Multi-objective optimization for curing process of thick composite based on multi-physics coupling method

-

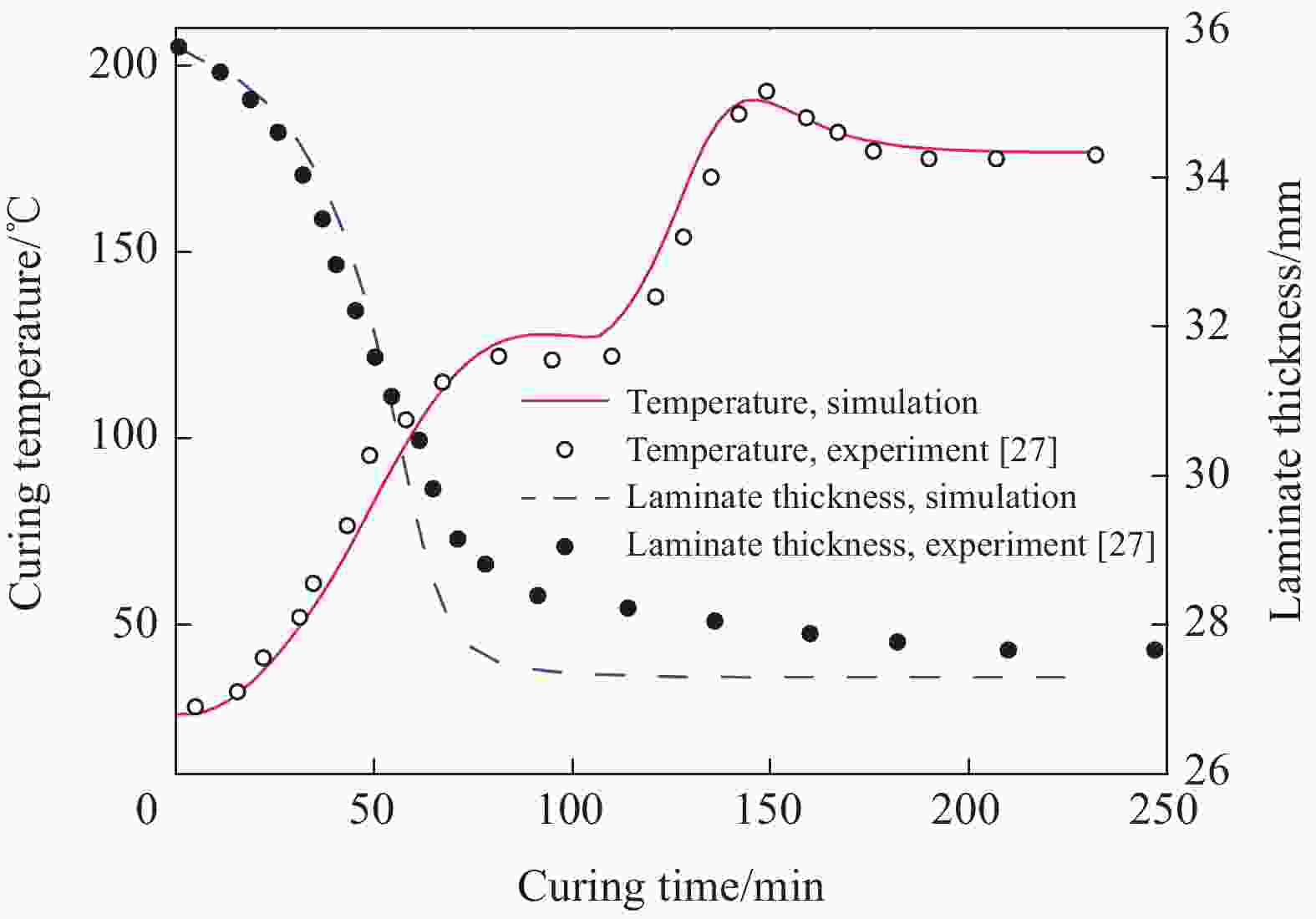

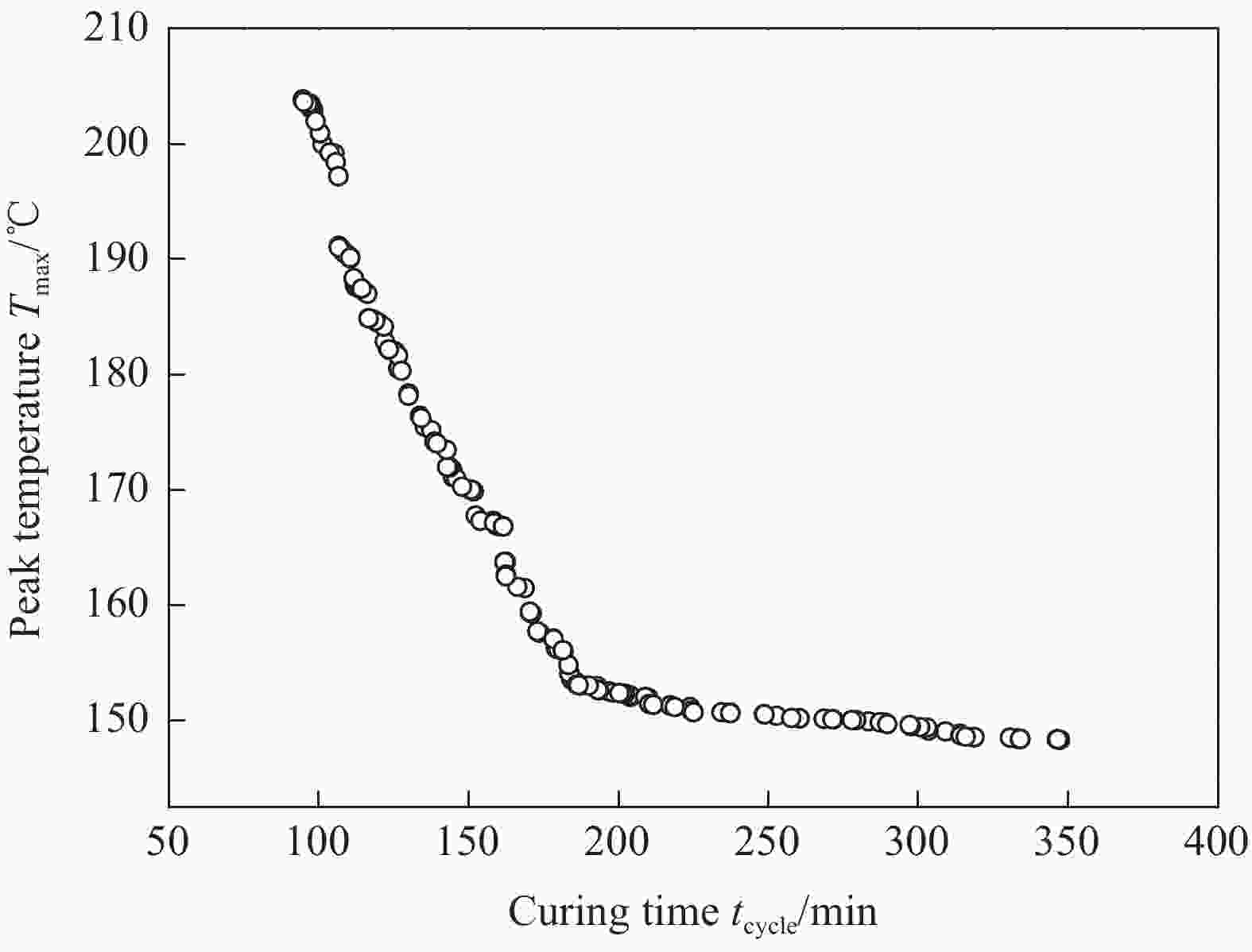

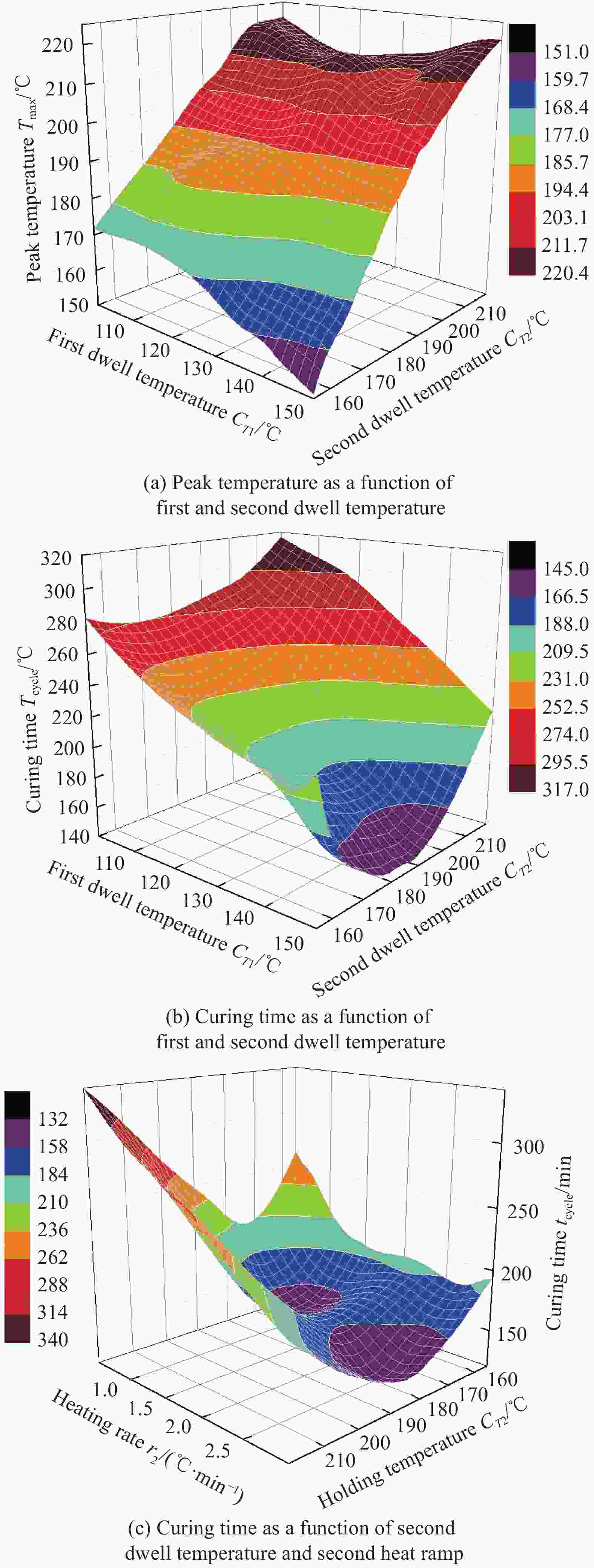

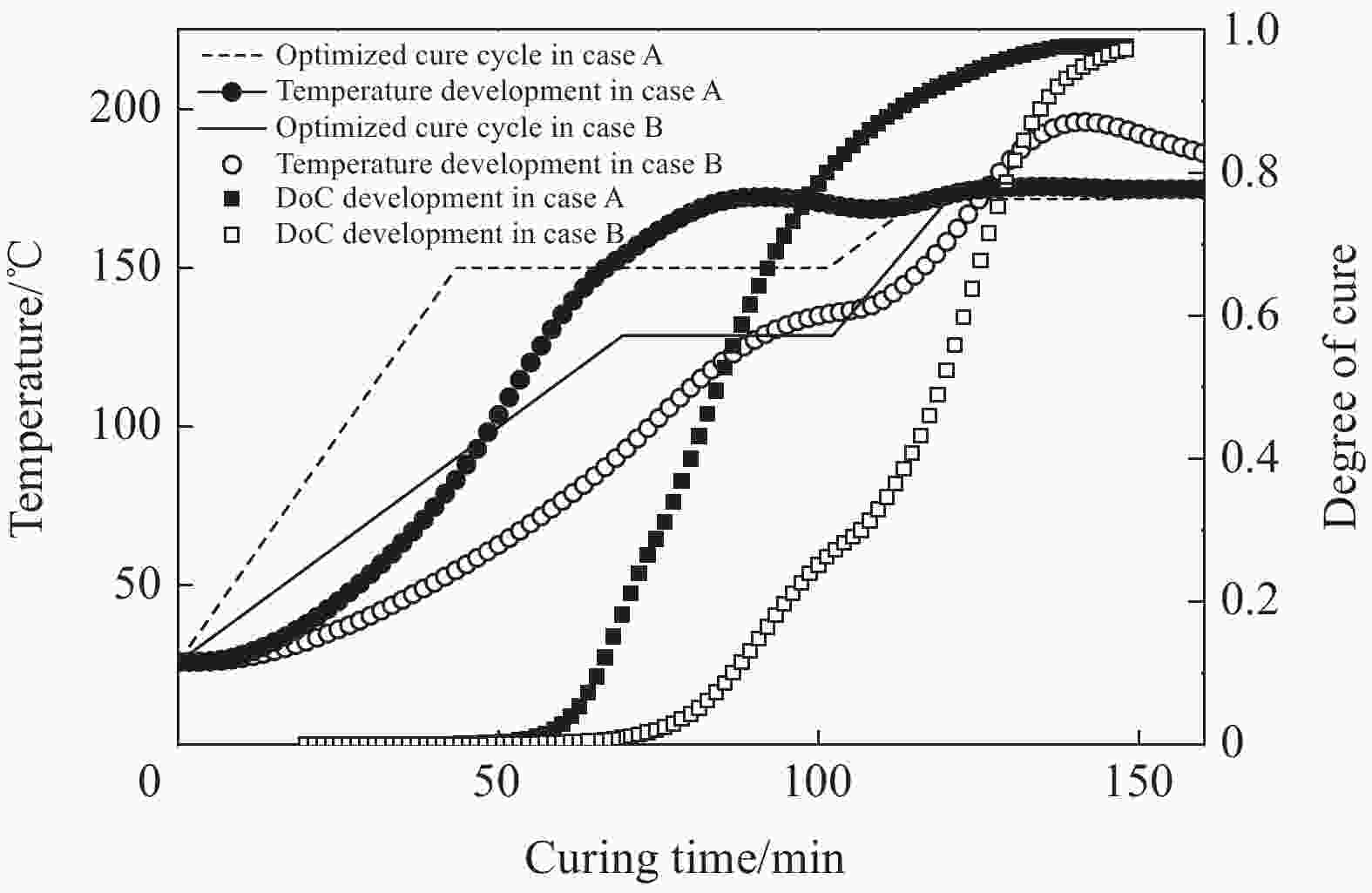

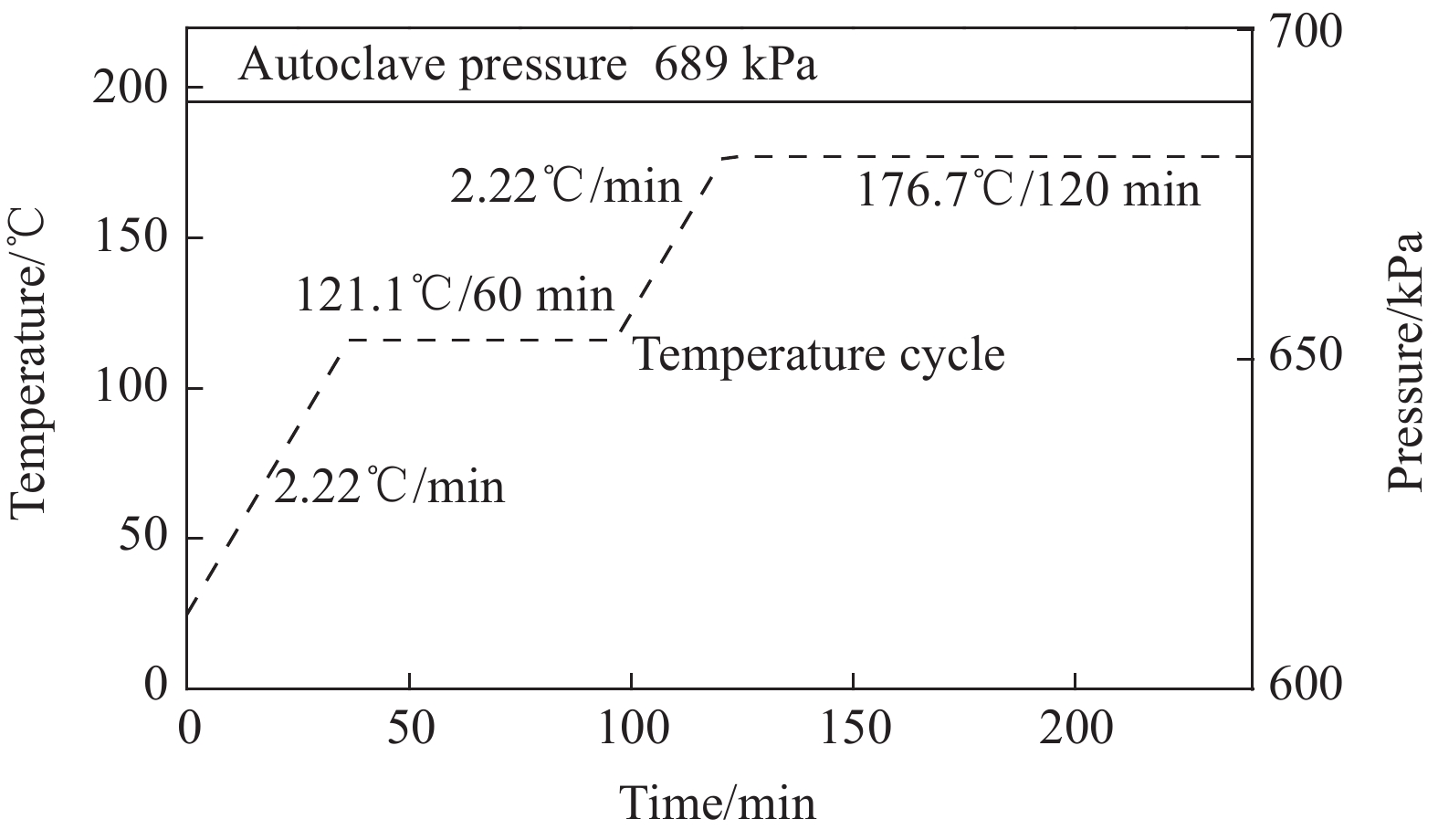

摘要: 针对厚截面复合材料固化过程温度峰值过大所引起的材料力学性能降低及残余应力过大等问题,建立了基于多场耦合方法的复合材料固化过程多目标优化模型,用以降低固化温度峰值和缩短固化时间。首先建立包含热化学子模型、树脂黏度子模型和流动压实子模型的固化温度多场耦合模型,用以准确描述固化过程复合材料内部温度及构件厚度的演化规律。通过与文献中已有实验结果比较,证明所建立的多场耦合模型的有效性。在该多场耦合模型基础上,引入径向基(RBF)神经网络作为代理模型,利用多目标优化方法,对固化工艺参数进行最佳组合匹配。研究表明,温度峰值与保温平台温度变化呈明显非线性关联,这与复合材料固化过程的非线性特性有很大关系。在保温温度层面,为了降低温度峰值,需要提高第一阶段的保温温度,降低第二阶段的保温温度,同时在保温平台的时间上进行调整,以缩短固化时长。相比较于原有固化工艺制度,本文提出的优化方法可以显著降低厚截面复合材料层合板的固化时长和温度峰值。Abstract: In order to reduce the mechanical properties and the curing residual stress of the thick composite caused by the excessive temperature peak during the curing process, a multi-objective optimization model based on the multi-physics coupling characteristics was developed to reduce the maximum curing temperature peak and the curing time. Firstly, a three-dimensional model which incorporated three typical sub-models including thermo-chemical model, resin viscosity model and resin flow model was established to investigate the development of temperature and thickness of laminate during curing process. The results of numerical model were compared with experiment data in reference and good accordance was obtained. Then, a multi-objective optimization method was applied to optimize curing process parameters by using a radial basis function neural network model (RBF) as the surrogate model. It is shown that the curing temperature peak has a nonlinear relationship with the first and second dwell temperature, which is related to the nonlinear characteristics of the curing process. In order to reduce the temperature peak, it is necessary to increase the first dwell temperature and reduce the second dwell temperature. Meanwhile, the dwell time should also be adjusted to shorten the total curing time. Compared to standard cure profiles, the proposed optimization method can significantly reduce the curing time and temperature peak for thick composite laminates.

-

Key words:

- composite /

- curing process /

- surrogate model /

- optimization /

- multi-physics coupling

-

表 1 3501-6环氧树脂和AS4碳纤维的材料性能

Table 1. Properties of 3501-6 epoxy resin and AS4 carbon fiber

Parameter Value Resource Resin density ρr/(kg·m−3) 90α+1 232(α ≤ 0.45)

1 272 (α>0.45)[27] Resin specific heat Cr/(J·(kg·K)−1) 4 184[0.468+5.975×10−4T−0.141α] [27] Resin thermal conductivity λr/(W·(m·K)−1) 0.04184[3.85+(0.035T−0.141)α] [27] Fiber density ρf/(kg·m−3) 1 790 [24] Fiber specific heat variation with cure Cf/(J·(kg·K)−1) 750+2.05×T(℃) [24] Fiber conductivity in the longitudinal direction $\lambda _{\rm{f}}^{\rm{L}} $/(W·(m·K)−1) 7.69+0.0156×T(℃) [24] Fiber conductivity in the transverse direction $\lambda _{\rm{f}}^{\rm{T}} $/(W·(m·K)−1) 2.4+0.00507×T(℃) [24] Resin viscosity constant η∞/(Pa·s) 7.93×10−14 [23] Activation energy of viscous flow U/(J·mol−1) 9.08×104 [23] Constant irrelevant with temperature ηβ 14.1 [23] Preexponential factor of autocatalysis model A1/min−1 2.101×109 [23] A2/min−1 −2.014×109 [23] A3/min−1 1.96×105 [23] Activity energy of autocatalysis model ∆E1/(J·mol−1) 8.07×104 [23] ∆E2/(J·mol−1) 7.78×104 [23] ∆E3/(J·mol−1) 5.66×104 [23] Notes: ρr—Density of resin; Cr—Specific heat of resin; λr—Heat conduction coefficient of resin; ρf—Density of fiber; Cf—Specific heat of fiber; $\lambda _{\rm{f}}^{\rm{L}} $—Heat conduction coefficient of fiber along the fiber direction; $\lambda _{\rm{f}}^{\rm{T}} $ — Heat conduction coefficient of fiber perpendicular the fiber direction; kx and ky—Permeability of composite along x direction and y direction; η∞—Viscosity constant; U—Activation energy of viscose flow; ηβ—Constant irrelevant with temperature; A1, A2 and A3—Frequency factor of autocatalysis model; ∆E1, ∆E2 and ∆E3—Activation energy of autocatalysis model. 表 2 AS4/3501-6预浸料固化工艺参数设计区间

Table 2. Design space of curing process parameters of AS4/3501-6 prepregs

Parameter Maximum value Minimum value CT1/℃ 100 150 CT2/℃ 155 220 r1/(℃·min−1) 0.5 3 r2/(℃·min−1) 0.5 3 t1/min 30 120 t2/min 30 120 Notes: CT1—First holding-stage temperature; CT2—Second holding-stage temperature; r1—First heating rate; r2—Second heating rate; t1—Duration of first holding-stage; t2—Duration of second holding-stage. -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] DING A X, WANG J H, NI A Q, et al. A new analytical solution for cure-induced spring-in of L-shaped composite parts[J]. Composites Science and Technology,2019,171:1-12. doi: 10.1016/j.compscitech.2018.12.004 [3] ZHANG J T, ZHANG M, LI S X, et al. Residual stresses created during curing of a polymer matrix composite using a viscoelastic model[J]. Composites Science and Technology,2016,130:20-27. doi: 10.1016/j.compscitech.2016.05.002 [4] SINGH S B, VUMMADISETTI S, CHAWLA H. Influence of curing on the mechanical performance of FRP laminates[J]. Journal of Building Engineering,2018,16:1-19. doi: 10.1016/j.jobe.2017.12.002 [5] DANZI F, FANTERIA D, PANETTIERI E, et al. A numerical micro-mechanical study on damage induced by the curing process in carbon/epoxy unidirectional material[J]. Composite Structures,2019,210:755-766. doi: 10.1016/j.compstruct.2018.11.059 [6] LUCA E, LUCA S, FRANCESCO P, et al. Effect of curing overheating on interlaminar shear strength and its modelling in thick FRP laminates[J]. The International Journal of Advanced Manufacturing Technology,2016,87:2213-2220. doi: 10.1007/s00170-016-8613-5 [7] 王猛, 郭飞, 于静巍, 等. 热残余应力对考虑微观孔隙碳纤维增强环氧树脂复合材料横向拉伸性能的影响[J]. 复合材料学报, 2019, 36(5):1101-1113.WANG Meng, GUO Fei, YU Jingwei, et al. Effects of thermal residual stress on transverse ensile strength of unidirectional carbon fiber reinforced epoxy composites considering void[J]. Acta Materiae Compositae Sinica,2019,36(5):1101-1113(in Chinese). [8] UMARFAROOQ M A, GOUDA P S S, KUMAR G B V, et al. Impact of process induced residual stresses on interlaminar fracture toughness in carbon epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2019,127:105652. doi: 10.1016/j.compositesa.2019.105652 [9] SORRENTINO L, ESPOSITO L, BELLINI C. A new methodology to evaluate the influence of curing overheating on the mechanical properties of thick FRP laminates[J]. Compo-sites Part B: Engineering,2016,109:187-196. [10] STRUZZIERO G, SKORDOS A A. Multi-objective optimisation of the cure of thick components[J]. Composites Part A: Applied Science and Manufacturing,2017,93:126-136. doi: 10.1016/j.compositesa.2016.11.014 [11] HU H X, CAO D F, PAVIER M, et al. Investigation of non-uniform gelation effects on residual stresses of thick laminates based on tailed FBG sensor[J]. Composite Structures,2018,202:1361-1372. doi: 10.1016/j.compstruct.2018.06.074 [12] 刘桂铭, 湛利华, 陈效平, 等. 厚截面复合材料固化温度不均匀性对力学性能的影响[J]. 玻璃钢/复合材料, 2018, 9:23-29. doi: 10.3969/j.issn.1003-0999.2018.01.004LIU Guiming, ZHAN Lihua, CHEN Xiaoping, et al. Effects of thick composite curing temperature non-uniformity on mechanical properties[J]. Fiber Reinforced Plastic/Composites,2018,9:23-29(in Chinese). doi: 10.3969/j.issn.1003-0999.2018.01.004 [13] WHITE S R, HAHN H T. Cure cycle optimization for the reduction of processing-induced residual stresses in composite materials[J]. Journal of Composite Materials,1993,27(14):1352-1378. doi: 10.1177/002199839302701402 [14] 杨洋, 王洪恩, 袁协尧, 等. 碳纤维/环氧超厚度复合材料壁板的固化工艺优化及性能[J]. 高分子材料科学与工程, 2017, 33(10):101-107.YANG Yang, WANG Hongen, YUAN Xieyao, et al. Curing process optimization with extra-thickness carbon fiber reinforced epoxy resin matrix composites and their properties[J]. Polymer Materials Science and Engineering,2017,33(10):101-107(in Chinese). [15] WANG L Y, ZHU W D, WANG Q, et al. A heat-balance method for autoclave process of composite manufacturing[J]. Journal of Composite Materials,2018,53:641-652. [16] 傅承阳, 李迎光, 李楠垭, 等. 飞机复合材料制件热压罐成型温度场均匀性优化方法[J]. 材料科学与工程学报, 2013, 31(2):273-277.FU Chengyang, LI Yingguang, LI Nanya, et al. Temperature uniformity optimizing method of the aircraft compo-site parts in autoclave processing[J]. Journal of Material Science and Engineering,2013,31(2):273-277(in Chinese). [17] LI N, LI Y, JELONNEK J, et al. A new process control method for microwave curing of carbon fibre reinforced composites in aerospace applications[J]. Composites Part B: Engineering,2017,122:61-70. doi: 10.1016/j.compositesb.2017.04.009 [18] TIFKITSIS K I, MESOGITIS T S, STRUZZIERO G, et al. Stochastic multi-objective optimisation of the cure process of thick laminates[J]. Composites Part A: Applied Science and Manufacturing,2018,112:383-394. doi: 10.1016/j.compositesa.2018.06.015 [19] CHANG T, ZHAN L, TAN W, et al. Optimization of curing process for polymer-matrix composites based on orthogonal experimental method[J]. Fibers and Polymers,2017,18(1):148-154. doi: 10.1007/s12221-017-6606-0 [20] 元振毅, 王永军, 张跃, 等. 基于材料性能时变特性的复合材料固化过程多场耦合数值模拟[J]. 复合材料学报, 2015, 32(1):167-175.YUAN Zhenyi, WANG Yongjun, ZHANG Yue, et al. Multi-field coupled numerical simulation for curing process of composites with time-dependent properties of materials[J]. Acta Materiae Compositae Sinica,2015,32(1):167-175(in Chinese). [21] 李树健, 湛利华, 白海明, 等. 基于树脂流动的变截面复合材料结构固化过程热-流-固多场强耦合数值仿真[J]. 复合材料学报, 2018, 35(8):2095-2102.LI Shujian, ZHAN Lihua, BAI Haiming, et al. Numerical simulation of heat-flow-solid multi-field strong coupling in curing process of variable cross-section composite structures based on the resin flow[J]. Acta Materiae Compositae Sinica,2018,35(8):2095-2102(in Chinese). [22] BOGETTI T A, GILLESPIE J W. Two-dimensional cure simulation of thick thermosetting composites[J]. Journal of Composite Materials,1991,25(3):239-273. doi: 10.1177/002199839102500302 [23] LEE W I, LOOS A C, SPRINGER G S. Heat of reaction, degree of cure, and viscosity of Hercules 3501-6 resin[J]. Journal of Composite Materials,1982,16(6):510-520. doi: 10.1177/002199838201600605 [24] JOHNSTON A A. An integrated model of the development of process-induced deformation in autoclave processing of composite structures[D]. Vancouver: University of British Columbia, 1997. [25] SPRINGER G S, TSAI S W. Thermal conductivities of unidirectional materials[J]. Journal of Composite Materials,1979,1(2):166-173. [26] DAVE R. A unified approach to modeling resin flow during composite processing[J]. Journal of Composite Materials,1990,24(1):22-41. doi: 10.1177/002199839002400102 [27] SHIN D D, HAHN H T. Compaction of thick composites: Simulation and experiment[J]. Polymer Composites,2004,25(1):49-59. doi: 10.1002/pc.20004 [28] SHAH P H, HALLS V A, ZHENG J Q, et al. Optimal cure cycle parameters for minimizing residual stresses in fiber-reinforced polymer composite laminates[J]. Journal of Composite Materials,2017,52(6):773-792. -

下载:

下载: