Prediction of thrust force in CFRP composite drilling considering tool wear effect

-

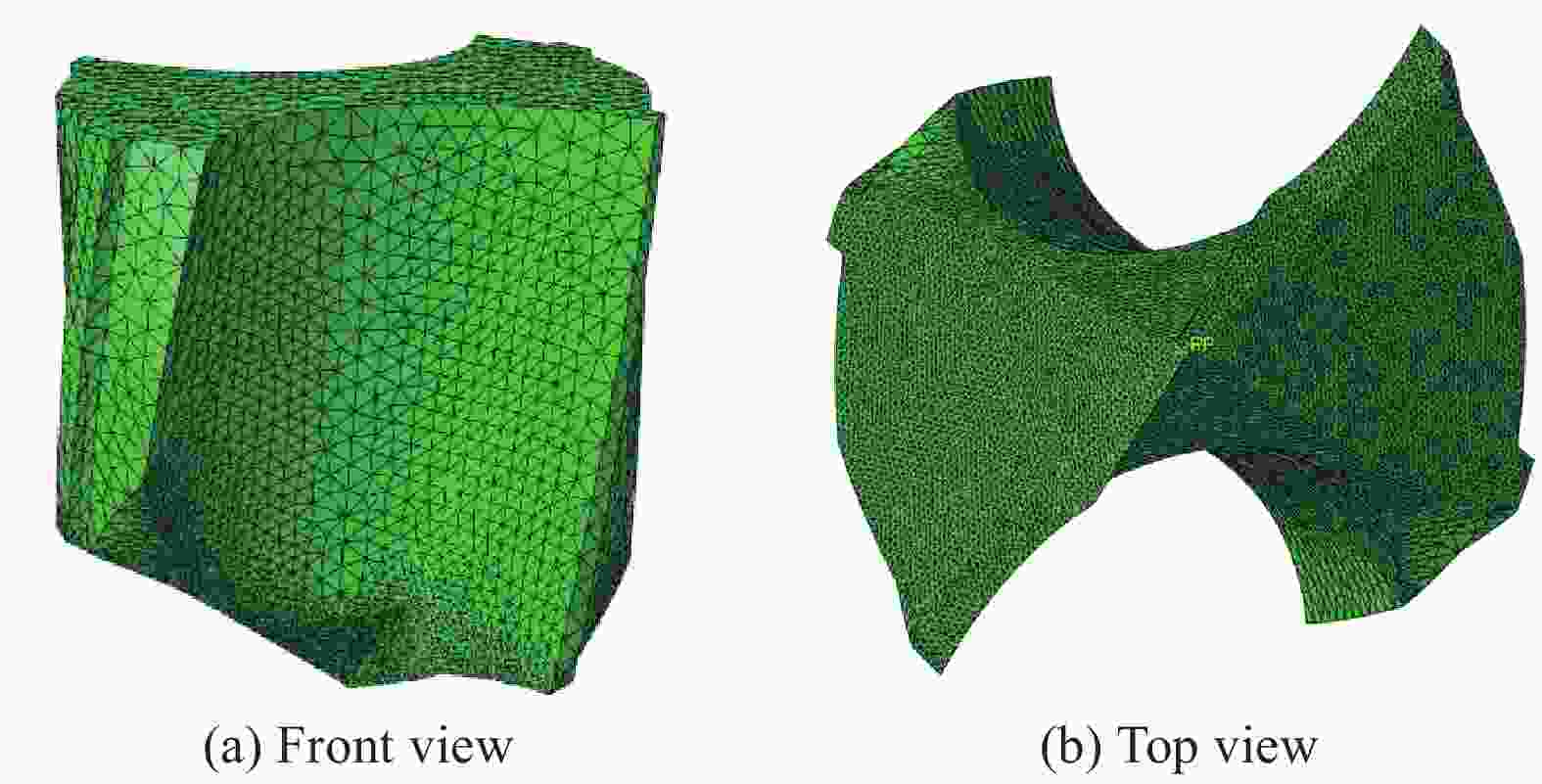

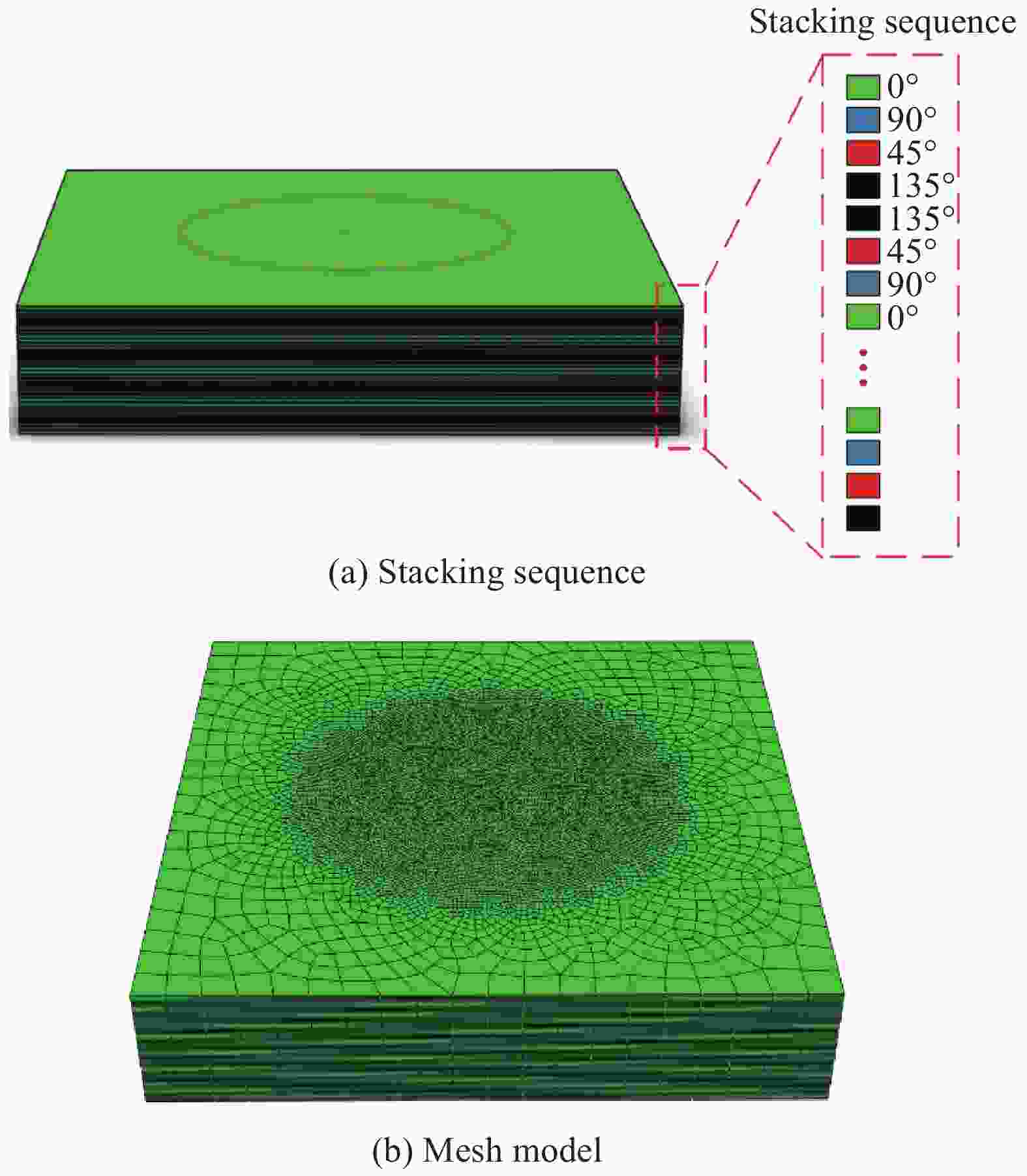

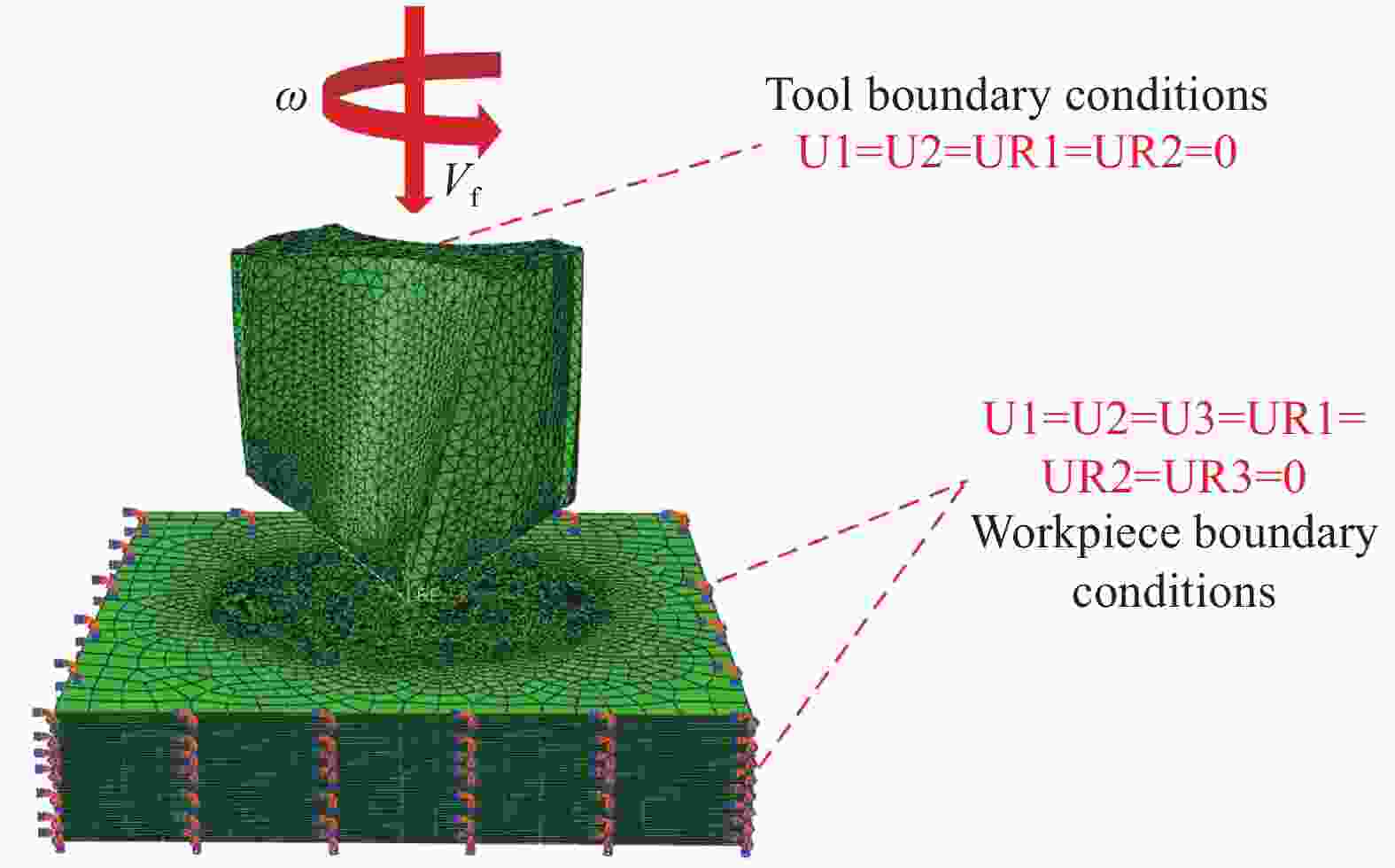

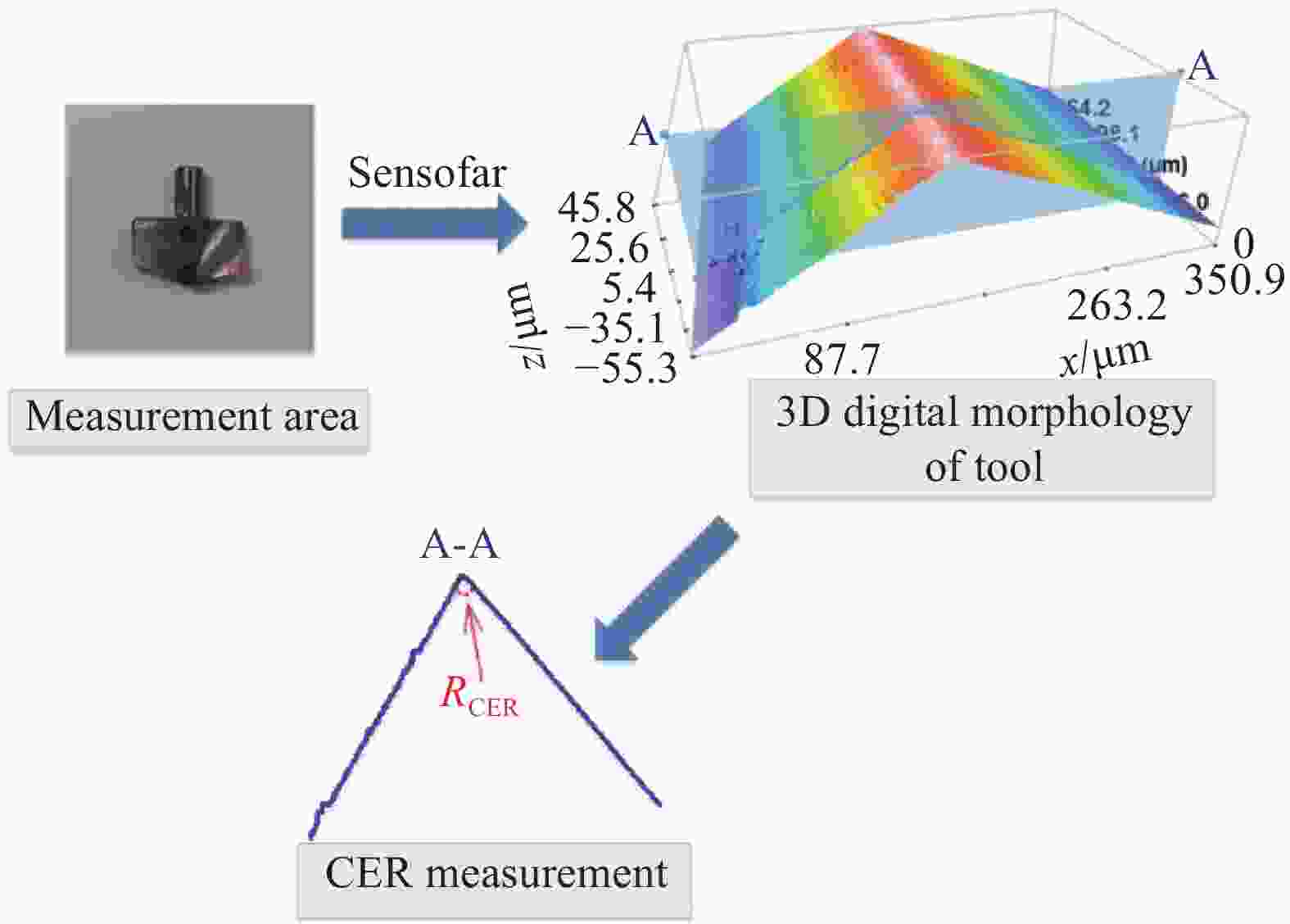

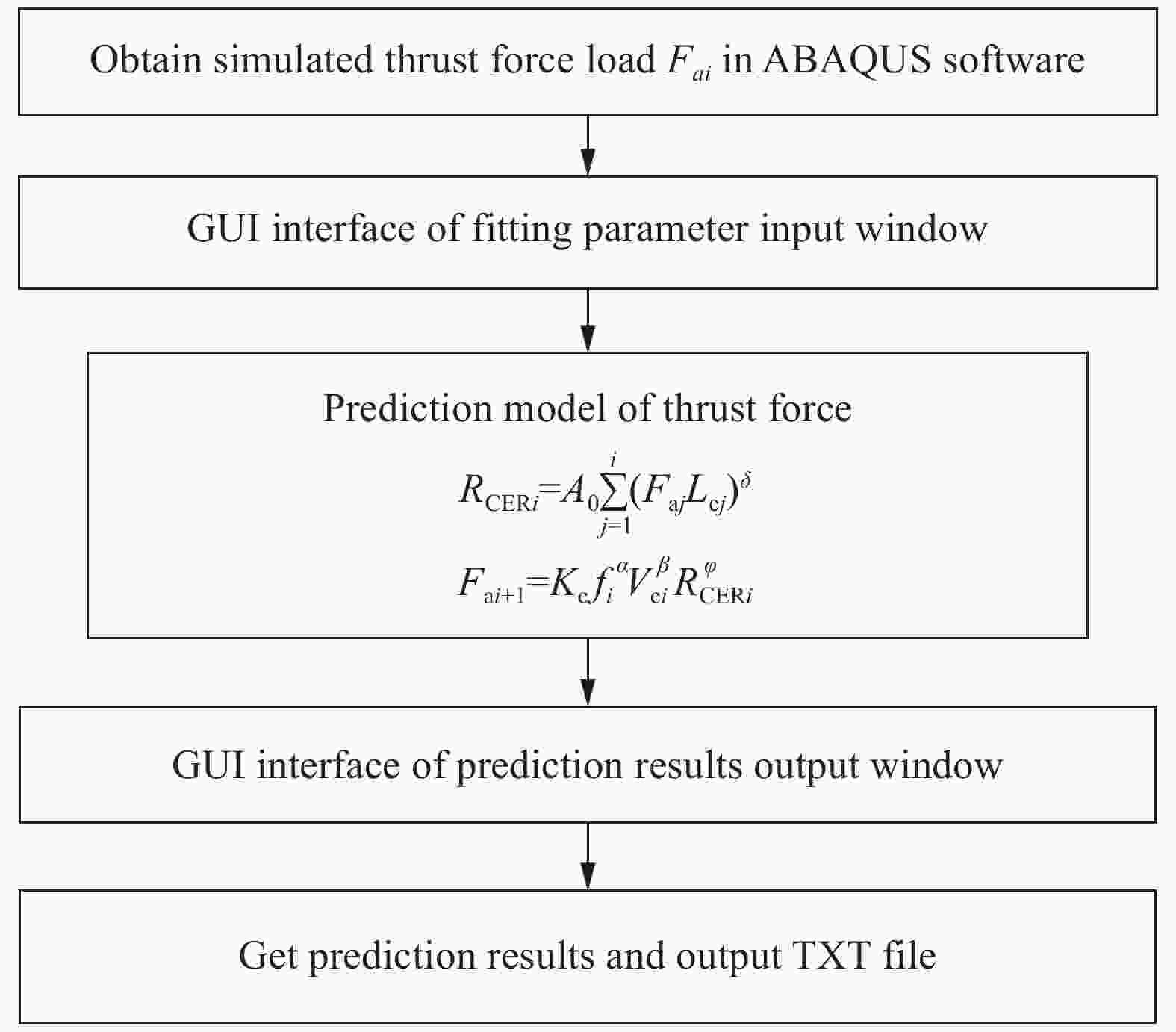

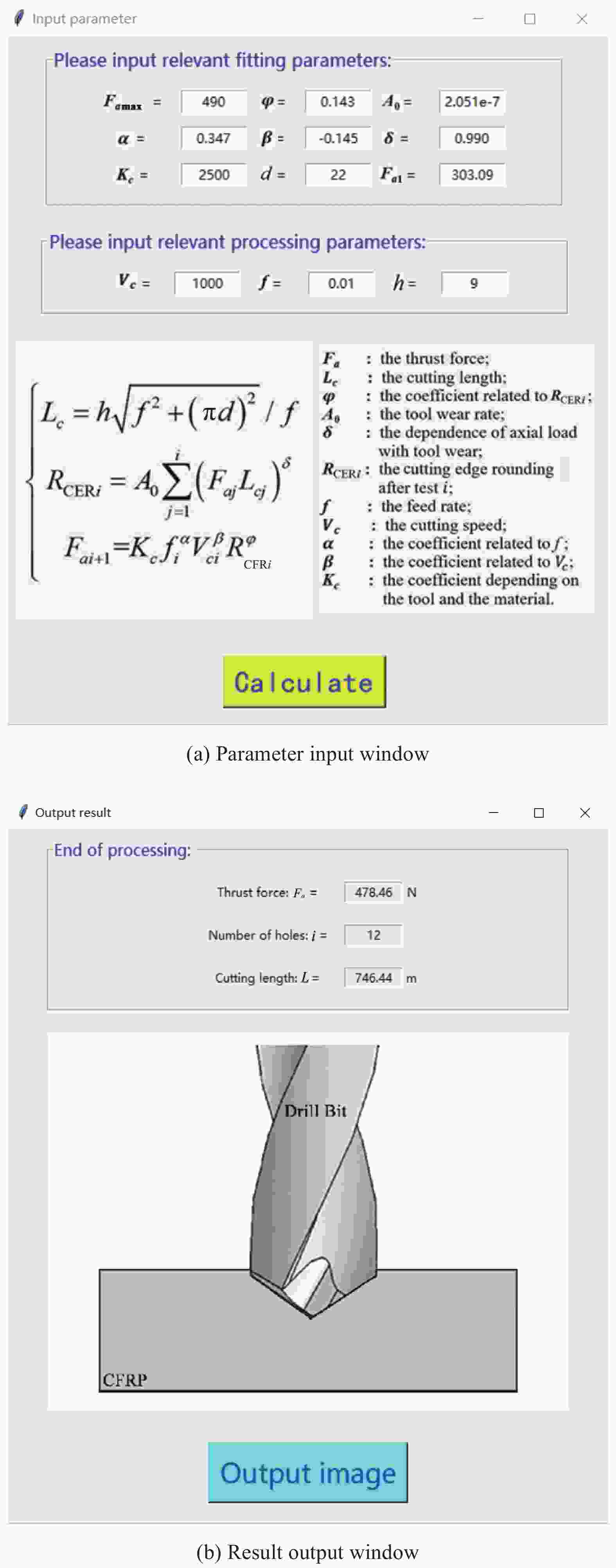

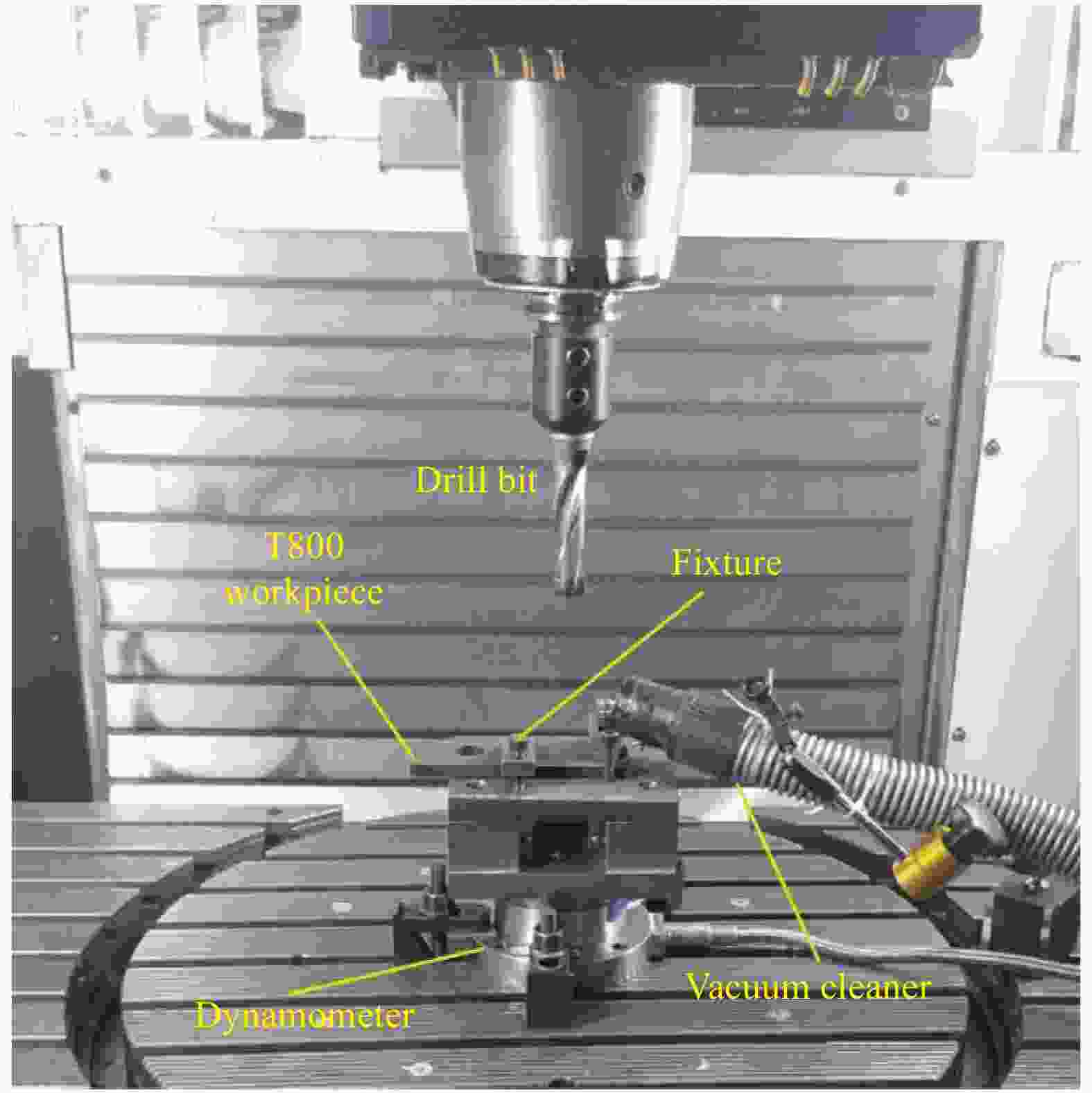

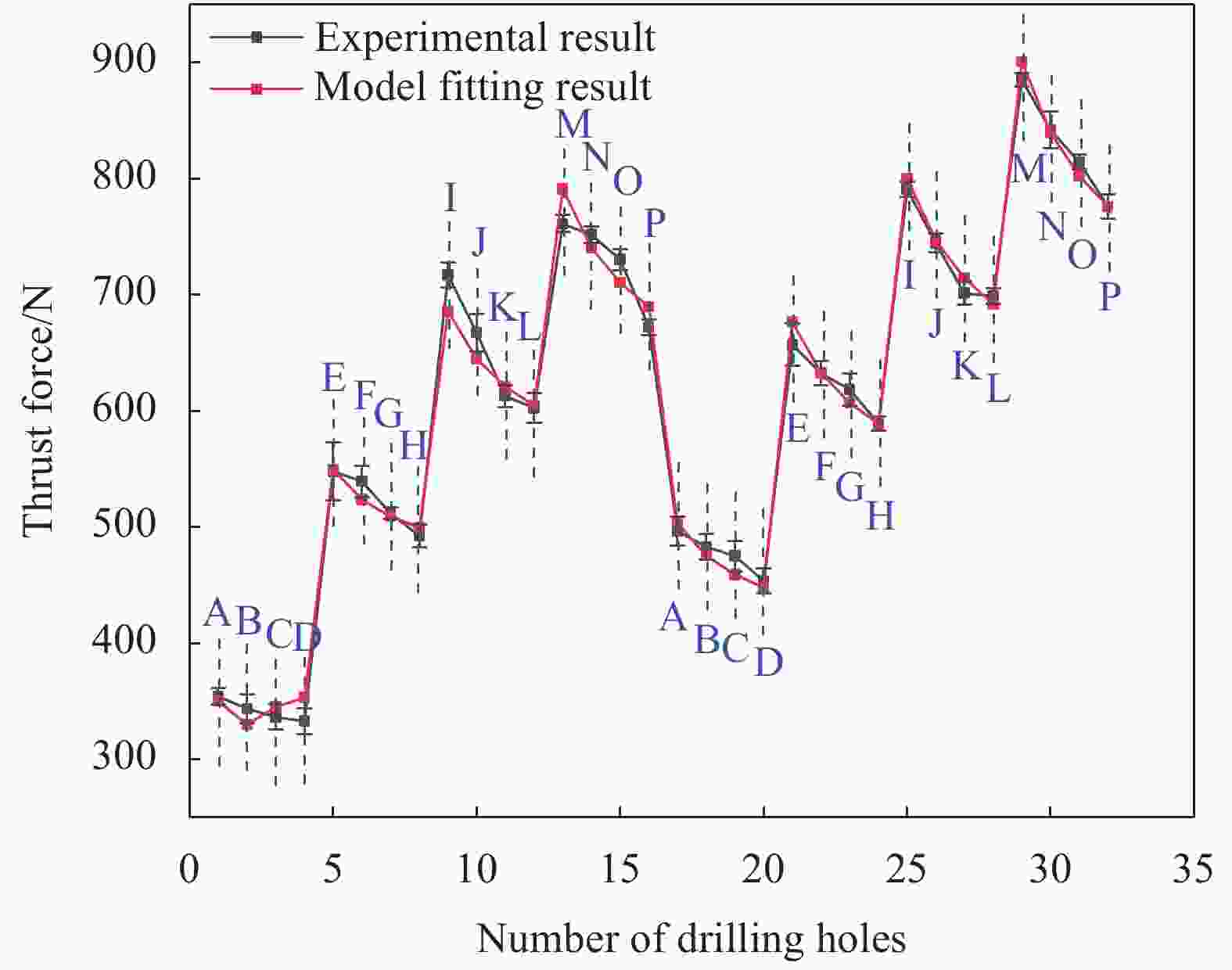

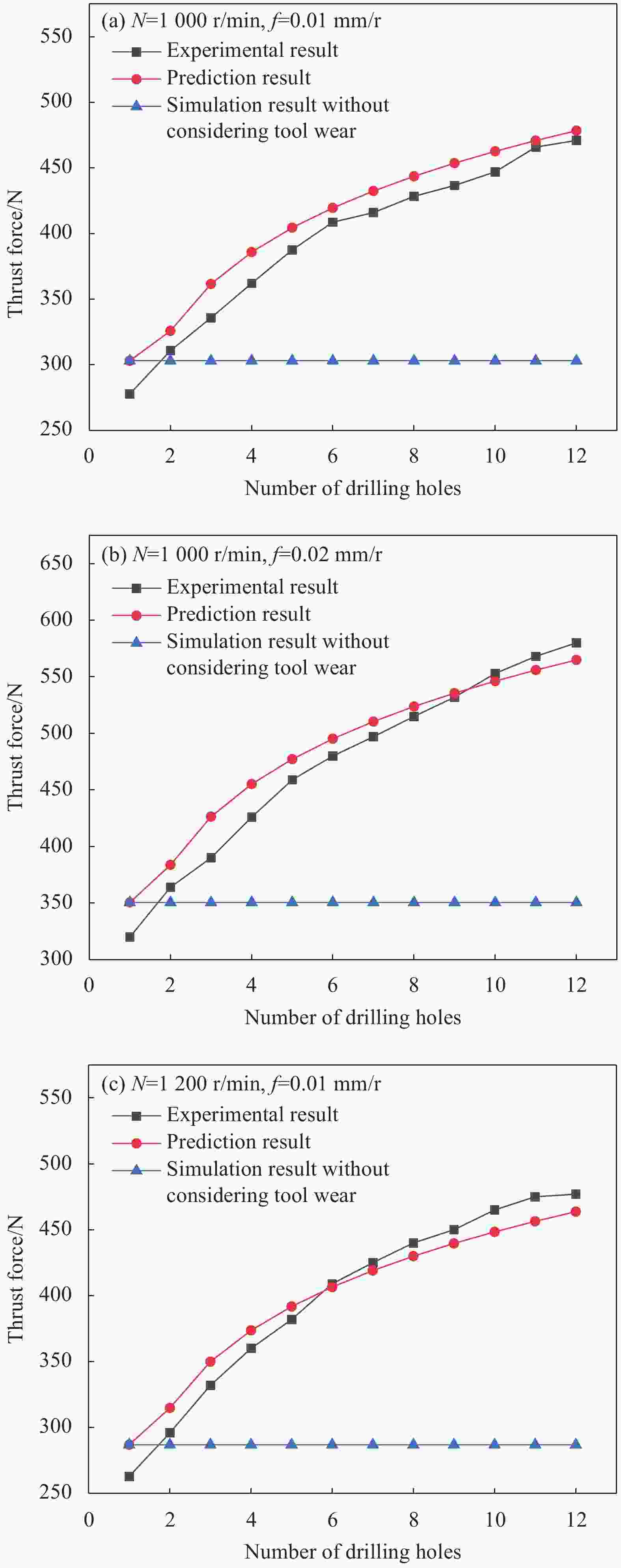

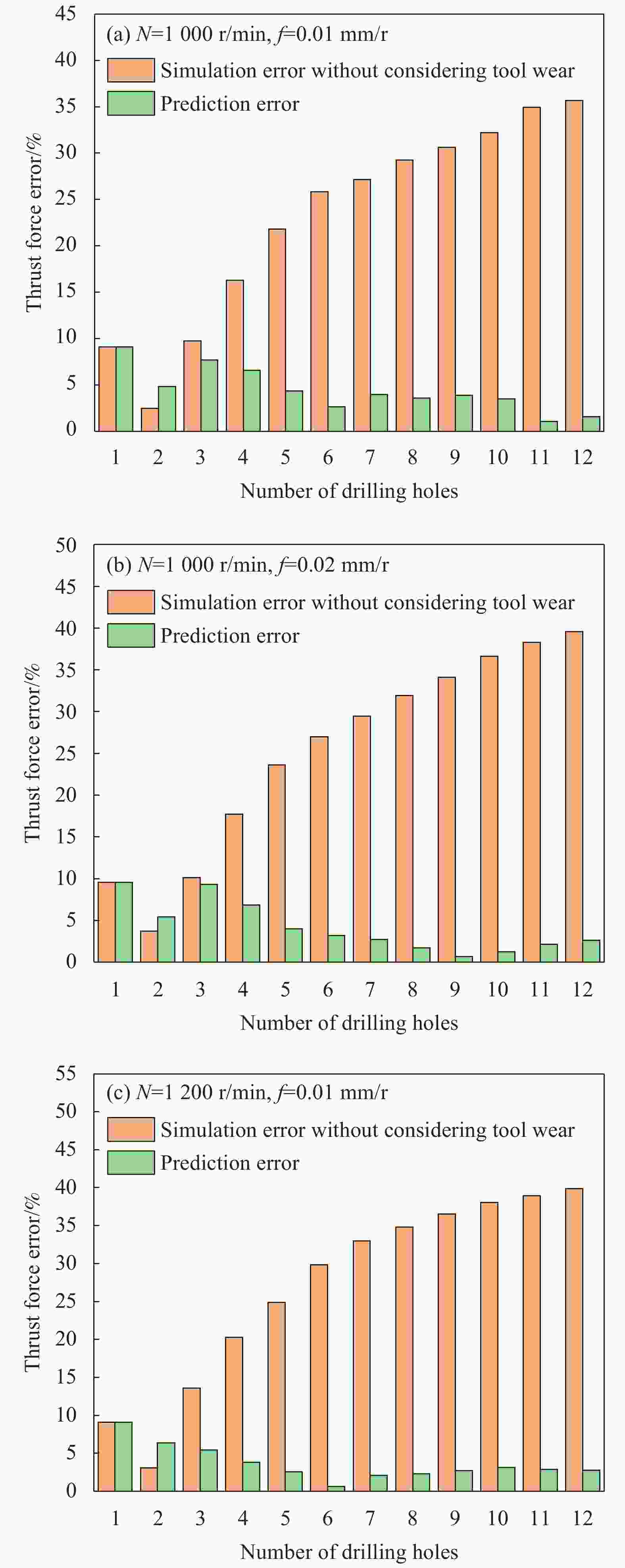

摘要: 在碳纤维增强树脂(CFRP)复合材料钻削过程中,随着刀具磨损量的累积,轴向力会逐渐增加,轴向力过大会导致CFRP复合材料一系列的加工缺陷。为实现在CFRP复合材料钻削过程中随刀具磨损量的累积轴向力变化的有限元分析及预测,建立了CFRP复合材料钻削仿真模型,通过对ABAQUS仿真软件二次开发,利用Python语言开发子程序,将考虑磨损量累积的轴向力预测模型导入仿真软件,运用ABAQUS软件对CFRP复合材料钻削中轴向力进行研究,实现了随着刀具磨损量累积轴向力变化的预测功能。随后通过CFRP复合材料钻削试验,分析了轴向力随钻削孔数的变化规律,以验证轴向力的预测结果。结果表明:3D钻削有限元模型能够良好地预测实际加工过程中刀具未磨损时轴向力的大小,其误差为9.10%;在考虑磨损量累积后,轴向力预测模型能够较准确地预测实际加工过程轴向力的大小,其最大误差不超过10%。Abstract: In the drilling process of carbon fiber reinforced polymer (CFRP) composite, the thrust force gradually increases with the accumulation of tool wear. Excessive thrust force can cause a series of machining defects in CFRP composite. In order to realize the finite element analysis and prediction of the thrust force changing with the accumulation of tool wear in the process of CFRP composite drilling, the simulation model of CFRP composite drilling was established. Through the secondary development of the ABAQUS simulation software, the thrust force prediction model considering the wear accumulation was imported into the simulation software by using the Python language development subroutine. The thrust force in the CFRP composite drilling was studied by using the ABAQUS software, and the prediction function of thrust force change with tool wear was realized. Then, through CFRP composite drilling experiments, the changes in thrust force with the number of drilling holes were analyzed to verify the prediction results of the model. The results show that the 3D finite element model of drilling without considering the change of wear can well predict the thrust force in the actual machining process, with the error of 9.10%. After considering the wear accumulation, the thrust force prediction model can predict the thrust force in the actual machining process, with the maximum error less than 10%.

-

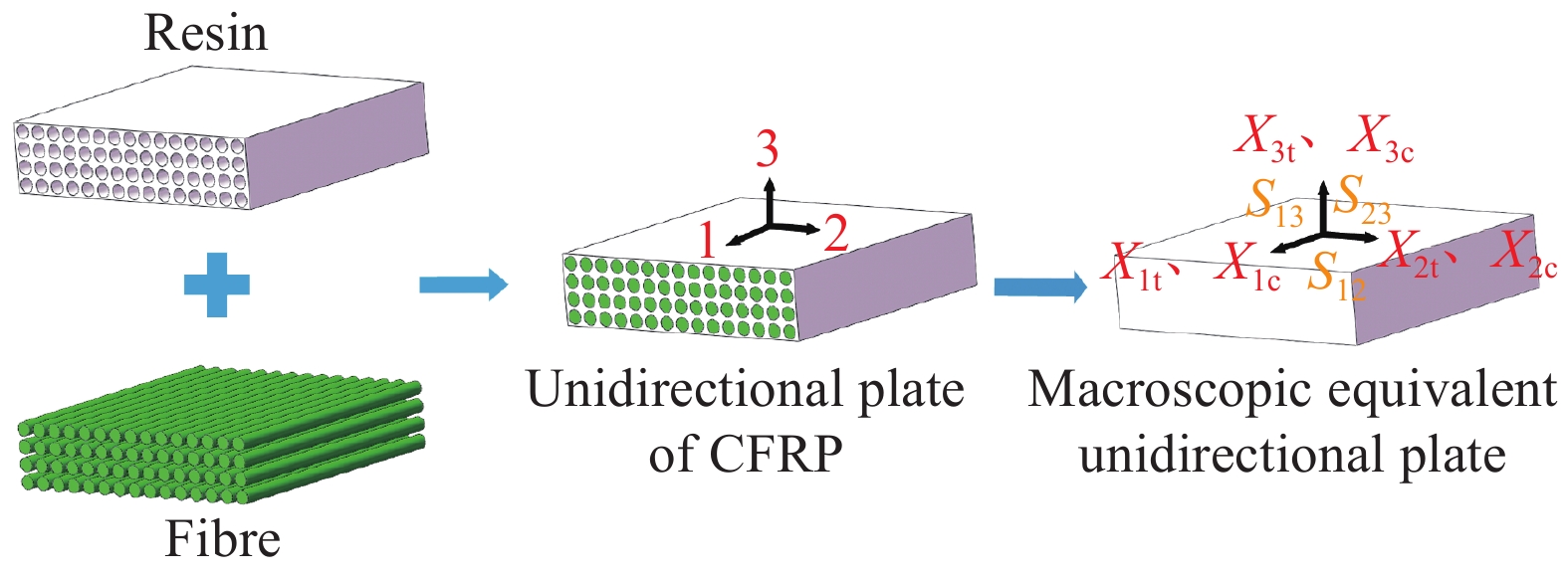

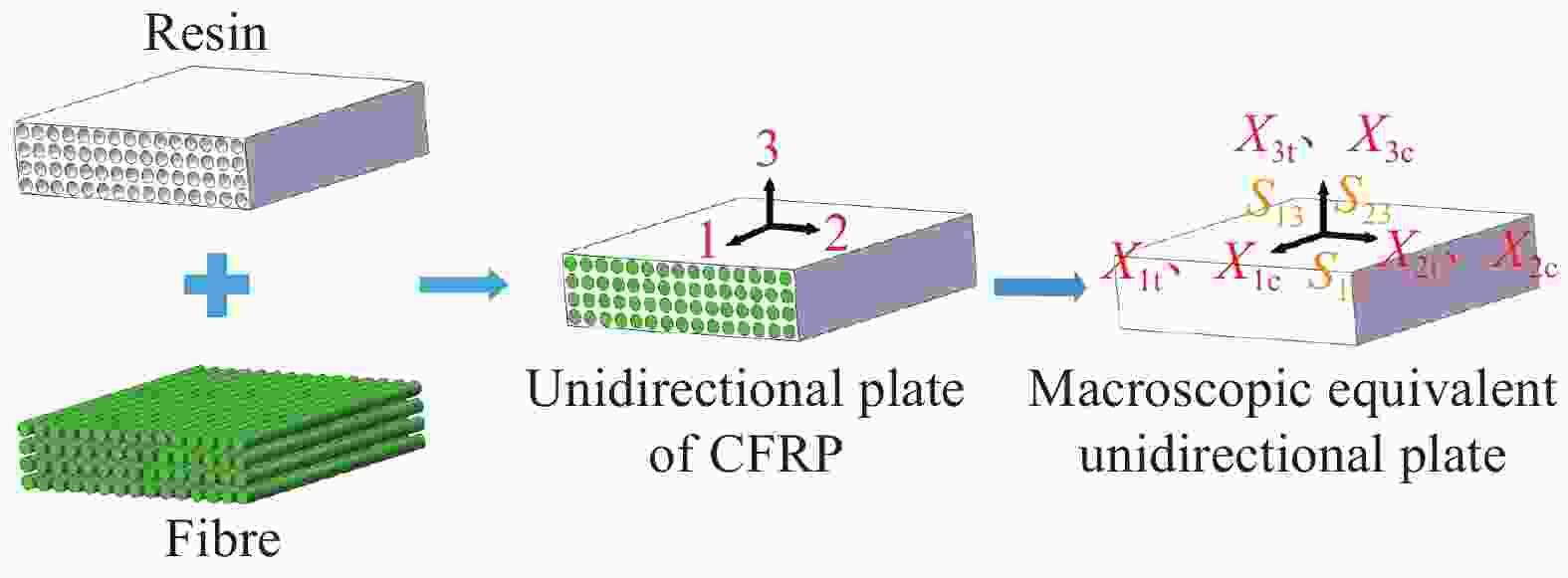

CFRP strength parameter Value X1t/MPa 2720 X2t=X3t/MPa 111 X1c/MPa 1690 X2c=X3c/MPa 214 S12=S23=S13/MPa 115 Notes: X1t—Tensile strength in 1 direction; X2t—Tensile strength in 2 directions; X3t—Tensile strength in 3 directions; X1c—Compressive strength in the 1 direction; X2c—Compressive strength in 2 directions; X3c—Compressive strength in 3 directions; S12—Shear strength in 1-2 plane; S23—Shear strength in 2-3 planes; S13—Shear strength in 1-3 planes. 表 2 YTDI-220T-FSL型冠齿钻主要参数

Table 2. Main parameters of YTDI-220T-FSL crown drill

Main parameter of tool Value Diameter/mm 22 Helix angle/(°) 15 Point angle/(°) 130 表 3 钻削试验参数

Table 3. Experiment parameters of drilling

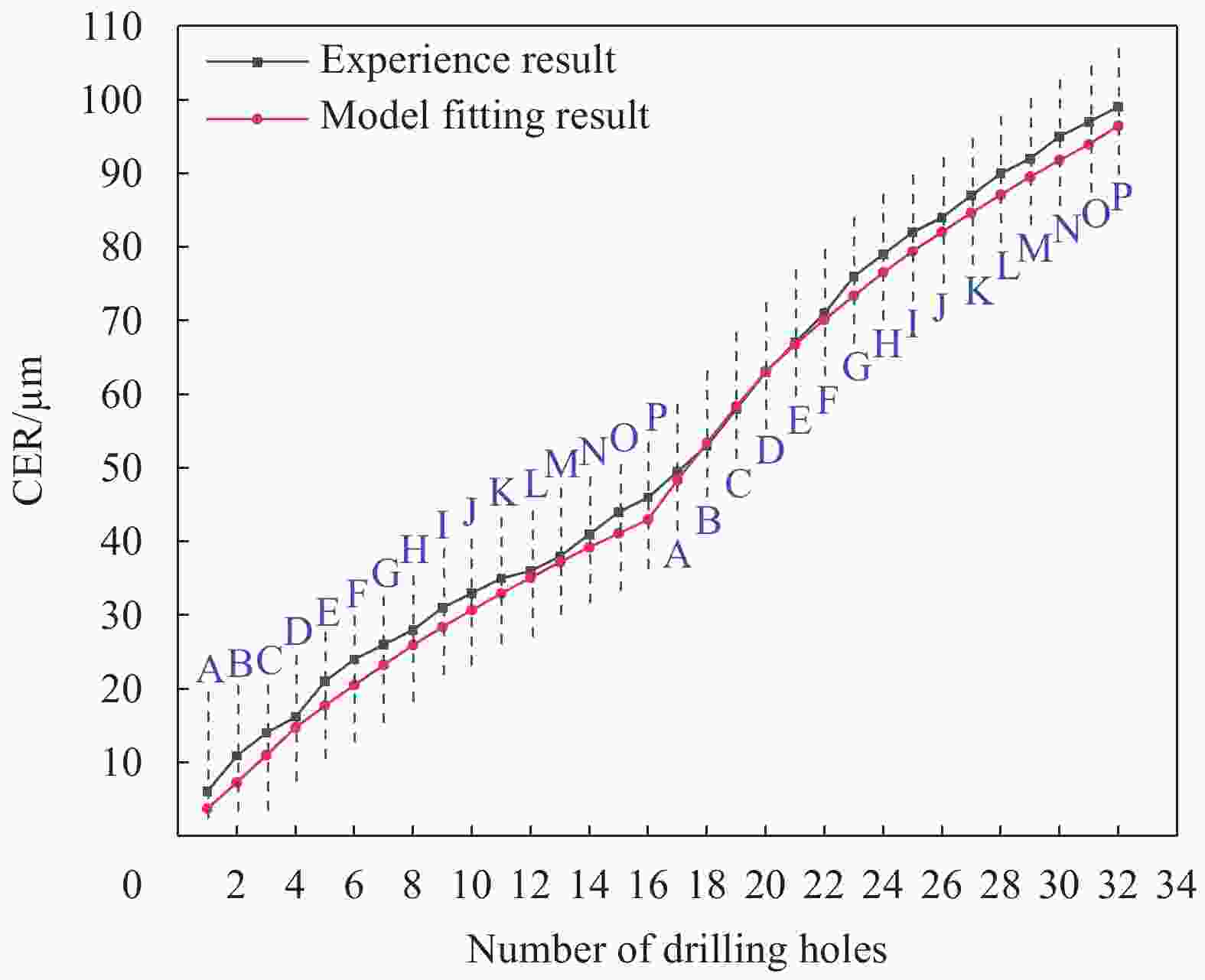

Test

conditionSpindle speed/

(r·min−1)Feed rate/

(mm·r−1)Cutting speed/

(m·min−1)A 600 0.01 41.47 B 1000 0.01 69.12 C 1400 0.01 96.76 D 1800 0.01 124.41 E 600 0.02 41.47 F 1000 0.02 69.12 G 1400 0.02 96.76 H 1800 0.02 124.41 I 600 0.03 41.47 J 1000 0.03 69.12 K 1400 0.03 96.76 L 1800 0.03 124.41 M 600 0.04 41.47 N 1000 0.04 69.12 O 1400 0.04 96.76 P 1800 0.04 124.41 Drilling sequence: A B C D E F G H I J K L M N O P A B C D E F G H I J K L M N O P 表 4 轴向力验证试验参数

Table 4. Experimental parameters of thrust force verification

Spindle speed/

(r·min−1)Feed rate/

(mm·r−1)Cutting speed/

(m·min−1)1000 0.01 69.12 1000 0.02 69.12 1200 0.01 82.94 -

[1] VIGNESHWARAN S, UTHAYAKUMAR M, ARUMUGAPRABU V. Review on machinability of fiber reinforced polymers: A drilling approach[J]. Silicon,2018,10(5):2295-2305. doi: 10.1007/s12633-018-9764-9 [2] KOVÁCS L, ROMHÁNY G. Derivation of ply specific stiffness parameters of fiber reinforced polymer laminates via inverse solution of classical laminate theory[J]. Periodica Polytechnica Mechanical Engineering,2018,62(2):158-164. [3] LIU D, TANG Y, CONG W L. A review of mechanical drilling for composite laminates[J]. Composite Structures,2012,94(4):1265-1279. doi: 10.1016/j.compstruct.2011.11.024 [4] ABRÃO A M, FARIA P E, RUBIO J C C, et al. Drilling of fiber reinforced plastics: A review[J]. Journal of Materials Processing Technology,2007,186(1-3):1-7. doi: 10.1016/j.jmatprotec.2006.11.146 [5] PANCHAGNULA K K, PALANIYANDI K. Drilling on fiber reinforced polymer/nanopolymer composite laminates: A review[J]. Journal of Materials Research and Technology,2018,7(2):180-189. doi: 10.1016/j.jmrt.2017.06.003 [6] 陈绍杰. 复合材料技术与大型飞机[J]. 航空学报, 2008, 29(3):605-610. doi: 10.3321/j.issn:1000-6893.2008.03.011CHEN S J. Composite technology and large aircraft[J]. Acta Aeronautica et Astronautica Sinica,2008,29(3):605-610(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.011 [7] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316.CHEN Y, GE E D, FU Y C, et al. Review and prospect of drilling technologies of carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). [8] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(02):317-322.MA L M, ZHANG J Z, YUE G Q, et al. Appli-cation of composite materials in new generation large civil aircraft[J]. Acta Materiae Composi-tae Sinica,2015,32(02):317-322(in Chinese). [9] 陈亚莉. 从A350XWB看大型客机的选材方向[J]. 航空制造技术, 2009(12):34-37. doi: 10.3969/j.issn.1671-833X.2009.12.003CHEN Y L. Looking at the material selection direction of large aircraft from A350XWB[J]. Aeronautical Manufacturing Technology,2009(12):34-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2009.12.003 [10] 李桂玉, 汪海晋, 孙杰, 等. 基于复合材料钻削缺陷容差值的工艺参数优化[J]. 复合材料学报, 2014, 31(4):1022-1029.LI G Y, WANG H J, SUN J, et al. Optimization of process parameters based on the tolerance value of drilling defects in composite materials[J]. Acta Materiae Compositae Sinica,2014,31(4):1022-1029(in Chinese). [11] NGUYEN D, ABDULLAH M S B, KHAWARIZMI R, et al. The effect of fiber orientation on tool wear in edge-trimming of carbon fiber reinforced plastics (CFRP) laminates[J]. Wear,2020,450-451:203213. doi: 10.1016/j.wear.2020.203213 [12] POULACHON G, OUTEIRO J, RAMIREZ C, et al. Hole surface topography and tool wear in CFRP drilling[J]. Procedia CIRP,2016,45:35-38. doi: 10.1016/j.procir.2016.02.348 [13] 黄树涛, 张攀, 王浩涛. 高速钻削碳纤维/铝合金叠层复合材料的钻削力有限元仿真[J]. 工具技术, 2018, 52(5):63-68. doi: 10.3969/j.issn.1000-7008.2018.05.015HUANG S T, ZHANG P, WANG H T. Finite element analysis on thrust force of carbon fiber reinforced plastic and aluminum stacks composite material drilling[J]. Tool Engineering,2018,52(5):63-68(in Chinese). doi: 10.3969/j.issn.1000-7008.2018.05.015 [14] 金晓波, 康万军, 曹军, 等. 碳纤维复合材料/钛合金叠层板钻孔有限元仿真研究[J]. 工具技术, 2015, 49(1):24-28. doi: 10.3969/j.issn.1000-7008.2015.01.006JIN X B, KANG W J, CAO J, et al. Finite element analysis of drilling of carbon fiber reinforced plastics and titanium stack[J]. Tool Engineering,2015,49(1):24-28(in Chinese). doi: 10.3969/j.issn.1000-7008.2015.01.006 [15] RAO G V G, MAHAJAN P, BHATNAGAR N. Micro-mechanical modeling of machining of FRP composites: Cutting force analysis[J]. Composites Science and Technology,2007,67(3-4):579-593. doi: 10.1016/j.compscitech.2006.08.010 [16] RAO G V G, MAHAJAN P, BHATNAGAR N. Machining of UD-GFRP composites chip formation mechanism[J]. Composites Science and Technology,2007,67(11-12):2271-2281. doi: 10.1016/j.compscitech.2007.01.025 [17] PHADNIS V A, MAKHDUM F, ROY A, et al. Drilling in carbon/epoxy composites: Experimental investigations and finite element implementation[J]. Composites Part A: Applied Science and Manufacturing,2013,47:41-51. doi: 10.1016/j.compositesa.2012.11.020 [18] PENG R T, LI J, TANG X Z, et al. Simulation of tool wear in prestressed cutting superalloys[J]. Materials Science Forum,2016,836-837:402-407. [19] YUE C X, LIU X L, PEN H M, et al. 2D FEM estimate of tool wear in hard cutting operation: Extractive of interrelated parameters and tool wear simulation result[J]. Advanced Materials Research,2009,69-70:316-321. [20] ILIESCU D, GEHIN D, GUTIERREZ M E, et al. Modeling and tool wear in drilling of CFRP[J]. International Journal of Machine Tools and Manufacture,2010,50(2):204-213. doi: 10.1016/j.ijmachtools.2009.10.004 [21] PINILLOS U A, VIDAL S R F, CALAMAZ M, et al. Wear mechanisms and wear model of carbide tools during dry drilling of CFRP/TiAl6V4 stacks[J]. Materials,2019,12(18):2843. doi: 10.3390/ma12182843 [22] WANG G, MELLY S K. Three-dimensional finite element modeling of drilling CFRP composites using ABAQUS/CAE: A review[J]. International Journal of Advanced Manufacturing Technology,2017,94(1-4):599-614. [23] DANDEKAR C R, SHIN Y C. Modeling of machining of composite materials: A review[J]. International Journal of Machine Tools & Manufacture,2012,57:102-121. [24] FARAZ A, BIERMANN D, WEINERT K. Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates[J]. International Journal of Machine Tools and Manufacture,2009,49(15):1185-1196. doi: 10.1016/j.ijmachtools.2009.08.002 [25] 张勋, 陈燕, 徐九华, 等. 大厚径碳纤维复合材料三维钻削有限元仿真及试验研究[J]. 金刚石与磨料磨具工程, 2020, 40(2):53-60.ZHANG X, CHEN Y, XU J H, et al. Finite element simulation and experimental study on three-dimensional drilling of large diameter carbon fiber composites[J]. Diamond & Abrasives Engineering,2020,40(2):53-60(in Chinese). -

下载:

下载: