Preparation and properties of spreading carbon cloth stitched C/C composites

-

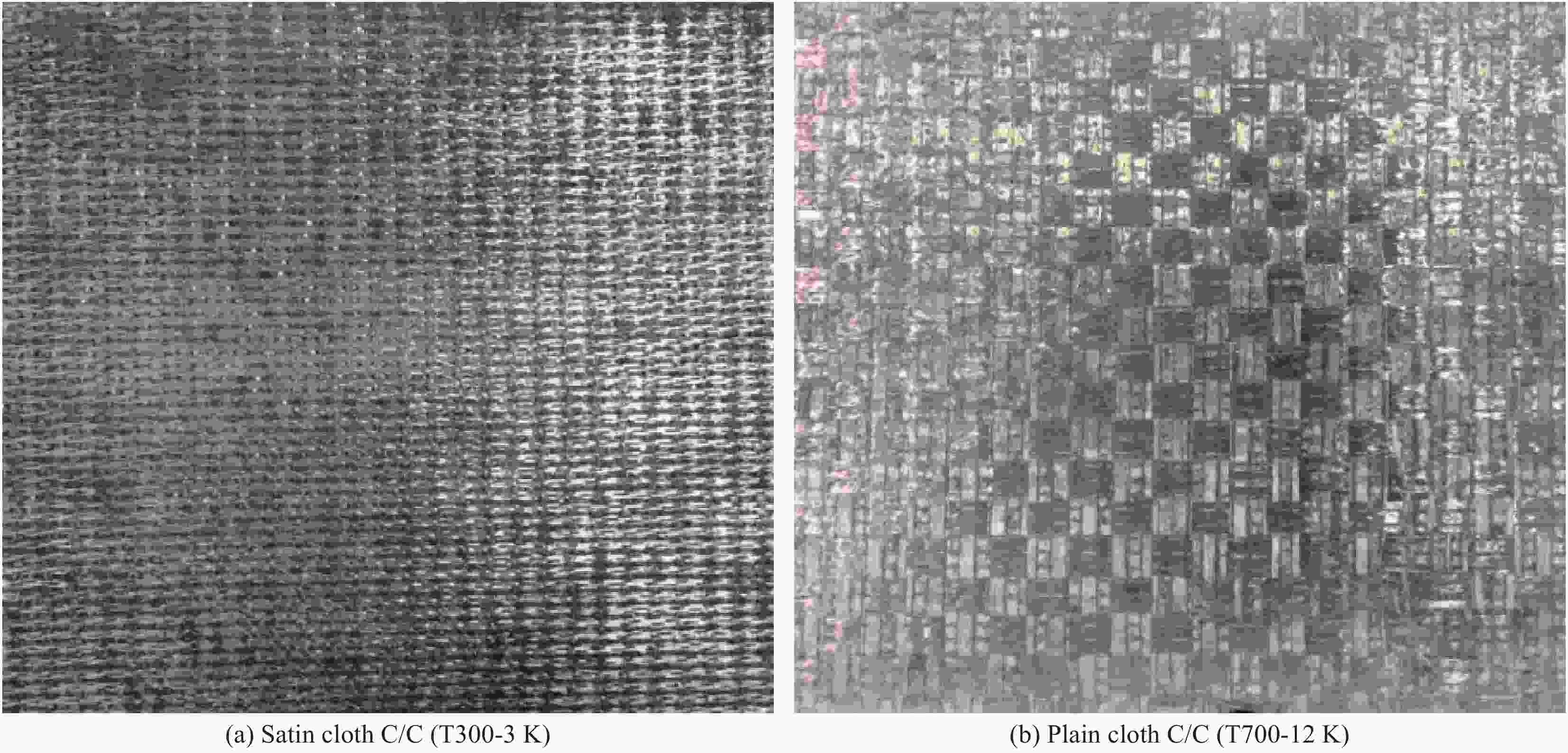

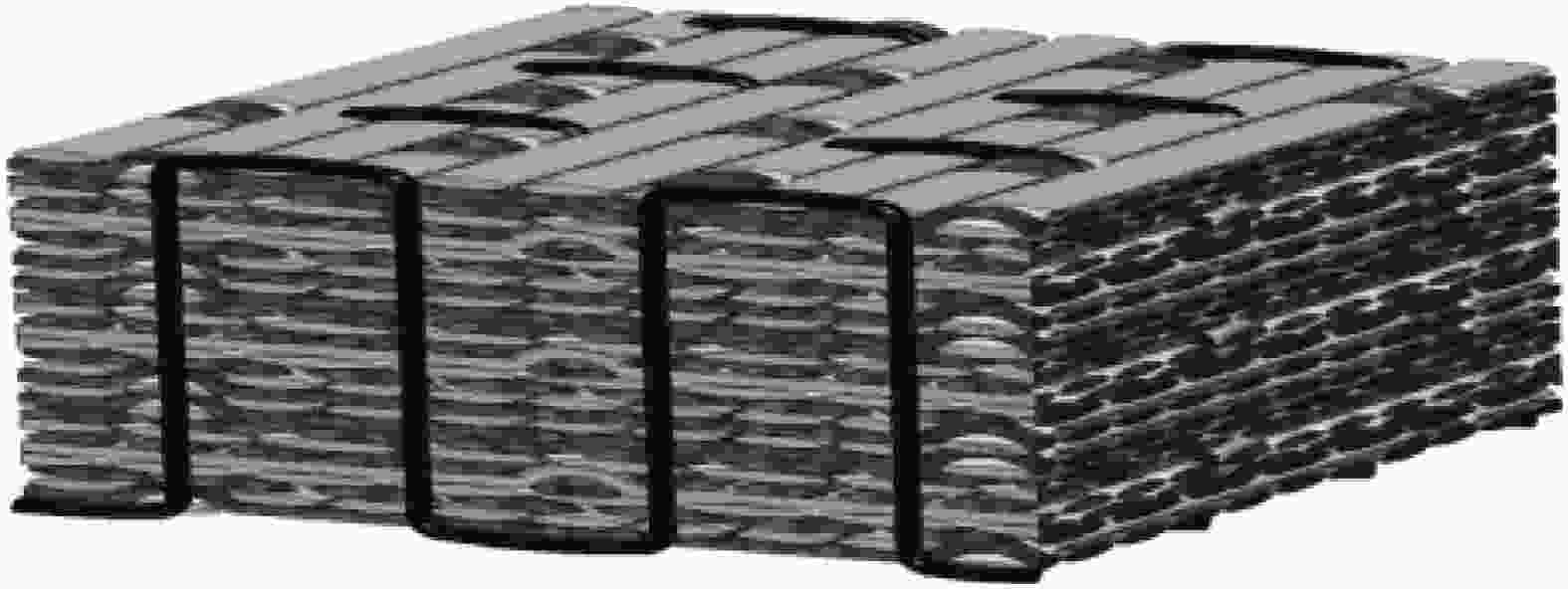

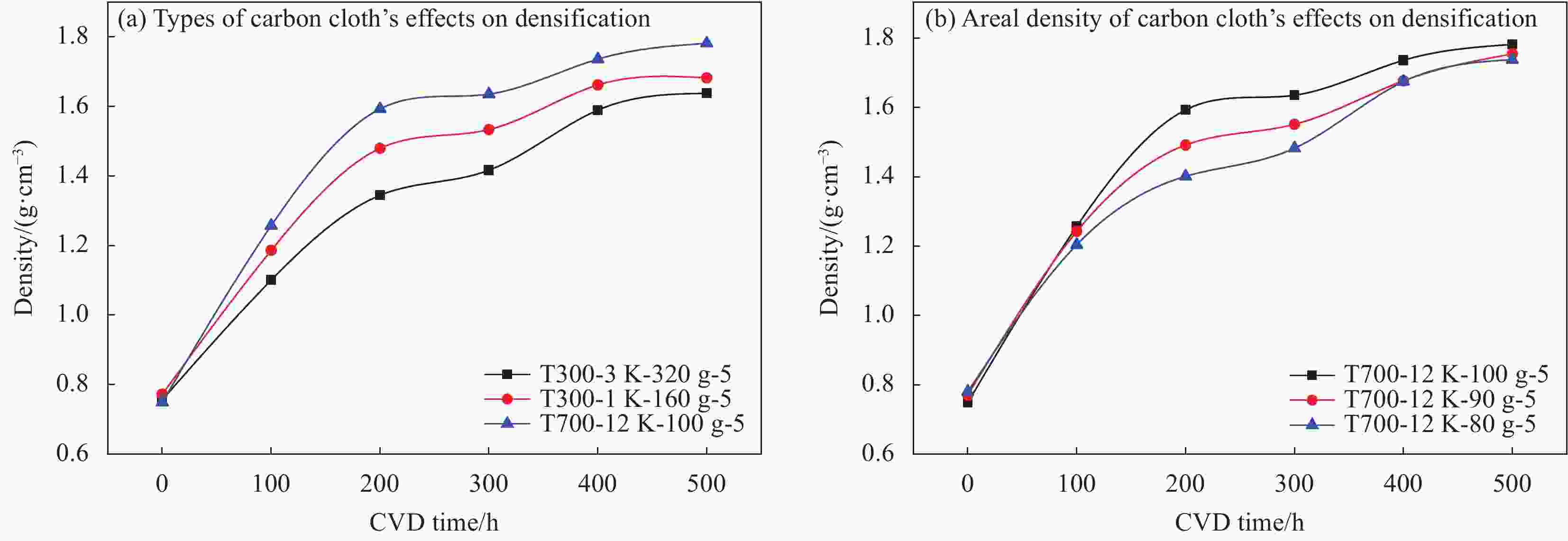

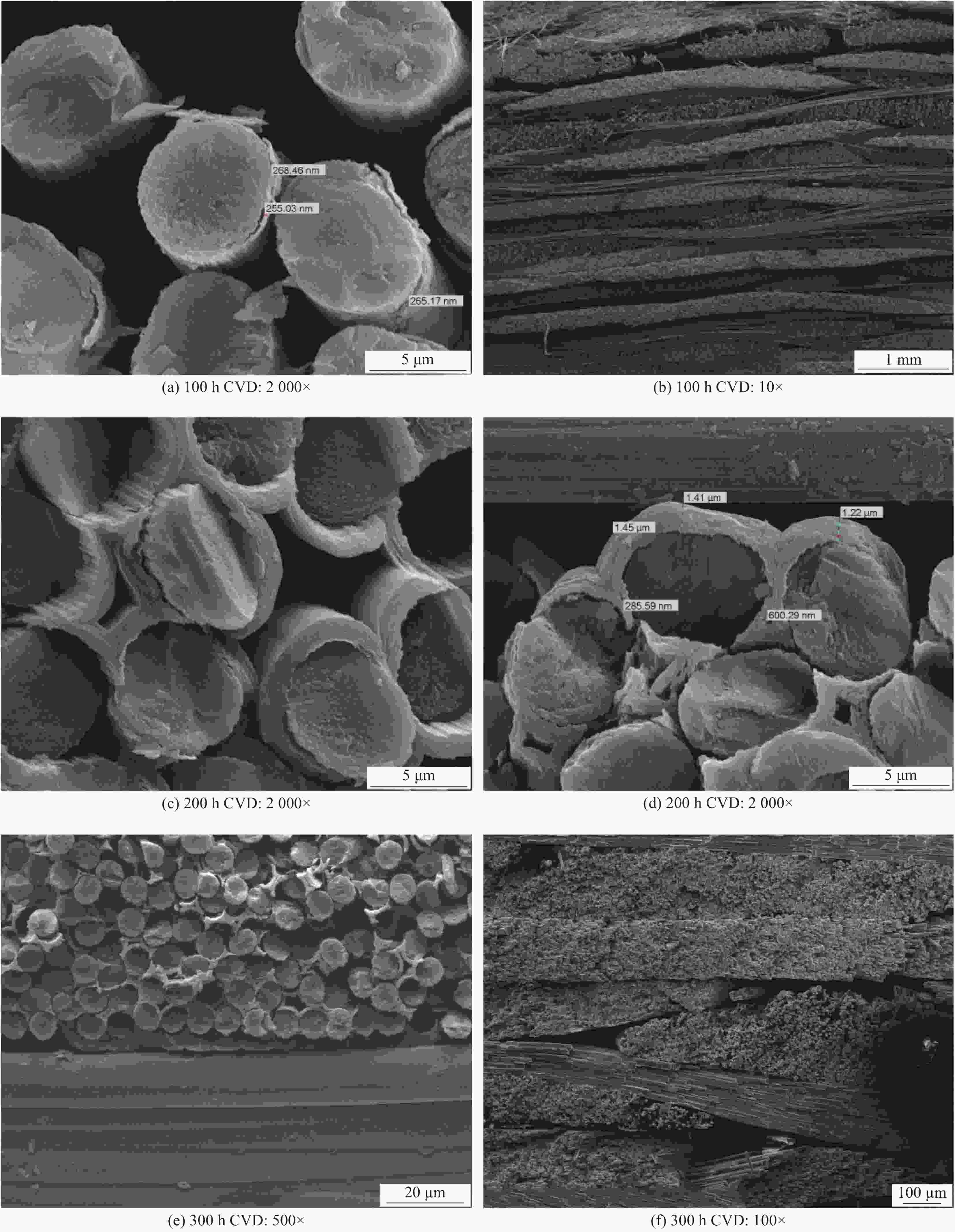

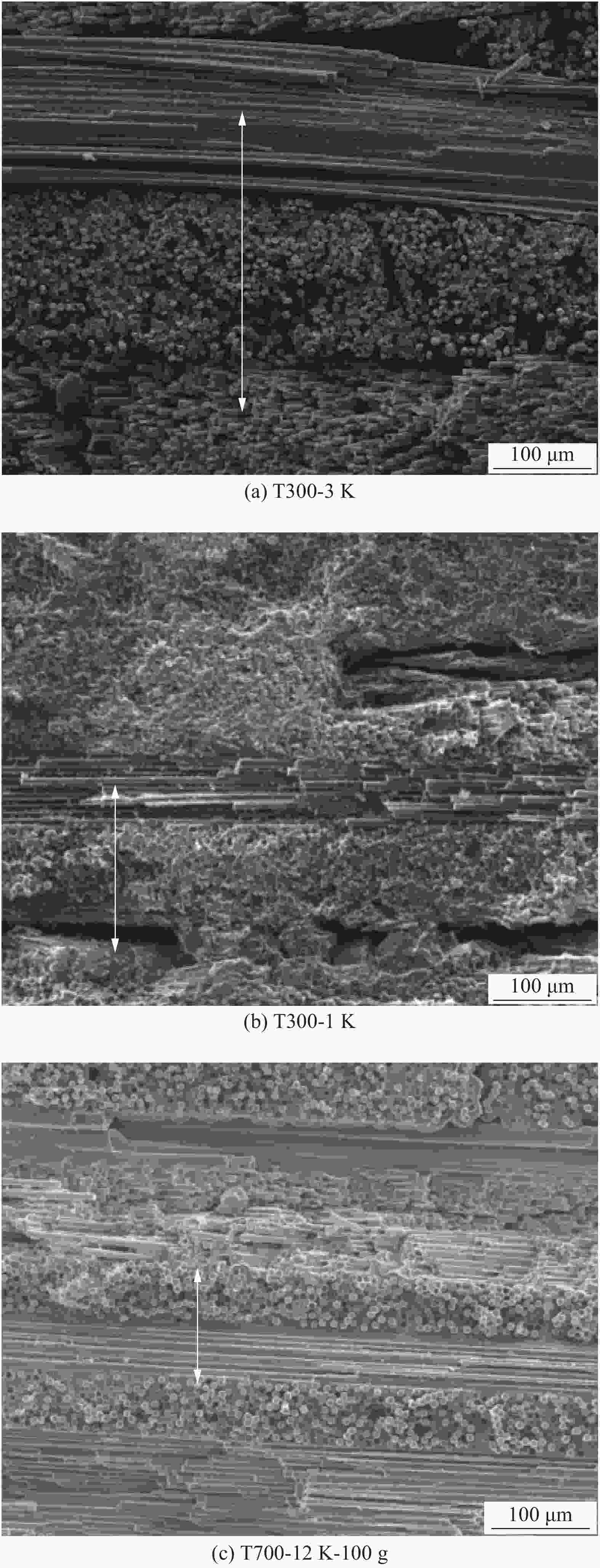

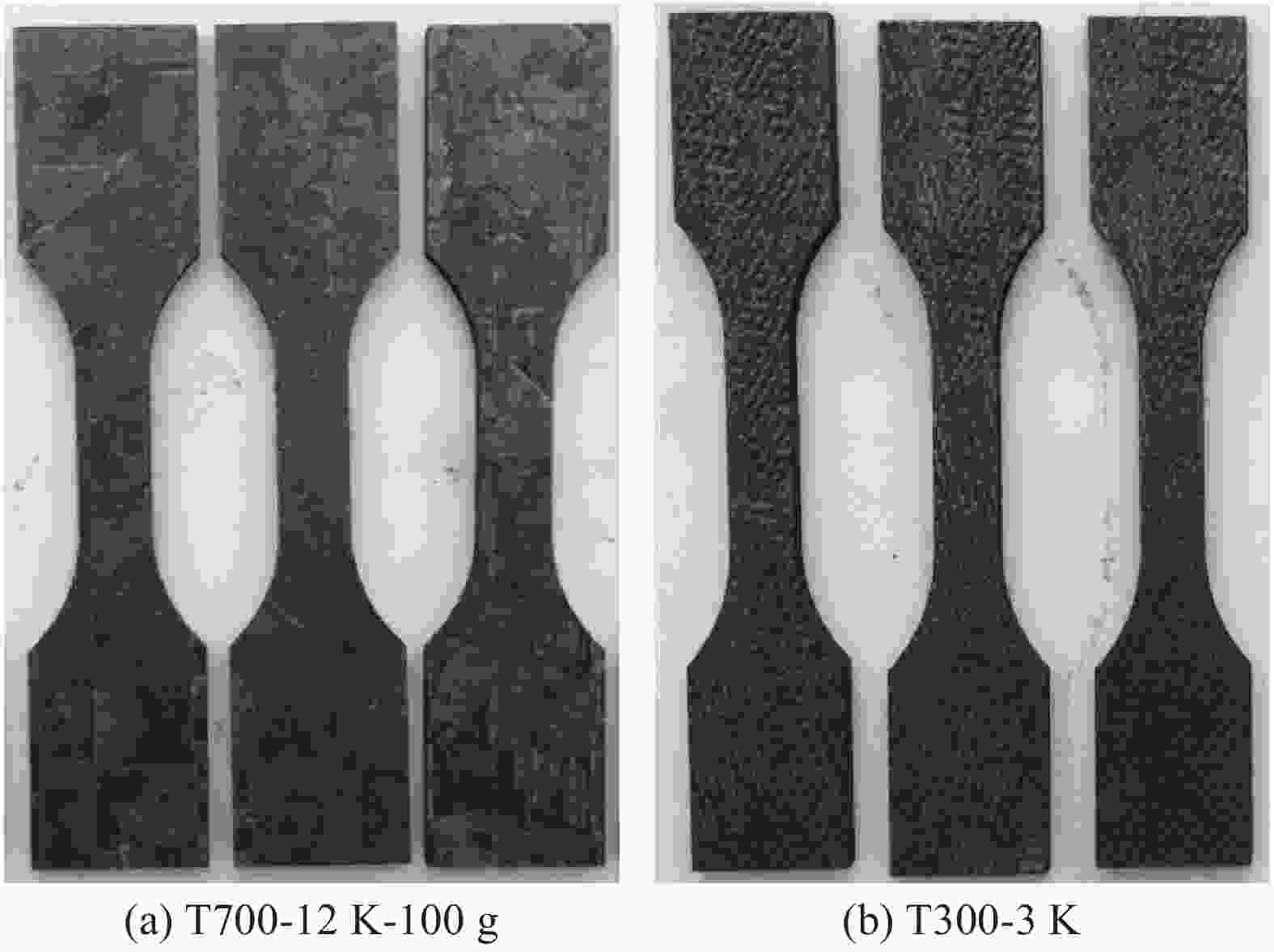

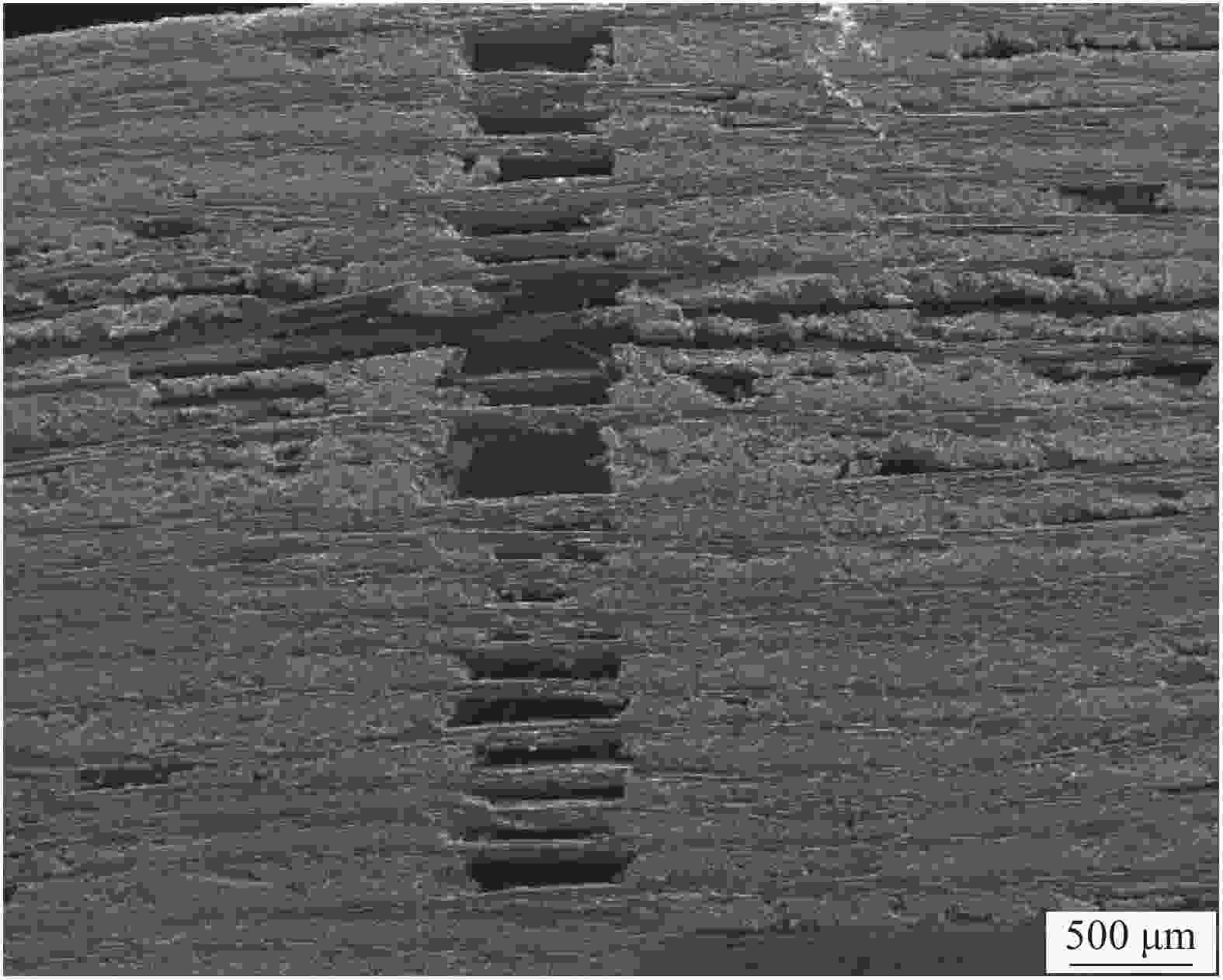

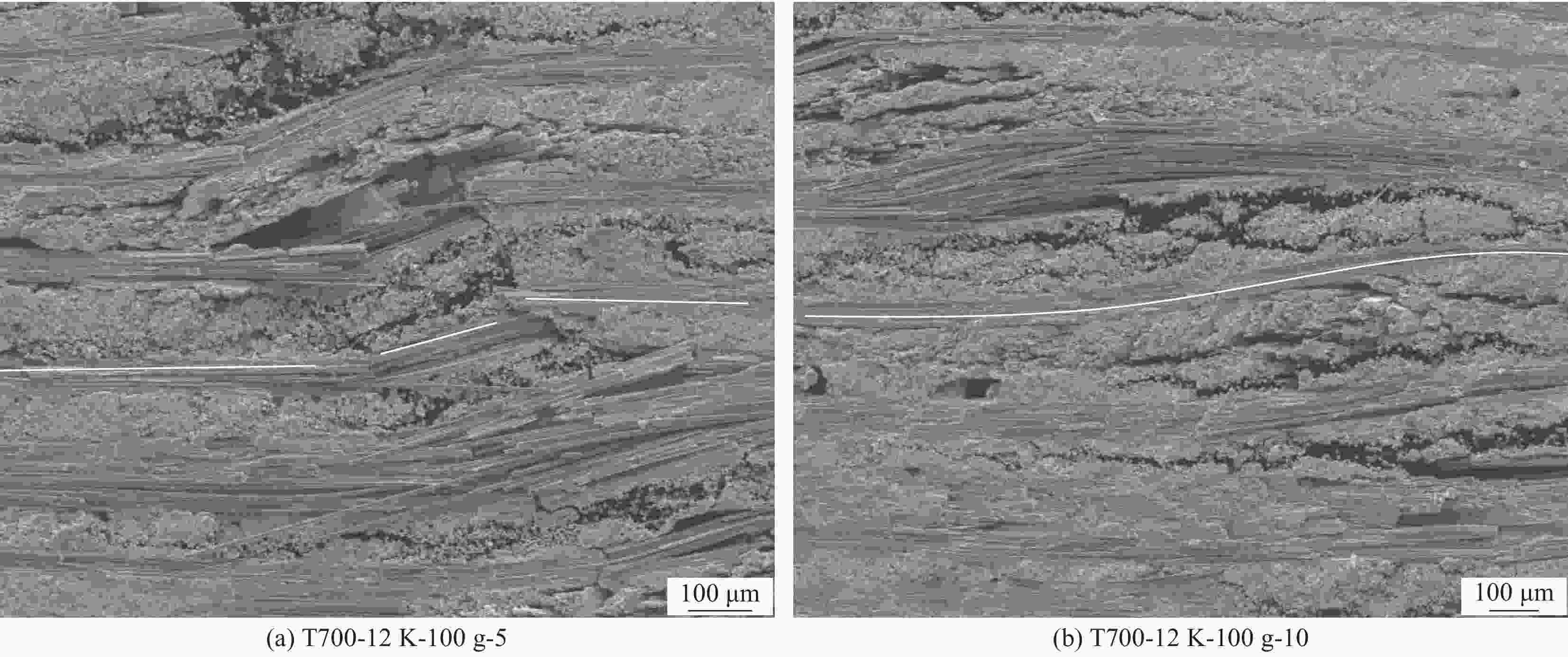

摘要: 为获得高性能、低成本碳/碳复合材料,以商用级T700大丝束薄层化碳纤维展宽平纹布和航空航天级T300小丝束碳纤维缎纹布为原材料制备缝合预制体,采用化学气相沉积工艺方法制备了一系列缝合碳/碳复合材料,对材料的气相致密化特征、微观结构特征和力学性能进行了测试与分析。研究结果表明,碳布规格和缝合间距对材料气相致密化效果和力学性能有较大影响。当选用T700-12 K、展宽16 mm大丝束纤维编织的面密度100 g/m2的平纹布为原材料且预制体缝合间距为5 mm×5 mm时,制备的密度为1.781 g/cm3薄层化碳布缝合碳/碳复合材料表现出良好的气相沉积工艺适应性和优异的力学性能,材料拉伸强度、压缩强度、弯曲强度和层间剪切强度高达342.9 MPa、285.5 MPa、328.4 MPa和15.2 MPa。通过商用级大丝束薄层化碳纤维的应用,大幅降低了高性能碳/碳复合材料的原材料成本,且制备的碳/碳复合材料性能达到了国际先进水平。Abstract: In order to obtain high-performance and low-cost C/C composites, a series of preforms stitched with commercial grade large tow spreading carbon fiber cloth or aerospace grade small tow carbon fiber cloth were prepared. The carbon cloth stitched C/C composites were prepared by chemical vapor deposition (CVD), and the densification characteristics, microstructure features and mechanical properties of stitched C/C composites were characterized and discussed. The investigation results show that the types of carbon cloth and stitching density have obvious effects on the densification and mechanical properties of stitched C/C composites. When the type of preform selects key characteristics as spreading fiber cloth T700-12 K-100 g and stitching density 5 mm×5 mm, the values of tensile strength, compression strength, flexural strength and interlaminar shear strength for stitched C/C composites (1.781 g/cm3) reach 342.9 MPa、285.5 MPa、328.4 MPa and 15.2 MPa respectively, which are the international advanced level. The cost of high-performance C/C composites is greatly reduced by using spreading carbon cloth.

-

Key words:

- C/C composites /

- spreading /

- stitch /

- chemical vapor deposition /

- mechanical properties

-

表 1 不同预制体结构参数

Table 1. Parameters of stitched preform

No. Types of

preformTypes of

fiberAreal density

of carbon

cloth/(g·m−2)Stitching

density/

mm1 T300-3 K-320 g-5 T300-3 K 320 5×5 2 T300-1 K-160 g-5 T300-1 K 160 5×5 3 T700-12 K-100 g-5 T700-12 K 100 5×5 4 T700-12 K-100 g-10 T700-12 K 100 10×10 5 T700-12 K-100 g-15 T700-12 K 100 15×15 6 T700-12 K-100 g-20 T700-12 K 100 20×20 7 T700-12 K-100 g-25 T700-12 K 100 25×25 8 T700-12 K-100 g-40 T700-12 K 100 40×40 9 T700-12 K-90 g-5 T700-12 K 90 5×5 10 T700-12 K-80 g-5 T700-12 K 80 5×5 表 2 不同种碳布实测参数

Table 2. Parameters of different carbon cloths

Type of fiber T300-3 K T300-1 K T700-12 K Fiber linear density/tex 198 66 797 Tensile strength of fiber/GPa 4.09 3.85 5.05 Tensile modulus of fiber/GPa 232.5 233.5 227.0 Fracture elongation of fiber/% 1.76 1.84 2.00 Spreading width of fiber/mm − − 16 18 20 Tensile strength of spreading fiber/GPa − − 5.01 4.96 4.89 Strength retention/% − − 99.2 98.2 96.3 Type of carbon cloth Satin cloth Plain cloth Areal density of carbon cloth/(g·m−2) 320 160 100 90 80 Thickness of carbon cloth/mm 0.31 0.17 0.11 0.091 0.075 Tensile strength of carbon cloth(warp)/(N·50mm−1) 5 604 3241 3639 3406 2706 Tensile strength of carbon cloth(weft)/(N·50mm−1) 5 432 3335 3580 3354 2936 表 3 不同预制体结构参数及最终碳/碳复合材料密度

Table 3. Parameters of stitched preform and density of C/C composites

No. Type of

fiberAreal density

of carbon

cloth/(g·m−2)Stitching

density/

mmLayer

density/

layer/cmTheoretical

fiber volume

fraction/vol%Experimental

fiber volume

fraction/vol%Density of C/C

composites/

(g·cm−3)1 T300-3 K 320 5×5 24.9 45.3 46.9 1.637 2 T300-1 K 160 5×5 50.2 45.6 48.1 1.682 3 T700-12 K 100 5×5 81.8 46.0 45.7 1.781 4 T700-12 K 100 10×10 86.5 48.6 48.2 1.731 5 T700-12 K 100 15×15 90.0 50.6 50.0 1.675 6 T700-12 K 100 20×20 89.5 50.3 49.7 1.624 7 T700-12 K 100 25×25 90.5 50.8 50.3 1.571 8 T700-12 K 100 40×40 89.3 50.2 49.6 1.542 9 T700-12 K 90 5×5 95.7 48.4 47.8 1.754 10 T700-12 K 80 5×5 109.8 49.3 49.0 1.737 表 4 碳/碳复合材料力学性能

Table 4. Mechanical properties of C/C composites

No. Tensile In-plane compression Flexural Interlaminar shear

strength/MPaStrength/

MPaDiscrete

valuesModulus/

GPaStrength/

MPaModulus/

GPaStrength/

MPaModulus/

GPa1 141.3 13.1% 52.8 121.2 65.0 132.3 50.5 7.2 2 237.4 14.6% 61.4 176.2 63.8 196.3 52.9 19.7 3 342.9 5.30% 67.6 285.5 63.8 328.4 53.8 15.2 4 366.6 5.90% 73.9 256.8 60.1 216.4 56.9 11.7 5 298.3 10.7% 63.9 177.2 57.4 186.9 52.5 7.9 6 196.1 21.2% 52.3 99.1 45.9 112.1 30.8 5.0 7 150.1 18.6% 53.1 56.8 42.9 33.1 18.1 4.5 8 139.2 16.9% 43.6 54.8 48.7 27.9 11.2 3.5 9 351.3 7.10% 70.9 259.1 62.6 307.7 54.1 14.7 10 324.1 6.50% 62.8 241.6 59.1 227.0 52.9 12.9 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 冯志海. 关于我国高性能碳纤维需求和发展的几点想法[J]. 新材料产业, 2010(9):19-24. doi: 10.3969/j.issn.1008-892X.2010.09.005FENG Zhihai. Ideas on the demand and development of high performance carbon fiber in China[J]. Advanced Materials Industry,2010(9):19-24(in Chinese). doi: 10.3969/j.issn.1008-892X.2010.09.005 [3] 李贺军. 炭/炭复合材料[J]. 新型炭材料, 2001, 16(2):79-80. doi: 10.3321/j.issn:1007-8827.2001.02.017LI Hejun. Carbon/carbon composites[J]. New carbon materials,2001,16(2):79-80(in Chinese). doi: 10.3321/j.issn:1007-8827.2001.02.017 [4] SHARMA R, RAVIKUMAR N L, DASGUPTA K, et al. Advanced carbon-carbon composites: Processing properties and applications[J]. Composite Materials,2016(4):315-367. [5] 徐林, 杨文彬, 陈铮, 等. 高性能二维碳/碳复合材料的制备与性能[J]. 复合材料学报, 2016, 33(12):2877-2883.XU Lin, YANG Wenbin, CHEN Zheng, et al. Preparation and properties of high performance two-dimensional carbon/carbon composites[J]. Acta Materiae Compositae Sinica,2016,33(12):2877-2883(in Chinese). [6] 嵇阿琳, 李贺军, 崔红, 等. 不同预制体结构C/C复合材料轴向热力学性能分析[J]. 无机材料学报, 2010, 25(9):994-998. doi: 10.3724/SP.J.1077.2010.00994JI Alin, LI Hejun, CUI Hong, et al. Axial thermodynamic performance analysis of the different preform C/C compo-sites[J]. Journal of Inorganic Materials,2010,25(9):994-998(in Chinese). doi: 10.3724/SP.J.1077.2010.00994 [7] 刘宇峰, 俸翔, 王金明, 等. 高性能针刺碳/碳复合材料的制备与性能[J], 无机材料学报, 2020, 35(10): 1105-1111.LIU Yufeng, FENG Xiang, WANG Jinming, et al. Preparation and properties of high-performance needled C/C composites[J]. Journal of Inorganic Materials, 2020, 35(10): 1105-1111(in Chinese). [8] 罗云烽, 孙永春, 段跃新, 等. 大丝束碳纤维薄层化技术[J]. 复合材料学报, 2010, 27(1):123-128.LUO Yunfeng, SUN Yongchun, DUAN Yuexin, et al. A technology used in spreading large tow carbon fibers[J]. Acta Materiae Compositae Sinica,2010,27(1):123-128(in Chinese). [9] LIFKE J L, BUSSELLE L D, FINLEY D J, et al. Method and apparatus for spreading fiber: United States, 6049956[P]. 2000-04-18. [10] SIHNA S, KIMA R Y, TSAI S W, et al. Experimental studies of thin ply laminated composites[J]. Composites Science and Technology,2007,67:996-1008. doi: 10.1016/j.compscitech.2006.06.008 [11] 杨薇薇, 于亮, 郭志强. 薄层碳纤维织物预浸料的制备与性能[J]. 纤维复合材料, 2017, 9(3):8-11. doi: 10.3969/j.issn.1003-6423.2017.03.002YANG Weiwei, YU Liang, GUO Zhiqiang. Preparation and properties of thin ply carbon fiber fabric prepreg[J]. Fiber Composites,2017,9(3):8-11(in Chinese). doi: 10.3969/j.issn.1003-6423.2017.03.002 [12] 罗云烽, 孙永春, 段跃新, 等. 薄层化大丝束碳纤维复合材料性能研究[J]. 航空制造技术, 2010, 20:75-78. doi: 10.3969/j.issn.1671-833X.2010.02.014LUO Yunfeng, SUN Yongchun, DUAN Yuexin, et al. Study on property of spreaded large tow carbon fiber compo-sites[J]. Aeronautical Manufacturing Technology,2010,20:75-78(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.02.014 [13] 刘军, 朱星名, 胡伯仁, 等. 基于超声引导法的薄层化碳纤维性能研究[J]. 热加工工艺, 2014, 43(8):108-119.LIU Jun, ZHU Xingming, HU Boren, et al. Research on property of spread carbon fiber based on supersonic and traction method[J]. Hot Working Technology,2014,43(8):108-119(in Chinese). [14] 孙乐, 王成, 李晓飞, 等. C/C复合材料预制体的研究进展[J]. 航空材料学报, 2018, 38(2):86-95. doi: 10.11868/j.issn.1005-5053.2017.000010SUN L, WANG C, LI X F, et al. Research progress on preforms of C/C composites[J]. Journal of Aeronautical Materials,2018,38(2):86-95(in Chinese). doi: 10.11868/j.issn.1005-5053.2017.000010 [15] 吴宁宁, 张中伟, 梅敏, 等. 缝合结构碳/碳复合材料层间性能测试方法研究[C]. 第六届无机材料结构、性能及测试表征技术研讨会, 2015.WU Ningning, ZHANG Zhongwei, MEI Min, et al. Study on interlaminar properties testing method of stitched C/C composites[C]. TEIM 2015(in Chinese). [16] 房金铭, 许正辉, 张中伟, 等. 碳布缝合预制体孔隙与热解碳沉积时变相依的多尺度研究[J]. 宇航材料工艺, 2015, 45(5):36-39. doi: 10.3969/j.issn.1007-2330.2015.05.007FANG Jinming, XU Zhenghui, ZHANG Zhongwei, et al. Multi-scale relationship of pores in carbon cloth stitched preform and deposition of pyrocarbon[J]. Aerospace Materials and Technology,2015,45(5):36-39(in Chinese). doi: 10.3969/j.issn.1007-2330.2015.05.007 [17] 航天材料及工艺研究所. 细编穿刺碳/碳复合材料拉伸试验方法: DqES415—2005[S]. 北京: 航天材料及工艺研究所, 2005.Aerospace Research Institute of Materials and Processing Technology. Test method for tensile properties of fine weave pierced carbon/carbon composites: DqES415—2005[S]. Beijing: Aerospace Research Institute of Materials and Processing Technology, 2005(in Chinese). [18] 国防科学技术工业委员会. 连续纤维增强陶瓷基复合材料常温压缩性能试验方法: GJB 6476—2008[S]. 北京: 国防科学技术工业委员会, 2008.State Administration of Science Technology and Industry for National Defense. Test method for compressive properties of continuous fiber-reinforced ceramic composites at ambient temperature: GJB 6476—2008[S]. Beijing: State Administration of Science Technology and Industry for National Defense, 2008(in Chinese). [19] American Society for Testing and Materials International. Standard method for flexural properties of continuous fiber-reinforced advanced ceramic composites: ASTM C1341—00[S]. West Conshohocken: ASTM International, 2000. [20] 中华人民共和国工业和信息化部. 纤维增强塑料短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国建材工业出版社, 2010.Ministry of Industry and Information Technology of the People’s Republic of China. Fiber-reinforced plastics composites-Determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Building Materials Press, 2010(in Chinese). -

下载:

下载: