Effect of Sn modification on microstructure and mechanical properties of graphite/Cu composites

-

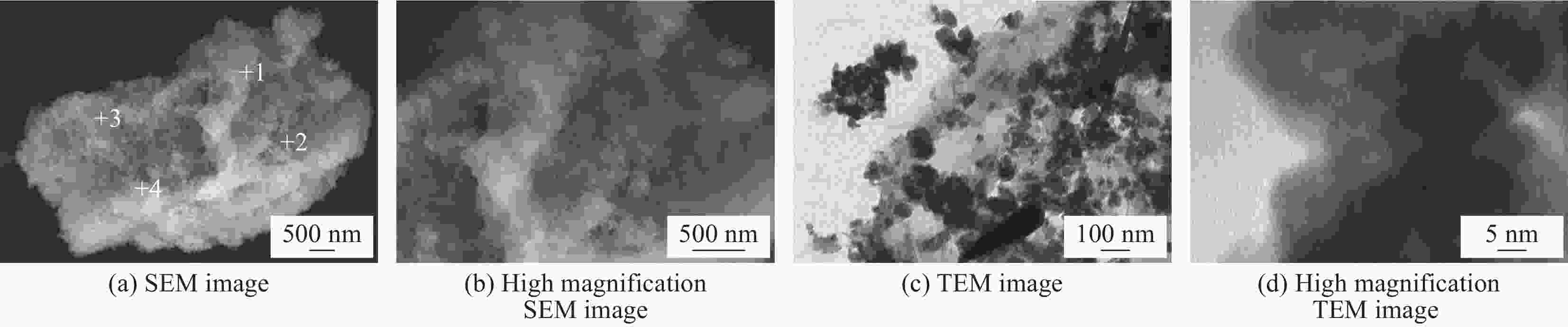

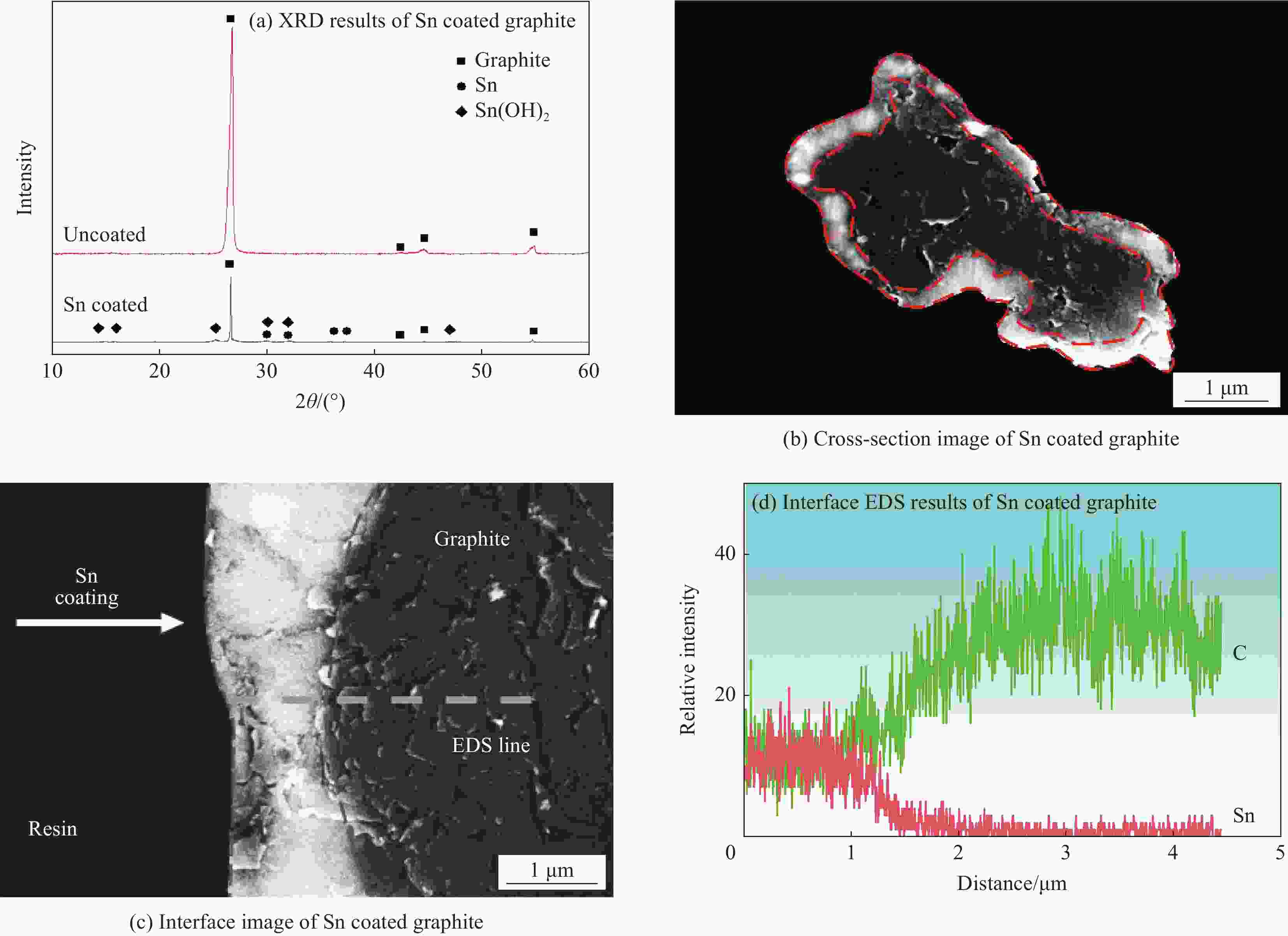

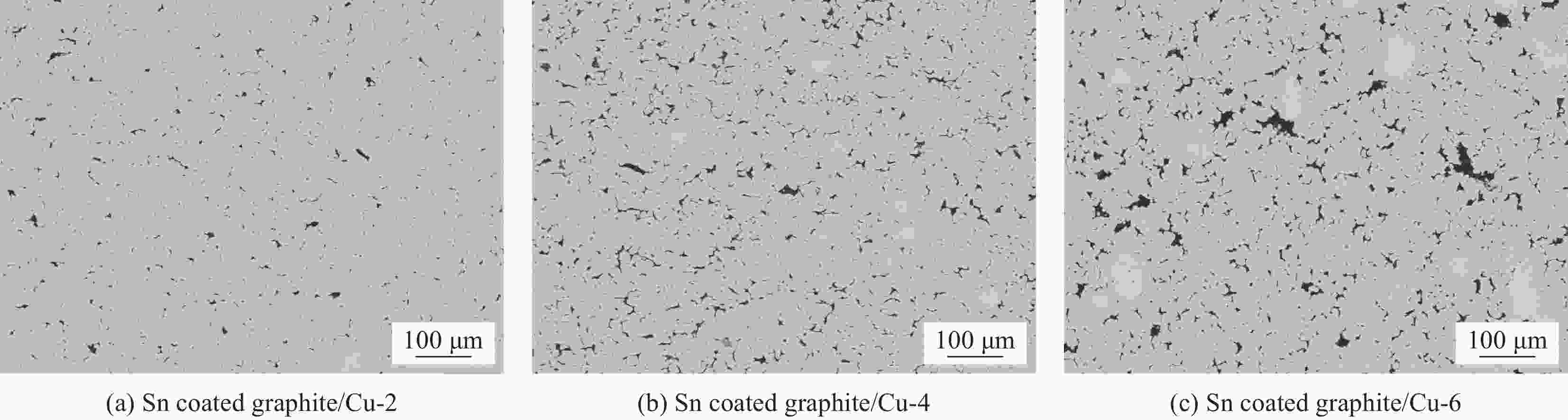

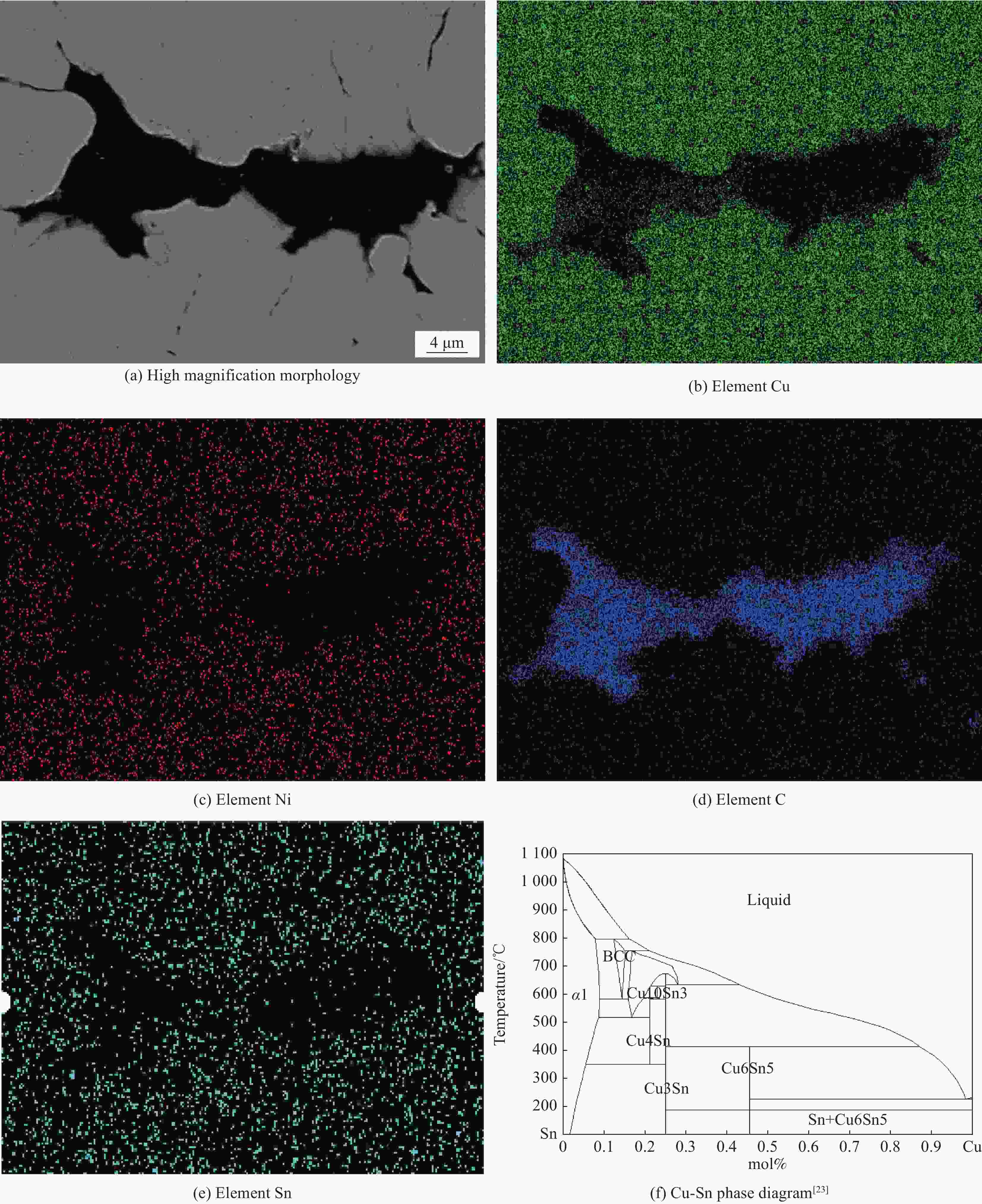

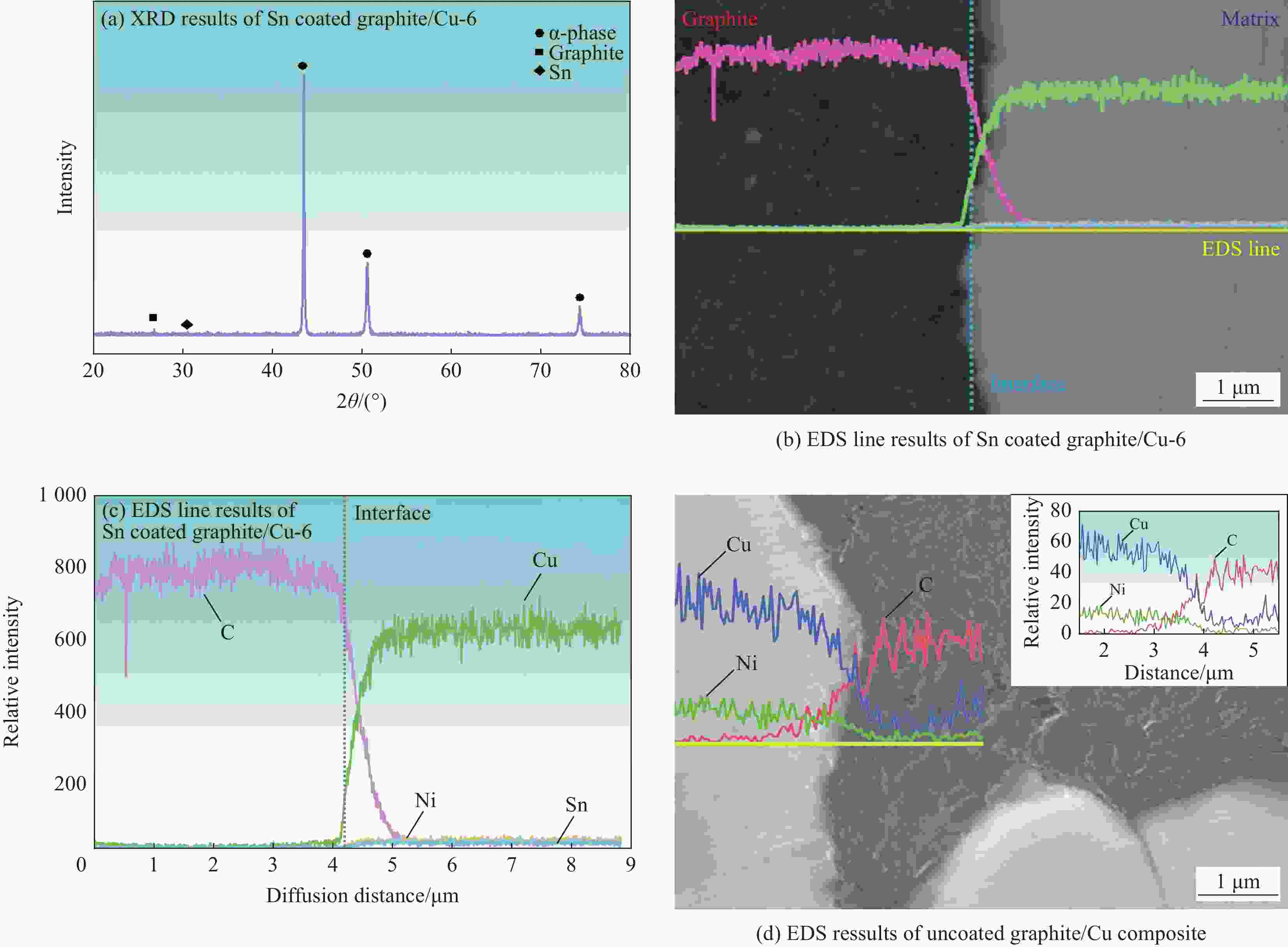

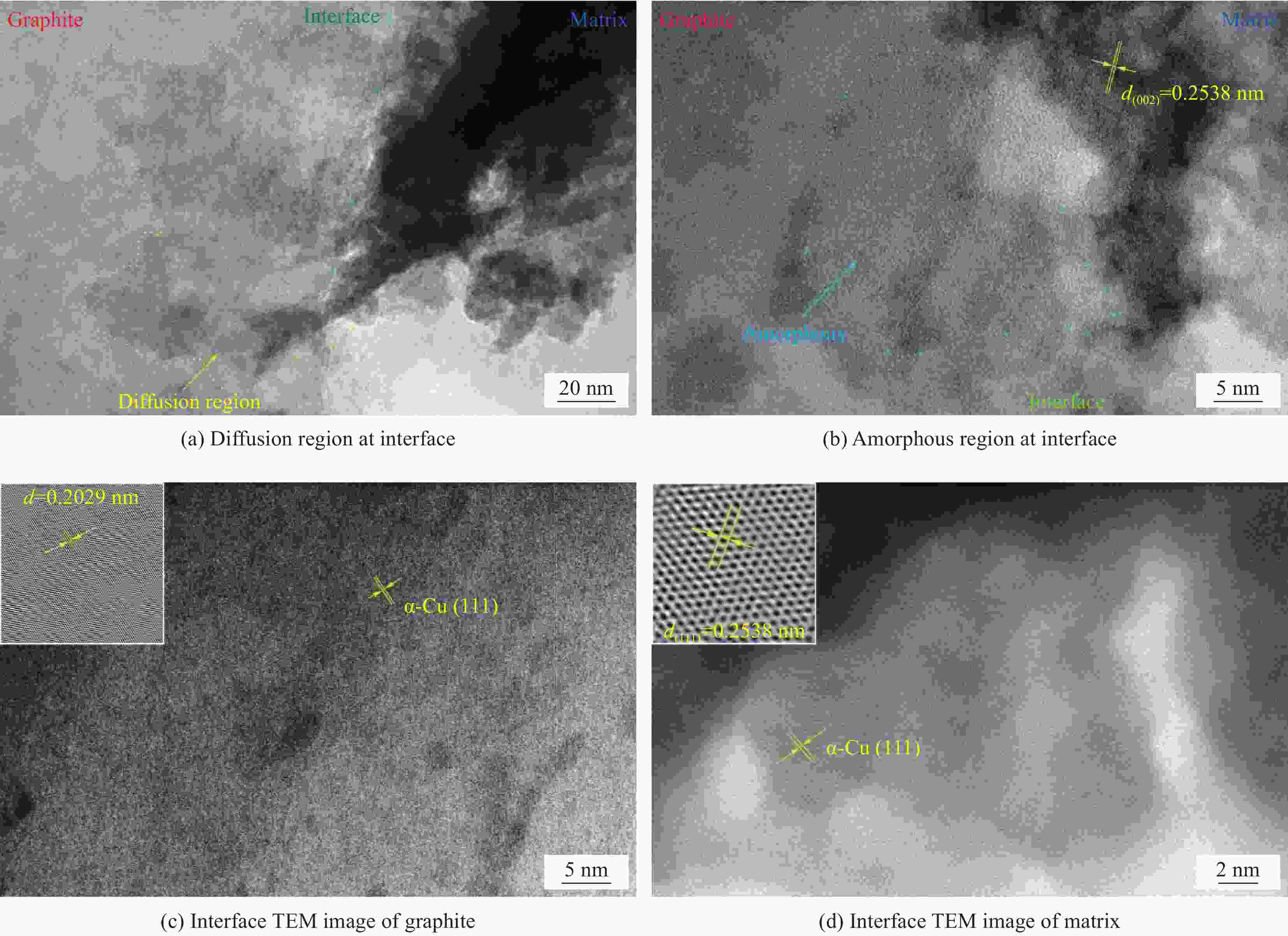

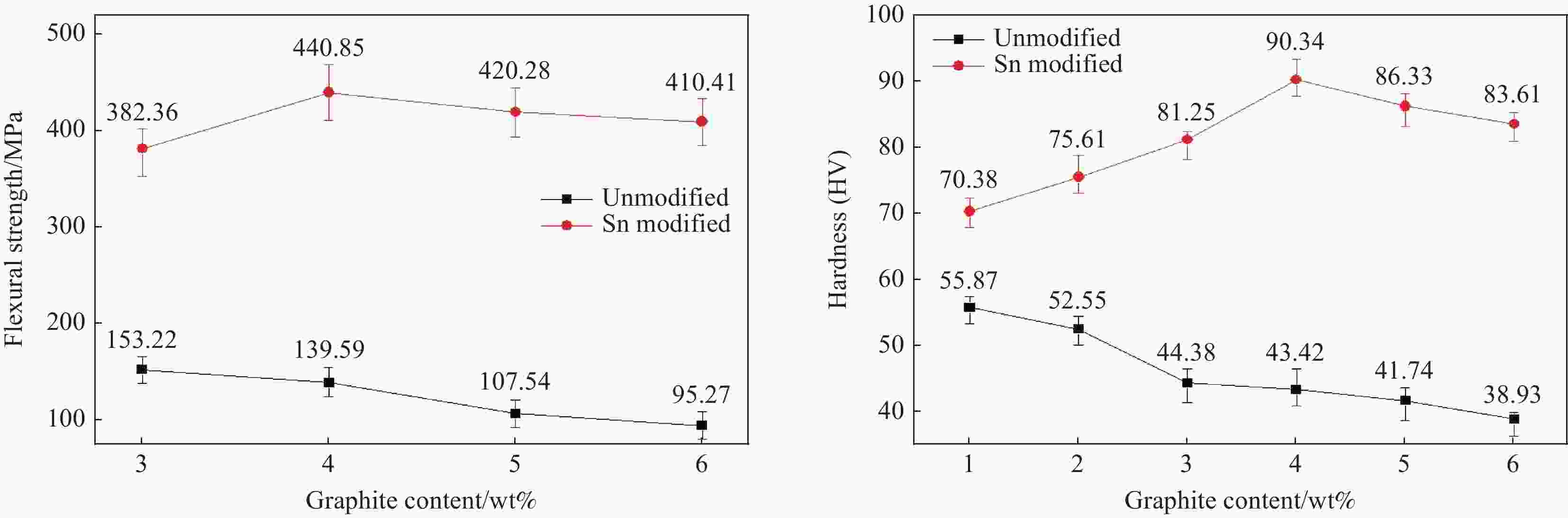

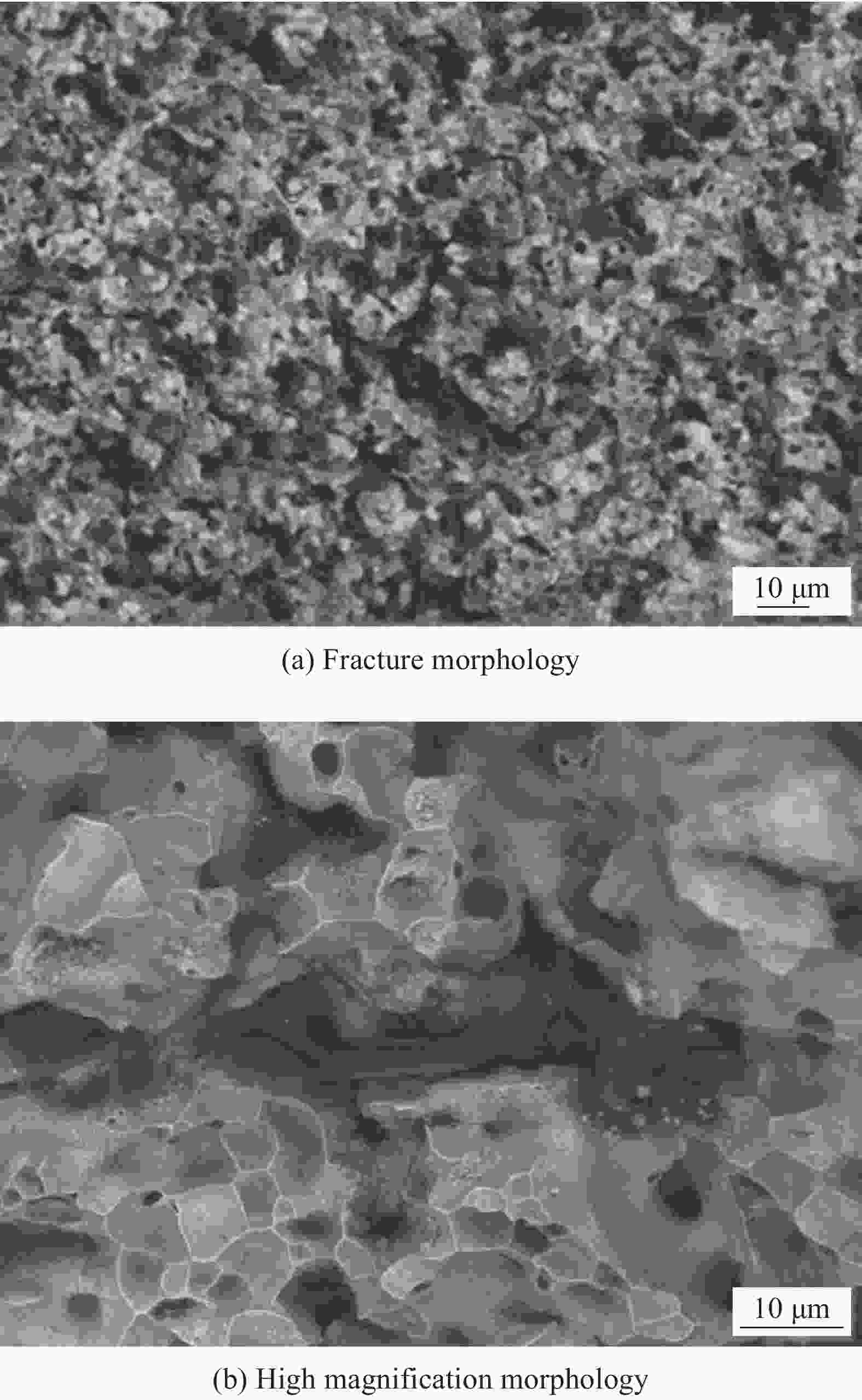

摘要: 石墨/Cu自润滑复合材料具有良好的摩擦学性能和耐腐蚀性能,在高速铁路领域具有广阔的应用前景。传统石墨/Cu自润滑复合材料中由于石墨与基体不润湿,复合材料界面结合强度低,在材料承受载荷时容易造成石墨相的剥离、脱落,导致复合材料在高载荷服役条件下性能较差。采用化学镀覆工艺在石墨表面镀覆软金属Sn元素调控石墨/Cu复合材料界面,既能够改善复合材料材料组织,又改善了复合材料的力学性能,使复合材料满足服役条件。结果表明:通过石墨镀Sn调控技术,Sn调控石墨/Cu复合材料的组织并无新相生成,复合材料界面处发生强烈的原子互扩散,界面由机械结合变成扩散结合。Sn调控石墨/Cu复合材料的力学性能有显著提高,其中硬度平均提高了80.43%,抗弯强度平均提高了246.74%;当石墨含量为6wt%时,Sn调控石墨/Cu复合材料的硬度提高至(83.61±4.33) HV,抗弯强度提高至(410.41±20.52) MPa,适应并满足复合材料在未来愈加严酷工况环境下的服役需求。Abstract: The graphite/Cu composites have excellent tribological properties and corrosion resistance so which show a broad application prospect in the field of high-speed railway. Due to the non-wetting of graphite with Cu and the low interfacial bonding strength of graphite/Cu composites, the graphite easily peels off under the high load and it could result in the poor performance of the composites. The interface of graphite/Cu composite could be modified by the surface treatment of the graphite with Sn element, which could not only improve the interfacial bonding but also improve the mechanical properties, so that the composites could meet the service conditions. The results show that there is no new phase formation in the microstructure of Sn coated graphite/Cu composites by the interfacial modification. A strong interdiffusion occurs at the interface of the Sn coated graphite/Cu composites and the interfacial bonding changes from mechanical bonding to diffusion bonding. The mechanical properties of the Sn coated graphite/Cu composites are significantly improved. The hardness and flexural strength increase 80.43% and 246.74%, respectively. When the graphite content is 6wt%, the hardness is (83.61±4.33) HV, and the bending strength is (410.41±20.52) MPa, which could meet the service requirements in the future.

-

表 1 镀Sn石墨的化学镀液成分

Table 1. Composition of chemical plating solution of Sn coated graphite

SnCl2/(g·L−1) HCl/(mL·L−1) Thiourea/(g·L−1) PEG-6000/(g·L−1) Hydroquinone/(g·L−1) NaH2PO2/(g·L−1) Content 30.0 45.0 100.0 2.0 3.5 80.0 Note: PEG-6000—Polyethylene glycol-6000. 表 2 Sn调控石墨/Cu复合材料样品编号及成分

Table 2. Sample number and chemical composition of Sn coated graphite/Cu composites

No. Sn coated

graphite/wt%Ni/

wt%Cu/

wt%Sn coated graphite/Cu-1 1 8 Balance Sn coated graphite/Cu-2 2 Sn coated graphite/Cu-3 3 Sn coated graphite/Cu-4 4 Sn coated graphite/Cu-5 5 Sn coated graphite/Cu-6 6 表 3 镀Sn石墨表面EDS点扫描结果

Table 3. EDS point results of Sn coated graphite

Point C element Sn element O element Mass fraction/wt% Atom fraction/at% Mass fraction/wt% Atom fraction/at% Mass fraction/wt% Atom fraction/at% 1 13.8 37.7 64.4 17.8 21.8 44.5 2 13.8 38.7 65.8 42.8 20.4 18.5 3 14.2 55.5 81.7 32.3 4.1 12.2 4 12.8 40.6 72.1 36.2 15.1 23.3 表 4 6wt%石墨含量的镀Cu、Ni、Ti、Ag、Sn调控石墨/Cu复合材料力学性能对比

Table 4. Comparison of mechanical properties of Cu, Ni, Ti, Ag, Sn modified graphite/Cu composites with 6wt% content of graphite

Sample Hardness (HV) Flexural strength/MPa Unmodified 38.93 95.27 Cu modified 41.85 125.42 Ni modified 45.25 137.14 Ti modified 50.23 190.54 Ag modified 59.25 275.19 Sn modified 83.61 410.41 -

[1] 沈巍, 崔冬芳, 史玉杰. 自润滑道岔滑床板的研制[J]. 中国铁道科学, 1998, 19(4):103-110.SHEN Wei, CUI Dongfang, SHI Yujie. Re-search and manufacture of self-lubricating switch glide[J]. China Railway Science,1998,19(4):103-110(in Chinese). [2] DONG S K, WAN Y C. An accident causation model for the railway industry: Application of the model to 80 rail accident investigation reports from the UK[J]. Safety Science,2013,60:57-68. doi: 10.1016/j.ssci.2013.06.010 [3] MOUSTAFA S F, EL-BADRY S A, SANAD A M, et al. Friction and wear of copper-graphite composites made with Cu-coated and uncoated graphite powders[J]. Wear,2002,253(7-8):699-710. doi: 10.1016/S0043-1648(02)00038-8 [4] HE D H, MANORY R. A novel electrical contact material with improved self-lubrication for railway current collectors[J]. Wear,2001,249(7):626-636. doi: 10.1016/S0043-1648(01)00700-1 [5] PRABHU T R, VARMA V K, VEDANTAM S. Tribological and mechanical behavior of multilayer Cu/SiC+Gr hybrid composites for brake friction material applications[J]. Wear,2014,317(1-2):201-212. doi: 10.1016/j.wear.2014.06.006 [6] WANG Y R, GAO Y M, SUN L, et al. Effect of physical properties of Cu-Ni-graphite composites on tribological characteristics by grey cor-relation analysis[J]. Results in Physics,2017,7:263-271. doi: 10.1016/j.rinp.2016.12.041 [7] WANG Y R, GAO Y M, LI Y F, et al. The study on graphite coated with titanium by multi-arc ion plating[C]//International Union of Materials Research Societies: The 15th International Conference on Advanced Materials. Kyoto: 2017. [8] WANG Y R, GAO Y M, LI Y F. Effect of milling time on microstructure and mechanical properties of Cu-Ni-graphite composites[J]. Materials Research Express,2017,4(9):096506. doi: 10.1088/2053-1591/aa84a7 [9] WANG Y R, GAO Y M, LI Y F, et al. Research on nickel modified graphite/Cu composites interface[J]. Surface & Coatings Technology,2017,328:70-79. [10] 王怡然, 高义民, 李梦婷, 等. Sn改性对道岔滑床板用铜基石墨复合材料摩擦磨损性能影响研究[C]//第十五届全国耐磨材料大会. 合肥: 2018.WANG Yiran, GAO Yimin, LI Mengting, et al. Effect of stannum on tribological properties of Cu-Ni-graphite composites used as switch slide baseplate[C]//15th China Wear Resistance Materials Conference. Hefei: 2018(in Chinese). [11] WANG Y R, GAO Y M, TAKAHASHI J, et al. The study of microstructure characterization Cu modified Cu-Ni-graphite composite[J]. Composite Interfaces,2020,27(3):249-262. [12] WANG Y R, GAO Y M, TAKAHASHI J, et al. Effect of graphite content on Cu-Ni-graphite composite for use as switch slide baseplate materials sliding against U75V steel[J]. Journal of Tribology,2019,141(12):121603. doi: 10.1080/09276440.2019.1621598 [13] WANG Y R, GAO Y M, TAKAHASHI J, et al. Effect of plating time on surface evolution of chromium modified graphite powder by multi-arc ion plating[J]. Surface Topography-Metrology and Properties,2019,7(3):015009. [14] WANG Y R, GAO Y M, LI Y F. Titanium modified interface of Cu-Ni-graphite composites used as switch slide baseplates[C]//The 3rd China International Congress on Composite Materials. Hangzhou: 2017. [15] WANG Y R, GAO Y M, TAKAHASHI J, et al. Titanium-modified graphite reinforced Cu-Ni composite by multi-arc ion plating technology[J]. Vacuum,2019,168:108829. doi: 10.1016/j.vacuum.2019.108829 [16] WANG Y R, GAO Y M, TAKAHASHI J, et al. Investigation of modification of Cu-Ni-graphite composite by silver[J]. Materials Chemistry and Physics,2019,239:121990. [17] WANG Y R, GAO Y M, LI Y F, et al. Research on synergistic lubrication effect of silver modified Cu-Ni-graphite composite[J]. Wear,2020,444-445:203140. doi: 10.1016/j.wear.2019.203140 [18] WANG Y R, GAO Y M, LI Y F, et al. Review on preparation and application of copper-steel bimetal composites[J]. Emerging Materials Research,2019,8(4):538-551. doi: 10.1680/jemmr.17.00008 [19] 伍勇. 碱金属在石墨表面化学吸附的EHT研究[J]. 复旦学报(自然科学版), 2000, 39(2):167-173.WU Yong. EHT Study on chemical adsorption of alkali metals on graphite surface[J]. Journal of Fudan University (Natural Science),2000,39(2):167-173(in Chinese). [20] 杨余芳, 衷明华, 黄俊生. 化学镀锡反应动力学特性研究[J]. 表面技术, 2014, 43(6):64-68.YANG Yufang, ZHONG Minghua, HUANG Junsheng. Dynamic characteristics of electroless tin plating reaction[J]. Surface Technology,2014,43(6):64-68(in Chinese). [21] 贾德昌, 宋桂明. 无机非金属材料性能[M]. 北京: 科学出版社, 2008.JIA Dechang, SONG Guiming. Properties of inorganic nonmetallic material[M]. Beijing: Science Press, 2008(in Chinese). [22] 中国国家标准化管理委员会. 精细陶瓷弯曲强度试验方法: GB/T 6569—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Fine ceramics (advanced ceramics,advanced technical ceramics): Test method for for flexural strength of monolithic ceramics at room temperature: GB/T 6569—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [23] PREDEL B. Phase equilibria, crystallographic and thermodynamic data of binary alloys[M]. Berlin: Springer, 2013. -

下载:

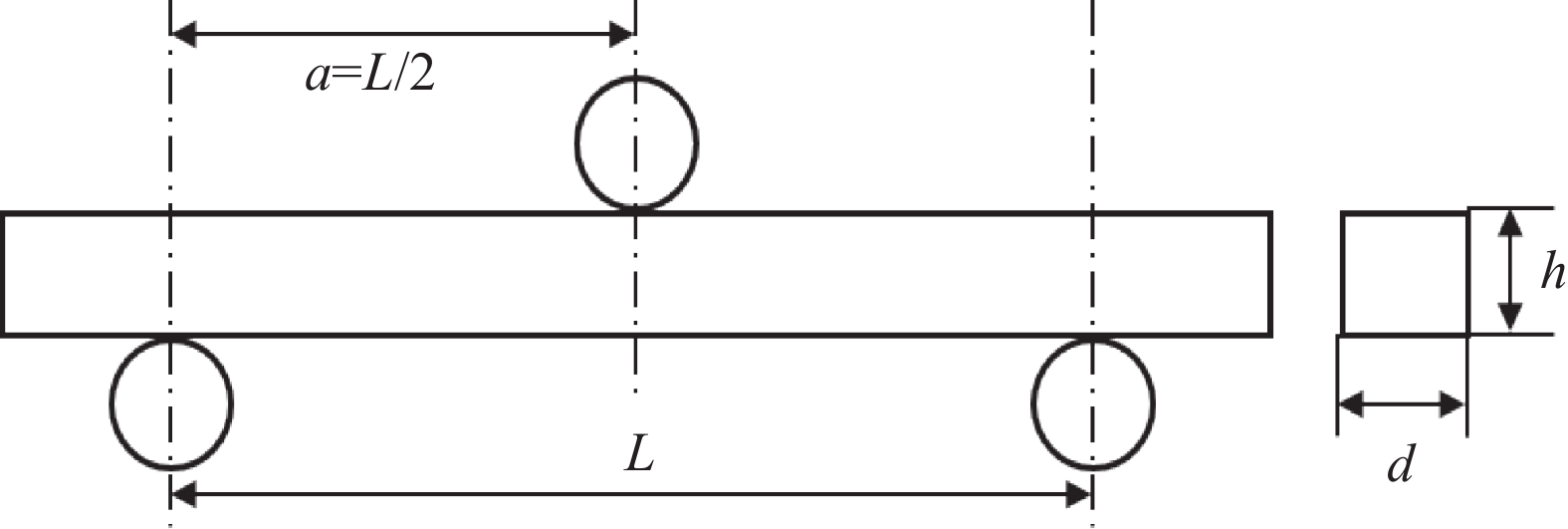

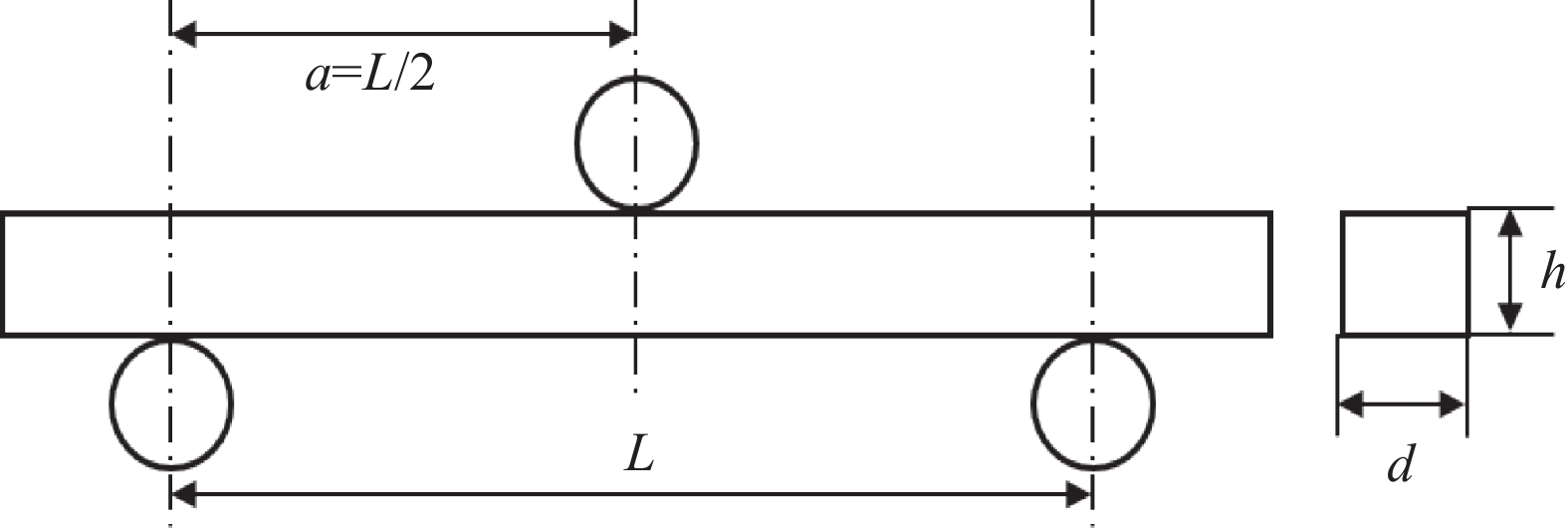

下载: