Temperature stability of strain performance of piezoelectric fiber composites with different polymer matrices

-

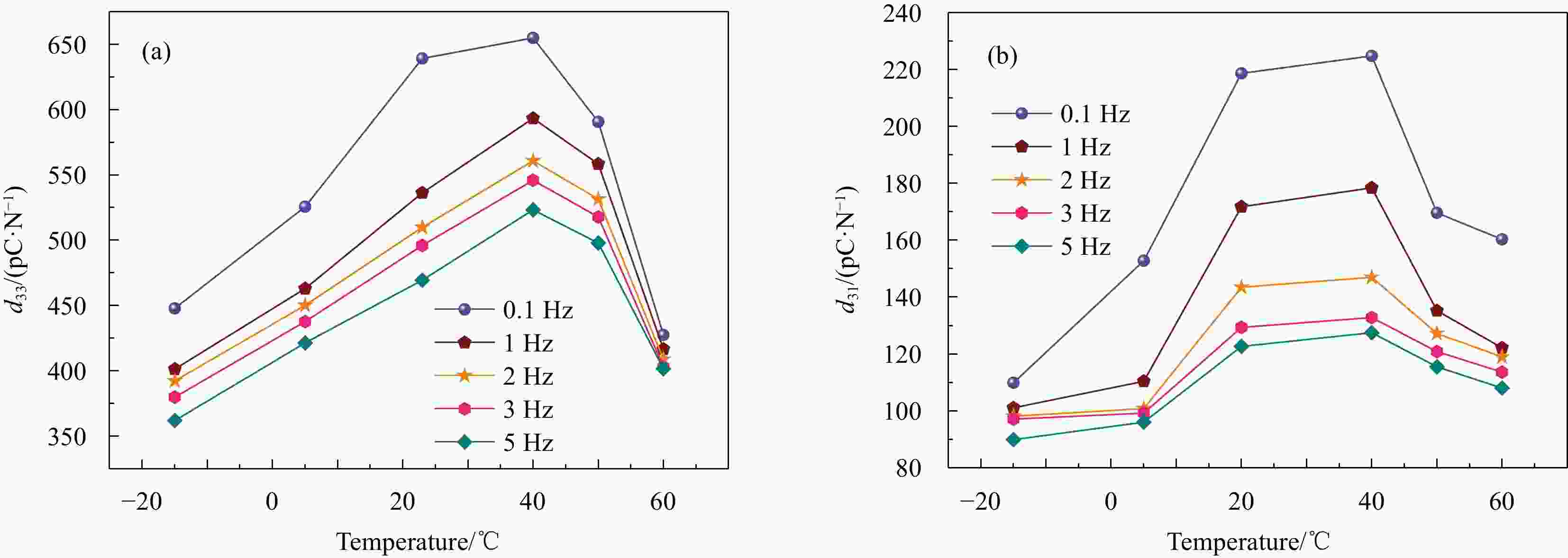

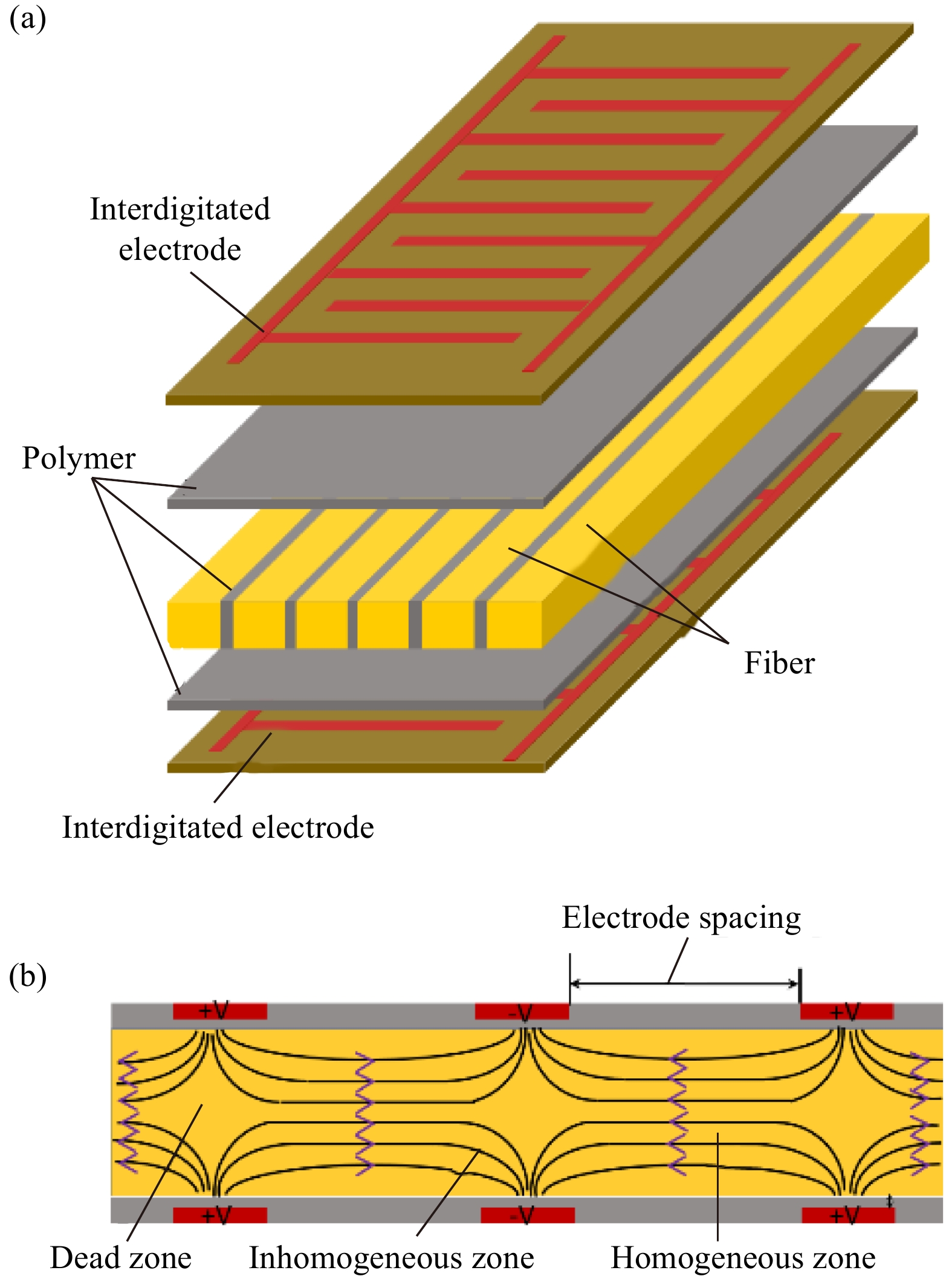

摘要: 压电纤维复合材料驱动器应用于航天器件中时要经历严酷的环境载荷,其中温度对压电纤维复合材料驱动性能的影响至关重要。本研究制备了三种不同聚合物基压电纤维复合材料,并在−15~60℃的环境温度下测试了压电纤维复合材料的自由应变性能。结果表明,不同聚合物基压电纤维复合材料的自由应变性能均强烈依赖于环境温度,其自由应变性能均呈现随温度升高先增大后减小的趋势。在−500~1 000 V、0.1 Hz的正弦激励电压下,低玻璃化转变温度(Tg)环氧树脂基和高Tg环氧树脂基压电纤维复合材料均在40℃时具有最大纵向自由应变值1 416×10−6和1 060×10−6,聚氨酯基压电纤维复合材料则在30℃时具有最大纵向自由应变值2 361×10−6,相较前两种分别提高了66.7%和122.7%。低Tg环氧树脂基和聚氨酯基压电纤维复合材料在−15℃时的纵向自由应变值较40℃时均下降了约27.5%,而高Tg环氧树脂基压电纤维复合材料在−15~60℃温度范围内具有更高的温度稳定性,其纵向自由应变值仅下降了10.5%。Abstract: Piezoelectric fiber composite faces a challenge of an extremely wide temperature range when it is used in aerospace devices. So it is necessary to investigate the influence of temperature on the strain performance of piezoelectric fiber composite. In this paper, the free strain properties of piezoelectric fiber composites prepared using three kinds of polymer matrices were evaluated from −15℃ to 60℃. The results show that the free strain properties of all piezoelectric fiber composites are strongly dependent on the ambient temperature. The free strain values of piezoelectric fiber composites increase firstly and then decrease with the rising temperature. When the sinusoidal voltage of 0.1 Hz and −500 V-1 000 V is applied, the maximum longitudinal free strain values of the piezoelectric fiber composites with low glass transition temperature (Tg) and high Tg epoxy are 1 416×10−6 and 1 060×10−6 at 40℃, respectively. While the free strain value of the piezoelectric fiber composite with polyurethane reaches 2 361×10−6 at 30℃, which is 66.7% and 122.7% higher than the formers, respectively. The longitudinal free strain values of the piezoelectric fiber composites both with low Tg epoxy and polyurethane reduce about 27.5% as the temperature increases from −15℃ to 40℃. Although the longitudinal free strain of the piezoelectric fiber composite with high Tg epoxy is small, its longitudinal free strain value at −15℃ is only 10.5% lower than that at 40℃, so this kind of composite possesses a high temperature stability in the range of −15-60℃.

-

表 1 实验所用聚合物的性能参数

Table 1. Physical properties of polymer

Polymer

matrixDielectric

constantElastic

modulus/MPaJH (Low Tg epoxy) 4.3 54 Adbest 3601 (High Tg epoxy) 7.2 90 GF-5 polyurethane 5.6 10 Note: Tg—Glass transition temperature. 表 2 实验所用锆钛酸铅(PZT)陶瓷的性能参数

Table 2. Physical properties of lead zirconate titanate (PZT) ceramic

Dieletric constant Eletromchanical coupling coefficient Dielectric loss Bulk density/(kg·m−3) Curie temperature/℃ 2 200 0.50 0.02 7 600 270 -

[1] BENT A A, HAGOOD N W. Piezoelectric fiber composites with interdigitated electrodes[J]. Journal of Intelligent Material Systems and Structures,1997,8:903-919. doi: 10.1177/1045389X9700801101 [2] 李春晖. MFC驱动的可变形机翼缩比模型主动变形仿真与验证[D]. 大连: 大连理工大学, 2017.LI C H. Active deformation simulation and verification for the morphing wing scale model under drive of MFC[D]. Dalian: Dalian University of Technology, 2017(in Chinese). [3] 张红艳, 白长青, 沈亚鹏. 粗纤维压电复合材料(MFC)对旋翼桨叶模型扭转控制的实验及数值研究[J]. 应用力学学报, 2009, 26(3):456-460.ZHANG H Y, BAI C Q, SHEN Y P. Experimental and numerical analysis for twist control of rotor blade model with macro fiber composite (MFC)[J]. Chinese Journal of Applied Mechanics,2009,26(3):456-460(in Chinese). [4] PEARSON M R, EATON M J, FEATHERSON C A, et al. Impact damage detection and assessment in composite panels using macro fibre composites transducers[J]. Journal of Physics: Conference Series,2011,305:0120491. [5] PARK S, INMAN D J, YUN C B. An outlier analysis of MFC-based impedance sensing data for wireless structural health monitoring of railroad tracks[J]. Engineering Structures,2008,30(10):2792-2799. doi: 10.1016/j.engstruct.2008.02.019 [6] SHAN X B, SONG R J, LIU B, et al. Novel energy harvesting: A macro fiber composite piezoelectric energy harvester in the water vortex[J]. Ceramics International,2015,41:S763-S767. doi: 10.1016/j.ceramint.2015.03.219 [7] VAN DEN ENDE D A, VAN DE WIEL H J, GROEN W A, et al. Direct strain energy harvesting in automobile tires using piezoelectric PZT-polymer composites[J]. Smart Materials and Structures,2012,21(1):0150111. [8] 徐志伟, 黄雪峰, 沈星. 基于PT和MFC的飞机垂直尾翼振动主动控制[J]. 南京航空航天大学学报, 2008, 40(3):313-318. doi: 10.3969/j.issn.1005-2615.2008.03.008XU Z W, HUANG X F, SHEN X. Active vibration control of perpendicular empennage based on piezoelectric tran-sformer and micro fiber composites[J]. Journal of Nanjing University of Aeronautics & Astronautics,2008,40(3):313-318(in Chinese). doi: 10.3969/j.issn.1005-2615.2008.03.008 [9] 盛贤君, 王爱武, 杨睿. 基于LaRC-MFC致动器的振动主动控制[J]. 压电与声光, 2010, 32(4):568-570. doi: 10.3969/j.issn.1004-2474.2010.04.014SHENG X J, WANG A W, YANG R. Active vibration control based on LaRC-MFC actuators[J]. Piezoelectrics & Acoustooptics,2010,32(4):568-570(in Chinese). doi: 10.3969/j.issn.1004-2474.2010.04.014 [10] BAPTISTA F G, FILHO J V, INMAN D J. Real-time multi-sensors measurement system with temperature effects compensation for impedance-based structural health monitoring[J]. Structural Health Monitoring,2012,11(2):173-186. doi: 10.1177/1475921711414234 [11] DODSON J C, INMAN D J. Thermal sensitivity of Lamb waves for structural health monitoring applications[J]. Ultrasonics,2013,53(3):677-685. doi: 10.1016/j.ultras.2012.10.007 [12] HOBECK J D, OWEN R B, INMAN D J. Residual thermal effects in macro fiber composite actuators exposed to persistent temperature cycling[J]. Applied Physics Letters,2016,108(11):1119011. [13] DANO M L, GAKWAYA M, BENJAMIN J. Compensation of thermally induced distortion in composite structures using macro-fiber composites[J]. Journal of Intelligent Material Systems and Structures,2008,19(2):225-233. doi: 10.1177/1045389X06074679 [14] DANO M L, BENJAMIN J. Active control of thermally induced distortion in composite structures using macro fiber composite actuators[J]. Smart Materials and Structures,2007,16(6):2315-2322. doi: 10.1088/0964-1726/16/6/035 [15] PARK J S, KIM J H. Suppression of aero-thermal large deflections and snap-through behaviors of composite panels using macro fiber composite actuators[J]. Smart Materials and Structures,2004,13(6):1448-1459. doi: 10.1088/0964-1726/13/6/016 [16] PARK J S, KIM J H. Coefficients of thermal expansion for single crystal piezoelectric fiber composites[J]. Composites Part B: Engineering,2007,38(7–8):795-799. [17] 张炯炯, 袁晰, 闫明洋, 等. 环境温度对压电纤维复合材料性能的影响[J]. 复合材料学报, 2021, 38(2):583-590.ZHANG J J, YUAN X, YAN M Y, et al. Effect of ambient temperature on the properties of piezoelectric fiber compo-sites[J]. Acta Materiae Compositae Sinica,2021,38(2):583-590(in Chinese). [18] WANG X Y, YUAN X, WU M L, et al. Effect of epoxy resin on the actuating performance of piezoelectric fiber compo-sites[J]. Sensors,2019,19(8):1809. [19] LIN X J, CHEN HY, MA Y P, et al. Investigation of temperature sensitivity of actuation performance for piezoelectric fiber composites[J]. Ceramics International, 2017, 43(13): 10590–10594. [20] WILLIAMS R B, INMAN D J, WILKIE W K. Temperature-dependent thermoelastic properties for macro fiber compo-site actuators[J]. Journal of Thermal Stresses,2004,27(10):903-915. doi: 10.1080/01495730490498386 [21] PRASATH S S, AROCKIARAJAN A. Experimental and theoretical investigation on the thermo-electro-elastic properties of macro-fiber composites (MFC)[J]. Composite Structures,2015,122:8-22. doi: 10.1016/j.compstruct.2014.11.046 [22] HOOKER M W. Properties of PZT-based piezoelectric ceramics between −150 and 250℃. NASA/CR-1998-208708[R]. Hampton: NASA, 1998. -

下载:

下载: