Measurement and analysis of in-plane tensile non-uniform full-field strain of ceramic fiber reinforced SiO2 aerogel composites

-

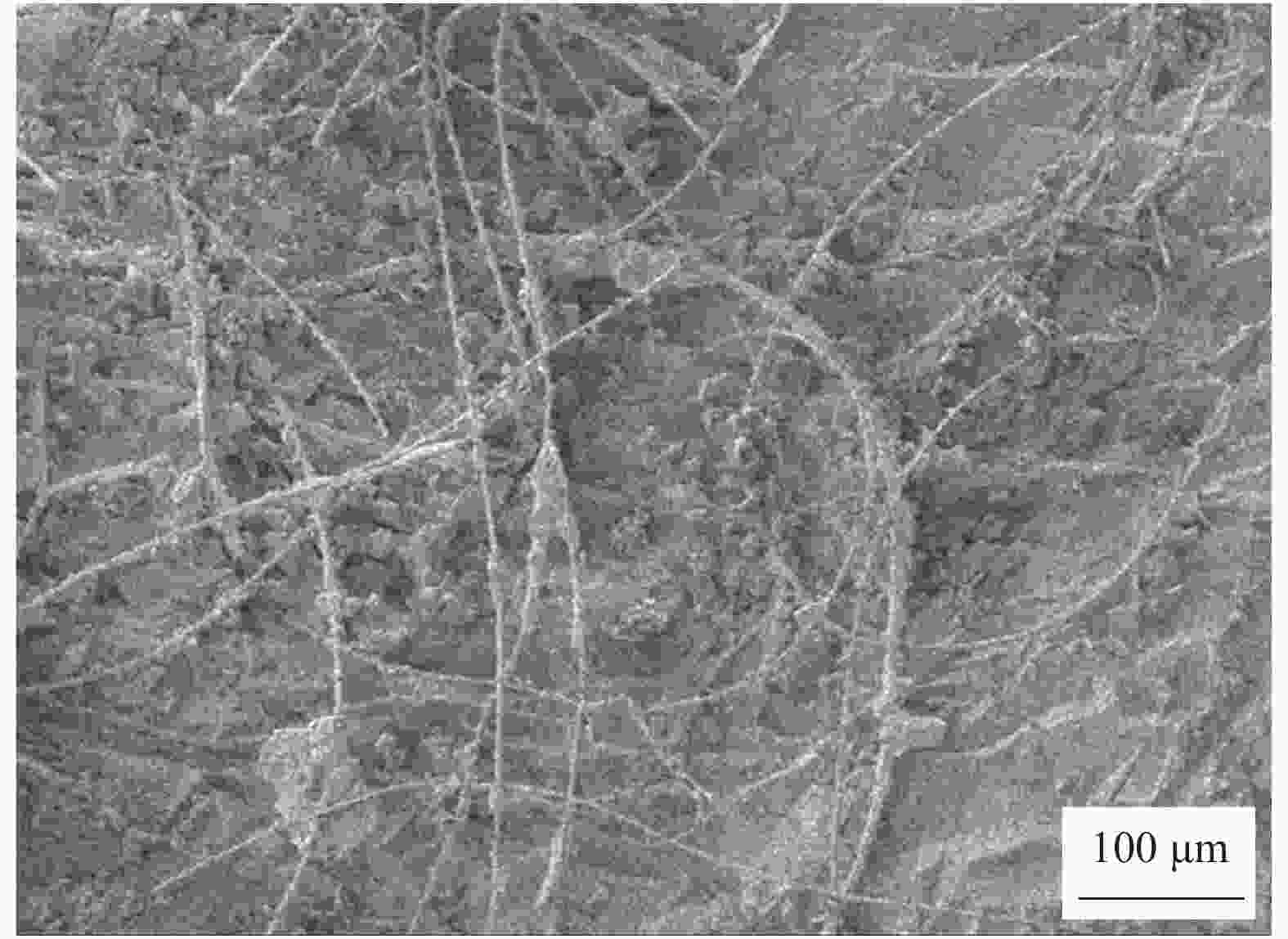

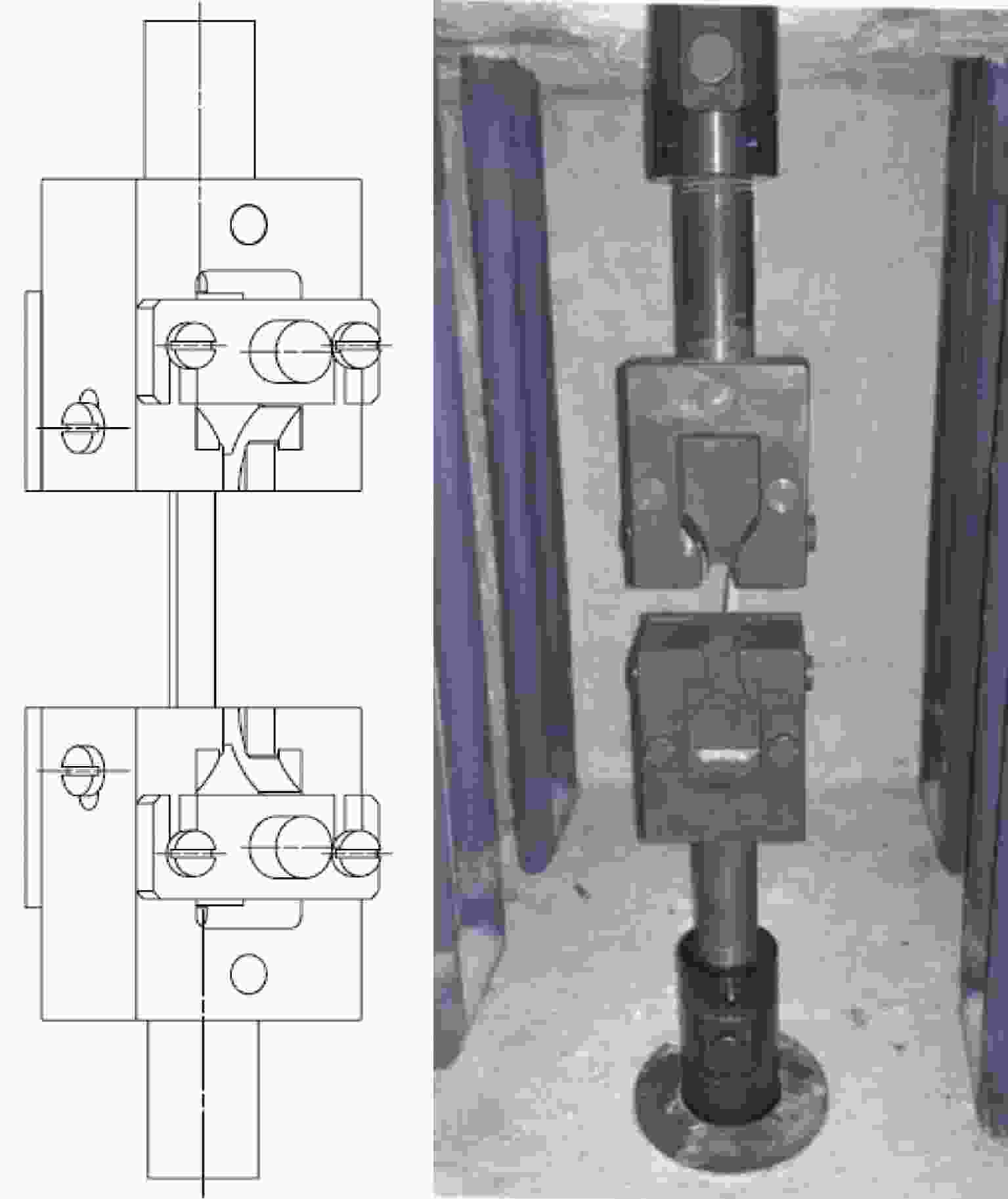

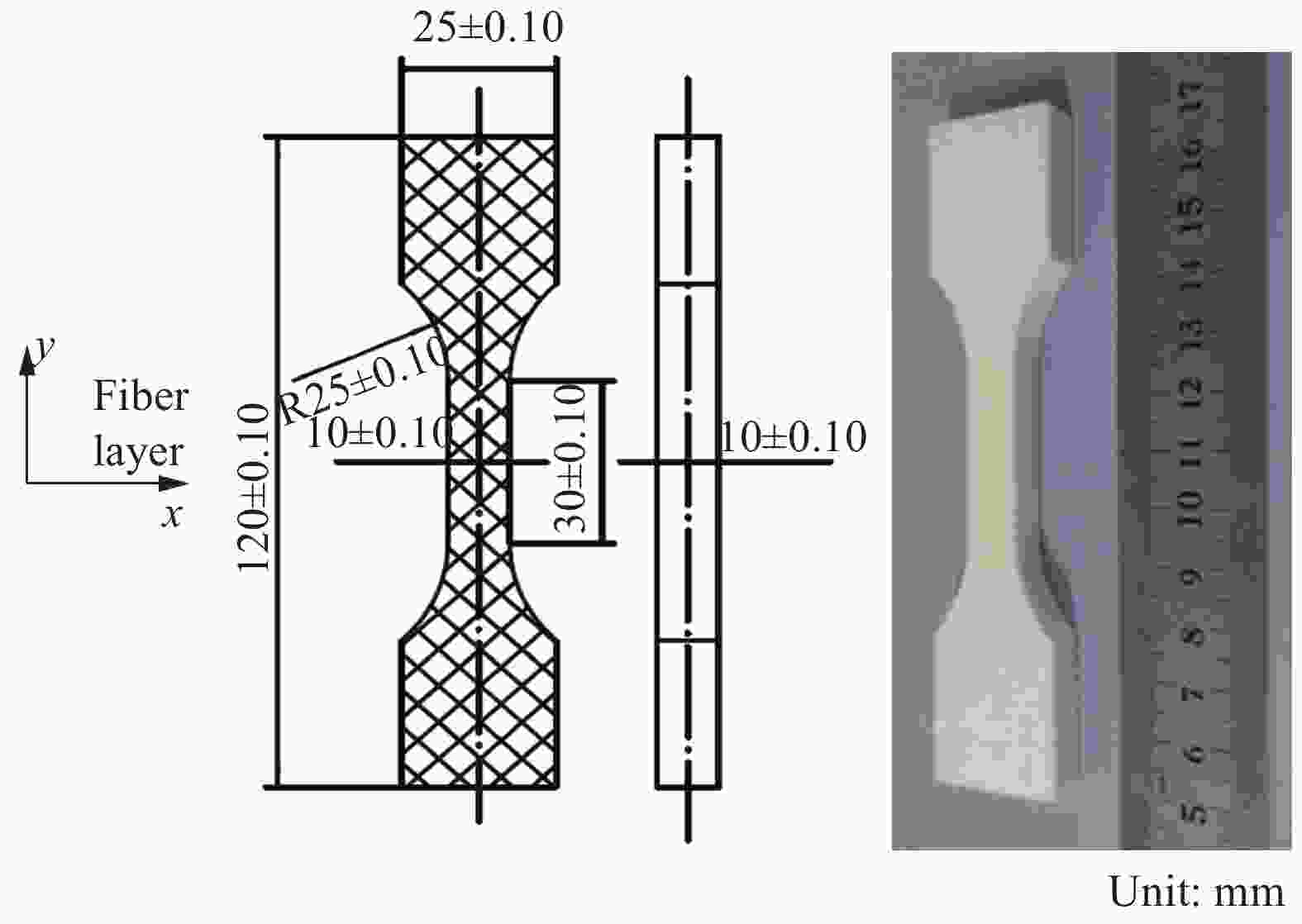

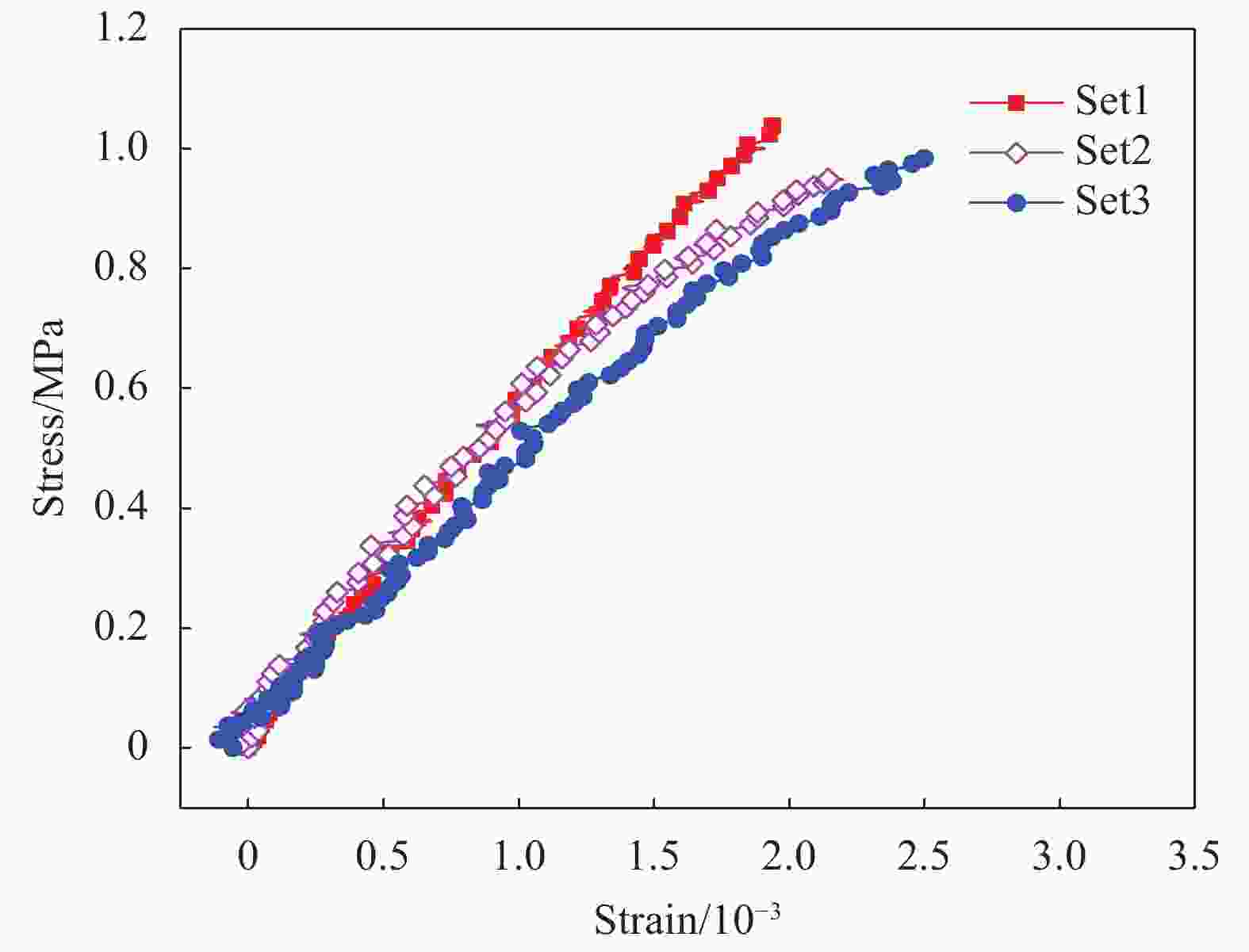

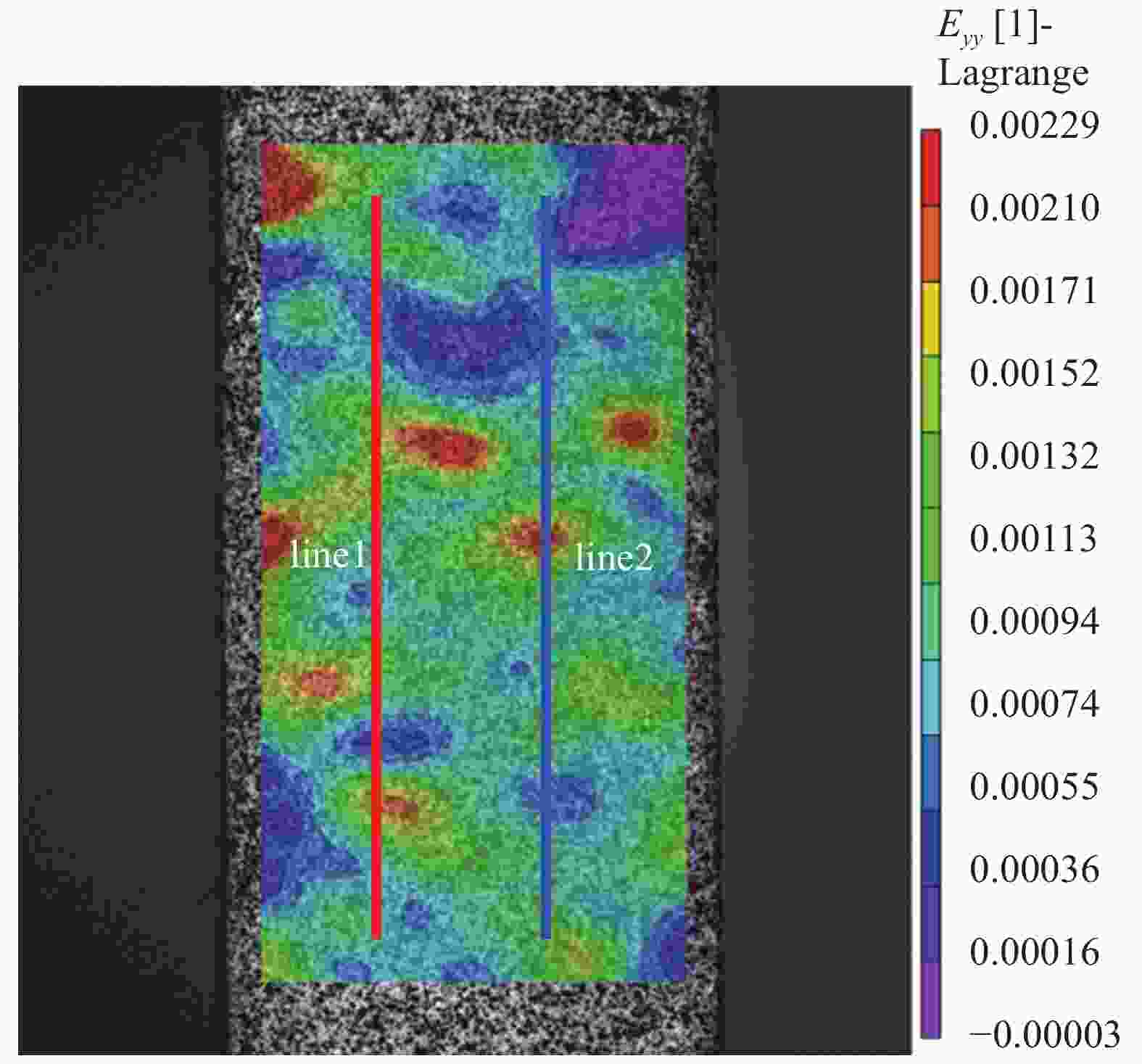

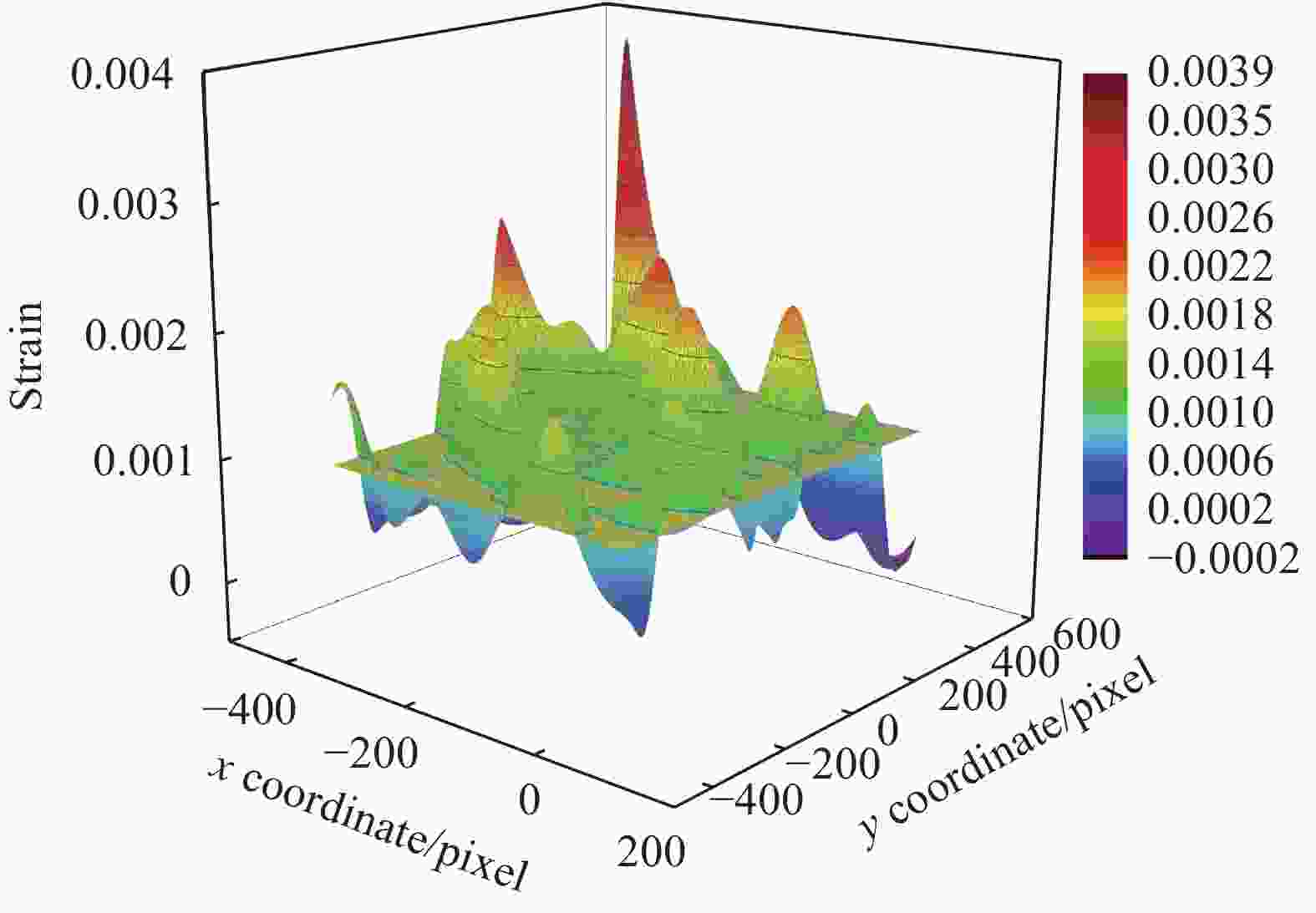

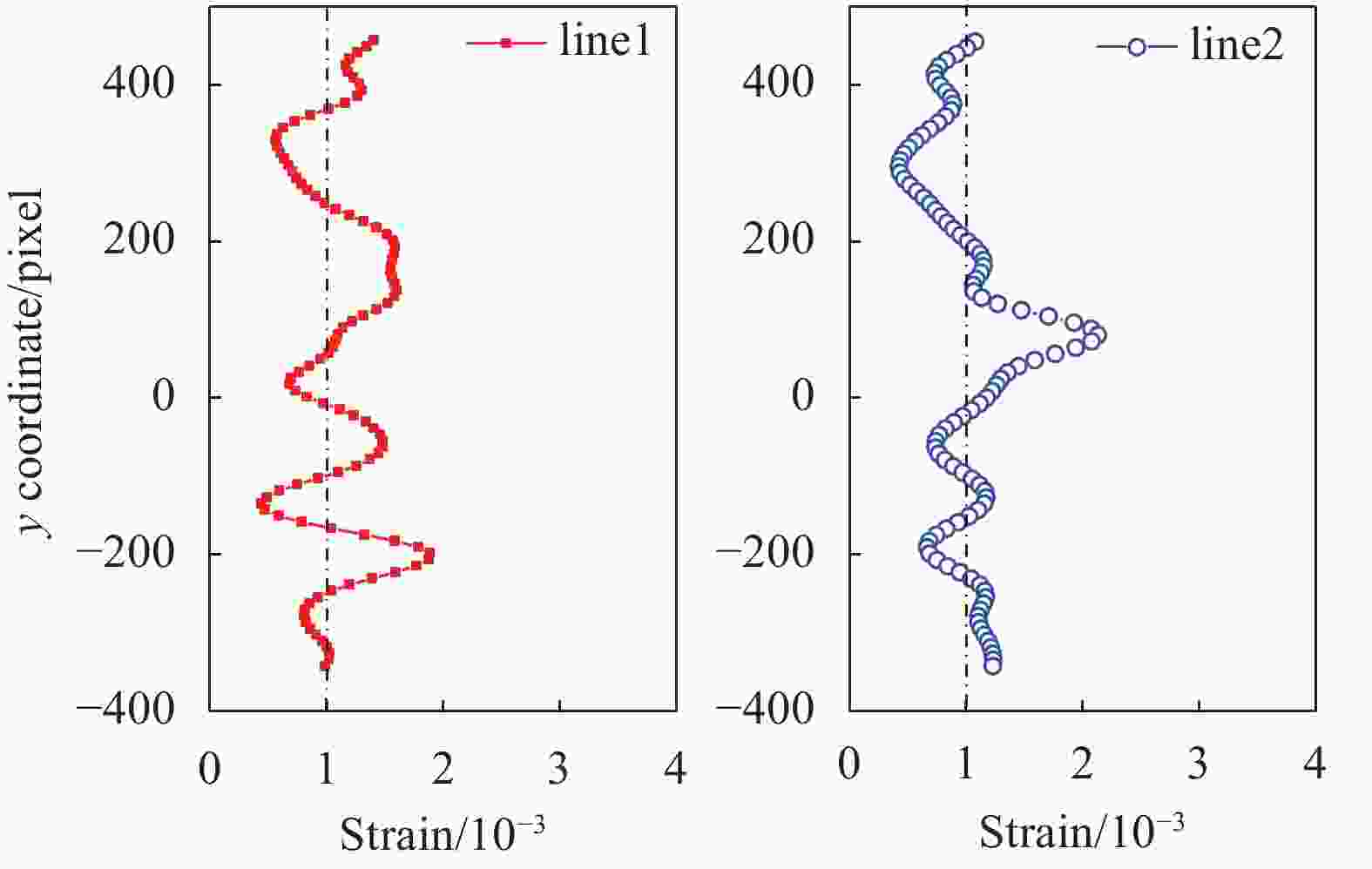

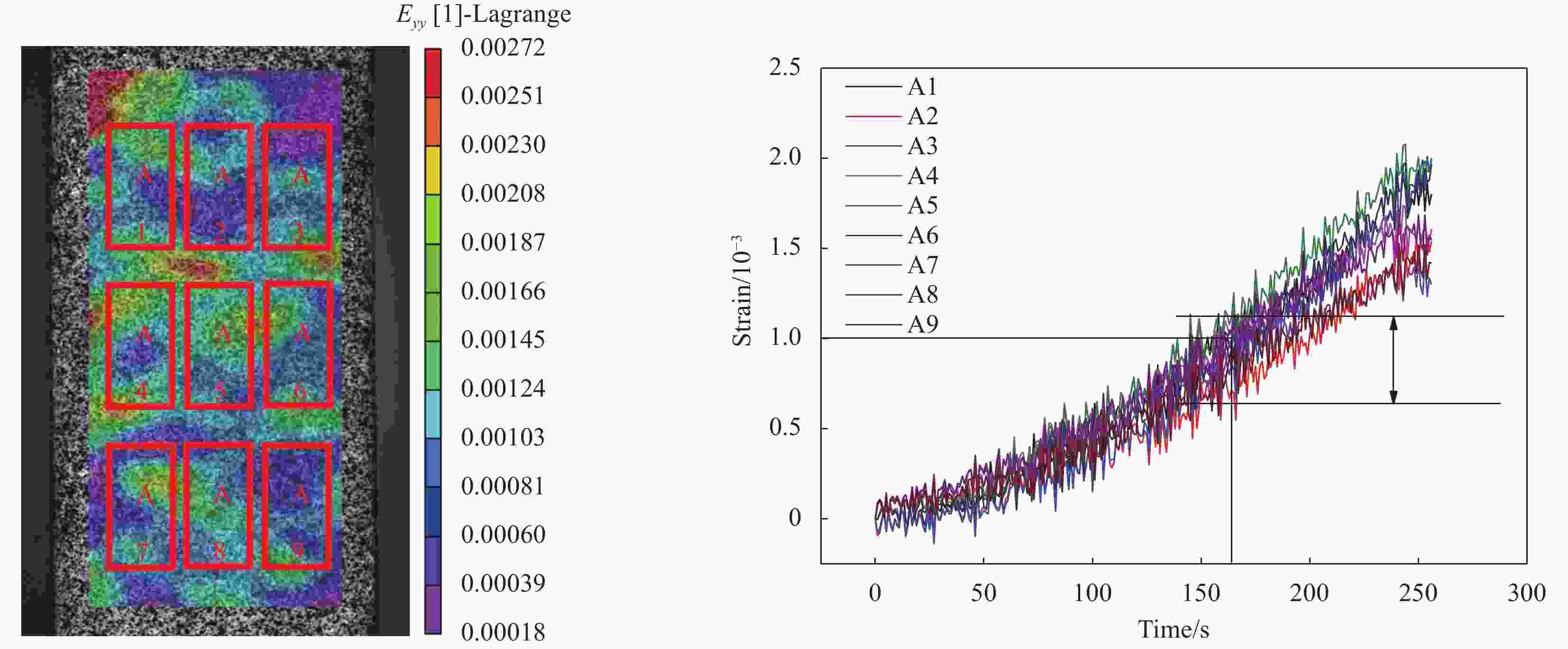

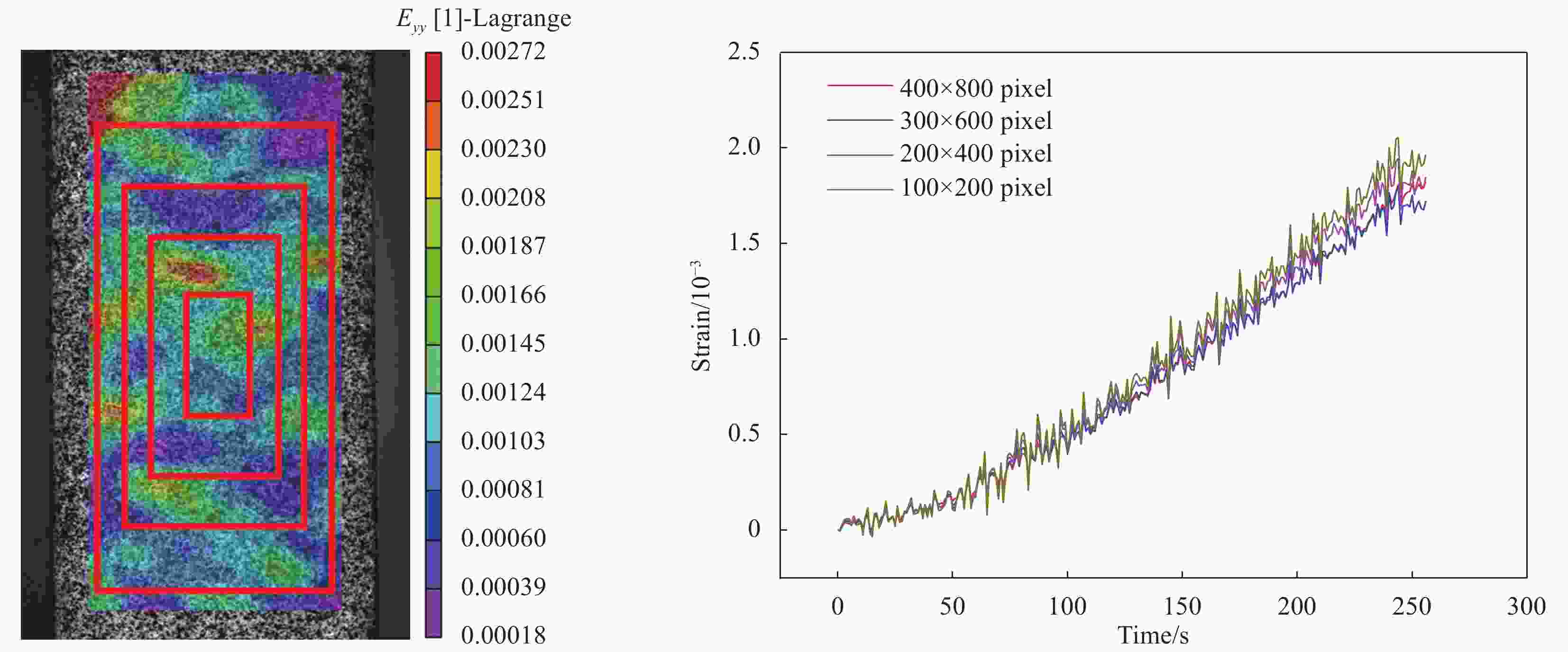

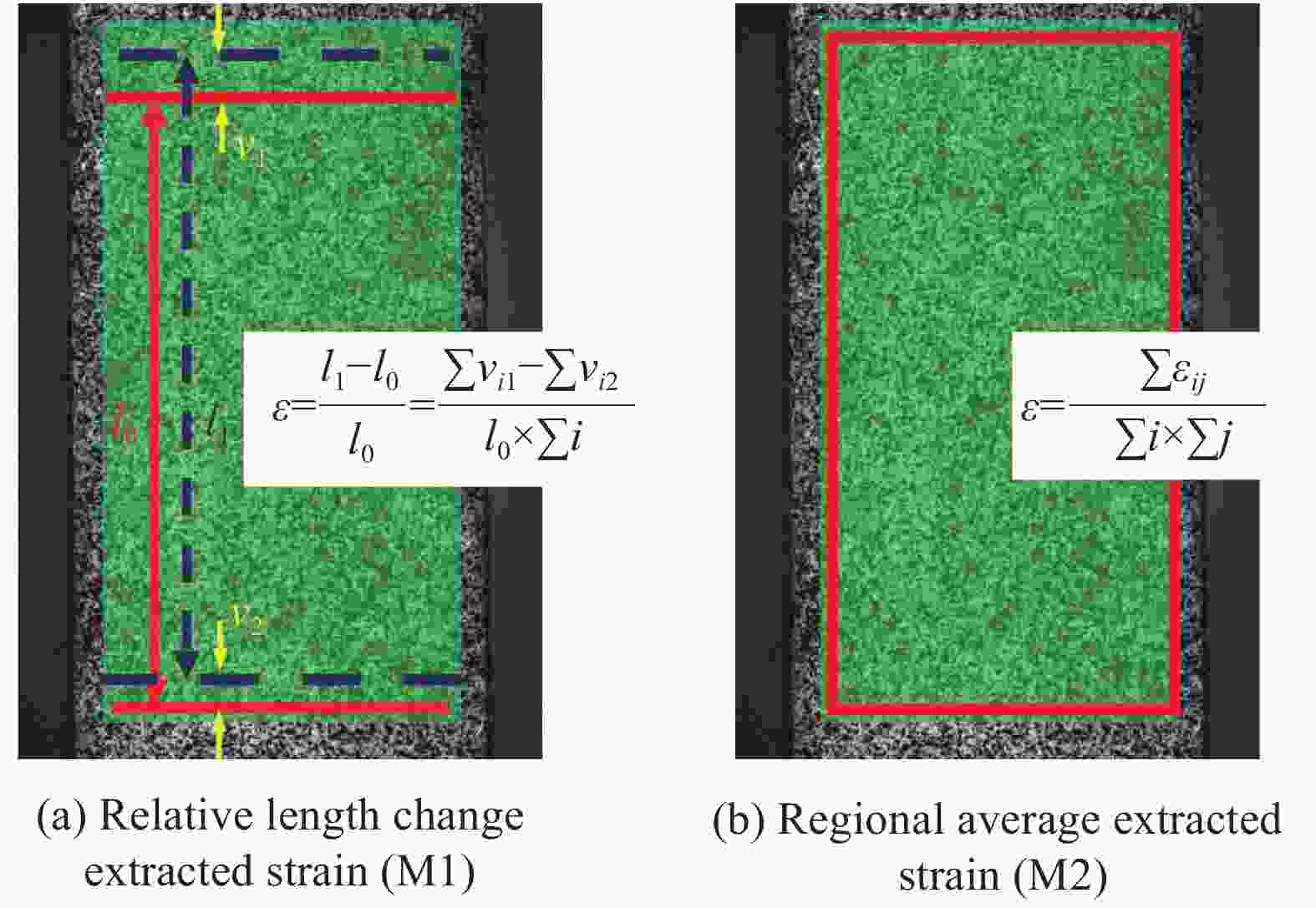

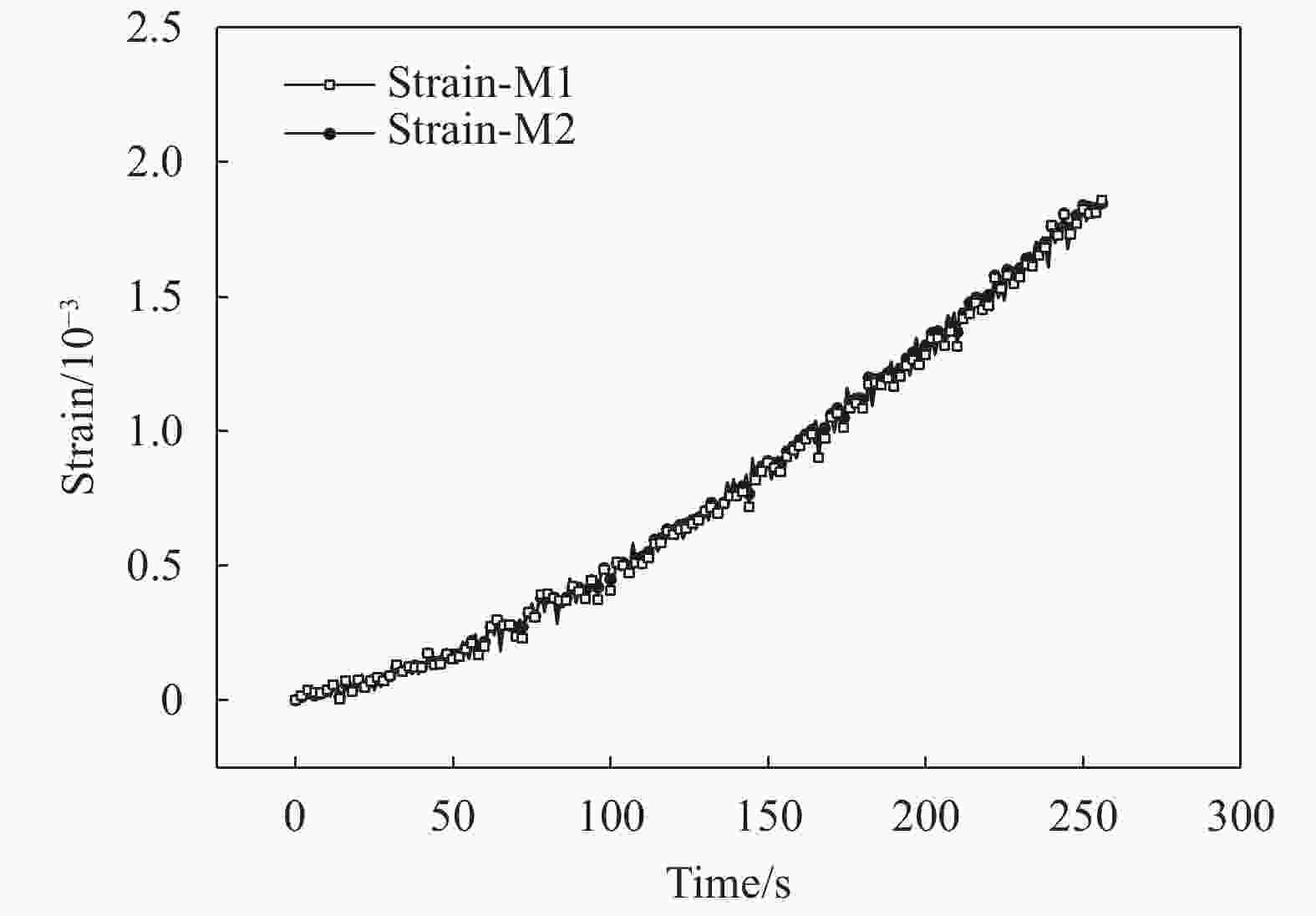

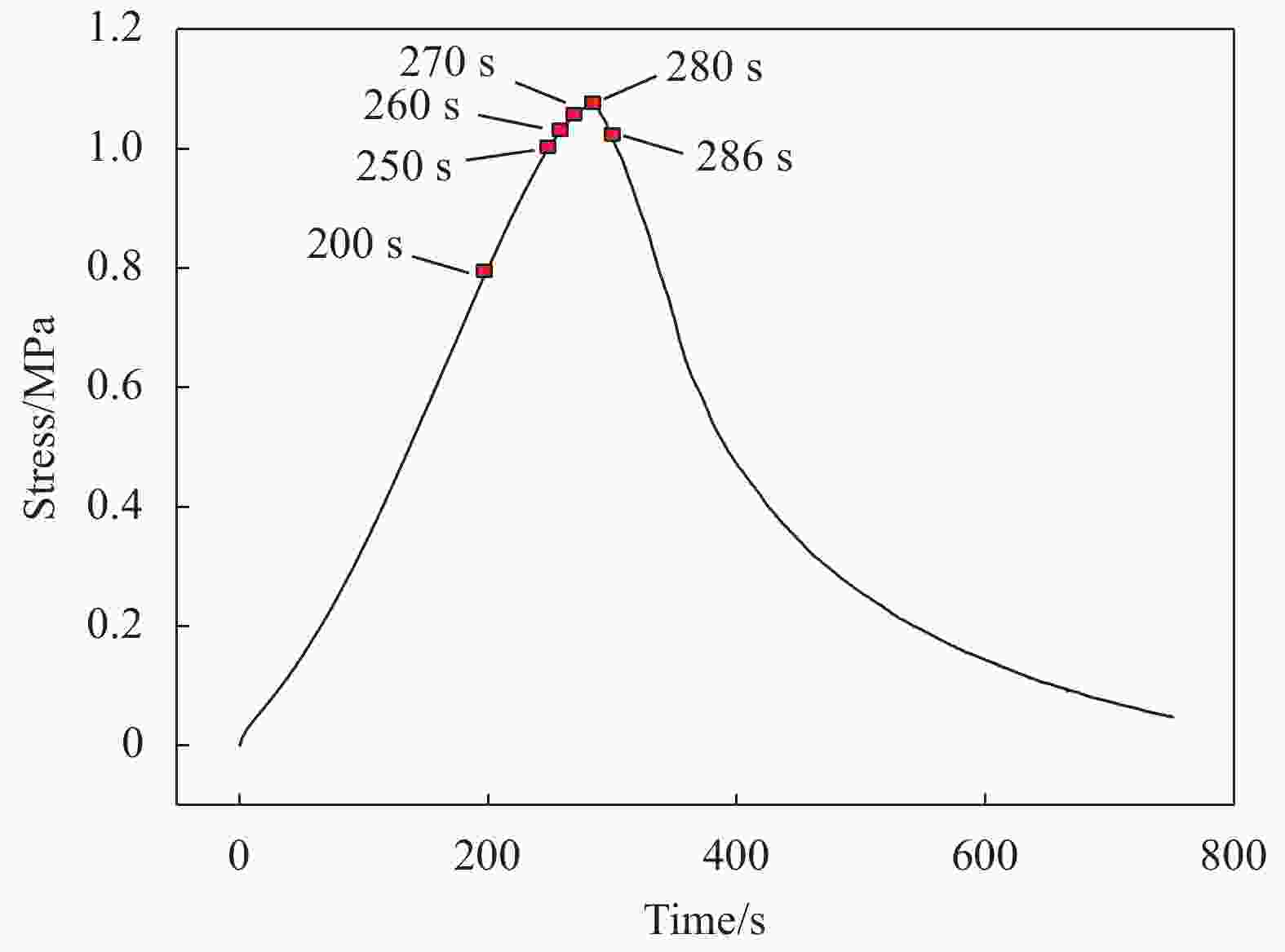

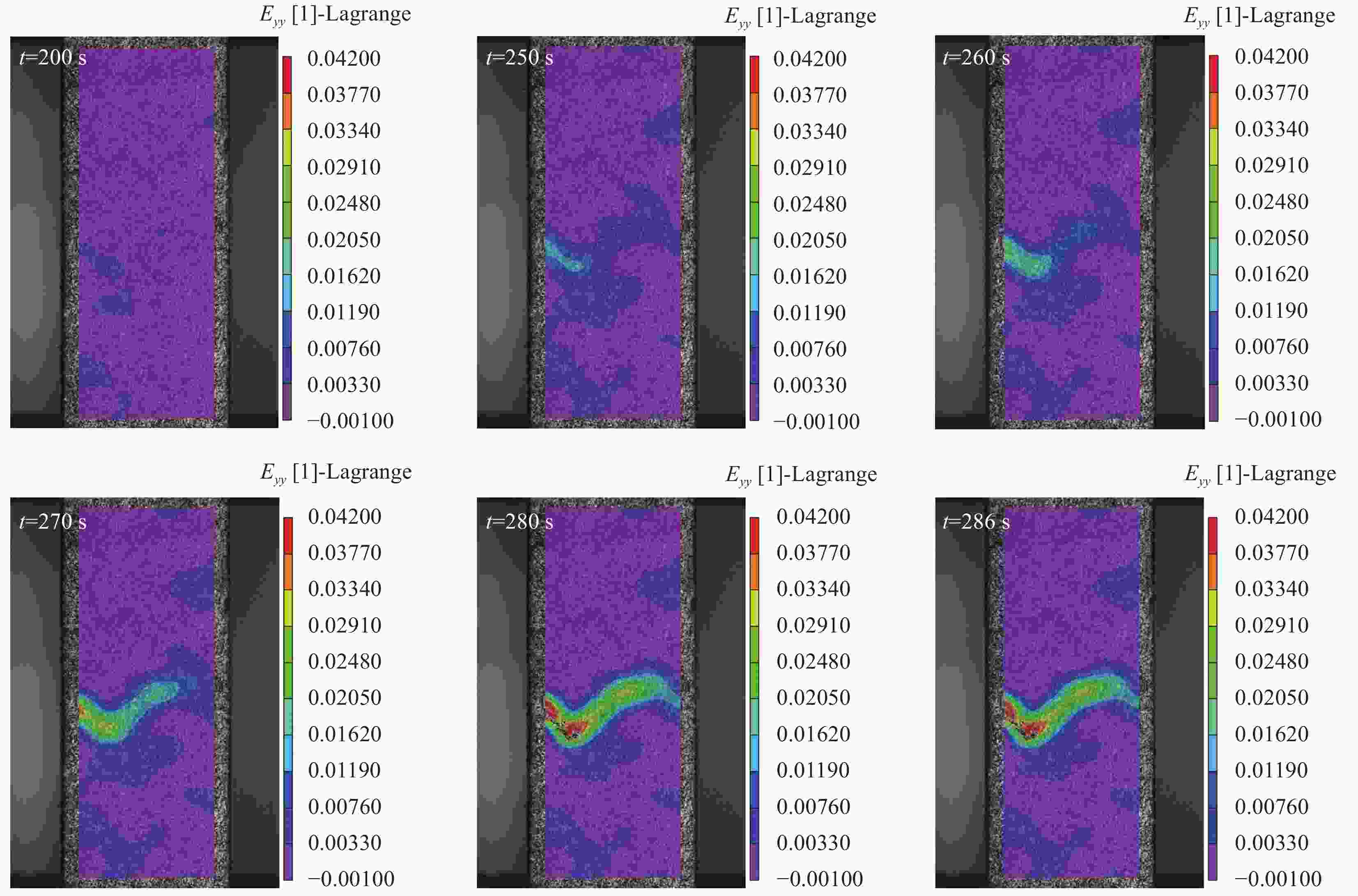

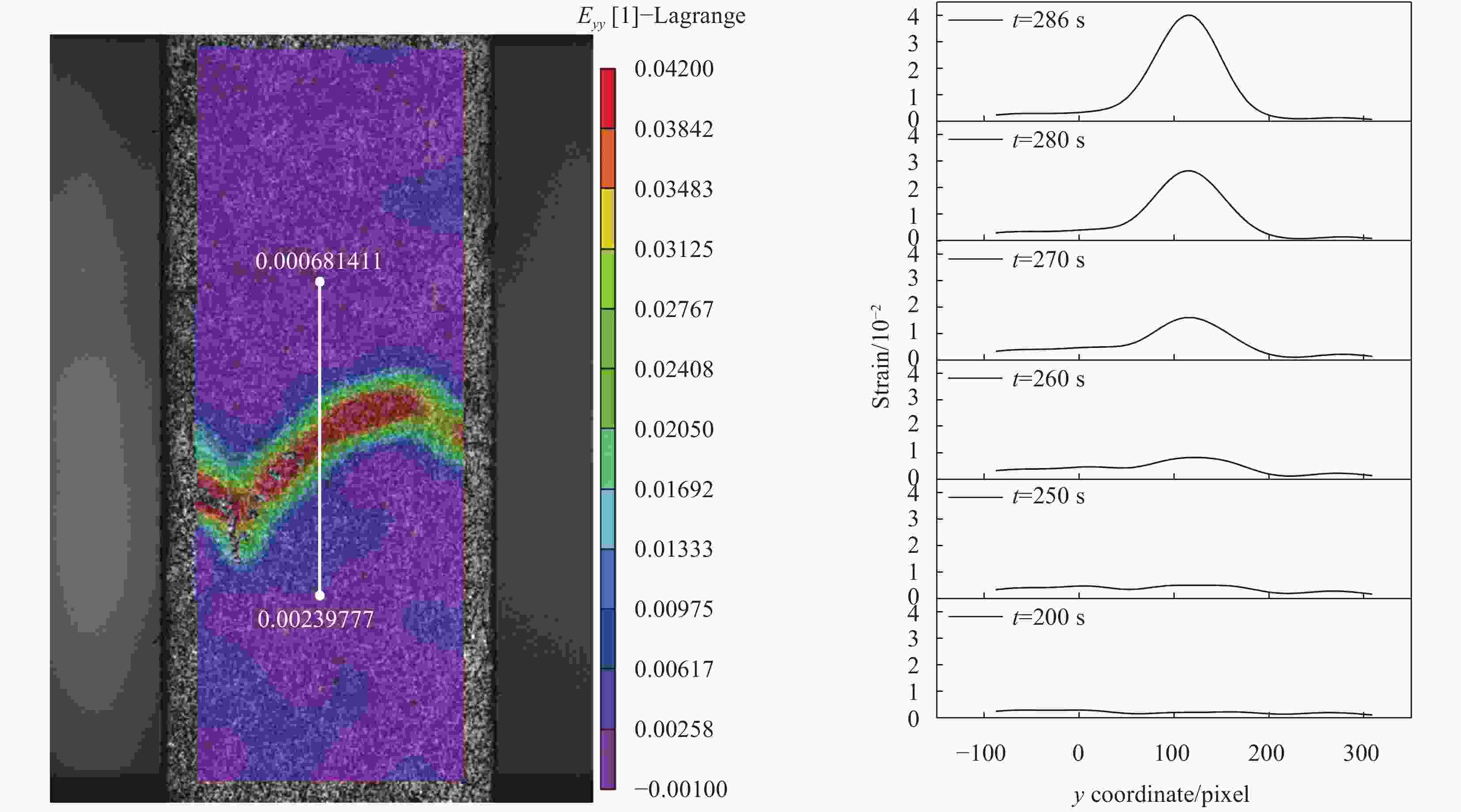

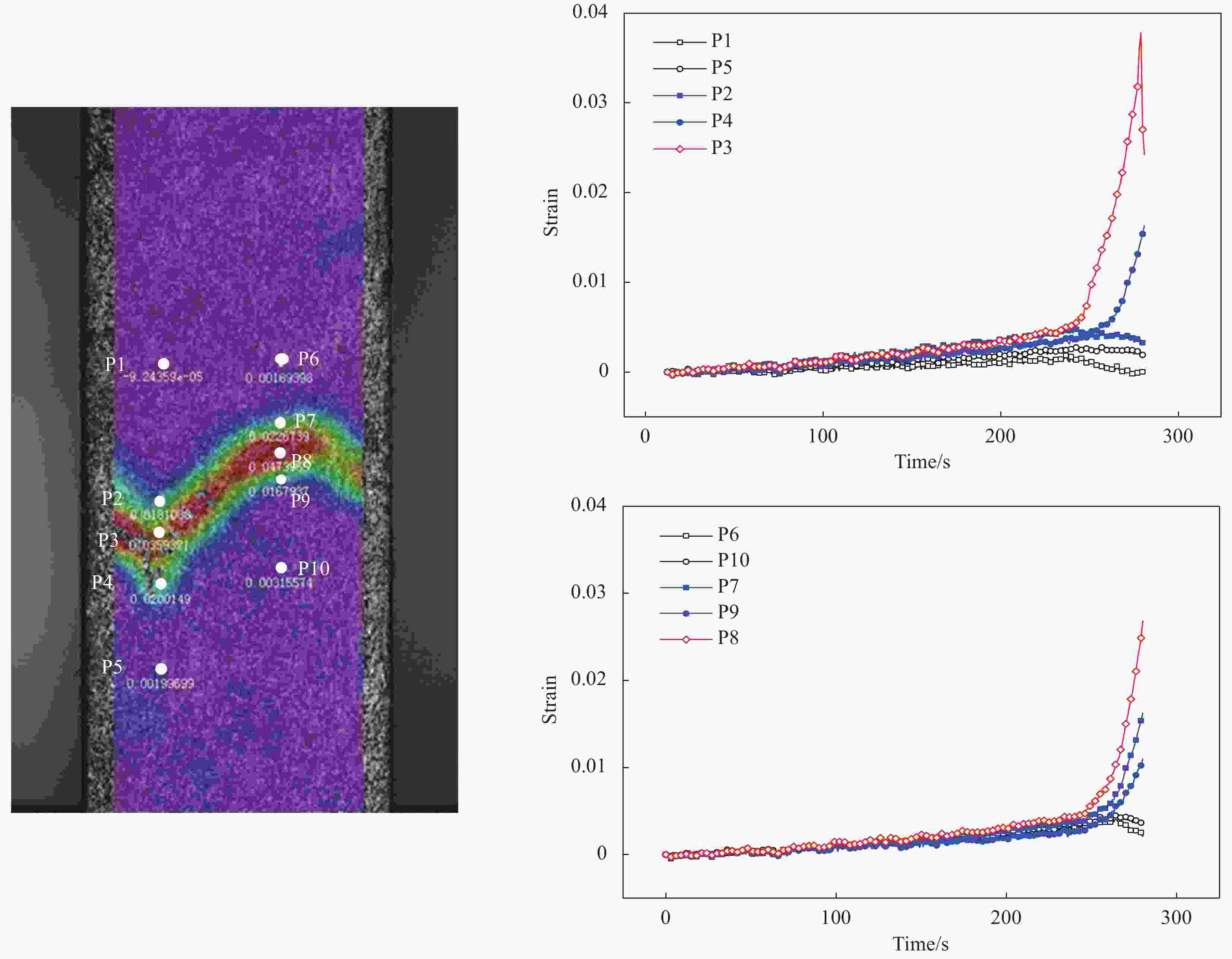

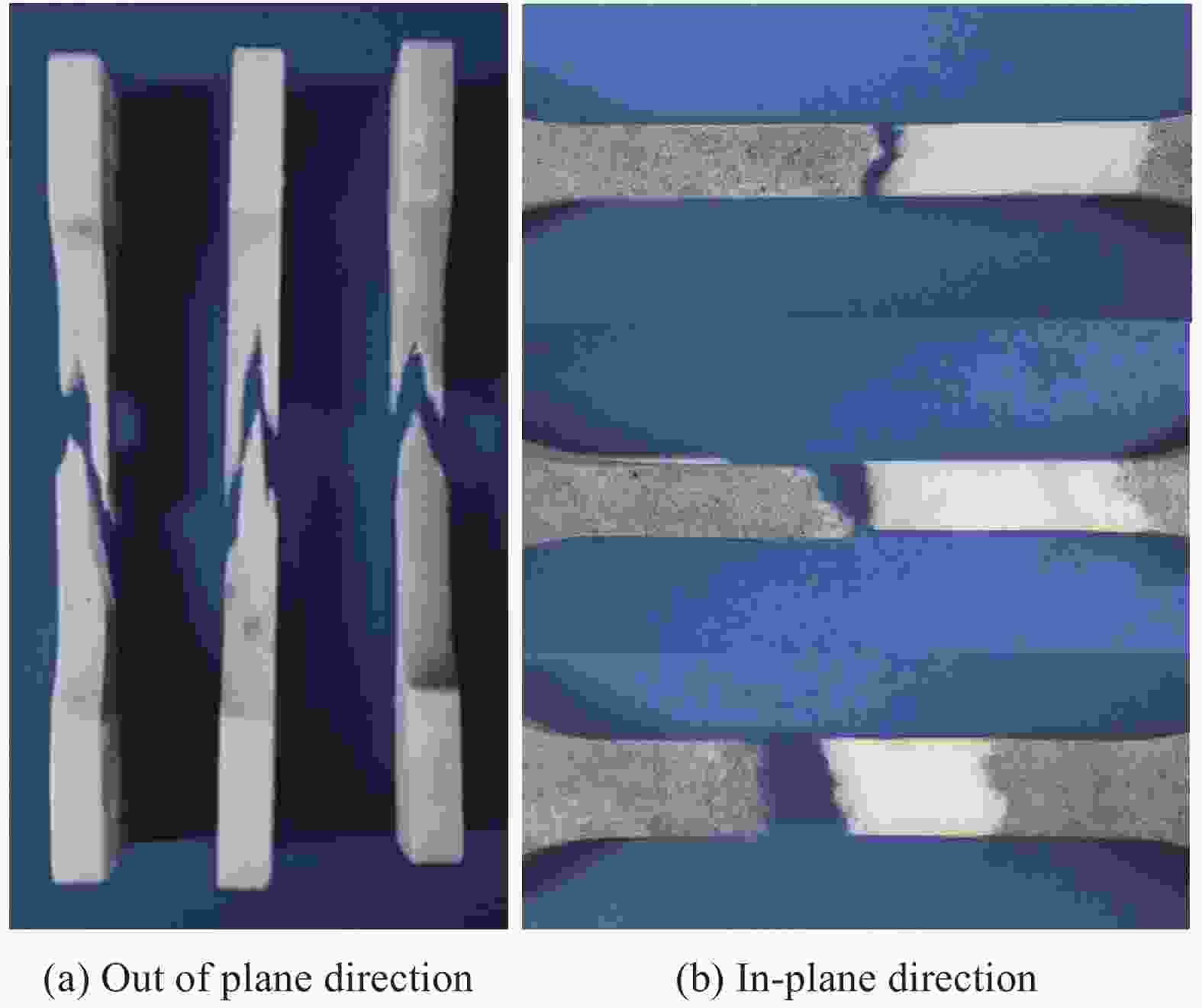

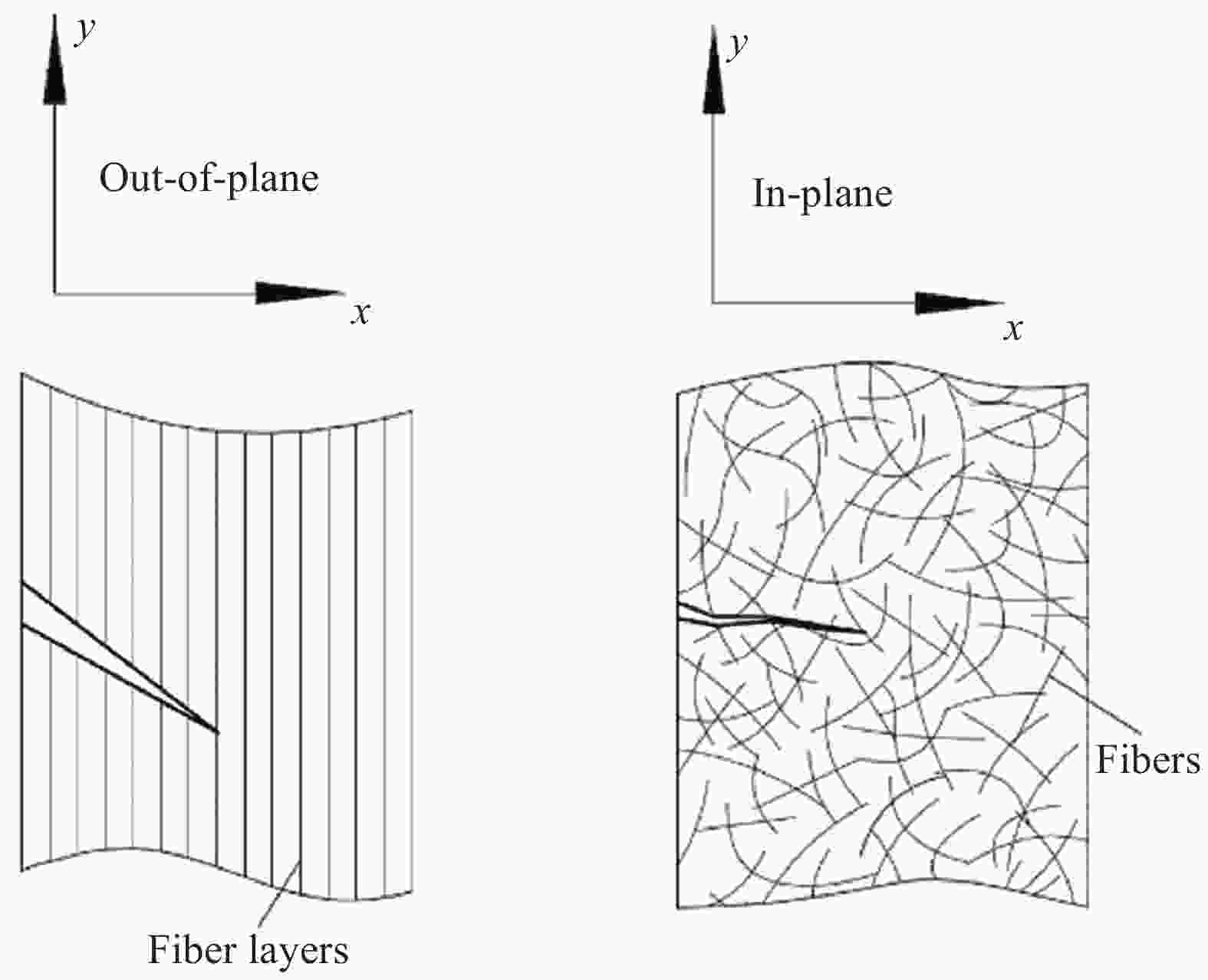

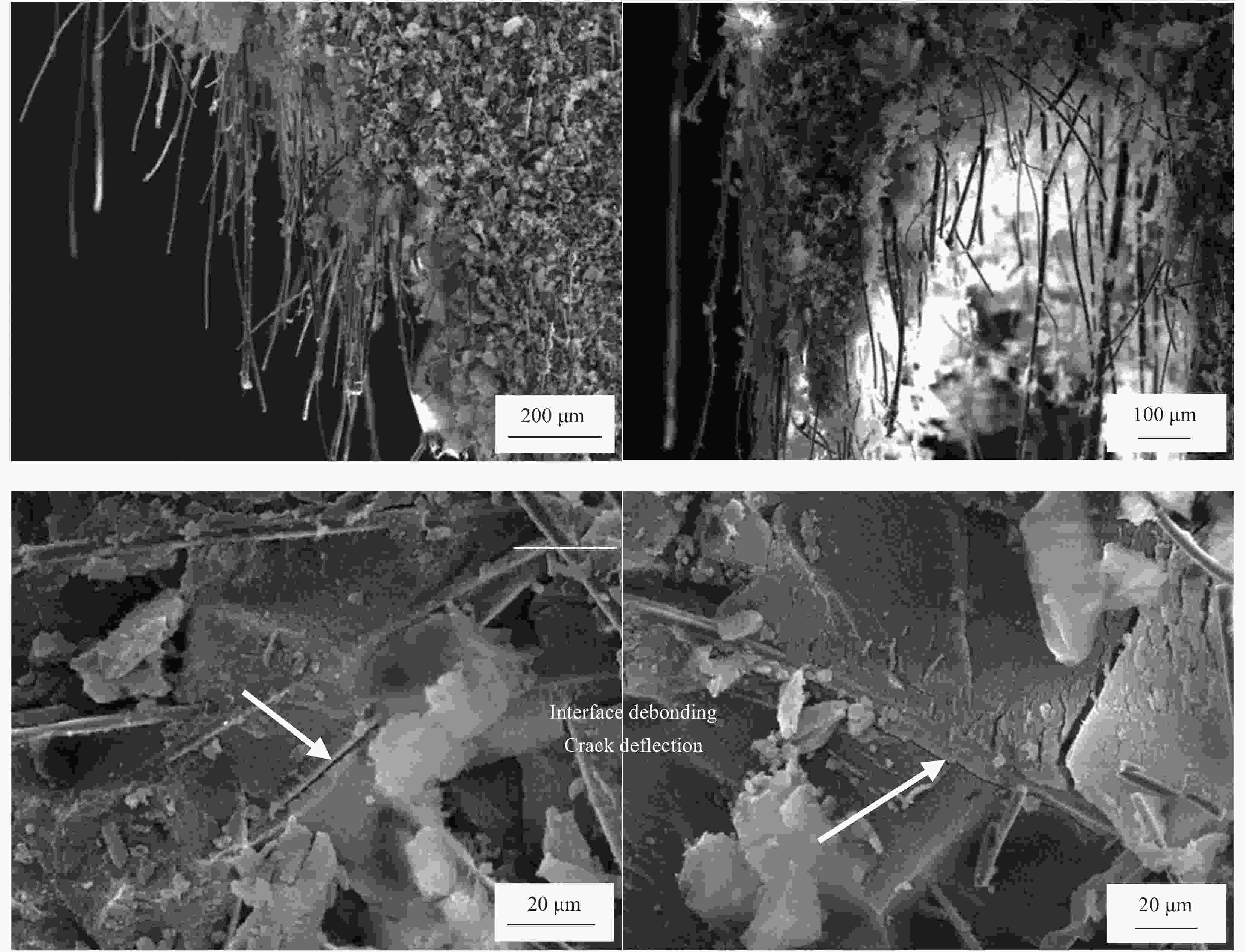

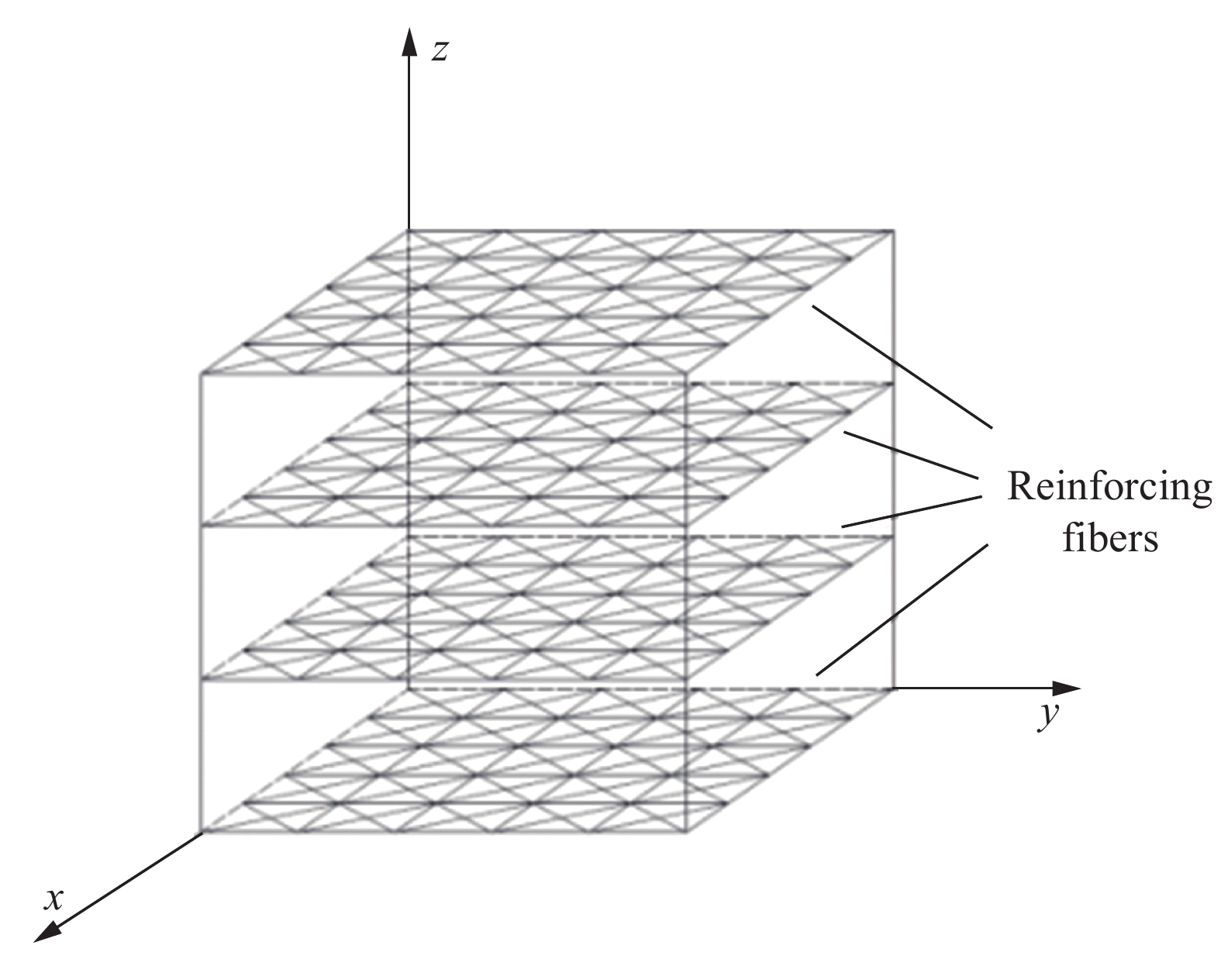

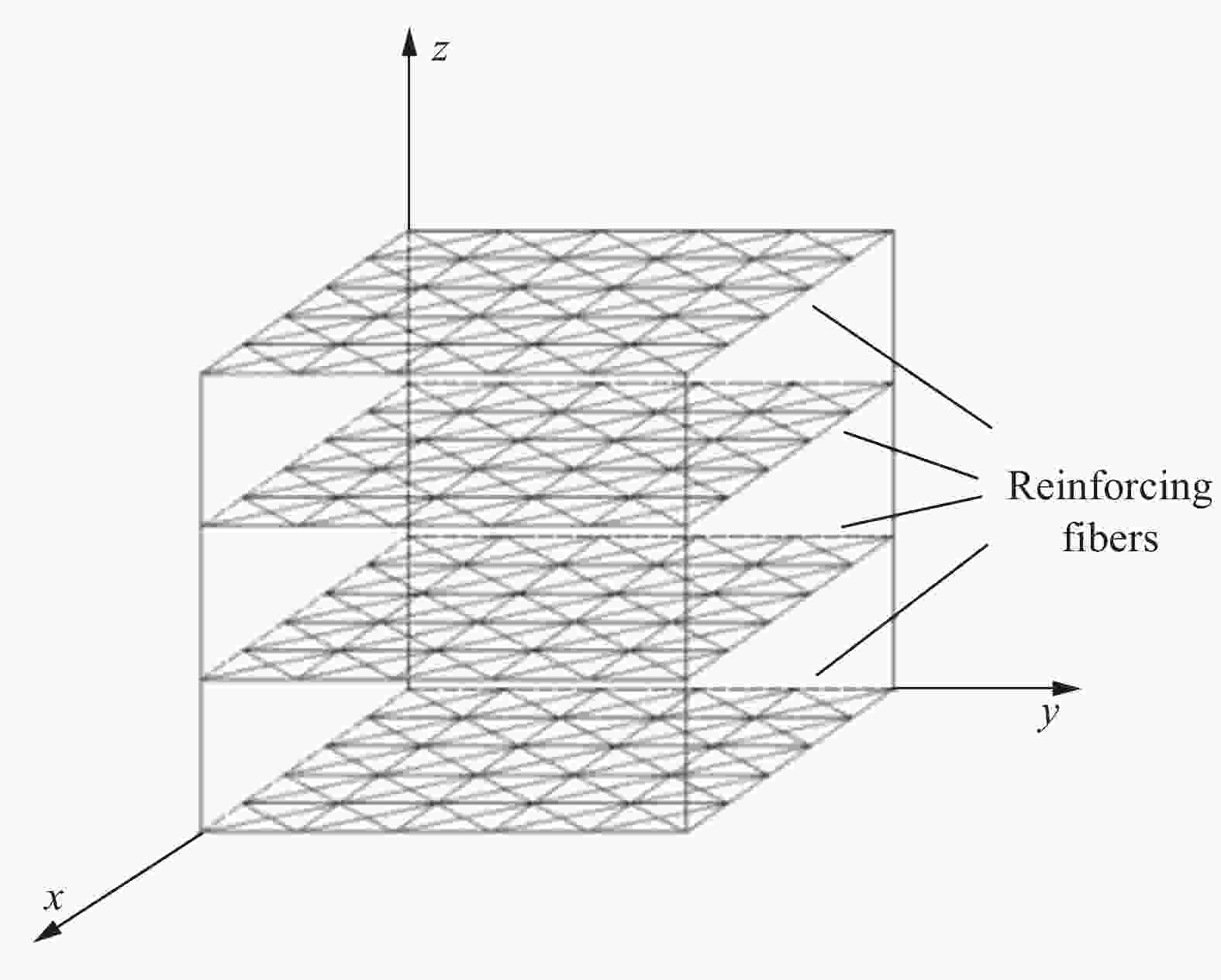

摘要: 通过设计圆弧边缘夹持方案和狗骨形拉伸试样,开展了陶瓷纤维增强SiO2气凝胶复合材料室温环境中的面内拉伸性能试验,采用数字图像相关方法对陶瓷纤维增强SiO2气凝胶复合材料表面的全场变形进行测量和分析,并结合获得的非均匀应变分布情况进一步讨论其力学行为特征和变形断裂机制。结果表明:纤维增强增韧机制使陶瓷纤维增强SiO2气凝胶复合材料的面内拉伸行为表现出一定的非线性及韧性特征;在一定载荷水平下,陶瓷纤维增强SiO2气凝胶复合材料表面应变分布呈显著的非均匀特征,与内部随机的纤维排布及各处传力情况不同相关,可选择较大计算区域进行平均化处理来减弱对测试中应变度量的影响;在加载和断裂过程中陶瓷纤维增强SiO2气凝胶复合材料表面存在局部应变集中现象,并随着裂纹扩展而发生演变,面内拉伸载荷下的宏观断口呈锯齿状特征,主要由剪应力主导的基体断裂、法向针刺对纤维铺层的约束等原因所致。本文研究结果为隔热复合材料的强韧化性能提高指明了方向。Abstract: By designing the circular arc edge griping scheme and dog bone type tensile specimen, the in-plane tensile property tests of ceramic fiber reinforced SiO2 aerogel composites at room temperature were conducted. The full field deformation of ceramic fiber reinforced SiO2 aerogel composites surface was measured and analyzed based on digital image correlation method. The non-uniform strain distribution results were obtained and discussed. The mechanical behavior characteristics and deformation and fracture mechanisms were further discussed. The results show that the in-plane tensile behavior of the ceramic fiber reinforced SiO2 aerogel composites exhibits some nonlinear and ductile characteristics due to fiber reinforced and toughened mechanisms. Under certain load level, the strain distribution on the ceramic fiber reinforced SiO2 aerogel composites surface shows significantly non-uniform. This is related to the internal random fiber arrangements and the different force transferring situations. In the mechanical tests, larger calculation areas can be selected for averaging treatment to reduce the non-uniform influence on the strain measurement. In the process of loading and fracture, the local strain concentration phenomenon exists on the ceramic fiber reinforced SiO2 aerogel composites surface and evolves with the crack propagation. The fracture appearance under the in-plane tensile load has a serrated feature. It is mainly caused by the matrix fracture dominated by shear stress and the constraint effect of normal needling on the fiber layers. Results can point out the direction to improve the strengthening and toughening of thermal insulation composites.

-

表 1 陶瓷纤维增强SiO2气凝胶复合材料面内拉伸弹性模量和抗拉强度

Table 1. In-plane tensile elastic modulus and strength of ceramic fiber reinforced SiO2 aerogel composites

Test number E/MPa σb/MPa Set 1 542.86 1.00 Set 2 479.69 1.05 Set 3 414.91 1.07 Notes:E—Elastic modulus; σb—Tensile strength. -

[1] AEGERTER M. Aerogels handbook[M]. New York: Springer, 2011. [2] KOEBEL M, RIGACCI A, ACHARD P. Aerogel-based thermal superinsulation: An overview[J]. Journal of Sol-Gel Science and Technology,2012,63(3):315-339. doi: 10.1007/s10971-012-2792-9 [3] 冯坚. 气凝胶高效隔热材料[M]. 北京: 科学出版社, 2016.FENG Jian. Aerogel materials for high efficiency thermal insulation[M]. Beijing: Science Press, 2016(in Chinese). [4] 瑚佩, 姜勇刚, 张忠明, 等. 耐高温、高强度隔热复合材料研究进展[J]. 材料导报, 2020, 34(4):7082-7090.HU Pei, JIANG Yonggang, ZHANG Zhongming, et al. Research process on high-temperature insulation composites with high mechanical property[J]. Materials Reports,2020,34(4):7082-7090(in Chinese). [5] 高庆福. 纳米多孔SiO2、Al2O3气凝胶及其高效隔热复合材料研究[D]. 长沙: 国防科学技术大学, 2009.GAO Qingfu. Nano-porous silica, alumina aerogels and thermal super-insulation composites[D]. Changsha: National University of Defense Technology, 2009(in Chinese). [6] 赵南, 冯坚, 姜勇刚, 等. 纤维增强Si-C-O气凝胶隔热复合材料的制备与表征[J]. 硅酸盐学报, 2012, 40(10):1473-1477.ZHAO Nan, FENG Jian, JIANG Yonggang, et al. Preparation and characterization of Si-C-O aerogel composites for thermal insulation[J]. Journal of the Chinese Ceramic Society,2012,40(10):1473-1477(in Chinese). [7] HOU X, ZHANG R, FANG D. An ultralight silica-modified ZrO2- SiO2 aerogel composite with ultra-low thermal conductivity and enhanced mechanical strength[J]. Scripta Materialia,2018,143:113-116. doi: 10.1016/j.scriptamat.2017.09.028 [8] 于登云. 新型航天器发展对力学学科的挑战[J]. 科学通报, 2015, 60(12):1085-1094.YU Dengyun. Mechanical challenges in advanced spacecraft development[J]. Chinese Science Bulletin,2015,60(12):1085-1094(in Chinese). [9] 孟松鹤, 杨强, 霍施宇, 等. 一体化热防护技术现状和发展趋势[J]. 宇航学报, 2013, 34(10):1295-1302. doi: 10.3873/j.issn.1000-1328.2013.10.001MENG Songhe, YANG Qiang, HUO Shiyu, et al. State-of-arts and trend of integrated thermal protection systems[J]. Journal of Astronautics,2013,34(10):1295-1302(in Chinese). doi: 10.3873/j.issn.1000-1328.2013.10.001 [10] 孙燕涛, 石多奇, 杨晓光, 等. 纤维增强SiO2气凝胶复合材料压缩性能和变形机制[J]. 复合材料学报, 2013, 30(4):225-230.SUN Yantao, SHI Duoqi, YANG Xiaoguang, et al. Compression and deformation mechanisms of SiO2 fiber-reinforced aerogel composite[J]. Acta Materiae Compositae Sinica,2013,30(4):225-230(in Chinese). [11] 米春虎, 姜勇刚, 石多奇, 等. 陶瓷纤维增强氧化硅气凝胶复合材料力学性能试验[J]. 复合材料学报, 2014, 31(3):635-643.MI Chunhu, JIANG Yonggang, SHI Duoqi, et al. Mechanical property test of ceramic fiber reinforced silica aerogel composites[J]. Acta Materiae Compositae Sinica,2014,31(3):635-643(in Chinese). [12] YANG J, LI S, LUO Y, et al. Compressive properties and fracture behavior of ceramic fiber-reinforced carbon aerogel under quasi-static and dynamic loading[J]. Carbon,2011,49(5):1542-1549. doi: 10.1016/j.carbon.2010.12.021 [13] YANG J, LI S, YAN L, et al. Dynamic compressive properties and failure mechanism of glass fiber reinforced silica hydrogel[J]. Materials Science & Engineering A,2010,527(3):824-827. [14] YANG X, SUN Y, SHI D, et al. Experimental investigation on mechanical properties of a fiber-reinforced silica aerogel composite[J]. Materials Science & Engineering A,2011,528(13):4830-4836. [15] YANG X, WEI J, SHI D, et al. Comparative investigation of creep behavior of ceramic fiber-reinforced alumina and silica aerogel[J]. Materials Science & Engineering A,2014,609:125-130. [16] PAN B, QIAN K, XIE H, et al. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review[J]. Measurement Science and Technology,2009,20(6):062001. doi: 10.1088/0957-0233/20/6/062001 [17] 刘小勇. 数字图像相关方法及其在材料力学性能测试中的应用[D]. 长春: 吉林大学, 2012.LIU Xiaoyong. Digital image correlation method and its application on mechanical properties measurement of materials[D]. Changchun: Jilin University, 2012(in Chinese). [18] HUANG J, SHI D Q, YANG X G, et al. Experimental investigation and numerical modeling for elastoplastic notch-root stress/strain analysis under monotonic loadings[J]. Science China Technologial Sciences,2014,57(7):1411-1424. doi: 10.1007/s11431-014-5555-8 [19] MAO W G, CHEN J, SI M S, et al. High temperature digital image correlation evaluation of in-situ failure mechanism: An experimental framework with application to C/SiC composites[J]. Materials Science & Engineering A,2016,665:26-34. [20] KASHFUDDOJA M, RAMJI M. Assessment of local strain field in adhesive layer of an unsymmetrically repaired CFRP panel using digital image correlation[J]. International Journal of Adhesion and Adhesives,2015,57:57-69. doi: 10.1016/j.ijadhadh.2014.10.005 [21] 冯坚, 高庆福, 冯军宗, 等. 纤维增强SiO2气凝胶隔热复合材料的制备及其性能[J]. 国防科技大学学报, 2010, 32(1):40-44. doi: 10.3969/j.issn.1001-2486.2010.01.008FENG Jian, GAO Qingfu, FENG Junzong, et al. Preparation and properties of fiber-reinforced SiO2 aerogel insulation composites[J]. Journal of National University of Defense Technology,2010,32(1):40-44(in Chinese). doi: 10.3969/j.issn.1001-2486.2010.01.008 [22] ASTM International. Standard test method for monotonic tensile strength testing of continuous fiber-reinforced advanced ceramics with solid rectangular cross section test specimens at elevated temperatures: ASTM C1359—18[S]. West Conshohocken: ASTM International, 2018. -

下载:

下载: