Adhesion of SiO2-methyl vinyl silicone rubber molecular interface modified by silane coupling agents

-

摘要: 纳米SiO2掺杂已经成为提升甲基乙烯基硅橡胶(MVSR)性能的有效方法,但是纳米SiO2容易发生团聚现象,将其直接掺到MVSR基体中时,纳米SiO2难以在MVSR基体中分散,从而造成SiO2-MVSR分子界面粘结效果不佳、分子界面存在缺陷等不利影响,进而无法实现提升MVSR性能的目的。为了提升SiO2-MVSR分子界面的粘结性,使纳米SiO2在MVSR基体中更易分散,本文构建了未修饰和KH550、KH560、KH570、KH792四种硅烷偶联剂修饰下的SiO2-MVSR分子界面模型,并对模型进行结构优化和分子动力学计算。通过比较不同模型中分子界面的结合能、粘结深度和粘结热稳定性的变化规律,从分子结构角度分析硅烷偶联剂修饰下SiO2-MVSR分子界面粘结性提升的原因。研究表明:提升SiO2-MVSR分子界面粘结性的关键在于优选硅烷偶联剂的非水解基团,当非水解基团中与MVSR分子链相同的化学键占比越大,包含电负性较强原子的数量越多时,修饰后SiO2-MVSR分子界面粘结性的提升效果就越好,同时,硅烷偶联剂较长的链长与较大的相对分子质量也会对粘结性的提升起到一定帮助。

-

关键词:

- 硅烷偶联剂 /

- 修饰 /

- 二氧化硅-甲基乙烯基硅橡胶分子界面 /

- 粘结性 /

- 分子动力学模拟

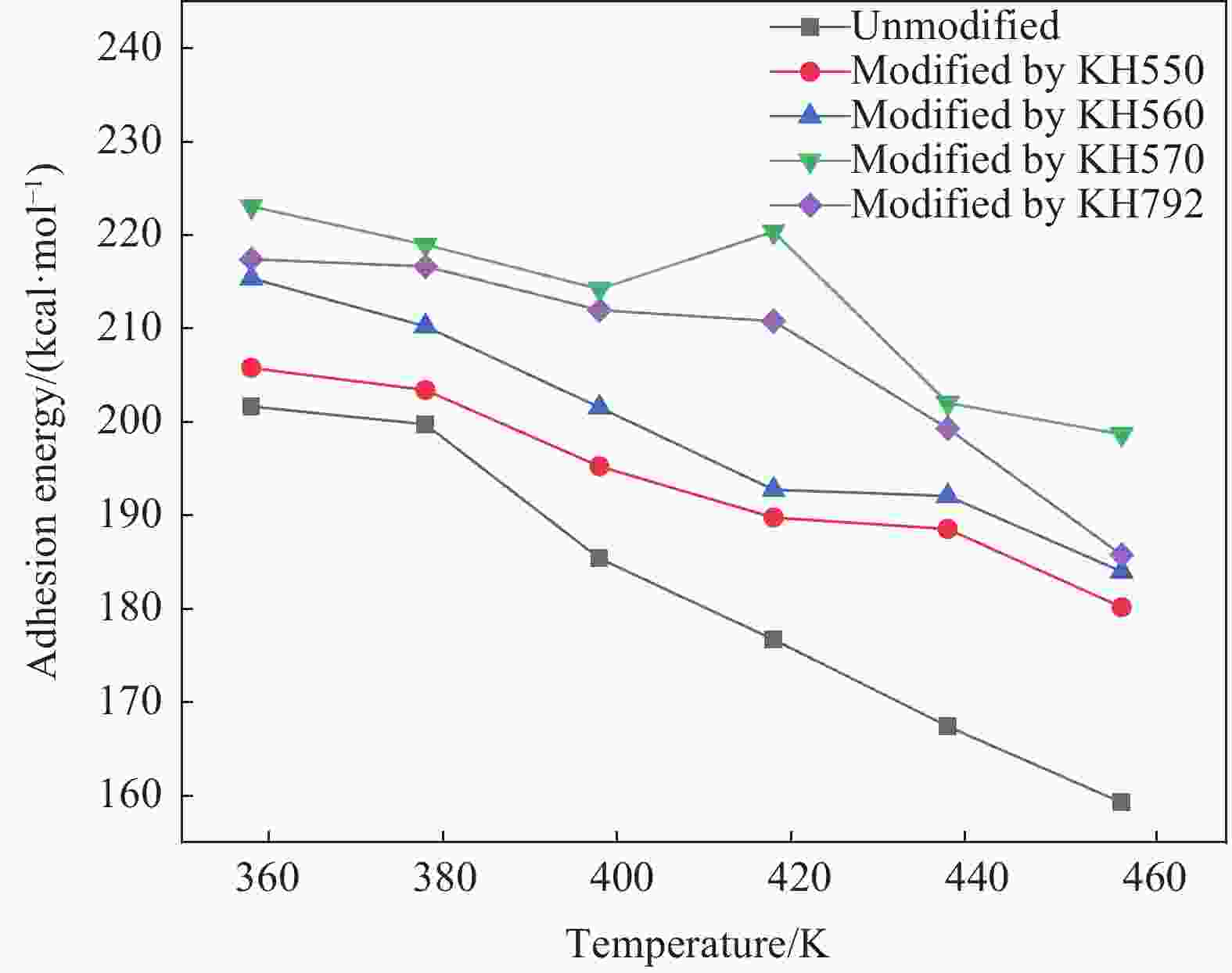

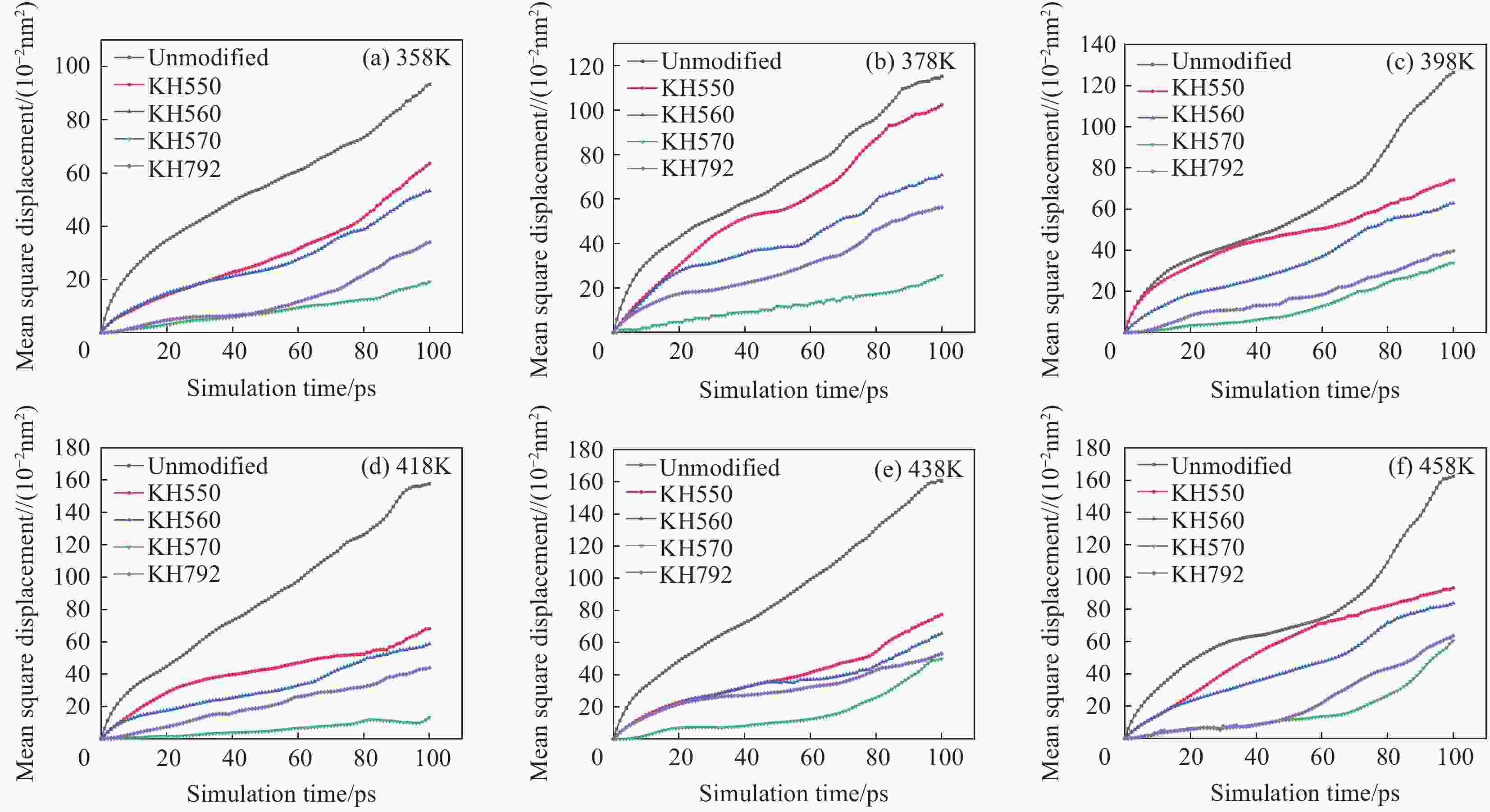

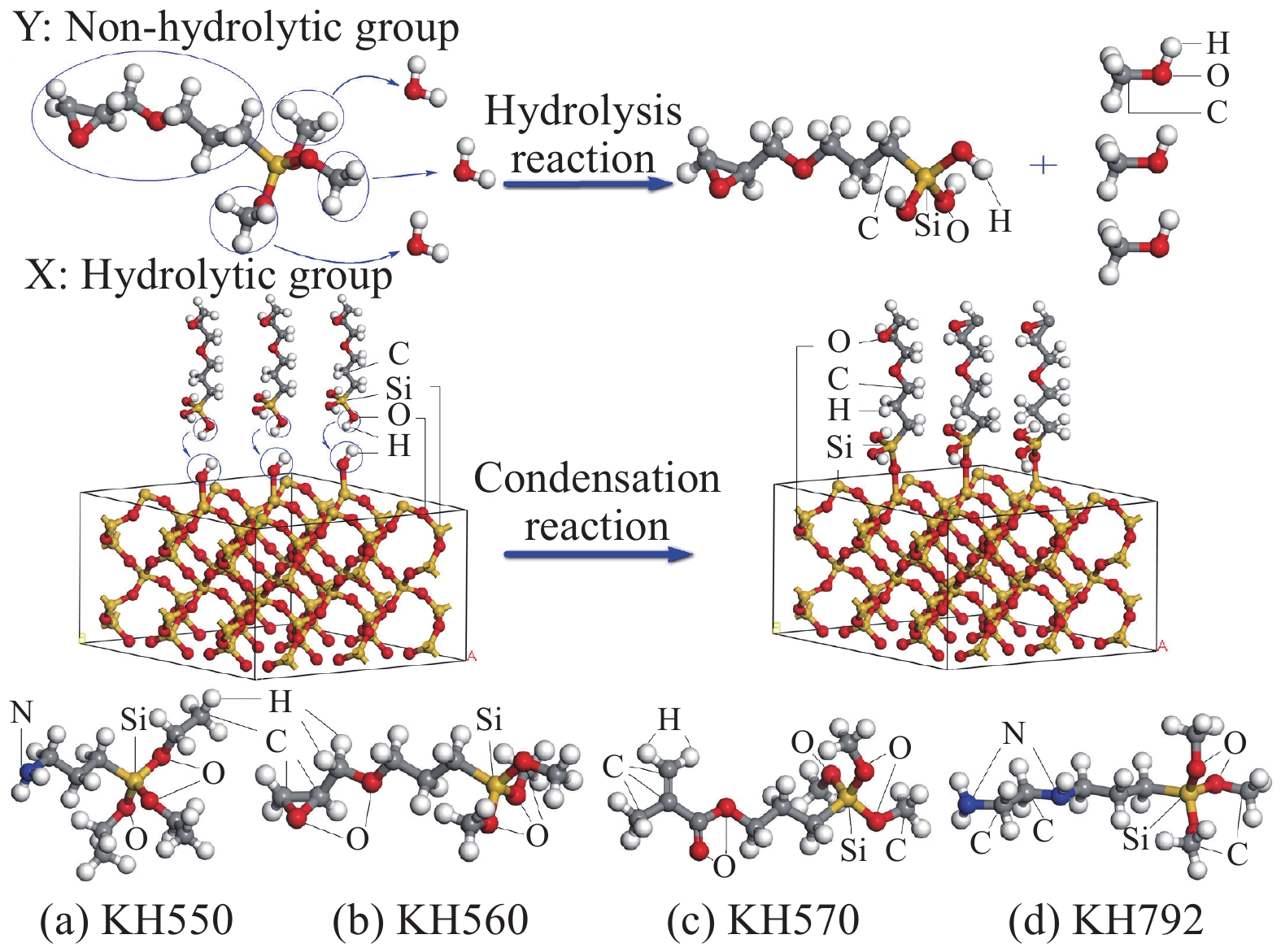

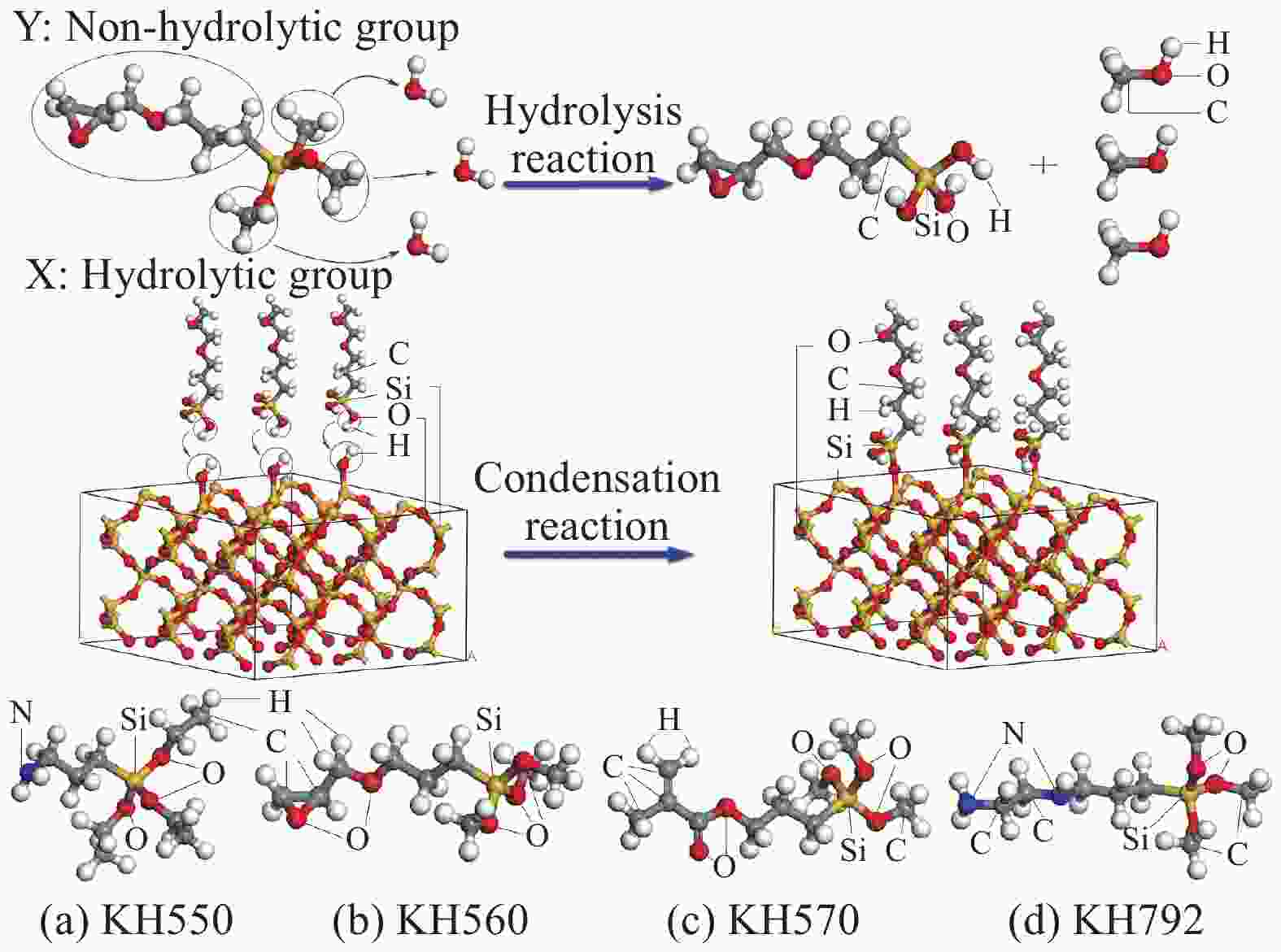

Abstract: Nano-SiO2 doping has become an effective way to improve the performance of methyl vinyl silicone rubber (MVSR). However, nano-SiO2 is easy to agglomerate. When it is directly mixed into MVSR matrix, nano-SiO2 is difficult to disperse in MVSR matrix, resulting in poor adhesion effect of SiO2-MVSR molecular interface, defects in the molecular interface and other adverse effects, so that the purpose of improving MVSR performance cannot be achieved. In order to improve the adhesion of SiO2-MVSR molecular interface and make nano-SiO2 more easily dispersed in MVSR matrix, this paper constructed the SiO2-MVSR molecular interface models that unmodified and modified by KH550, KH560, KH570 and KH792, and carried out structural optimization and molecular dynamics calculation. By comparing the adhesion energies, adhesion depths and adhesion thermal stabilities of the molecular interface in different models, the reason for the improvement of the adhesion of SiO2-MVSR molecular interface modified by silane coupling agents was analyzed from the perspective of molecular structure. The results show that the key to improve the adhesion of SiO2-MVSR molecular interface is to select the non-hydrolytic group of the silane coupling agents. When the proportion of the same chemical bond between the non-hydrolytic group and MVSR molecular chain is larger, and the number of more electronegative atoms is more, the effect of improving the adhesion of SiO2-MVSR molecular interface is better. At the same time, the longer chain length and larger relative molecular weight of silane coupling agent will also help to improve the adhesion. -

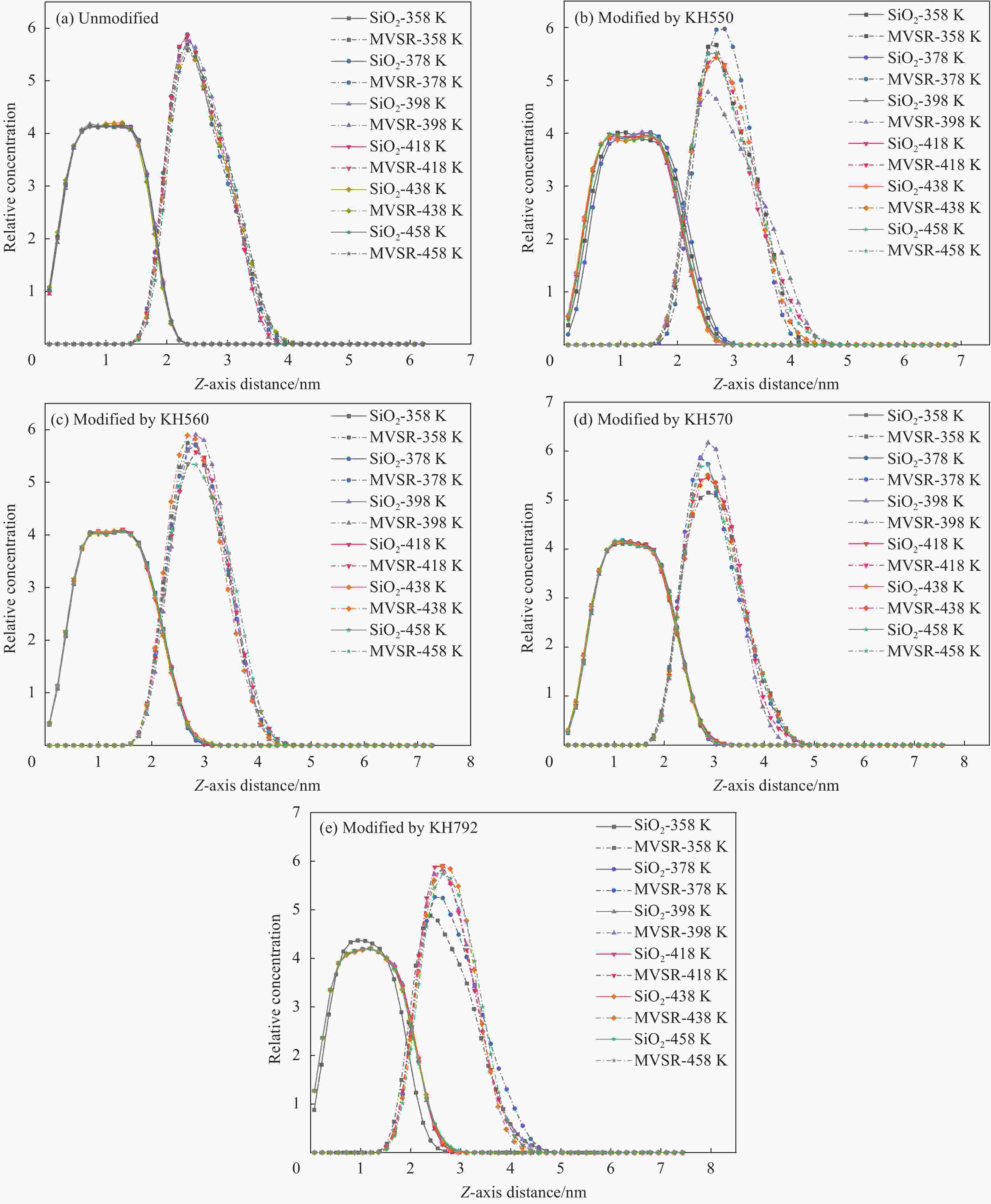

表 1 不同分子界面模型中SiO2及MVSR沿Z轴方向分布的重叠区域及粘结深度

Table 1. Overlapping regions and adhesion depths of SiO2 and MVSR along Z-axis in different molecular interface models

Model category Overlapping area/nm Adhesion depth/nm Unmodified 1.402-2.203 0.801 Modified by KH550 1.522-2.971 1.449 Modified by KH560 1.605-3.283 1.678 Modified by KH570 1.634-3.345 1.711 Modified by KH792 1.358-3.016 1.658 表 2 4种硅烷偶联剂的链长与相对分子质量

Table 2. Chain lengths and relative molecular weights of 4 kinds of silane coupling agents

Category Chain length/nm Relative molecular weight KH550 0.5426 221 KH560 0.8965 236 KH570 0.9140 248 KH792 0.8639 222 表 3 4种硅烷偶联剂的结构信息

Table 3. Structure information of 4 kinds of silane coupling agents

Category Non-hydrolytic group Central element Hydrolytic group Hetero group Same group KH550 NH2— CH2—CH2—CH2— Si —(OCH3)3 KH560 CH2—(O)CH—CH2—O— KH570 CH2=(CH3)C—(O)C—O— KH792 NH2—CH2—CH2—NH— 表 4 358~458 K温度条件下SiO2-MVSR不同分子界面模型中形成的氢键数量

Table 4. Numbers of hydrogen bonds formed in different SiO2-MVSR molecular interface models at 358-458 K

Model category 358 K 378 K 398 K 418 K 438 K 458 K Unmodified 195 167 181 174 176 190 Modified by KH550 270 258 280 287 265 265 Modified by KH560 237 240 234 227 196 216 Modified by KH570 242 247 243 247 231 257 Modified by KH792 299 280 289 300 308 283 表 5 甲基乙烯基硅橡胶分子单链结构信息

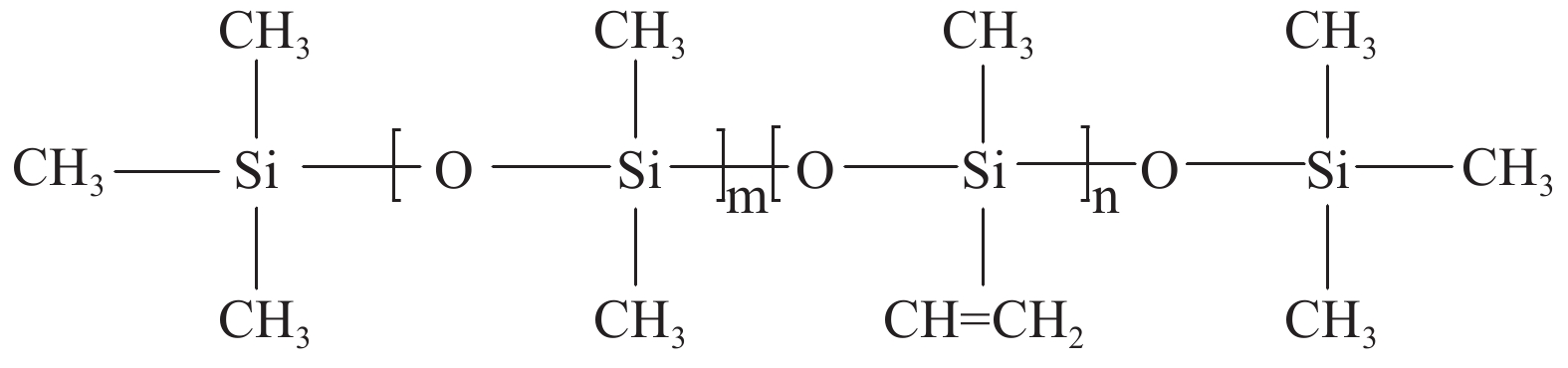

Table 5. Single chain structure information of methyl vinyl silicone rubber

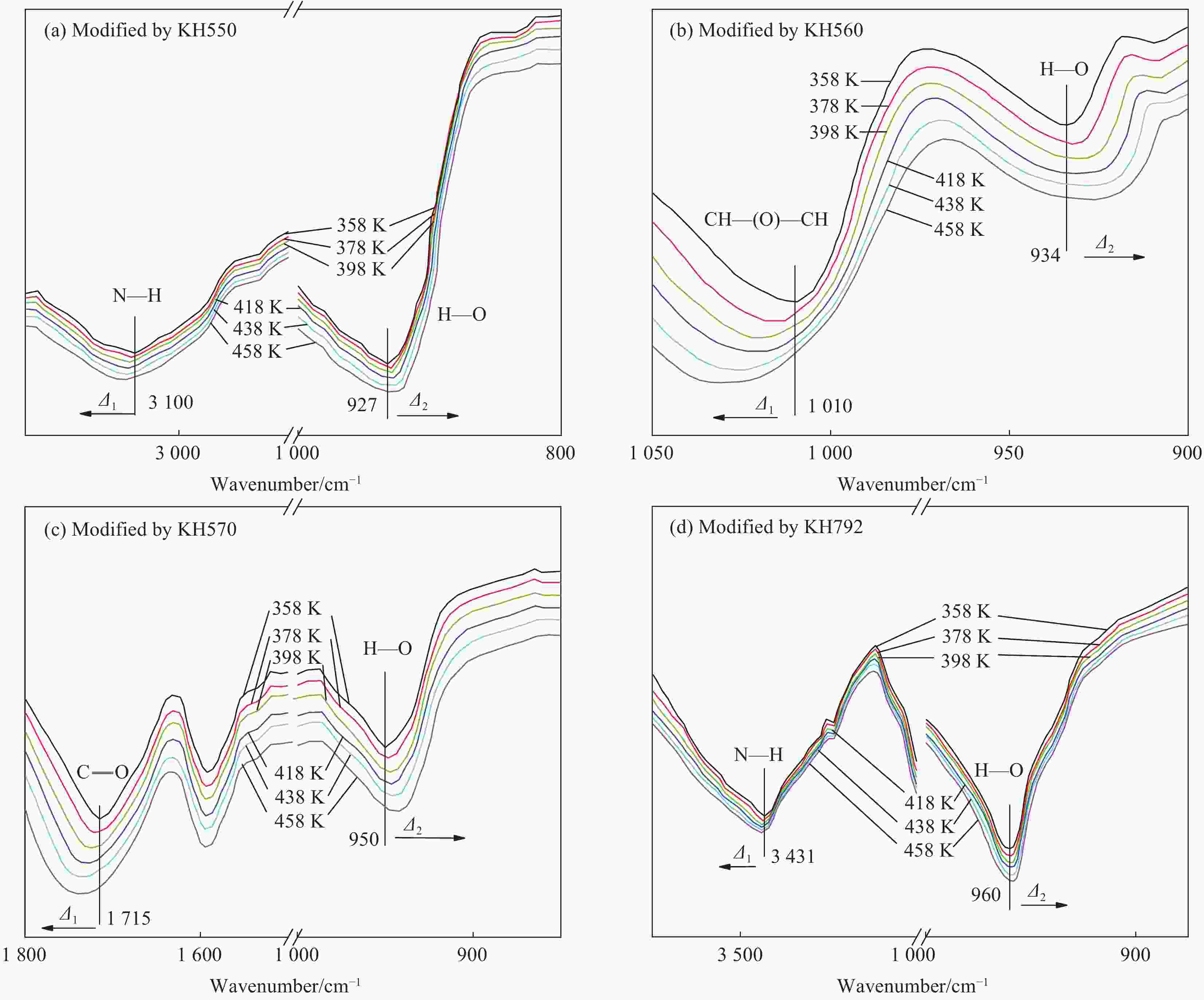

Head/tail group Link formation Functional group Link trunk Different groups Same group —Si(CH3)3 Dimethylsiloxane chain link CH3— CH3— Si—O —OSi(CH3)3 Methyl vinyl siloxane chain link CH2=CH— CH3— 表 6 各试样中硅烷偶联剂官能团与SiO2表面上的H—O峰位变化

Table 6. Peak position change of the functional group of silane coupling agent and H—O on the surface of silicon dioxide in each sample

Model category Δ1/cm−1 Δ2/cm−1 Modified by KH550 19 4 Modified by KH560 24 13 Modified by KH570 23 9 Modified by KH792 9 2 Notes: Δ1—Absolute value of the difference between the peak position of the stretching vibration peak of the silane coupling agent at 358 K and the peak position at 458 K; Δ2—Absolute value of the difference between the peak position of the bending vibration peak of H—O at 358 K and the peak position at 458 K on the surface of SiO2. -

[1] 欧阳舴艋, 李双双, 石琢, 等. 改性纳米SiO2/硅橡胶复合材料的制备及性能[J]. 复合材料学报, 2019, 36(7):1700-1707.OUYANG Zemeng, LI Shuangshuang, SHI Zhuo, et al. Preparation and properties of modified nano-SiO2/silicone rubber composite[J]. Acta Materiae Compositae Sinica,2019,36(7):1700-1707(in Chinese). [2] 穆晓东, 崔雨果, 方庆红, 等. 白炭黑的功能化改性及其改性橡胶基复合材料的制备与表征[J]. 复合材料学报, 2017, 34(1):67-74.MU Xiaodong, CUI Yuguo, FANG Qinghong, et al. Preparation and characterization of functionalization of silica and its rubber matrix composites[J]. Acta Materiae Compositae Sinica,2017,34(1):67-74(in Chinese). [3] 宋英泽, 宋丽贤, 芦艾, 等. 白炭黑表面接枝乙烯基改性及其对硅橡胶硫化性能的影响[J]. 硅酸盐学报, 2013, 41(5):674-678.SONG Yingze, SONG Lixian, LU Ai, et al. Modi fication of silica surface by grafting vinyl and its effect on vulcanization of silicone rubber[J]. Journal of the Chinese Ceramic Society,2013,41(5):674-678(in Chinese). [4] 欧宝立, 李笃信. 表面修饰纳米SiO2增强增韧聚氯乙烯[J]. 复合材料学报, 2009, 26(1):48-53. doi: 10.3321/j.issn:1000-3851.2009.01.009OU Baoli, LI Duxin. Surface modified nano-SiO2 reinforced and toughened PVC[J]. Acta Materiae Compositae Sinica,2009,26(1):48-53(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.009 [5] 杜高翔, 左然芳, 梅乐夫, 等. 硅烷偶联剂改性硅藻土及其对天然橡胶/丁苯橡胶补强效果的影响[J]. 稀有金属材料与工程, 2013, 42(1):412-417.DU Gaoxiang, ZUO Ranfang, MEI Lefu, et al. Surface modification of diatomite by silane coupling agent and its effect on the reinforcing efficiency of NR/SBR blend[J]. Rare Metal Materials and Engineering,2013,42(1):412-417(in Chinese). [6] YAN F H, ZHANG X B, LIU F, et al. Adjusting the properties of silicone rubber filled with nanosilica by changing the surface organic groups of nanosilica[J]. Composites Part B: Engineering,2015,75:47-52. doi: 10.1016/j.compositesb.2015.01.030 [7] ZHANG X P, GUAN Y Y, ZHAO Y F, et al. Reinforcement of silicone rubber with raspberry-like SiO2@polymer composite particles[J]. Polymer International,2015,64(8):992-998. doi: 10.1002/pi.4900 [8] 陈宇飞, 岳春艳, 李治国, 等. 有机蒙脱土/聚氨酯弹性体复合材料的微观形貌及力学性能[J]. 复合材料学报, 2019, 36(9):2086-2092.CHEN Yufei, YUE Chunyan, LI Zhiguo, et al. Microstruc ture and mechanical properties of organic montmorillonite/polyurethane elastomer composites[J]. Acta Materiae Compositae Sinica,2019,36(9):2086-2092(in Chinese). [9] 谢艳霞, 毕松梅, 王东强, 等. 聚乙烯醇修饰Sb2O3/氯丁胶乳复合材料的制备及其分散稳定性[J]. 复合材料学报, 2018, 35(9):2535-2541.XIE Yanxia, BI Songmei, WANG Dongqiang, et al. Preparation and dispersion stability of Sb2O3/chloroprene latex composite modified with polyvinyl alcohol[J]. Acta Materiae Compositae Sinica,2018,35(9):2535-2541(in Chinese). [10] SONG Y Z, YU J H, DAI D, et al. Effect of silica particles modified by in-situ and ex-situ methods on the reinforcement of silicone rubber[J]. Materials & Design,2014,64:687-693. [11] 张超灿, 何东铭, 郝爽. 两亲性聚合物改性二氧化硅及其与聚丙烯酸酯乳液复合体系性能研究[J]. 武汉理工大学学报, 2000, 22(6):8-17. doi: 10.3321/j.issn:1671-4431.2000.06.003ZHANG Chaocan, HE Dongming, HAO Shuang. Study on properties of two affinity polymer modified silica and its polyacrylate emulsion composite system[J]. Journal of Wuhan University of Technology,2000,22(6):8-17(in Chinese). doi: 10.3321/j.issn:1671-4431.2000.06.003 [12] MA X K, NAM-HEE L, HYO-JIN O, et al. Surface modification and characterization of highly dispersed silica nanoparticles by a cationic surfactant[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2010,358(1):172-176. [13] ZHU J, JONG D K, PENG H Q, et al. Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization[J]. Nano Letters. 2003, 3(8): 1107-1113. [14] 张径晗. 二氧化硅/聚丙烯酰胺-丙烯酸核壳微球的分子动力学模拟与实验研究[D]. 成都: 西南石油大学, 2016.ZHANG Jinghan. Molecular dynamics simulation and experimental study of silica/polyacrylamide acrylic core-shell microspheres[D]. Chengdu: Southwest Petroleum University, 2016(in Chinese). [15] 高俊国, 孙伟峰, 李明, 等. 石墨纳米片/聚乙烯复合物分子动力学模拟[J]. 复合材料学报, 2018, 35(8):2274-2285.GAO Junguo, SUN Weifeng, LI Ming, et al. Molecular dynamics simulation of graphite-nanoplatelet/polyethylene composites[J]. Acta Materiae Compositae Sinica,2018,35(8):2274-2285(in Chinese). [16] 郭睿. 聚乙烯/二氧化硅纳米复合材料微观结构与电学性能仿真[D]. 哈尔滨: 哈尔滨理工大学, 2019.GUO Rui. Simulation of microstructure and electrical properties of polyethylene/silica nanocomposites[D]. Harbin: Harbin University of Science and Technology, 2019(in Chinese). [17] JENSEN A, LOHMANN S, BENZON H. Molecular dynamics simulation of aqueous solutions using interaction energy components: application to the solvation Gibbs energy[J]. Journal of Solution Chemistry,2005,34(4):407-414. doi: 10.1007/s10953-005-5191-9 [18] 王小波. 硅烷偶联剂修饰纳米SiO2对其改性纤维素绝缘纸性能的微观机理研究[D]. 重庆: 西南大学, 2019.WANG Xiaobo. Study on the micro mechanism of Nano-SiO2 modified by silane coupling agent on the properties of cellulose insulating paper[D]. Chongqing: Southwest University, 2019(in Chinese). [19] GUN’KO V M, BORYSENKO M V, et al. Polydimethylsiloxane at the interfaces of fumed silica[J]. Applied Surface Science,2007,25(3):7143-7156. [20] OZAKI H, NARITA T, KOGA T, et al. Theoretical analysis of critical flowable physical gel cross-linked by metal ions and polyacrylamide-derivative associating polymers containing imidazole groups[J]. Polymers,2017,9(7):256. [21] SINGH P. A molecular scale perspective: Monte Carlo simulation for rupturing of ultra thin polymer film melts[J]. Physics Letters A,2017,25(2):381-386. [22] 陈柯旭, 芦艾, 康明, 等. 改性荧光SiO2微球在硅橡胶中分散性的可视化研究[J]. 功能材料, 2019, 50(7):7060-7065, 7070.CHEN Kexu, LU Ai, KANG Ming, et al. Visualization of dispersion of modified fluorescent SiO2 microspheres in silicone rubber[J]. Jorunal of Functional Materials,2019,50(7):7060-7065, 7070(in Chinese). [23] MA Q, MAO B, Cebe P. Chain confinement in electrospun nanocomposites[J]. Ploymer,2011,52(4):3190-3200. [24] 陈玉刚, 李晓, 赵慧欣, 等. 硅烷偶联剂对纳米二氧化硅/硅橡胶复合材料界面作用及性能的影响[J]. 合成橡胶工业, 2015, 38(3):200-205. doi: 10.3969/j.issn.1000-1255.2015.03.008CHEN Yugang, LI Xiao, ZHAO Huixin, et al. Effect of silane coupling agent on the interface action and properties of nano silica/silicone rubber composite[J]. China Synthetic Rubber Industry,2015,38(3):200-205(in Chinese). doi: 10.3969/j.issn.1000-1255.2015.03.008 -

下载:

下载: