Preparation and photocatalytic properties of TiO2/electrospinning PAN-based carbon composite material

-

摘要: 为了同时提高催化剂的光催化和回收能力,以聚丙烯腈(PAN)和钛酸四丁酯(TBT)作为碳纳米纤维(CNFs)和TiO2前驱体,通过静电纺丝和热处理方法制备了TiO2/CNFs复合材料,并通过SEM、XRD、Raman、UV-vis分光光度计等对TiO2/CNFs复合材料的形貌、晶体结构、光吸收性能、导电性和光催化性能进行了研究。结果表明:随TBT添加量的逐渐增多,TiO2/CNFs复合材料在热处理过程中卷曲形态逐渐消失,并且TBT在碳化过程中完全转化为锐钛矿TiO2;TiO2/CNFs复合材料光吸收边缘由纯TiO2的紫外光区扩展至可见光区,提高了催化剂对太阳光的利用率;同时,在模拟太阳光照射180 min,TiO2/CNFs复合材料对RhB的光催化降解率最大可达到95.71%,并且在连续重复使用5次后光催化降解效率仍可达到约90%。

-

关键词:

- TiO2 /

- 碳纳米纤维(CNFs) /

- 复合材料 /

- 电子-空穴对 /

- 光催化

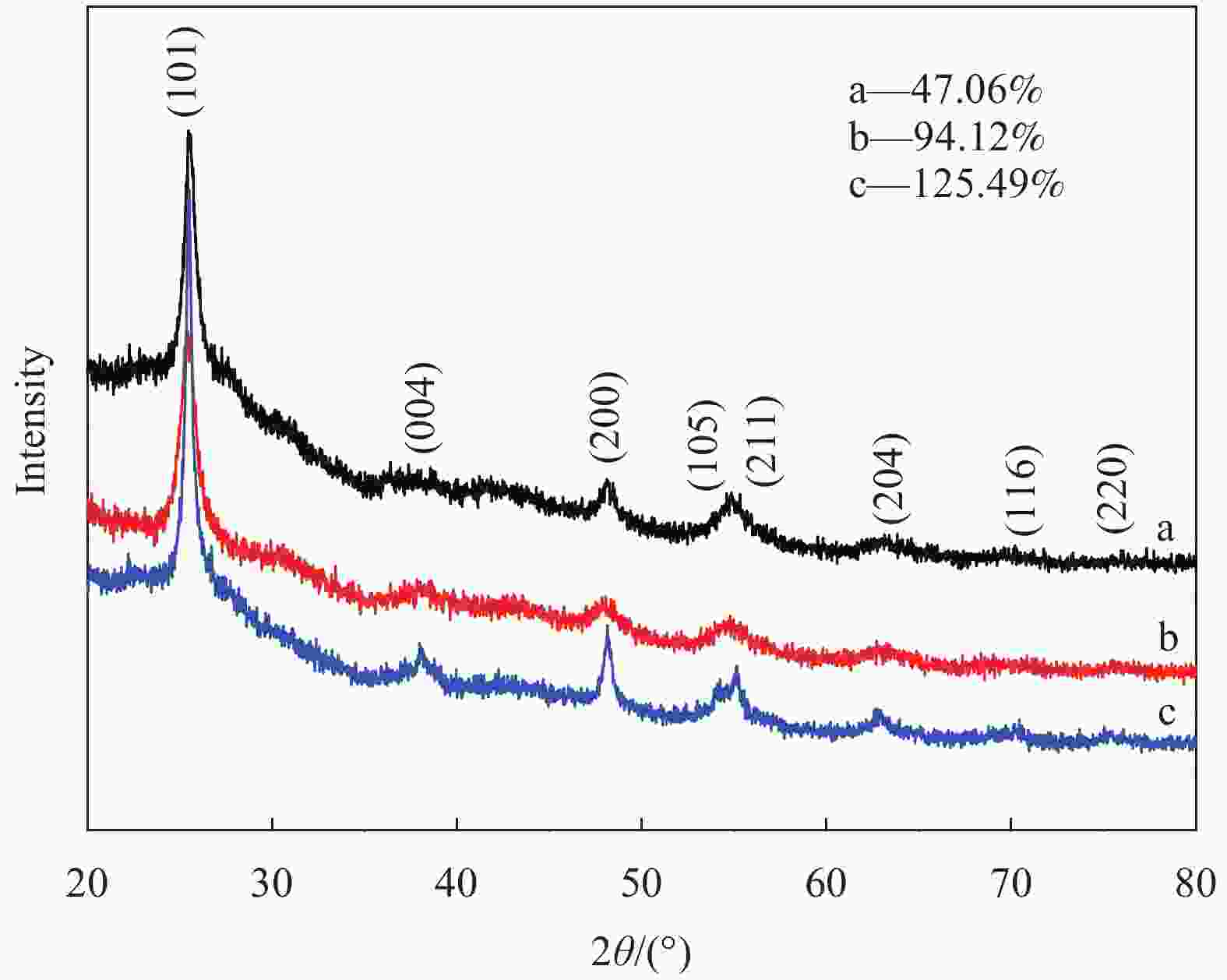

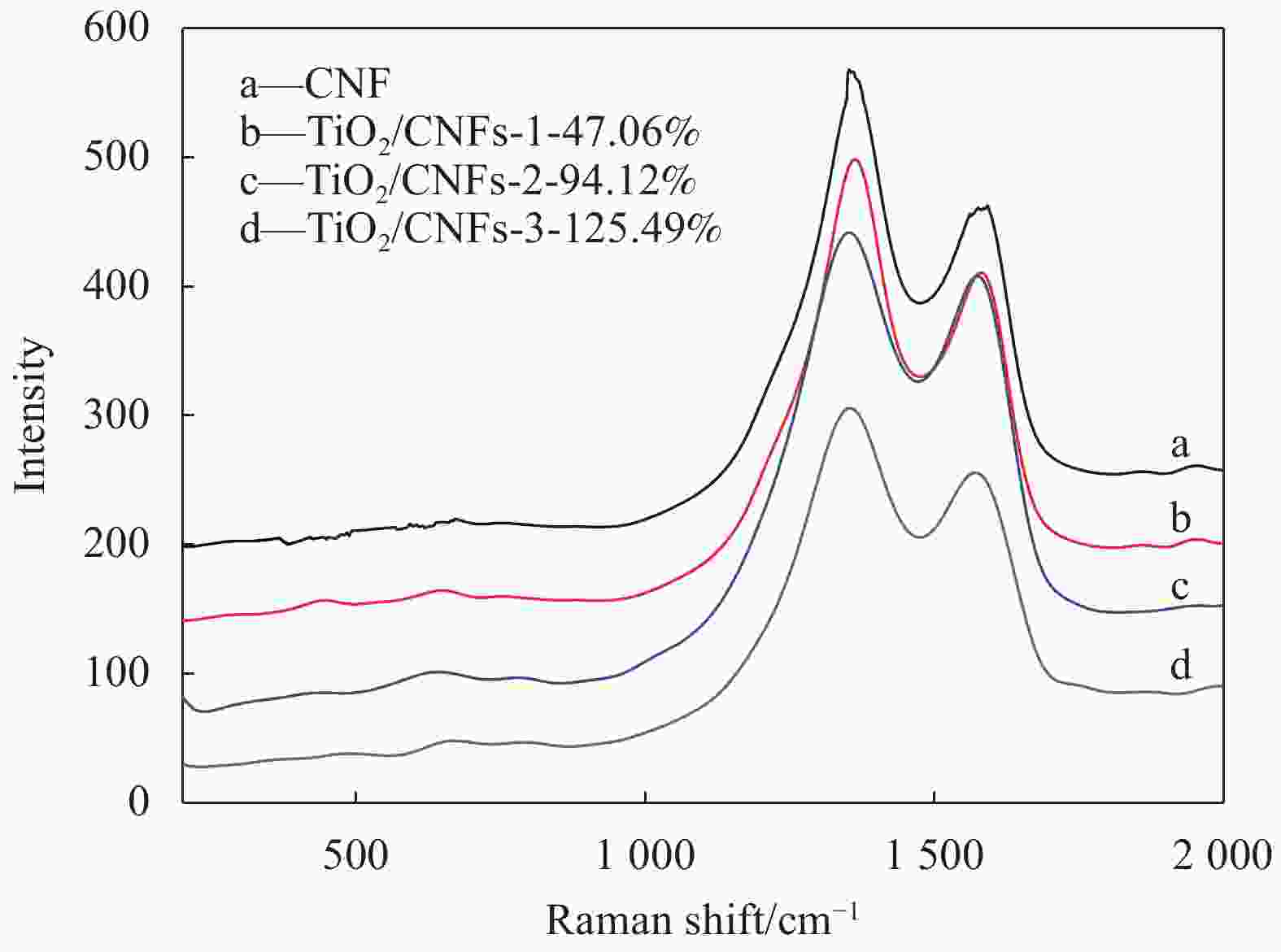

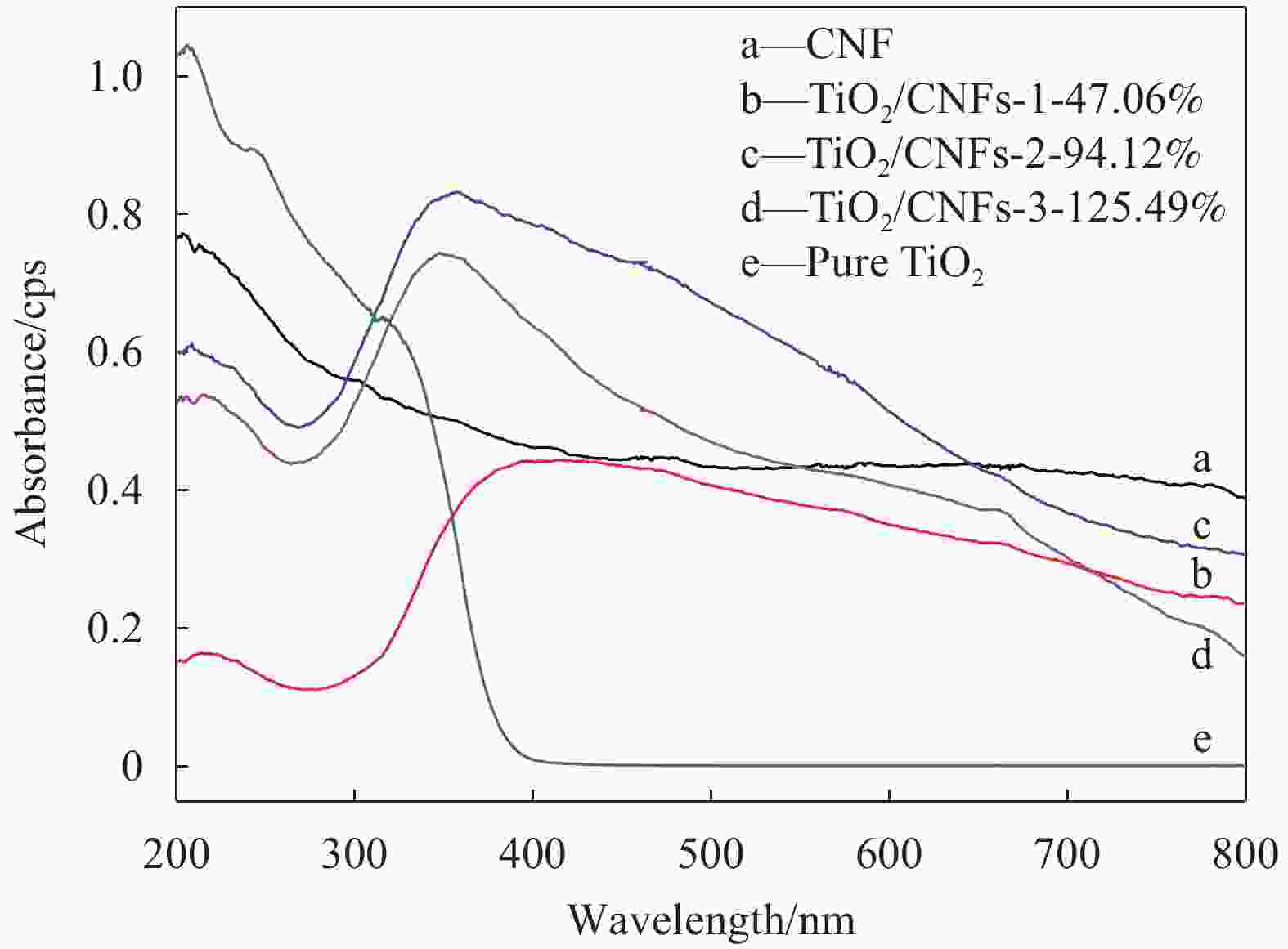

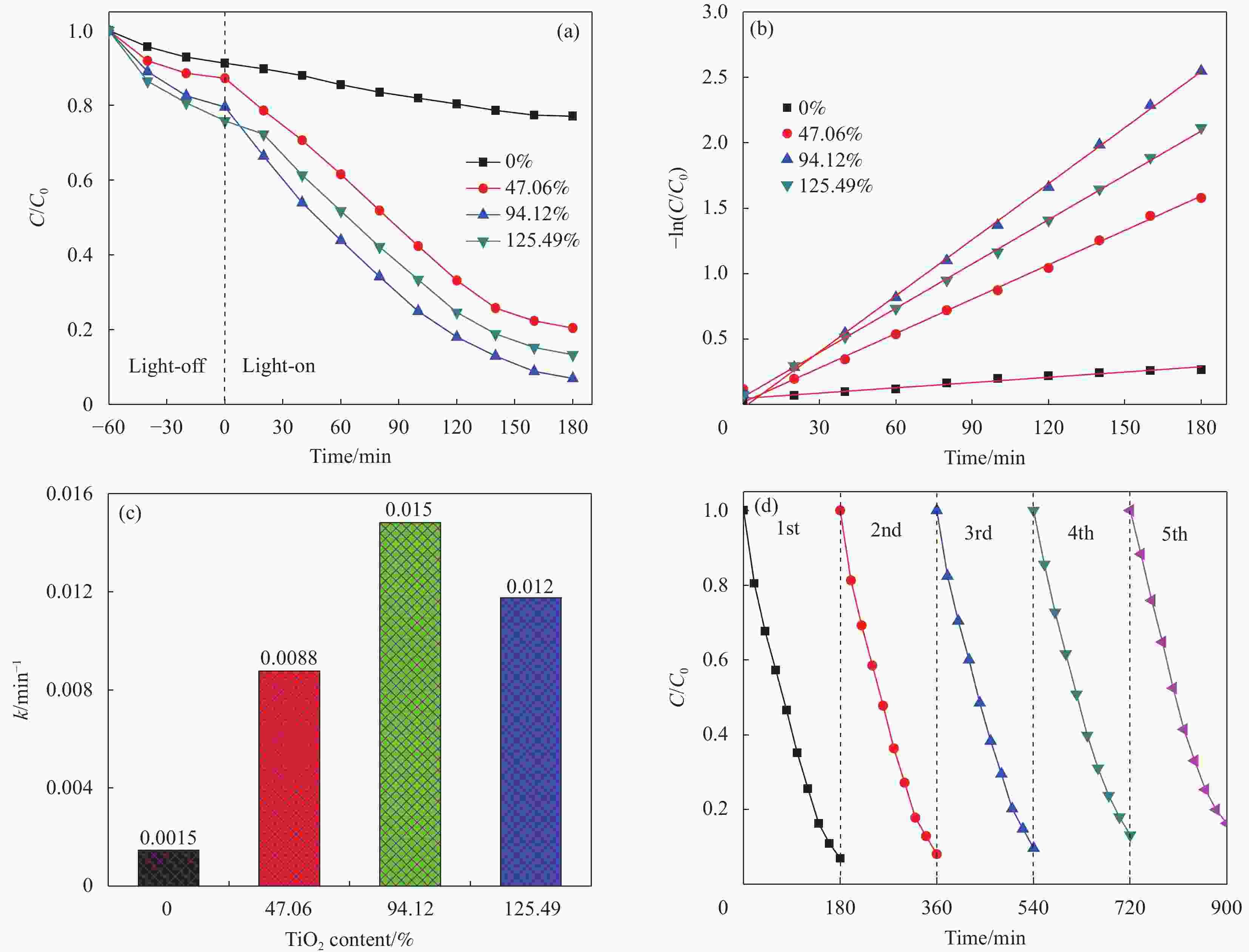

Abstract: To enhance the photocatalysis and recycling abilities of catalyst simultaneously, polyacrylonitrile (PAN) and tetrabutyltitanate (TBT) were used as carbon-nanofibers (CNFs) and TiO2 precursors, and TiO2/CNFs composite materials were successfully prepared via electrospinning and heat treatment, and its morphology, crystal structure, optical performance and photocatalytic properties were studied by SEM, XRD, Raman, UV-vis Spectrophotometer and so on. The results show that the crimp shape of the composite material gradually disappears during heat treatment, and TBT is completely transformed into anatase TiO2 during carbonization with the increase of TBT content. The absorption edge of TiO2/CNFs composite material is extended from the ultraviolet region of pure TiO2 to visible, which can improve the utilization of sunlight. At the same time, after simulated solar irradiation for 180 min, the maximum photocatalytic degradation rate of RhB by TiO2/CNFs composite material reaches 95.71%. Moreover, the photocatalytic degradation efficiency can still reach about 90% after repeated useage for 5 times.-

Key words:

- TiO2 /

- carbon nanofibers (CNFs) /

- composite material /

- electron-hole pairs /

- photocatalysis

-

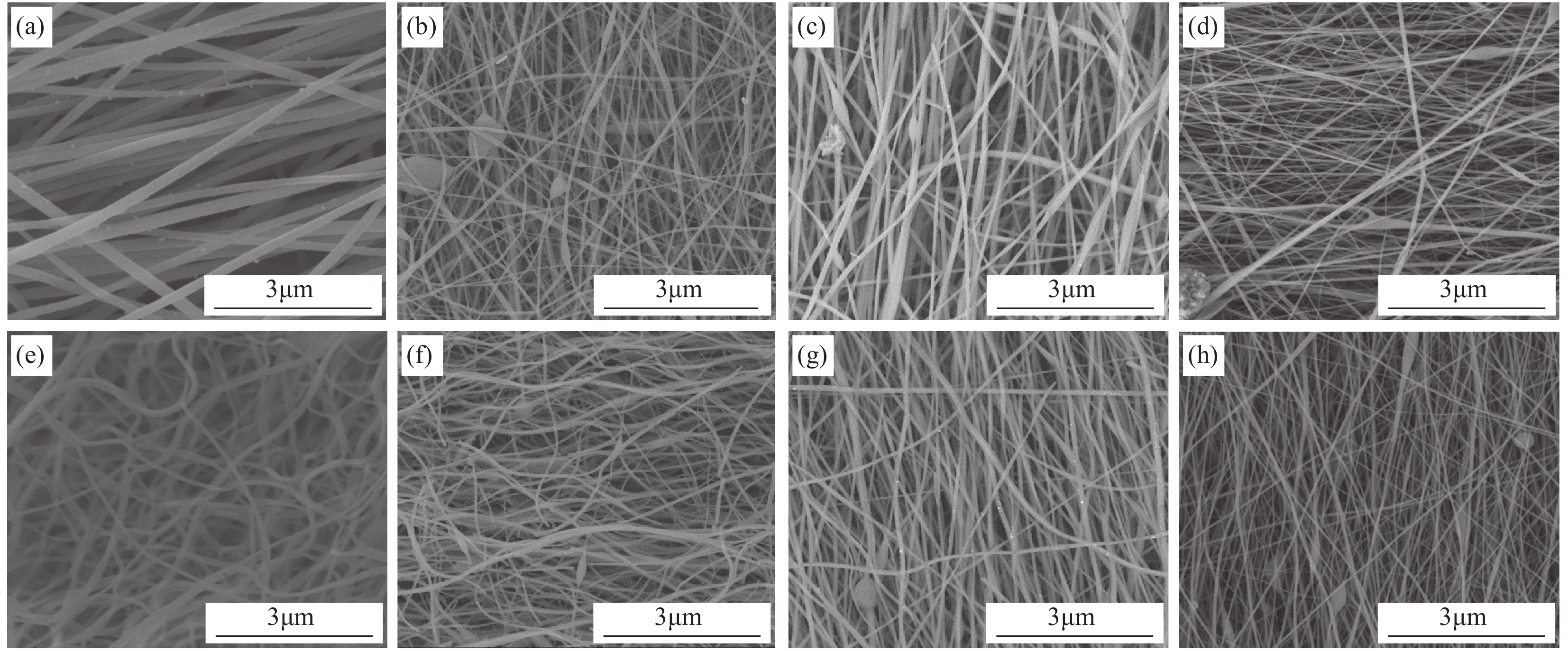

图 1 不同TBT添加量的钛酸四丁酯 (TBT)/聚丙烯腈 (PAN) 复合材料((a)~(d))和不同TiO2含量的TiO2/CNFs复合材料的SEM图像((e)~(h)

Figure 1. SEM images of TBT/PAN composite with different TBT additions ((a)-(d)) and TiO2/CNFs composite with different TiO2 contents((e)-(h)) ((a)PAN; (b)TBT/PAN-1; (c)TBT/PAN-2; (d)TBT/PAN-3; (e)CNF; (f)TiO2/CNFs-1-47.06%; (g)TiO2/CNFs-2-94.12%; (h)TiO2/CNFs-3-125.49%)

图 6 不同TiO2含量的TiO2/CNFs复合材料光催化降解图

Figure 6. Photocatalytic degradation analysis diagrams of TiO2/CNFs composites with different TiO2 contents ((a) Plots of relative concentration of RhB(C/C0) versus time (t); (b) Photocatalytic degradation kinetics curve; (c) Photocatalytic kinetics constant; (d) Cyclic degradation curve of TiO2/CNFs-2-94.12%)

表 1 TiO2/碳纳米管(CNFs)复合材料成分

Table 1. Composition of TiO2/ carbon-nanofibers (CNFs) composite

Sample

numberMass ratio of

TBT:PANMass ratio of

TiO2:CNFs/%CNFs 0 0 TiO2/CNFs-1-47.06% 1∶1 47.06 TiO2/CNFs-2-94.12% 2∶1 94.12 TiO2/CNFs-3-125.49% 3∶1 125.49 Notes: TiO2/CNFs-a-b: a—Mass ratio of tetrabutyltitanate (TBT) to polyacrylonitrile (PAN) in TBT/PAN composite; b—Mass ratio of TiO2 to CNFs in TiO2/CNFs composite. 表 2 不同TiO2含量的TiO2/CNFs复合材料Raman特征峰强度数据

Table 2. Data of Raman characteristic peak intensity of TiO2/CNFs composites with different TiO2 contents

TiO2 content/% ID IG ID/IG 0 570.7 463.2 1.232 47.06 498.4 409.7 1.216 94.12 441.4 408.5 1.081 125.49 307.8 260.3 1.182 Notes: ID—D band strength; IG—G band strength. -

[1] 潘会, 胡轶, 兀晓文, 等. ZnO/CNTs复合材料的制备、表征及光催化性能[J]. 材料导报, 2018, 32(24):4224-4229. doi: 10.11896/j.issn.1005-023X.2018.24.003PAN Hui, HU Yi, WU Xiaowen, et al. Preparation, characterization and photocatalytic properties of ZnO/CNTs composites[J]. Materials Reports,2018,32(24):4224-4229(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.24.003 [2] LIU X F, XING Z P, ZHANG Y, et al. Fabrication of 3D flower-like black N-TiO2-x@MoS2 for unprecedented-high visible-light-driven photocatalytic performance[J]. Applied Catalysis B: Environmental,2017,201:119-127. doi: 10.1016/j.apcatb.2016.08.031 [3] 吴奕初. WO3/BiVO4复合光阳极光催化分解水性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.WU Yichu. WO3/BiVO4 composite photoanodes for photoelectrochemical water splitting[J]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [4] 董双石, 程汉卿, 邓贝奇, 等. Bi与rGO共修饰SnO2光催化高效降解TCH和染料研究[J]. 安全与环境学报, 2019, 19(3):992-1002.DONG Shuangshi, CHENG Hanqing, DENG Beiqi, et al. Photocatalytic degradation of TCH and dyes by bismuth and reduced graphene oxide co-modified SnO2[J]. Journal of Safety and Environment,2019,19(3):992-1002(in Chinese). [5] CAO X R, TIAN G H, CHEN Y J, et al. Hierarchical compo-sites of TiO2 nanowire arrays on reduced graphene oxide nanosheets with enhanced photocatalytic hydrogen evolution performance[J]. Journal of Materials Chemistry A,2014,2:4366-4374. doi: 10.1039/C3TA14272H [6] KANG Q, WANG T, LI P, et al. Photocatalytic reduction of carbon dioxide by Hydrous Hydrazine over Au-Cu alloy nanoparticles supported on SrTiO3/TiO2 coaxial nanotube arrays[J]. Angewandte Chemie International Edition,2014,54(3):841-845. [7] 费锡智, 杨晶晶, 白仁碧. 光催化-膜分离耦合技术的水处理应用研究进展[J]. 水处理技术, 2014(12):11-18.FEI Xizhi, YANG Jingjing, BAI Renbi. Progress of combined photocatalytic and membrane separation technologies for the application of water treatment[J]. Technology of Water Treatment,2014(12):11-18(in Chinese). [8] QIU J L, LIU F Q, YUE C L, et al. A recyclable nanosheet of Mo/N-doped TiO2 nanorods decorated on carbon nanofibers for organic pollutants degradation under simulated sunlight irradiation[J]. Chemosphere,2019,215:280-293. doi: 10.1016/j.chemosphere.2018.09.182 [9] 张梦媛, 黄庆林, 黄岩, 等. 静电纺聚四氟乙烯/二氧化钛光催化纳米纤维膜的制备及其应用[J]. 纺织学报, 2019, 40(9):1-7.ZHANG Mengyuan, HUANG Qinglin, HUANG Yan, et al. Electrospun poly (tetrafluoroethylene) /TiO2 photocatalytic nanofiber membrane and its application[J]. Journal of Textile Research,2019,40(9):1-7(in Chinese). [10] LEE C G, JAVED H, ZHANG D N, et al. Porous electrospun fibers embedding TiO2 for adsorption and photocatalytic degradation of water pollutants.[J]. Environmental Science & Technology,2018,52(7):4285-4293. [11] 拓晓. 负载纳米二氧化钛织物在可见光下降解甲醛气体的研究[D]. 天津: 天津工业大学, 2015.TUO Xiao. Study on the degradation of formaldehyde in visible light by nanotitalia loaded fabric[D]. Tianjin: Tianjin Polytechnic University, 2015(in Chinese). [12] 陈星. TiO2@GO@C纳米纤维膜的制备及其光催化性能和机械性能的研究[D]. 太原: 太原理工大学, 2019.CHEN Xing. Preparation of TiO2@GO@C nanofiber membrane and study on its photocatalytic and mechanical properties[D]. Taiyuan: Taiyuan University of Technology, 2019(in Chinese). [13] WANG H, HUANG X W, LI W, et al. TiO2 nanoparticle decorated carbon nanofibers for removal of organic dyes[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2018,549:205-211. [14] LIANG Y H, ZHOU B M, LI N, et al. Enhanced dye photocatalysis and recycling abilities of semi-wrapped TiO2@ carbon nanofibers formed via foaming agent driving[J]. Ceramics International,2018,44(2):1711-1718. doi: 10.1016/j.ceramint.2017.10.101 [15] YUSOF N, ISMAIL A F. Post spinning and pyrolysis processes of polyacrylonitrilr (PAN)-based carbon fiber and activated carbon fiber: A review[J]. Journal of Analytical and Applied Pyrolysis,2012,93:1-13. doi: 10.1016/j.jaap.2011.10.001 [16] MARSH H, WARBURTON A P. Catalytic graphitization of carbon using titanium and zirconium[J]. Carbon,1976,14(1):47-52. doi: 10.1016/0008-6223(76)90082-8 [17] TENG W, WANG Y M, HUANG H H, et al. Enhanced photoelectrochemical performance of MoS2 nanobelts-loaded TiO2 nanotube arrays by photo-assisted electrodeposition[J]. Applied Surface Science,2017,425:507-517. doi: 10.1016/j.apsusc.2017.06.297 [18] SHAO J, SHENG W C, WANG M S, et al. In situ synthesis of carbon-doped TiO2 single-crystal nanorods with a remarkably photocatalytic efficiency[J]. Applied Catalysis B: Environmental,2017,209:311-319. doi: 10.1016/j.apcatb.2017.03.008 [19] GE G, LIU M, LIU C, et al. Ultrathin FeOOH nanosheets as an efficient cocatalyst for photocatalytic water oxidation[J]. Journal of Materials Chemistry A,2019,7:9222-9229. doi: 10.1039/C9TA01740B -

下载:

下载: