Flexible capacitive pressure sensor based on expandable microsphere/ polydimethylsiloxane composite dielectric layer

-

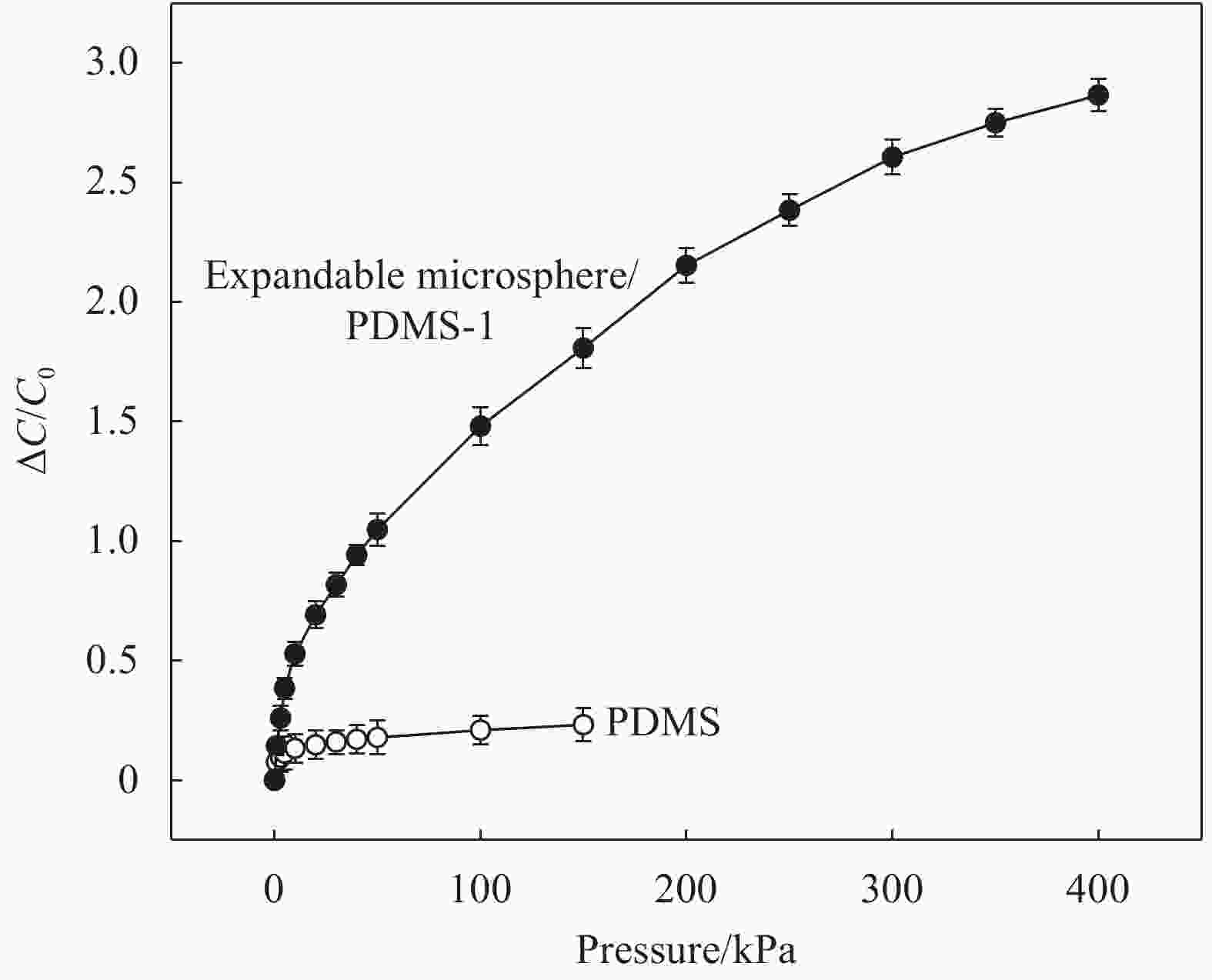

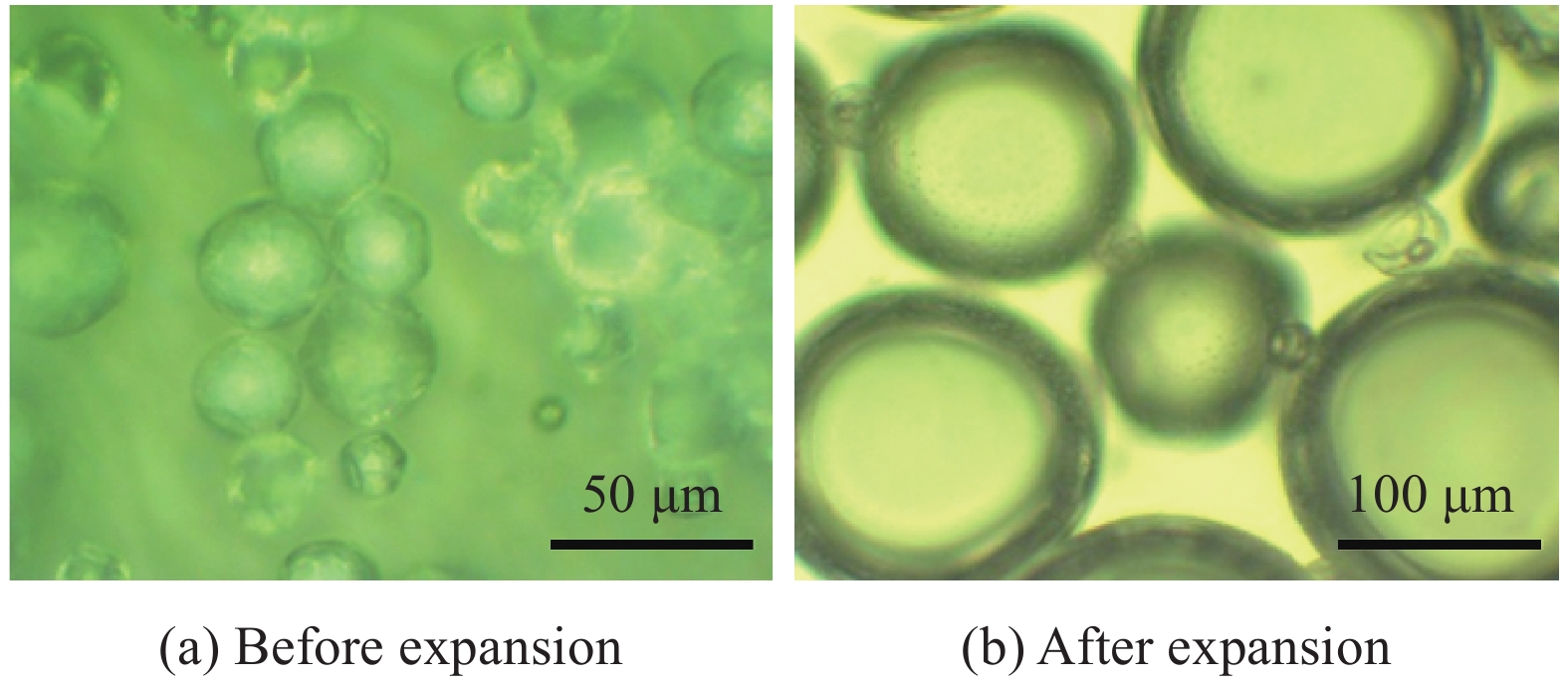

摘要: 为解决含有微结构的柔性电容式压力传感器工作范围较窄的问题,设计了一种基于可膨胀微球/聚二甲基硅氧烷(PDMS)介电层的柔性“三明治”结构电容式压力传感器,并对介电层的结构和形貌进行表征。通过自行搭建的压力设备和电容采集设备研究了基于可膨胀微球/PDMS介电层传感器的力学性能和电学性能。结果表明:通过向PDMS介电层中加入可膨胀微球显著降低了介电层的杨氏模量,同时提高了压力下介电层的介电常数,可膨胀微球/PDMS介电层传感器的工作范围可达400 kPa,最大灵敏度达到0.06 kPa−1,在100 kPa的负载循环下具有较好的重复性和稳定性,且具有较低的迟滞性(4.7%),可以准确迅速地检测到指尖压力,在生命健康等领域具有潜在的应用前景。Abstract: In order to solve the problem of narrow working pressure range of microstructured flexible capacitive pressure sensors, a flexible “sandwich” structure capacitive pressure sensor based on expandable microsphere/polydimethylsiloxane (PDMS) dielectric layer was designed in this paper. Then the structure and morphology of the expandable microsphere/PDMS dielectric layer were characterized. The mechanical and electrical properties of the expandable microsphere/PDMS dielectric layer sensor based on expandable microsphere/PDMS dielectric layer were tested by self-built pressure and capacitance acquisition equipment. The results show that the Young’s modulus of the expandable microsphere/PDMS dielectric layer is significantly reduced due to the addition of expandable microsphere into PDMS, and the dielectric constant of the expandable microsphere/PDMS dielectric layer is increased under pressure. The working pressure range of the expandable microsphere/PDMS dielectric layer sensor is up to 400 kPa, and the maximum sensitivity reaches 0.06 kPa−1. The expandable microsphere/PDMS dielectric layer sensor has good repeatability and stability under the load cycle of 100 kPa, and low hysteresis (4.7%). It can detect fingertip pressure accurately and rapidly, which has potential applications in areas of life and health.

-

Key words:

- capacitive pressure sensors /

- polydimethylsiloxane /

- porous materials /

- fabrics /

- sensitivity

-

表 1 不同电容式压力传感器的灵敏度对比

Table 1. Sensitivity comparison of different capacitive pressure sensors

Electrode Dielectric layer Sensitivity/kPa−1 Ref. Carbon nanotube (CNTs) Ecoflex 0.00059 [28] Silver nanowire (AgNW) PDMS 0.00040 [29] Conductive knitted fabrics Microporous silicone elastomer 0.01210 [7] Multiwall carbon nanotubes (MWNTs) and poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) composite electrodes Porous PDMS 0.00112 [30] CNTs yarn Ecoflex 0.05000 [31] Indium tin oxide (ITO)/polyester (PET) Microstructured PDMS 0.05500 [32] AgNW Ecoflex 0.00162 [33] Conductive woven fabrics Expandable microsphere/PDMS 0.06000 This work -

[1] 于红涛, 孙雷, 肖瑶, 等. 压阻式柔性压力传感器的研究进展[J]. 电子元件与材料, 2019, 38(6):1-11.YU H T, SUN L, XIAO Y, et al. Progress in the research of piezo-resistive flexible pressure sensor[J]. Electronic Composites and Materials,2019,38(6):1-11(in Chinese). [2] CHEN W F, YAN X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review[J]. Journal of Materials Science & Technology,2020,43:175-188. [3] 张明艳, 杨振华, 吴子剑, 等. 新型三明治结构聚二甲基硅氧烷/聚偏氟乙烯-纳米Ag线/聚二甲基硅氧烷柔性应变传感器的制备与性能[J]. 复合材料学报, 2020, 37(5):175-188.ZHANG M Y, YANG Z H, WU Z J, et al. Preparation and properties of a novel sandwich structure polydimethylsiloxane/polyvinylidene fluoride-Ag nanowires/polydimethylsiloxane flexible strain sensor[J]. Acta Materiae Compositae Sinica,2020,37(5):175-188(in Chinese). [4] TRUNG T Q, TIEN N T, SEOL Y G, et al. Transparent and flexible organic field-effect transistor for multi-modal sensing[J]. Organic Electronics,2012,13(4):533-540. doi: 10.1016/j.orgel.2011.12.015 [5] LI X P, LI Y, LI X F, et al. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets[J]. Journal of Colloid and Interface Science,2019,542:54-62. [6] LI H F, DING G F, YANG Z Q. A high sensitive flexible pressure sensor designed by silver nanowires embedded in polyimide (AgNW-PI)[J]. Micromachines,2019,10(3):206. doi: 10.3390/mi10030206 [7] ATALAY O, ATALAY A, GAFFORD J, et al. A highly sensitive capacitive-based soft pressure sensor based on a conductive fabric and a microporous dielectric layer[J]. Advance Materials Technologies,2018,3(1):1700237. doi: 10.1002/admt.201700237 [8] HE Z F, CHEN W J, LIANG B H, et al. Capacitive pressure sensor with high sensitivity and fast response to dynamic interaction based on graphene and porous nylon networks[J]. ACS Applied Materials & Interfaces,2018,10(15):12816-12823. [9] YANG J, LUO S, ZHOU X, et al. Flexible, tunable, and ultrasensitive capacitive pressure sensor with microconformal graphene electrodes[J]. ACS Applied Materials & Interfaces,2019,11(16):14997-15006. [10] LEE J, KWON H, SEO J, et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics[J]. Advanced Materials,2015,27(15):2433-2439. doi: 10.1002/adma.201500009 [11] LIU S, LU J, SHIEH H D. Influence of permittivity on the sensitivity of porous elastomer-based capacitive pressure sensors[J]. IEEE Sensors Journal,2018,18(5):1870-1876. doi: 10.1109/JSEN.2017.2789242 [12] 杜青, 李刚, 胡杰, 等. 基于C-PDMS介质层的柔性电容式传感器研究[J]. 仪表技术与传感器, 2019(2):1-3, 8. doi: 10.3969/j.issn.1002-1841.2019.09.001DU Q, LI G, HU J, et al. Flexible capacitive sensor based on C-PDMS composites as dielectric layer[J]. Instrument Technique and Sensor,2019(2):1-3, 8(in Chinese). doi: 10.3969/j.issn.1002-1841.2019.09.001 [13] 高会, 黄龙男, 刘彦菊, 等. 形状记忆聚合物在柔性光/电子器件领域的发展与挑战[J]. 复合材料学报, 2018, 35(12):3255-3246.GAO H, HUANG L N, LIU Y J, et al. Developments and challenges of shape memory polymers in flexible optoelectronics[J]. Acta Materiae Compositae Sinica,2018,35(12):3255-3246(in Chinese). [14] PANG C, KOO J H, NGUYEN A, et al. Sensors: Highly skin-conformal microhairy sensor for pulse signal amplification[J]. Advanced Materials,2015,27(4):589. [15] XU F L, LI X Y, SHI Y, et al. Recent developments for flexible pressure sensors: A review[J]. Micromachines,2018,9(11):580. doi: 10.3390/mi9110580 [16] WEHNER M, TRUBY R L, FITZGERALD D J, et al. An integrated design and fabrication strategy for entirely soft, autonomous robots[J]. Nature,2016,536(7617):451-455. doi: 10.1038/nature19100 [17] MA L Q, SHUAI X T, HU Y G, et al. A highly sensitive and flexible capacitive pressure sensor based on a micro-arrayed polydimethylsiloxane dielectric layer[J]. Journal of Materials Chemistry C, 2018, 6(48): 13232-13240. [18] LUO Y S, SHAO J Y, CHEN S R, et al. Flexible capacitive pressure sensor enhanced by tilted micropillar arrays[J]. ACS Applied Materials & Interfaces,2019,11(19):17796-17803. [19] KWON D, LEE T I, KIM M S, et al. Porous dielectric elastomer based ultra-sensitive capacitive pressure sensor and its application to wearable sensing device[C]//2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS). Anchorage: IEEE, 2015. [20] WAN Y B, QIU Z G, HONG Y, et al. A highly sensitive flexible capacitive tactile sensor with sparse and high-aspect-ratio microstructures[J]. Advanced Electronic Materials,2018,4(4):1700586. doi: 10.1002/aelm.201700586 [21] GUO Z X, MO L X, DING Y, et al. Printed and flexible capacitive pressure sensor with carbon nanotubes based composite dielectric layer[J]. Micromachines,2019,10(11):715. doi: 10.3390/mi10110715 [22] LEE B Y, KIM J, KIM H, et al. Low-cost flexible pressure sensor based on dielectric elastomer film with micro-pores[J]. Sensors and Actuators A: Physical,2016,240:103-109. doi: 10.1016/j.sna.2016.01.037 [23] 李思明, 吴官正, 胡雨洁, 等. 压力分布监测袜的制备及其传感器性能[J]. 纺织学报, 2019, 40(7):138-144.LI S M, WU G Z, HU Y J, et al. Preparation of pressure distribution monitoring socks and related sensing properties[J]. Journal of Textile Research,2019,40(7):138-144(in Chinese). [24] KANG S B, LEE J, LEE S, et al. Highly sensitive pressure sensor based on bioinspired porous structure for real-time tactile sensing[J]. Advanced Electronic Materials,2016,2(12):1600356. doi: 10.1002/aelm.201600356 [25] NIU H S, GAO S, YUE W J, et al. Highly morphology-controllable and highly sensitive capacitive tactile sensor based on epidermis-dermis-inspired interlocked asymmetric-nanocone arrays for detection of tiny pressure[J]. Small,2020,16(4):1904774. doi: 10.1002/smll.201904774 [26] GUO Y J, GAO S, YUE W J, et al. Anodized aluminum oxide-assisted low-cost flexible capacitive pressure sensors based on double-sided nanopillars by a facile fabrication method[J]. ACS Applied Materials & Interfaces,2019,11(51):48594-48602. [27] LI S M, GU Y J, WU G Z, et al. A flexible piezoresistive sensor with highly elastic weave pattern for motion detection[J]. Smart Materials and Structures,2019,28(3):035020. doi: 10.1088/1361-665X/ab0002 [28] WANG X, LI T, ADAM J, et al. Transparent, stretchable, carbon-nanotube-inlaid conductors enabled by standard replication technology for capacitive pressure, strain and touch sensors[J]. Journal of Materials Chemistry A,2013,11(1):3580-3586. [29] ZHANG B, XIANG Z M, ZHU S W, et al. Dual functional transparent film for proximity and pressure sensing[J]. Nano Research,2014,10(7):1488-1496. [30] PARK S W, DAS P S, PARK J Y. Development of wearable and flexible insole type capacitive pressure sensor for continuous gait signal analysis[J]. Organic Electronics,2018,53:213-220. [31] KIM S Y, PARK S, PARK H W, et al. Highly sensitive and multimodal all-carbon skin sensors capable of simultaneously detecting tactile and biological stimuli[J]. Advanced Materials,2015,27(28):4178-4185. doi: 10.1002/adma.201501408 [32] MAHATA C, ALGADI H, LEE J, et al. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications[J]. Measurement,2020,151:107095. [33] YAO S S, ZHU Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires[J]. Nanoscale,2014,6(4):2345-2352. doi: 10.1039/c3nr05496a [34] CHENG W, WANG J, MA Z, et al. Flexible pressure sensor with high sensitivity and low hysteresis based on a hierarchically microstructured electrode[J]. IEEE Electronic Device Letters,2018,39(2):288-291. doi: 10.1109/LED.2017.2784538 [35] QIU J, GUO X H, CHU R, et al. Rapid-response, low detection limit, and high-sensitivity capacitive flexible tactile sensor based on three-dimensional porous dielectric layer for wearable electronic skin[J]. ACS Applied Materials & Interfaces,2019,11(43):40716-40725. [36] GUO X H, HUANG Y, CAI X, et al. Capacitive wearable tactile sensor based on smart textile substrate with carbon black/silicone rubber composite dielectric[J]. Measurement Science and Technology,2016,27(4):04105. [37] RANA A, ROBERGE J P, DUCHAINE V. An improved soft dielectric for a highly sensitive capacitive tactile sensor[J]. IEEE Sensors Journal,2016,16(22):7852-7863. [38] LI M M, LIANG J M, WANG X D, et al. Ultra-sensitive flexible pressure sensor based on microstructured electrode[J]. Sensors,2020,20(2):371. doi: 10.3390/s20020371 [39] MANNSFELD S C B, TEE B C K, STOLTENBERG R M, et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers[J]. Nature Materials,2010,9(10):859-864. doi: 10.1038/nmat2834 -

下载:

下载: