Effects of macro fibers on crack permeability evolution of concrete under loading

-

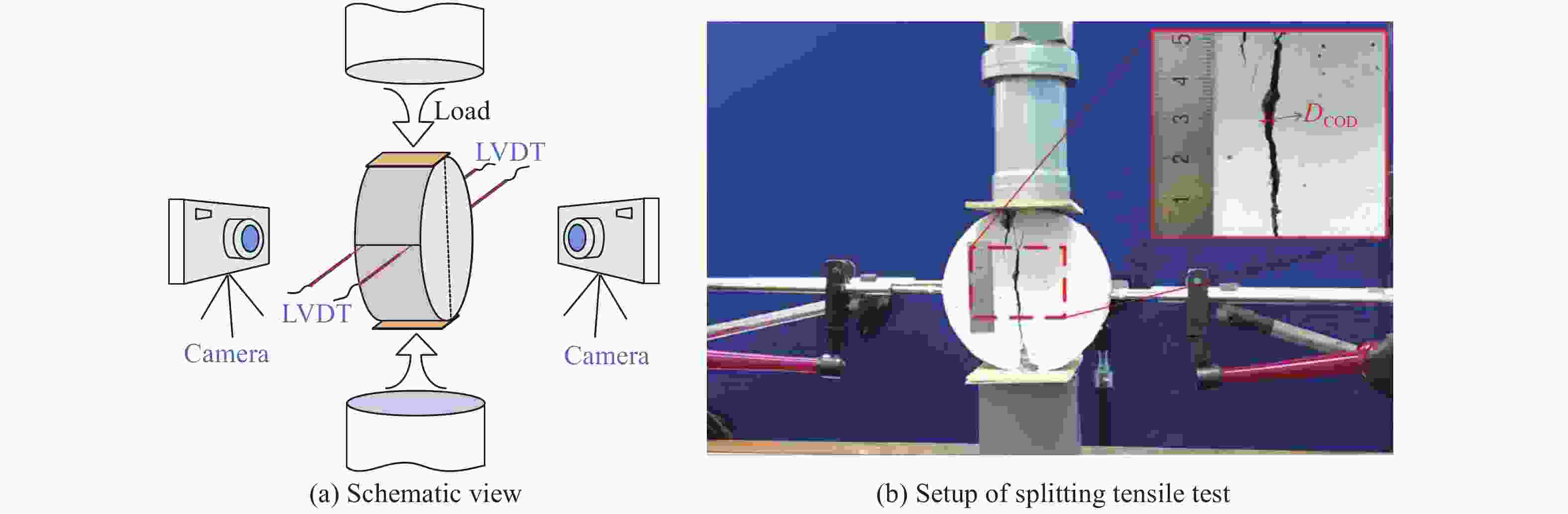

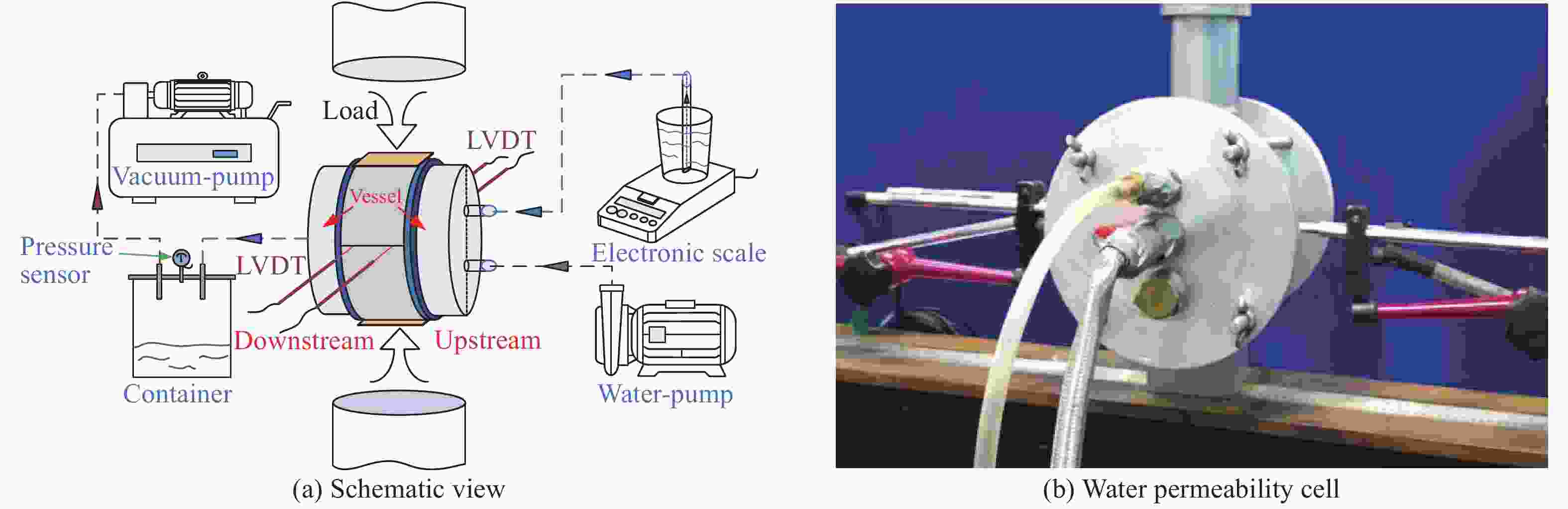

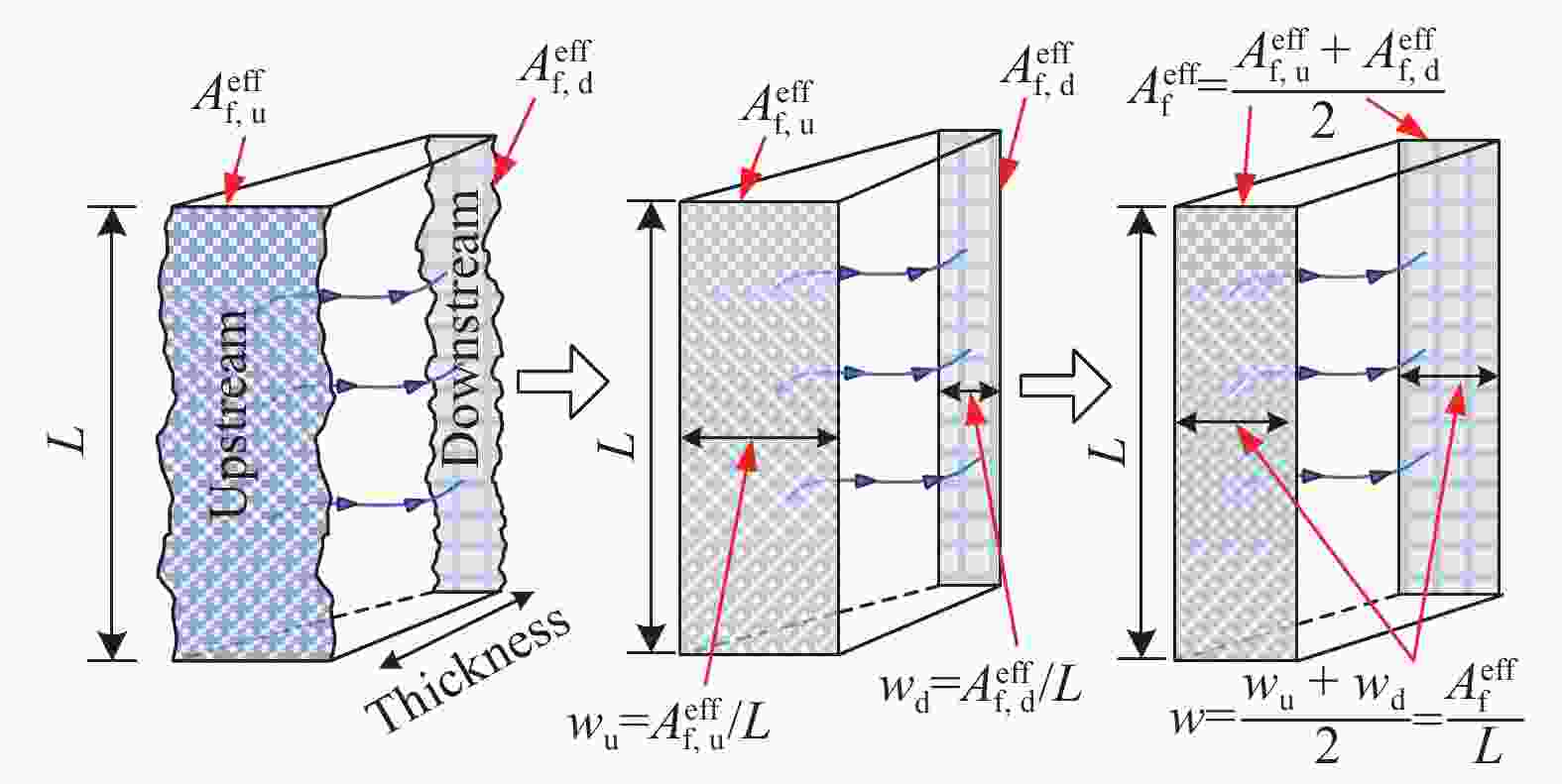

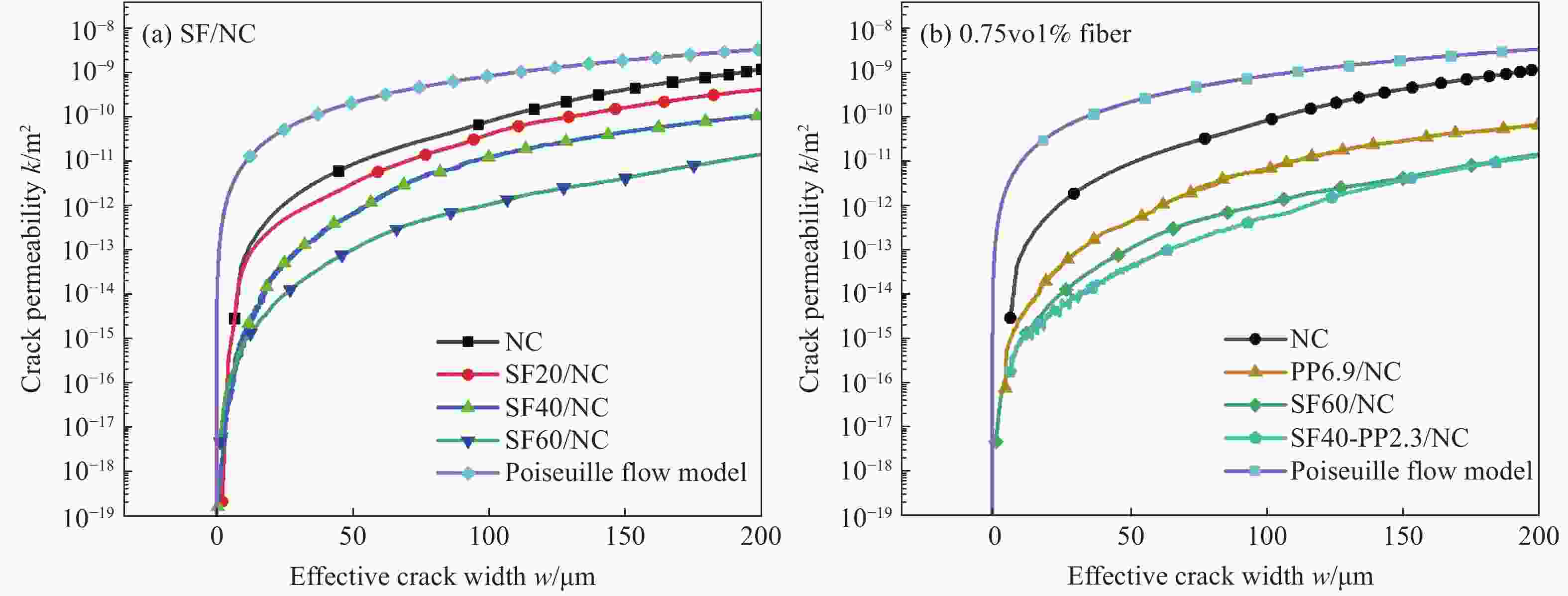

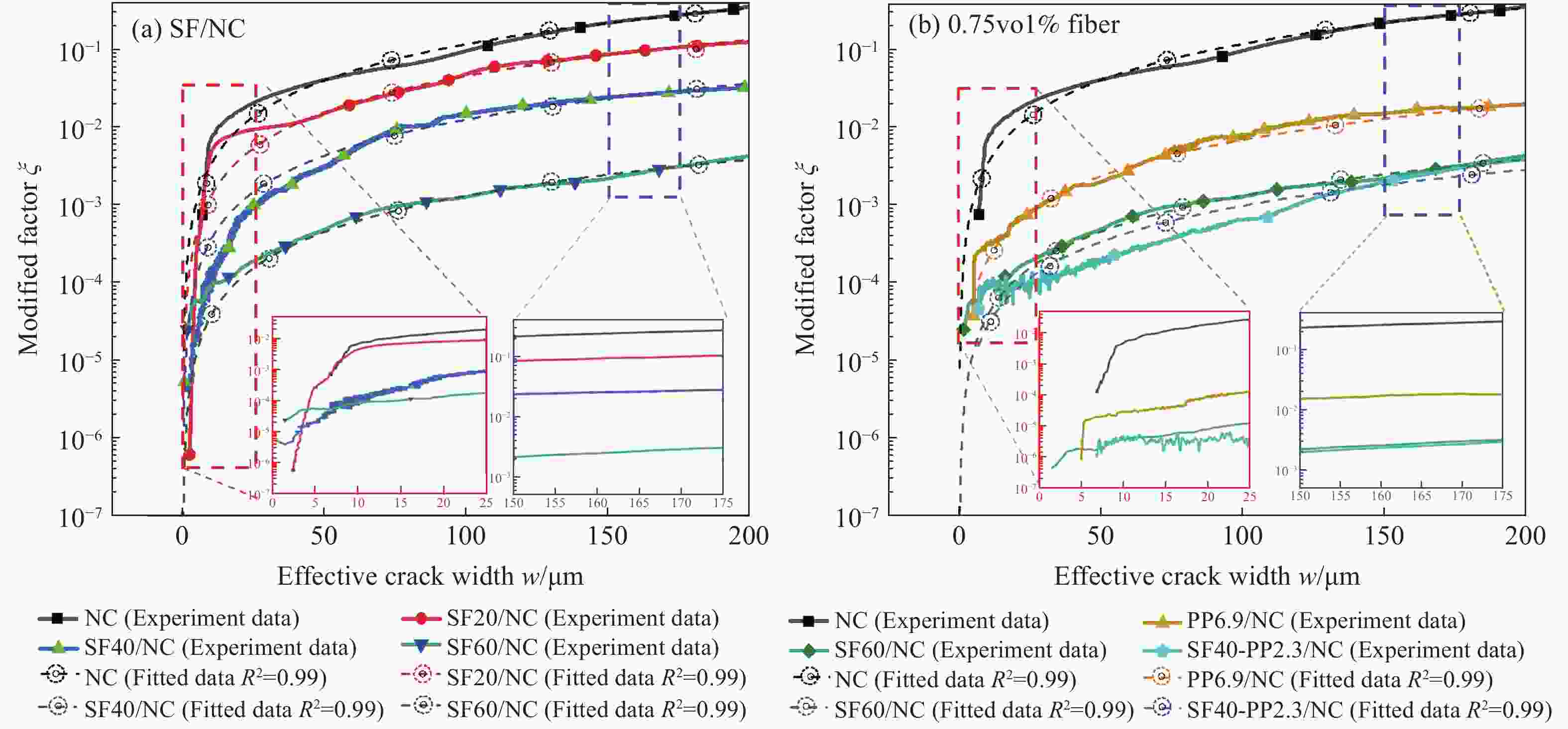

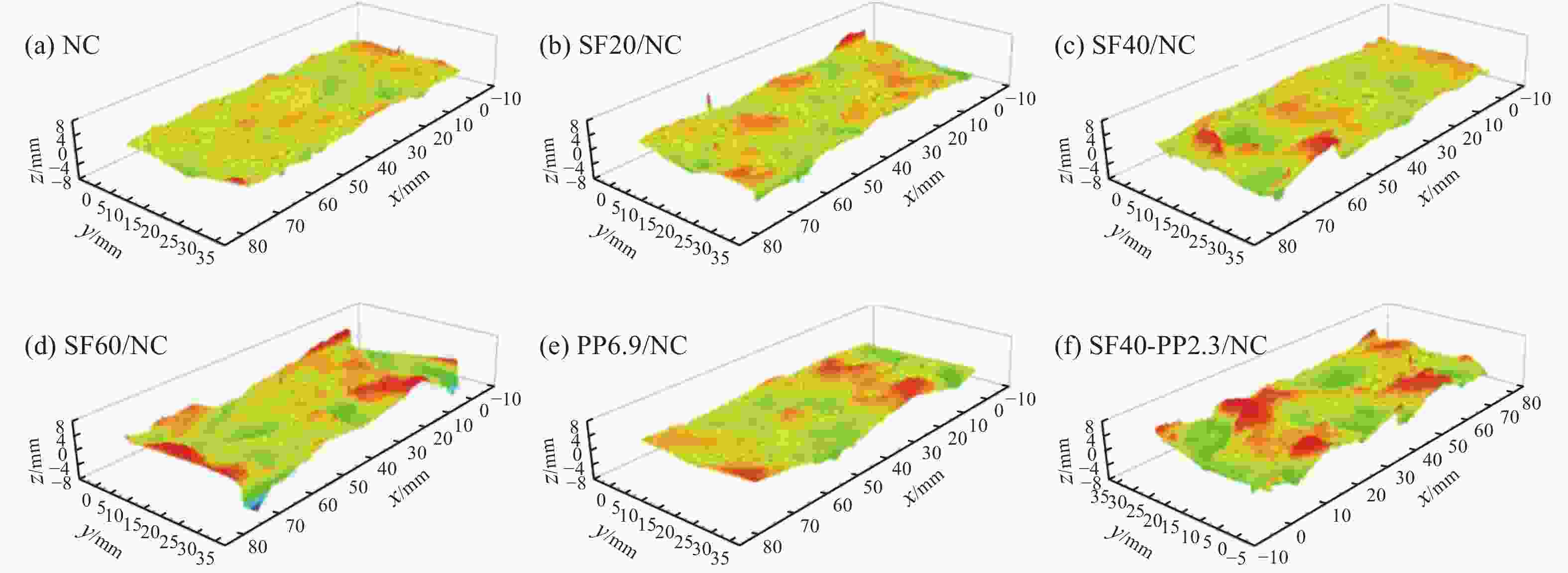

摘要: 为研究荷载作用下结构型钢纤维和结构型聚丙烯纤维对混凝土裂缝渗透率演化的影响,通过劈拉试验引入混凝土裂缝,同时利用真空渗水试验装置对不同裂缝宽度下混凝土裂缝渗透率进行实时测量和分析。借助激光扫描仪对混凝土裂缝表面形态进行信息采集和形态重构。对比分析了结构型钢纤维、结构型聚丙烯纤维及混杂纤维(包括结构型钢纤维和结构型聚丙烯纤维)对混凝土裂缝渗透率及裂缝表面形态的影响。研究表明:结构型纤维可通过增大裂缝表面粗糙程度降低混凝土裂缝渗透率,且随着纤维掺量的增高,混凝土裂缝渗透率随之减小。对比单掺纤维混凝土,混杂纤维混凝土具有更粗糙的裂缝表面,且展现出更显著的裂缝抗渗性能;随着裂缝的扩展,混凝土裂缝渗透率更接近于泊肃叶渗流模型;相比于泊肃叶渗流模型修正系数ξ,本文所用渗透率参数α更适合量化结构型纤维对混凝土裂缝渗透率的影响。Abstract: In order to study the effects of macro fibers on the crack permeability evolution of concrete under loading, the splitting test was adopted to generate cracks on the concrete specimens. The crack permeability of different crack widths was measured in real time using the vacuum permeability test. The laser scanning equipment was adopted for the measurement of information and the reconstruction of the topography of crack surface. The effects of macro steel fiber, macro polypropylene fiber and hybrid fiber(including macro polypropylene fiber and macro steel fiber) on the crack permeability of concrete and the topography of crack surface were analyzed and compared. The results show that the macro fibers increase the crack surface roughness of concrete and indirectly decrease the crack permeability of concrete. With the increasing of fiber content, the crack permeability decreases. Compared to mono fiber reinforcement, the crack surface of hybrid fiber reinforced concrete is rough and the crack permeability of hybrid fiber reinforced concrete is small. With the increase of crack width, the crack permeability is closer to the value predicted by the Poiseuille flow model. Compared to modified factor ξ of Poiseuille flow model, parameter α of permeability is suitable for quantifying the effect of macro fibers on the crack permeability of concrete.

-

Key words:

- macro fiber /

- crack permeability /

- crack surface topography /

- Poiseuille flow model /

- roughness number

-

表 1 混凝土基准配比

Table 1. Basic mix proportion of concrete

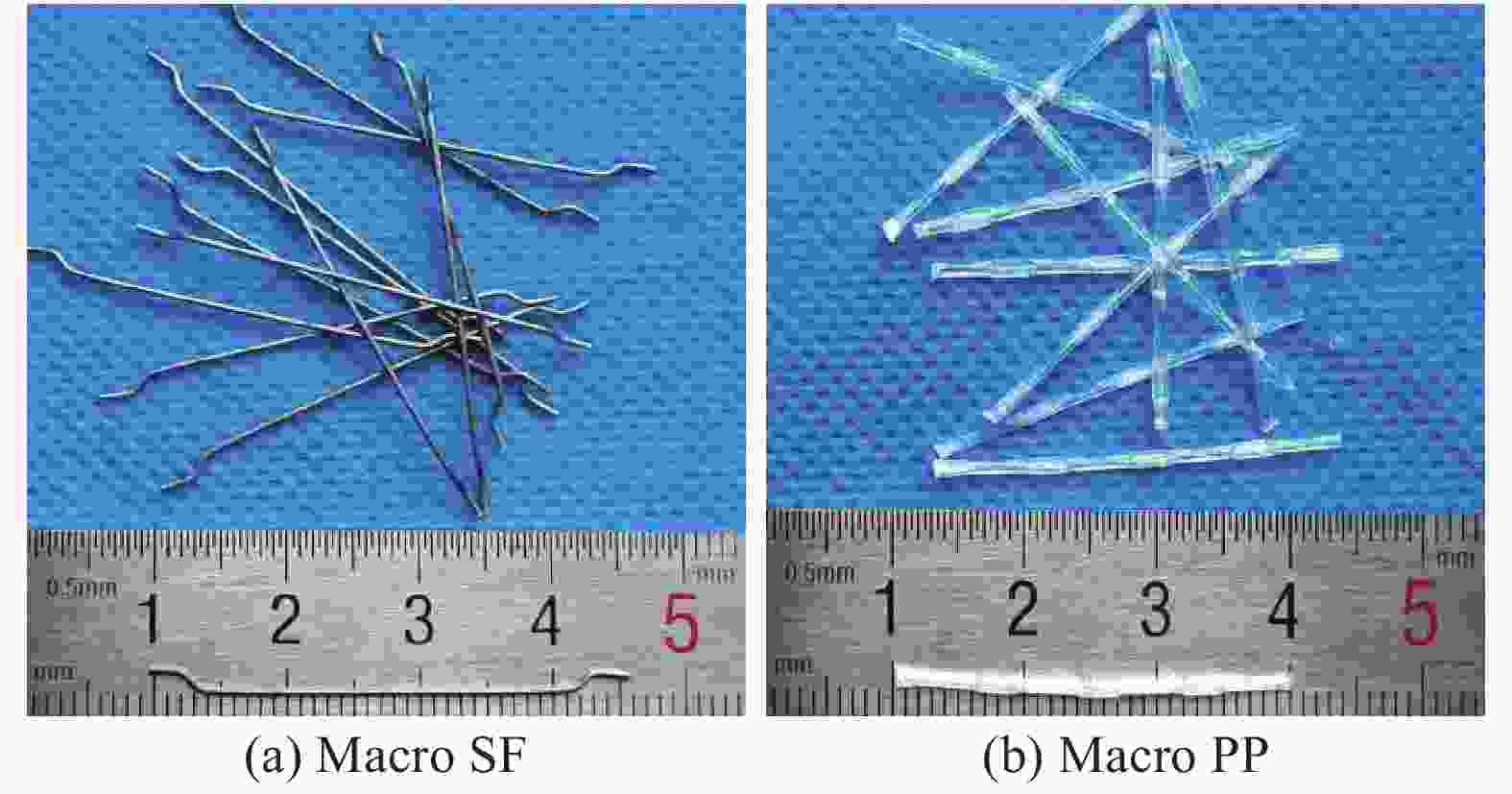

kg·m−3 Cement Fly ash Fine aggregate Coarse aggregate Water Superplasticizer 390 155 822 848 272.5 5.5 表 2 结构型SF和结构型PP的性能参数

Table 2. Properties of macro SF and macro PP

Type Length/mm Diameter/mm Aspect ratio Tensile strength/MPa E-modulus/GPa Number/(pieces·kg−1) Macro SF 35 0.54 65 1 345 200.0 14 500 Macro PP 30 0.67 45 490 3.9 96 000 表 3 结构型SF和结构型PP掺量

Table 3. Contents of macro SF and macro PP

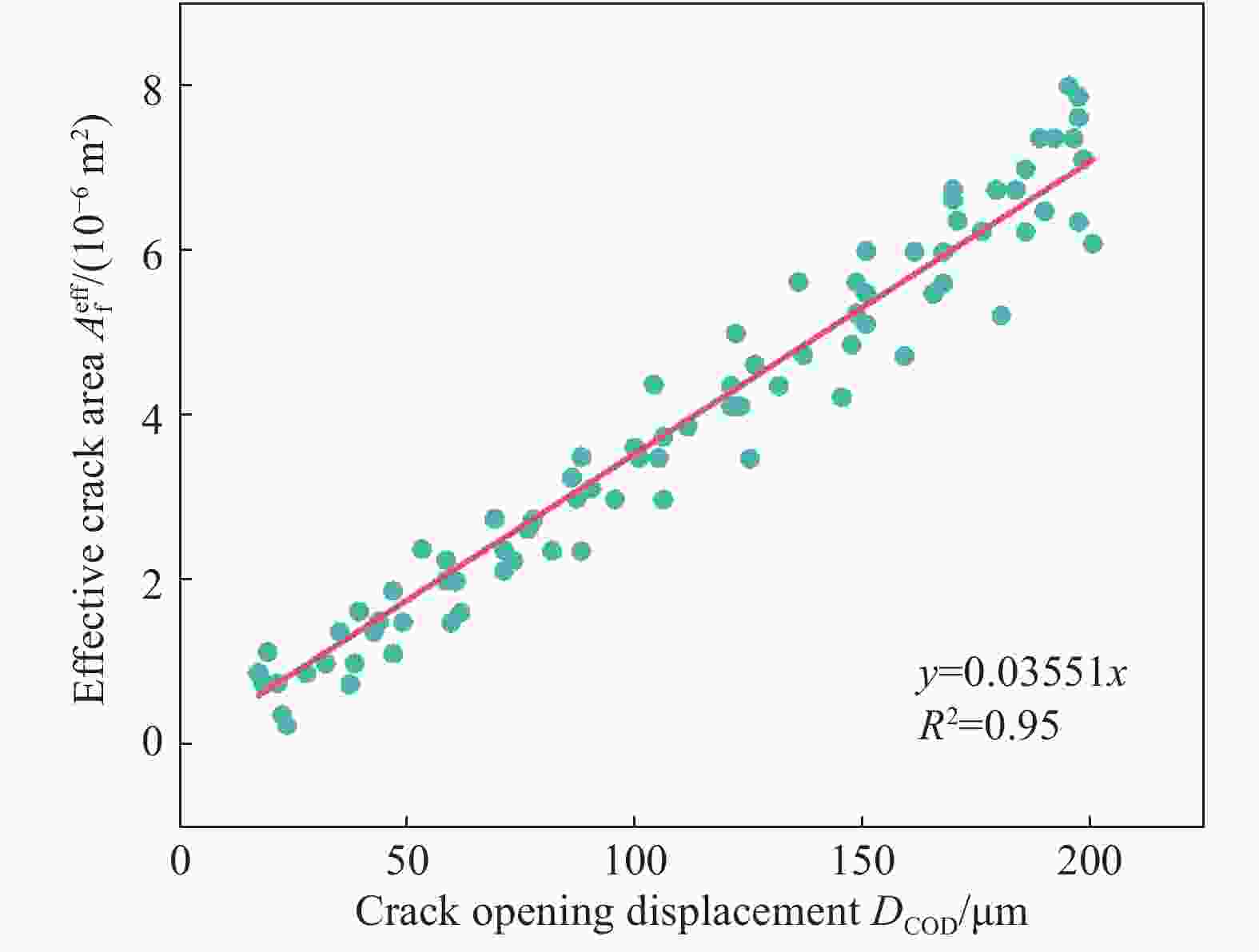

Type Macro SF Macro PP NC — — SF20/NC 20 kg/m3 (0.25vol%) — SF40/NC 40 kg/m3 (0.50vol%) — SF60/NC 60 kg/m3 (0.75vol%) — PP6.9/NC — 6.9 kg/m3 (0.75vol%) SF40-PP2.3/NC 40 kg/m3 (0.50vol%) 2.3 kg/m3 (0.25vol%) 表 4 普通混凝土(NC)、结构型钢纤维增强混凝土(SF/NC)、结构型聚丙烯纤维增强混凝土(PP/NC)和混杂纤维增强混凝土(SF-PP/NC)的DCOD与Afeff的拟合曲线参数的对比

Table 4. Comparison of fitted parameter between DCOD and Afeff of normal concrete(NC), macro steel fiber reinforced concrete(SF/NC), macro polypropylene fiber reinforced concrete(PP/NC) and hybrid fiber reinforced concrete(SF-PP/NC)

NC SF20/NC SF40/NC SF60/NC PP6.9/NC SF40-PP2.3/NC 0.02906 (R2=0.99) 0.03256 (R2=0.99) 0.03551(R2=0.95) 0.04039 (R2 =0.98) 0.03016 (R2=0.96) 0.04237 (R2=0.97) Note: R2—Coefficient of determination. 表 5 NC、SF/NC、PP/NC和SF-PP/NC拟合曲线的参数

Table 5. Fitted parameters of curves of NC, SF/NC, PP/NC and SF-PP/NC

Parameter β Fitted parameter α NC SF20/NC SF40/NC SF60/NC PP6.9/NC SF40-PP2.3/NC 1.541 171 465.3(Cv=6.1%) 66 963.0(Cv=8.9%) 18 477.5(Cv=5.4%) 1 942.1(Cv=7.6%) 10 020.3(Cv=3.8%) 1 431.0(Cv=5.1%) Note: Cv—Coefficient of variation. 表 6 NC、SF/NC、PP/NC和SF-PP/NC裂缝粗糙度

Table 6. Crack roughness number of NC, SF/NC, PP/NC and SF-PP/NC

NC SF20/NC SF40/NC SF60/NC PP6.9/NC SF40-PP2.3/NC 1.133 (Cv=1.9%) 1.214 (Cv=3.6%) 1.299 (Cv=6.9%) 1.430 (Cv=4.7%) 1.304(Cv=3.7%) 1.480(Cv=4.1%) -

[1] NILSON A H, DARWIN D, DOLAN C. Design of concrete structures[M]. New York: McGraw Hill, 2011. [2] Fédération Internationale du Béton. Model code for concrete structures 2010[M]. Berlin: Wilhelm Ernst & Sohn, 2013. [3] DING Y, LI D, ZHANG Y. Quantitative analysis of macro steel fiber influence on crack geometry and water permeability of concrete[J]. Composite Structures,2018,187:325-335. doi: 10.1016/j.compstruct.2017.12.074 [4] 施锦杰, 孙伟. 混凝土中钢筋锈蚀研究现状与热点问题分析[J]. 硅酸盐学报, 2010, 38(9):1753-1764.SHI Jinjie, SUN Wei. Recent research on steel corrosion in concrete[J]. Journal of the Chinese Ceramic Society,2010,38(9):1753-1764(in Chinese). [5] 牛荻涛, 孙丛涛. 混凝土碳化与氯离子侵蚀共同作用研究[J]. 硅酸盐学报, 2013, 41(8):1094-1099.NIU Ditao, SUN Congtao. Study on interaction of concrete carbonation and chloride corrosion[J]. Journal of the Chinese Ceramic Society,2013,41(8):1094-1099(in Chinese). [6] 丁一宁, 王卿, 林宇栋. 纤维对开裂后混凝土渗透性及裂缝恢复的影响[J]. 复合材料学报, 2017, 34(8):1853-1861.DING Yining, WANG Qing, LIN Yudong. Effect of fibers on permeability and crack relaxation of cracked concrete[J]. Acta Materiae Compositae Sinica,2017,34(8):1853-1861(in Chinese). [7] 杨成蛟, 黄承逵, 车轶, 等. 混杂纤维混凝土的力学性能及抗渗性能[J]. 建筑材料学报, 2008, 11(1):89-93. doi: 10.3969/j.issn.1007-9629.2008.01.017YANG Chengjiao, HUANG Chengkui, CHE Yi, et al. Mechanical properties and impermeability of hybrid fiber reinforced concrete[J]. Journal of Building Materials,2008,11(1):89-93(in Chinese). doi: 10.3969/j.issn.1007-9629.2008.01.017 [8] 孙家瑛. 应力作用下纤维混凝土抗渗特征研究[J]. 建筑材料学报, 2012, 15(4):474-477. doi: 10.3969/j.issn.1007-9629.2012.04.007SUN Jiaying. Study on influence of external load on fiber concrete impermeability[J]. Journal of Building Materials,2012,15(4):474-477(in Chinese). doi: 10.3969/j.issn.1007-9629.2012.04.007 [9] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for test methods of long-term performance and durability of ordinary concrete: GB/T 50082—2009[S]. Beijing: China Architecture & Building Press, 2009(in Chinese). [10] 丁一宁, 任县伟, 李冬. 结构型钢纤维对混凝土单裂缝渗透特性的影响[J]. 水利学报, 2017, 48(1):13-20.DING Yining, REN Xianwei, LI Dong. Investigation of the fiber effect on the permeability of cracked concrete[J]. Journal of Hydraulic Engineering,2017,48(1):13-20(in Chinese). [11] BODIN J, DELAY F, MARSILY G D. Solute transport in a single fracture with negligible matrix permeability: 1. Fundamental mechanisms[J]. Hydrogeology Journal,2003,11(4):418-433. doi: 10.1007/s10040-003-0268-2 [12] WANG K, JANSEN D C, SHAH S P, et al. Permeability study of cracked concrete[J]. Cement and Concrete Research,1997,27(3):381-393. doi: 10.1016/S0008-8846(97)00031-8 [13] ALDEA C M, SHAH S P, KARR A. Permeability of cracked concrete[J]. Materials and Structures,1999,32(5):370-376. doi: 10.1007/BF02479629 [14] RAPOPORT J, ALDEA C, SHAH S P, et al. Permeability of cracked steel fiber-reinforced concrete[J]. Journal of Materials in Civil Engineering,2002,14(4):355-358. doi: 10.1061/(ASCE)0899-1561(2002)14:4(355) [15] YI S T, HYUN T Y, KIM J K. The effects of hydraulic pressure and crack width on water permeability of penetration crack-induced concrete[J]. Construction and Building Materials,2011,25(5):2576-2583. doi: 10.1016/j.conbuildmat.2010.11.107 [16] AKHAVAN A, SHAFAATIAN S M H, RAJABIPOUR F. Quantifying the effects of crack width, tortuosity, and roughness on water permeability of cracked mortars[J]. Cement and Concrete Research,2012,42(2):313-320. doi: 10.1016/j.cemconres.2011.10.002 [17] BOULAY C, PONT S D, BELIN P. Real-time evolution of electrical resistance in cracking concrete[J]. Cement and Concrete Research,2009,39(9):825-831. doi: 10.1016/j.cemconres.2009.06.003 [18] RASTIELLO G, BOULAY C, PONT S D, et al. Real-time water permeability evolution of a localized crack in concrete under loading[J]. Cement and Concrete Research,2014,56:20-28. doi: 10.1016/j.cemconres.2013.09.010 [19] PICANDET V, KHELIDJ A, BELLEGOU H. Crack effects on gas and water permeability of concretes[J]. Cement and Concrete Research,2009,39(6):537-547. doi: 10.1016/j.cemconres.2009.03.009 [20] JOHN S L, DAVIDE Z, SURENDRA P S. Permeability of cracked hybrid fiber-reinforced mortar under load[J]. ACI Materials Journal,2002,99(4):379-385. [21] 丁一宁, 李林泽, 曾伟. 纤维对混凝土的损伤、裂缝曲折度及裂缝恢复的影响[J]. 复合材料学报, 2019, 36(10):2439-2447.DING Yining, LI Linze, ZENG Wei. Fibers effect on the concrete damage, crack tortuosity and crack recovery[J]. Acta Materiae Compositae Sinica,2019,36(10):2439-2447(in Chinese). [22] 丁一宁, 郝晓卫, 门旭. 纤维对混凝土裂缝宽度、曲折度及渗透性的影响[J]. 复合材料学报, 2019, 36(2):491-497.DING Yining, HAO Xiaowei, MEN Xu. Effect of fiber on the crack width, tortuosity and permeability of concrete[J]. Acta Materiae Compositae Sinica,2019,36(2):491-497(in Chinese). [23] WAGNER C, VILLMANN B, SLOWIK V, et al. Water permeability of cracked strain-hardening cement-based composites[J]. Cement and Concrete Composites,2017,82:234-241. doi: 10.1016/j.cemconcomp.2017.06.003 -

下载:

下载: