| [1] |

LIU Z X , MO F N, LI H F, et al. Advances in flexible and wearable energy-storage textiles[J]. Small Methods,2018,2(11):1800124.

|

| [2] |

WANG B H, FACCHETTI A. Mechanically flexible conductors for stretchable and wearable E-skin and E-textile device[J]. Advance Material,2019,31(28):1901408.

|

| [3] |

ZHANG T Y, LI X, ASHER E, et al. Paper with power: Engraving 2D materials on 3D structures for printed, high-performance, binder-free, and all-solid-state supercapacitors[J]. Advanced Functional Materials,2018,28(37):1803600.

|

| [4] |

ZHU Y H, YUAN S, BAO D, et al. Decorating waste cloth via industrial wastewater for tube-type flexible and wearable sodium-ion batteries[J]. Advanced Materials,2017,29(16):1603719.

|

| [5] |

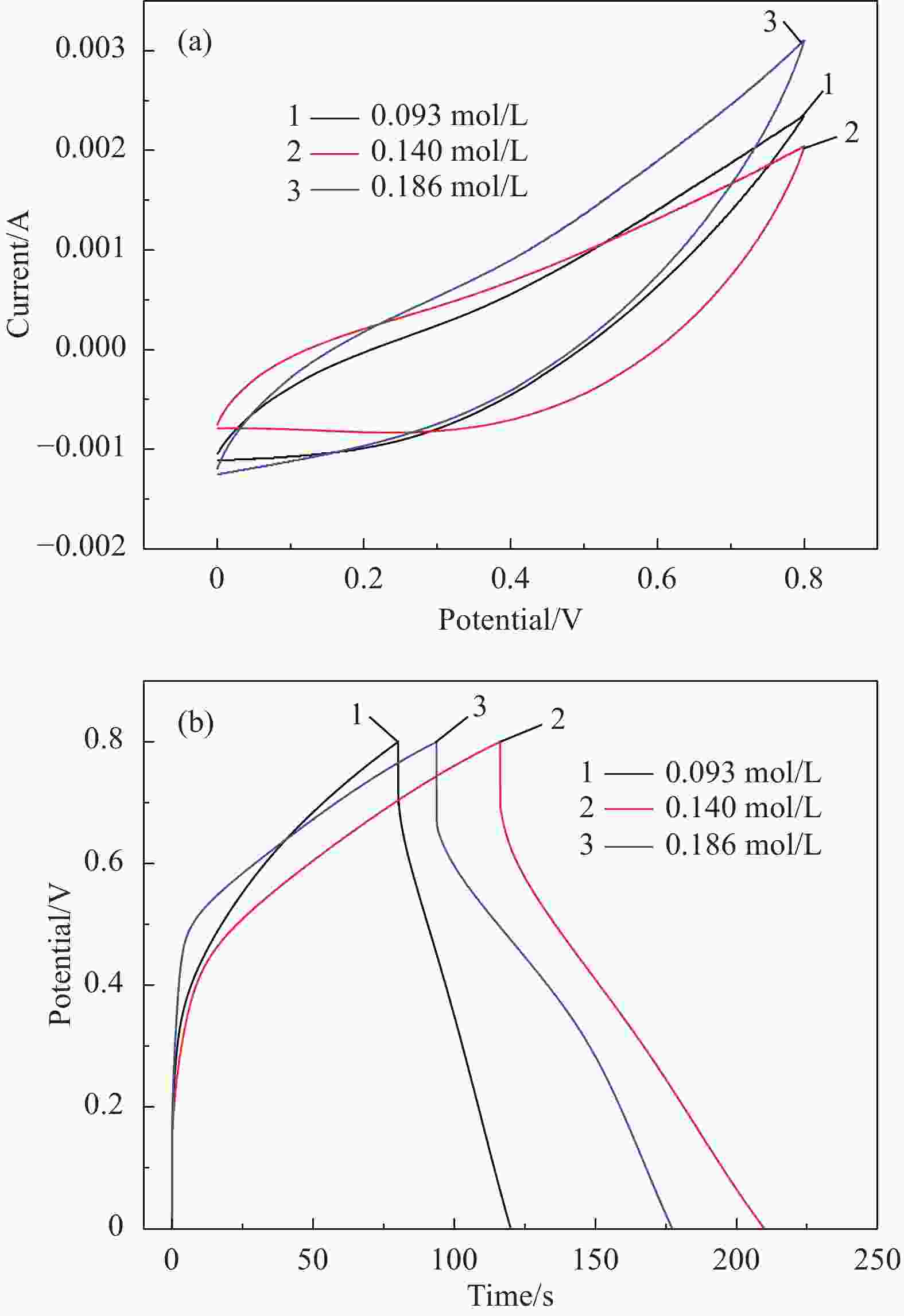

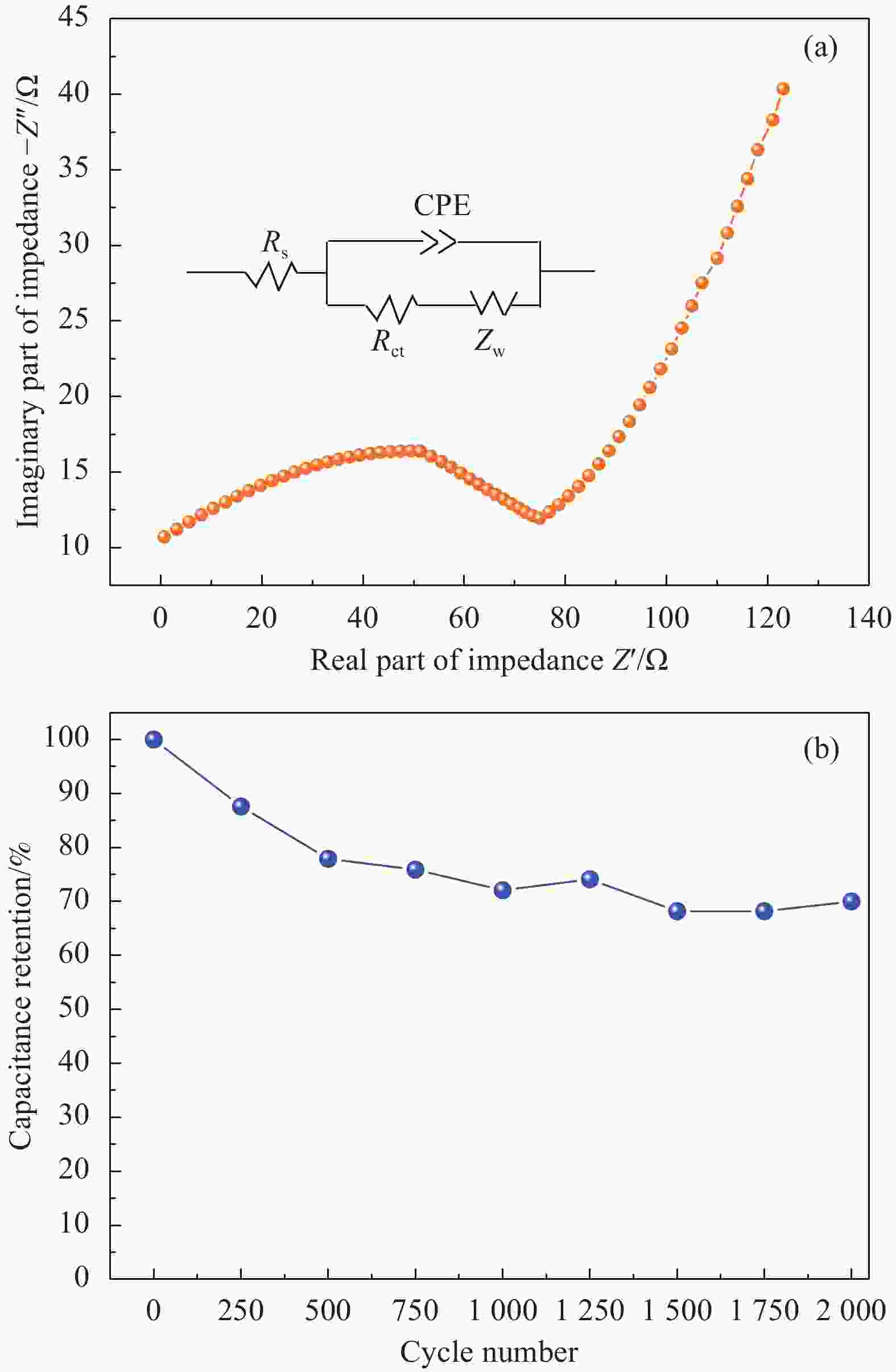

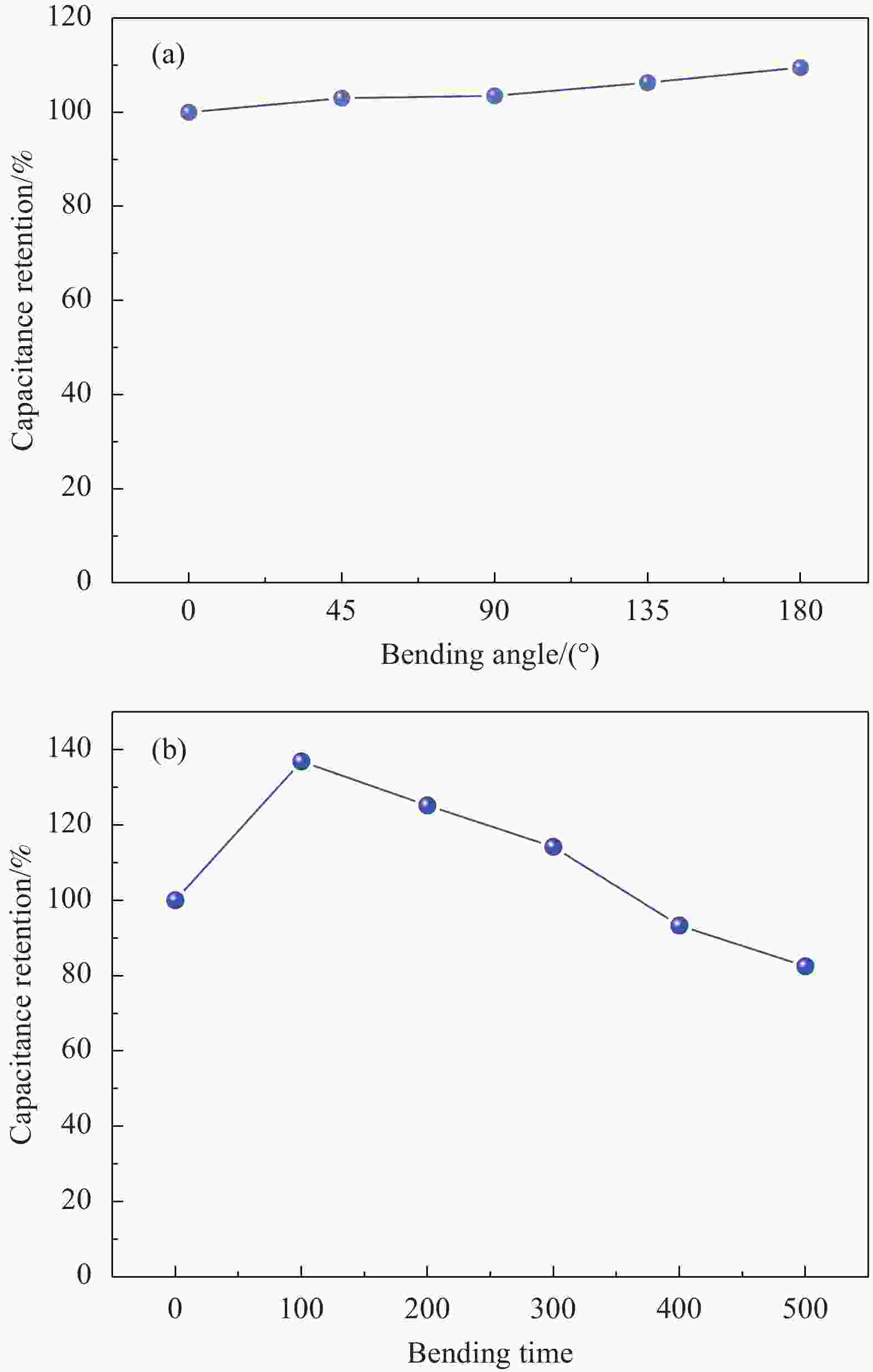

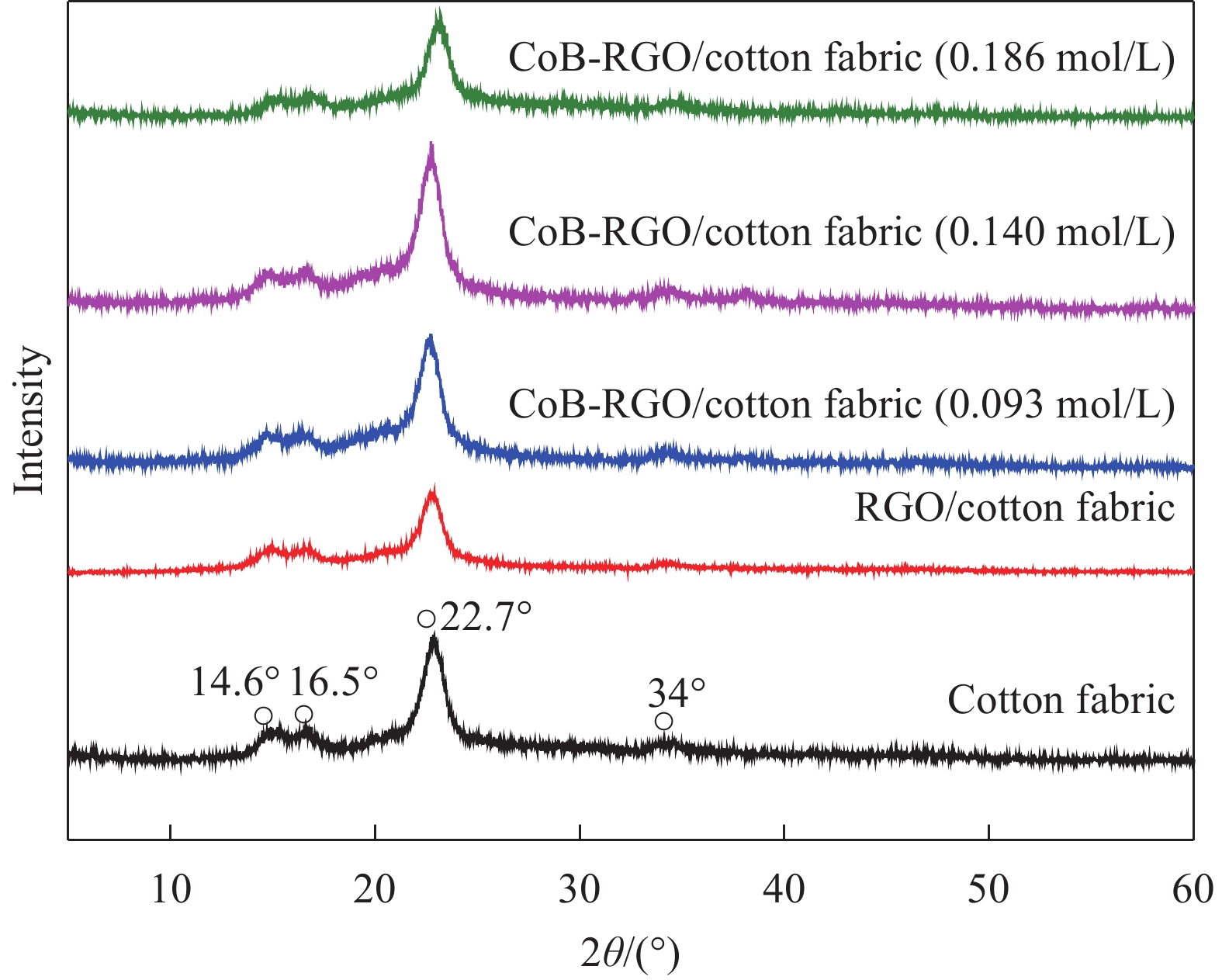

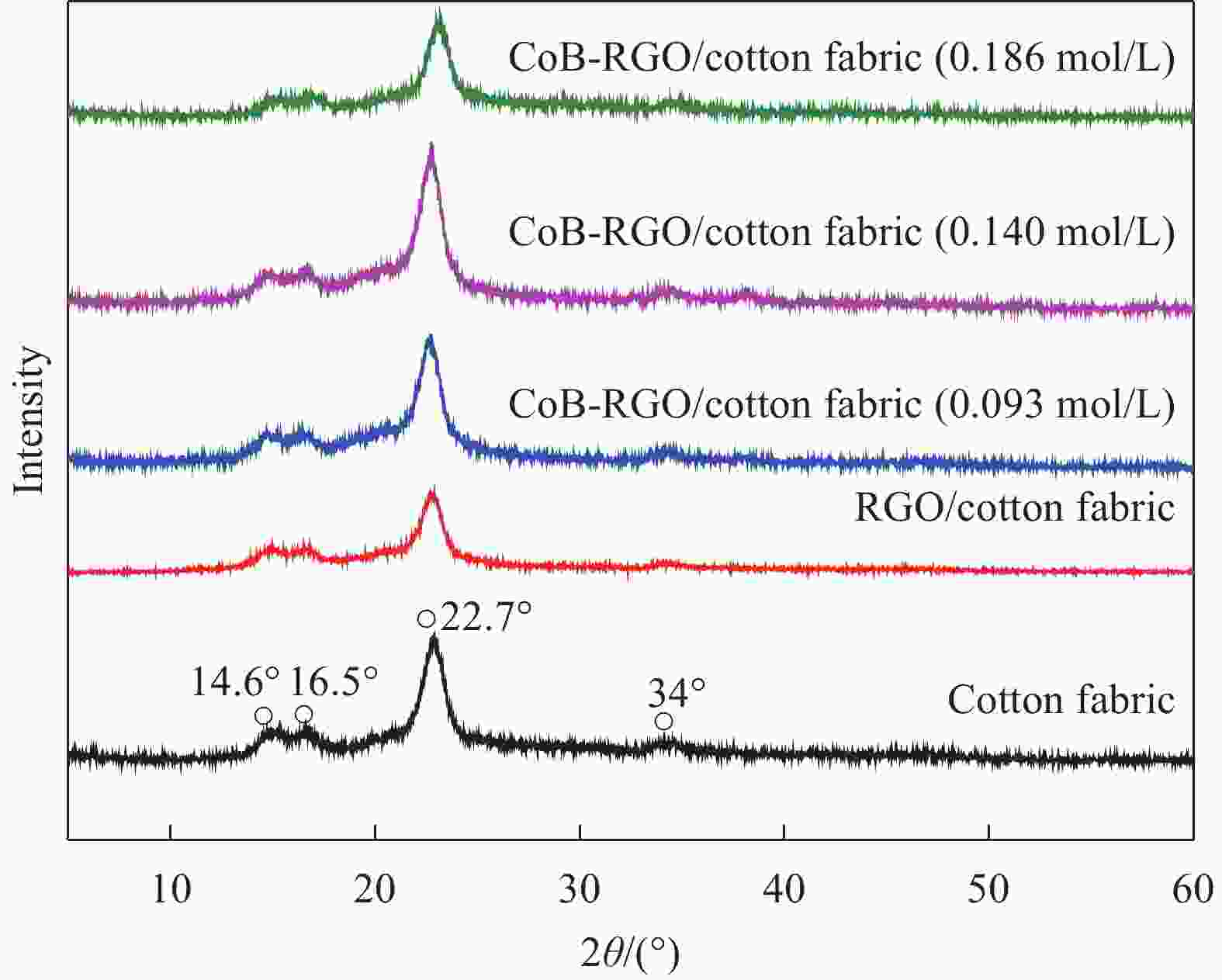

LI Y Z, ZHANG Y F, ZHANG H R, et al. A facile approach to prepare a flexible sandwichstructured supercapacitor with rGO-coated cotton fabric as electrodes[J]. RSC Advances,2019,9(8):4180-4189. doi: 10.1039/C9RA00171A

|

| [6] |

GOPI C V V M, VINODH R, SAMBASIVAM S, et al. Recent progress of advanced energy storage materials for flexible and wearable supercapacitor: From design and development to applications[J]. Journal of Energy Storage,2020,27:101035. doi: 10.1016/j.est.2019.101035

|

| [7] |

TEBYETEKERWA M, MARRIAM I, XU Z, et al. Critical insight: Challenges and requirements of fibre electrodes for wearable electrochemical energy storage[J]. Energy & Environmental Science,2019,12(7):2148-2160.

|

| [8] |

SHAO F, HU N T, SU Y J, et al. Non-woven fabric electrodes based on graphene-based fibers for areal-energy-dense flexible solid-state supercapacitors[J]. Chemical Engineering Journal,2020,392:123692. doi: 10.1016/j.cej.2019.123692

|

| [9] |

TENG W L, ZHOU Q Q, WANG X K, et al. Hierarchically interconnected conducting polymer hybrid fiber with high specific capacitance for flexible fiber-shaped supercapacitor[J]. Chemical Engineering Journal,2020,390:122569.

|

| [10] |

DUBAL D P, CHODANKAR N R, KIM D, et al. Towards flexible solid-state supercapacitors for smart and wearable electronics[J]. Chemical Society Review,2018,47(6):2065-2129. doi: 10.1039/C7CS00505A

|

| [11] |

MAILE N, SHINDE S K, PATIL S S, et al. Capacitive property studies of electrochemically synthesized Co3O4 and Mn3O4 on inexpensive stainless steel current collector for supercapacitor application[J]. Ceramics International,2020,46(10):14640-14649. doi: 10.1016/j.ceramint.2020.02.265

|

| [12] |

LIN R, ZHU Z H, YU X, et al. Facile synthesis of TiO2/Mn3O4 hierarchical structures for fiber-shaped flexible asymmetric supercapacitors with ultrahigh stability and tailorable performance[J]. Journal of Materials Chemistry A,2020,5(2):814-821.

|

| [13] |

KIRANSAN K D, TOPCU E. SnS2-gC3N4/rGO composite paper as an electrode for high-performance flexible symmetric supercapacitors[J]. Synthetic Metals,2020,264:116390. doi: 10.1016/j.synthmet.2020.116390

|

| [14] |

WANG T, CHEN H C, YU F, et al. Boosting the cycling stability of transition metal compounds-based supercapacitors[J]. Energy Storage Materials,2019,16:545-573. doi: 10.1016/j.ensm.2018.09.007

|

| [15] |

CHEN H C, QIN Y L, CAO H J, et al. Synthesis of amorphous nickel-cobalt-manganese hydroxides for supercapacitor-battery hybrid energy storage system[J]. Energy Storage Materials,2019,17:194-203. doi: 10.1016/j.ensm.2018.07.018

|

| [16] |

CHEN H Y, OUYANG S X, ZHAO M, et al. The synergistic activity of Co and Fe in amorphous Cox-Fe-B catalyst for efficient oxygen evolution reaction[J]. ACS Applied Materials & Interfaces,2017,9(46):40333-40343.

|

| [17] |

LI H B, YU M H, WANG F X, et al. Amorphous nickel hydroxide nanospheres with ultrahigh capacitance and energy density as electrochemical pseudocapacitor materials[J]. Nature Communications,2013,4:1894.

|

| [18] |

WANG S, HE P, XIE Z W, et al. Tunable nanocotton-like amorphous ternary Ni-Co-B: A highly efficient catalyst for enhanced oxygen evolution reaction[J]. Electrochimica Acta,2019,296:644-652. doi: 10.1016/j.electacta.2018.11.099

|

| [19] |

LI Q, XU Y X, ZHENG S S, et al. Recent progress in some amorphous materials for supercapacitors[J]. Small,2018,14(28):1800426.

|

| [20] |

WANG H, MA Y, WANG R, et al. Liquid-liquid interface-mediated room-temperature synthesis of amorphous NiCo pompoms fromultrathin nanosheets with high catalytic activity for hydrazine oxidation[J]. Chemical Communications,2015,51(17):3570-3573. doi: 10.1039/C4CC09928A

|

| [21] |

QIN W, LIU Y, LIU X Y, et al. Facile scalable production of amorphous nickel borate for high performance hybrid supercapacitors[J]. Journal of Materials Chemistry A,2018,6(40):19689-19695. doi: 10.1039/C8TA07385F

|

| [22] |

MENG Q Z, XU W, ZHU S L, et al. Low-cost fabrication of amorphous cobalt-iron-boron nanosheets for high performance asymmetric supercapacitors[J]. Electrochimica Acta,2019,296:198-205. doi: 10.1016/j.electacta.2018.11.067

|

| [23] |

CHEN R N, LIU L, ZHOU J S, et al. High-performance nickel-cobalt-boron material for an asymmetric supercapacitor with an ultrahigh energy density[J]. Journal of Power Sources,2017,341:75-82. doi: 10.1016/j.jpowsour.2016.11.108

|

| [24] |

WANG W, LI T, SUN Y Y, et al. Facile and mild method to fabricate a flexible cellulose based electrode with reduced graphene and amorphous cobalt-iron-boron alloy for wearable electronics[J]. Cellulose,2020,27:7079-7092. doi: 10.1007/s10570-020-03269-5

|

下载:

下载: