Structural design and mechanical characterization of an auxetic advanced grid structure composite

-

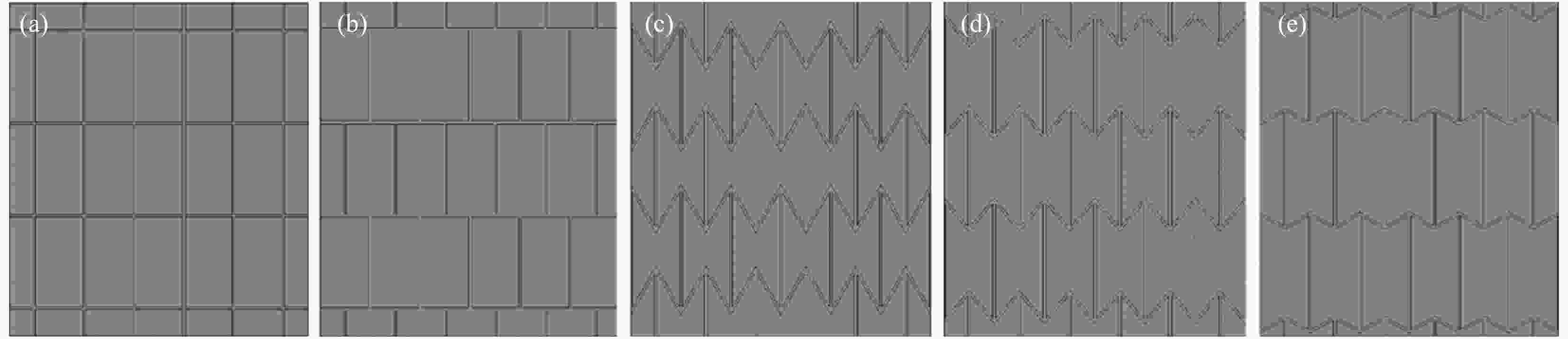

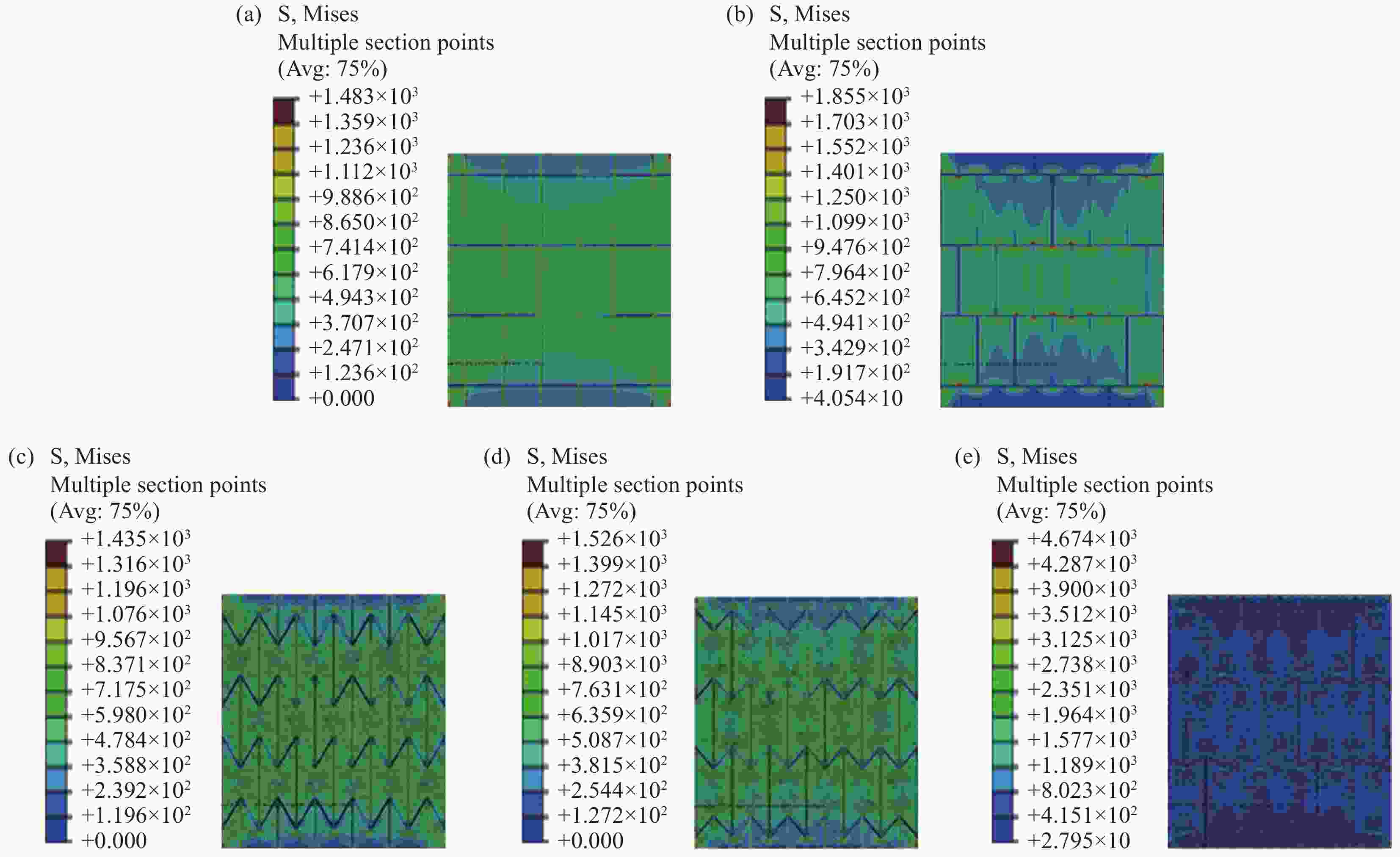

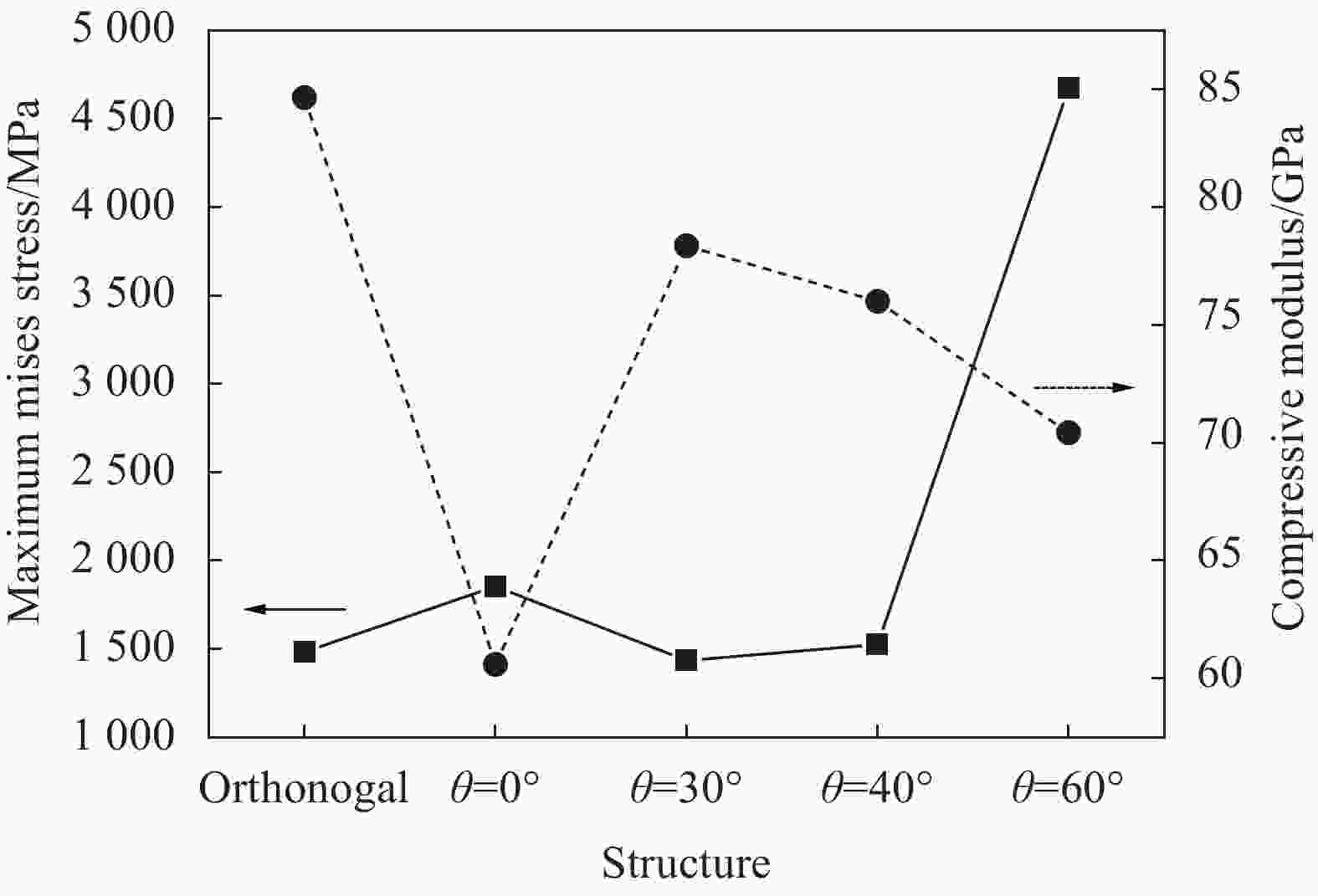

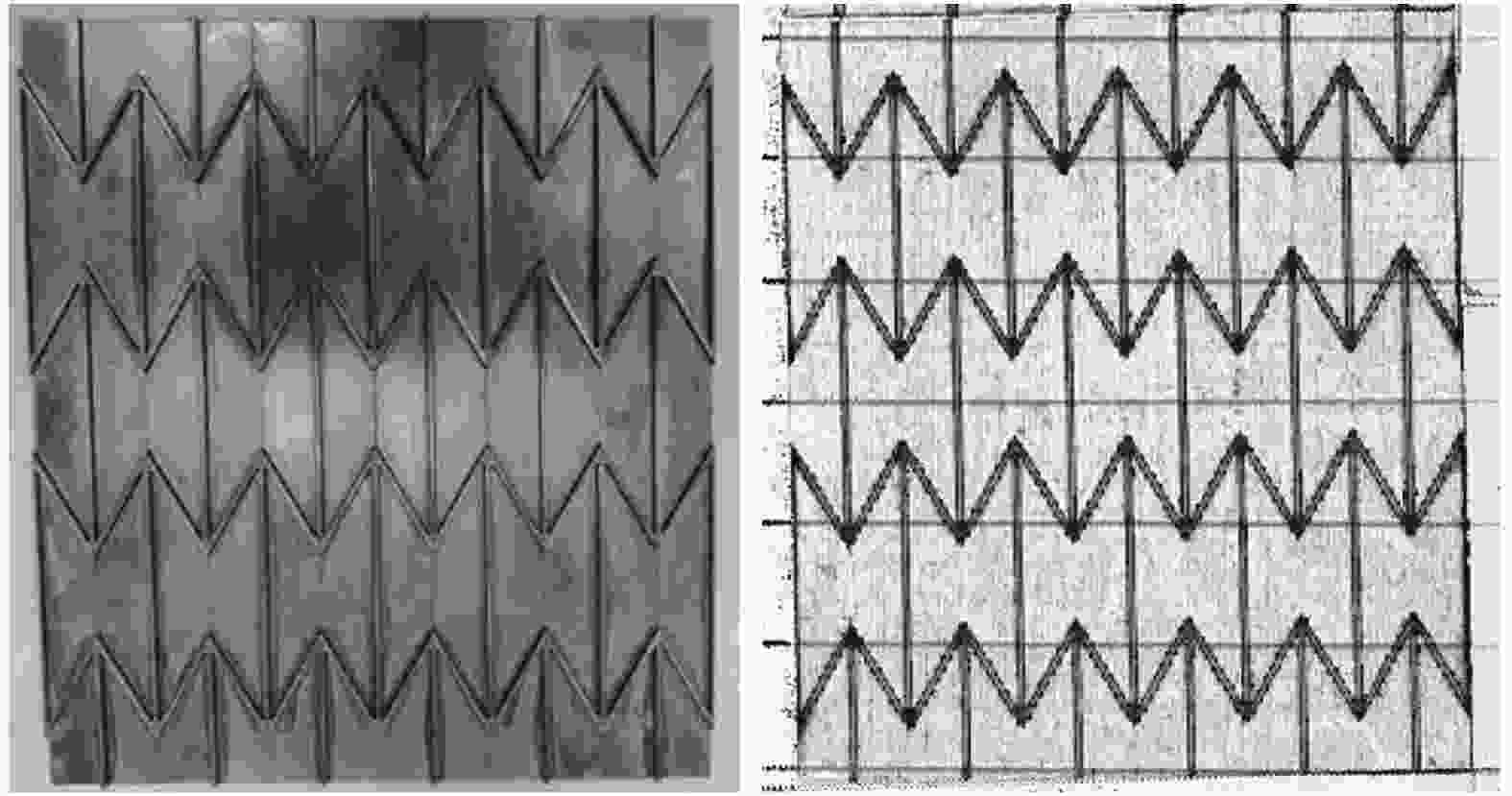

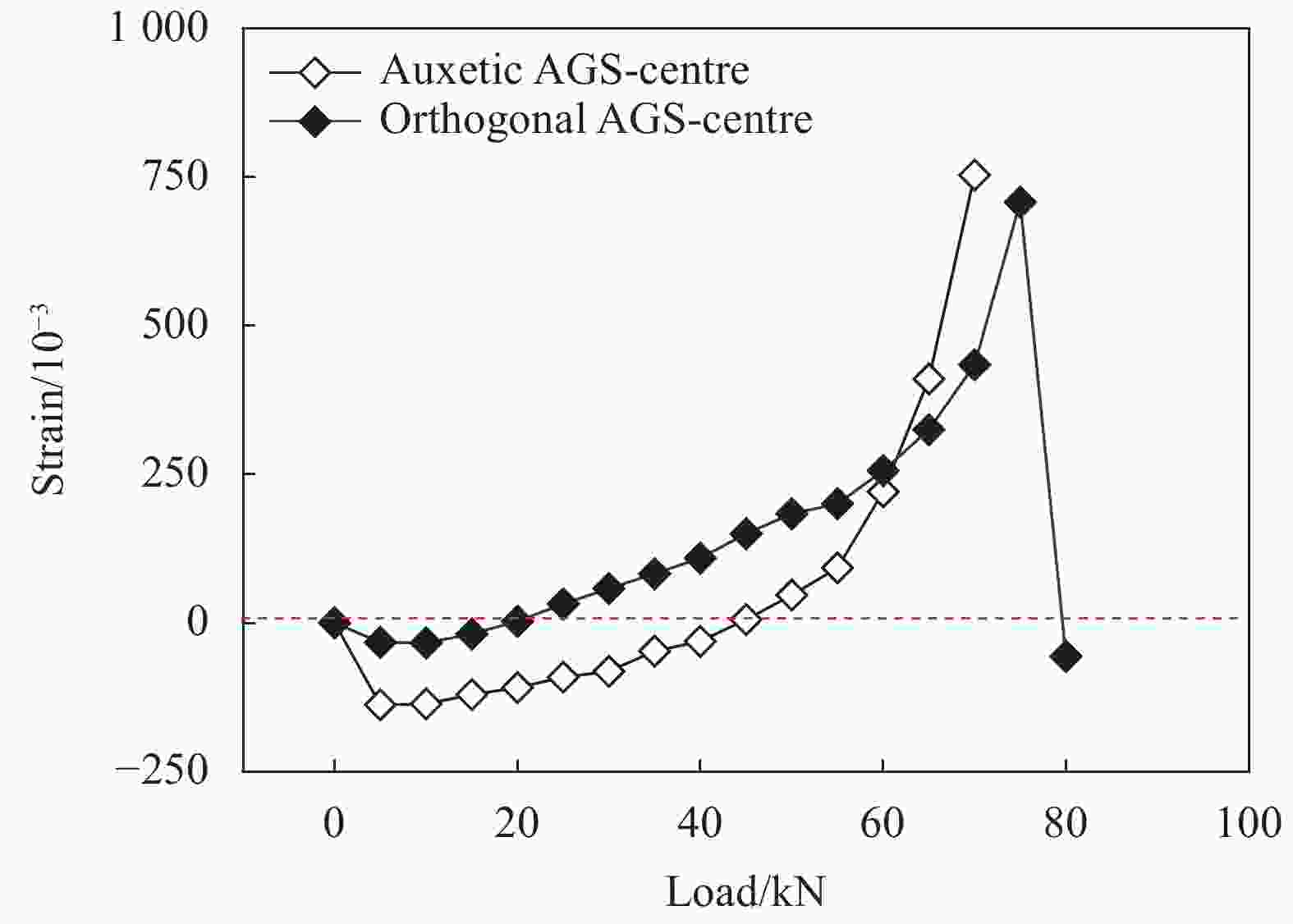

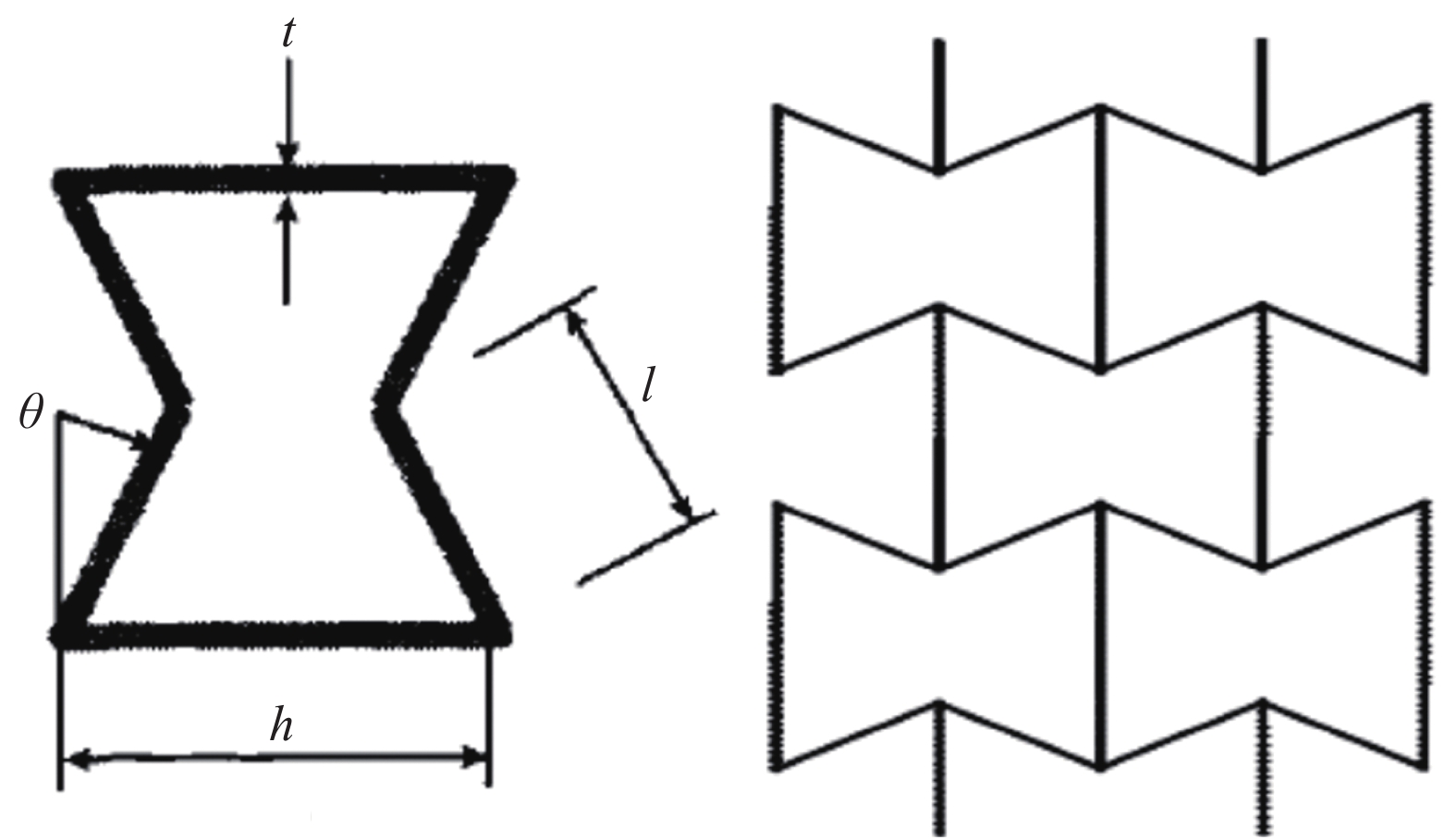

摘要: 对复合材料负泊松比格栅新结构的设计、制备与评价进行了研究,采用有限元方法模拟了负泊松比结构单元在轴压载荷作用下的力学行为,通过热压罐成型制备复合材料负泊松比格栅结构,并评估其成型质量、蒙皮及筋条的力学性能、结构抗轴压性能。数值模拟结果表明,负泊松比格栅结构与正交格栅结构相比,变形形式从马鞍形变为波纹形,横向膨胀量降低,应力分布均匀性提升,筋条-轴线夹角θ=30°时,负泊松比格栅结构达到最优。采用热压罐成型的MT300/603碳纤维/环氧树脂负泊松比格栅试件成型质量良好,蒙皮及筋条的力学性能优异。力学测试结果表明,筋条-轴线夹角θ=30°时,MT300/603负泊松比格栅结构轴压模量为65.92 GPa,轴压失效载荷为64.65 kN。轴压失效模式为筋条节点处的蒙皮-筋条开裂。筋条-轴线夹角θ=30°的MT300/603负泊松比格栅结构抗压强度高于正交格栅结构,且力学行为呈现明显的负泊松比特征,是一种具备优异综合力学性能的新格栅结构,在航天飞行器蒙皮结构等领域具有潜在的应用价值。Abstract: The structural design, manufacture and mechanical evaluation of an auxetic advanced grid structure (AGS) composite were investigated. The mechanical behavior of the auxetic AGS composite under the compressive loading was simulated via finite element method (FEM). The auxetic AGS composite was fabricated via autoclave processing, and the processing quality and mechanical properties were evaluated. The simulation results show that the auxetic AGS composite after deformation is in a corrugation shape, which is different from the saddle deformation shape of the orthogonal AGS composite. Compared with the orthogonal AGS composite, the transverse expansion is lower and the stress is more uniformly distributed. An 30° included angle between grid and axis is the most optimal structure for the auxetic AGS composite. Excellent manufacturing quality and superior mechanical properties are found for the MT300/603 carbon fiber/epoxy auxetic AGS composite. The mechanical experiment results show the optimal MT300/603 auxetic AGS composites have a compression modulus of 65.92 GPa and a compression failure load of 64.65 kN. The failure occurs between the grid and skin at the crossing of the grids, showing a higher compression strength than the orthogonal AGS composite. The optimal MT300/603 auxetic AGS composite exhibits a characteristic negative Poisson’s ratio. The AGS composite structure with superior overall mechanical performance can potentially be used on aerospace structures.

-

Key words:

- composites /

- auxetics /

- grid structure /

- structural design /

- mechanical property

-

表 1 内凹六边形几何参数

Table 1. Geometrical parameters of re-entrant chiral auxetic structures

No. l/mm h/mm θ/(°) Structure 1 67.5 70.0 0 Orthogonal grid 2 67.5 70.0 0 Re-entrant grid 3 77.6 70.0 30 Re-entrant grid 4 82.2 70.0 40 Re-entrant grid 5 97.8 70.0 60 Re-entrant grid 表 2 MT300/603复合材料单向板力学性能

Table 2. Mechanical properties of MT300/603 unidirectional composite laminates

Mechanical parameter Average value 0° tensile modulus/GPa 148 Poisson’s ratio ν12 0.31 90° tensile modulus/GPa 10.5 Poisson’s ratio ν21 0.02 0° compressive modulus/GPa 143 90° compressive modulus/GPa 11.2 In-plane shear modulus/GPa 5.6 表 3 复合材料负泊松比格栅结构力学性能

Table 3. Mechanical properties of the auxetic AGS composites

No. Vf /% σc of skin Ec of skin τ of skin σc of grid Ec of grid τ of skin-grid X/MPa CV/% X/GPa CV/% X/MPa CV/% X/MPa CV/% X/GPa CV/% X/MPa CV/% 1 60.5 799 1 61.8 2.2 62.6 5.2 698 7.9 119 6 75.8 12 2 59.5 860 7.2 60.8 3.3 65.2 3.8 648 9.1 121 4.1 83.5 15 3 63.4 800 5.5 60.4 5 67.9 7 650 12 122 4.5 75.1 8.9 Notes:Vf—Fiber volume fraction; σc—Compressive strength; Ec—Compressive modulus; τ—Interlaminar strength; X—Average value; CV—Coefficient of variation. -

[1] 杜善义, 章继峰, 张博明. 先进复合材料格栅结构(AGS)应用与研究进展[J]. 航空学报, 2007, 28(2):419-424. doi: 10.3321/j.issn:1000-6893.2007.02.033DU Shanyi, ZHANG Jifeng, ZHANG Boming. Overview of application and research on advanced composite grid structures[J]. Acta Aeronautica et Astronautica Sinica,2007,28(2):419-424(in Chinese). doi: 10.3321/j.issn:1000-6893.2007.02.033 [2] TOTARO G, GÜRDAL Z. Optimal design of composite lattice shell structures for aerospace applications[J]. Aerospace Science & Technology,2009,13(4-5):157-164. [3] 王世勋, 石玉红, 张希, 等. 复合材料格栅结构研究进展与应用[J]. 宇航材料工艺, 2017, 47(1):5-12. doi: 10.12044/j.issn.1007-2330.2017.01.002WANG Shixun, SHI Yuhong, ZHANG Xi, et al. Application and research progress of composite lattice grids structure[J]. Aerospace Materials & Technology,2017,47(1):5-12(in Chinese). doi: 10.12044/j.issn.1007-2330.2017.01.002 [4] PETER M, WEGNER, JOHN E, et al. Application of advanced grid-stiffened structures technology to the Minotaur payload fairing[J]. AIAA,2002,1336:1-7. [5] QUAN C, HAN B, HOU Z, et al. 3D printed continuous fiber reinforced composite auxetic honeycomb structures[J]. Composites Part B: Engineering,2020,187:107858. doi: 10.1016/j.compositesb.2020.107858 [6] FANTUZZI, N, TROVALUSCI, P, LUCIANO R. Material symmetries in homogenized hexagonal-shaped composites as cosserat continua[J]. Symmetry,2020,12(3):21. doi: 10.3390/sym12030441 [7] NOVAK N, KRSTULOVI-OPARA L, REN Z, et al. Mechanical properties of hybrid metamaterial with auxetic chiral cellular structure and silicon filler[J]. Composite Structures,2020,234:111718. doi: 10.1016/j.compstruct.2019.111718 [8] 张伟, 侯文彬, 胡平. 新型负泊松比多孔吸能盒平台区力学性能[J]. 复合材料学报, 2015, 32(2):534-541.ZHANG Wei, HOU Wenbin, HU Ping, et al. Mechanical properties of new negative Poisson’s ratio crush box with cellular structure in plateau stage[J]. Acta Materiae Compositae Sinica,2015,32(2):534-541(in Chinese). [9] 邸馗, 茅献彪. 对边简支负泊松比蜂窝夹层板的弯曲自由振动[J]. 复合材料学报, 2016, 33(4):910-920.DI Kui, MAO Xianbiao. Free flexural vibration of honeycomb sandwich plate with negative Poisson's ratio simply supported on opposite edges[J]. Acta Materiae Compositae Sinica,2016,33(4):910-920(in Chinese). [10] 龙凯, 谷先广, 韩丹. 考虑泊松效应的材料/结构一体化设计方法[J]. 复合材料学报, 2017, 34(6):1252-1260.LONG Kai, GU Xianguang, HAN Dan. A concurrent design method for microstructures of materials and macrostructures by considering the Poisson effect[J]. Acta Materiae Compositae Sinica,2017,34(6):1252-1260(in Chinese). [11] 秦浩星, 杨德庆. 任意负泊松比超材料结构设计的功能基元拓扑优化法[J]. 复合材料学报, 2018, 35(4):1014-1023.QIN Haoxing, YANG Deqing. Functional element topology optimal method of metamaterial design with arbitrary negative Poisson's ratio[J]. Acta Materiae Compositae Sinica,2018,35(4):1014-1023(in Chinese). [12] 吕亦乐. 负泊松比超材料的减振性能研究[D]. 成都: 电子科技大学, 2019.LU Yile. Study on damping performance of negative Poisson’s ratio metamaterials[D]. Chengdu: University of Electronic Science and Technology of China, 2019(in Chinese). [13] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3):656-689. doi: 10.6052/0459-1879-18-381REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics,2019,51(3):656-689(in Chinese). doi: 10.6052/0459-1879-18-381 [14] 于靖军, 谢岩, 裴旭. 负泊松比超材料研究进展[J]. 机械工程学报, 2018, 54(13):1-14. doi: 10.3901/JME.2018.13.001YU Jingjun, XIE Yan, PEI Xu. State-of-art of Metamaterials with negative Poisson's ratio[J]. Journal of Mechanical Engineering,2018,54(13):1-14(in Chinese). doi: 10.3901/JME.2018.13.001 [15] 王信涛. 三维有序负泊松比结构的设计、制备与力学性能表征[D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Xintao. The design, fabrication and mechanical characterization of three-dimensional periodic auxetic cellular structures[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [16] 杨志春, 邓庆田. 负泊松比材料与结构的力学性能研究与应用[J]. 力学进展, 2011, 41(3):335-350.YANG Zhichun, DENG Qingtian. Mechanical property and application of materials and structures with negative poisson's ratio[J]. Advances in Mechanics,2011,41(3):335-350(in Chinese). [17] 黄智, 王万录, 廖克俊, 等. 具有负泊松比材料的研究进展[J]. 材料导报, 2002, 16(10):49-51.HUANG Zhi, WANG Wanlu, LIAO Kejun, et al. Advances in research on with negative Poisson’s ratio materials[J]. Materials Review,2002,16(10):49-51(in Chinese). [18] 蒋欣程. 双箭头蜂窝夹层式军车装甲的防弹分析与优化[D]. 大连: 大连理工大学, 2016.JIANG Xincheng. Analysis and optimization of the ballistic resistance performance of the double arrowhead sandwich military vehicle armor[D]. Dalian: Dalian University of Technology, 2016(in Chinese). [19] LU Zixing, LI Xiang, YANG Zhenyu, et al. Novel structure with negative Poisson's ratio and enhanced Young's modulus[J]. Composite Structures,2016,138:243-252. [20] LI Yang, OLA Harrysson, HARVEY West. Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing[J]. International Journal of Solids & Structures, 2015, 69-70: 475-490. [21] YU X, ZHOU J, LIANG H, et al. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review[J]. Progress in Materials Science,2018,94:114-173. [22] CHAO M, HONGSHUAI L, JUN L, et al. Macroscopic mechanical response of chiral-type cylindrical metastructures under axial compression loading[J]. Materials & Design,2018,158:198-212. [23] SPADONI A, RUZZENE M. Elasto-static micropolar behavior of a chiral auxetic lattice[J]. Journal of the Mechanics & Physics of Solids,2012,60(1):156-171. [24] PRAWOTO Y. Seeing auxetic materials from the mechanics point of view: A structural review on the negative Poisson’s ratio[J]. Computational Materials Science,2012,58:140-153. [25] GRIMA J N, ATTARD D, ELLUL B, et al. An improved analytical model for the elastic constants of auxetic and conventional hexagonal honeycombs[J]. Cellular Polymers,2011,30(6):287-310. doi: 10.1177/026248931103000602 [26] BEZAZI A F S, REMILLAT C. A novel centersymmetric honeycomb composite structure[J]. Composite Structures,2005,71:536-564. [27] 国防科学技术工业委员会. 纤维增强复合材料无损检测方法: 第一部分超声波检验: GB/T 1038.1A—2004[S]. 北京: 中国标准出版社, 2004.Commission of Science, Technology and Industry for National Defence. Non-destructive inspecting methods for fiber reinforced plastics: Part 1: Ultrasonic inspecting: GB/T 1038.1A—2004[S], Beijing: China Standards Press, 2004(in Chinese). [28] 中国国家标准化管理委员会. 碳纤维增强塑料孔隙含量和纤维体积含量试验方法: GB/T 3365—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Carbon fiber reinforced plastics-Determination of void content and fiber volume content: GB/T 3365—2008[S]. Beijing: China Standards Press, 2008(in Chinese). -

下载:

下载: