Effect of nano-montmorillonite on foaming properties of wood flour/polypropylene composites

-

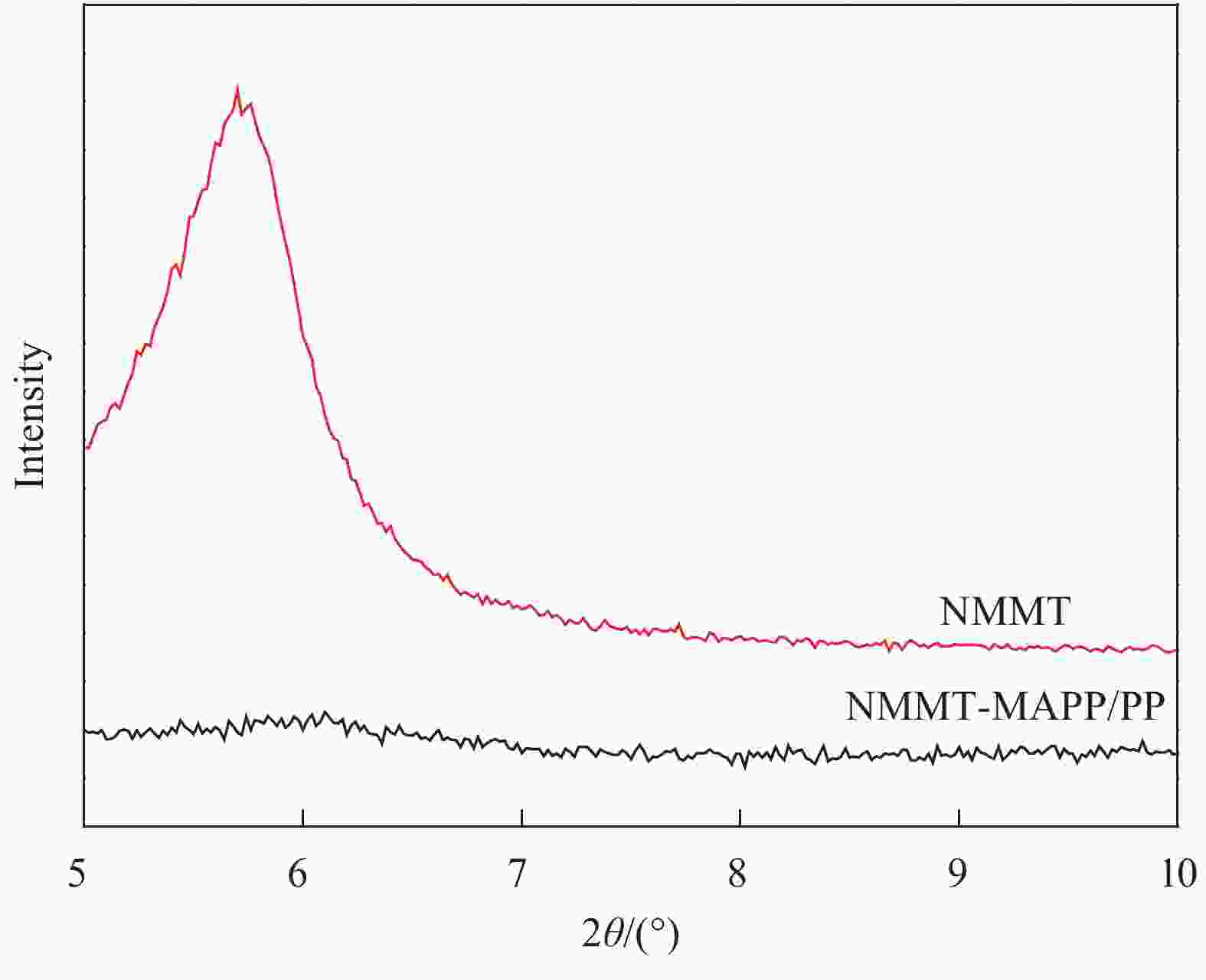

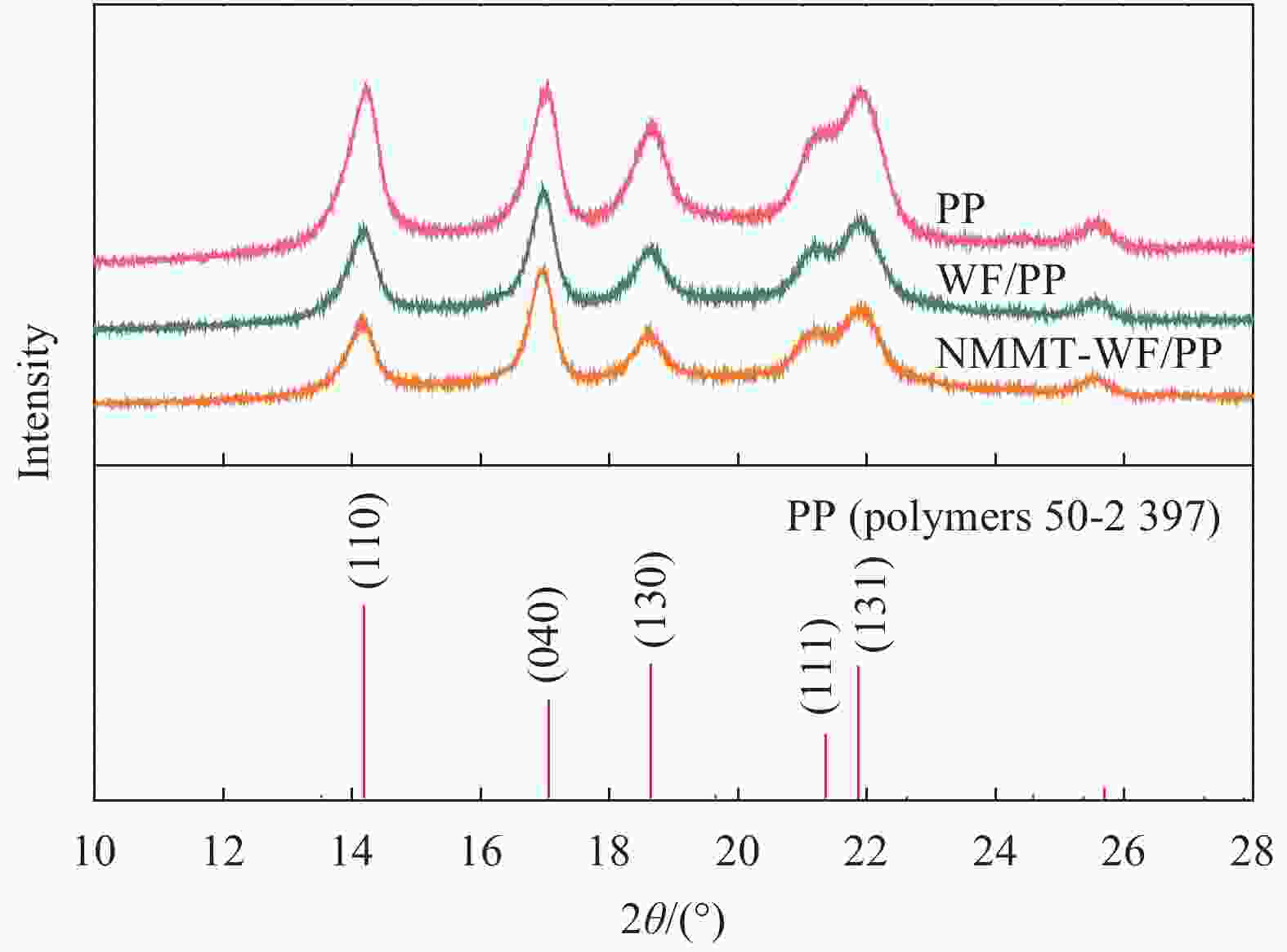

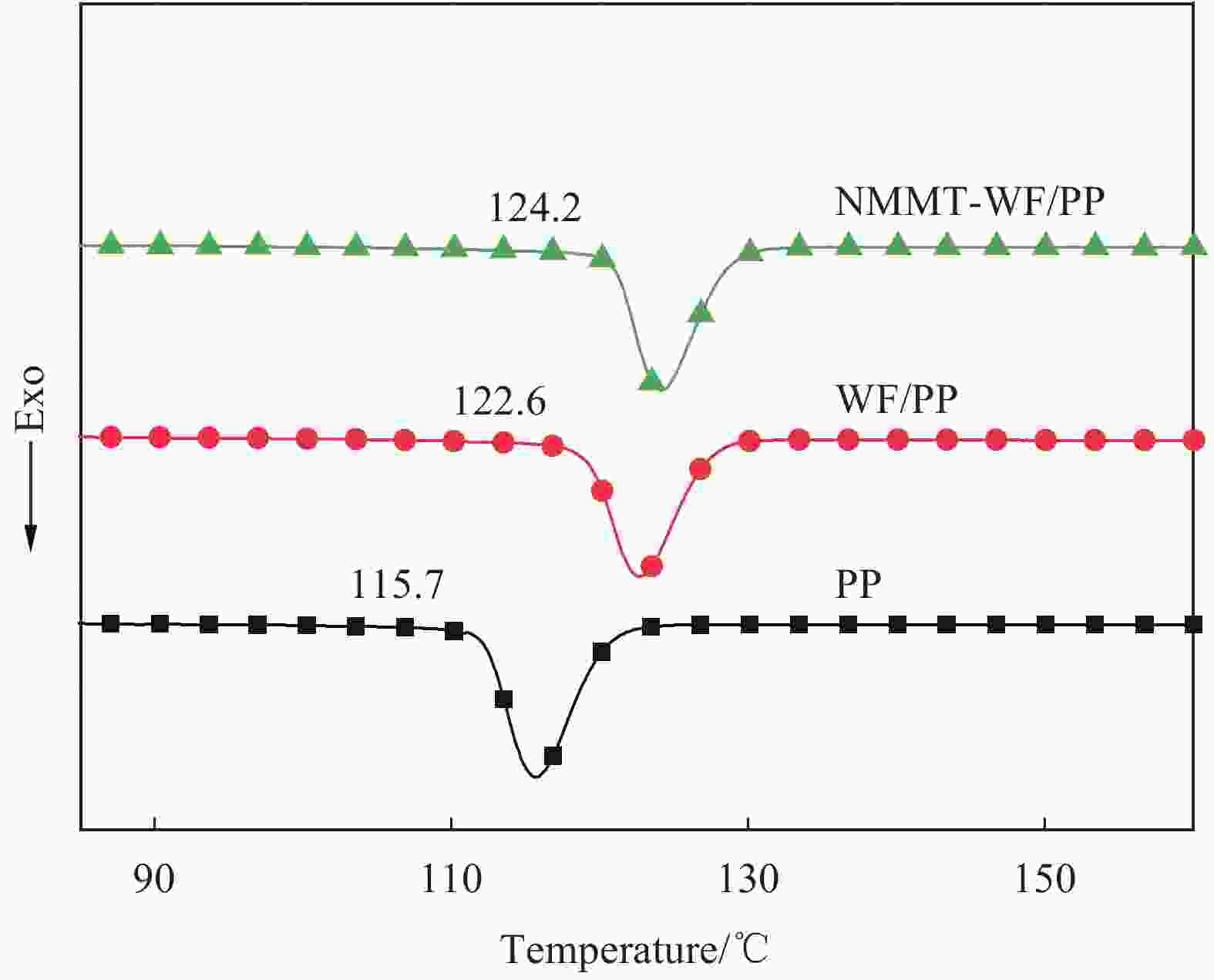

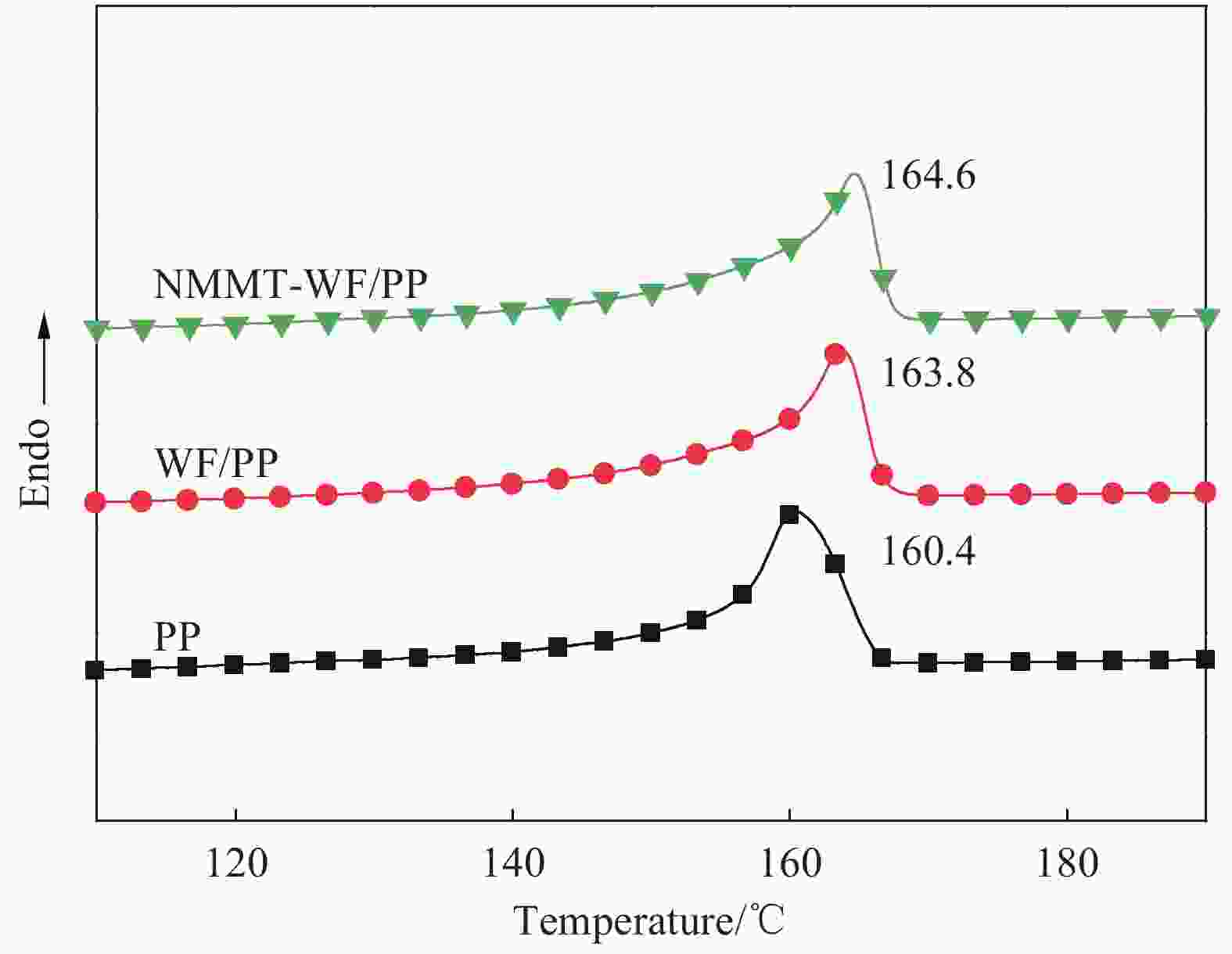

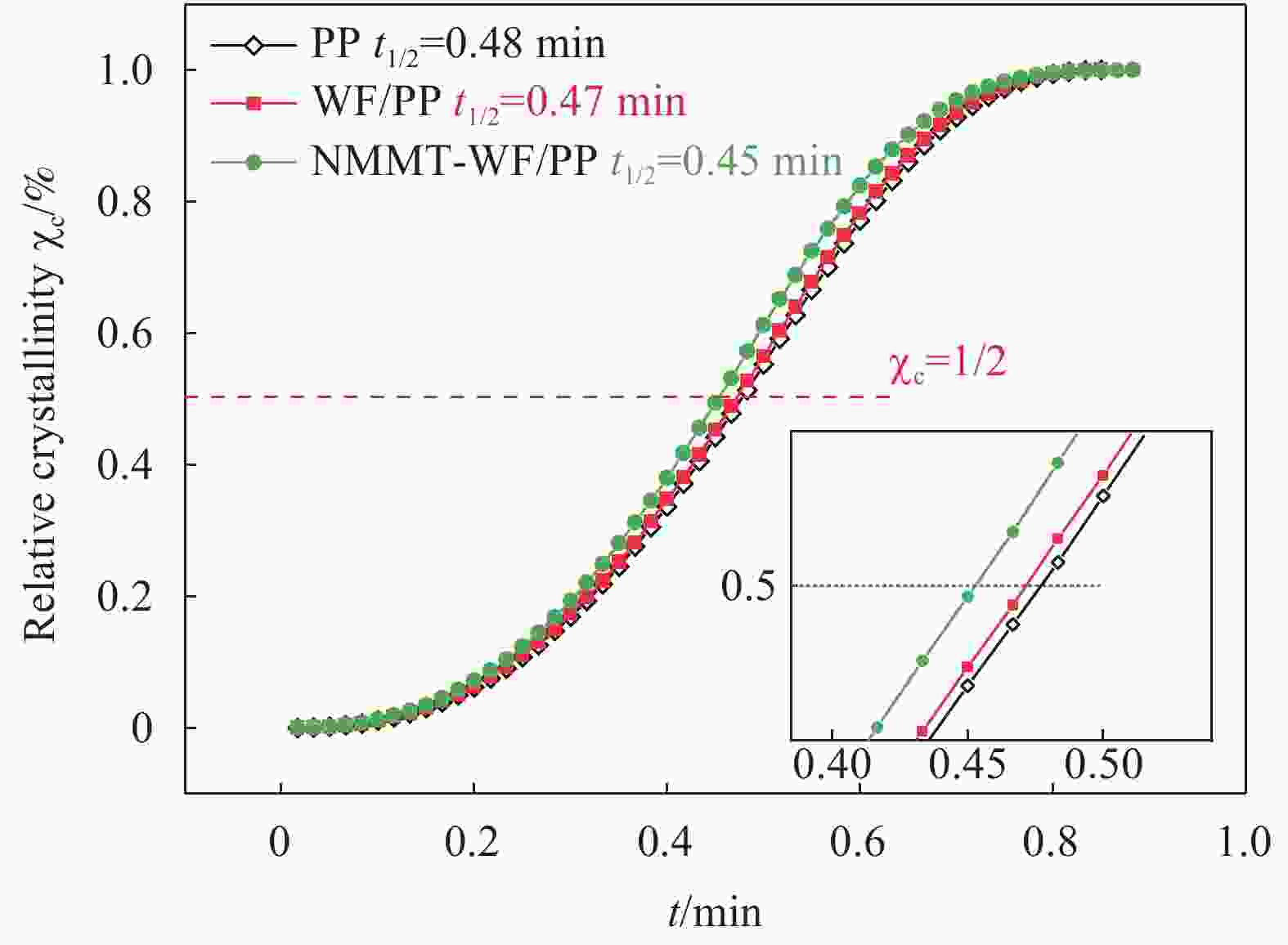

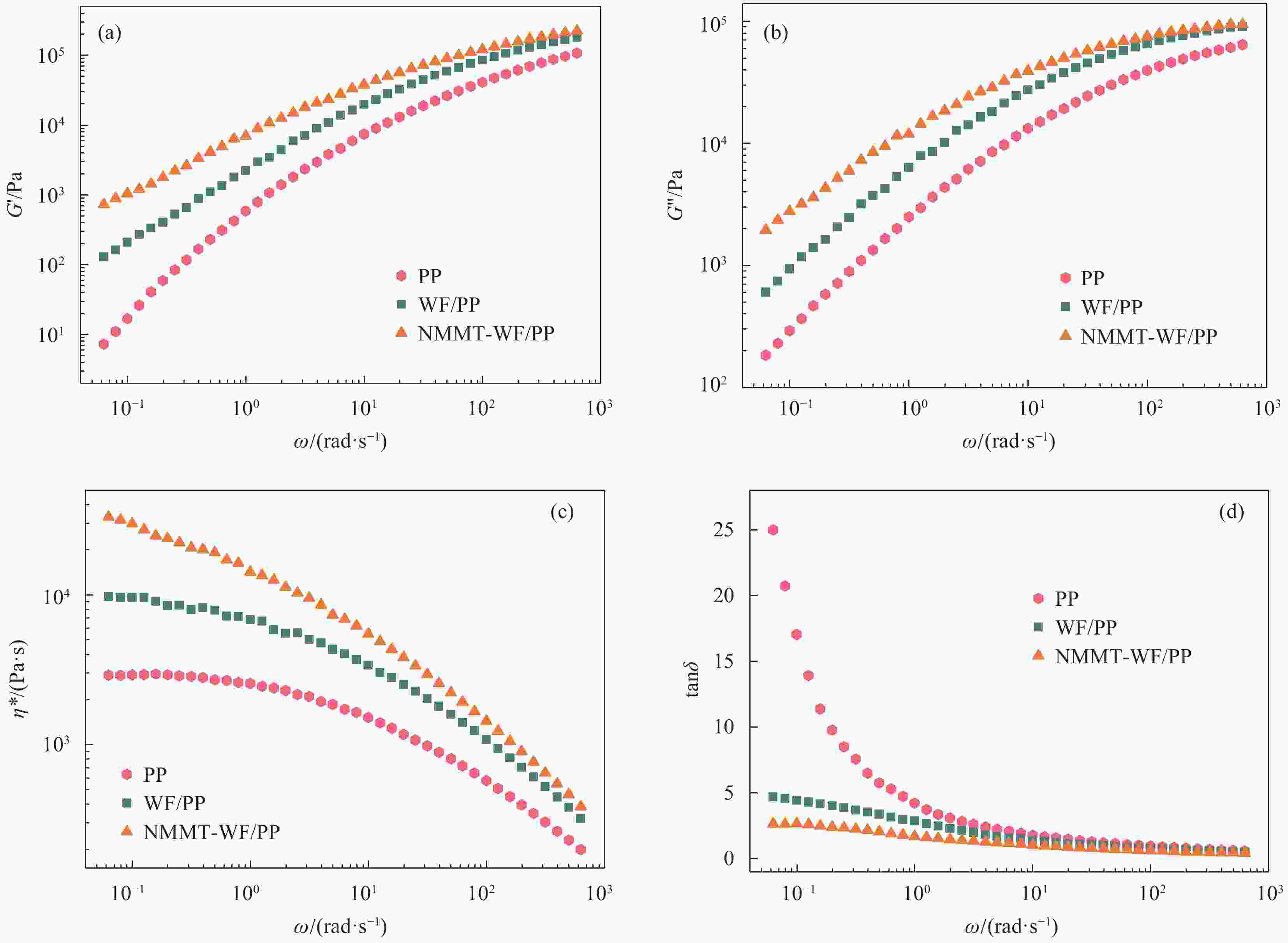

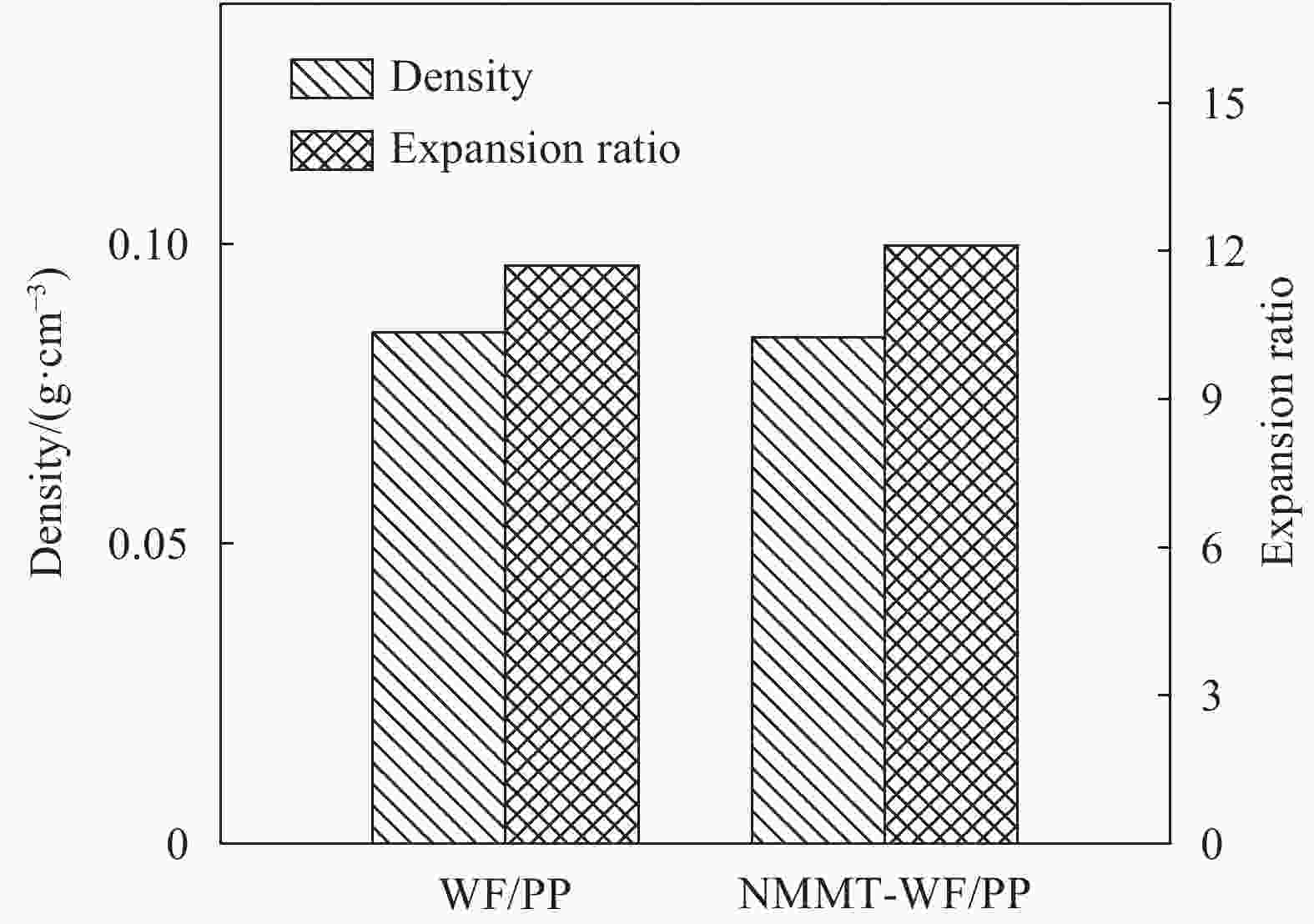

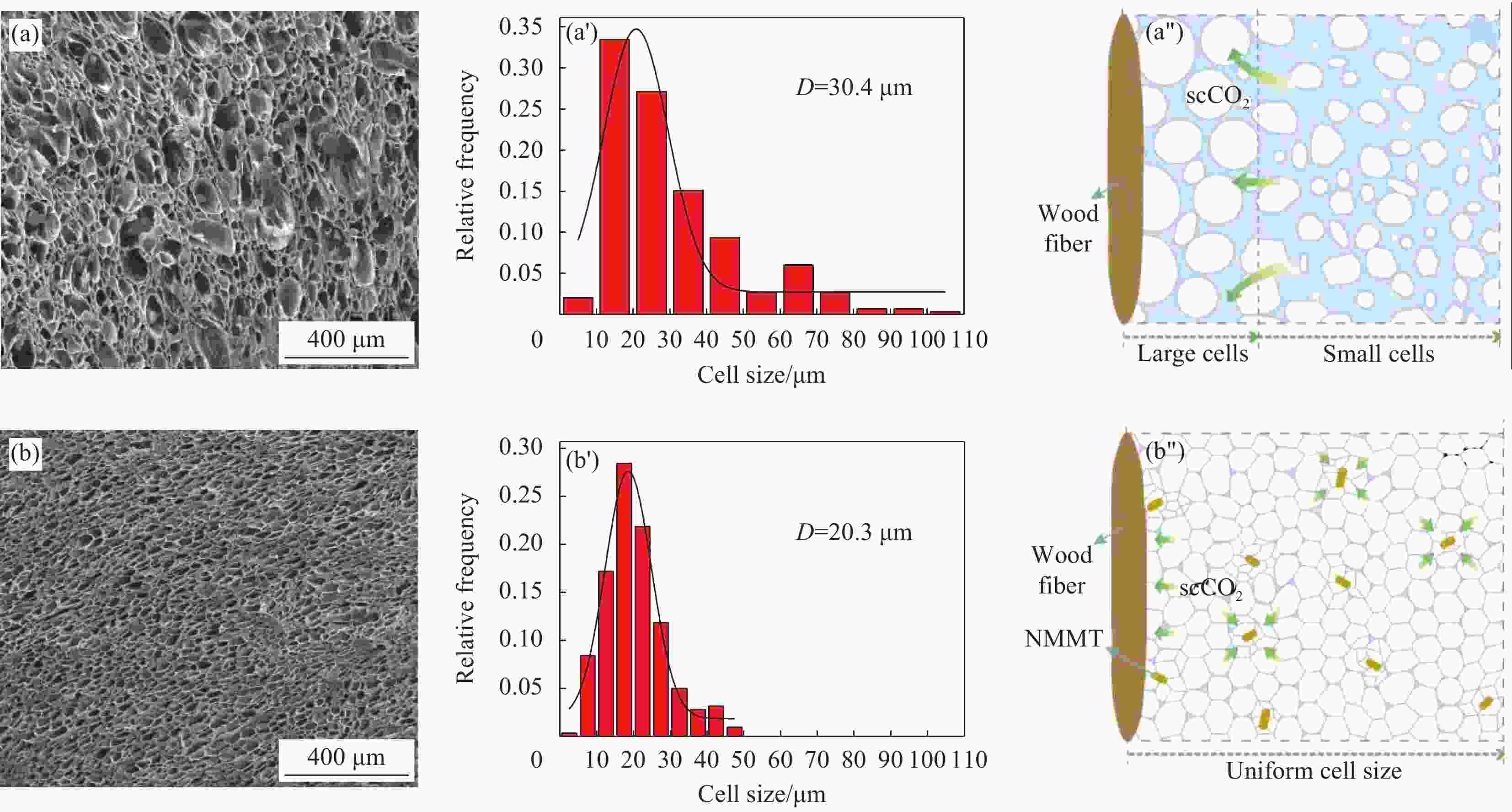

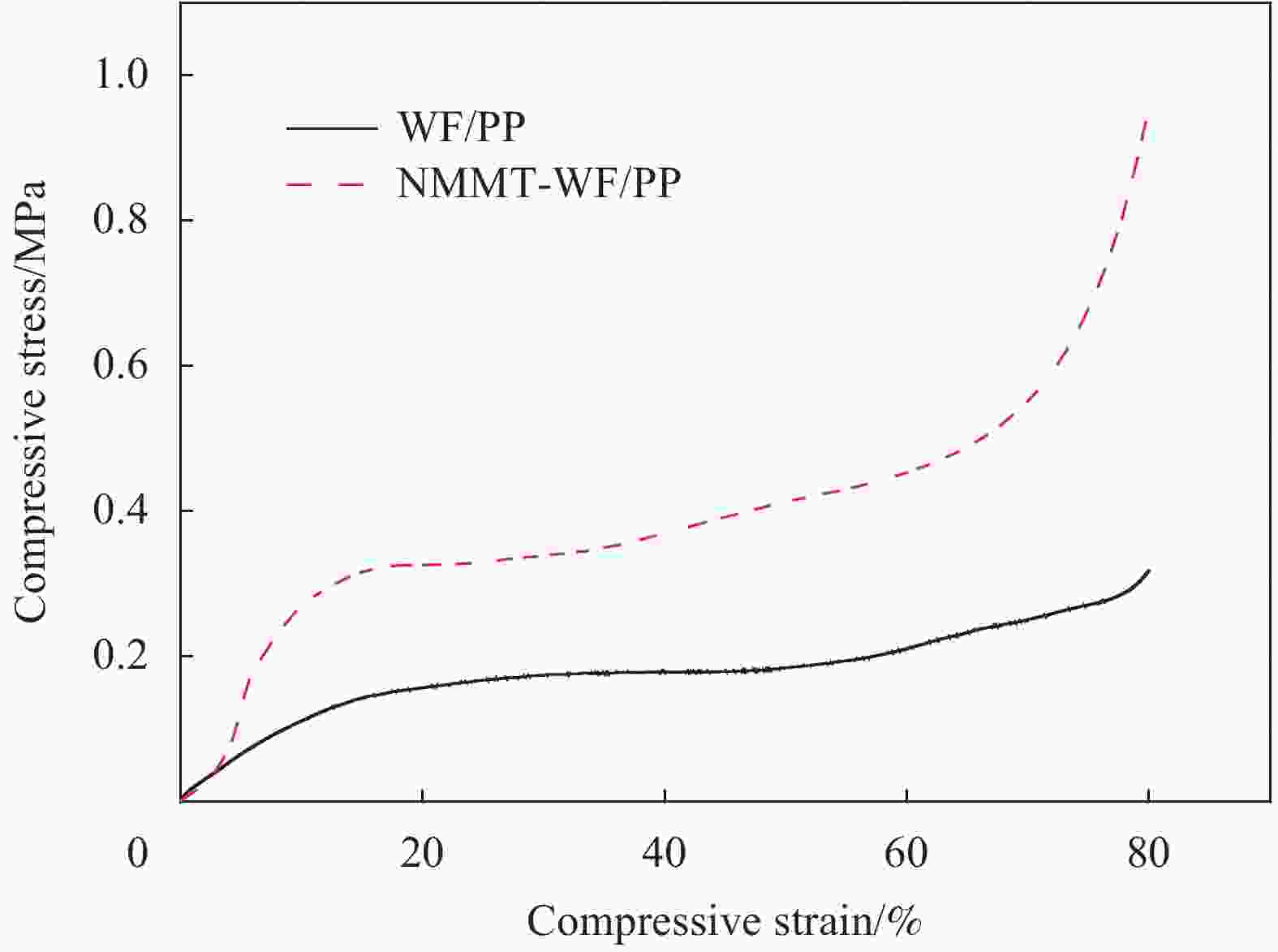

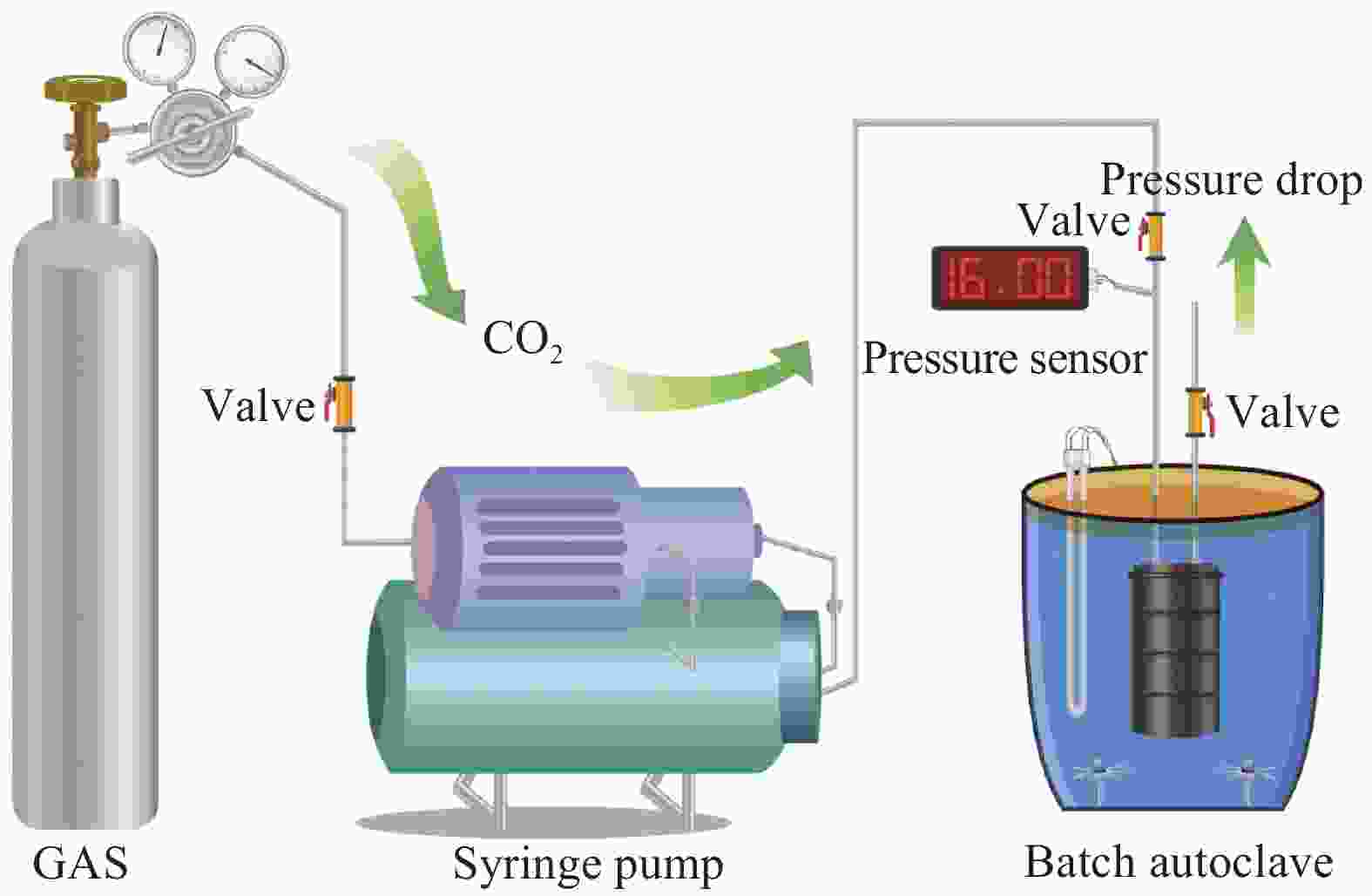

摘要: 采用高压釜间歇式发泡法,结合超临界CO2微孔发泡技术制备了发泡木粉-纳米蒙脱土(NMMT)/聚丙烯(PP)复合材料。通过对复合材料的结晶行为、流变性能、泡孔形貌及压缩性能进行分析,主要研究了NMMT对其微孔结构及力学性能的改善作用。结果表明:NMMT的引入使木粉/PP复合材料中PP基体的结晶速率加快,结晶度减小,有利于发泡均相体系的形成和泡孔生长;PP分子链的运动受到NMMT片层的抑制作用,导致木粉/PP复合材料的熔体弹性提高,泡孔合并与塌陷的现象减少,发泡材料的平均泡孔直径从30.4 μm降低至20.3 μm,并且泡孔尺寸的均匀性得到明显改善,压缩强度和模量分别提高了187%和223%。Abstract: The foamed wood flour-nano-montmorillonite (NMMT)/polypropylene (PP) composites were prepared by the batch foaming method using supercritical CO2 microcellular foaming technology. Effects of NMMT on the microcellular structure and mechanical properties of the composites were explored by investigating crystallization behavior, rheological properties, cell morphology and compression properties. The results show that NMMT accelerates the crystallization rate of the PP matrix in the wood flour/PP composites, and reduces the crystallinity rate. This is beneficial to the formation of foamed homogeneous system and cell growth. The PP molecular chain is inhibited by the NMMT interlayer, resulting in the melt elasticity increasement of the wood flour/PP composites. The phenomena of cell coalescence and collapse are reduced, the average cell diameter of the foamed composites is decreased from 30.4 μm to 20.3 μm, and the uniformity of cell size is obviously improved. The compressive strength and modulus are increased by 187% and 223%, respectively.

-

图 7 PP、WF/PP复合材料与NMMT-WF/PP复合材料的储能模量

$G'$ (a)、损耗模量$G'' $ (b)、复数黏度$\eta ^*$ (c)、损耗角正切值${\rm{tan}}\delta $ (d) 随角频率$\omega $ 变化曲线Figure 7. Storage modulus

$G'$ (a), loss modulus$G'' $ (b), complex viscosity$\eta ^*$ (c) and loss tangent${\rm{tan}}\delta $ (d) curves with angular frequency of PP, WF/PP composites and NMMT-WF/PP composites图 9 发泡WF/PP复合材料 (a) 与发泡NMMT-WF/PP复合材料 (b) 的SEM图像,WF/PP复合材料 (a′) 与发泡NMMT-WF/PP复合材料 (b′) 的直方图,发泡WF/PP复合材料 (a′′) 与发泡NMMT-WF/PP复合材料 (b′′) 的泡孔生长示意图

Figure 9. SEM images of fracture surface of foamed WF/PP composites (a) and foamed NMMT-WF/PP composites (b), frequency histogram of foamed WF/PP composites (a′) and foamed NMMT-WF/PP composites (b′), cell growth schematic diagram of foamed WF/PP composites (a′′) and foamed NMMT-WF/PP composites (b′′)

表 1 未发泡PP、WF/PP复合材料与NMMT-WF/PP复合材料的熔融峰温度、熔融焓和结晶度

Table 1. Molten peak temperature, melting enthalpy and crystallinity of unfoamed PP, WF/PP composites and NMMT-WF/PP composites

Type Melting

peak/℃Melting enthalpy/

(J·g−1)Crystallinity/

%PP 160.4 71.6 34.2 WF/PP 163.8 68.6 41.0 NMMT-WF/PP 164.6 53.5 34.5 -

[1] FARUK O, BLEDZKI A K, MATUANA L M. Microcellular foamed wood-plastic composites by different processes: A review[J]. Macromolecular Materials and Engineering,2007,292(2):113-127. doi: 10.1002/mame.200600406 [2] WANG Y Y, SONG Y M, DU J, et al. Preparation of desirable porous cell structure polylactide/wood flour composite foams assisted by chain extender[J]. Materials,2017,10(9):999. doi: 10.3390/ma10090999 [3] ASHORI A. Wood-plastic composites as promising green-composites for automotive industries[J]. Bioresource Technology,2008,99(11):4661-4667. doi: 10.1016/j.biortech.2007.09.043 [4] FOREST C, CHAUMONT P, CASSAGNAU P, et al. Polymer nano-foams for insulating applications prepared from CO2 foaming[J]. Progress in Polymer Science,2015,41:122-145. doi: 10.1016/j.progpolymsci.2014.07.001 [5] WANG L, ANDO M, KUBOTA M, et al. Effects of hydrophobic-modified cellulose nanofibers (CNFs) on cell morphology and mechanical properties of high void fraction polypropylene nanocomposite foams[J]. Composites Part A: Applied Science and Manufacturing,2017,98:166-173. doi: 10.1016/j.compositesa.2017.03.028 [6] YANG C G, XING Z, WANG M H, et al. Merits of the addition of PTFE micropowder in supercritical carbon dioxide foaming of polypropylene: Ultrahigh cell density, high tensile strength, and good sound insulation[J]. Industrial & Engineering Chemistry Research,2018,57(5):1498-1505. [7] HUANG L, WANG H G, WANG W H, et al. Non-isothermal crystallization kinetics of wood-flour/polypropylene composites in the presence of β-nucleating agent[J]. Journal of Forestry Research,2016,27(4):949-958. doi: 10.1007/s11676-016-0209-2 [8] ZHANG J J, RIZVI G M, PARK C B, et al. Study on cell nucleation behavior of HDPE–wood composites/supercritical CO2 solution based on rheological properties[J]. Journal of Materials Science,2011,46(11):3777-3784. doi: 10.1007/s10853-011-5291-4 [9] 李浩, 宋永明, 王海刚, 等. 滑石粉对微孔发泡木粉/聚丙烯复合材料结晶行为及泡孔结构的影响[J]. 复合材料学报, 2017, 34(8):1636-1644.LI Hao, SONG Yongming, WANG Haigang, et al. Influence of talc on crystallization behavior and cellular structure of microcellular foamed wood flour/PP composites[J]. Acta Materiae Compositae Sinica,2017,34(8):1636-1644(in Chinese). [10] ZHAO J C, ZHAO Q L, WANG G L, et al. Injection molded strong polypropylene composite foam reinforced with rubber and talc[J]. Macromolecular Materials and Engineering,2019,305(1):1900630. [11] LEUNG S N, WONG A, WANG L C, et al. Mechanism of extensional stress-induced cell formation in polymeric foaming processes with the presence of nucleating agents[J]. The Journal of Supercritical Fluids,2012,63:187-198. doi: 10.1016/j.supflu.2011.12.018 [12] PAIVA L B D, MORALES A R, FRANCISCO R, et al. Organoclays: Properties, preparation and applications[J]. Applied Clay Science,2008,42(1-2):8-24. doi: 10.1016/j.clay.2008.02.006 [13] SRIVABUT C, RATANAWILAI T, HIZIROGLU S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber[J]. Construction and Building Materials,2018,162:450-458. doi: 10.1016/j.conbuildmat.2017.12.048 [14] RIZVI A, PARK C B, FAVIS B D. Tuning viscoelastic and crystallization properties of polypropylene containing in-situ generated high aspect ratio polyethylene terephthalate fibrils[J]. Polymer,2015,68:83-91. doi: 10.1016/j.polymer.2015.04.081 [15] LEE Y H, PARK C B, WANG K H, et al. HDPE-clay nanocomposite foams blown with supercritical CO2[J]. Journal of Cellular Plastics,2005,41(5):487-502. doi: 10.1177/0021955X05056964 [16] LEE Y H, KUBOKI T, PARK C B, et al. The effects of nanoclay on the extrusion foaming of wood fiber/polyethylene nanocomposites[J]. Polymer Engineering & Science,2011,51(5):1014-1022. [17] American Society for Testing and Materials International. Standard test methods for density and specific gravity (relative density) of plastics by displacemen: ASTM D792-00[S]. West Conshohocken: ASTM International, 2000. [18] 解云川, 范晓东, 孔杰, 等. 聚乙烯/蒙脱土复合材料的结晶行′为[J]. 高分子材料科学与工程, 2005, 21(3):117-120. doi: 10.3321/j.issn:1000-7555.2005.03.029XIE Yunchuan, FAN Xiaodong, KONG Jie, et al. Study on the crystallization behaviors of polyethylene/MMT hybrid system[J]. Polymer Materials Science & Engineering,2005,21(3):117-120(in Chinese). doi: 10.3321/j.issn:1000-7555.2005.03.029 [19] 王丽梅, 贺爱华, 杜凯, 等. 聚丙烯/蒙脱土纳米复合材料的结构及物理性能研究[J]. 高校化学工程学报, 2010, 24(1):132-137. doi: 10.3969/j.issn.1003-9015.2010.01.024WANG Limei, HE Aihua, DU Kai, et al. Structure characterization and physical properties of exfoliated polypropylene/montmorillonite nanocomposites synthegized via in situ polymerization[J]. Journal of Chemical Engineering of Chinese Universities,2010,24(1):132-137(in Chinese). doi: 10.3969/j.issn.1003-9015.2010.01.024 [20] ROSA C D, CORRADINI P. Crystal structure of syndiotactic polypropylene[J]. Journal of Polymer Science Part C Polymer Symposia,1967,16(5):2477-2484. doi: 10.1002/polc.5070160503 [21] DING W D, JAHANI D, CHANG E, et al. Development of PLA/cellulosic fiber composite foams using injection molding: Crystallization and foaming behaviors[J]. Composites Part A: Applied Science and Manufacturing,2016,83:130-139. doi: 10.1016/j.compositesa.2015.10.003 [22] JIANG X L, LIU T, XU Z M, et al. Effects of crystal structure on the foaming of isotactic polypropylene using supercritical carbon dioxide as a foaming agent[J]. The Journal of Supercritical Fluids,2009,48(2):167-175. doi: 10.1016/j.supflu.2008.10.006 [23] KONISHI T, SAKATSUJI W, FUKAO K, et al. Temperature dependence of lamellar thickness in isothermally crystallized poly(butylene terephthalate)[J]. Macromolecules,2016,49(2016):2272-2280. [24] KRIKORIAN V, POCHAN D J. Unusual crystallization behavior of organoclay reinforced poly (l-lactic acid) nanocomposites[J]. Macromolecules,2004,37(17):6480-6491. doi: 10.1021/ma049283w [25] FORNES T D, PAUL D R. Crystallization behavior of nylon 6 nanocomposites[J]. Polymer,2003,44(14):3945-3961. doi: 10.1016/S0032-3861(03)00344-6 [26] ATAEI M, SHAAYEGAN V, WANG C D, et al. Numerical analysis of the effect of the local variation of viscosity on bubble growth and deformation in polymer foaming[J]. Journal of Rheology,2019,63(6):895-903. doi: 10.1122/1.5113802 [27] 王友勇, 李浩, 宋永明, 等. 木粉对聚乳酸流变、结晶及发泡行为的影响[J]. 高分子材料科学与工程, 2017(8):108-113.WANG Youyong, LI Hao, SONG Yongming, et al. Effect of wood flour on the rheology, crystallization and foaming behavior of polylactide[J]. Polymer Materials Science & Engineering,2017(8):108-113(in Chinese). [28] WANG C, LEUNG S N, BUSSMANN M, et al. Numerical Investigation of nucleating-agent-enhanced heterogeneous nucleation[J]. Industrial & Engineering Chemistry Research,2010,49(24):12783-12792. [29] NISTOR A, TOPIAR M, SOVOVA H, et al. Effect of organic co-blowing agents on the morphology of CO2 blown microcellular polystyrene foams[J]. The Journal of Supercritical Fluids,2017,130:30-39. doi: 10.1016/j.supflu.2017.07.026 [30] WANG C D, SHAAYEGAN V, ATAEI M, et al. Accurate theoretical modeling of cell growth by comparing with visualized data in high-pressure foam injection molding[J]. European Polymer Journal,2019,119:189-199. doi: 10.1016/j.eurpolymj.2019.07.023 -

下载:

下载: