Effects of hygrothermal environment on quasi-static failure of CFRP composite-aluminum alloy bolted joints

-

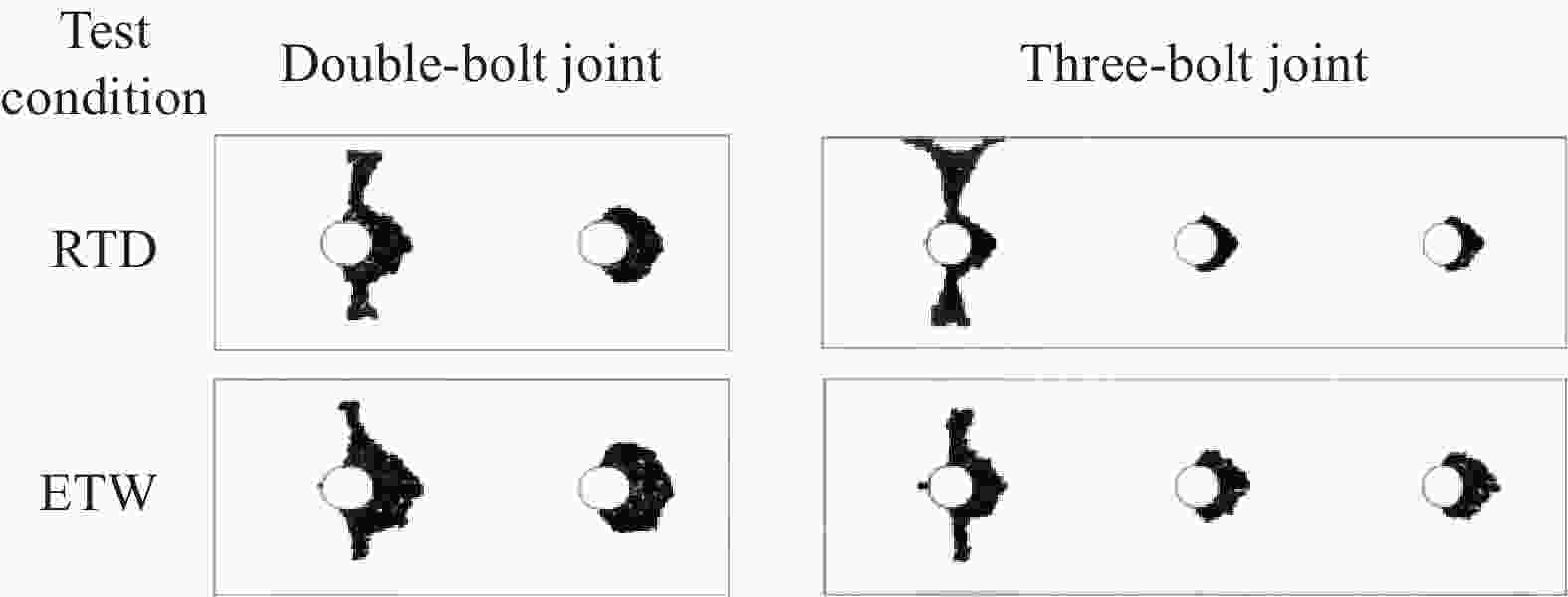

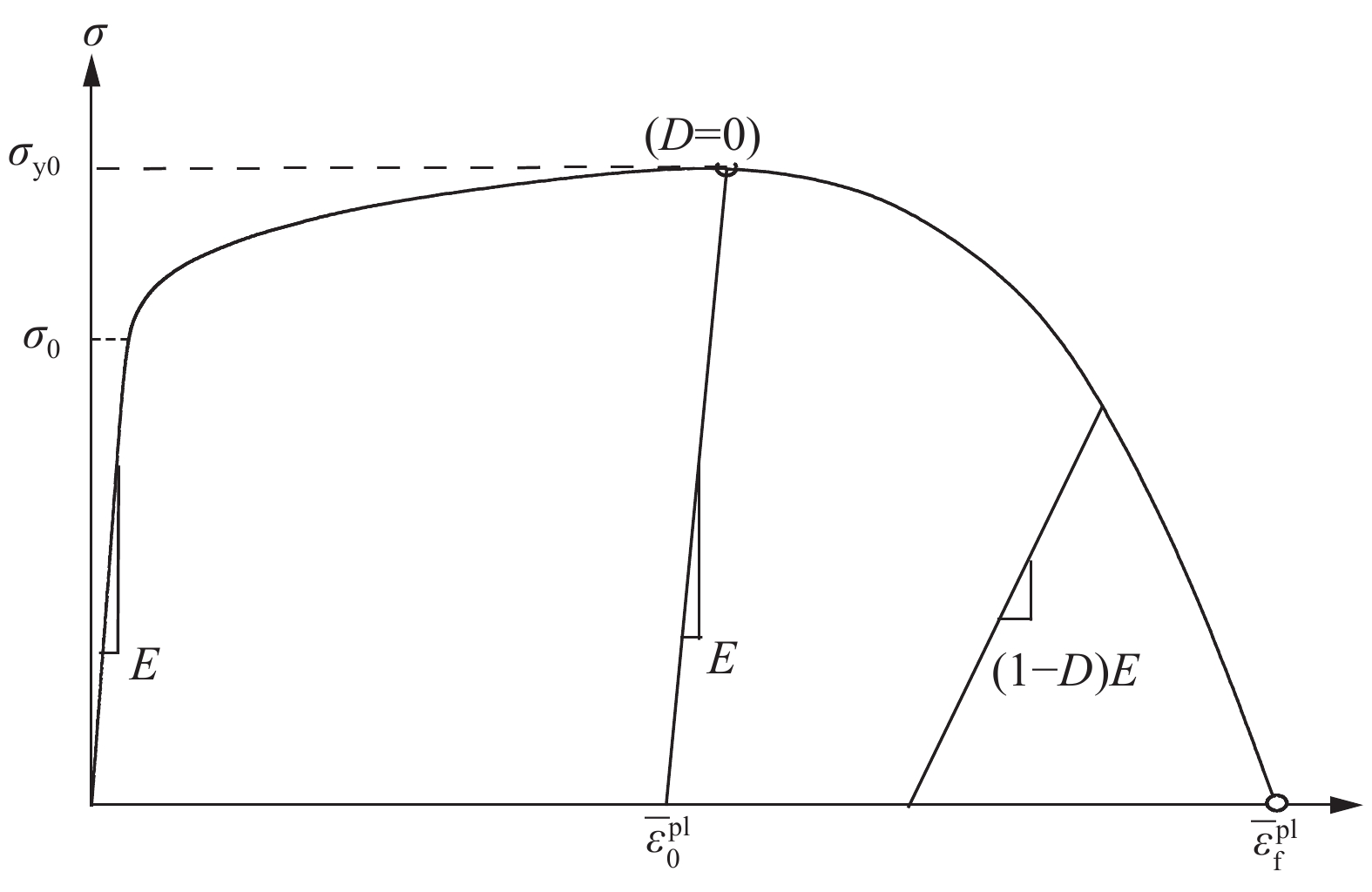

摘要: 湿热环境对碳纤维增强树脂(CFRP)复合材料-铝合金螺栓连接结构失效的显著影响给整体结构带来了安全隐患。为准确评估湿热环境对混合螺栓连接静力失效的影响,基于复合材料渐进损伤模型及金属韧性断裂准则,建立了考虑湿热效应的复合材料-金属螺栓连接静力失效预测模型。采用该模型预测了CFRP复合材料-铝合金单钉双剪连接结构在23℃干态、70℃平衡吸湿状态下的静强度和失效模式,与试验结果吻合良好,验证了模型的有效性。在此基础上,进一步揭示了不同湿热工况对CFRP复合材料-铝合金单钉双剪、多钉双剪连接结构静力拉伸失效的影响规律。结果表明:相比于23℃干态条件,23℃平衡吸湿条件、70℃干态条件和70℃平衡吸湿条件下CFRP复合材料-铝合金单钉双剪连接结构的失效载荷分别下降了4.5%、7.2%和13.9%;高温是导致湿热环境中CFRP复合材料层板损伤区域增大的主要因素;随着螺栓数目的增加,70℃平衡吸湿状态时连接结构静强度相比于23℃干态的下降幅度逐渐降低。Abstract: The significant influence of the hygrothermal environment on the failure of the carbon fiber reinforced polymer (CFRP) composite-aluminum alloy bolted joints has threatened the safety of the overall structures. In order to accurately assess the influence of hygrothermal environment on the quasi-static failure of CFRP composite-metal bolted joints, a quasi-static failure prediction model of composite-metal bolted joints considering hygrothermal effects was established, based on the existing progressive damage analysis of composites and Ductile damage criteria of metal. This model is validated by good consistency between the numerical and experimental results of CFRP composite-aluminum alloy single-bolt double-lap joints under 23℃/dry and 70℃/wet conditions, respectively. The proposed model was further used to reveal the influence laws of different hygrothermal environments on the quasi-static tensile failure of CFRP composite-aluminum alloy single-bolt double-lap and multi-bolt double-lap joints. The research shows that the failure loads of the single-bolt double-lap joints under 23℃/wet condition, 70℃/dry condition and 70℃/wet condition are reduced by 4.5%, 7.2% and 13.9%, respectively, compared with 23℃/dry condition. The high temperature condition is the main factor that leads to the increase of the failure area above the CFRP composite laminate under hygrothermal environments. As the number of the bolt increases, the declining degree of the quasi-static failure strength under 70℃/wet condition decreases gradually compared with 23℃/dry condition.

-

表 1 复合材料失效准则

Table 1. Failure criteria of composites

Failure mode Failure criteria Matrix tension (MT) ($ {\sigma }_{22}>0$) $ {\left(\dfrac{{\sigma }_{\rm{22}}}{{Y}_{\rm{T}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{12}}}{{S}_{12}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{23}}}{{S}_{23}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Matrix compression (MC) ($ {\sigma }_{22}<0$) $ {\left(\dfrac{{\sigma }_{\rm{22}}}{{Y}_{\rm{C}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{12}}}{{S}_{12}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{23}}}{{S}_{23}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Fiber tension (FT) ($ {\sigma }_{11}>0$) $ {\left(\dfrac{{\sigma }_{\rm{11}}}{{X}_{\rm{T}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{12}}}{{S}_{12}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{13}}}{{S}_{13}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Fiber compression (FC) ($ {\sigma }_{11}<0$) $ {\left(\dfrac{{\sigma }_{\rm{11}}}{{X}_{\rm{C}}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Fiber-matrix shear-out (FMS) ($ {\sigma }_{11}<0$) $ {\left(\dfrac{{\sigma }_{\rm{11}}}{{X}_{\rm{C}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{12}}}{{S}_{12}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{13}}}{{S}_{13}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Interlaminar tension (IT) ($ {\sigma }_{33}>0$) $ {\left(\dfrac{{\sigma }_{\rm{33}}}{{Z}_{\rm{T}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{13}}}{{S}_{13}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{23}}}{{S}_{23}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Interlaminar compression (IC) ($ {\sigma }_{33}<0$) $ {\left(\dfrac{{\sigma }_{\rm{33}}}{{Z}_{\rm{C}}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{13}}}{{S}_{13}^{\rm{ht}}}\right)}^{2}+{\left(\dfrac{{\tau }_{\rm{23}}}{{S}_{23}^{\rm{ht}}}\right)}^{2}\geqslant 1$ Notes: $ {\sigma }_{ij}$,$ {\tau }_{ij}$(1≤i≤j≤3)—Stress components on material coordinate system; Superscript “ht”—Mechanical properties at ETW condition; $ {X}_{\rm{T}}$—Longitudinal tensile strength; $ {X}_{\rm{C}}$—Longitudinal compressive strength; $ {Y}_{\rm{T}}$,$ {Z}_{\rm{T}}$—Transverse tensile strengths; $ {Y}_{\rm{C}}$,$ {Z}_{\rm{C}}$—Transverse compressive strengths; $ {S}_{12}$—In-plane shear strength; $ {S}_{13}$,$ {S}_{23}$—Out-of-plane shear strengths. Failure mode Material degradation rule MT $ {E}_{\rm{22}}^{\rm{d}}={d}_{\rm{mt}}{E}_{\rm{22}}^{\rm{ht}}$,$ {G}_{\rm{12}}^{\rm{d}}={d}_{\rm{mt}}{G}_{\rm{12}}^{\rm{ht}}$,$ {G}_{\rm{23}}^{\rm{d}}={d}_{\rm{mt}}{G}_{\rm{23}}^{\rm{ht}}$,$ {\nu }_{\rm{12}}^{\rm{d}}={d}_{\rm{mt}}{\nu }_{\rm{12}}^{\rm{ht}}$,$ {\nu }_{\rm{23}}^{\rm{d}}={d}_{\rm{mt}}{\nu }_{\rm{23}}^{\rm{ht}}$ MC $ {E}_{\rm{22}}^{\rm{d}}={d}_{\rm{mc}}{E}_{\rm{22}}^{\rm{ht}}$,$ {G}_{\rm{12}}^{\rm{d}}={d}_{\rm{mc}}{G}_{\rm{12}}^{\rm{ht}}$,$ {G}_{\rm{23}}^{\rm{d}}={d}_{\rm{mc}}{G}_{\rm{23}}^{\rm{ht}}$,$ {\nu }_{\rm{12}}^{\rm{d}}={d}_{\rm{mc}}{\nu }_{\rm{12}}^{\rm{ht}}$,$ {\nu }_{\rm{23}}^{\rm{d}}={d}_{\rm{mc}}{\nu }_{\rm{23}}^{\rm{ht}}$ FT $ {E}_{\rm{11}}^{\rm{d}}\rm{\hspace{0.17em}}={d}_{\rm{ft}}{E}_{\rm{11}}^{\rm{ht}}$ FC $ {E}_{\rm{11}}^{\rm{d}}={d}_{\rm{fc}}{E}_{\rm{11}}^{\rm{ht}}$ FMS $ {G}_{\rm{12}}^{\rm{d}}={d}_{\rm{fm1}}{G}_{\rm{12}}^{\rm{ht}}$,$ {G}_{\rm{13}}^{\rm{d}}={d}_{\rm{fm1}}{G}_{\rm{13}}^{\rm{ht}}$,$ {G}_{\rm{23}}^{\rm{d}}={d}_{\rm{fm2}}{G}_{\rm{23}}^{\rm{ht}}$,$ {\nu }_{\rm{12}}^{\rm{d}}={d}_{\rm{fm1}}{\nu }_{\rm{12}}^{\rm{ht}}$,$ {\nu }_{\rm{13}}^{\rm{d}}={d}_{\rm{fm1}}{\nu }_{\rm{13}}^{\rm{ht}}$,$ {\nu }_{\rm{23}}^{\rm{d}}={d}_{\rm{fm2}}{\nu }_{\rm{23}}^{\rm{ht}}$ IT $ {E}_{\rm{33}}^{\rm{d}}={d}_{\rm{dt}}{E}_{\rm{33}}^{\rm{ht}}$,$ {G}_{\rm{13}}^{\rm{d}}={d}_{\rm{dt}}{G}_{\rm{13}}^{\rm{ht}}$,$ {G}_{\rm{23}}^{\rm{d}}={d}_{\rm{dt}}{G}_{\rm{23}}^{\rm{ht}}$,$ {\nu }_{\rm{13}}^{\rm{d}}={d}_{\rm{dt}}{\nu }_{\rm{13}}^{\rm{ht}}$,$ {\nu }_{\rm{23}}^{\rm{d}}={d}_{\rm{dt}}{\nu }_{\rm{23}}^{\rm{ht}}$ IC $ {E}_{\rm{33}}^{\rm{d}}={d}_{\rm{dc}}{E}_{\rm{33}}^{\rm{ht}}$,$ {G}_{\rm{13}}^{\rm{d}}={d}_{\rm{dc}}{G}_{\rm{13}}^{\rm{ht}}$,$ {G}_{\rm{23}}^{\rm{d}}={d}_{\rm{dc}}{G}_{\rm{23}}^{\rm{ht}}$,$ {\nu }_{\rm{13}}^{\rm{d}}={d}_{\rm{dc}}{\nu }_{\rm{13}}^{\rm{ht}}$,$ {\nu }_{\rm{23}}^{\rm{d}}={d}_{\rm{dc}}{\nu }_{\rm{23}}^{\rm{ht}}$ Notes: Superscript “d”—Degraded mechanical properties; Superscript “ht”—Mechanical properties at ETW condition; $ {E}_{11}$—Longitudinal modulus; $ {E}_{22}$,$ {E}_{33}$—Transverse moduli; $ {G}_{12}$—In-plane shear modulus; $ {G}_{13}$,$ {G}_{23}$—Out-of-plane shear moduli; $ {\nu }_{12}$—Major Poisson’s ratio; $ {\nu }_{13}$,$ {\nu }_{23}$—Through thickness Poisson’s ratios; $ {d}_{i}$(i=ft,fc,mt,mc,dt,dc,fm1,fm2) are degradation factors. 表 3 T800/X850复合材料23℃干态(RTD)力学性能[12]

Table 3. Mechanical properties of T800/X850 composites under 23℃/dry (RTD) condition[12]

Elastic constant Value Strength Value $ {E}_{11}^{\rm{0}}$/GPa 163.5 $ {X}_{\rm{T}}^{\rm{0}}$/MPa 2992 $ {E}_{22}^{\rm{0}}$=$ {E}_{33}^{\rm{0}}$/GPa 9 $ {X}_{\rm{C}}^{\rm{0}}$/MPa 1183 $ {G}_{12}^{\rm{0}}$=$ {G}_{13}^{\rm{0}}$/GPa 4.14 $ {Y}_{\rm{T}}^{\rm{0}}$=$ {Z}_{\rm{T}}^{\rm{0}}$/MPa 70.6 $ {G}_{23}^{\rm{0}}$/GPa 3.08 $ {Y}_{\rm{C}}^{\rm{0}}$=$ {Z}_{\rm{C}}^{\rm{0}}$/MPa 278 $ {\nu }_{12}^{\rm{0}}$=$ {\nu }_{13}^{\rm{0}}$ 0.32 $ {S}_{12}^{\rm{0}}$=$ {S}_{13}^{\rm{0}}$/MPa 172 $ {\nu }_{23}^{\rm{0}}$ 0.46 $ {S}_{23}^{\rm{0}}$/MPa 105 $ {E}_{\rm{m}}^{\rm{0}}$/GPa 3.5 $ {G}_{\rm{m}}^{\rm{0}}$/GPa 1.3 Notes: Superscript “0”—Mechanical properties at RTD condition; $ {E}_{\rm{m}}^{\rm{0}}$,$ {G}_{\rm{m}}^{\rm{0}}$—Matrix moduli. 表 4 T800/X850复合材料70℃平衡吸湿状态(ETW)应力分析参数[12,22]

Table 4. Stress analysis parameters of T800/X850 composite under 70℃/wet (ETW) condition[12,22]

αm /(10−6 K−1) αf /(10−6 K−1) $ {\nu }_{\rm{f}}^{\rm{0}}$ $ {\nu }_{\rm{m}}^{\rm{0}}$ βm 30.8 −3.16 0.32 0.35 0.3 ρ/(g∙cm−3) ρm/(g∙cm−3) $ {T}_{\rm{g}}^{\rm{0}}$/℃ ∆C/% k 1.58 1.25 185 0.624 5490 Notes: αm, αf—Thermal expansion coefficients of matrix and fiber; $ {\nu }_{\rm{f}}^{\rm{0}}$, $ {\nu }_{\rm{m}}^{\rm{0}}$—Poisson’s ratios of fiber and matrix; βm—Moisture expansion coefficient of matrix; ρ, ρm—Densities of the unidirectional composites and matrix; $ {T}_{\rm{g}}^{\rm{0}}$—Glass transition temperature at dry states; ∆C—Moisture content; k—Temperature shift per unit absorbed moisture. 表 5 T800/X850复合材料ETW的工程常数计算参数[12]

Table 5. Engineering constant calculation parameters of T800/X850 composite under ETW condition[12]

Item a b c d e Value 0.04 0.5 0.5 0.04 0.54 Item f g h i j Value 0.5 0.5 0.5 0.5 0.5 表 6 T800/X850复合材料-铝合金单钉双剪连接结构拉伸失效载荷预测结果与试验结果比较

Table 6. Comparison of tensile failure loads between numerical and experimental results of T800/X850 composite-aluminum single-bolt double-lap joints

Test Pult/kN Pave/kN COV/% Pnum/kN Re/% RTD 24.70 23.89 3.5 25.31 5.9 23.05 23.93 ETW 21.17 21.33 1.1 21.78 1.5 21.67 21.16 21.30 Notes: Pult—Test failure load; Pave—Average failure load; COV—Coefficient of variation; Pnum—Numerical simulation failure loads; Re—Relative error between simulated failure load and the test value. -

[1] JARED T, YIKAI Y, JEFFREY Y, et al. Environmentally assisted crack growth in adhesively bonded composite joints[J]. Composites Part A: Applied Science and Manufacturing,2017,102:368-377. doi: 10.1016/j.compositesa.2017.08.018 [2] GONG Y, ZHAO L B, ZHANG J Y, et al. A novel model for determining the fatigue delamination resistance in composite laminates from a viewpoint of energy[J]. Composites Science and Technology,2018,167:489-496. doi: 10.1016/j.compscitech.2018.08.045 [3] ZHANG J Y, QI D X, ZHOU L W, et al. A progressive failure analysis model for composite structures in hygrothermal environments[J]. Composite Structures,2015,133:331-342. doi: 10.1016/j.compstruct.2015.07.063 [4] 郭居上. 温度场中复合材料板与铝合金板钉接结构内应力研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.GUO J S. Internal stress analysis of bolted joints composed of composte plate and aluminum plate in thermal field[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [5] KAPIDZIC Z, ANSELL H, SCHON J, et al. Fatigue bearing failure of CFRP composite in bolted joints exposed to biaxial variable amplitude loading at elevated temperature[J]. Composite Structures,2016,142:71-77. doi: 10.1016/j.compstruct.2016.01.064 [6] 裴瑞光, 肖毅, 陈豪麟, 等. 复合材料螺栓连接预紧力松弛的温度-时间依存行为[J]. 复合材料学报, 2016, 33(4):768-778.PEI R G, XIAO Y, CHEN H L, et al. Temperature-time dependent behavior for preload relaxation in bolted composite joints[J]. Acta Materiae Compositae Sinica,2016,33(4):768-778(in Chinese). [7] TURVEY G J, SANA A. Pultruded GFRP double-lap single-bolt tension joints: Temperature effects on mean and characteristic failure stresses and knock-down factors[J]. Composite Structures,2016,153:624-631. doi: 10.1016/j.compstruct.2016.06.016 [8] LI H L, ZHANG K F, CHENG H, et al. Multi-stage mechanical behavior and failure mechanism analysis of CFRP/Al single-lap bolted joints with different seawater ageing conditions[J]. Composite Structures,2019,208:634-645. doi: 10.1016/j.compstruct.2018.10.044 [9] MIYANO Y, NAKADA M, SEKINE N. Life prediction of CFRP/metal bolted joint under water absorption condition[J]. Journal of Composite Materials,2010,44(20):2393-2411. doi: 10.1177/0021998310372697 [10] MARIAM M, AFENDI M, ABDUL M M S, et al. Hydrothermal ageing effect on the mechanical behaviour and fatigue response of aluminium alloy/glass/epoxy hybrid composite single lap joints[J]. Composites Structures,2019,219:69-82. doi: 10.1016/j.compstruct.2019.03.078 [11] LASZLO P, GEORGE S. Mechanics of composite structures[M]. Cambridge: Cambridge University Press, 2003. [12] SHAN M J, ZHAO L B, HONG H M, et al. A progressive fatigue damage model for composite structures in hygrothermal environments[J]. International Journal of Fatigue,2018,111:299-307. doi: 10.1016/j.ijfatigue.2018.02.019 [13] TSAI S W. Composite design, 4th edition[M]. Dayton: Think Composites, 1988. [14] SHEN C H, SPRINGER G S. Moisture absorption and desorption of composite materials[J]. Journal of Composite Materials, 1976, 10: 2-20. [15] POON C, LESSARD L, SHOKRIEH M. Three dimensional progressive failure analysis of pin/bolt loaded composite laminates[C]//The 83rd meeting of the AGARD SMP on bolted joints in polymeric composites. Italy: 1996. [16] ZHANG J Y, ZHOU L W, CHEN Y L, et al. A micromechanics-based degradation model for composite progressive damage analysis[J]. Journal of Composite Materials,2016,50(16):2271-2287. doi: 10.1177/0021998315602947 [17] YU H L, JEONG D Y. Application of a stress triaxiality dependent fracture criterion in the finite element analysis of unnotched Charpy specimens[J]. Theoretical and Applied Fracture Mechanics,2010,54(1):54-62. doi: 10.1016/j.tafmec.2010.06.015 [18] LEE Y W, WIERZBICKI T. Quick fracture calibration for industrial use[R]. Cambridge: MIT Impact and Crashworthiness Laboratory, 2004. [19] BAO Y B, WIERZBICKI T. On fracture locus in the equivalent strain and stress triaxiality space[J]. International Journal of Mechanical Sciences,2004,46(1):81-98. doi: 10.1016/j.ijmecsci.2004.02.006 [20] SONG Q, AMIN H, ZHAO X, et al. Experimental and numerical investigation of ductile fracture of carbon steel structural components[J]. Journal of Constructional Steel Research,2018,145:425-437. doi: 10.1016/j.jcsr.2018.02.032 [21] 李喜梅, 汤剑, 常万顺, 等. 采用Matlab测定铝合金形变硬化指数[J]. 辽宁工程技术大学学报(自然科学版), 2015, 34(2):208-211.LI X M, TANG J, CHANG W S, et al. Test of aluminum alloy strain hardening exponent based on Matlab[J]. Journal of Liaoning Technical University (Natural Science Edition),2015,34(2):208-211(in Chinese). [22] ZHAO L B, LI Y, ZHANG J Y, et al. A novel material degradation model for unidirectional CFRP composites[J]. Composites Part B: Engineering,2018,135:84-94. doi: 10.1016/j.compositesb.2017.09.038 [23] ASTM International. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229M—14[S]. West Conshohocken: ASTM International, 2014. [24] ASTM International. Standard test method for bearing response of polymer matrix composite laminates: ASTM D5961M—13[S]. West Conshohocken: ASTM International, 2013. [25] ZHANG J Y, ZHOU L W, CHEN Y L, et al. A micromechanics-based degradation model for composite progressive damage analysis[J]. Journal of Composite Materials,2016,50:1-17. -

下载:

下载: