Lamb wavefield reconstruction and damage imaging of composite plate based on compressed sensing

-

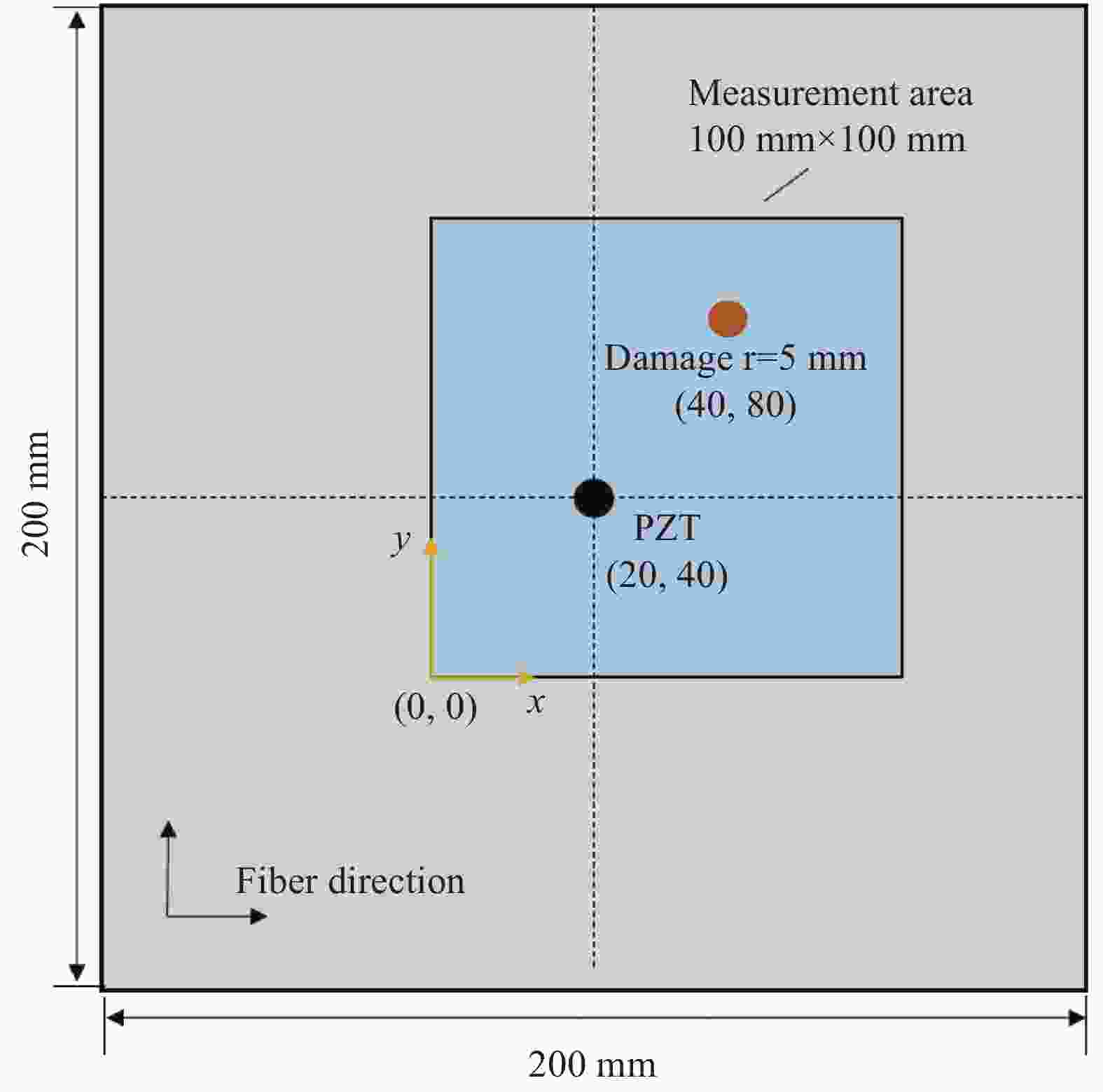

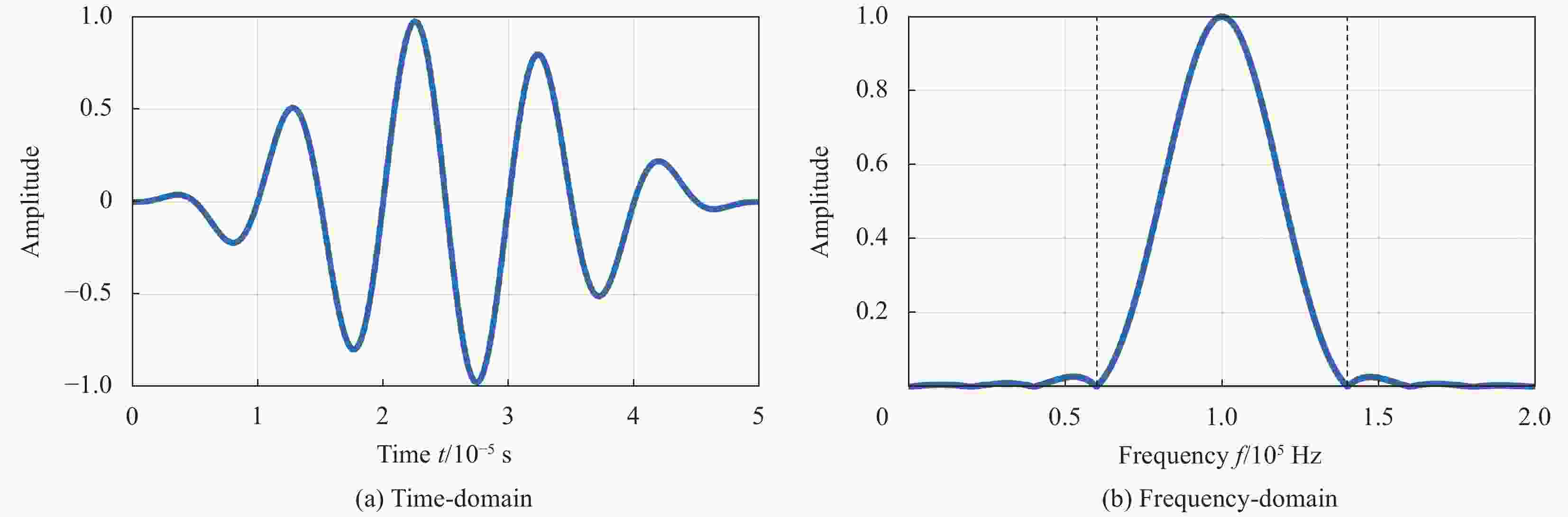

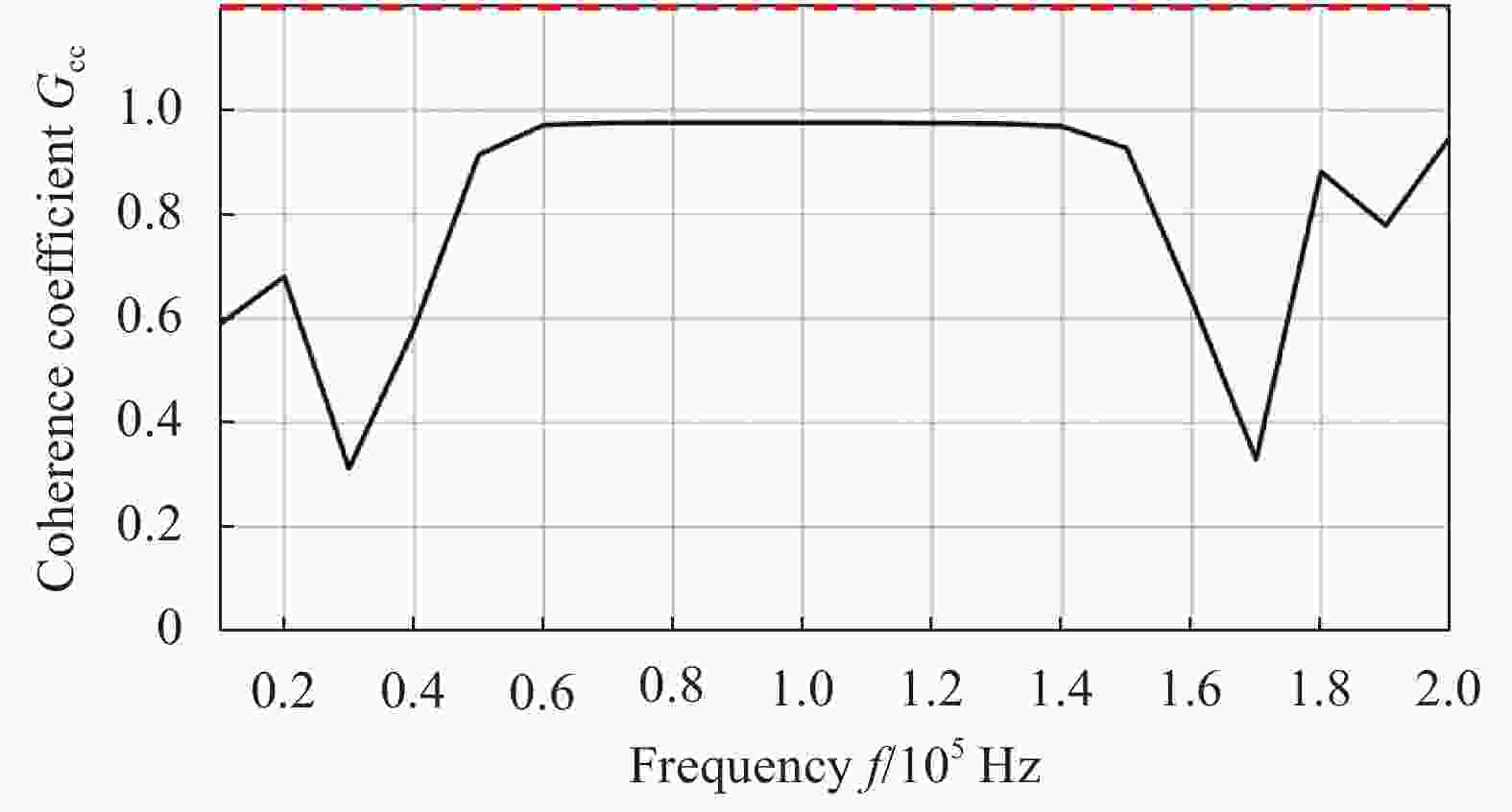

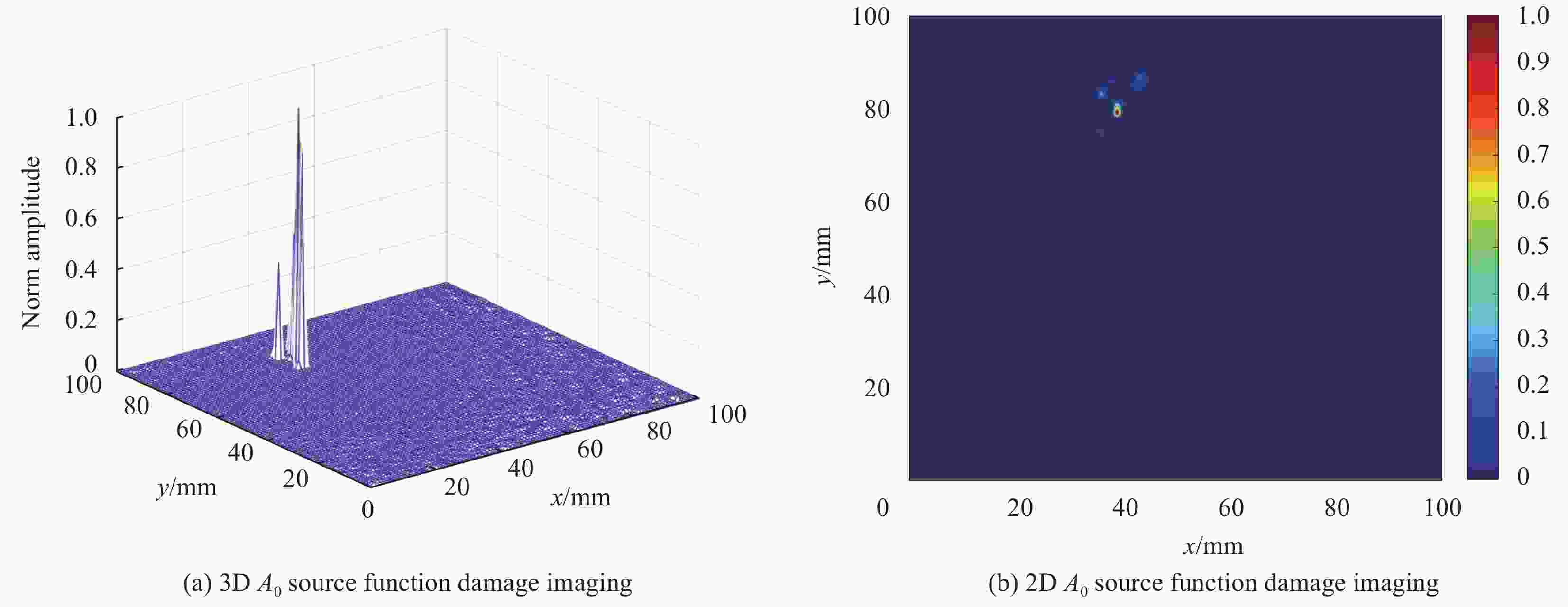

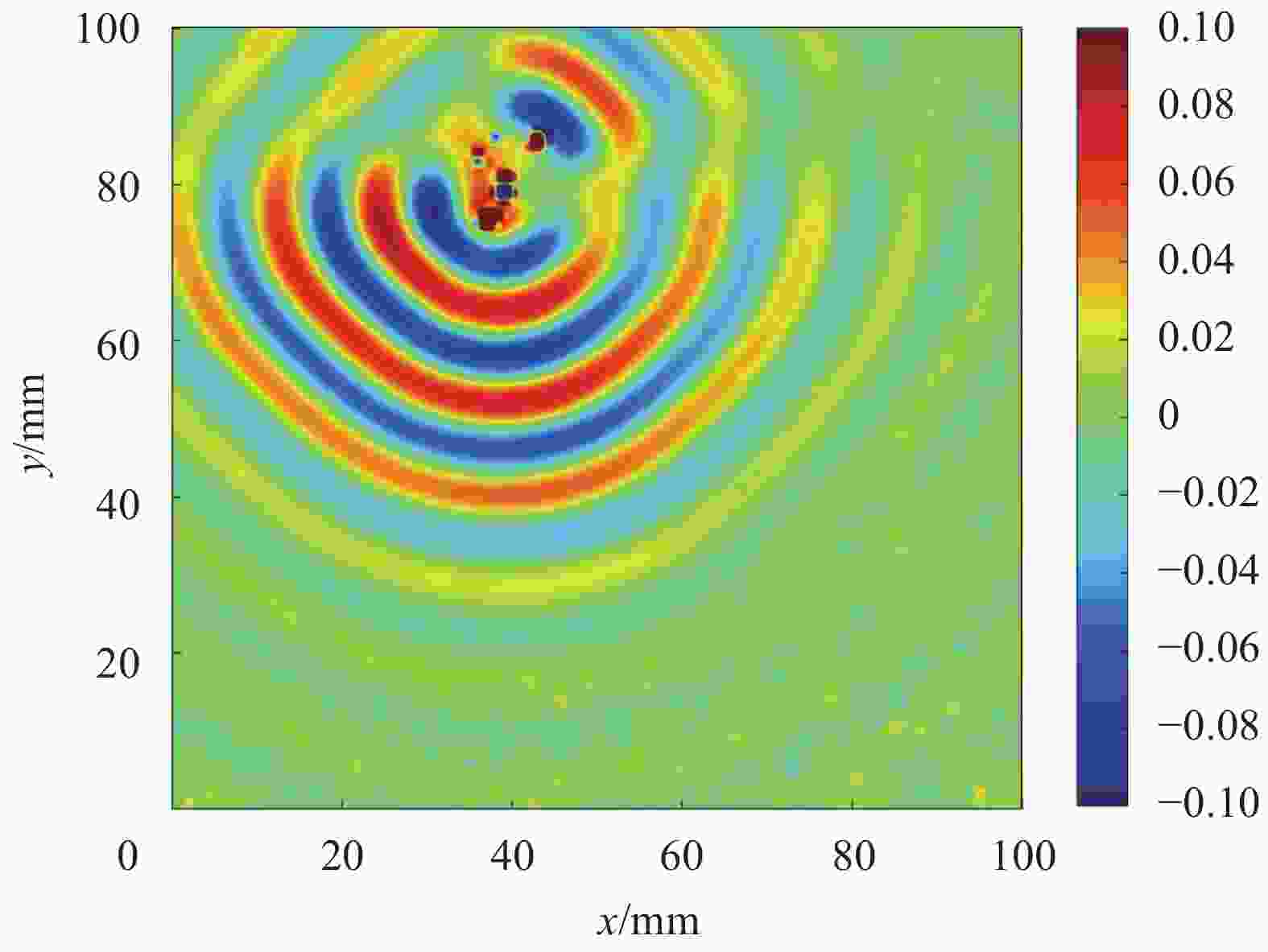

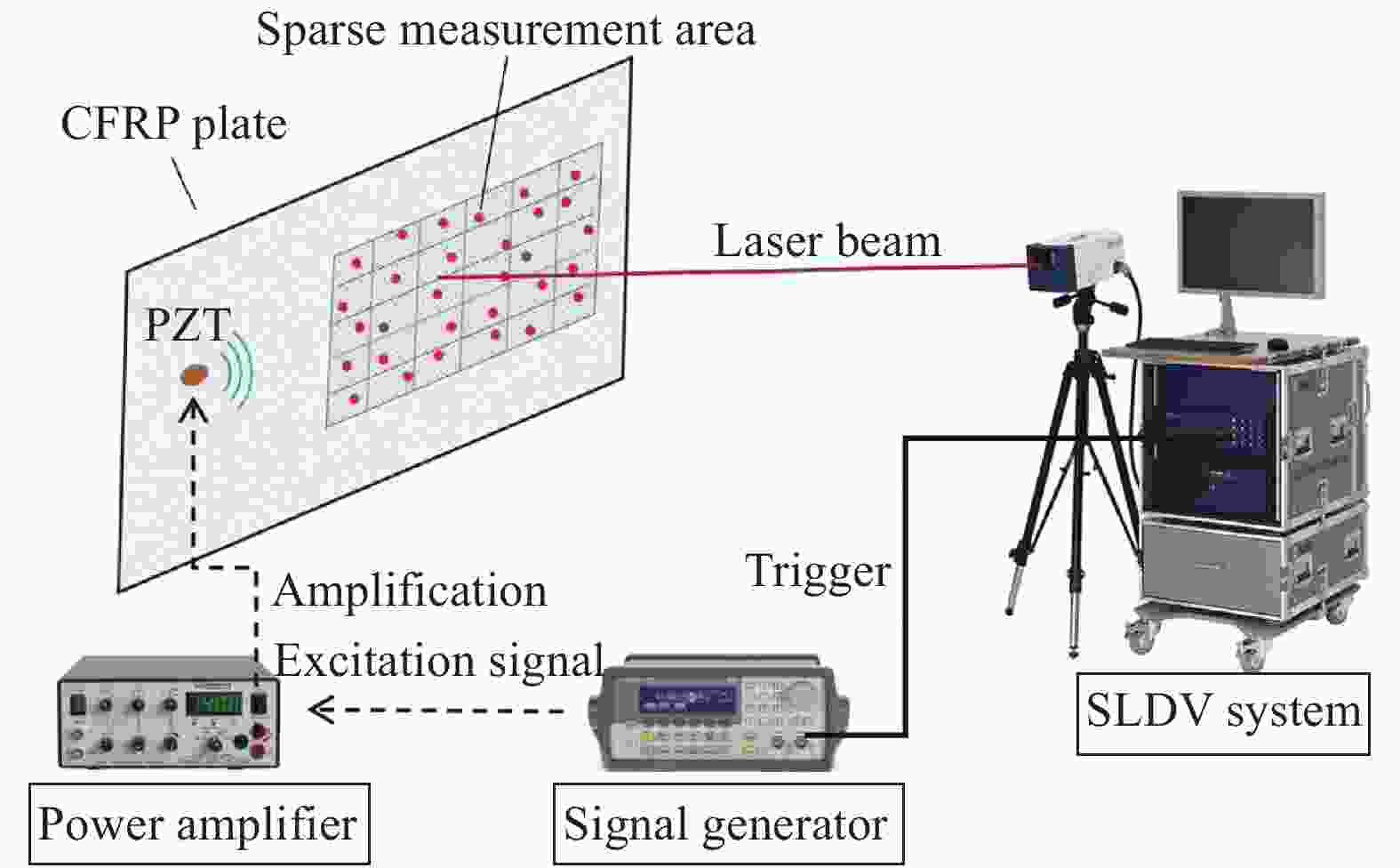

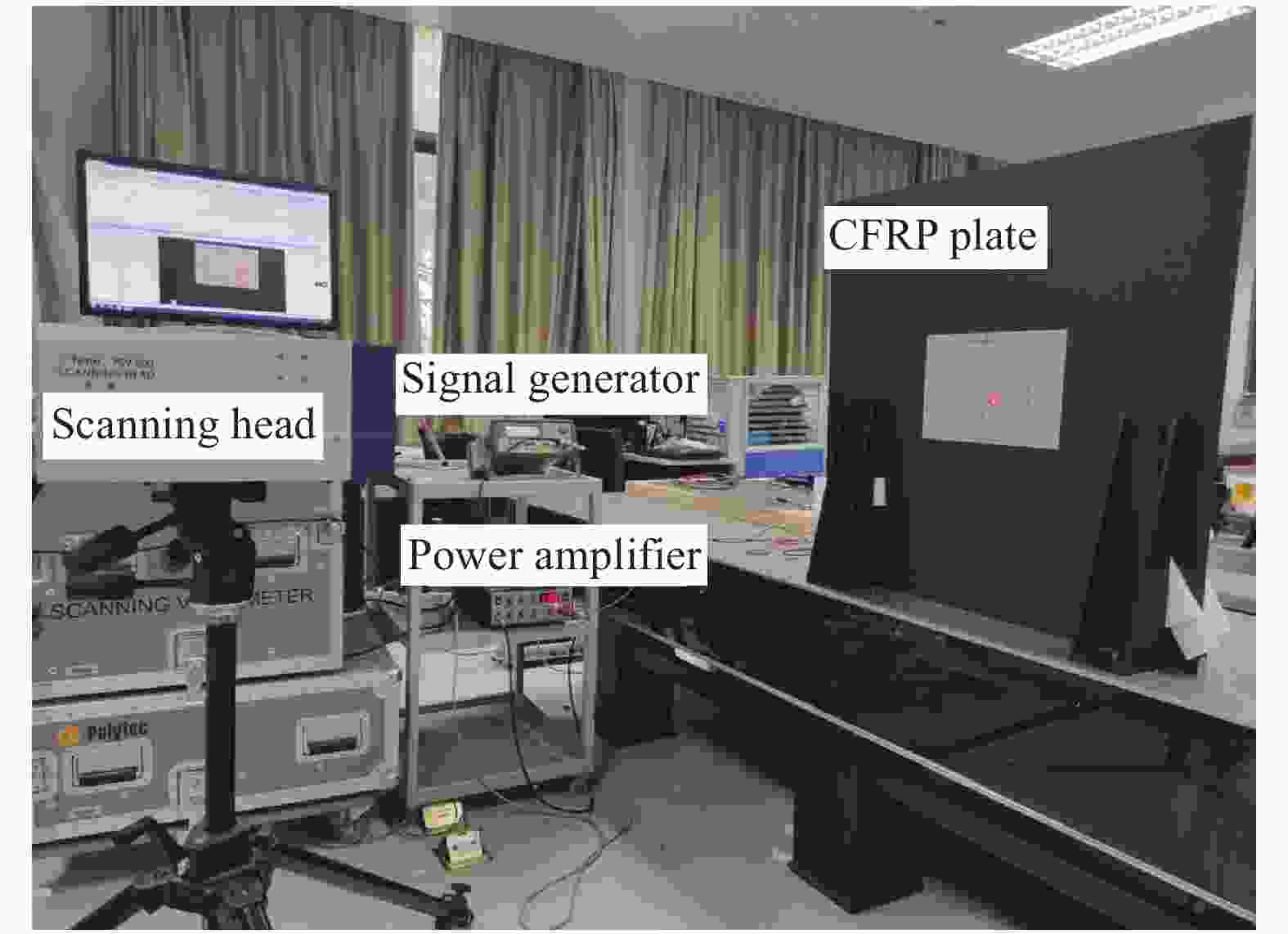

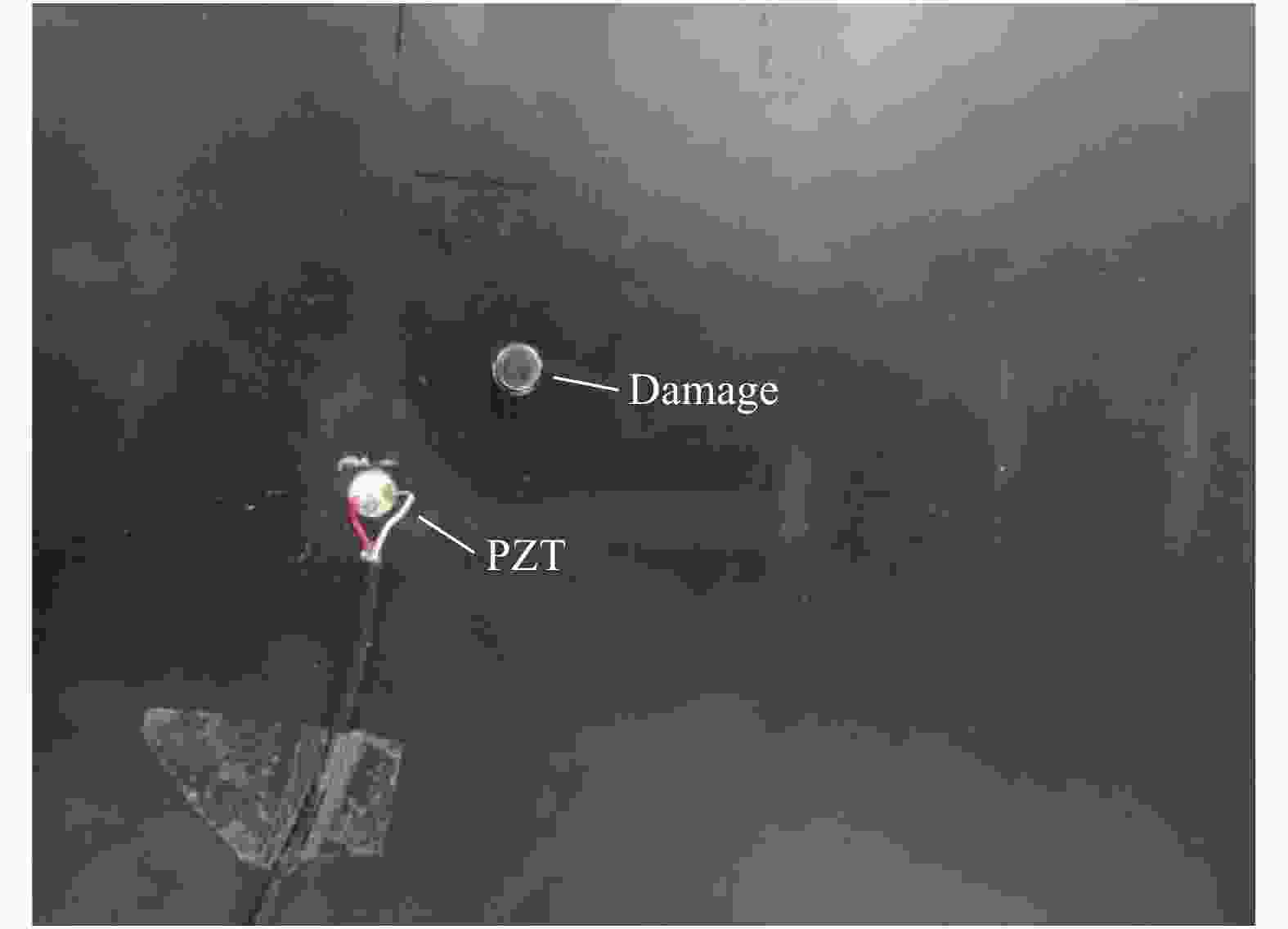

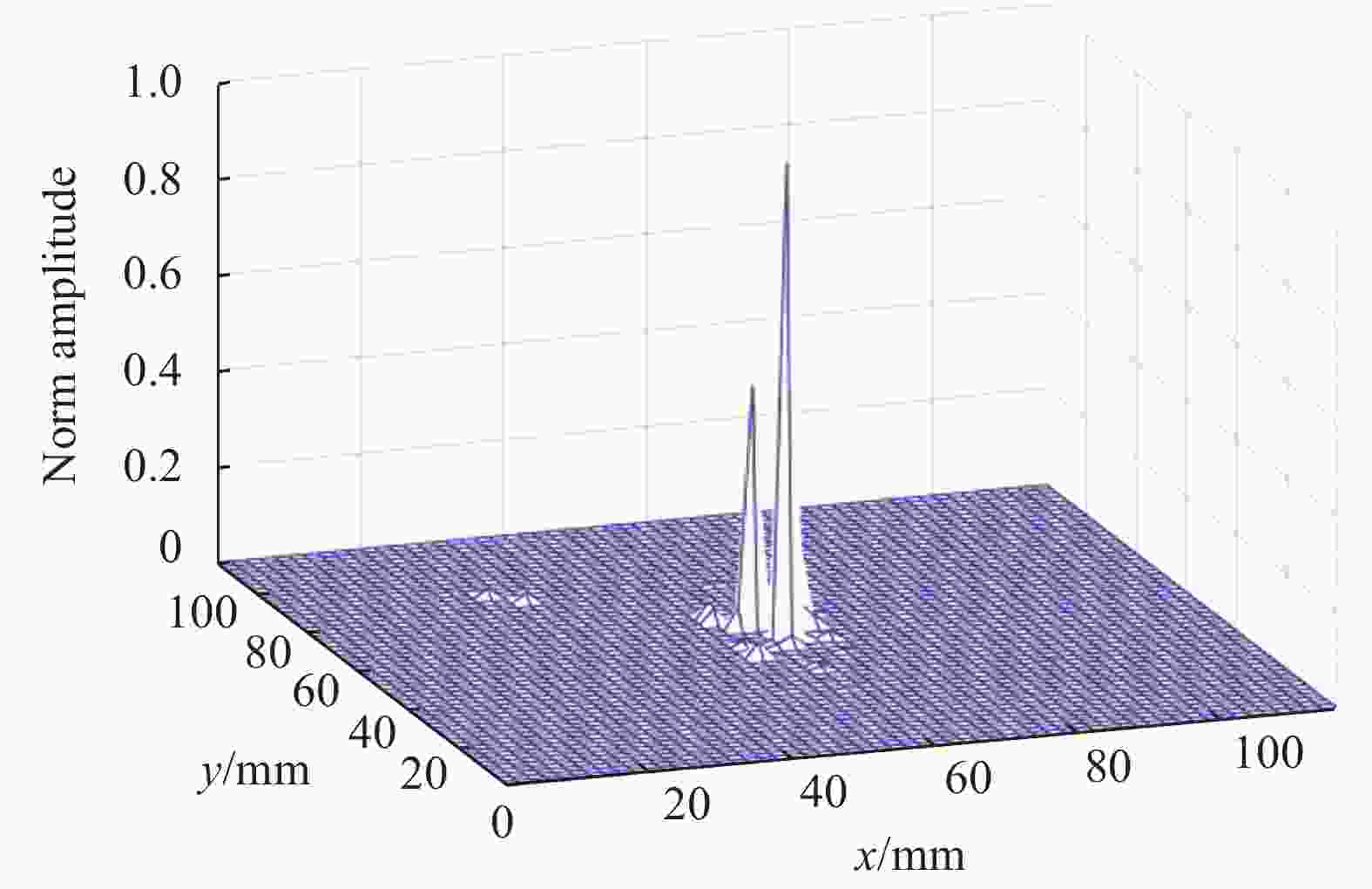

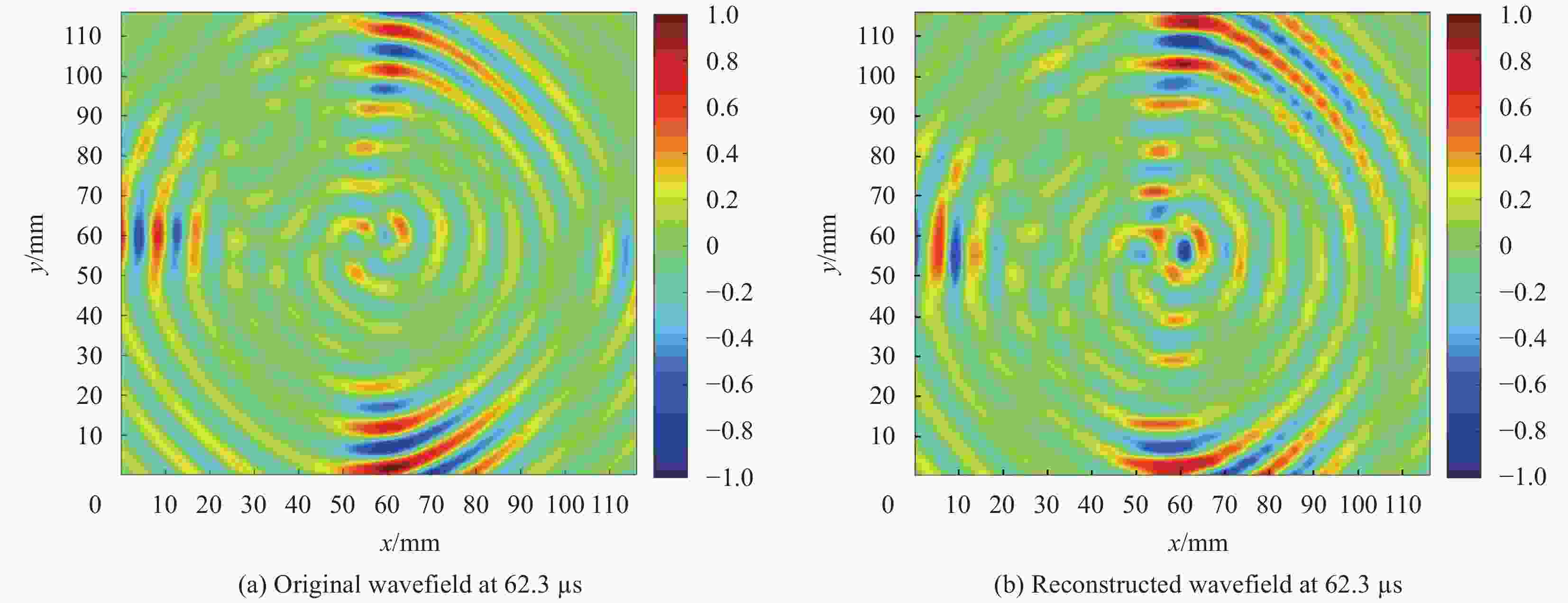

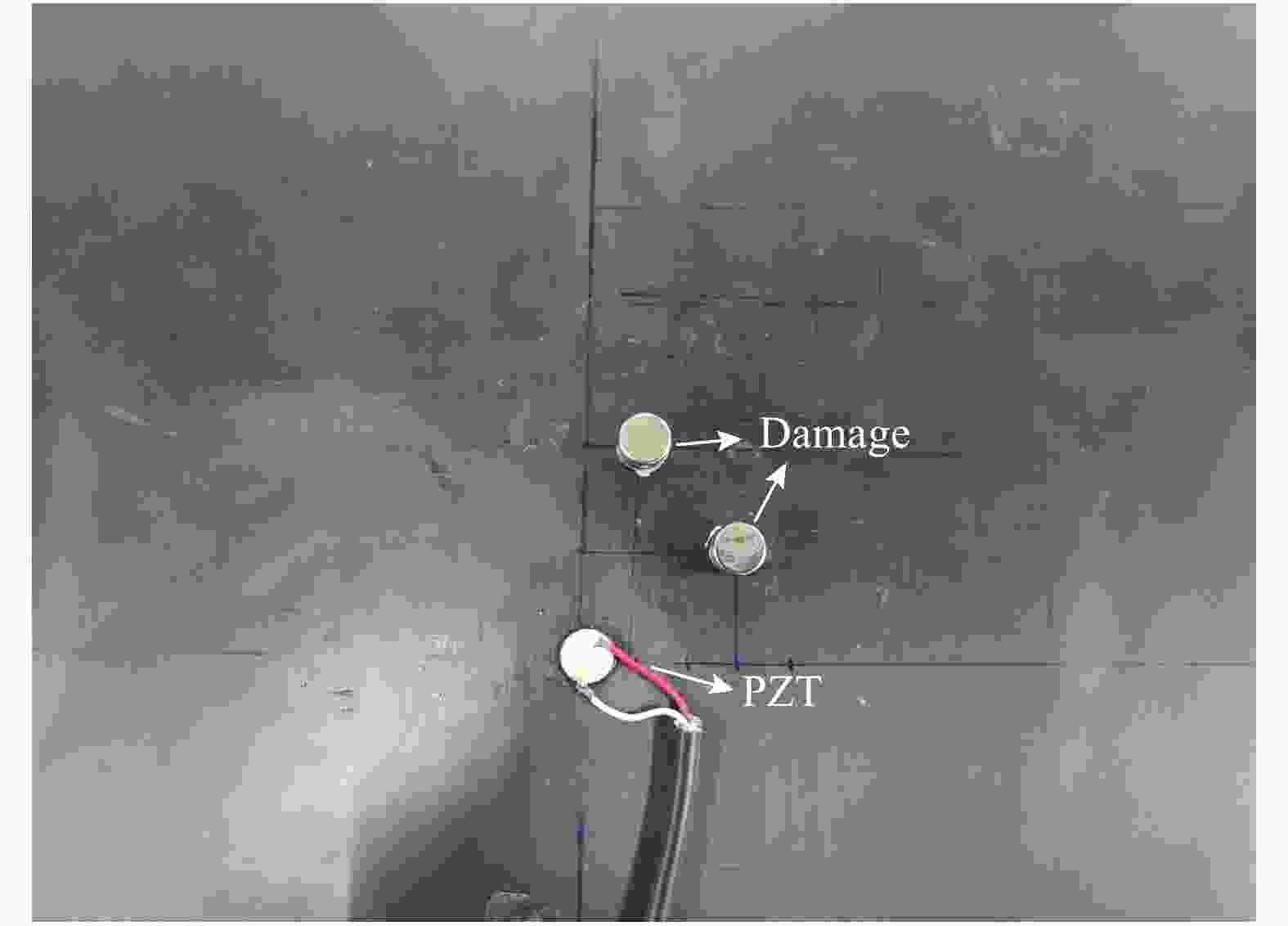

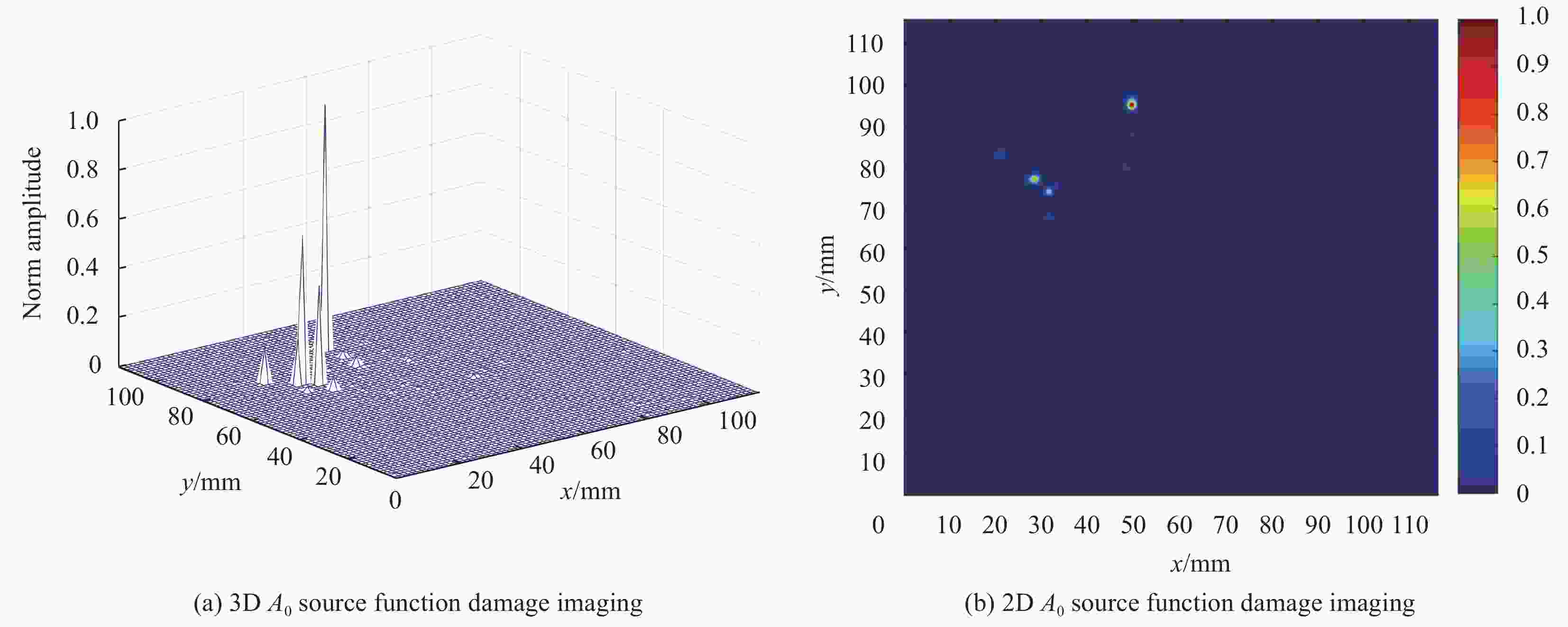

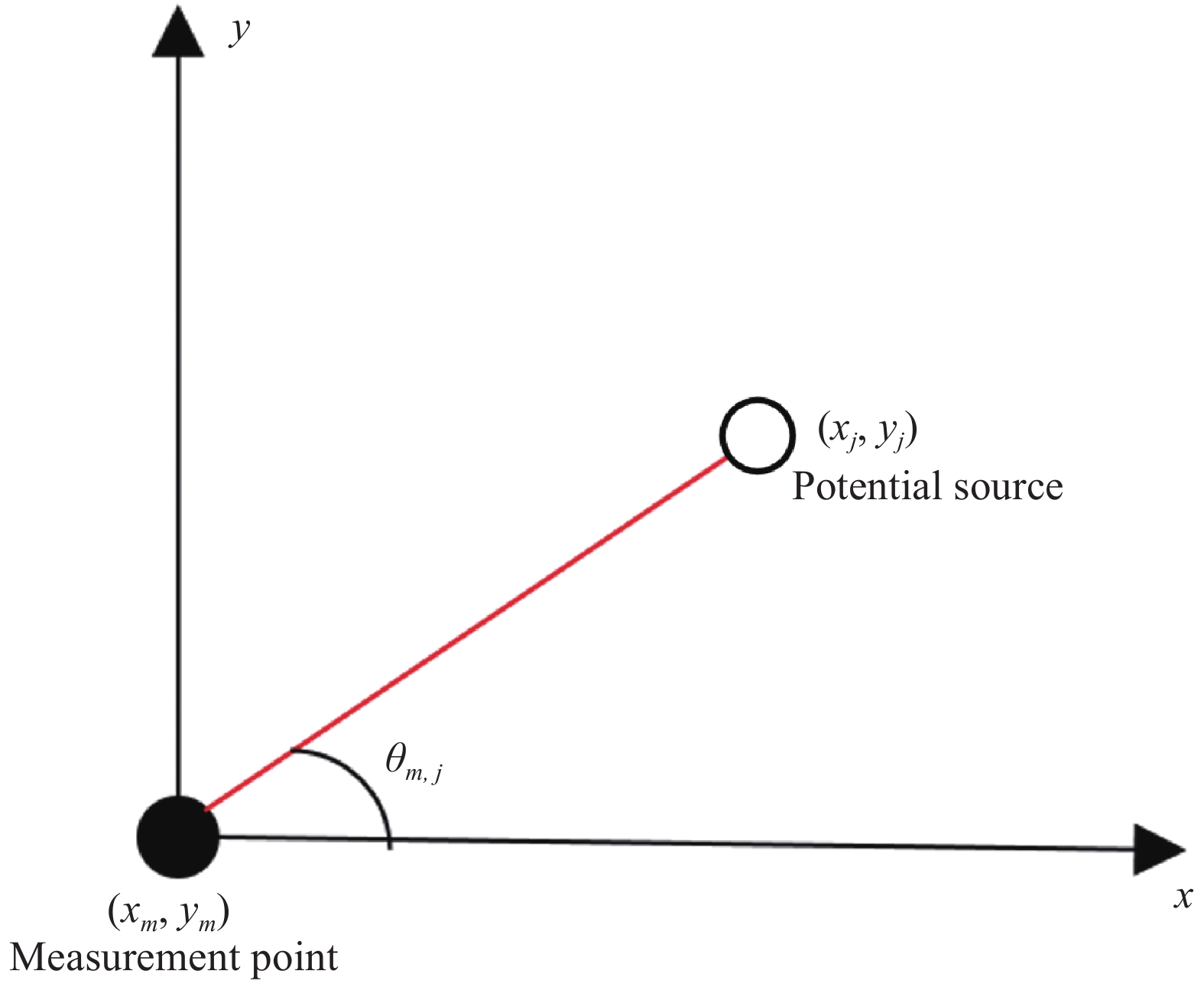

摘要: 为了解决全波场数据获取耗时的问题,引入压缩感知算法对波场进行稀疏表示。然而受限于导波在复合材料中复杂的传播特性,压缩感知在复合材料板中的应用成为难题。为此通过考虑导波在复合材料板中传播的各向异性波数特性,构建计算频带内不同角度下的波数库用于波场重构。同时在损伤分析阶段,提出了一种无需基准信号的复合材料损伤散射波场分离技术,精准实现入射波场的去除,提升损伤定位的精度。单损伤的实验和仿真结果表明,所提方法能够在低于90%的奈奎斯特采样点情况下实现波场的重构,且损伤定位误差均小于最小波长的2/3。双损伤的实验结果表明,所提方法可有效定位双损伤,相关成果可为复合材料损伤检测的实际运用提供理论和方法基础。Abstract: In order to solve the time-consuming problem of data acquisition of the whole wavefield, a compressed sensing algorithm was introduced to represent the wavefield sparsely. Due to the complex propagation characteristics of guided waves in composite materials, the application of compressed sensing in composite plates becomes difficult. Hence, by considering the anisotropic wavenumber characteristics of the guided waves propagating in the composite plate, a wavenumber library under different angles in the calculated frequency band was constructed for wavefield reconstruction. In the stage of damage analysis, a composite material damage scattering wavefield separation technology without reference signal technology was proposed to accurately remove the incident wavefield and improve the accuracy of damage location. Simulation and experimental results show that the proposed approach allows a reduction of the measurement locations required for accurate signal recovery to less than 90% of the original sampling grid and the single damage location error is less than 2/3 of the minimum wavelength. In addition, the double-damage experimental results show that the proposed method can effectively locate the double-damage, and related results can provide a theoretical and methodological basis for the practical application of composite damage detection.

-

Key words:

- nondestructive testing /

- Lamb wavefield /

- composite plate /

- compression sensing /

- damage imaging

-

表 1 碳纤维增强树脂复合材料(CFRP)板参数设置

Table 1. Carbon fiber reinforced polymer (CFRP) plate parameter setting

C11=C22/GPa C33/GPa C12/GPa C13=C23/GPa 197.67 8.76 60.75 4.25 C44=C55/GPa C66/GPa ρ/(kg·m−3) Thinckness/mm 5.2 2.0 1580 1 Notes: C—Stiffness coefficients; ρ—Density. 表 2 数值模拟的CFRP板损伤定位信息

Table 2. Damage location information of numerical simulation of CFRP plate

Real location/

mmEstimated location/

mmAbsolute error/

mm(40, 80) (39, 79) 1.4 表 3 单损伤实验的CFRP板损伤定位信息

Table 3. Damage location information of single damage experiment of CFRP plate

Real location/mm Estimated location/mm Absolute error/mm (28, 88) (24, 84) 5.66 表 4 CFRP板的双损伤实验损伤定位信息

Table 4. Damage location information of double damages experiment of CFRP plate

Damage Real location/

mmEstimated location/

mmAbsolute error/

mmNo. 1 (48, 98) (49, 94) 4.12 No. 2 (28, 78) (27, 76) 2.24 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 谌广昌, 吴明忠, 陈普会. 高性能复合材料在直升机结构上的应用展望[J]. 航空制造技术, 2019, 62(12):83-90.CHEN Guangchang, WU Mingzhong, CHEN Puhui. Prospects for the application of high-performance composite materials in helicopter structures[J]. Aeronautical Manufacturing Technology,2019,62(12):83-90(in Chinese). [3] FORINTOS N, CZIGANY T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers-A short review[J]. Composites Part B: Engineering,2019,162:331-343. doi: 10.1016/j.compositesb.2018.10.098 [4] 邱雷, 袁慎芳, 张逍越, 等. 基于Shannon复数小波的复合材料结构时间反转聚焦多损伤成像方法[J]. 复合材料学报, 2010, 27(2):101-107.QIU Lei, YUAN Shenfang, ZHANG Xiaoyue, et al. Time-reversed focusing multi-damage imaging method for composite structures based on Shannon complex wavelet[J]. Acta Materiae Compositae Sinica,2010,27(2):101-107(in Chinese). [5] 刘国强, 肖迎春, 张华, 等. 复合材料加筋壁板损伤识别的概率成像方法[J]. 复合材料学报, 2018, 35(2):311-319.LIU Guoqiang, XIAO Yingchun, ZHANG Hua, et al. Probabilistic imaging method for damage identification of reinforced composite siding[J]. Acta Materiae Compositae Sinica,2018,35(2):311-319(in Chinese). [6] WANG Q, YUAN S F. Baseline-free imaging method based on new PZT sensor arrangements[J]. Journal of Intelligent Material Systems & Structures,2009,20(14):1663-1673. [7] SAEEDIFAR M, MANSVELDER J, MOHAMMADI R, et al. Using passive and active acoustic methods for impact damage assessment of composite structures[J]. Composite Structures,2019,226:111252. doi: 10.1016/j.compstruct.2019.111252 [8] CHIA C C, LEE J R, PARK C Y, et al. Laser ultrasonic anomalous wave propagation imaging method with adjacent wave subtraction: Application to actual damages in composite wing[J]. Optics & Laser Technology,2012,44(2):428-440. [9] LONGO R, VANLANDUIT S, VANHERZEELE J, et al. A method for crack sizing using laser doppler vibrometer measurements of surface acoustic waves[J]. Ultrasonics,2010,50(1):76-80. doi: 10.1016/j.ultras.2009.08.001 [10] CAO X D. Non-contact damage detection under operational conditions with multipoint laservibrometry[J]. Sensors,2020,20(3):732. doi: 10.3390/s20030732 [11] HARLEY J B, MOURA J M F. Sparse recovery of the multimodal and dispersive characteristics of Lamb waves[J]. The Journal of the Acoustical Society of America,2013,133(5):2732. doi: 10.1121/1.4799805 [12] HARLEY J B, MOURA J M F. Data-driven matched field processing for Lamb wave structural health monitoring.[J]. Journal of the Acoustical Society of America,2014,135(3):1231-1244. doi: 10.1121/1.4863651 [13] LEVINE R M, MICHAELS J E. Block-sparse reconstruction and imaging for lamb wave structural health monitoring[J]. IEEE Transactions on Ultrasonics Ferroelectrics & Frequency Control,2014,61(6):1006-1015. [14] LEVINE R M, MICHAELS J E. Model-based imaging of damage with Lamb waves via sparse reconstruction[J]. The Journal of the Acoustical Society of America,2013,133(3):1525. doi: 10.1121/1.4788984 [15] PARK B, SOHN H. Reconstruction of laser ultrasonic wavefield images from reduced sparse measurements using compressed sensing aided super-resolution[C]. 43rd Review of Progress in Quantitative Nondestructive Evaluation, AIP Conference Proceedings, 2016: 1806(1): 030003. [16] IANNI T D, MARCHI L D, PERELLI A, et al. Compressive sensing of full wave field data for structural health monitoring applications[J]. IEEE Transactions on Ultrasonic Ferroelectrics & Frequency Control,2015,62(7):1373-1383. [17] ESFANDABADI Y K, MARCHI L D, TESTONI N, et al. Full wavefield analysis and damage imaging through compressive sensing in lamb wave inspections[J]. IEEE Transactions on Ultrasonic Ferroelectrics & Frequency Control,2018,65(2):269-280. [18] MESNIL O, RUZZENE M. Sparse wavefield reconstruction and source detection using compressed sensing[J]. Ultrasonics,2016,67:94-104. doi: 10.1016/j.ultras.2015.12.014 [19] 骆英, 周杨, 李鹏飞, 等. 一种基于均匀稀疏采样的Lamb波场重构方法[J]. 无损检测, 2019, 41(9):28-32, 38.LUO Ying, ZHOU Yang, LI Pengfei, et al. A Lamb wavefield reconstruction method based on uniform sparse sampling[J]. Nondestructive Testing,2019,41(9):28-32, 38(in Chinese). [20] CANDES E J. Compressive sampling[J]. Proceedings of the International Congress of Mathematicians,2006,3:1433-1452. [21] ROSE, JOSEPH L. Ultrasonic guided waves in solid media: Plates[M]. Cambridge: Cambridge University Press, 2014. [22] EWOUT V D B, FRIEDLANDER M P. Probing the pareto frontier for basis pursuit solutions[J]. Siam Journal on Entific Computing,2008,31(2):890-912. [23] LEVINE R M. Ultrasonic guided wave imaging via sparse reconstruction[D]. Atlanta: Georgia Institute of Technology, 2014. [24] SHORTER P J. Wave propagation and damping in linear viscoelastic laminates[J]. Journal of the Acoustical Society of America,2004,115(5):1917. doi: 10.1121/1.1689342 [25] 刘增华, 余锋祥, 于洪涛, 等. 基于群速度校准的超声导波技术及在复合材料缺陷检测中的应用[J]. 机械工程学报, 2012, 48(20):8-15. doi: 10.3901/JME.2012.20.008LIU Zenghua, YU Fengxiang, YU Hongtao, et al. Ultrasonic guided wave technology based on group velocity calibration and its application for defect detection in composite plates[J]. Journal of Mechanical Engineering,2012,48(20):8-15(in Chinese). doi: 10.3901/JME.2012.20.008 [26] GIURGIUTIU V. Tuned Lamb wave excitation and detection with piezoelectric wafer active sensors for structural health monitoring[J]. Journal of Intelligent Material Systems and Structures,2005,16(4):291-305. doi: 10.1177/1045389X05050106 [27] MOSER F, JACOBS L J, QU J. Modeling elastic wave propagation in waveguides with the finite element method[J]. NDT & E International,1999,32(4):225-234. -

下载:

下载: