Application of shape memory alloy in damage monitoring of composite materials

-

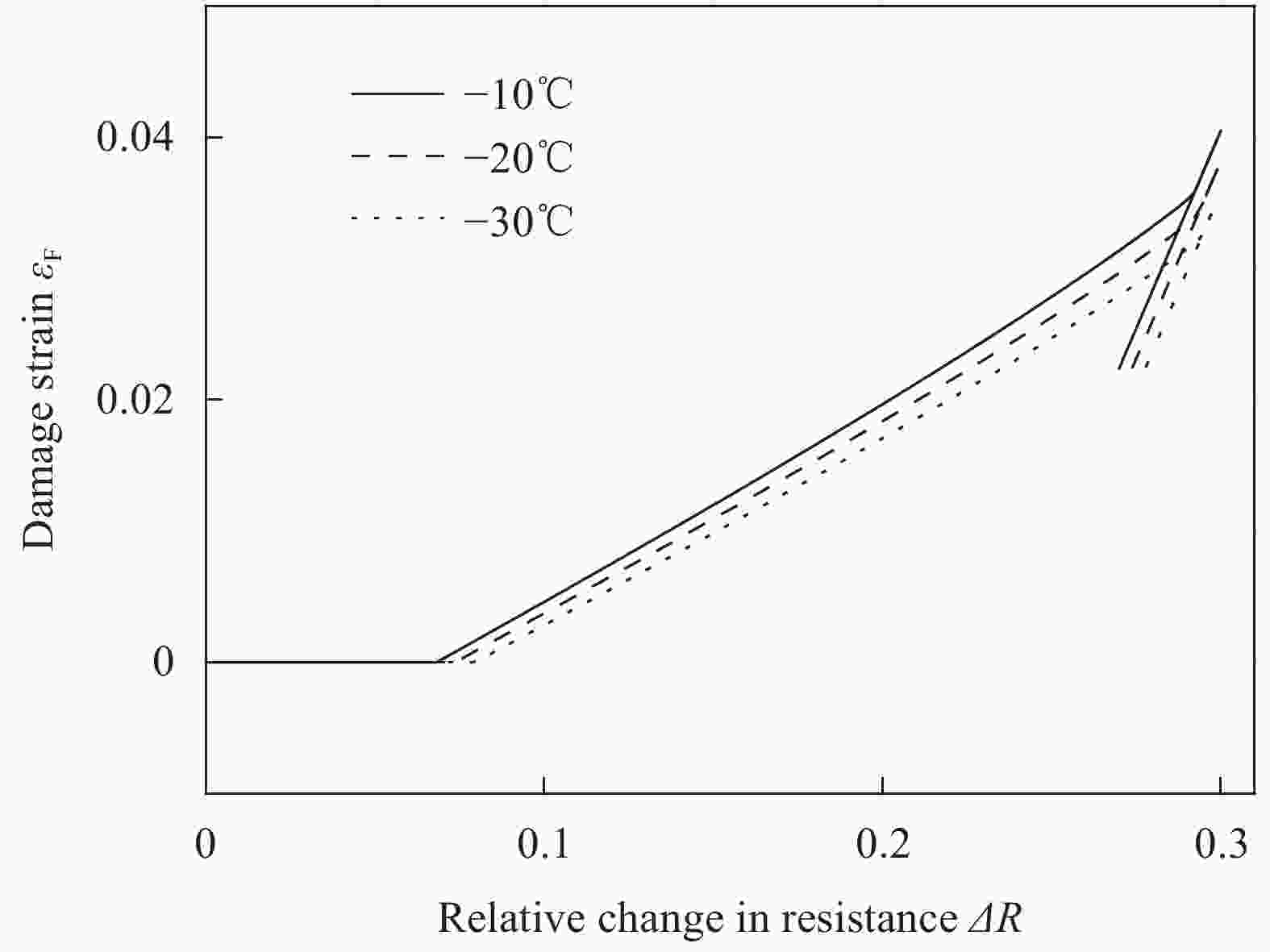

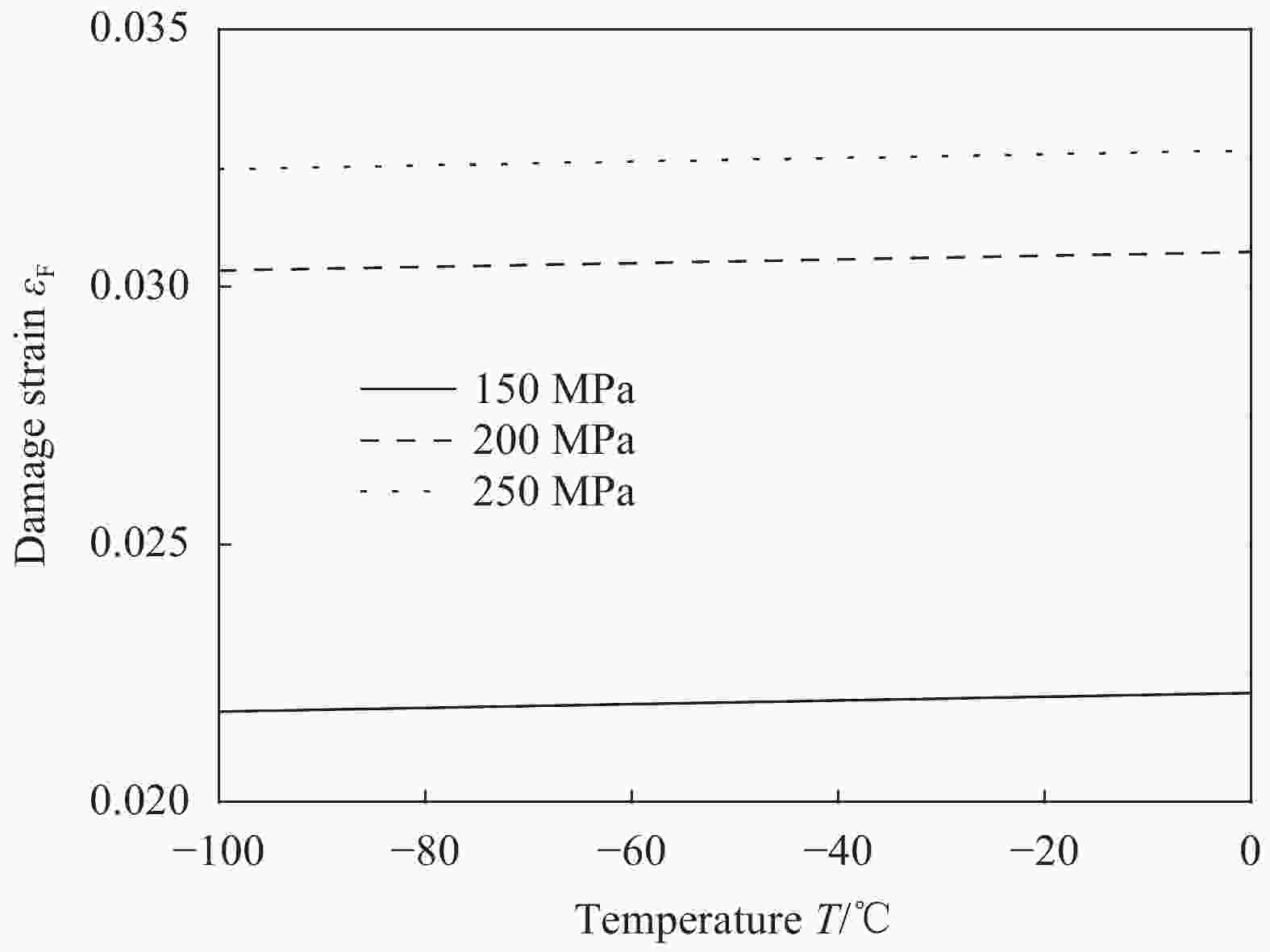

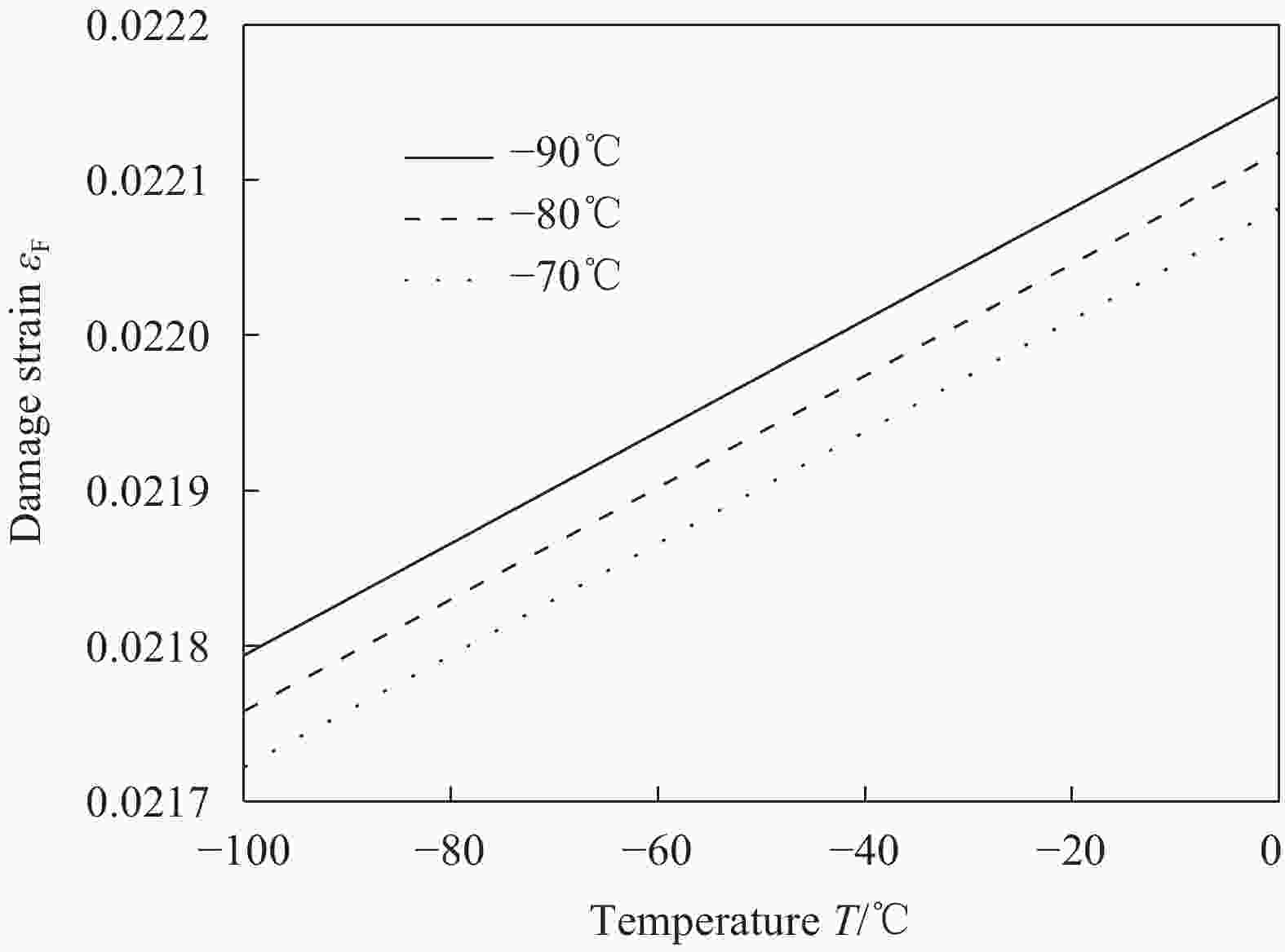

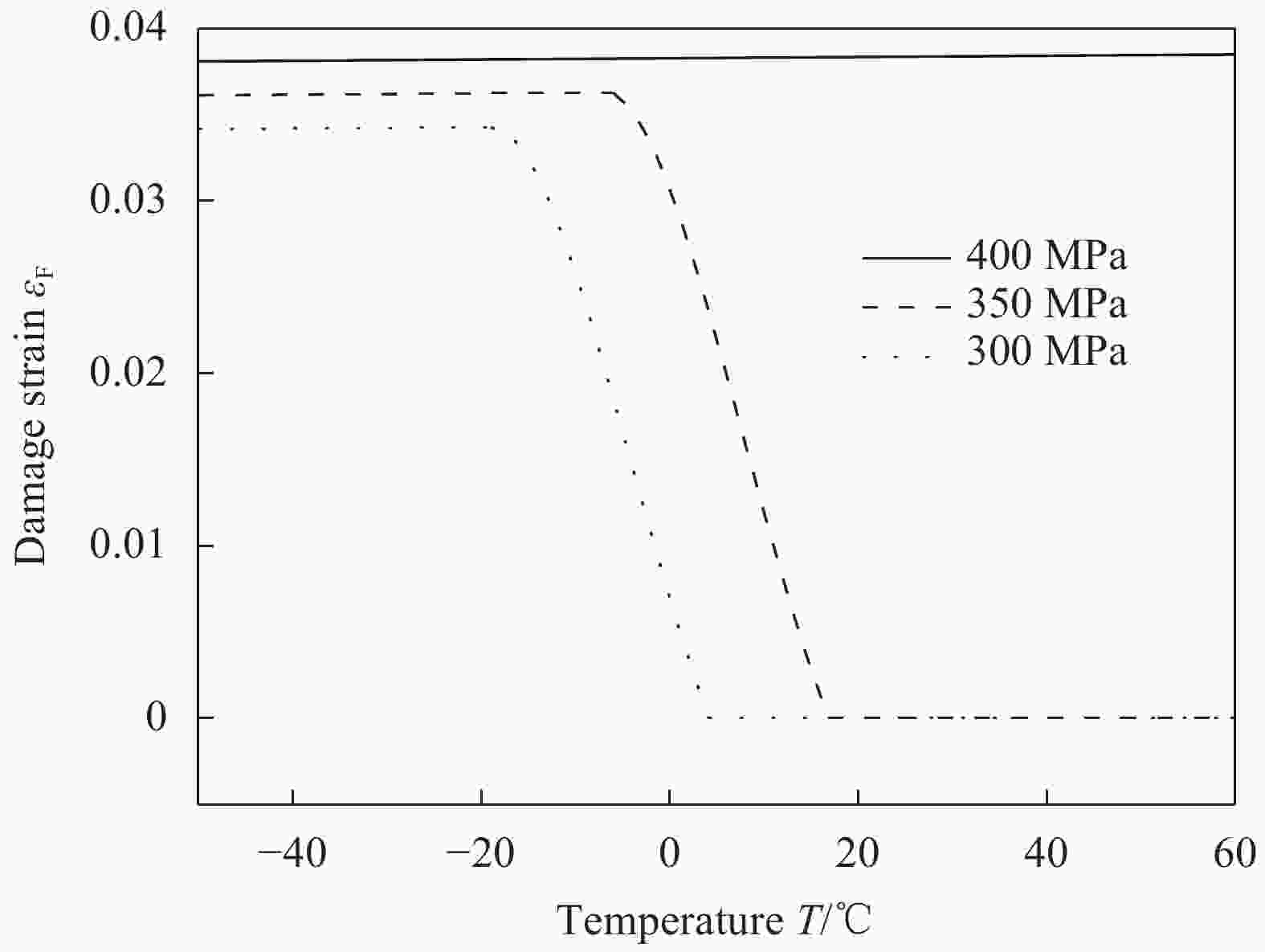

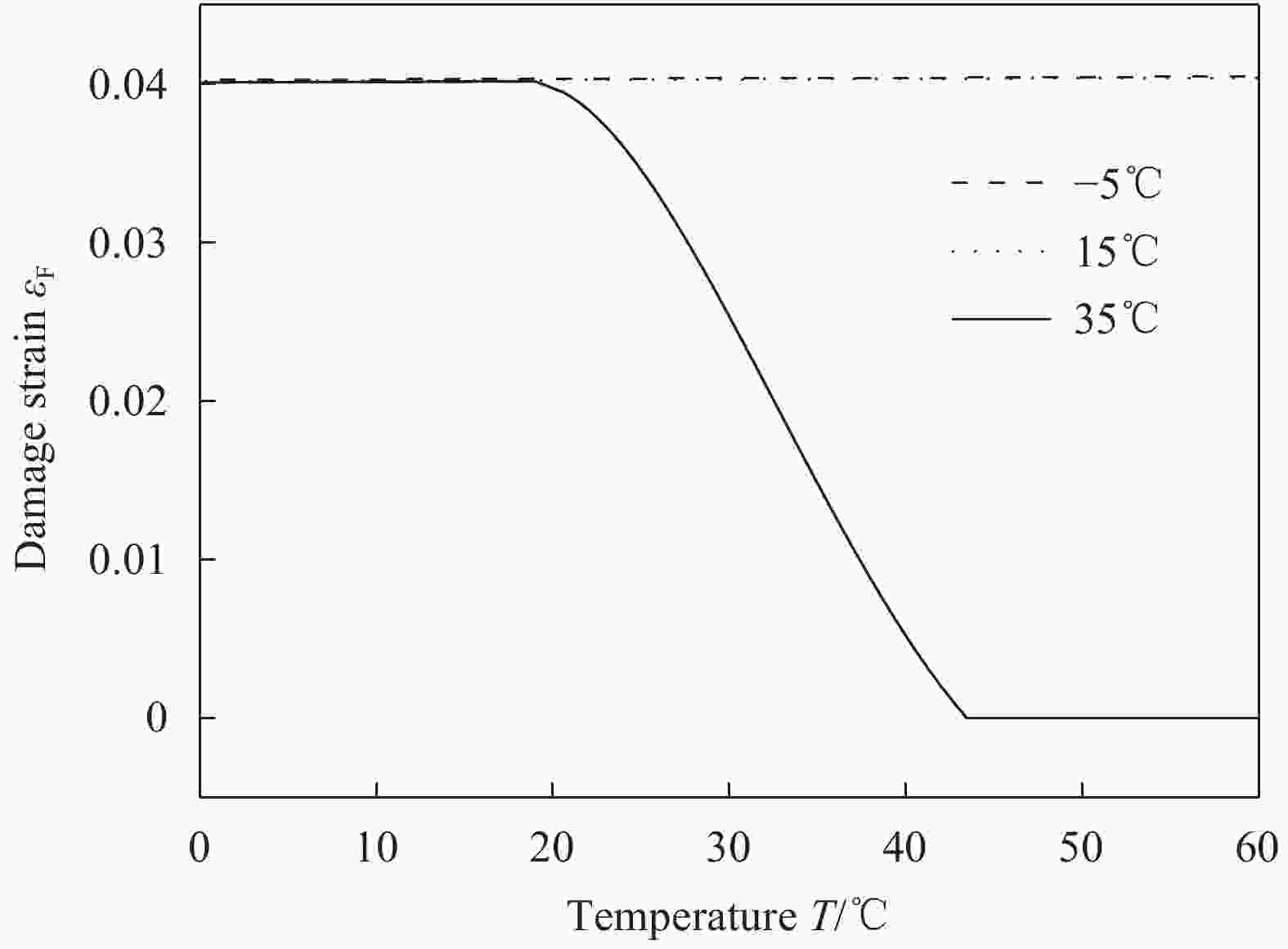

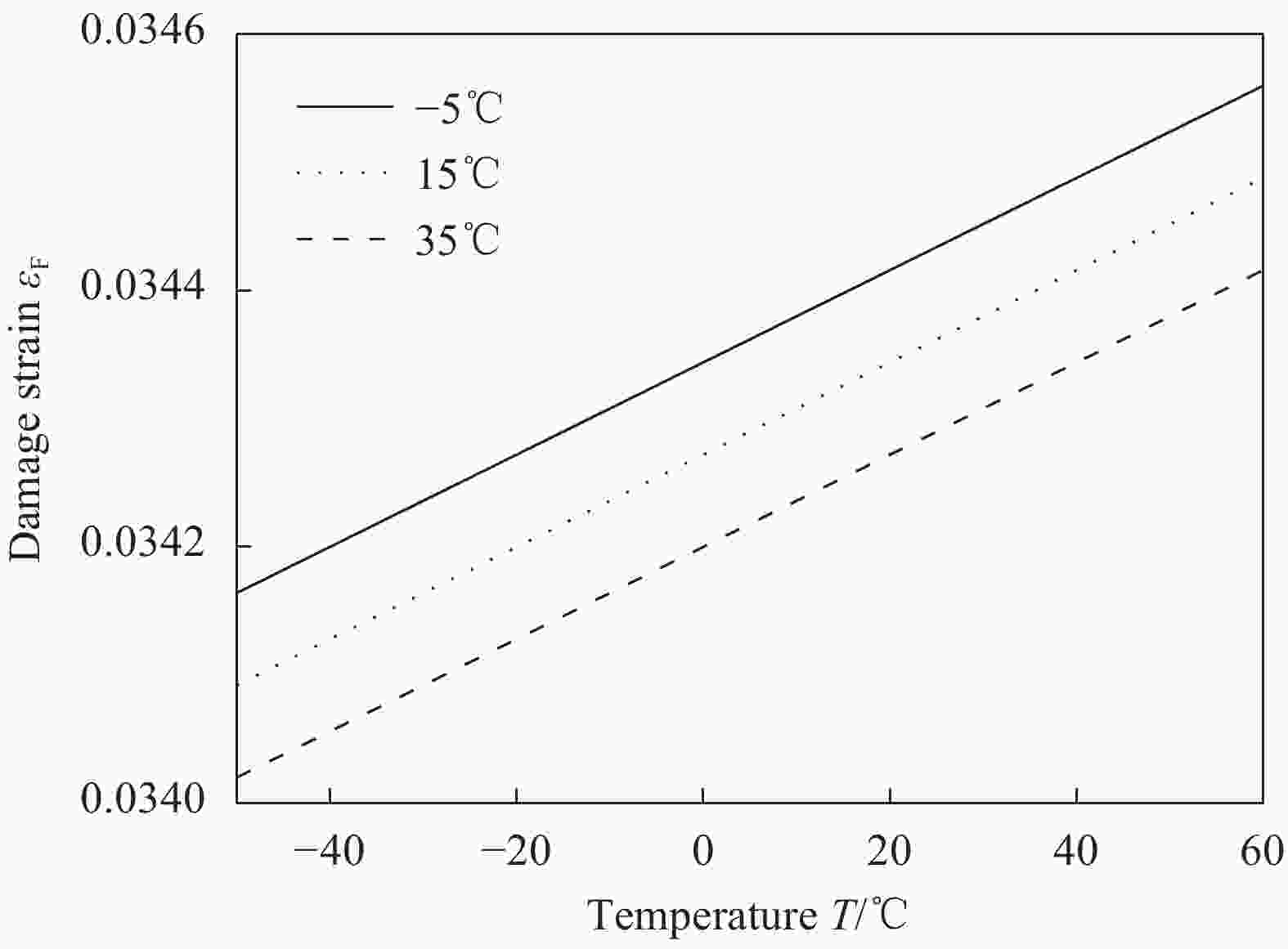

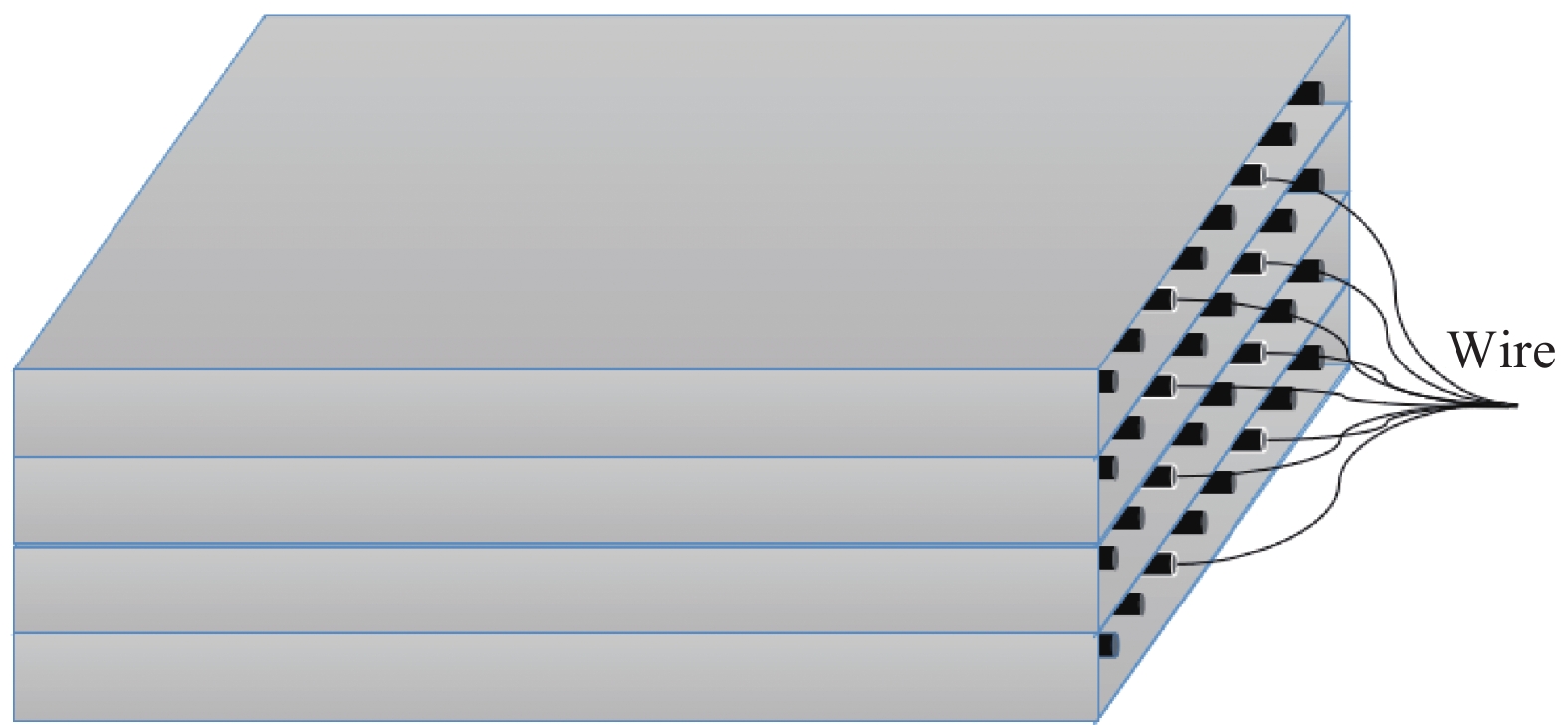

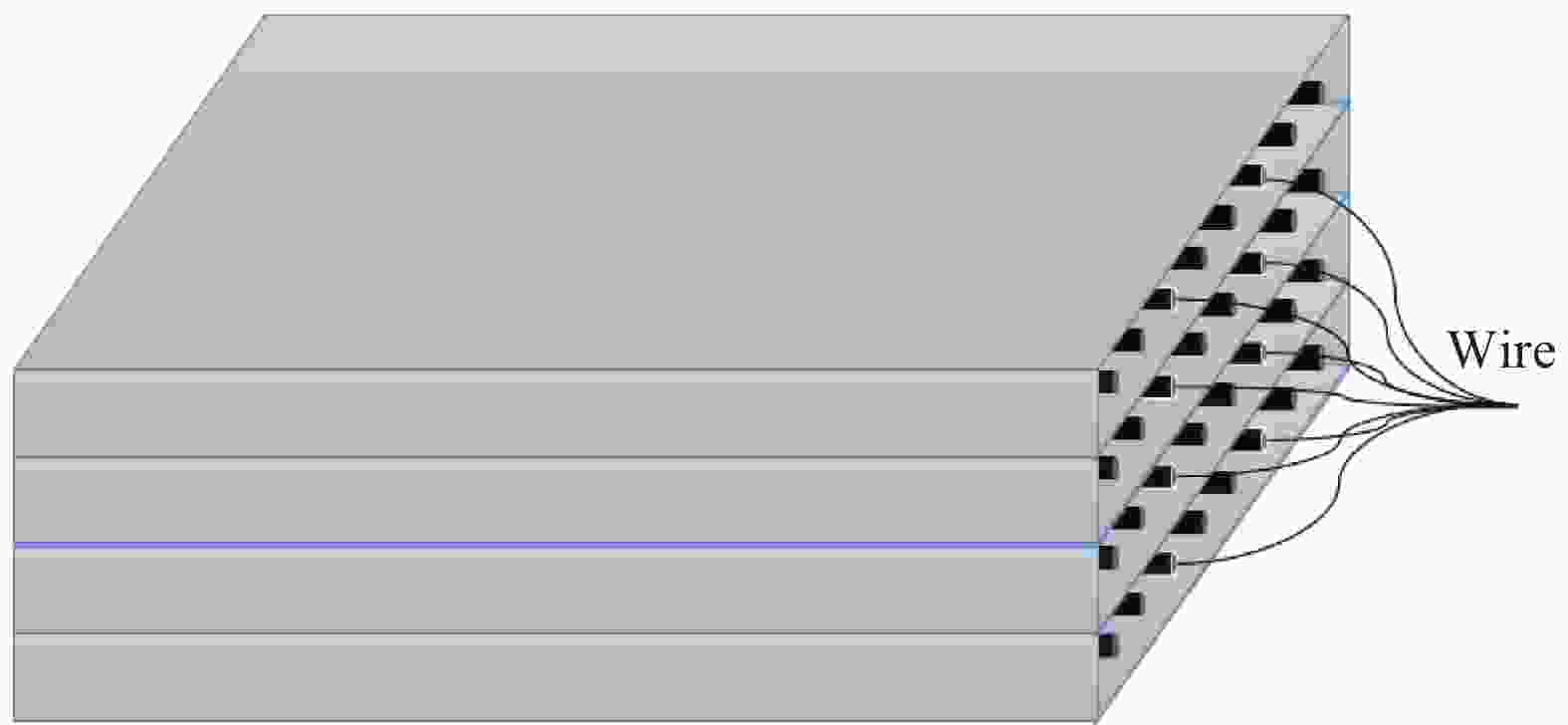

摘要: 复合材料的损伤会对结构的可靠性和安全性造成威胁,近年来引起国内外专家和学者的广泛关注。本文将形状记忆合金(SMA)埋入复合材料试件中,通过对SMA电阻变化与复合材料应变之间的关系进行讨论,建立不同监测条件下复合材料的损伤监测理论模型。基于该模型讨论了不同初始状态下SMA材料的损伤监测行为。研究结果表明:复合材料的损伤与SMA电阻变化呈线性关系,温度荷载在SMA未发生相变时对损伤监测影响较小,在SMA发生相变时对损伤监测影响较大。本研究可为基于SMA的复合材料损伤监测理论的进一步工程应用提供理论指导。Abstract: The damage of composite materials poses a threat to the reliability and safety of the structure, and has attracted widespread attention from domestic and foreign experts and scholars in recent years. This study embeded the shape memory alloy (SMA) in the composite material specimen, and discussed the relationship between the SMA resistance change and the composite material strain, established theoretical models of composite damage monitoring under different monitoring conditions. Based on this model, the damage monitoring behavior of SMA materials in different initial states was discussed. The research results show that the damage of the composite material has a linear relationship with the resistance change of the SMA. The temperature load has little influence on the damage monitoring when the SMA does not undergo a phase change, and has a greater influence on the damage monitoring when the SMA undergoes a phase change. The research can provide theoretical guidance for the further engineering application of SMA-based composite damage monitoring theory.

-

Key words:

- shape memory alloy /

- composite materials /

- damage monitoring /

- change temperature /

- phase tran-sition

-

表 1 对初始状态为低温马氏体相的SMA升温过程中的情况分类

Table 1. Classification of the conditions during the heating process of the SMA whose initial state is low-temperature martensite phase

Temperature section SMA initial state Loading phase Composite material Uninstall phase ${T_0} < {M^{\rm{f}}}$ Martensite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s1}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${\sigma _{{\rm{s1}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f1}}}}$ No damage Damaged ${\sigma _{{\rm{f1}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${M^{\rm{f}}} \leqslant {T_0} < {M^{\rm{s}}}$ Martensite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s1}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${\sigma _{{\rm{s1}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f1}}}}$ No damage Damaged ${\sigma _{{\rm{f1}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${M^{\rm{s}}} \leqslant {T_0} < {A^{\rm{s}}}$ Martensite $0 \leqslant {\sigma _{{\rm{SMA}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${A^{\rm{s}}} \leqslant {T_0} < {A^{\rm{f}}}$ Martensite and austenite mixed $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s4}}}}$ No damage ${\sigma _{{\rm{SMA}}}} \geqslant {\sigma _{{\rm{As4}}}}$ $0 \leqslant {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{As4}}}}$ Damaged ${\sigma _{{\rm{s4}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f4}}}}$ No damage Damaged ${\sigma _{{\rm{f4}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${A^{\rm{f}}} \leqslant {T_0}$ Austenite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s5}}}}$ No damage $\begin{array}{l} {\sigma _{{\rm{SMA}}}} \\ \geqslant {\sigma _{{\rm{As5}}}} \end{array} $ $\begin{array}{l} {\sigma _{{\rm{Af5}}}} < {\sigma _{{\rm{SMA}}}} \\ < {\sigma _{{\rm{As5}}}} \end{array} $ $\begin{array}{l} 0 \leqslant {\sigma _{{\rm{SMA}}}} \\ \leqslant {\sigma _{{\rm{Af5}}}} \end{array} $ Damaged ${\sigma _{{\rm{s5}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f5}}}}$ No damage Damaged ${\sigma _{{\rm{f5}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged Notes: Mf−Martensitic transformation completion temperature; Ms−Martensitic transformation start temperature; As−Austenite transformation start temperature; Af−Austenite transformation completion temperature; σSMA—Stress of the SMA; ${\sigma _{{\rm{s1}}}},{\sigma _{{\rm{f1}}}} $—SMA begins and completes redirection to critical stress; ${\sigma _{{\rm{f2}}}} $—SMA completes the critical stress of martensitic transformation in Mf≤T0<Ms; ${\sigma _{{\rm{s3}}}},{\sigma _{{\rm{f3}}}} $—Critical stress for the initiation and completion of martensitic transformation in Mf≤T0<As of SMA; ${\sigma _{{\rm{s4}}}},{\sigma _{{\rm{f4}}}} $, ${\sigma _{{\rm{As}}4}},{\sigma _{{\rm{Af4}}}} $—SMA begins and completes martensitic transformation and austenitic transformation in As≤T0<Af section; ${\sigma _{{\rm{s5}}}},{\sigma _{{\rm{f5}}}},{\sigma _{{\rm{As5}}}},{\sigma _{{\rm{Af5}}}} $—SMA begins and completes martensitic transformation and austenitic transformation in Af≤T0 section. 表 2 对初始状态为高温奥氏体相的SMA降温过程中的情况分类

Table 2. Classification of the conditions during the cooling process of the SMA whose initial state is high-temperature austenite phase

Temperature section SMA initial state Loading phase Composite material Uninstall phase ${T_0} < {M^{\rm{f}}}$ Martensite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s1}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${\sigma _{{\rm{s1}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f1}}}}$ No damage Damaged ${\sigma _{{\rm{f1}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${M^{\rm{f}}} \leqslant {T_0} < {M^{\rm{s}}}$ Martensite and austenite mixed $0 \leqslant {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f2}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${\sigma _{{\rm{f2}}}} \leqslant {\sigma _{{\rm{SMA}}}} < \sigma '_{{\rm{s2}}}$ No damage Damaged $\sigma' _{{\rm{s2}}} \leqslant {\sigma _{{\rm{SMA}}}} < \sigma' _{{\rm{f2}}}$ No damage Damaged $\sigma' _{{\rm{f2}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${M^{\rm{s}}} \leqslant {T_0} < {A^{\rm{s}}}$ Austenite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s3}}}}$ No damage $0 \leqslant {\sigma _{{\rm{SMA}}}}$ Damaged ${\sigma _{{\rm{s3}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f3}}}}$ No damage Damaged ${\sigma _{{\rm{f3}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${A^{\rm{s}}} \leqslant {T_0} < {A^{\rm{f}}}$ Austenite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s4}}}}$ No damage ${\sigma _{{\rm{SMA}}}} \geqslant {\sigma _{{\rm{As4}}}}$ $0 \leqslant {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{As4}}}}$ Damaged ${\sigma _{{\rm{s4}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f4}}}}$ No damage Damaged ${\sigma _{{\rm{f4}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged ${A^{\rm{f}}} \leqslant {T_0}$ Austenite $0 \leqslant {\sigma _{{\rm{SMA}}}} \leqslant {\sigma _{{\rm{s5}}}}$ No damage $\begin{array}{l} {\sigma _{{\rm{SMA}}}} \\ \geqslant {\sigma _{{\rm{As5}}}} \end{array} $ $\begin{array}{l} {\sigma _{{\rm{Af5}}}} < {\sigma _{{\rm{SMA}}}} \\ < {\sigma _{{\rm{As5}}}} \end{array} $ $\begin{array}{l} 0 \leqslant {\sigma _{{\rm{SMA}}}} \\ \leqslant {\sigma _{{\rm{Af5}}}} \end{array} $ Damaged ${\sigma _{{\rm{s5}}}} < {\sigma _{{\rm{SMA}}}} < {\sigma _{{\rm{f5}}}}$ No damage Damaged ${\sigma _{{\rm{f5}}}} \leqslant {\sigma _{{\rm{SMA}}}}$ No damage Damaged 表 3 与玻璃纤维/不饱和树脂和SMA有关的材料参数[16, 18-19]

Table 3. Material parameters related to glass fiber/unsaturated resin and SMA[16, 18-19]

Mf /℃ Ms /℃ As/℃ Af/℃ EA/MPa EM/MPa ${\alpha ^{\rm{A}}}$/℃−1 ${\alpha ^{\rm{M}}}$/℃−1 H/% −85 −52 0.2 28.4 60 000 25 400 1.1×10−5 6.6×10−6 3.5 EG/MPa C(MPa·℃−1) ${\sigma _{\rm{G}}}$/MPa $\sigma _{\rm{s}}^{{\rm{cr}}}$/MPa $\sigma _{\rm{f}}^{{\rm{cr}}}$/MPa ${\alpha_{\rm{G}} }$/℃−1 33 400 5 417.1 100 170 3×10−6 Notes: EA—Elastic modulus of SMA austenite; EM—Elastic modulus of SMA martensite; ${\alpha ^{\rm{A}}}$—Thermal expansion coefficient of SMA austenite; ${\alpha ^{\rm{M}}}$—Thermal expansion coefficient of SMA martensite; H—Maximum recoverable residual strain; EG—Elastic modulus of glass fiber unsaturated resin; C—Stress influence factor; ${\sigma _{\rm{G}}}$—Stress on glass fiber unsaturated resin; $\sigma _{\rm{s}}^{{\rm{cr}}}$—SMA reorientation starts critical stress; $\sigma _{\rm{f}}^{{\rm{cr}}}$—SMA reorientation ends critical stress; ${\alpha_{\rm{G}} }$—Thermal expansion coefficient of glass fiber unsaturated resin. ${C_{{\rm{M1}}}}$/(Ω·m·℃−1) ${C_{{\rm{M2}}}}$/(Ω·m) ${C_{{\rm{A1}}}}$/(Ω·m·℃−1) ${C_{{\rm{A2}}}}$/(Ω·m) 7×10−10 0.87×10−6 8×10−10 0.72×10−6 Note: ${C_{{\rm{M1}}}}$, ${C_{{\rm{M2}}}}$, ${C_{{\rm{A1}}}}$, ${C_{{\rm{A2}}}}$—Material parameters related to resistivity. -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] WU F, YAO W X. A fatigue damage model of composite materials[J]. International Journal of Fatigue,2010,32(1):134-138. doi: 10.1016/j.ijfatigue.2009.02.027 [3] EI-SABBAGH A, STEUERNAGEL L, ZIEGMANN G. Characterisation of flax polypropylene composites using ultrasonic longitudinal sound wave technique[J]. Composites: Part B,2013,45:1164-1172. doi: 10.1016/j.compositesb.2012.06.010 [4] FREEMANTLE R J, HANKINSON N, BROTHERHOOD C J. Rapid phased array ultrasonic imaging of large area composite aerospace structures[J]. Insight,2005,47(3):129-132. doi: 10.1784/insi.47.3.129.61315 [5] RYU C H, PARK S H, KIM D H, et al. Nondestructive evaluation of hidden multi-delamination in a glass-fiber-reinforced plastic composite using terahertz spectroscopy[J]. Composite Structures,2016,156:338-347. doi: 10.1016/j.compstruct.2015.09.055 [6] HOSOI A, YAMAGUCHI Y, JU Y, et al. Detection and quantitative evaluation of defects in glass fber reinforced plastic laminates by microwaves[J]. Composite Structures, 2015, 128: 134-144. [7] KALYANAVALLI V, ABILASHA R T K, SASTIKUMAR D. Long pulse thermography investigations of basalt fiber reinforced composite[J]. NDT & E International,2018,100:84-91. [8] 周玉敬, 任明伟, 刘刚, 等. 基于FBG传感技术的复合材料T型加筋板低速冲击损伤监测[J]. 复合材料学报, 2019, 36(10):2266-2274.ZHOU Y J, REN M W, LIU G, et al. Low-velocity impact damage monitoring of composite T-stiffened panels based on FBG sensors[J]. Acta Materiae Compositae Sinica,2019,36(10):2266-2274(in Chinese). [9] ZHAO H T, ZHANG B M, WU Z J, et al. Infrastructure study for optical fiber grating in smart composite materials[J]. Transducer and Microsystem Technologies,2007,26(12):27-30. [10] KAN Q, KANG G. Constitutive model for uniaxial transformation ratchetting of super-elastic NiTi shape memory alloy at room temperature[J]. International Journal of Plasticity,2010,26(3):441-465. doi: 10.1016/j.ijplas.2009.08.005 [11] SUN Q P, HWANG K C. Micromechanics modeling for the constitutive behavior of polycrystalline shape memory alloy[J]. Journal of the Mechanics and Physics of Solids,1993,41(1):1-33. doi: 10.1016/0022-5096(93)90060-S [12] WU X D, FAN Y Z, WU J S. A study on the variations of the electrical resistance for NiTi shape memory alloy wires during the thermo-mechanical loading[J]. Materials & Design,2000,21(6):511-515. [13] 狄生奎, 韩全治, 李慧, 等. SMA在结构健康监测中的应用研究[J]. 低温建筑技术, 2008(4):58-60. doi: 10.3969/j.issn.1001-6864.2008.04.027DI S K, HAN Q Z, LI H, et al. Research on the shape memory alloy applied in structural health monitoring[J]. Low Temperature Architecture Technology,2008(4):58-60(in Chinese). doi: 10.3969/j.issn.1001-6864.2008.04.027 [14] 狄生奎, 花尉攀, 汲生伟, 等. 约束态SMA混凝土梁的裂缝监测及自修复[J]. 建筑材料学报, 2010, 13(2):237-242. doi: 10.3969/j.issn.1007-9629.2010.02.021DI S K, HUA W P, JI S W, et al. Self-monitoring and self-repairing of crack in concrete beam with constraint super-elastic SMA[J]. Journal of Building Materials,2010,13(2):237-242(in Chinese). doi: 10.3969/j.issn.1007-9629.2010.02.021 [15] 袁江, 邱自学, 邵建新, 等. 基于无线射频识别传感标签的形状记忆合金增强复合结构低速冲击响应监测[J]. 机械工程学报, 2012, 48(18):89-96. doi: 10.3901/JME.2012.18.089YUAN J, QIU Z X, SHAO J X, et al. Low speed impact test for shape memory alloy-reinforced composite structure based on radio frequency idebtification sensortags[J]. Journal of Mechanical Engineering,2012,48(18):89-96(in Chinese). doi: 10.3901/JME.2012.18.089 [16] 王庆菲. SMA智能混凝土的裂缝监测与自修复理论研究[D]. 天津: 中国民航大学. 2020.WANG Q F. Theoretical research on crack monitoring and self-repairing mechanism for SMA intelligent concrete materials[D]. Tianjin: Civil Aviation University of China, 2020(in Chinese). [17] IKUTA K, TSUKAMOTO M, HIROSE S. Institute of electric and electronic engineer. mathematical model and experimental verification of shape memory alloy for designing micro actuator[C]//Micro Electro Mechanical Systems, 1991, MEMS '91, Proceedings. An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots. IEEE. 1991: 103-108. [18] BRINSON L C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable[J]. Journal of Intelligent Material Systems and Structures,1993,4(2):229-242. doi: 10.1177/1045389X9300400213 [19] 詹瑒. 纤维增强复合材料(FRP)格构柱基本性能研究[D]. 南京: 东南大学. 2016.ZHAN Y. Performance evaluation of lattice columns using pultruded fiber-reinforced polymer(FRP) structurak profiles[D]. Nanjing: Southeast University, 2016(in Chinese). [20] 崔迪, 李宏男, 宋钢兵. NiTi形状记忆合金电阻特性研究[J]. 建筑材料学报, 2008(5):68-74.CUI D, LI H N, SONG G B. Study on electrical resistance properties of NiTi shape memory alloy[J]. Journal of Building Materials,2008(5):68-74(in Chinese). -

下载:

下载: