| [1] |

杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composites and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001

|

| [2] |

武湛君, 渠晓溪, 高东岳, 等. 航空航天复合材料结构健康监测技术研究进展[J]. 航空制造技术, 2016(15):92-102, 109.WU Zhanjun, QU Xiaoxi, GAO Dongyue, et al. Research progress on structural health monitoring technology for aerospace composite structures[J]. Aeronautical Manufacturing Technology,2016(15):92-102, 109(in Chinese).

|

| [3] |

王奕首, 李煜坤, 吴迪, 等. 复合材料液体成型固化监测技术研究进展[J]. 航空制造技术, 2017(19):48-59.WANG Yishou, LI Yukun, WU Di, et al. Progress on cure monitoring for liquid composite molding[J]. Aeronautical Manufacturing Technology,2017(19):48-59(in Chinese).

|

| [4] |

王殿富, 万里冰, 张博明, 等. 光纤传感器在复合材料固化监测中的应用[J]. 哈尔滨工业大学学报, 2002, 34(5):710-714. doi: 10.3321/j.issn:0367-6234.2002.05.032WANG Dianfu, WAN Libing, ZHANG Boming, et al. Application of fiber optic sensors to monitoring of composite cures[J]. Journal of Harbin Institute of Technology,2002,34(5):710-714(in Chinese). doi: 10.3321/j.issn:0367-6234.2002.05.032

|

| [5] |

PINEDA U, MONTÉS N, SÁNCHEZ F, et al. Towards a quality monitoring to control the degree of cure in the manufacturing of composite parts[J]. Advanced Science Letters,2013,19(3):869-872.

|

| [6] |

赵瑾朝, 周兴平, 黄乐平. 树脂基复合材料固化过程的超声波在线监测研究进展[J]. 高分子材料科学与工程, 2018, 34(7):183-190.ZHAO Jinchao, ZHOU Xingping, HUANG Leping. Progress in cure monitoring of resin matrix composites via ultrasonics[J]. Polymer Materials Science & Engineering,2018,34(7):183-190(in Chinese).

|

| [7] |

LUO S, LIU T. Graphite nanoplatelet enabled embeddable fiber sensor for in situ curing monitoring and structural health monitoring of polymeric composites[J]. ACS Applied Materials & Interfaces,2014,6(12):9314-9320. doi: 10.1021/am5017039

|

| [8] |

卢少微, 陈铎, 王晓强. 聚合物基复合材料制造过程在线监测技术研究进展[J]. 航空制造技术, 2017(19):72-77.LU Shaowei, CHEN Duo, WANG Xiaoqiang. Review of in-situ cure monitoring techniques for polymer matrix composite manufacturing process[J]. Aeronautical Manufacturing Technology,2017(19):72-77(in Chinese).

|

| [9] |

QING X P, BEARD S J, KUMAR A, et al. A real-time active smart patch system for monitoring the integrity of bonded repair on an aircraft structure[J]. Smart Materials & Structures,2006,15(3):66-73.

|

| [10] |

陶博然, 郭婵, 李建新, 等. 超声波实时监测乙烯基酯树脂固化反应过程[J]. 复合材料学报, 2009, 26(3):73-77. doi: 10.3321/j.issn:1000-3851.2009.03.014TAO Boran, GUO Chan, LI Jianxin, et al. In-situ measurement of the curing behavior of vinyl-ester resin by ultrasonic wave propagation[J]. Acta Materiae Compositae Sinica,2009,26(3):73-77(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.03.014

|

| [11] |

胡焱, 黄贵飞, 梁科, 等. 超声波在线监测环氧树脂中温固化过程实验研究[J]. 玻璃钢/复合材料, 2017(5):11-15. doi: 10.3969/j.issn.1003-0999.2017.05.002HU Yan, HUANG Guifei, LIANG Ke, et al. Experimental study of online monitoring curing process of epoxy resin under medium temperature condition by ultrasonic technique[J]. Fiber Reinforced Plastics/Composites,2017(5):11-15(in Chinese). doi: 10.3969/j.issn.1003-0999.2017.05.002

|

| [12] |

DANISMAN M, TUNCOL G, KAYNAR A, et al. Monitoring of resin flow in the resin transfer molding (RTM) process using point-voltage sensors[J]. Composites Science & Technology,2007,67(3-4):367-379.

|

| [13] |

LIM Y Y, TANG Z S, SMITH S T. Piezoelectric-based monitoring of the curing of structural adhesives: A novel experimental study[J]. Smart Materials & Structures,2019,28(1):015016.

|

| [14] |

杨正岩, 张佳奇, 高东岳, 等. 航空航天智能材料与智能结构研究进展[J]. 航空制造技术, 2017(17): 36-48.YANG Zhengyan, ZHANG Jiaqi, GAO Dongyue, et al. Advance of aerospace smart material and structure[J]. 2017(17): 36-48(in Chinese).

|

| [15] |

GIURGIUTIU V, ZAGRAI A, BAO J J. Piezoelectric wafer embedded active sensors for aging aircraft structural health monitoring[J]. Structural Health Monitoring,2002,1(1):41-61. doi: 10.1177/147592170200100104

|

| [16] |

ZHOU K, ZHENG Y, ZHANG J, et al. A reconstruction-based mode separation method of Lamb wave for damage detection in plate structures[J]. Smart Materials & Structures,2019,28(3):035033.

|

| [17] |

刘科海. 飞行器关键构件的超声导波损伤诊断成像方法研究[D]. 大连: 大连理工大学, 2016.LIU Kehai. Damage diagnostic imaging using ultrasonic guided waves for key components in aerospace structures[D]. Dalian: Dalian University of Technology, 2016(in Chinese).

|

| [18] |

GAO D, WU Z, YANG L, et al. Guide waves-based multi-damage identification using a local probability-based diagnostic imaging method[J]. Smart Materials & Structures,2016,25(4):045009.

|

| [19] |

SU Z, YE L, LU Y. Guided Lamb waves for identification of damage in composite structures: A review[J]. Journal of Sound & Vibration,2006,295(3-5):753-780.

|

| [20] |

WU Z, LIU K, WANG Y, et al. Validation and evaluation of damage identification using probability-based diagnostic imaging on a stiffened composite panel[J]. Journal of Intelligent Material Systems & Structures,2015,26(16):2181-2195.

|

| [21] |

ZHOU K, XU X, ZHAO Z, et al. Excitation of plane Lamb wave in plate-like structures under applied surface loading[J]. Smart Materials & Structures,2018,27(2):025011.

|

| [22] |

朱宏平, 王丹生, 张俊兵. 基于压电阻抗技术的结构损伤识别基本理论及其应用[J]. 工程力学, 2008, 25(s2):34-43.ZHU Hongping, WANG Dansheng, ZHANG Junbing. Theory and application of structure damage detection based on piezoelectric impedance technique[J]. Engineering Mechanics,2008,25(s2):34-43(in Chinese).

|

| [23] |

LIANG C, SUN F P, ROGERS C A. Coupled electro-mechanical analysis of adaptive material systems-determination of the actuator power consumption and system energy transfer[J]. Journal of Intelligent Material Systems & Structures,1997,5(4):335-343.

|

| [24] |

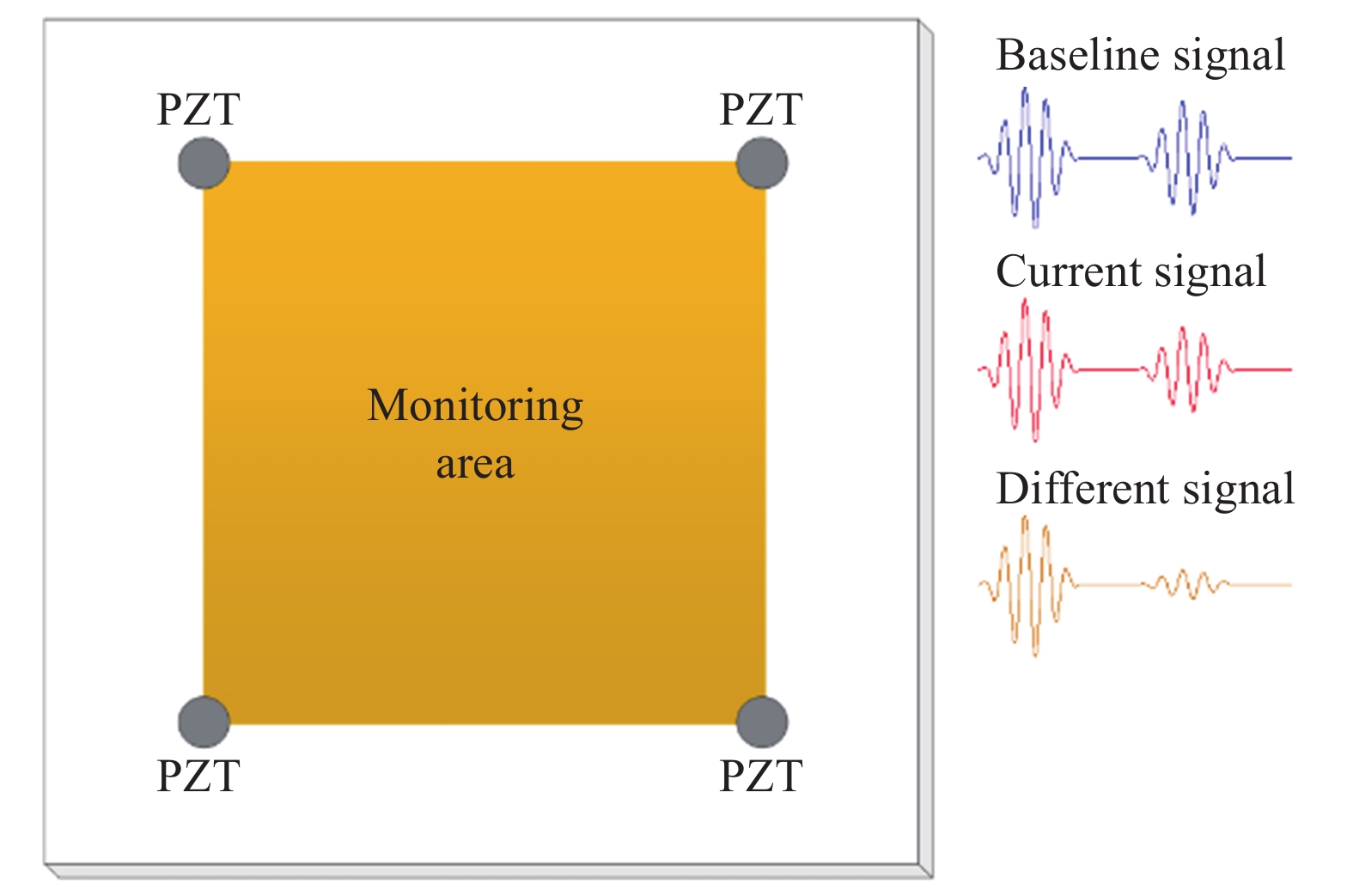

ZHENG Y, LIU K, WU Z, et al. Lamb waves and electro-mechanical impedance based damage detection using a mobile PZT transducer set[J]. Ultrasonics,2019,92:13-20. doi: 10.1016/j.ultras.2018.06.008

|

| [25] |

沈星, 吕娟, 章建文, 等. 基于压电阻抗技术和BP网络的结构健康监测[J]. 南京航空航天大学学报, 2010, 42(4):418-422. doi: 10.3969/j.issn.1005-2615.2010.04.005SHEN Xing, LV Juan, ZHANG Jianwen, et al. Experiment of structural health monitoring based on piezoelectric impedance technology and BP network[J]. Journal of Nanjing University of Aeronautics & Astronautics,2010,42(4):418-422(in Chinese). doi: 10.3969/j.issn.1005-2615.2010.04.005

|

| [26] |

LIONETTO F, RIZZO R, LUPRANO V A M, et al. Phase transformations during the cure of unsaturated polyester resins[J]. Materials Science & Engineering A,2004,370(1-2):284-287.

|

下载:

下载: