| [1] |

TWIGG G, POURSARTIP A, FERNLUND G. An experimental method for quantifying tool-part shear interaction during composites processing[J]. Composites Science and Technology,2003,63(13):1985-2002. doi: 10.1016/S0266-3538(03)00172-6

|

| [2] |

TWIGG G, POURSARTIP A, FERNLUND G. Tool-part interaction incomposites processing, Part I: Experimental investigation andanalytical model[J]. Composites Part A: Applied Science & Manufacturing,2004,35:121-133. doi: 10.1016/S1359-835X(03)00131-3

|

| [3] |

TWIGG G, POURSARTIP A, FERNLUND G. Tool-part interaction incomposites processing, PartⅡ: Numerical modeling[J]. Composites Part A: Applied Science & Manufacturing,2004,35:135-141. doi: 10.1016/S1359-835X(03)00132-5

|

| [4] |

SATISH K B, LLOYD V S. A linear finite element model topredict processing-induced distortion in FRP laminates[J]. Composites Part A: Applied Science & Manufacturing,2005,36:1666-1674. doi: 10.1016/j.compositesa.2005.03.018

|

| [5] |

KAPPEL E, STEFANIAK D, SPRÖWITZ T, et al. A semi-analytical simulation strategy and its application to warpage of autoclave-processed CFRP parts[J]. Composites Part A: Applied Science & Manufacturing,2011,42(12):1985-1994.

|

| [6] |

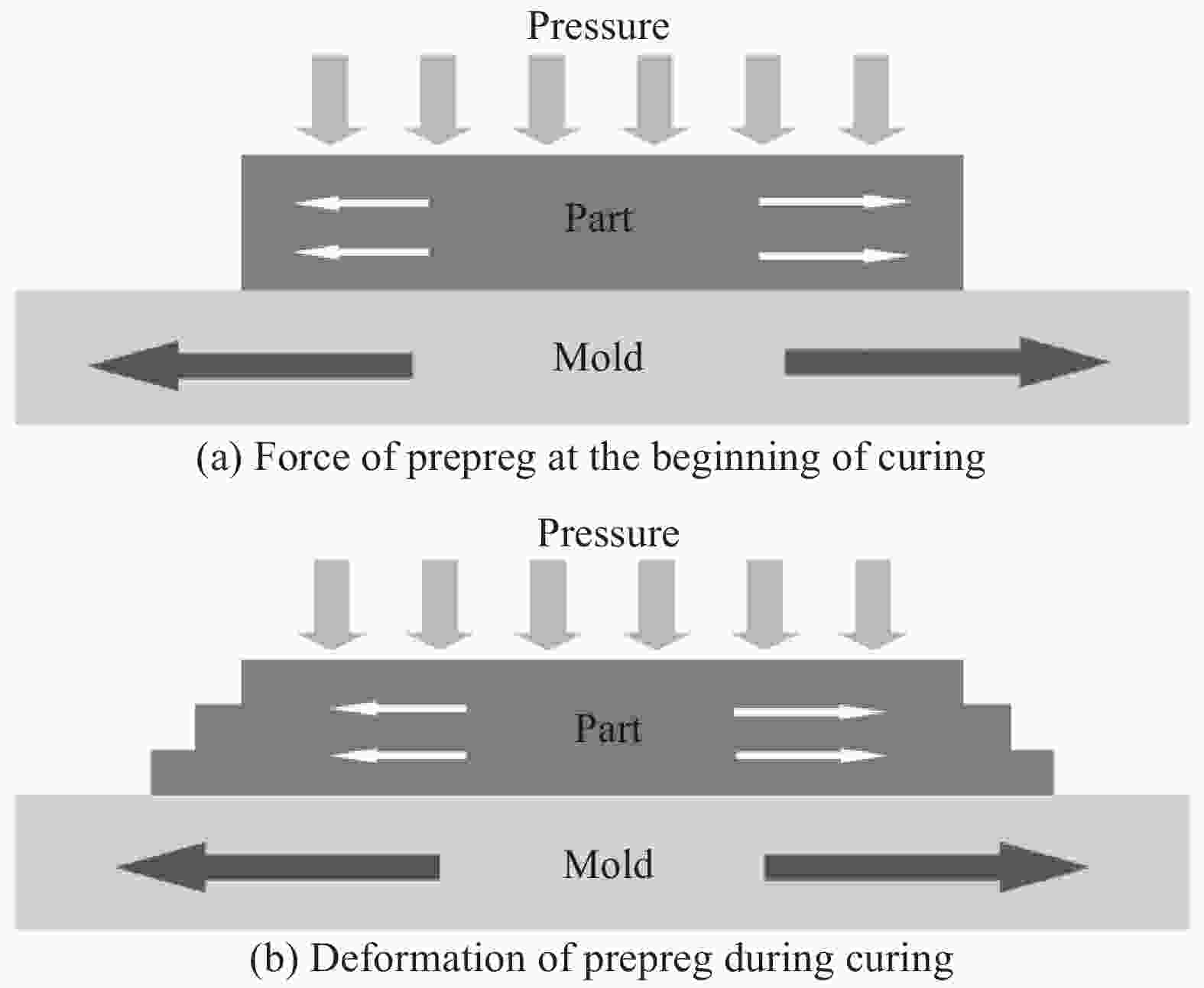

岳广全, 张博明, 戴福洪, 等. 固化过程中模具与复合材料构件相互作用分析[J]. 复合材料学报, 2010, 27(6):167-171.YUE G Q, ZHANG B M, DAI F H, et al. Interaction between mold and composite parts during curing process[J]. Acta Materiae Compositae Sinica,2010,27(6):167-171(in Chinese).

|

| [7] |

岳广全, 张嘉振, 张博明. 模具对复合材料构件固化变形的影响分析[J]. 复合材料学报, 2013, 30(4):212-216.YUE G Q, ZHANG J Z, ZHANG B M. Influence of mold on cured-induced deformation of composites structure[J]. Acta Materiae Compositae Sinica,2013,30(4):212-216(in Chinese).

|

| [8] |

元振毅, 王永军, 王俊彪, 等. 基于模具-制件相互作用的复合材料制件固化变形数值模型[J]. 复合材料学报, 2016, 33(4):902-909.YUAN Z Y, WANG Y J, WANG J B, et al. Numerical model on curing deformation of composite part based on tool-part interaction[J]. Acta Materiae Compositae Sinica,2016,33(4):902-909(in Chinese).

|

| [9] |

孙亮亮, 王继辉, 丁安心. 复合材料成形过程中模具-构件作用的一种表征方法[J]. 应用数学和力学, 2016, 37(3):245-255.SUN L L, WANG J H, DING A X. Characterization of the tool-part interaction during the curing of CFRP composites[J]. Applied Mathematics and Mechanics,2016,37(3):245-255(in Chinese).

|

| [10] |

杨晓波, 湛利华, 蒋成标, 等. 模具材料对复合材料制件固化过程应变的影响分析[J]. 南京航空航天大学学报, 2018, 50(1):24-29.YANG X B, ZHAN L H, JIANG C B, et al. Influence of mould materials on curing process and deformation of composite part[J]. Journal of Nanjing University of Aeronautics and Astronautics,2018,50(1):24-29(in Chinese).

|

| [11] |

蒋成标, 湛利华, 杨晓波, 等. 模具构件相互作用对复合材料固化应变的影响分析[J]. 玻璃钢/复合材料, 2018(6):11-15.JIANG C B, ZHAN L H, YANG X B, et al. Influence of tool-part interaction on cure-induced strain in composite[J]. Fiber Rnforced Plastics/Composites,2018(6):11-15(in Chinese).

|

| [12] |

刘德博, 湛利华, 丁星星, 等. 模具表面状态对复合材料构件固化变形的影响[J]. 宇航材料工艺, 2019, 49(1):63-67.LIU D B, ZHAN L H, DING X X, et al. Influence of tool surface condition on cure-induced deformation of composite structure[J]. Aerospace Materials & Technology,2019,49(1):63-67(in Chinese).

|

| [13] |

唐占文, 张博明. 复合材料设计制造一体化中的固化变形预报技术[J]. 航空制造技术, 2014(15):32-37. doi: 10.3969/j.issn.1671-833X.2014.15.003TANG Z W, ZHANG B M. Prediction of curing deformation in integrated design and manufacture of composites[J]. Aeronautical Manufacturing Technology,2014(15):32-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2014.15.003

|

| [14] |

ARAFATH A R A, VAZIRI R, POURSARTIP A. Closed-form solution for process-induced stresses and deformation of a composite part cured on a solid tool: Part II-Curved geometries[J]. Composites Part A: Applied Science & Manufacturing,2009,40(10):1545-1557.

|

| [15] |

NASIR M N M, AMINANDA Y, MEZEIX L, et al. Spring-back simulation of flat symmetrical laminates with angled plies manufactured through autoclave processing[C]//IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2016, 152(1): 012046.

|

| [16] |

岳广全. 整体化复合材料壁板结构固化变形模拟及控制方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.YUE G Q. Study on simulation and control method of cure-induced deformation for integrated composite panel[D]. Harbin: Harbin Institute of Technology, 2010(in Chinese).

|

| [17] |

胡海晓. 碳纤维增强热固性复合材料固化变形机理实验研究[D]. 武汉: 武汉理工大学, 2016.HU H X. Experimental study on curing deformation mechanism of carbon fiber reinforced thermosetting compo-sites[D]. Wuhan: Wuhan University of Technology, 2016(in Chinese).

|

| [18] |

SVANBERG J M, HOLMBERG J A. Prediction of shape distortions Part I. FE-implementation of a path dependent constitutive model[J]. Composites Part A: Applied Science & Manufacturing,2004,35(6):711-721. doi: 10.1016/j.compositesa.2004.02.005

|

| [19] |

元振毅, 王永军, 张跃, 等. 基于材料性能时变特性的复合材料固化过程多场耦合数值模拟[J]. 复合材料学报, 2015, 32(1):167-175.YUAN Z Y, WANG Y J, ZHANG Y, et, al. Multi-field coupled numerical simulation for curing process of composites with time-dependent properties of materials[J]. Acta Materiae Compositae Sinica,2015,32(1):167-175(in Chinese).

|

| [20] |

贺继林, 蒙元明, 王特, 等. 基于材料物性参数时变特性的复合材料层合板固化残余应变应力数值模拟[J]. 玻璃钢/复合材料, 2017(5):41-47.HE J L, MENG Y M, WANG T, et al. Numerical simulation of curing residual stress and strain of composite laminates with time-dependent physical parameters of materials[J]. Fiber Reinforced Plastics/Composites,2017(5):41-47(in Chinese).

|

| [21] |

BROUWER W D. VAN HERPT E. LABORDUS M. Vacuum injection moulding for large structural application[J]. Composites Part A: Applied Science & Manufacturing,2003(34):551-558.

|

| [22] |

HOSSEINI-TOUDESHKY H, SADIGHI M, VOJDANI A. Effects of curing thermal residual stresses on fatigue crack propagation of aluminum plates repaired by FML patches[J]. Composite Structures,2013,100:154-162. doi: 10.1016/j.compstruct.2012.12.052

|

| [23] |

WUCHER B, LANI F, PARDOEN T, et al. Tooling geometry optimization for compensation of cure-induced distortions of a curved carbon/epoxy C-spar[J]. Composites Part A: Applied Science & Manufacturing,2014,56:27-35. doi: 10.1016/j.compositesa.2013.09.010

|

| [24] |

李斌. 航空复合材料曲面结构件固化变形和残余应力研究[D]. 沈阳: 沈阳航空航天大学, 2019.LI B. The research of residual stress and deformation in the curing-process of composite surface part in aircraft industry[D]. Shenyang: Shenyang Aerospace University, 2019(in Chinese).

|

下载:

下载: