Bonding performance of domestic T800 carbon fiber/high toughness epoxy composite based on surface modification

-

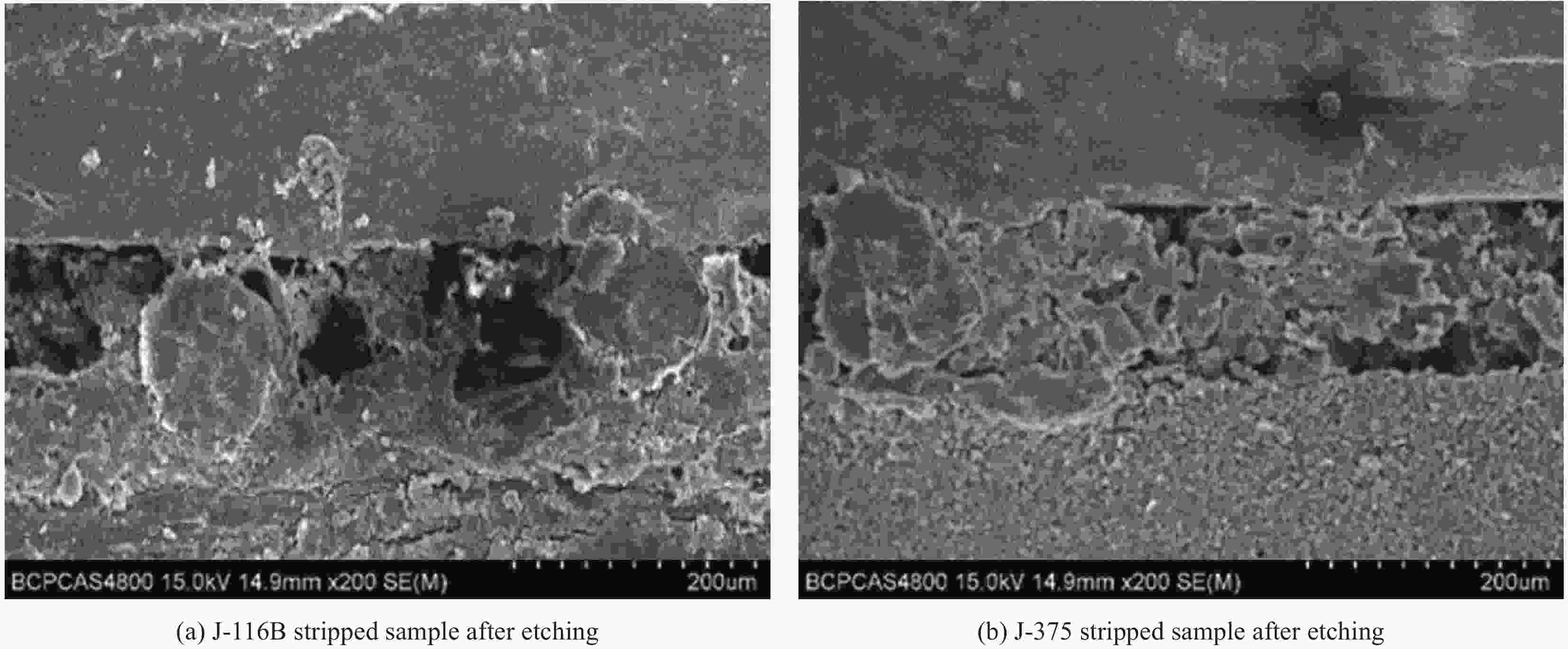

摘要: 本文通过打磨、喷砂、等离子处理方法对国产T800碳纤维/高韧性环氧树脂复合材料的待胶接面进行改性,分别制备了J-116B胶膜和J-375胶膜的浮辊剥离性能及拉伸剪切性能试验件。测试了不同处理条件下J-116B胶膜和J-375胶膜的剥离和剪切性能。采用SEM对老化前后、未经刻蚀和刻蚀后的剥离试样形貌进行观察。采用接触角测试仪测试了不同表面处理方法对国产T800碳纤维/高韧性环氧树脂复合材料胶接面润湿性的影响,并采用XPS光电子能谱分析仪对等离子处理前后的国产T800碳纤维/高韧性环氧树脂复合材料胶接面表面理化性能进行研究。结果表明:尽管J-375胶膜的室温剥离性能不如J-116B胶膜,但J-375胶膜具有更好的湿热老化性能。等离子处理后的国产T800碳纤维/高韧性环氧树脂复合材料的破坏模式由黏附破坏为主转变为内聚破坏为主,因此使两种胶膜的拉剪和剥离性能均有明显提高。这是由于等离子体处理能够重组复合材料表面的分子链,在胶接表面形成新的活性基团。Abstract: In this paper, the bonding surface of domestic T800 carbon fiber/high toughness epoxy composites was modified by grinding, sandblasting and plasma treatment. The test pieces of J-116B and J-375 adhesive films on floating roller peeling and tensile shear properties were prepared, respectively. The peel and shear properties of the J-116B and J-375 adhesive films were tested under different treatment conditions. The morphology of the samples before and after aging, without etching and after etching were observed by SEM. The contact angle tester was used to test the influence of different surface treatment methods on the wettability of the domestic T800 carbon fiber/high toughness epoxy composites bonding surface, and XPS was used to study the surface physicophysication performance of domestic T800 carbon fiber/high toughness epoxy composites before and after plasma treatment. The results show that J-375 film has better hygrothermal aging property although its room temperature peeling property is not as good as that of J-116B film. The failure mode of plasma treated domestic T800 carbon fiber/high toughness epoxy composites changed from adhesion failure to cohesive failure, so that the tensile shear and peel properties of the two films are significantly improved. This is because plasma treatment can recombine the molecular chain on the surface of the composite and form new active groups on the bonding surface.

-

Key words:

- secondary bonding /

- interface /

- modification /

- grinding /

- sand blasting /

- plasma treatment

-

表 1 浮辊剥离/拉伸剪切实验矩阵

Table 1. Experimental matrix of floating roller peeling/stretching shear

Sample No. Film type Grinding Sand blasting Plasma treatment Aging treatment SY-116B-1 J-116B Yes No No No SY-116B-2 J-116B Yes No No Yes SY-116B-3 J-116B No Yes No No SY-116B-4 J-116B No Yes No Yes SY-116B-5 J-116B No Yes Yes No SY-116B-6 J-116B No Yes Yes Yes SY-375-1 J-375 Yes No No No SY-375-2 J-375 Yes No No Yes SY-375-3 J-375 No Yes No No SY-375-4 J-375 No Yes No Yes SY-375-5 J-375 No Yes Yes No SY-375-6 J-375 No Yes Yes Yes 表 2 喷砂处理工艺参数

Table 2. Process parameters of sand blasting

No. Item Nominal parameter value 1 Jet pressure 0.02 MPa 2 Brown steel grit size 80# 3 Distance 20–30 mm 4 Speed 5 m/min 表 3 等离子体处理工艺参数

Table 3. Process parameters of plasma treatment

No. Item Nominal parameter value 1 Output power 800 W 2 Ionizing medium Air 3 Nozzle-sample distance 100 mm 4 Speed 5 m/min 5 Pressure 0.1 MPa 表 4 湿热老化后国产T800碳纤维/高韧性环氧树脂复合材料的性能保持率

Table 4. Performance retention rate of domestic T800 carbon fiber/high toughness epoxy composites after damp heat aging

Sample

No.Performance retention of

float roll peeling/%Performance retention

of stretch shear/%SY-116B-1

SY-116B-288.4 25.3 SY-116B-3

SY-116B-4100.5 16.9 SY-116B-5

SY-116B-697.2 15.5 SY-375-1

SY-375-2143.4 32.3 SY-375-3

SY-375-4136.3 33.4 SY-375-5

SY-375-6141.8 52.1 表 5 经不同表面处理的国产T800碳纤维/高韧性环氧树脂复合材料板接触角对比

Table 5. Comparison of contact angles of domestic T800 carbon fiber/high toughness epoxy composite boards with different surface treatments

Surface treatment Contact angle/(°) Grinding 89.5 Sand blasting 74.5 Sand blasting+plasma treatment 0 -

[1] 欧秋仁, 嵇培军, 肖军, 等. 国产T800碳纤维用氰酸酯树脂开发及其复合材料性能[J]. 材料工程, 2019, 47(8):125-131. doi: 10.11868/j.issn.1001-4381.2018.000289OU Qiuren, JI Peijun, XIAO Jun, et al. Cyanate ester for domestic T800 carbon fiber and its composites properties[J]. Journal of Materials Engineering,2019,47(8):125-131(in Chinese). doi: 10.11868/j.issn.1001-4381.2018.000289 [2] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [3] 李伟, 张晨乾, 叶宏军, 等. 固化工艺参数对国产T800增强高韧性复合材料性能的影响[J]. 复合材料科学与工程, 2020(6):98-104.LI Wei, ZHANG Chenqian, YE Hongjun, et al. Effect of curing process parameters on the properties of high toughness composites reinforced by domestic T800 carbon fiber[J]. Composites Science and Engineering,2020(6):98-104(in Chinese). [4] BALDAN A. Adhesion phenomena in bonded joints[J]. International Journal of Adhesion and Adhesives,2012,38(10):95-116. [5] VALENZA A, FIORE V, FRATINI L. Mechanical behaviour and failure modes of metal to composite adhesive joints for nautical applications[J]. The International Journal of Advanced Manufacturing Technology,2011,53(5):593-600. [6] WANG C, NIU Y. Influences of surface treatment on humidity aging properties of adhesive/carbon-carbon composite joints[C]//2007 Beijing International Bonding Technology Seminar and 2nd Asian Bonding Technology Seminar. Beijing: Beijing Adhesion Society, 2007. [7] 邹贤武, 乔海涛, 齐楠. SY-D15表面处理剂的性能研究[J]. 粘接, 2007, 28(2):10-12. doi: 10.3969/j.issn.1001-5922.2007.02.004ZOU Xianwu, QIAO Haitao, QI Nan. Study on properties of SY-D15 surface treating agent[J]. Adhension in China,2007,28(2):10-12(in Chinese). doi: 10.3969/j.issn.1001-5922.2007.02.004 [8] 李长青, 许艺, 任攀, 等. 碳纤维/环氧树脂复合材料表面激光选择性消融预处理[J]. 中国表面工程, 2016, 29(1):118-124.LI Changqing, XU Yi, REN Pan, et al. Pretreatment of carbon fiber reinforced epoxy resin composites by laser[J]. China Surface Enginering,2016,29(1):118-124(in Chinese). [9] 董立强, 张英辉, 胡高全, 等. 等离子体表面处理技术在橡胶粘合中的应用[J]. 轮胎工业, 2019, 39(4):235-238. doi: 10.12135/j.issn.1006-8171.2019.04.0235DONG Liqiang, ZHANG Yinghui, HU Gaoquan, et al. Application of plasma surface treatment technology in rubber adhesion[J]. Tire Industry,2019,39(4):235-238(in Chinese). doi: 10.12135/j.issn.1006-8171.2019.04.0235 [10] CHEN P, WANG J, WANG B, et al. Improvement of interfacial adhesion for plasma-treated aramid fiber-reinforced poly(phthalazinone ether sulfone ketone) composite and fiber surface aging effects[J]. Surface & Interface Analysis,2009,41(1):38-43. [11] 王静, 孟伶智, 任航, 等. 等离子体处理的时效性对芳Ⅲ/双马复合材料耐湿热性能的影响[J]. 装备环境工程, 2018, 15(2):41-44.WANG Jing, MENG Lingzhi, REN Hang, et al. Effect of plasma aging behaviour on damp heat resistance of aramid fiber Ⅲ/BMI composite[J]. Equipment Environmental Engineering,2018,15(2):41-44(in Chinese). [12] WILLIAMS D F, KELLAR E J C, JESSON D A, et al. Surface analysis of 316 stainless steel treated with cold atmospheric plasma[J]. Applied Surface Science,2017,403:240-247. [13] 李长青, 董怀斌, 邹育根, 等. 低温空气等离子体处理对铝合金表面粘接性能的影响[J]. 中国表面工程, 2017, 30(6):34-42. doi: 10.11933/j.issn.1007-9289.20170410003LI Changqing, DONG Huaibin, ZOU Yugen, et al. Effects of low temperature air plasma treatment on adhesive property of aluminum alloy[J]. China Surface Engineering,2017,30(6):34-42(in Chinese). doi: 10.11933/j.issn.1007-9289.20170410003 [14] 王云英, 孟江燕, 陈学斌, 等. 复合材料用碳纤维的表面处理[J]. 表面技术, 2007, 36(3):53-57, 60.WANG Yunying, MENG Jiangyan, CHEN Xuebin, et al. Surface treatment of carbonfiber for composites[J]. Surface Technology,2007,36(3):53-57, 60(in Chinese). [15] KOTÁL V, STOPKA P, SAJDL P, et al. Thin surface layer of plasma treated polyethylene[J]. Strength of Materials,2008,40(1):86-89. [16] YOOZBASHIZADEH M, CHARTOSIAS M, VICTORINO C, et al. Investigation on the effect of process parameters in atmospheric pressure plasma treatment on carbon fiber reinforced polymer surfaces for bonding[J]. Materials & Manufacturing Processes,2019,34(6):660-669. [17] 国家技术监督局. 高强度胶黏剂剥离强度的浮辊法测定: GB/T 7122—1996[S]. 北京: 中国标准出版社, 1996.State Bureau of Technical Supervision. Adhesives: Determination of peel resistance of high strength adhesive bonds floating roller method: GB/T 7122—1996[S]. Beijing: China Standards Press, 1996(in Chinese). [18] 中国国家标准化管理委员会. 胶粘剂拉伸剪切强度的测定(刚性材料对刚性材料): GB/T 7124—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Adhesives: Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies: GB/T 7124—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [19] 秦国锋, 那景新. 复合材料胶接接头温度-湿度-载荷老化机理研究概述[J]. 中国胶粘剂, 2020, 29(3):57-65.QIN Guofeng, NA Jingxin. Research on temperature-humidity-load aging mechanism of composite bonded joint[J]. China Adhesives,2020,29(3):57-65(in Chinese). [20] 熊玉成, 巴德玛, 李长青, 等. 表面处理对复合材料母板与维修补片粘接强度的影响[J]. 玻璃钢/复合材料, 2019(9):100-105.XIONG Yucheng, BA Dema, LI Changqing, et al. Effect of surface treatment on bond strength of the base laminate and reqair patches[J]. Fiber Reinforced Plastic/Composites,2019(9):100-105(in Chinese). [21] 朱家嵘, 顾振亚. 利用低温空气等离子体改善聚酯和聚乙烯薄膜表面亲水性的研究[J]. 天津工业大学学报, 2004, 23(4):40-43, 47. doi: 10.3969/j.issn.1671-024X.2004.04.011ZHU Jiarong, GU Zhenya. Research on surface hydrophilic modification of PET and PE films by low temperature air plasma[J]. Journal of Tianjin Polytechnic University,2004,23(4):40-43, 47(in Chinese). doi: 10.3969/j.issn.1671-024X.2004.04.011 -

下载:

下载: