Formation mechanism of diamond/Ti interface based on vacuum hotpressing diffusion method

-

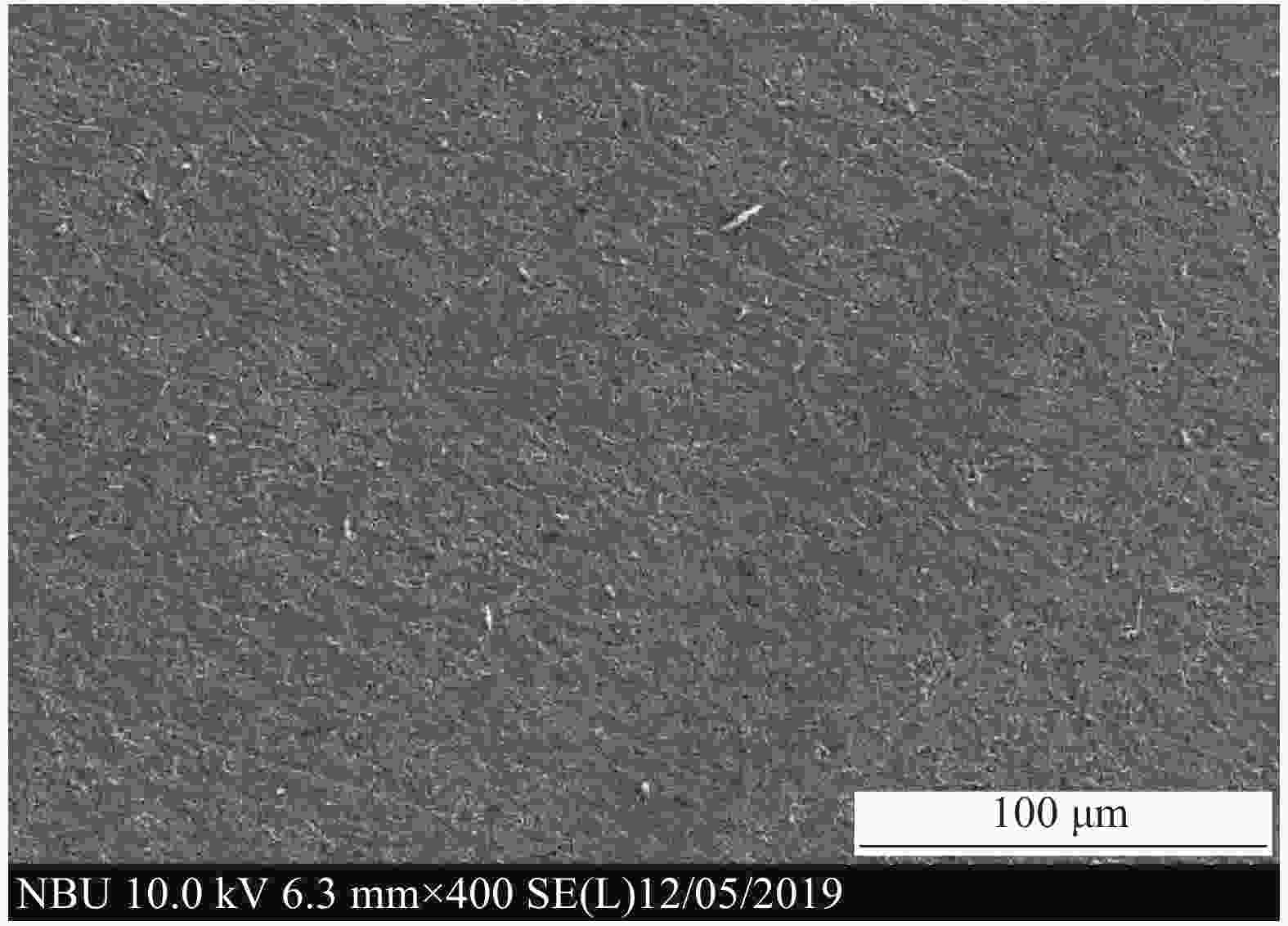

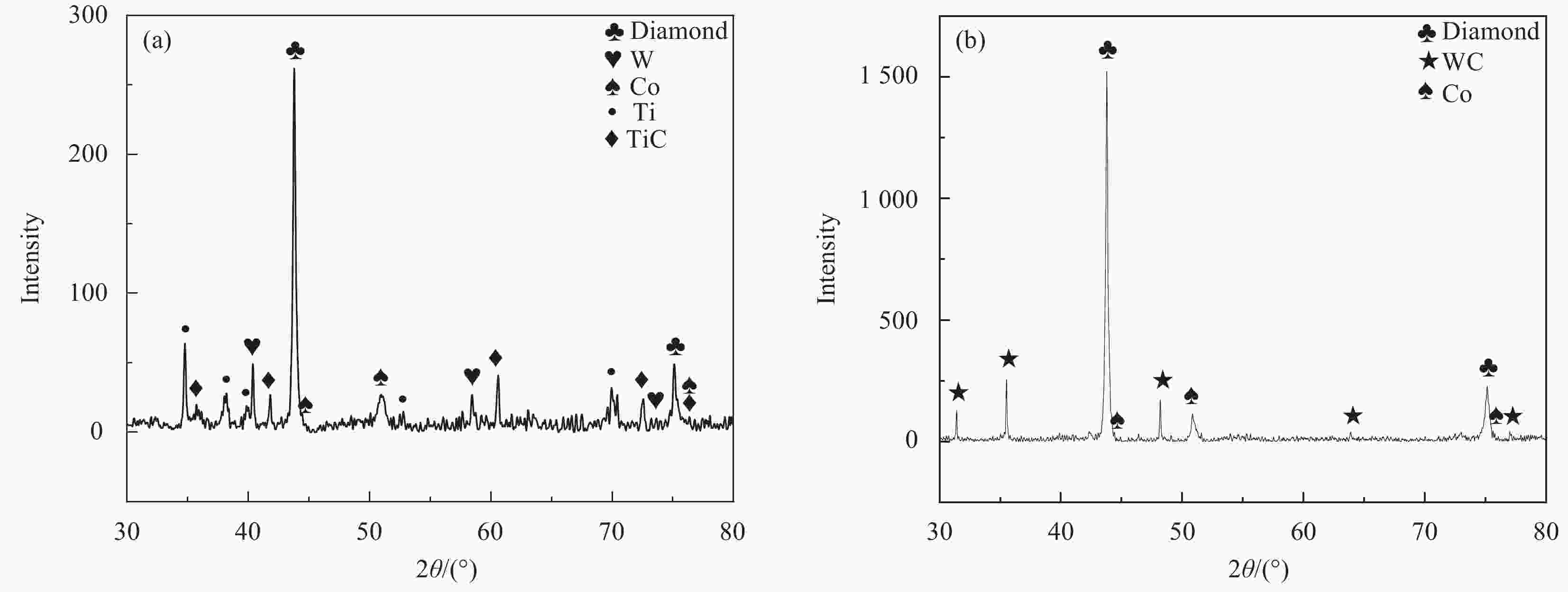

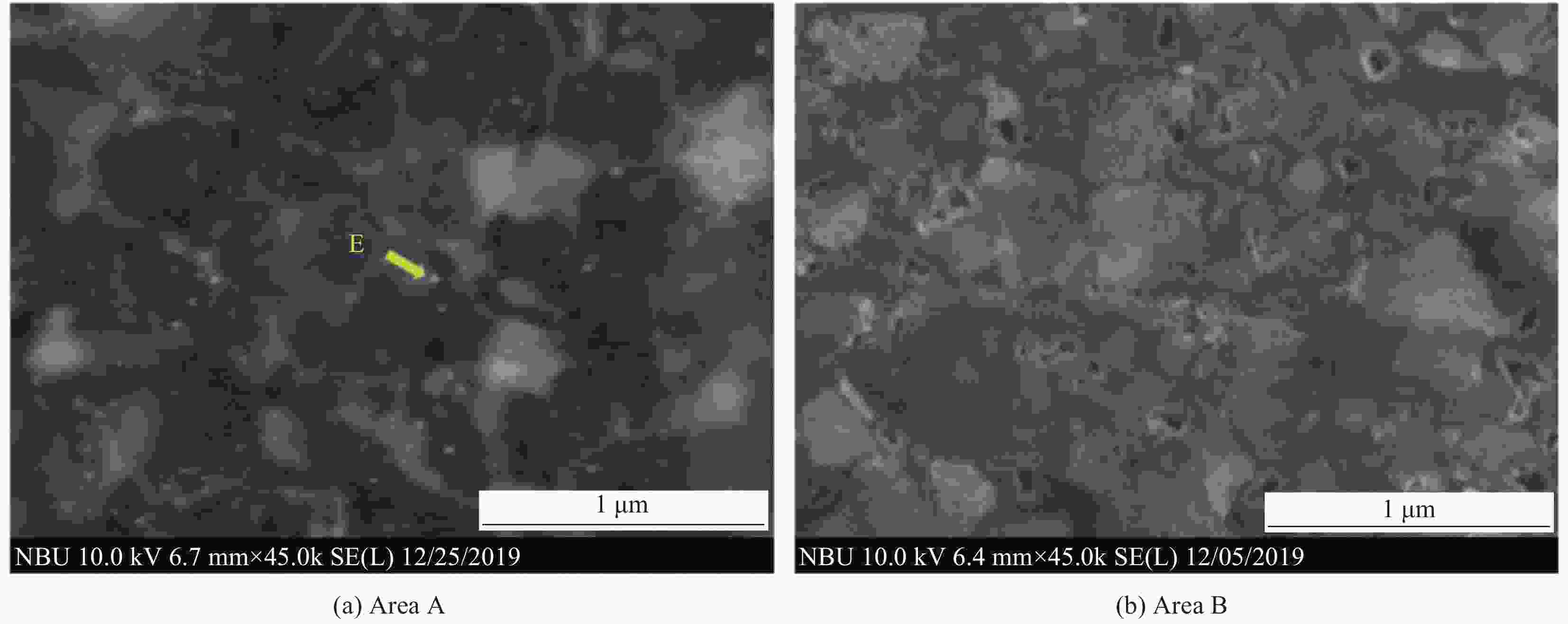

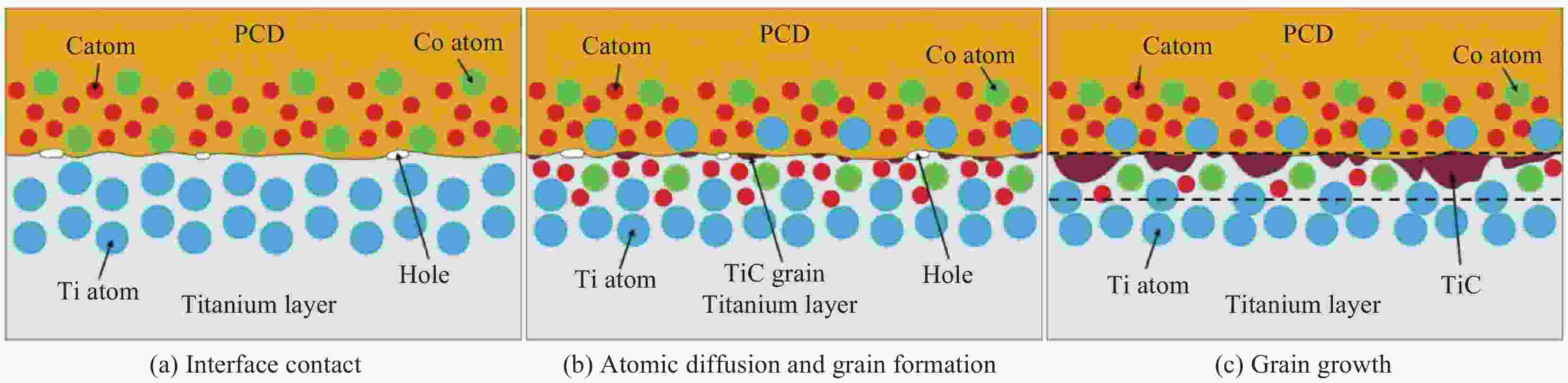

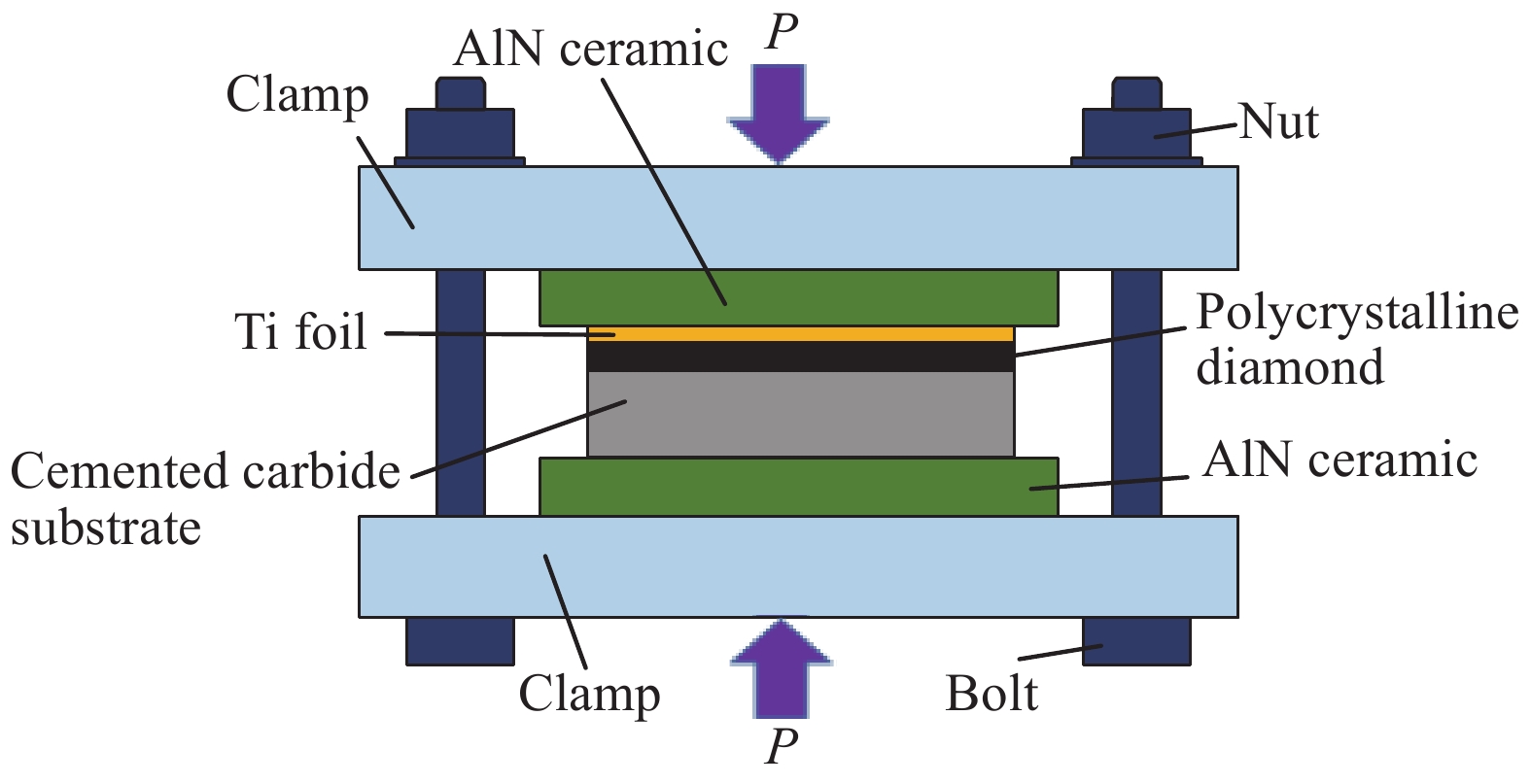

摘要: 采用真空热压扩散法在聚晶金刚石表面制备Ti层,探究金刚石表面金属化过程中的界面生成机制。利用扫描电子显微镜和X射线衍射仪,分析了钛层的表面形貌、界面结构和界面间的物相组成,采用能谱仪对界面进行了元素分析,计算了聚晶金刚石与Ti层之间界面的扩散带宽度及生成TiC的化学反应吉布斯自由能变。研究结果表明:在聚晶金刚石表面形成了平整、致密的Ti层,在聚晶金刚石与Ti层界面之间存在C、Ti和Co元素的扩散,在结合界面处产生了一定宽度的元素扩散带,同时在金刚石表面生成了点状TiC。真空热压扩散法实现了金刚石与Ti层的化学结合,可以提高金刚石与Ti层的结合强度。Abstract: With the vacuum hot pressing diffusion method, Ti coating layer was prepared on the surface of polycrystalline diamond to investigate the formation mechanism of the interface during diamond metallization. The surface morphology, interface structure and phase composition of the Ti coating layer were analyzed with a scanning electron microscope and an X-ray diffractometer. The interfacial elements were analyzed with an energy disperse spectrometer. The width of the element diffusion zone between polycrystalline diamond and Ti layer and the free enthalpy change for the chemical reaction to generate TiC were calculated. The research results show that flat and dense Ti layer is formed on the surface of polycrystalline diamond. There is diffusion of carbon, Ti and cobalt elements on bonding interface between Ti coating layer and polycrystalline diamond. An element diffusion zone with a certain width is generated on bonding interface. At the same time, spot-shaped TiC particles are formed on diamond surface. The vacuum hot pressing diffusion method can realize a chemical combination between diamond grain and a Ti layer, and can improve the bonding strength between diamond grain and Ti layer.

-

Key words:

- hotpressing diffusion /

- interface /

- formation mechanism /

- diamond /

- Ti

-

表 1 钛箔和PCD的化学成分

Table 1. Chemical composition of TA1 and PCD

Material C/wt% Fe/wt% Ti/wt% Co/wt% W/wt% Si/wt% N/wt% H/wt% TA1 0.01 0.05 99.87 — — 0.05 0.015 0.005 PCD 88.12 — — 8.99 2.89 — — — Notes: TA1—Pure titanium grade TA1;PCD—Polycrystalline diamond. -

[1] 龙伟民. 超硬工具钎焊技术[M]. 郑州: 河南科学技术出版社, 2017: 1-4.LONG Weimin. Brazing technology of superhard tools[M]. Zhengzhou: Henan Science and Technology Press, 2017: 1-4(in Chinese). [2] BLANK V, POPOV M, PIVOVAROV G, et al. Mechanical properties of different types of diamond[J]. Diamond and Related Materials,1999,8(8-9):1531-1535. doi: 10.1016/S0925-9635(99)00079-5 [3] QURESHI A, GURBUZ Y, HOWELL M, et al. Nanocrystalline diamond film for biosensor applications[J]. Diamond and Related Materials,2010,19(5-6):457-461. doi: 10.1016/j.diamond.2010.01.012 [4] ZHANG C, WANG R C, CAI Z Y, et al. Effects of dual-layer coatings on microstructure and thermal conductivity of diamond/Cu composites prepared by vacuum hot pressing[J]. Surface and Coatings Technology,2015,277:299-307. doi: 10.1016/j.surfcoat.2015.07.059 [5] 张晓宇, 蔺伟康, 许旻 , 等. 添加稀土 Nd 改善金刚石/铜复合材料界面[J]. 表面技术, 2018, 47(5):27-32.ZHANG Xiaoyu, LIN Weikang, XU Min, et al. Addition of rare earth neodymium to improve interface of diamond/copper composites[J]. Surface Technology,2018,47(5):27-32(in Chinese). [6] 郭宏, 王光宗, 贾成厂, 等. 高压熔渗金刚石/铜复合材料的低温导热特性[J]. 复合材料学报, 2014, 31(3):550-555.GUO Hong, WANG Guangzong, JIA Chengchang, et al. Low-temperature heat conduction characteristics of diamond/Cu composite by high pressure infiltration[J]. Acta Materiae Compositae Sinica,2014,31(3):550-555(in Chinese). [7] ZHU Y F, WANG L, YAO W Q, et al. The interface diffusion and reaction between Cr layer and diamond particle during metallization[J]. Applied Surface Science,2001,171(1-2):143-150. doi: 10.1016/S0169-4332(00)00555-9 [8] KHMELNITSKY R A, EVLASHIN S A, MARTOVITSKY V P, et al. Heteroepitaxy of Ni-based alloys on diamond[J]. Crystal Growth & Design,2016,16(3):1420-1427. [9] 王元元, 马捷, 李辉, 等. 金刚石粉体表面 CVD 法镀钨的工艺研究[J]. 表面技术, 2017, 46(2):98-102.WANG Yuanyuan, MA Jie, LI Hui, et al. Technical study of tungsten plating on surface of diamond powder by CVD[J]. Surface Technology,2017,46(2):98-102(in Chinese). [10] 向波, 谢志刚, 贺跃辉, 等. 金刚石表面镀覆金属钨的新方法[J]. 中国有色金属学报, 2007, 17(9):1511-1515. doi: 10.3321/j.issn:1004-0609.2007.09.021XIANG Bo, XIE Zhigang, HE Yuehui, et al. Novel method for coating tungsten on diamond[J]. Journal of Nonferrous Metals,2007,17(9):1511-1515(in Chinese). doi: 10.3321/j.issn:1004-0609.2007.09.021 [11] ABYZOV A M, KIDALOV S V, SHAKHOV F M. High thermal conductivity composite of diamond particles with tungsten coating in a copper matrix for heat sink application[J]. Applied Thermal Engineering,2012,48:72-80. doi: 10.1016/j.applthermaleng.2012.04.063 [12] ZUO Z, HU B, CHEN H, et al. Effect of activators on the properties of nickel coated diamond composite powders[J]. Journal of Materials Science & Technology,2017,33(11):1409-1415. [13] BEX P. The influence of temperature and heating time on PCD performance[J]. Industrial Diamond Review,1984,44(502):128-139. [14] 邹家生. 材料连接原理与工艺[M]. 哈尔滨: 哈尔滨工业大学出版社, 2005: 356-357.ZOU Jiasheng. Principles and technology of material connection[M]. Harbin: Harbin Institute of Technology Press, 2005: 356-357(in Chinese). [15] 丁大伟, 陈燕, 傅玉灿. 含硼金刚石钎焊界面分析及磨粒强度研究[J]. 金刚石与磨料磨具工程, 2015, 35(5):9-14.DING Dawei, CHEN Yan, FU Yucan. Investigation of grain strength and interfacial microstructure in the brazed joint of boron-doped diamond[J]. Diamond & Abrasives Engineering,2015,35(5):9-14(in Chinese). [16] TANABE J, SASAKI T, KISHI S. Diffusion bonding of Ti/graphite and Ti/diamond by hot isostatic pressing method[J]. Journal of Materials Processing Technology,2007,192:453-458. [17] ZHANG Y, ZHANG H L, WU J H, et al. Enhanced thermal conductivity in copper matrix composites reinforced with titanium-coated diamond particles[J]. Scripta Materialia,2011,65(12):1097-1100. doi: 10.1016/j.scriptamat.2011.09.028 [18] 靳正国, 郭瑞松, 师春生. 材料科学基础[M]. 天津: 天津大学出版社, 2008: 231-244.JIN Zhengguo, GUO Ruisong, SHI Chunsheng. Foundation of materials science[M]. Tianjin: Tianjin University Press, 2008: 231-244 (in Chinese). [19] 杨浩. 钛表面等离子无氢渗碳及其耐腐蚀性能研究[D]. 沈阳: 东北大学, 2011: 34-35.YANG Hao. Plasma non-hydrogen carburizing on titanium surface and its corrosion resistance[D]. Shenyang: Northeastern University, 2011: 34-35 (in Chinese). [20] 王娟, 李亚江. 钎焊与扩散焊[M]. 北京: 化学工业出版社, 2016: 197-199.WANG Juan, LI Yajiang. Brazing and diffusion welding[M]. Beijing: Chemical Industry Press, 2016: 197-199 (in Chinese). [21] 丁大伟, 陈燕, 傅玉灿. 镀钛金刚石钎焊界面微区结构分析[J]. 南京航空航天大学学报, 2016, 48(9):879-883.DING Dawei, CHEN Yan, FU Yucan. Brazing interface microstructure analysis of Ti-coated diamond[J]. Journal of Nanjing University of Aeronautics & Astronautics,2016,48(9):879-883(in Chinese). [22] 王艳辉, 王明智, 关长斌, 等. Ti镀层对金刚石-铜基合金复合材料界面结构和性能的作用[J]. 复合材料学报, 1993, 10(2):107-112. doi: 10.3321/j.issn:1000-3851.1993.02.001WANG Yanhui, WANG Mingzhi, GUAN Changbin, et al. Effect of Ti coating on the interfacial structure and properties of diamond-copper-based alloy composites[J]. Acta Materiae Compositae Sinica,1993,10(2):107-112(in Chinese). doi: 10.3321/j.issn:1000-3851.1993.02.001 [23] 伊赫桑·巴伦. 纯物质热化学数据手册(上、下卷)[M]. 北京: 科学出版社, 2003: 211, 1666-1674.IHSAN Barron. Thermochemical data of pure substances(Volume 1 and 2)[M]. Beijing: Science Press, 2003: 211, 1666-1674 (in Chinese). [24] LEROY W P, DETAVERNIER C, VAN MEIRHAEGHE R L, et al. Thin film solid-state reactions forming carbides as contact materialsfor carbon-containing semiconductors[J]. Journal of Applied Physics,2007,101(5):053714. doi: 10.1063/1.2561173 -

下载:

下载: