 SF40-CB/concrete-100 17.7 17.7 17.3 5.2 15.5 4.7 32.6 SF80-CB/concrete-20 19.1 19.1 15.9 4.8 14.4 4.3 32.2 SF80-CB/concrete-40 18.4 18.4 17.8 5.3 14.5 4.4 33.3 SF80-CB/concrete-60 20.4 20.6 20.4 6.1 16.2 4.9 37.3 SF80-CB/concrete-80 16.8 19.4 17.3 5.2 18.7 5.6 35.9 SF80-CB/concrete-100 21.0 27.5 23.6 7.1 25.6 7.7 50.5 Notes: P1—First peak load; PP—Peak load; $P_{{\rm{600}}}^{\rm{D}}$—Residual load at deflection of 0.5 mm; $P_{{\rm{150}}}^{\rm{D}}$—Residual load at deflection of 2 mm; $f_{{\rm{600}}}^{\rm{D}}$—Residual strength at deflection of 0.5 mm; $f_{{\rm{150}}}^{\rm{D}}$—Residual strength at deflection of 2 mm; $T_{{\rm{150}}}^{\rm{D}}$—Area under load vs. deflection curve 0–2 mm. 表 4 双层混凝土在不同裂缝扩展宽度ωCOD下的电阻变化率ρFCR

Table 4. Fractional change in resistance ρFCR of concrete specimens with double layers at different crack opening displacement ωCOD

Specimen ρFCR/% 0.2 mm 0.5 mm 1.0 mm 2.0 mm 3.0 mm 4.0 mm 5.0 mm 6.0 mm SF40-CB/concrete-20 1.61 10.35 25.16 44.29 52.87 63.87 71.77 82.63 SF40-CB/concrete-40 1.61 19.40 36.73 54.07 64.10 69.88 73.20 75.87 SF40-CB/concrete-60 2.68 10.60 23.36 42.08 50.93 57.33 63.58 65.42 SF40-CB/concrete-80 1.91 10.27 21.61 39.54 49.47 55.71 60.37 64.88 SF40-CB/concrete-100 1.94 9.58 18.18 26.99 33.20 37.14 40.47 43.01 SF80-CB/concrete-20 0.85 8.79 22.28 42.04 53.20 60.57 67.66 73.38 SF80-CB/concrete-40 1.14 7.49 17.56 32.26 44.70 51.48 57.98 62.69 SF80-CB/concrete-60 3.32 14.26 23.49 30.32 33.92 35.38 37.31 38.64 SF80-CB/concrete-80 1.44 8.44 17.74 29.42 38.73 43.86 47.51 52.58 SF80-CB/concrete-100 1.66 4.09 9.55 13.10 15.23 16.07 16.34 18.31 表 5 ρFCR-ωCOD曲线一阶衰减函数拟合结果

Table 5. Fitting results of ρFCR-ωCOD curves by first order exponential decay function

Specimen y0 A B R2 SF40-CB/concrete-20 91.5 −92.1 3.2 0.998 SF40-CB/concrete-40 76.4 −76.6 1.6 0.999 SF40-CB/concrete-60 71.2 −72.0 2.4 0.999 SF40-CB/concrete-80 70.6 −71.4 2.5 0.999 SF40-CB/concrete-100 44.1 −44.1 2.0 0.999 SF80-CB/concrete-20 83.7 −84.7 3.0 0.998 SF80-CB/concrete-40 78.5 −79.2 3.7 0.998 SF80-CB/concrete-60 37.1 −36.7 1.1 0.997 SF80-CB/concrete-80 58.1 −58.5 2.8 0.999 SF80-CB/concrete-100 16.9 −17.0 1.3 0.994 -

[1] CHEN P W, CHUNG D D L. Carbon fiber reinforced concrete for smart structures capable of non-destructive flaw detection[J]. Smart Materials & Structures,1993,2(1):22-30. [2] MONTEIRO A O, CACHIM P B, COSTA P M J C. Self-sensing piezoresistive cement composite loaded with carbon black particles[J]. Cement and Concrete Composites,2017,81:59-65. doi: 10.1016/j.cemconcomp.2017.04.009 [3] FU X, LU W, CHUNG D D L. Ozone treatment of carbon fiber for reinforcing cement[J]. Carbon,1998,36(9):1337-1345. doi: 10.1016/S0008-6223(98)00115-8 [4] 贾兴文, 张新, 马冬, 等. 导电混凝土的导电性能及影响因素研究进展[J]. 材料导报, 2017, 31(21):90-97. doi: 10.11896/j.issn.1005-023X.2017.021.013JIA Xingwen, ZHANG Xin, MA Dong, et al. Conductive properties and influencing factors of electrically conductive concrete: A review[J]. Materials Review,2017,31(21):90-97(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.021.013 [5] 范晓明, 敖芳, 孙明清, 等. 嵌入式碳纤维石墨水泥基复合材料的压阻特性[J]. 建筑材料学报, 2011, 14(1):88-91. doi: 10.3969/j.issn.1007-9629.2011.01.018FAN Xiaoming, AO Fang, SUN Mingqing, et al. Piezoresistivity of carbon fiber graphite cement-based composites embedded in concrete column[J]. Journal of Building Materials,2011,14(1):88-91(in Chinese). doi: 10.3969/j.issn.1007-9629.2011.01.018 [6] 欧进萍, 关新春, 李惠. 应力自感知水泥基复合材料及其传感器的研究进展[J]. 复合材料学报, 2006, 23 (4):1-8. doi: 10.3321/j.issn:1000-3851.2006.04.001OU Jinping, GUAN Xinchun, LI Hui. State-of-the-art of stress-sensing cement composite material and sensors[J]. Acta Materiae Compositae Sinica,2006,23 (4):1-8(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.04.001 [7] 欧进萍. 土木工程结构智能感知材料、传感器与健康监测系统[J]. 功能材料, 2005, 35(5):12-22.OU Jinping. Smart sensing materials, sensors and structural health monitoring in civil engineering[J]. Journal of Functional Materials,2005,35(5):12-22(in Chinese). [8] HAN B G, DING S Q, YU X. Intrinsic self-sensing concrete and structures: A review[J]. Measurement,2015,59:110-128. doi: 10.1016/j.measurement.2014.09.048 [9] HAN B G, OU J P. Embedded piezoresistive cement-based stress/strain sensor[J]. Sensors and Actuators A: Physical,2007,138(2):294-298. doi: 10.1016/j.sna.2007.05.011 [10] FU X, CHUNG D D L. Contact electrical resistivity between cement and carbon fiber: Its decrease with increasing bond strength and its increase during fiber pull-out[J]. Cement and Concrete Research,1995,25(7):1391-1396. doi: 10.1016/0008-8846(95)00132-V [11] FU X, CHUNG D D L. Sensitivity of the bond strength to the structure of the interface between reinforcement and cement, and the variability of this structure[J]. Cement and Concrete Research,1998,28(6):787-793. doi: 10.1016/S0008-8846(98)00055-6 [12] HOWSER R N, DHONDE H B, MO Y L. Self-sensing of carbon nanofiber concrete columns subjected to reversed cyclic loading[J]. Smart Materials and Structures,2011,20(8):1-13. [13] DING Y N, HAN Z B, ZHANG Y L, et al. Concrete with triphasic conductive materials for self-monitoring of cracking development subjected to flexure[J]. Composite Structures,2016,138:184-91. doi: 10.1016/j.compstruct.2015.11.051 [14] DOWNEY A, D’ALESSANDRO A, BAQUERA M, et al. Damage detection, localization and quantification in conductive smart concrete structures using a resistor mesh model[J]. Engineering Structures, 2017, 148: 924-935. [15] NGUYEN D L, SONG J, MANATHAMSOMBAT C, et al. Comparative electromechanical damage-sensing behaviors of six strain-hardening steel fiber-reinforced cementitious composites under direct tension[J]. Composites Part B: Engineering, 2015, 69: 159-168. [16] BURATTI N, MAZZOTTI C, SAVOIA M. Post-cracking behaviour of steel and macro-synthetic fibre-reinforced concretes[J]. Construction & Building Materials,2011,25(5):2713-2722. [17] KIM D J, PARK S H, RYU G S, et al. Comparative flexural behavior of hybrid ultra high performance fiber reinforced concrete with different macro fibers[J]. Construction and Building Materials,2011,25(11):4144-4155. doi: 10.1016/j.conbuildmat.2011.04.051 [18] DHANAPAL J, JEYAPRAKASH S. Mechanical properties of mixed steel fiber reinforced concrete with the combination of micro and macro steel fibers[J]. Structural Concrete,2020,21(1):458-467. doi: 10.1002/suco.201700219 [19] 李冬. 结构型纤维对混凝土韧性及裂后渗透性能的影响[D]. 大连: 大连理工大学, 2018.LI Dong. The influence of macro fibers on toughness and water permeability of cracked concrete[D]. Dalian: Dalian University of Technology, 2018(in Chinese). [20] 柳根金, 丁一宁, 衡震. 不同导电相对混凝土裂缝智能化自监测的灵敏度与噪声水平的影响[J]. 复合材料学报, 2020, 37(10): 2610-2618.LIU Genjin, DING Yining, HENG Zhen. Influence of conductive materials on the crack sensing sensitivity and noise signal of smart concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(10): 2610-2618(in Chinese). [21] LAYSSI H, GHODS P, ALIZADEH A R, et al. Electrical resistivity of concrete[J]. Concrete International,2015,37(5):41-46. [22] SENGUL O, GJØRV O E. Effect of embedded steel on electrical resistivity measurements on concrete structures[J]. ACI Materials Journal,2009,106(1):11-18. [23] SONG G. Equivalent circuit model for AC electrochemical impedance spectroscopy of concrete[J]. Cement & Concrete Research,2000,30(11):1723-30. [24] KIM M K, PARK J, KIM D J. Characterizing the electro-mechanical response of self-sensing steel-fiber-reinforced cementitious composites[J]. Construction and Building Materials,2020,240:1-10. [25] AZHARI F. Cement-based sensors for structural health monitoring[D]. Vancouver: University of British Columbia, 2008. -

下载:

下载: