Preparation of flexible sensing material of flax fiber combined carbon nanotubes

-

摘要: 导电的碳纳米管(CNTs)与不导电的亚麻纤维(CEL)相结合,可以得到柔性导电复合材料。拉伸或弯曲该材料对其导电性能影响很大。根据电阻变化率(ΔR/R0)可以敏锐地检测到材料形状的变化,因此CNTs/CEL复合材料适用于柔性传感器。用NaOH/尿素水体系处理亚麻纤维,得到CEL浆,再与不同浓度的CNTs悬浊液混合、抽滤、干燥,制得了CNTs/CEL复合材料。用XRD、FTIR和SEM分析了CNTs/CEL复合材料的结构形态。将CNTs/CEL复合材料制成形变传感器,用拉伸导电性能测试了拉伸对传感器导电性能的影响;将传感器应用到手指关节上,用电阻变化监测了手指弯曲时传感器的形变敏感性。结果发现,随着拉伸应变的增加,CNTs/CEL传感器的电阻变化率

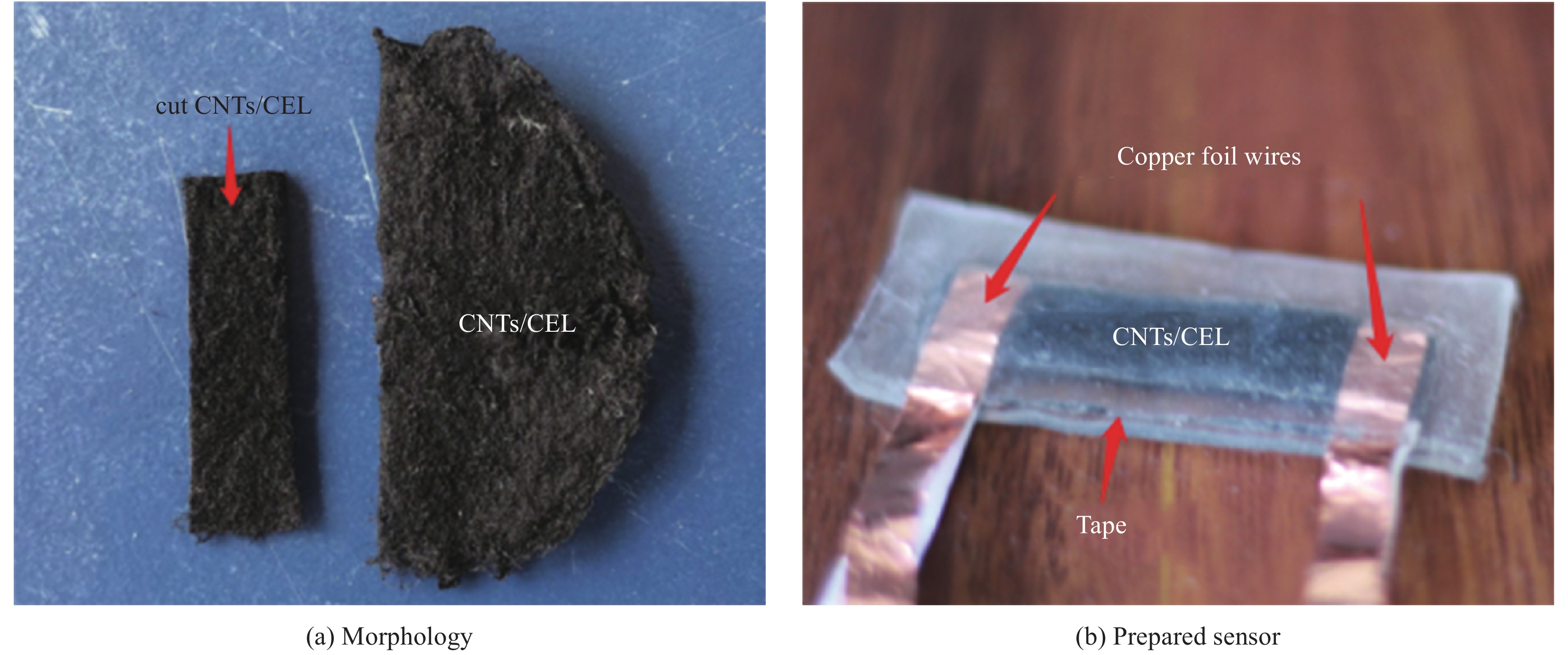

ΔR/R0逐渐增大,50%应变下,ΔR/R0达到980以上,能灵敏地感知到形状的变化;随着手指关节弯曲程度的增加,CNTs/CEL传感器电阻随之增大,手指最大程度弯曲时,CNTs/CEL传感器电阻可以达到12000 Ω以上,而且重复性良好。 Abstract: The combination of conductive carbon nanotubes (CNTs) and non-conductive flax fibers (CEL) can produce flexible conductive composites. Stretching or bending the material greatly affects its electrical conductivity. According to the resistance change rate(ΔR/R0), the change in the shape of the material can be sensitively detected, so the material is suitable for deformation sensors. The flax fiber pulp was obtained using sodium hydroxide/urea water system to treat flax fibers, which is then mixed with different concentrations CNTs suspensions, filtered, and dried to prepare conductive CNTs/CEL composite. The structure and morphology of the CNTs/CEL composites were evaluated withXRD, FTIR and SEM. The CNTs/CEL composite materials were made into deformation sensors, and the tensile conductivity was used to test the effect of stretching on the conductivity of the sensors; the optimized sensor was used to monitor the finger joints bent movement on the bases of the resistance change to test the deformation sensitivity of the sensor. The results show that with the increase of tensile strain, ΔR/R0 of CNTs/CEL sensor increases gradually. Under 50% strain, ΔR/R0 reaches over 980 and could be sensitively sensed shape changes. As the degree of bending of the finger joint increases, the resistance of the CNTs/CEL sensor increases as well. When the finger is bent to the greatest extent, the resistance of the CNTs/CEL sensor can reach more than 12000 Ω, and the repeatability is good.-

Key words:

- carbon nanotubes /

- flax fiber /

- composite materials /

- flexible sensor /

- intelligent monitoring

-

表 1 碳纳米管/亚麻纤维复合材料(CNTs/CEL)的主要组成

Table 1. Main components of carbon nanotube/flax fiber composite materials (CNTs/CEL) composites

Sample m1/g m2/mg c/(g·L−1) 1CNTs/CEL 2 31.25 1 2CNTs/CEL 2 62.5 2 4CNTs/CEL 2 125 4 8CNTs/CEL 2 250 8 16CNTs/CEL 2 500 16 32CNTs/CEL 2 1 000 32 Notes: m1—Mass of the flax fiber; m2—Mass of the CNTs; c—Concentration of the used CNTs. -

[1] FENG J. Cellulose fibers[M]//Handbook of Fibrous Materials. Wiley-VCH Verlag GmbH & Co. KGaA, 2020, 95-124. [2] 明瑞豪, 杨革生, 李玉增, 等. 亚麻纤维/立构聚乳酸复合材料的制备与性能表征[J]. 高分子材料科学与工程, 2015, 36(5):169-172.MING Ruihao, YANG Gesheng, LI Yuzeng, et al. Preparation and characterization of flax fiber reinforced polylactid stereocomplex composites[J]. Polymer Materials Science and Engineering,2015,36(5):169-172(in Chinese). [3] NAYAK S Y, HECKADKA S S, SETH A, et al. Effect of chemical treatment on the physical and mechanical properties of flax fibers: A comparative assessment[J]. Materials Today: Proceedings,2020. doi: 10.1016/j.matpr.2020.07.380 [4] TEIXEIRA M, SONNIER R, OTAZAGHINE B, et al. Radiation-grafting of flame retardants on flax fabrics—A comparison between different flame retardant structures[J]. Radiation Physics & Chemistry,2018,145:135-142. [5] 李代培, 马慧玲, 矫阳, 等. 纳米碳材料的辐射改性及其应用进展[J]. 材料导报, 2019, 33(3):6-16.DAI Pei, MA Huiling, JIAO Yang, et al. Radiation modification of nano-carbon materials and its application progress[J]. Materials Review,2019,33(3):6-16(in Chinese). [6] KOH A L, GIDCUMB E, ZHOU O, et al. Oxidation of carbon nanotubes in an ionizing environment[J]. Nano Letters,2016,16(2):856-863. [7] SHEN X J, HUANG P L, CHEN J H, et al. Comparison of acid-hydrolyzed and TEMPO-oxidized nanocellulose for reinforcing alginate fibers[J]. Bioresources,2017,12(4):8180-8198. [8] ZHANG H, SUN X, HUBBE M A, et al. Highly conductive carbon nanotubes and flexible cellulose nanofibers composite membranes with semi-interpenetrating networks structure[J]. Carbohydrate Polymers,2019,222:115013. [9] VINU MOHAN A M, VINOTH RAJENDRAN, RUPESH K MISHRA, et al. Recent advances and perspectives in sweat based wearable electrochemical sensors[J]. TrAC Trends in Analytical Chemistry,2020,131:116024. [10] SANJAYA D GUNAWARDHANA K R, NANDULA D WANASEKARA, ISHARA G DHARMASENA R D. Towards truly wearable systems: Optimizing and scaling up wearable triboelectric nanogenerators[J]. Science,2020,23(8):101360. [11] SOURI H, BHATTACHARYYA D. Highly sensitive, stretchable and wearable strain sensors using fragmented conductive cotton fabric[J]. Journal of Materials Chemistry C,2018,6:10524-10531. [12] NASIRI S, KHOSRAVANI M R. Progress and challenges in fabrication of wearable sensors for health monitoring[J]. Sensors and Actuators A Physical,2020,312:112105. [13] WANG Y, CANG S, YU H. A survey on wearable sensor modality centred human activity recognition in health care[J]. Expert Systems with Applications,2019,137:167-190. [14] ATALLA R H, VANDERHART D L. Native cellulose: A composite of two distinct crystalline forms[J]. Science,1984,223(4633):283-285. [15] SASRIMUANG S, CHUCHUEN O, ARTNASEAW A. Synthesis, characterization, and electrochemical properties of carbon nanotubes used as cathode materials for Al–air batteries from a renewable source of water hyacinth[J]. Green Processing and Synthesis,2020,9(1):340-348. [16] 姜大伟, 徐庆玲, 任彪彪, 等. Na+阻燃改性亚麻纤维及其对纤维性能的影响[J]. 精细化工, 2019, 36(9):1809-1815.JIANG Dawei, XU Qingling, REN Biaobiao, et al. Na+ flame retardant modified flax fiber and its effect on fiber properties[J]. Fine Chemical Engineering,2019,36(9):1809-1815(in Chinese). [17] 韩景泉, 王思伟, 岳一莹, 等. 静电纺定向纳米纤维素-碳纳米管/聚乙烯醇复合纤维导电膜及性能[J]. 复合材料学报, 2018, 35(9):2351-2361.HAN Jingquan, WANG Siwei, YUE Yiying, et al. Preparation and characterization of cellulose nanocrystal-carbon nanotube/polyvinyl alcohol composite conductive membranes with oriented fibers by electrospinning[J]. Acta Materiae Compositae Sinica,2018,35(9):2351-2361(in Chinese). [18] DANDY L O, OLIVEUX G, WOOD J, et al. Counting carbon fibres by electrical resistance measurement[J]. Composites: Part A,2015,68:276-281. [19] 张永翔, 孙晓刚, 庞志鹏, 等. 碳纳米管/纤维素纤维复合纸及其电磁屏蔽性能研究[J]. 化工新型材料, 2017, 45(9):71-73.ZHANG Yongxiang, SUN Xiaogang, PANG Zhipeng, et al. Preparation and electromagnetic shielding property of carbon nanotube-cellulose fiber composite paper[J]. New Chemical Materials,2017,45(9):71-73(in Chinese). -

下载:

下载: