Preparation and properties of flame retardant rigid polyurethane foam composites based on microencapsulated ammonium polyphosphate and microencapsulated expanded graphite

-

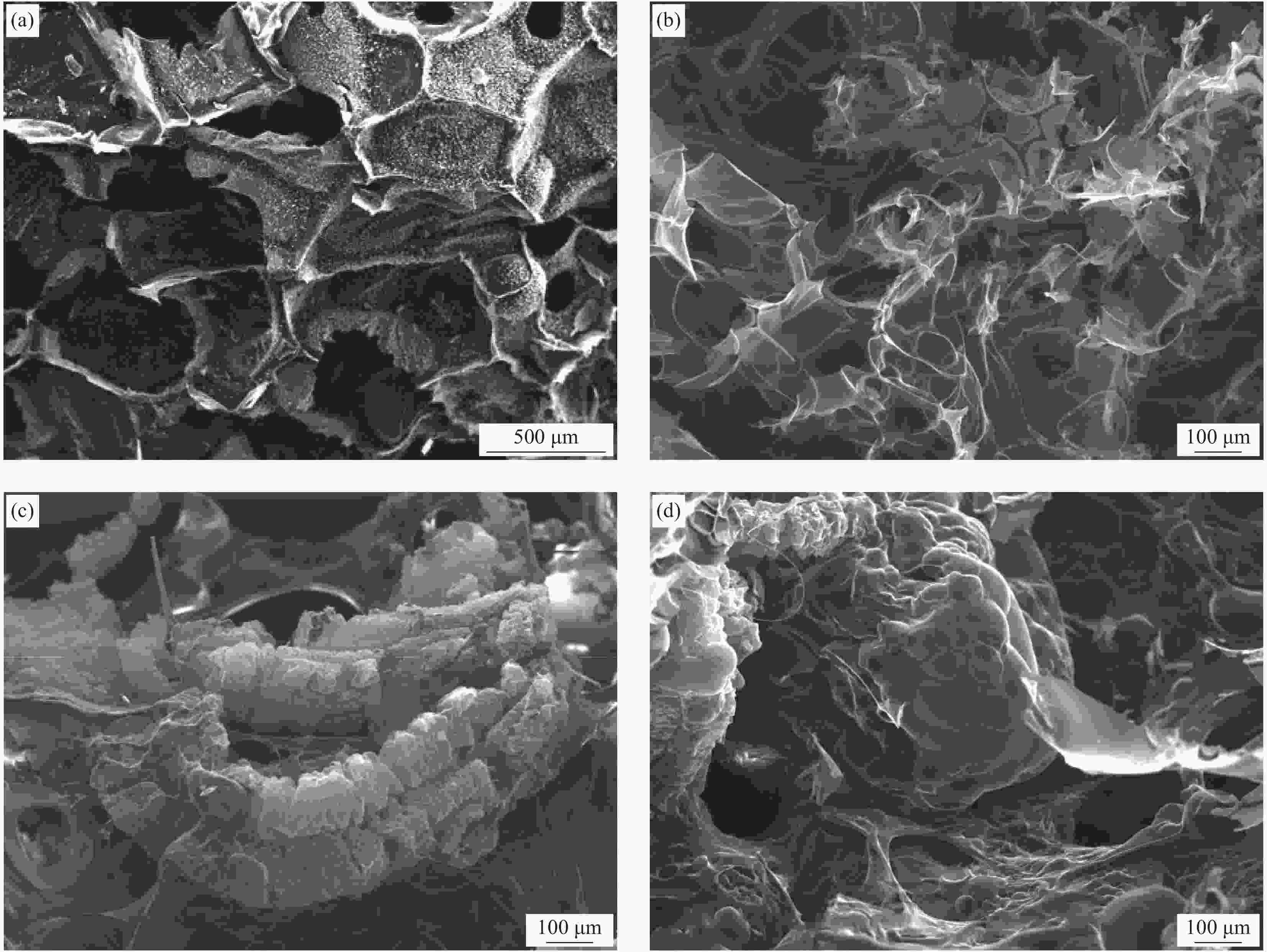

摘要: 采用原位聚合法,以聚氨酯为壳材,制备微胶囊化聚磷酸铵(PUAPP)和微胶囊化膨胀石墨(PUEG)。采用XPS、FTIR、TG和SEM分别对PUAPP和PUEG进行表征,结果表明,聚氨酯有效包覆在聚磷酸铵和膨胀石墨表面,成功制备了PUAPP和PUEG。在此基础上,采用一步法全水发泡工艺将PUAPP和PUEG引入到聚氨酯硬泡(RPUF)中,制备出一系列阻燃RPUF复合材料。采用极限氧指数(LOI)、垂直燃烧(UL-94)、TG、万能试验机、导热及密度测试研究了PUAPP/RPUF、PUEG/RPUF及PUAPP-PUEG/RPUF复合材料的阻燃性能、力学性能、保温性能及热稳定性。研究表明,微胶囊化阻燃剂的加入可以提高RPUF复合材料的高温稳定性,PUEG/RPUF、PUAPP/RPUF和PUAPP-PUEG/RPUF复合材料在700℃的残炭率从1.2wt%分别提高至6.9wt%、11.2wt%和10.7wt%。阻燃测试表明,PUAPP和PUEG可以有效提高RPUF复合材料的阻燃性能,当加入10.4wt% PUAPP时,PUAPP/RPUF复合材料的LOI提高到22.3vol%,UL-94等级为V-0级;当加入10.4wt% PUEG时,PUEG/RPUF复合材料的LOI达到25.3vol%,UL-94等级为V-0级;PUAPP-PUEG/RPUF复合材料的LOI达到24.3vol%,UL-94等级为V-0级。SEM和拉曼测试表明,PUAPP和PUEG可以提高RPUF复合材料的炭渣石墨化程度,使炭渣的致密性更强。Abstract: Microencapsulated ammonium polyphosphate (PUAPP) and microencapsulated expanded graphite (PUEG) were prepared by in situ polymerization with polyurethane as shell material. XPS, FTIR, TG and SEM were used to characterize PUAPP and PUEG. The results show that polyurethane is effectively coated on the surface of ammonium polyphosphate and expanded graphite, and PUAPP and PUEG are successfully fabricated. On this basis, a series of flame-retardant rigid polyurethane foam (RPUF) composites were prepared with PUAPP and PUEG loading by one-step water-blown method. The flame retardancy, mechanical properties, thermal insulation and thermal stability of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF composites were investigated by limiting oxygen index (LOI), underwriters laboratories vertical burning test (UL-94), TG, universal testing machine, heat conduction and density test. The results show that the thermal stability at high temperature of RPUF composites can be improved by the addition of PUAPP and PUEG. The charresidues of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF at 700℃ are increased from 1.2wt% to 6.9wt%, 11.2wt% and 10.7wt%, respectively. Flame retardant tests show that the microencapsulated flame retardant can effectively improve flame retardancy of RPUF composites. When 10.4wt% PUAPP is added, the LOI of the PUAPP/RPUF composite is increased to 22.3vol% with V-0 rating in UL-94 test; when 10.4 wt% PUEG is added, the LOI of the PUAPP/RPUF composite is increased to 25.3vol% with UL-94 V-0 rating; PUAPP-PUEG/RPUF composite presents LOI of 24.3vol% with UL-94 V-0 rating. SEM and Raman tests indicate that PUAPP and PUEG can increase graphitization degree of char residues for RPUF composites with enhanced compactness of the char residues.

-

表 1 硬质聚氨酯泡沫(RPUF)、微胶囊化聚磷酸铵(PUAPP)/RPUF、微胶囊化膨胀石墨(PUEG)/RPUF和PUAPP-PUEG/RPUF复合材料配比

Table 1. Formulation of rigid polyurethane foam (RPUF), microencapsulated ammonium polyphosphate (PUAPP)/RPUF, microencapsulated expanded graphite (PUEG)/RPUF and PUAPP-PUEG/RPUF composites

Sample LY-4110/g PM-200/g LC/g AK-8805/g A33/g TEOA/g Water/g PUEG/g PUEG/wt% PUAPP/g PUAPP/wt% RPUF 100 150 0.5 2 1 3 2 0 0 0 0 PUEG/RPUF 100 150 0.5 2 1 3 2 30 10.4 0 0 PUAPP/RPUF 100 150 0.5 2 1 3 2 0 0 30 10.4 PUAPP-PUEG/

RPUF100 150 0.5 2 1 3 2 10 3.5 20 6.9 Notes: LY-4110—Polyether polyol; PM-200—Polyarylpolymethyleneisocyanate; LC—Dibutyltindilaurate; AK-8805—Silicone surfactant; A33—Triethylenediamine; TEOA—Triethanolamine. 表 2 空气条件下APP、PUAPP、EG和PUEG的TGA数据

Table 2. TGA data of APP, PUAPP, EG and PUEG under air conditions

Sample T−5%/℃ Tmax1/℃ Tmax2/℃ Residues at 700℃/wt% APP 331 357 606 10.4 EG 204 215 — 24.8 RPUF 271 313 569 1.2 PUAPP 285 299 568 10.0 PUEG 203 216 — 21.8 Notes: T−5%—Onset degradation temperature; Tmax1, Tmax2—Maximum decomposition temperature in the first and second stage, respectively. 表 3 空气条件下RPUF、PUAPP/RPUF、PUEG/RPUF和PUAPP-PUEG/RPUF的TGA数据

Table 3. TGA data of RPUF, PUAPP/RPUF, PUEG/RPUF and PUAPP-PUEG/RPUF under air conditions

Sample T−5%/℃ Tmax1/℃ Tmax2/℃ Residues at 700℃/wt% RPUF 271 312 569 1.2 PUEG/RPUF 249 319 572 6.9 PUAPP/RPUF 264 315 565 11.2 PUAPP-PUEG/RPUF 262 308 566 10.7 表 4 RPUF、PUAPP/RPUF、PUEG/RPUF和PUAPP-PUEG/RPUF复合材料的密度、导热系数和压缩强度

Table 4. Density, thermal conductivity and compressive strength of RPUF, PUAPP/RPUF, PUEG/RPUF, PUAPP-PUEG/RPUF composites

Sample RPUF PUEG/RPUF PUAPP/RPUF PUAPP-PUEG/RPUF ρ/(kg·m−3) 64.16±0.91 57.92±0.23 59.92±5.77 55.84±1.36 λ/(W(m·K)−1) 0.0390±0.00038 0.0394±0.000436 0.0389±0.000493 0.0395±0.00029 Pressure/MPa 0.325±0.0075 0.276±0.0151 0.286±0.0205 0.271±0.0411 Notes: ρ—Density; λ—Thermal conductivity; Pressure—Compressive strength. -

[1] WANG X, LI J Q, LIN J L, et al. Flame retardant behavior of ternary synergistic systems in rigid polyurethane foams[J]. Polymers,2019,11(2):207. doi: 10.3390/polym11020207 [2] TANG G, LIU X, ZHOU L, et al. Steel slag waste combined with melamine pyrophosphate as a flame retardant for rigid polyurethane foams[J]. Advanced Powder Technology,2020,31(1):279-286. doi: 10.1016/j.apt.2019.10.020 [3] 宋艳,许亮,李锦春,等. 新型磷氮型阻燃剂的制备及其阻燃聚氨酯泡沫塑料[J]. 复合材料学报, 2016, 33(11):2461-2467.SONG Y, XU L, LI J C, et al. Synthesis of novel flame retardant containing phosphorus and nitrogen and its application in retardant polyurethane foam plastic[J]. Acta Materiae Compositae Sinica,2016,33(11):2461-2467(in Chinese). [4] TANG G, ZHOU L, ZHANG P, et al. Effect of aluminum diethylphosphinate on flame retardant and thermal properties of rigid polyurethane foam composites[J]. Journal of Thermal Analysis and Calorimetry,2020,140(2):625-636. doi: 10.1007/s10973-019-08897-z [5] LIU L, WANG Z Z, ZHU M H. Flame retardant, mechanical and thermal insulating properties of rigid polyurethane foam modified by nano zirconium amino-tris-(methylenephosphonate) and expandable graphite[J]. Polymer Degradation and Stability,2019,170:108997. [6] YUNG K C, ZHU B L, YUE T M, et al. Preparation and properties of hollow glass microsphere-filled epoxy-matrix composites[J]. Composites Science and Technology,2009,69(2):260-264. doi: 10.1016/j.compscitech.2008.10.014 [7] 徐文总,李冲冲,汪贵松,等. 不同阴离子插层的ZnMgAl层状双氢氧化物对聚氨酯弹性体阻燃抑烟性能的影响[J]. 复合材料学报, 2017, 34(8):1683-1692.XU W Z, LI C C, WANG G S, et al. Effects of ZnMgAl layered double hydroxide with different interlayer anions on flame retardant and smoke suppressant of polyurethane elastomer[J]. Acta Materiae Compositae Sinica,2017,34(8):1683-1692(in Chinese). [8] TANG G, LIU X L, YANG Y D, et al. Phosphorus-containing silanemodified steel slag waste to reduce fire hazards of rigid polyurethane foams[J]. Advanced Powder Technology, 2020, 31(4): 1420-1430 [9] CHEN Y J, LI L S, WANG W, et al. Preparation and characterization of surface-modified ammonium polyphosphate and its effect on the flame retardancy of rigid polyurethane foam[J]. Journal of Applied Polymer Science,2017,134(40):45369. [10] 姜浩浩,刘新亮,邹勇,等. 硬质聚氨酯泡沫/聚磷酸铵复合材料的制备及阻燃性能研究[J]. 塑料工业, 2019, 47(1):89-93. doi: 10.3969/j.issn.1005-5770.2019.01.019JIANG H H, LIU X L, ZOU Y, et al. Preparation and flame retardancy of rigid polyurethane foam/ammonium polyphosphate composites[J]. China Plastics Industry,2019,47(1):89-93(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.01.019 [11] XU W Z, LIU L, WANG S Q, et al. Synergistic effect of expandable graphite and aluminum hypophosphite on flame-retardant properties of rigid polyurethane foam[J]. Journal of Applied Polymer Science,2015,132(47):42842. [12] DING H Y, HUANG K, LI S H, et al. Flame retardancy and thermal degradation of halogen-free flame-retardant biobased polyurethane composites based on ammonium polyphosphate and aluminium hypophosphite[J]. Polymer Testing,2017,62:325-334. doi: 10.1016/j.polymertesting.2017.07.017 [13] CHEN X L, JIANG Y F, JIAO C M. Synergistic effects between hollow glass microsphere and ammonium polyphosphate on flame-retardant thermoplastic polyurethane[J]. Therm Anal Calorim,2014,117:857-66. doi: 10.1007/s10973-014-3831-2 [14] NI J, SONG L, HU Y, et al. Preparation and characterization of microencapsulated ammonium polyphosphate with polyurethane shell by in situ polymerization and its flame retardance in polyurethane[J]. Polymers for Advanced Technologies,2009,20(12):999-1005. doi: 10.1002/pat.1354 [15] SHEN M Y, CHEN W J, KUAN C F, et al. Preparation, characterization of microencapsulated ammonium polyphosphate and its flame retardancy in polyurethane composites[J]. Materials Chemistry and Physics,2016,173:205-212. doi: 10.1016/j.matchemphys.2016.02.006 [16] 中国国家标准化管理委员会. 硬质泡沫塑料压缩性能的测定: GB/T 8813—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Rigid cellular plastics: Determination of compression properties: GB/T 8813—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [17] 中国国家标准化管理委员会. 非金属固体材料导热系数的测定热线法: GB/T 10297—2015[S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People’s Republic of China. Test method for thermal conductivity of nonmetal solid materials: Hot-wire method: GB/T 10297—2015[S]. Beijing: China Standards Press, 2016(in Chinese). [18] 中国国家标准化管理委员会. 塑料燃烧性能的测定水平法和垂直法: GB/T 2408—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Plastics: Determination of burning characteristics: Horizontal and vertical test: GB/T 2408—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [19] American Society for Testing Material International. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863—19[S]. West Conshohocken: ASTM International, 2019. [20] LIU Z T, DAI M Q, HU Q H, et al. Effect of microencapsulated ammonium polyphosphate on the durability and fire resistance of waterborne intumescent fire-retardant coatings[J]. Journal of Coatings Technology & Research,2019,16(1):135-145. [21] WANG F, ZHANG P, MOU Y, et al. Synthesis of the polyethylene glycol solid-solid phase change materials with a functionalized graphene oxide for thermal energy storage[J]. Polymer Testing,2017,63:494-504. doi: 10.1016/j.polymertesting.2017.09.005 [22] ZHOU S, LU H, SONG L, et al. Microencapsulated ammonium polyphosphate with polyurethane shell: Application to flame retarded polypropylene/ethylene-propylene dieneterpolymer blends[J]. Journal of Macromolecular Science Part A,2009,46(2):136-144. [23] ZHENG Z H, YAN J T, SUN H M, et al. Preparation and characterization of microencapsulated ammonium polyphosphate and its synergistic flame-retarded polyurethane rigid foams with expandable graphite[J]. Polymer International,2014,63(1):84-92. doi: 10.1002/pi.4477 [24] ZHENG X R, WANG G J, XU W. Roles of organically-modified montmorillonite and phosphorous flame retardant during the combustion of rigid polyurethane foam[J]. Polymer Degradation and Stability,2014,101:32-39. doi: 10.1016/j.polymdegradstab.2014.01.015 [25] MODESTIM, LORENZETTI A, BESCO S, et al. Synergism between flame retardant and modified layered silicate on thermal stability and fire behaviour of polyurethane nanocomposite foams[J]. Polymer Degradation and Stability,2008,93(12):2166-2171. doi: 10.1016/j.polymdegradstab.2008.08.005 [26] WANG S, GAO R, ZHOU K. The influence of cerium dioxide functionalized reduced graphene oxide on reducing fire hazards of thermoplastic polyurethane nanocomposites[J]. Journal of Colloid and Interface Science,2019,536:127-134. doi: 10.1016/j.jcis.2018.10.052 -

下载:

下载: