Experimental analysis of the causes of skin wrinkles below the radius filler of hat-stiffened skins

-

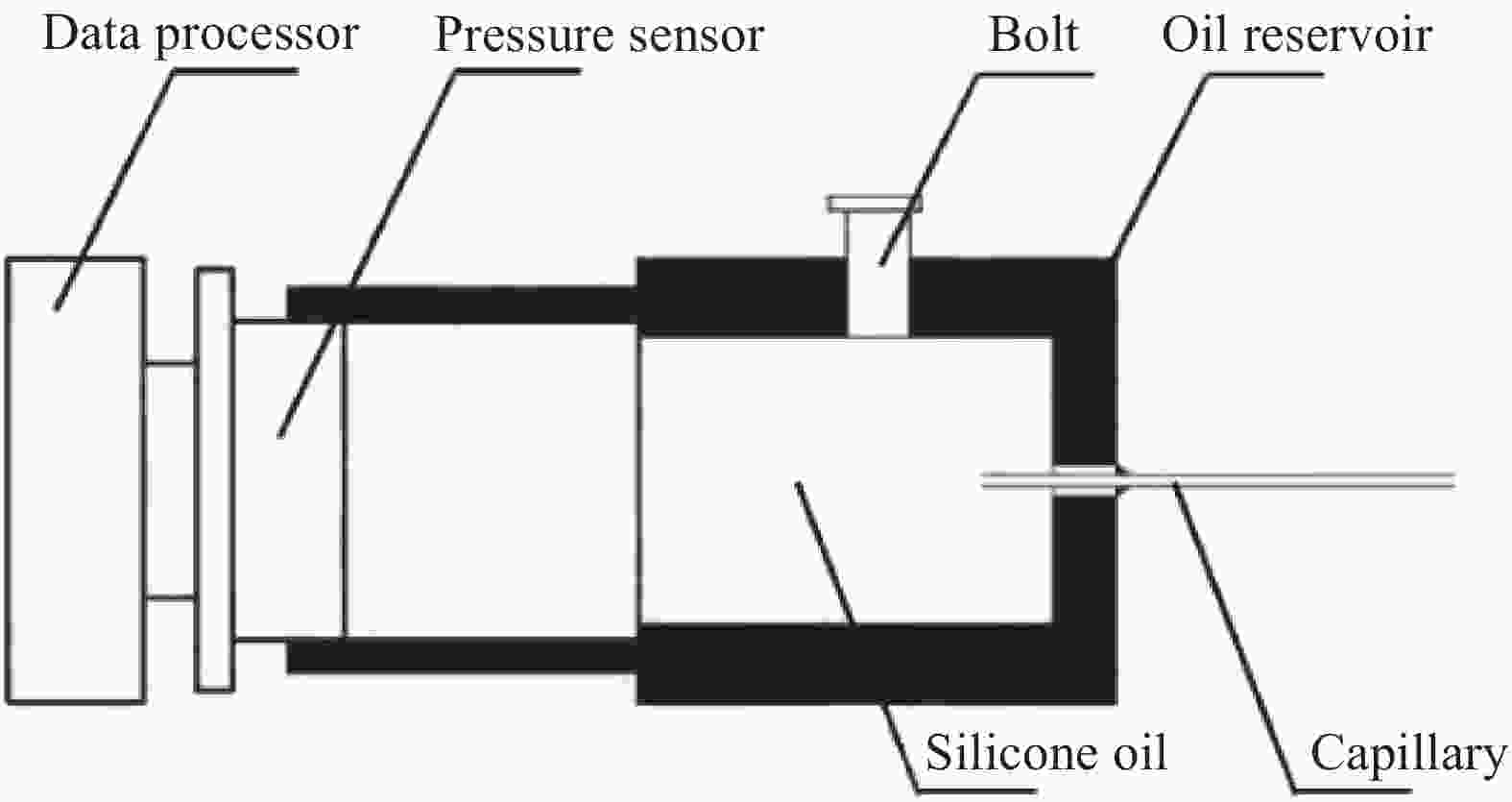

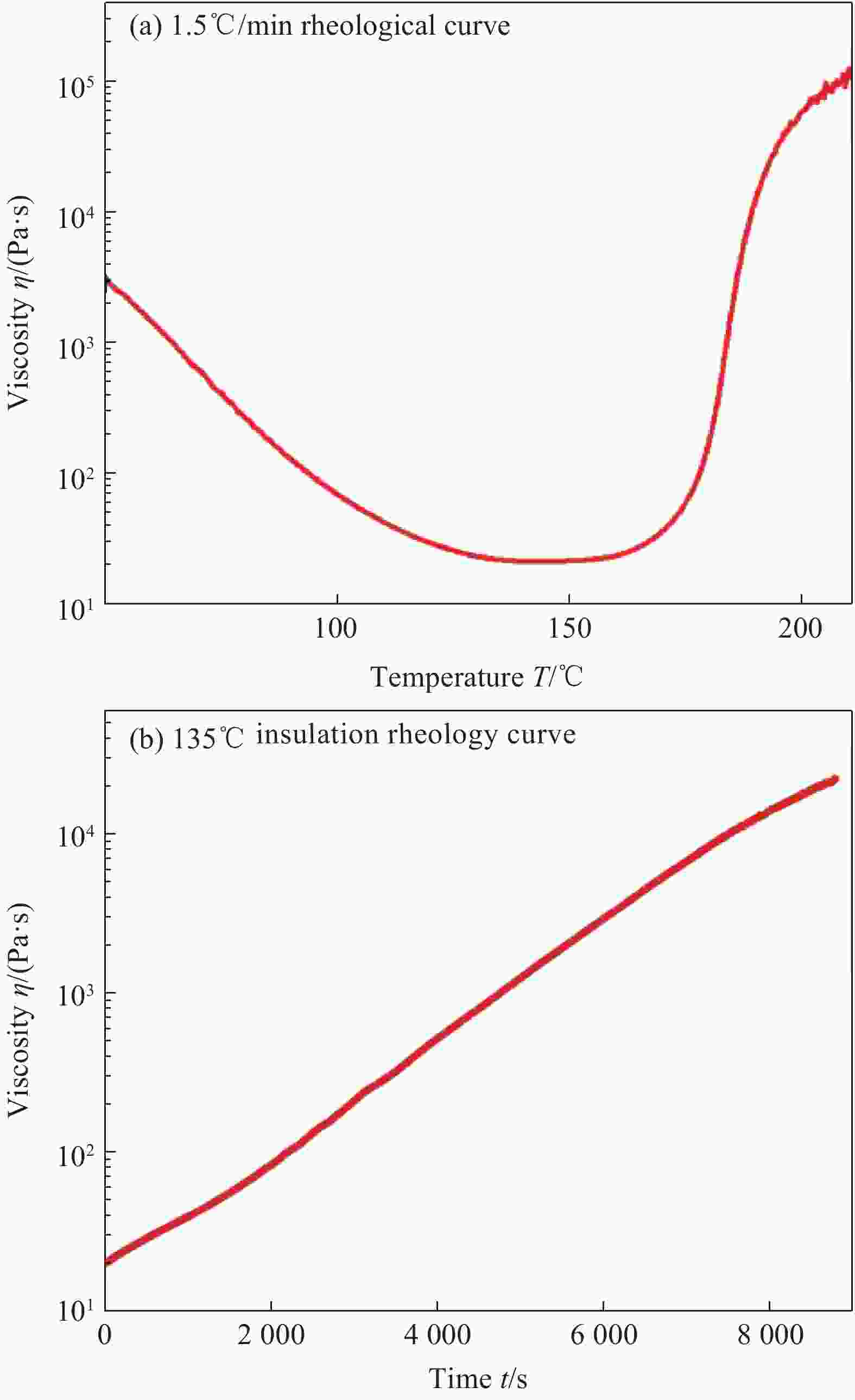

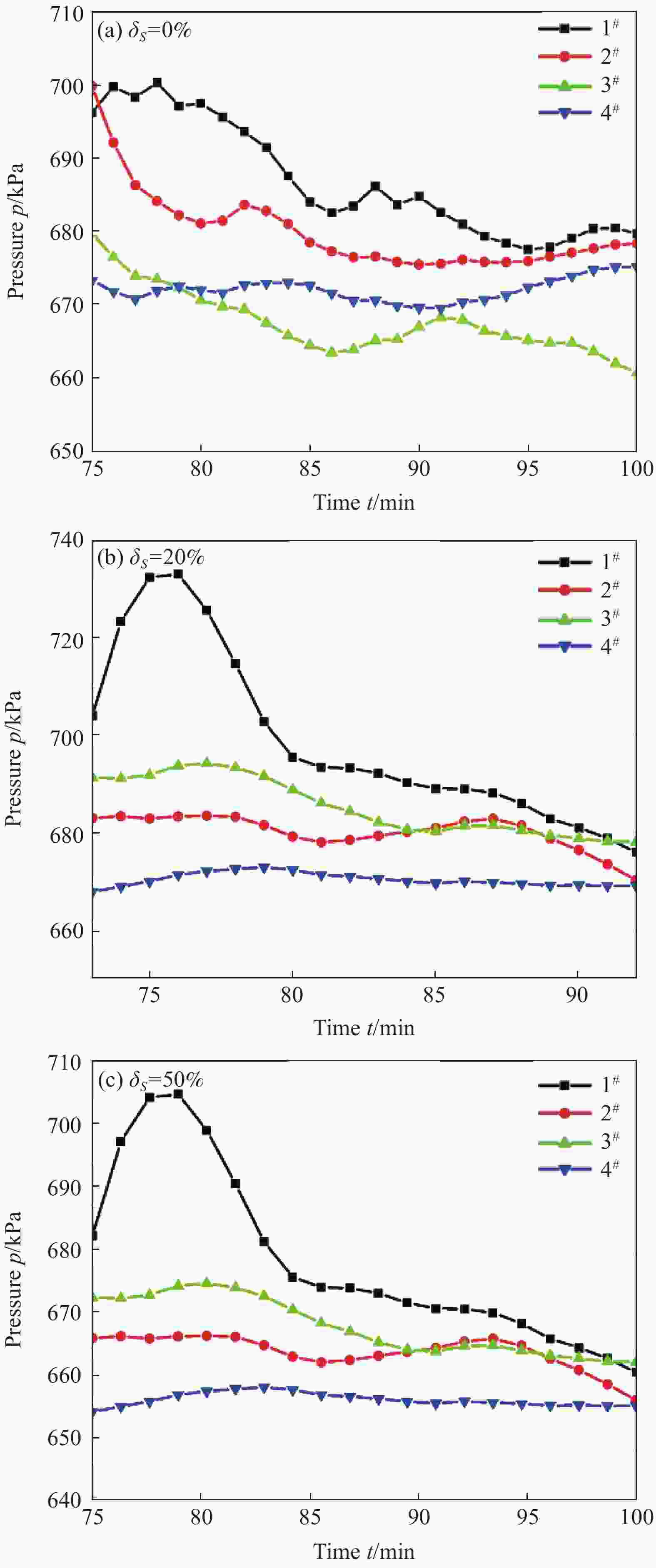

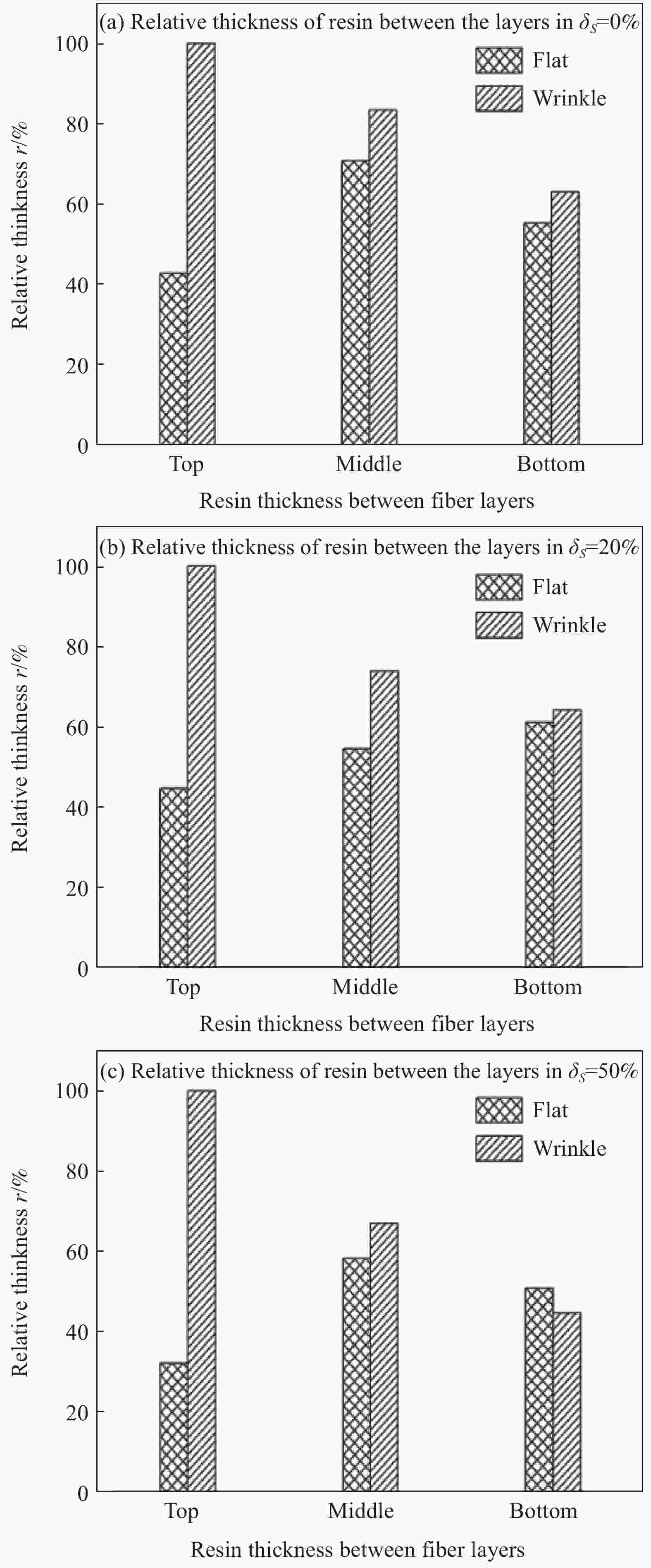

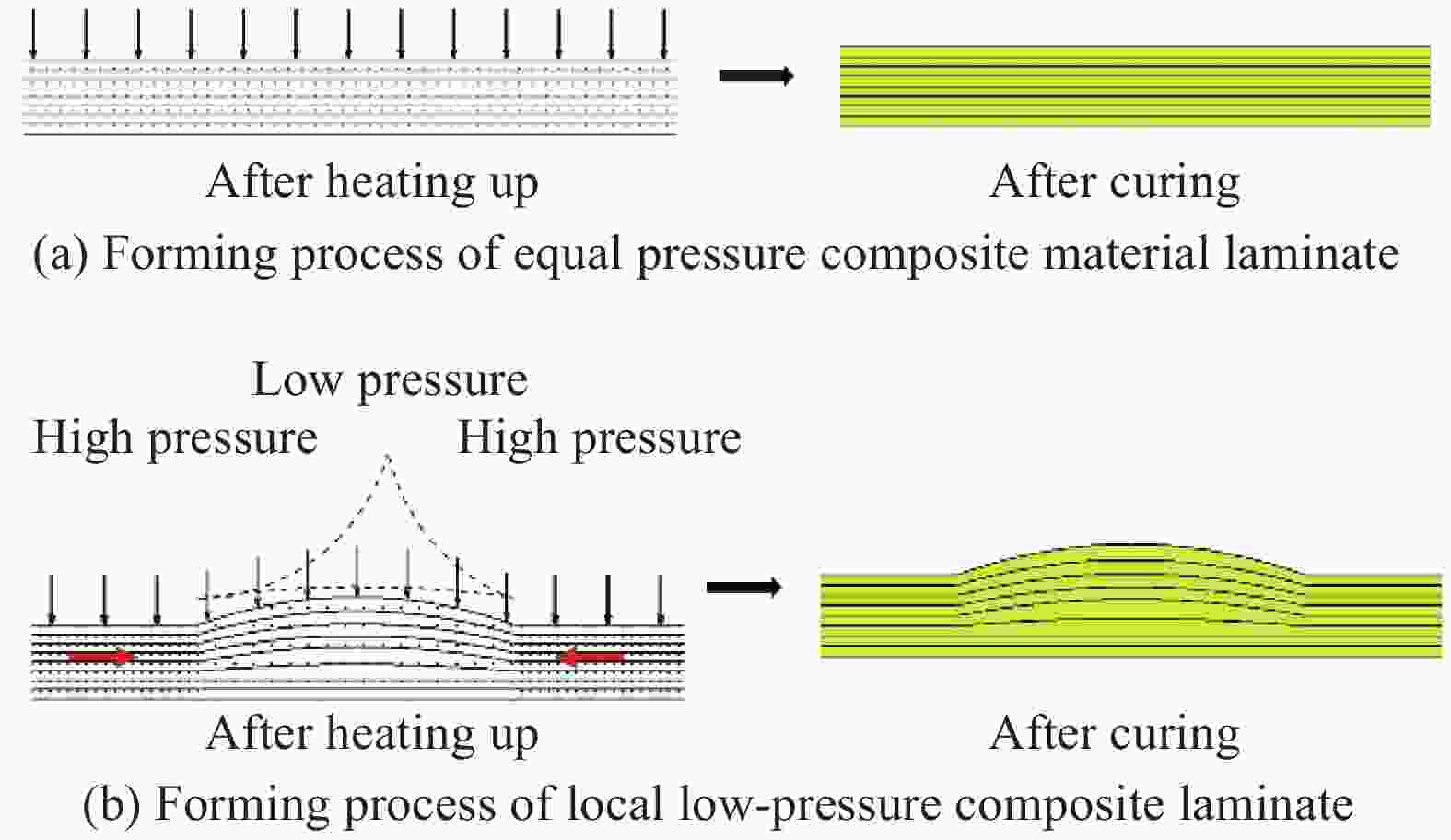

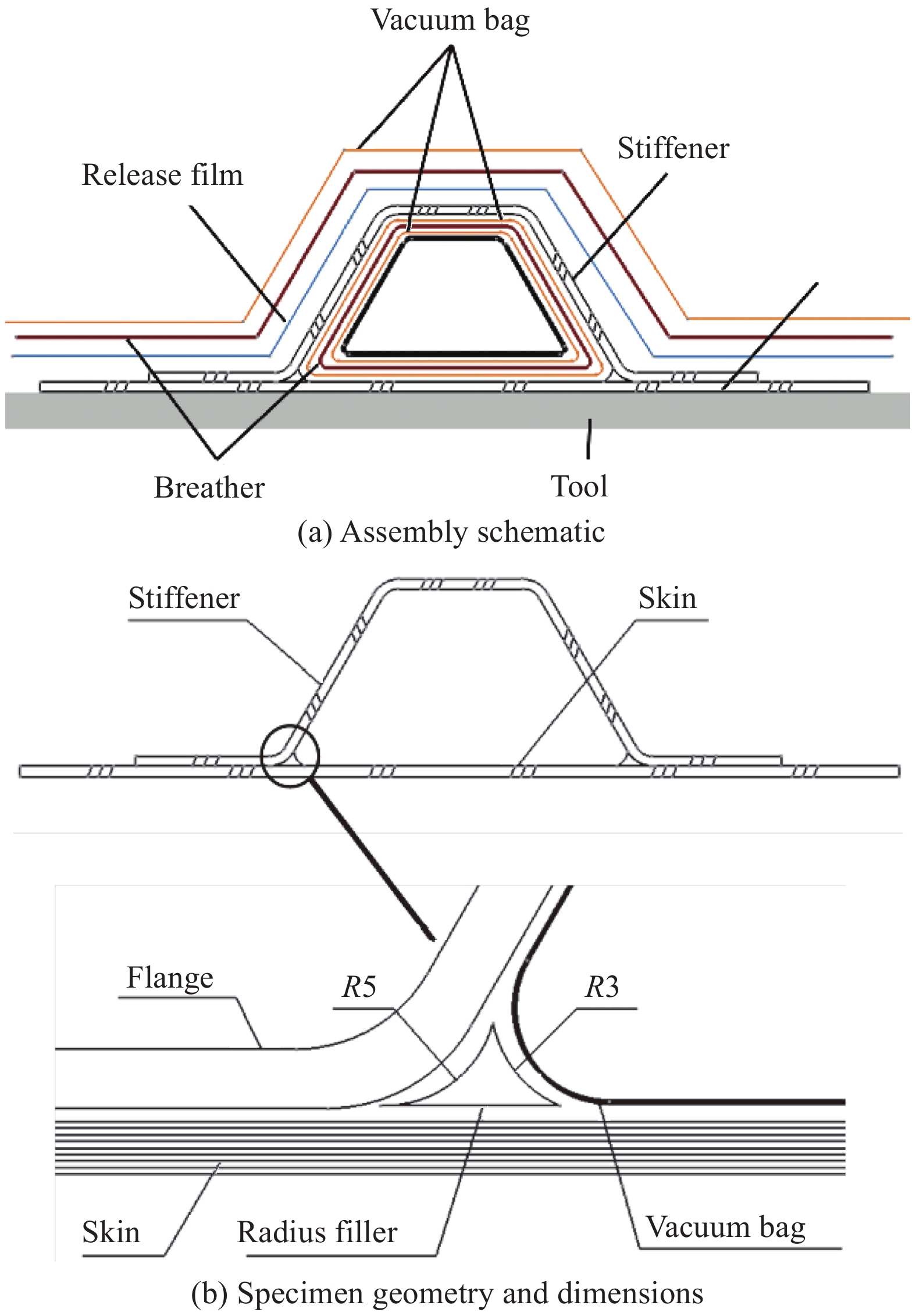

摘要: 研究了碳纤维/环氧树脂复合材料帽型加筋壁板在长桁先固化、蒙皮未固化的共胶接工艺下,填充芯材下方蒙皮褶皱的形成过程及产生原因。测试了预浸料的树脂流变特性,由压力监测设备对填充芯材下方蒙皮内部压力进行监测获得了其内部压力的分布,采用金相显微镜对褶皱进行了表征。结果表明:在树脂流动的窗口期,当填充芯材下方蒙皮内部出现压力差时,树脂向低压区流动并聚集,导致褶皱产生。Abstract: The formation process and causes of the skin wrinkles under the radius filler were studied in the co-bonding process of the hat-stiffened skins of carbon fiber/epoxy resin composite with the pre-cured stiffener and uncured skin. The rheological properties of the resin of the prepreg were tested. The internal pressure distribution of the skin under the radius filler was monitored by pressure monitoring equipment, and the wrinkles were characterized by metallographic microscope. The results show that during the window period of the resin flow, the resin flows to the low-pressure area and aggregates, resulting in wrinkles when a pressure difference occurs inside the skin under the radius filler.

-

Key words:

- hat-stiffened skins /

- radius filler /

- skin wrinkles /

- pressure difference /

- resin flow

-

表 1 填充芯材下方蒙皮内部的压强对比

Table 1. Comparison of pressure inside the skin under the radius filler

Radius filler cross-

sectional deviationAverage pressure/kPa Pressure

difference/kPa1# 2# 3# 4# 0% 688.31 684.74 670.53 672.42 17.78 20% 699.29 679.99 685.31 670.26 29.04 50% 689.08 661.97 665.19 656.17 32.91 表 2 蒙皮平整区和褶皱区厚度对比

Table 2. Comparison of skin thickness in flat and wrinkle positions

Radius filler cross-sectional deviation Area Skin thickness/mm Theoretical thickness/mm 0% Flat 8.04 8.22 Wrinkle 8.96 8.22 20% Flat 8.03 8.22 Wrinkle 9.16 8.22 50% Flat 8.02 8.22 Wrinkle 9.42 8.22 -

[1] 王犇. 复合材料的应用与展望[J]. 中国新技术新产品, 2018(06):40-41. doi: 10.3969/j.issn.1673-9957.2018.06.023WANG Ben. Application and prospect of composite materials[J]. China New Technology and Products,2018(06):40-41(in Chinese). doi: 10.3969/j.issn.1673-9957.2018.06.023 [2] 周长庚, 荀国立, 邱启艳, 等. 航空复合材料整体成型技术应用现状与分析[J]. 新材料产业, 2016(5):52-57. doi: 10.3969/j.issn.1008-892X.2016.05.011ZHOU Changgeng, XUN Guoli, QIU Qiyan, et al. Application status and analysis of aerospace composite material integral molding technology[J]. Advanced Materials Industry,2016(5):52-57(in Chinese). doi: 10.3969/j.issn.1008-892X.2016.05.011 [3] 熊文磊, 苏佳智, 刘小林, 等. 热压罐工艺帽型加筋壁板长桁胶接变形问题[J]. 航空学报, 2019, 40(12):423108.XIONG Wenlei, SU Jiazhi, LIU Xiaolin, et al. Bonding deformation of long truss of hat-shaped stiffened wall plate in autoclave process[J]. Acta Aeronautica et Astronautica Sinica,2019,40(12):423108(in Chinese). [4] 李进, 应斌, 郑秀楠. 复合材料超级壁板装配工艺技术研究[J]. 纤维复合材料, 2019, 36(2):39-43.LI Jin, YING Bin, ZHENG Xiunan. Research on assembly technology of composite super panel[J]. Fiber Composites,2019,36(2):39-43(in Chinese). [5] 谢富原, 王雪明, 李敏, 等. T形加筋板热压罐成型过程压力分布与树脂流动实验研究[J]. 复合材料学报, 2009, 26(6):66-71. doi: 10.3321/j.issn:1000-3851.2009.06.011XIE Fuyuan, WANG Xueming, LI Min, et al. Experimental research on pressure distribution and resin flow of T-shaped stiffened plate during autoclave forming[J]. Acta Materiae Compositae Sinica,2009,26(6):66-71(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.06.011 [6] GUTOWSKI T G, CAI Z, BAUER S, et al. Consolidation experiments for laminate composites[J]. Journal of Compo-site Materials,1987,21(7):650-669. doi: 10.1177/002199838702100705 [7] GUTOWSKI T G, MORIGAKI T, ZHONG C. The consolidation of laminate composites[J]. Journal of Composite Materials,1987,21(2):172-188. doi: 10.1177/002199838702100207 [8] DAVE R. A unified approach to modeling resin flow during composite processing[J]. Journal of Composite Materials,1990,24(1):22-41. doi: 10.1177/002199839002400102 [9] GU Y Z, LI M, ZHANG Z, et al. Numerical simulation and experimental study on consolidation of toughened epoxy resin composite laminates[J]. Journal of Composite Materials,2006,40(24):2257-2277. doi: 10.1177/0021998306062319 [10] GU Y Z, XIN C, LI M, et al. Resin pressure and resin flow inside tapered laminates during zero-bleeding and bleeding processes[J]. Journal of Reinforced Plastics and Compo-sites,2012,31(4):205-214. doi: 10.1177/0731684411434149 [11] GANAPATHI A S, JOSHI S C, CHEN Z. Simulation of bleeder flow and curing of thick composites with pressure and temperature dependent properties[J]. Simulation Modelling Practice and Theory,2013,32:64-82. doi: 10.1016/j.simpat.2012.12.002 [12] SEBASTIEN B, BAILLY C, DEVAUX J, et al. Rheological properties of flowable resin composites and pit and fissure sealants[J]. Dental Materials,2008,24(4):548-555. doi: 10.1016/j.dental.2007.05.019 [13] HUANG C K. Study on co-cured composite panels with blade-shaped stiffeners[J]. Composites Part A: Applied Science & Manufacturing,2003,34(5):403-410. [14] WANG X, XIE F, LI M, et al. Influence of core fillers on resin flow and fiber compaction of cocured skin-to-stiffener structures[J]. Polymer Composites,2010,31(8):1360-1368. [15] WANG X, XIE F, LI M, et al. Experimental investigation of the compaction and tensile strength of co-cured skin-to-stiffener structures[J]. Applied Composite Materials,2011,18(5):371-383. doi: 10.1007/s10443-010-9162-y [16] 罗刚堂, 李敏, 顾轶卓, 等. 共胶接T型加筋壁板模具设计及成型工艺研究[J]. 玻璃钢/复合材料, 2012(5):58-64. doi: 10.3969/j.issn.1003-0999.2012.05.011LUO Gangtang, LI Min, GU Yizhuo, et al. Research on mold design and forming process of co-bonded T-shaped reinforced siding[J]. Fiber Reinforced Plastics/Composites,2012(5):58-64(in Chinese). doi: 10.3969/j.issn.1003-0999.2012.05.011 [17] KOUSHYAR H, ALAVISOLTANI S, MINAIE B, et al. Effects of variation in autoclave pressure, temperature, and vacuum-application time on porosity and mechanical properties of a carbon fiber/epoxy composite[J]. Journal of Composite Materials,2012,46(16):1985-2004. doi: 10.1177/0021998311429618 [18] 汪赫男, 张佐光, 顾轶卓, 等. 环氧复合材料层板热压成型孔隙缺陷影响因素[J]. 复合材料学报, 2007, 24(5):55-60. doi: 10.3321/j.issn:1000-3851.2007.05.011WANG Henan, ZHANG Zuoguang, GU Yizhuo, et al. Influencing factors of void defects in hot pressing of epoxy composite laminates[J]. Acta Materiae Compositae Sinica,2007,24(5):55-60(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.05.011 [19] SMITH G D, POURSARTIP A. A comparison of two resin flow models for laminate processing[J]. Journal of Composite Materials,1993,27(17):1695-1711. doi: 10.1177/002199839302701704 [20] 苏小虎. 含褶皱复合材料层合板的拉伸性能[C]. 风能产业(2018年6月): 中国农业机械工业协会风力机械分会, 2018: 114-117.SU Xiaohu. Tensile properties of wrinkled composite laminates[C]. Wind Energy Industry (June 2018): Wind Machinery Branch of China Agricultural Machinery Industry Association, 2018: 114-117(in Chinese). [21] 叶梯. 含纤维褶皱复合材料层压板压缩性能研究[C]. 中国复合材料学会、杭州市人民政府. 第三届中国国际复合材料科技大会论文集. 中国复合材料学会、杭州市人民政府: 中国复合材料学会, 2017: 708-714.YE Ti. Study on compressive properties of fiber-wrinkled composite laminates[C]. Chinese Composites Society, Hangzhou Municipal People's Government. Proceedings of the Third China International Composites Technology Conference. Chinese Composites Society, Hangzhou People Government: China Composites Society, 2017: 708-714(in Chinese). [22] 欧阳佳斯. 带波纹/褶皱类缺陷的纤维增强树脂基复合材料压缩性能研究[D]. 武汉: 武汉理工大学, 2016.OUYANG Jiasi. Study on compression properties of fiber-reinforced resin matrix composites with corrugated/wrinkle-like defects[D]. Wuhan: Wuhan University of Technology, 2016(in Chinese). [23] 李韦清, 杨涛, 杨冠侠,等. 内嵌褶皱对自动铺丝层合板构件拉伸性能的影响[J]. 固体火箭技术, 2018, 41(5):621-626.LI Weiqing, YANG Tao, YANG Guanxia, et al. Effects of embedded wrinkles on the tensile properties of auto-laminated laminated panel members[J]. Solid Rocket Technology,2018,41(5):621-626(in Chinese). [24] 邓帆, 湛利华, 邹靖. 树脂基复合材料帽型加筋构件固化过程压力在线监测研究[J]. 玻璃钢/复合材料, 2018(7):36-41. doi: 10.3969/j.issn.1003-0999.2018.07.013DENG Fan, ZHAN Lihua, ZOU Jing. On-line monitoring of pressure during curing process of resin-based composite hat-shaped reinforced members[J]. Fiber Reinforced Plastics/Composites,2018(7):36-41(in Chinese). doi: 10.3969/j.issn.1003-0999.2018.07.013 [25] 胡江波, 薛向晨, 郑晓玲, 等. 叠层滑移工艺对M21C层压板力学性能的影响[J]. 复合材料学报, 2020, 37(5):1184-1190.HU Jiangbo, XUE Xiangchen, ZHENG Xiaoling, et al. Effect of laminated slip process on mechanical properties of M21C laminates[J]. Acta Materiae Compositae Sinica,2020,37(5):1184-1190(in Chinese). [26] 薛向晨, 王犇, 胡江波, 等. 大型机身复合材料加筋壁板制造技术及应用[J]. 航空制造技术, 2019, 62(16):88-93.XUE Xiangchen, WANG Ben, HU Jiangbo, et al. Manufacturing technology and application of large airframe compo-site material reinforced wallboard[J]. Aeronautical Manufacturing Technology,2019,62(16):88-93(in Chinese). -

下载:

下载: