Influence of laying process parameters on curve trajectory placement quality of prepreg tow

-

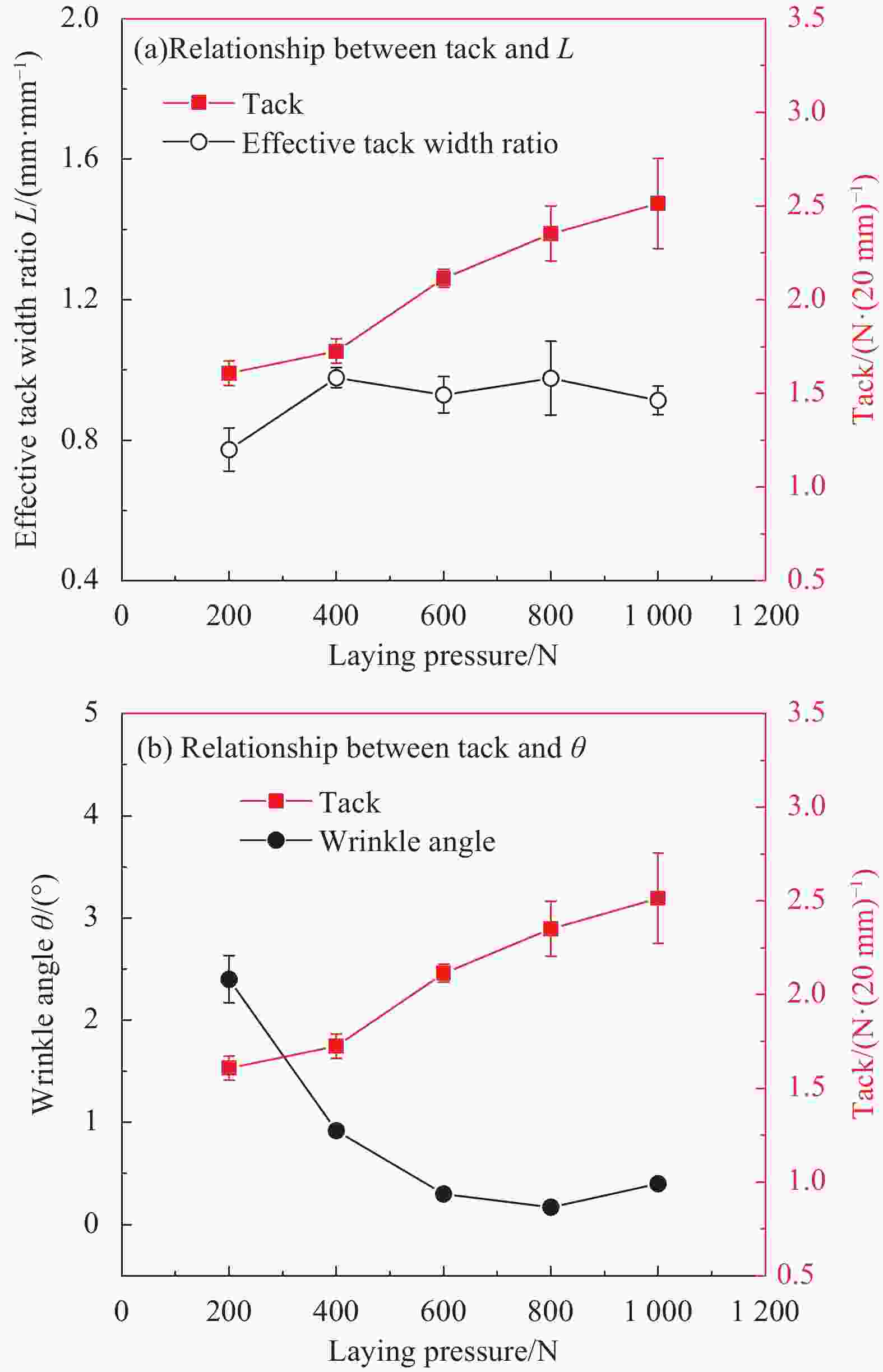

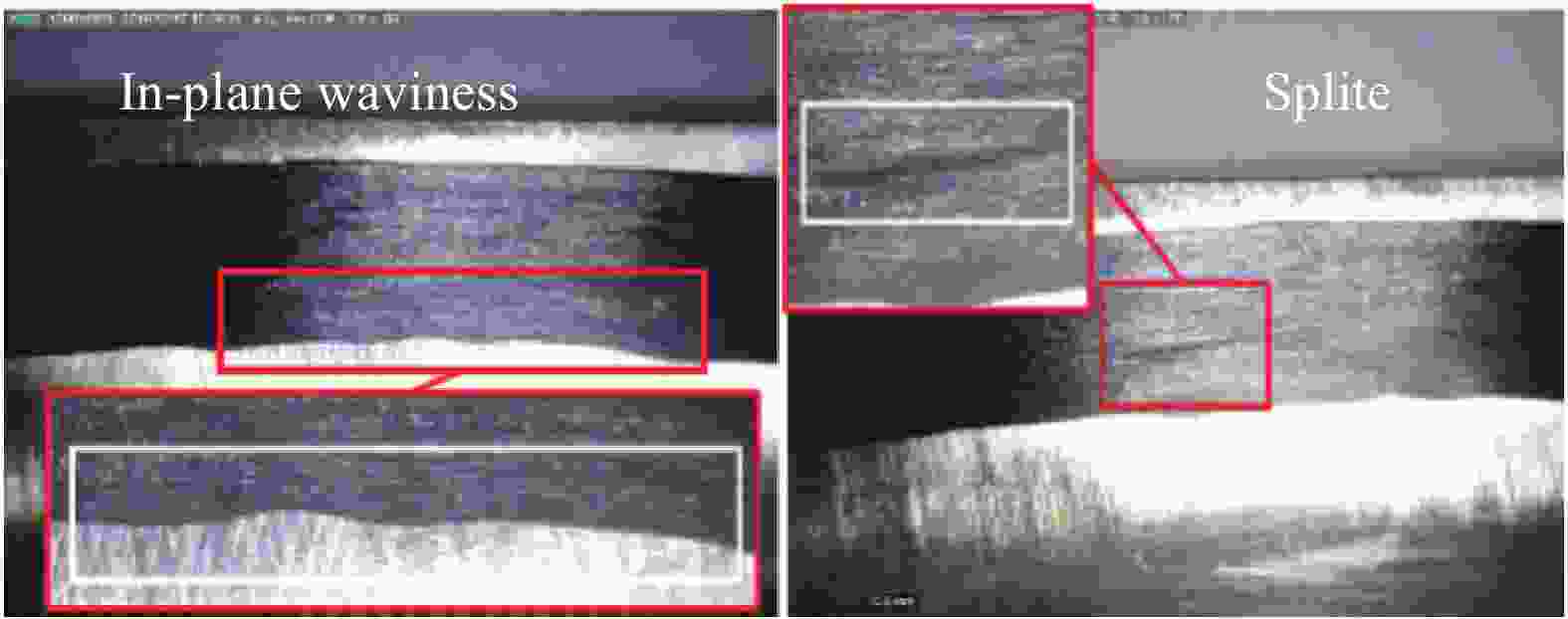

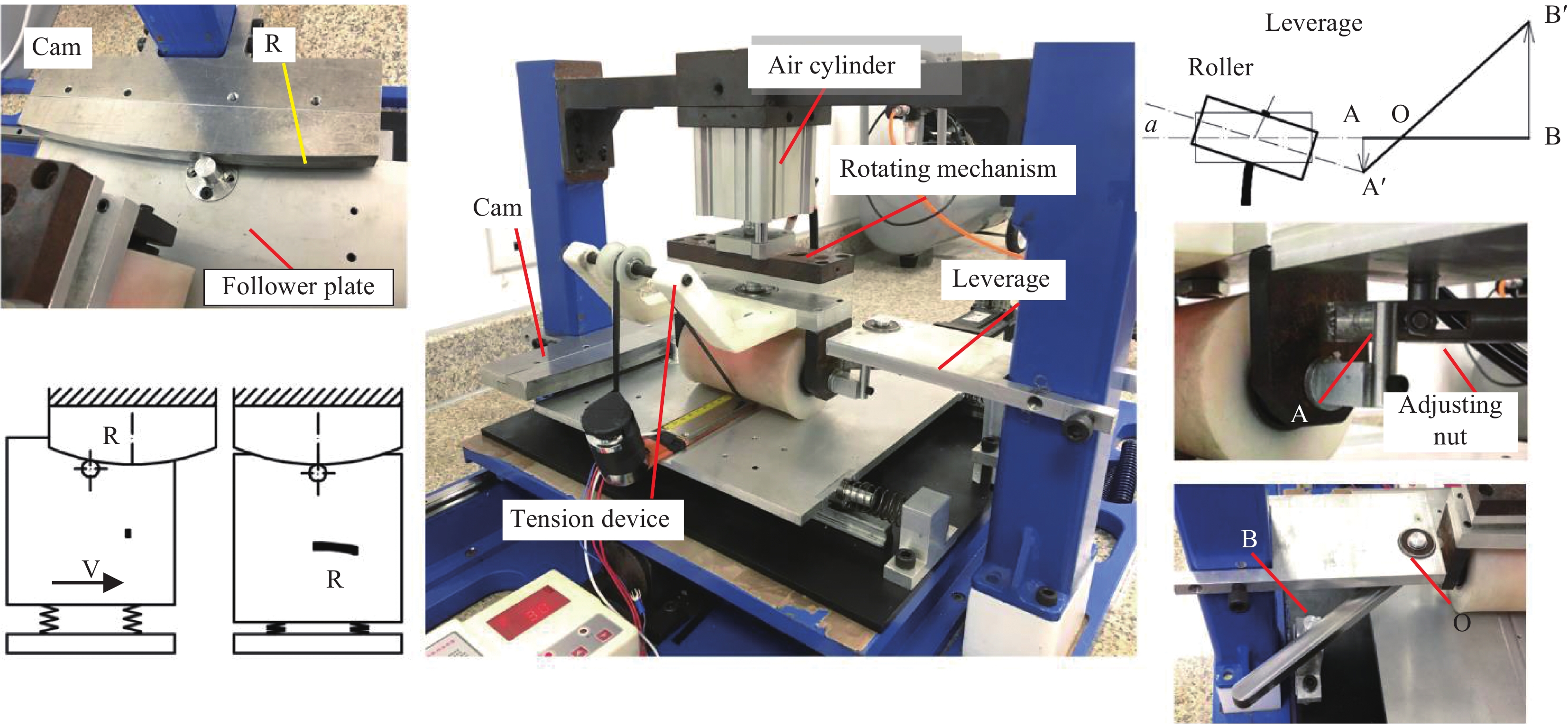

摘要: 为研究铺放工艺参数对复合材料预浸料丝束曲线铺贴质量的影响规律及作用机制,首先自主设计并搭建了可模拟铺丝机曲线铺贴运动的试验平台,进行了变铺放工艺参数与变铺放半径的预浸料丝束曲线铺贴试验。通过测量计算有效贴合长度比、褶皱角度及曲率半径比,并结合变铺放工艺参数的单因素剥离试验对铺放质量进行了表征。结果表明:曲线铺贴质量与预浸料丝束黏结力及弯曲刚度密切相关;随铺放温度、压力和张力增大、铺放速率减小,丝束黏结力上升,曲线铺贴质量提高;铺放温度升高引起的丝束弯曲刚度下降可提升曲线铺贴准确性,但过高的铺放温度会导致丝束黏性下降,曲线铺贴缺陷显著;铺放张力会改变丝束的受力状态,进而影响曲线铺贴路径的准确性;此外,曲线铺贴半径越小,铺放质量对工艺参数的变化越敏感。Abstract: In order to study the effect and mechanism of laying process parameters on the curve trajectory placement quality of prepreg tow, an automated fiber placement simulation test platform was designed and built firstly, and the test of curve trajectory placement was carried out by changing the laying process parameters and laying radius. The laying quality was represented by the measurement and calculation of effective tack width ratio, wrinkle angle and curvature radius ratio and also the results of peeling test of variable laying process parameters. The results show that the curve trajectory placement quality is closely related to the tack and bending stiffness of prepreg tow. With the increase of laying temperature, pressure and tension and the decrease of laying velocity, the tack of prepreg tow increases and the curve trajectory placement quality is improved. Due to the increase of laying temperature, the bending stiffness of the prepreg tow decreases, which can improve the accuracy of laying. However, excessive temperature will cause the tack of the prepreg tow to decrease, make the defect of curve placement obvious. The laying tension will change the stress state of the prepreg tow, thus affecting the accuracy of the laying path. In addition, the smaller the curve placement radius is, the more sensitive the placement quality is to the change of process parameters.

-

Key words:

- automated fiber placement /

- process parameter /

- curve trajectory placement /

- peel test /

- prepreg /

- tack behavior

-

表 1 不同曲率半径下铺放台尺寸设计

Table 1. Size design of placement table under different curve radius

Laying radius/mm 500 750 1 000 1 500 2 000 2 500 LOA/LOB 0.24 0.16 0.12 0.08 0.06 0.048 a/rad 0.190 0.130 0.100 0.067 0.049 0.040 Notes: LOA—Length of OA; LOB—Length of OB; a—Rotation arc of the roller. 表 2 预浸料曲线铺贴工艺参数区间

Table 2. Interval of process parameters for prepreg curve placement

Group T/℃ P/N V/(mm·s−1) F/N Temperature group 20-40 600 20 4 Pressure group 30 200-1 000 20 4 Velocity group 30 600 20-100 4 Tension group 30 600 20 2-10 Orthogonal test group 20-35 200-800 20-80 2-8 Notes: T—Laying temperature; P—Laying pressure; V—Laying velocity; F—Laying tension. 表 3 铺放温度对T700/7901预浸料黏结力及弯曲力的影响

Table 3. Influence of laying temperature on the tack and bending of T700/7901 prepreg

Laying temperature/℃ 20 25 30 35 40 Tack/(N·(20 mm)−1) 1.315 1.578 2.114 1.045 0.625 Tack CV/% 6.48 5.38 4.85 9.29 13.40 Bending/(N·(20 mm)−1) 0.513 0.427 0.374 0.208 0.139 Bending CV/% 8.42 4.41 9.80 8.31 12.20 Note: CV—Coefficient of variation. 表 4 铺放压力对T700/7901预浸料黏结力及弯曲力的影响

Table 4. Influence of laying pressure on the tack and bending force of T700/7901 prepreg

Laying pressure/N 200 400 600 800 1 000 Tack/(N·(20 mm)−1) 1.608 1.725 2.114 2.352 2.514 Tack CV/% 6.48 3.74 4.85 6.52 9.59 Bending/(N·(20 mm)−1) 0.384 0.410 0.374 0.365 0.395 Bending CV/% 5.52 3.58 9.80 6.55 7.11 表 5 铺放张力对T700/7901预浸料黏结力及弯曲刚度的影响

Table 5. Influence of laying tension on the tack and bending of T700/7901 prepreg

Laying tension/N 2 4 6 8 10 Tack /(N·(20 mm)−1) 1.747 2.114 2.294 2.351 2.408 Tack CV/% 7.72 4.85 5.44 8.85 9.58 Bending/(N·(20 mm)−1) 0.380 0.374 0.395 0.368 0.385 Bending CV/% 4.53 9.80 3.48 7.56 5.16 表 6 铺放速率对T700/7901预浸料黏结力及弯曲刚度的影响

Table 6. Influence of laying velocity on the tack and bending stiffness of T700/7901 prepreg

Laying velocity/(mm·s−1) 20 40 60 80 100 Tack/(N·(20 mm)−1) 2.114 1.682 1.435 1.287 1.098 Tack CV/% 4.85 3.57 4.84 5.52 7.94 Bending/(N·(20 mm)−1) 0.374 0.385 0.368 0.378 0.395 Bending CV/% 9.80 3.52 3.44 6.53 8.19 表 7 曲线铺贴正交试验结果

Table 7. Orthogonal test results of curve trajectory placement

Group T/℃ P/N V/(mm·s−1) F/N L θ R’/R 1 20 200 20 2 0.31 9.46 2.91 2 20 400 40 4 0.24 10.59 2.23 3 20 600 60 6 0 12.85 2.58 4 20 800 80 8 0 11.31 3.24 5 25 200 40 6 0.53 9.53 1.33 6 25 400 20 8 0.78 3.71 1.64 7 25 600 80 2 0.31 14.73 1.88 8 25 800 60 4 0.43 10.35 1.15 9 30 200 60 8 0.75 8.54 1.53 10 30 400 80 6 0.42 10.9 1.12 11 30 600 20 4 1 0 1.04 12 30 800 40 2 0.84 4.21 1.20 13 35 200 80 4 0.25 10.84 1.02 14 35 400 60 2 0.61 9.04 1.52 15 35 600 40 8 0.71 5.34 1.67 16 35 800 20 6 0.98 2.38 1.08 表 8 曲线铺贴正交试验结果分析

Table 8. Analysis of curve trajectory placement orthogonal test results

Attribute Statistics T/℃ P/N V/(mm·s−1) F/N L s2 0.27 0.04 0.23 0.038 θ 2.37 1.04 3.52 0.98 R’/R 0.71 0.03 0.08 0.31 L Significance level T>V>P>F θ V>T>P>F R’/R T>F>V>P Note:s2—Statistical variance. -

[1] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322.MA L M, ZHANG J Z, YUE G Q, et al. Application of compo-sites in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). [2] 肖军, 李勇, 李建龙. 自动铺放技术在大型飞机复合材料结构件制造中的应用[J]. 航空制造技术, 2008(1):50-53. doi: 10.3969/j.issn.1671-833X.2008.01.009XIAO J, LI Y, LI J L. Automated placement technology application on large airplane composite component manufacture[J]. Aeronautical Manufacturing Technology,2008(1):50-53(in Chinese). doi: 10.3969/j.issn.1671-833X.2008.01.009 [3] KROLEWSKI S, GUTOWSKI T. Effect of the automation of advanced composite fabrication process on part cost[J]. Cell Biochemistry & Function,1986,25(5):591-596. [4] HYER M W, CHARETTE R F. Use of curvilinear fiber format in composite structure design[J]. AIAA Journal,1991,29(6):1011-1015. doi: 10.2514/3.10697 [5] LOPES C S, GǛRDAL Z, CAMANHO P P. Variable-stiffness composite panels: Buckling and first-ply failure improvements over straight-fibre laminates[J]. Computers and Structures,2008,86:897-907. doi: 10.1016/j.compstruc.2007.04.016 [6] GǛRDAL Z, OLMEDO R. In-plane response of laminates with spatially varying fiber orientations-Variable stiffness concept[J], AIAA Journal, 1993, 31(4): 751-758. [7] 卫宇璇, 张明, 刘佳, 等. 基于自动铺放技术的高精度变刚度复合材料层合板屈曲性能[J]. 复合材料学报, 2020, 37(11):2807-2815.WEI Y X, ZHANG M, LIU J, et al. Buckling performance of high-precision variable stiffness composites laminate based on automatic placement technology[J]. Acta Materiae Compositae Sinica,2020,37(11):2807-2815(in Chinese). [8] RIBEIRO P. Non-linear modes of vibration of thin cylindrical shells in composite laminates with curvilinear fibres[J]. Composite Structures,2015,122:184-197. doi: 10.1016/j.compstruct.2014.11.019 [9] 李俊斐, 王显峰, 肖军. 开孔曲面自动铺放轨迹规划算法研究[J]. 航空学报, 2013, 34(7):1716-1723.LI J F, WANG X F, XIAO J. Research on trajectory planning method of automated tape laying and automated fiber placement for surface with holes[J]. Acta Aeronautica et Astronautica Sinica,2013,34(7):1716-1723(in Chinese). [10] 朱伟东, 张笑, 齐德胜, 等. 变刚度复合材料开孔板拉伸行为数值模拟及试验验证[J]. 复合材料学报, 2018, 35(3):599-606.ZHU W D, ZHANG X, QI D S, et al. Numerical simulation and experiment validation of variable stiffness composite laminates with open holes under unidirectional tension[J]. Acta Materiae Composite Sinica,2018,35(3):599-606(in Chinese). [11] LOPES C S, GURDAL Z, CAMANHO P P. Tailoring for strength of composite steered-fibre panels with cutouts[J]. Composites: Part A,2010,41:1760-1767. doi: 10.1016/j.compositesa.2010.08.011 [12] BAKHSHI N, HOJJATI M. An experimental and simulative study on the defects appeared during tow steering in automated fiber placement[J]. Composites: Part A,2018,113:122-131. doi: 10.1016/j.compositesa.2018.07.031 [13] OROMIEHIE E, PRUSTY B G, COMPSTON P. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques[J]. Compo-sites Structures,2019,224:1-14. [14] SHAMS S S, ELHAJJAR R F. Investigation into the effects of fiber waviness in standard notched composite specimens[J]. CEAS Aeronautical Journal,2015,6(4):541-555. doi: 10.1007/s13272-015-0161-4 [15] KASHTALYAN M. Application of the boundary shape perturbation method to stress analysis of laminated compo-sites with ply waviness[J]. Composites Part A: Applied Science and Manufacturing,2005,36:137-143. doi: 10.1016/S1359-835X(04)00154-X [16] MUKHOPADHYAY S, JONES M I, HALLETT S R. Compressive failure of laminates containing an embedded wrinkle: Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing,2015,73:132-142. [17] LUKASZEWICZ D H, WARDC, POTTER K D. The engineering aspects of automated prepreg layup: History, present and future[J]. Composites Part B: Engineering,2012,43(3):997-1009. doi: 10.1016/j.compositesb.2011.12.003 [18] RAJAN S, SUTTON M A, WEHBE R, et al. Experimental investigation of prepreg slit tape wrinkling during automated fiber placement process using stereoDIC[J]. Composites Part B: Engineering,2019,160:546-557. doi: 10.1016/j.compositesb.2018.12.017 [19] 黄新杰, 肖军, 赵聪, 等. 工艺参数对平面曲线铺放过程丝束铺放效果的影响[J]. 玻璃纤维, 2016, 1:13-18. doi: 10.3969/j.issn.1005-6262.2016.02.004HUANG X J, XIAO J, ZHAO C, et al. The influence of process parameters on result of towpreg during the curve trajectory placement on the plane[J]. Fiber glass,2016,1:13-18(in Chinese). doi: 10.3969/j.issn.1005-6262.2016.02.004 [20] BUDELMANN D, DETAMPEL H, SCHMIDT C, et al. Interaction of process parameters and material properties with regard to prepreg tack in automated lay-up and draping processes[J]. Composites Part A: Applied Science and Manufacturing,2019,117:308-316. doi: 10.1016/j.compositesa.2018.12.001 [21] CROSSLEY R J, SCHUBEL P J, WARRIOR N A. The experimental determination of prepreg tack and dynamic stiffness[J]. Composites Part A: Applied Science and Manufacturing,2012,43(3):423-434. doi: 10.1016/j.compositesa.2011.10.014 [22] 陆楠楠, 肖军, 齐俊伟, 等. 面向自动铺放的预浸料动态黏性实验[J]. 航空学报, 2014, 35(1):317-322.LU N N, XIAO J, QI J W, et al. Experimental research on prepreg dynamic tack based on automated placement process[J]. Acta Aeronautica et Astronautica Sinica,2014,35(1):317-322(in Chinese). [23] 方宜武, 王显峰, 顾善群, 等. 自动铺丝过程中预浸料的侧向弯曲[J]. 材料工程, 2015, 43(4):47-52. doi: 10.11868/j.issn.1001-4381.2015.04.009FANG Y W, WANG X F, GU S Q, et al. Lateral bending of prepreg during automated fiber placement[J]. Journal of Materials Engineering,2015,43(4):47-52(in Chinese). doi: 10.11868/j.issn.1001-4381.2015.04.009 [24] 谢林杉, 陈浩然, 王浩宇. 面向复杂回转体T700级碳纤维/双马树脂材料铺放适应性[J]. 航空学报, 2020, 41(4):423279.XIE L S, CHEN H R, WANG H Y. Placement suitability of T700 carbon fiber/bismaleimide resin prepreg for complex rotary bodies in AFP[J]. Acta Aeronautica et Astronautica Sinica,2020,41(4):423279(in Chinese). [25] 张洋, 钟翔屿, 包建文. 先进树脂基复合材料自动丝束铺放技术研究现状及发展方向[J]. 航空制造技术, 2013, 443(23-24):131-140.ZHANG Y, ZHONG X Y, BAO J W. Research status and future trend of automated fiber placement technology for advanced polymer matrix composites[J]. Aeronautical Manufacturing Technology,2013,443(23-24):131-140(in Chinese). [26] ZHANG P, SUN R L, ZHAO X Y, et al. Placement suitability criteria of composite tape for mould surface in automated tape placement[J]. Chinese Journal of Aeronautics,2015,28(5):1574-1581. doi: 10.1016/j.cja.2015.06.002 [27] 周煦洁, 肖军, 李勇, 等. 面向高速铺放预浸料层间粘结性能研究[J]. 航空科学技术, 2016, 27(11):12-18. doi: 10.3969/j.issn.1007-5453.2016.11.003ZHOU X J, XIAO J, LI Y, et al. Experimental research on prepreg tack between layers based on highvelocity automated placement process[J]. Aeronautical Science & Technology,2016,27(11):12-18(in Chinese). doi: 10.3969/j.issn.1007-5453.2016.11.003 [28] 黄文宗, 孙容磊, 张鹏, 等. 预浸料的铺放适宜性评价(二)铺覆性篇[J]. 玻璃钢/复合材料, 2013, 8(8):3-7.HUANG W Z, SUN R L, ZHANG P, et al. Assessment for placement suitability of prepreg-part of drape[J]. Fiber Reinforced Plastic/Composite,2013,8(8):3-7(in Chinese). [29] 舒展, 彭啸, 李发飞, 等. 基于探针试验的预浸料黏性内聚力模型[J]. 航空学报, 2018, 39(2):421416.SHU Z, PENG X, LI F F, et al. Cohesive zone model for prepreg tack based on probe test[J]. Acta Aeronautica et Astronautica Sinica,2018,39(2):421416(in Chinese). [30] 赵聪, 肖军, 王显峰, 等. 丝束张力对自动铺丝成型工艺的影响[J]. 航空学报, 2016, 37(4):1384-1392.ZHAO C, XIAO J, WANG X F, et al. Effect of tows tension on automated fiber placement process[J]. Acta Aeronautica et Astronautica Sinica,2016,37(4):1384-1392(in Chinese). -

下载:

下载: