Preparation and properties of steel-polypropylene fiber reinforced artificial granite composite

-

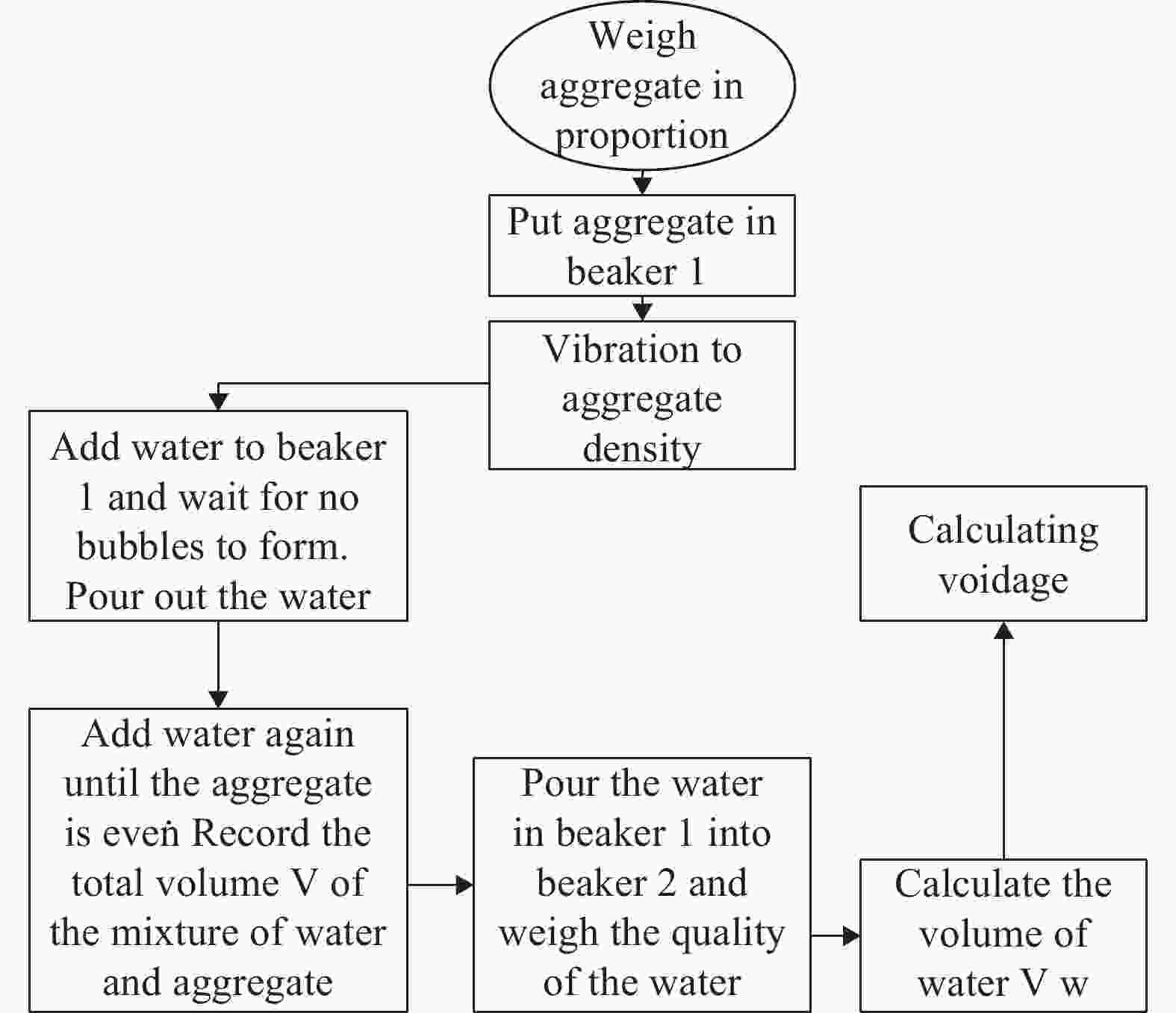

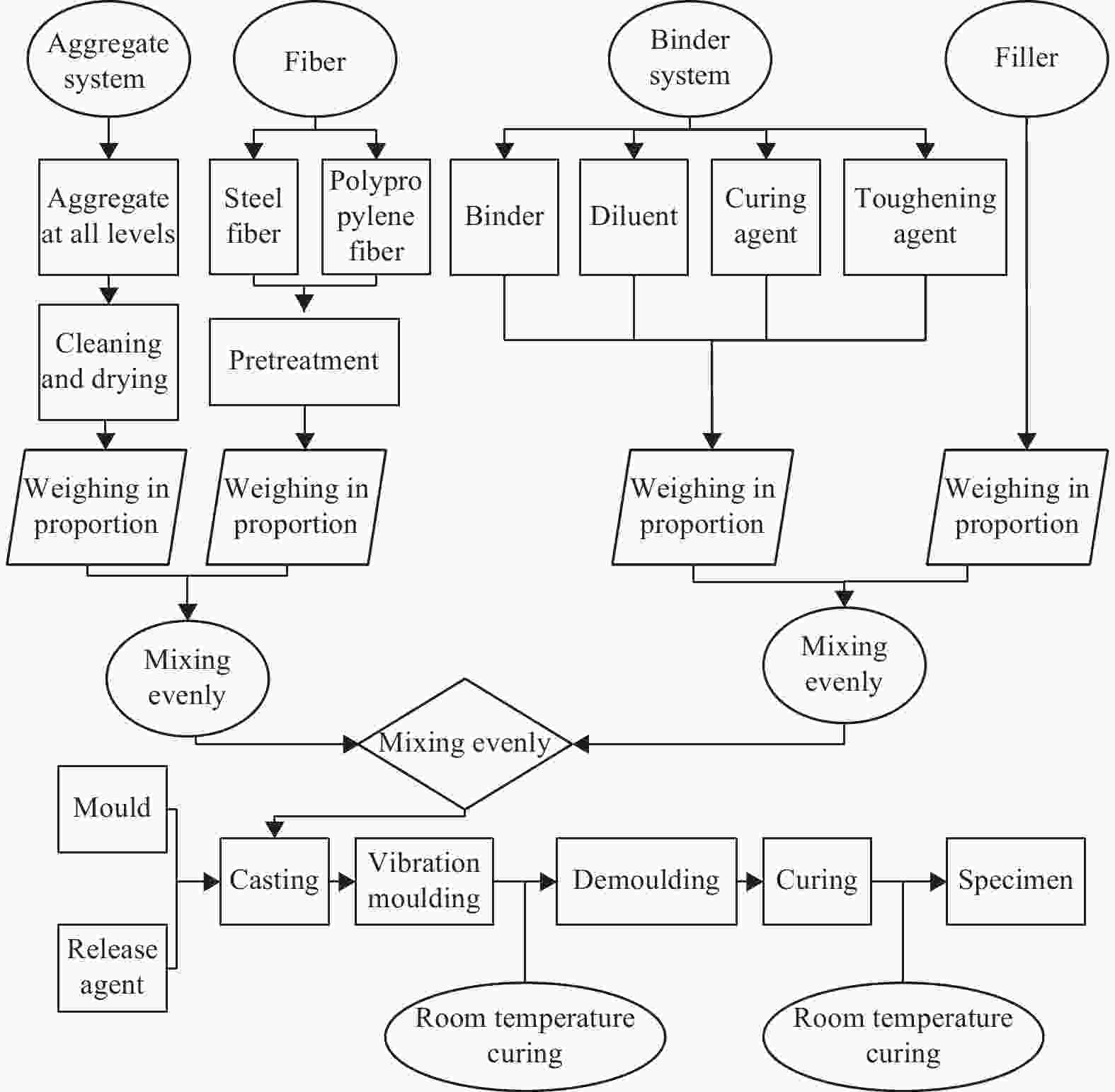

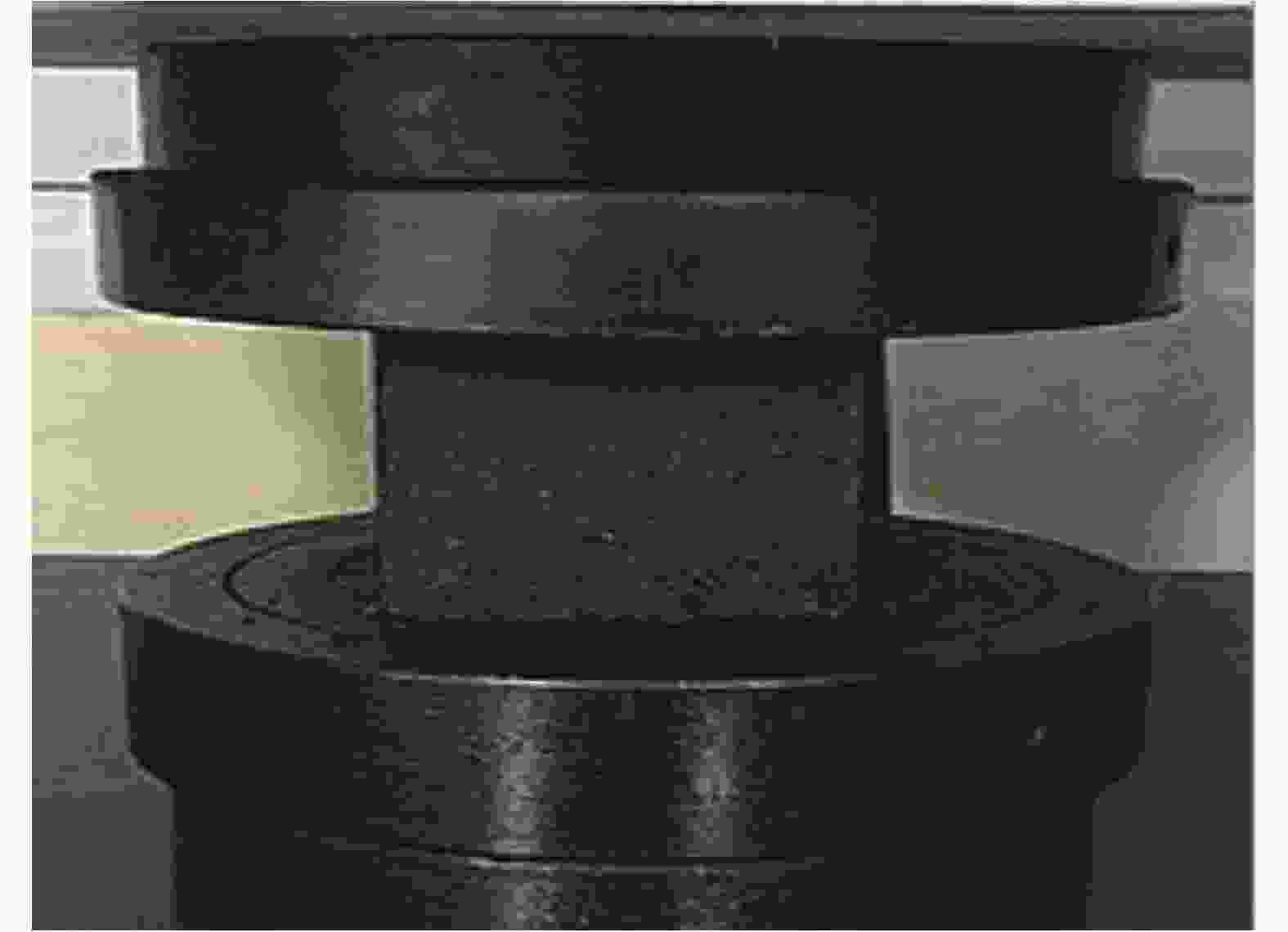

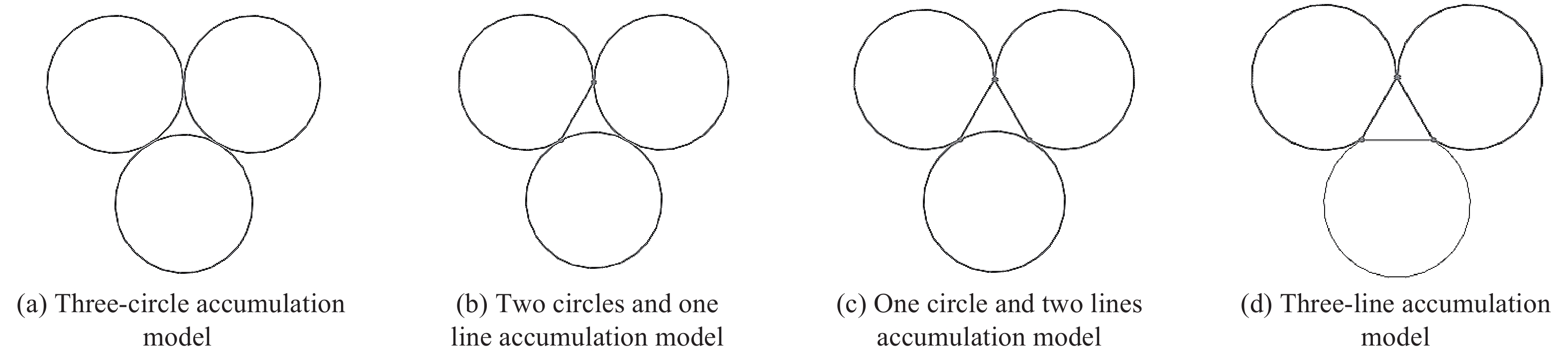

摘要: 为深入研究钢-聚丙烯纤维增强人造花岗岩复合材料(钢-聚丙烯纤维/人造花岗岩)抗压、抗弯强度的影响因素,通过排水法实验研究了骨料堆积的空隙率,确定了骨料级配和实验指数q并对大量试件进行了抗压、抗弯强度测试,分析了钢-聚丙烯纤维/人造花岗岩复合材料各组分质量分数、骨料堆积空隙率等因素对钢-聚丙烯纤维/人造花岗岩复合材料抗压、抗弯强度的影响。实验结果表明:钢纤维与聚丙烯纤维能够明显增大钢-聚丙烯纤维/人造花岗岩复合材料的抗弯强度,随着钢-聚丙烯纤维质量分数的增加,钢-聚丙烯纤维/人造花岗岩复合材料试件的抗压和抗弯强度都逐渐增大;当钢纤维与聚丙烯纤维质量比为30∶1、钢-聚丙烯纤维质量分数为1.7wt%时,钢-聚丙烯纤维/人造花岗岩复合材料试件的抗压强度达到最大,当钢-聚丙烯纤维质量分数为1.9wt%时,钢-聚丙烯纤维/人造花岗岩试件的抗弯强度达到最大;黏结剂质量分数越接近骨料堆积空隙率,钢-聚丙烯纤维/人造花岗岩复合材料试件的抗压和抗弯强度越大,当骨料质量分数为80wt%、黏结剂质量分数为11wt%时,钢-聚丙烯纤维/人造花岗岩复合材料试件的抗压、抗弯强度同时达到最大。Abstract: In order to further study the influence factors of compressive strength and flexural strength of steel-polypropylene fiber reinforced artificial granite (steel polypropylene fiber/artificial granite) composite, the void ratio of aggregate accumulation was studied by drainage method. The aggregate gradation and experimental index q were determined, and the compressive strength and flexural strength of a large number of specimens were tested. The influences of the mass fraction of each component and the void ratio of aggregate on the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite were analyzed. The experimental results show that steel fibers and polypropylene fibers can significantly increase the flexural strength of steel polypropylene fiber/artificial granite composite. With the increase of the content of steel-polypropylene fibers, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite specimens increase gradually. When the mass ratio of steel fibers to polypropylene fibers is 30∶1 and the content of steel-polypropylene fiber is 1.7wt%, the compressive strength of the steel polypropylene fiber/artificial granite composite specimens increases gradually. The flexural strength of the steel polypropylene fiber/artificial granite specimens reaches the maximum when the steel-polypropylene fiber content is 1.9wt%. The closer the mass fraction of binder to the void ratio of the aggregate, the greater the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite are. When the aggregate is 80wt% and the binder is 11wt%, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite specimen reach the maximum at the same time.

-

表 1 HORSFIELD最密填充数据

Table 1. HORSFIELD's closest filling data

Filling state Particle size of aggregate Relative number of aggregates Void fraction First filling D 1 0.2595 Second filling d=0.414D 1 0.207 Notes: D—Primary aggregate size; d—Diameter of the sieve hole. 表 2 不同骨料堆积模式对应的次级骨料粒径

Table 2. Secondary aggregate size corresponding to different aggregate accumulation models

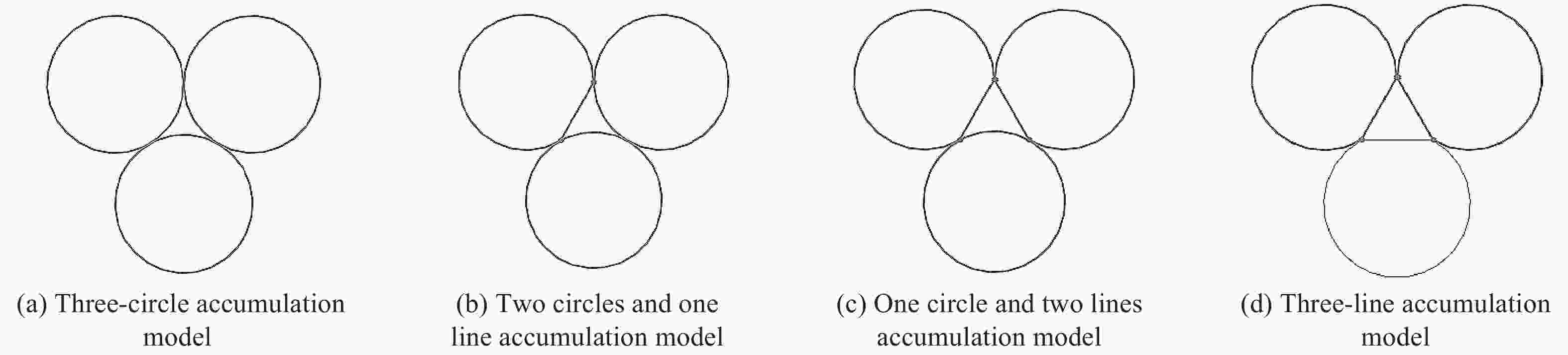

Aggregate accumulation model Three-

circleTwo circles and one line One circle and two lines Three-

lineSecondary aggregate size 0.15D 0.2D 0.24D 0.29D 表 3 五种筛孔直径

Table 3. Five sieve hole diameters

Controlling sizes of

sieve holed1/mm d2/mm d3/mm d4/mm d5/mm Size 0.11 0.52 2.36 4.75 10.00 表 4 两种纤维主要性能指标

Table 4. Main performance indicators of two fibers

Fiber type Diameter/

μmTensile strength/

MPaModulus of elasticity/

GPaDensity/

(g·cm−3)Steel fiber 500 3 000 210 7.8 Polypropylene fiber 35 700 4.2 0.9 表 5 钢-聚丙烯纤维/人造花岗岩复合材料力学性能实验设计

Table 5. Design of mechanical property experiment of steel polypropylene fiber/artificial granite composites

Serial

numberFibre/wt% Filler/wt% Aggregate/wt% Binder/wt% 1 1.3 7.7 83 8 2 1.5 7.5 83 8 3 1.7 7.3 83 8 4 1.9 7.1 83 8 5 2.1 6.9 83 8 6 1.3 7.7 82 9 7 1.5 7.5 82 9 8 1.7 7.3 82 9 9 1.9 7.1 82 9 10 2.1 6.9 82 9 11 1.3 7.7 81 10 12 1.5 7.5 81 10 13 1.7 7.3 81 10 14 1.9 7.1 81 10 15 2.1 6.9 81 10 16 1.3 7.7 80 11 17 1.5 7.5 80 11 18 1.7 7.3 80 11 19 1.9 7.1 80 11 20 2.1 6.9 80 11 21 1.3 7.7 79 12 22 1.5 7.5 79 12 23 1.7 7.3 79 12 24 1.9 7.1 79 12 25 2.1 6.9 79 12 26 0 9.0 83 8 27 0 9.0 82 9 28 0 9.0 81 10 29 0 9.0 80 11 30 0 9.0 79 12 -

[1] 刘敬福, 李赫亮, 牟新. 钢纤维增强聚合物树脂混凝土力学性能研究[J]. 机械工程材料, 2005(8):49-51. doi: 10.3969/j.issn.1000-3738.2005.08.017LIU Jingfu, LI Heliang, MOU Xin. Study on mechanical properties of steel fiber reinforced polymer resin concrete[J]. Mechanical Engineering Materials,2005(8):49-51(in Chinese). doi: 10.3969/j.issn.1000-3738.2005.08.017 [2] 丁一宁, 朱昊, 李冬. 结构型钢纤维对单轴受压下混凝土渗透性及损伤的影响[J]. 复合材料学报, 2019, 36(12):2942-2949. doi: 10.13801/j.cnki.fhclxb.20190314.004DING Yining, ZHU Hao, LI Dong. Influence of structural steel fiber on permeability and damage of concrete under uniaxial compression[J]. Acta Materiae Compositae Sinica,2019,36(12):2942-2949(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190314.004 [3] 王涛. 机床用碳纤维增强树脂矿物复合材料的制备与性能研究[D]. 济南: 山东大学, 2014.WANG Tao. Study on preparation and properties of carbon fiber reinforced resin mineral composites for machine tools[D]. Ji'nan: Shandong University, 2014(in Chinese). [4] 姜焕英, 王大鹏, 王志明, 等. 玻璃纤维增强热塑性树脂复合材料界面表征方法的研究[J]. 玻璃钢/复合材料, 2019(5):77-82. doi: 10.3969/j.issn.1003-0999.2019.05.013JIANG Huanying, WANG Dapeng, WANG Zhiming, et al. Study on the characterization of the interface of glass fiber reinforced thermoplastic resin composites[J]. FRP/Composites,2019(5):77-82(in Chinese). doi: 10.3969/j.issn.1003-0999.2019.05.013 [5] 王泽宁. 钼纤维增强树脂矿物复合材料机理研究[D]. 济南: 山东大学, 2013.WANG Zening. Mechanism of molybdenum fiber reinforced resin mineral composites[D]. Ji'nan: Shandong U-niversity, 2013(in Chinese). [6] 于英华, 梁宇, 沈佳兴, 等. 玄武岩纤维增强树脂混凝土机床基础件结构设计及其性能仿真分析[J]. 机械设计, 2017, 34(1):71-75.YU Yinghua, LIANG Yu, SHEN Jiaxing, et al. Basalt fiber reinforced resin concrete machine tool foundation structure design and performance simulation analysis[J]. Mechanical Design,2017,34(1):71-75(in Chinese). [7] 杰德尔别克, 赵海涛, 巴合特别克, 等. 钢纤维和聚丙烯纤维高性能混凝土力学性能试验研究[J]. 新型建筑材料, 2018, 45(2):22-25. doi: 10.3969/j.issn.1001-702X.2018.02.007JIEDEER Bieke, ZHAO Haitao, BA Hetebieke, et al. Experimental study on mechanical properties of high performance steel fiber and polypropylene fiber concrete[J]. New Building Materials,2018,45(2):22-25(in Chinese). doi: 10.3969/j.issn.1001-702X.2018.02.007 [8] 马芳武, 杨猛, 蒲永锋, 等. 混杂比对碳纤维-玄武岩纤维混杂增强环氧树脂基复合材料弯曲性能的影响[J]. 复合材料学报, 2019, 36(2):362-369.MA Fangwu, YANG Meng, PU Yongfeng, et al. Effect of hybrid ratio on bending properties of carbon fiber basalt fiber hybrid reinforced epoxy resin matrix composite[J]. Acta Materiae Compositae Sinica,2019,36(2):362-369(in Chinese). [9] 徐平, 沈佳兴, 于英华, 等. 偶联时间对玄武岩纤维树脂混凝土强度的影响[J]. 非金属矿, 2016, 39(3):47-49, 80. doi: 10.3969/j.issn.1000-8098.2016.03.015XU Ping, SHEN Jiaxing, YU Yinghua, et al. Effect of coupling time on the strength of basalt fiber resin concrete[J]. Non Metallic Minerals,2016,39(3):47-49, 80(in Chinese). doi: 10.3969/j.issn.1000-8098.2016.03.015 [10] 朋改非, 牛旭婧, 赵怡琳. 异形钢纤维对超高性能混凝土增强增韧的影响[J]. 建筑材料学报, 2016, 19(6):1013-1018. doi: 10.3969/j.issn.1007-9629.2016.06.010PENG Gaifei, NIU Xujing, ZHAO Yilin. The influence of profiled steel fiber on the reinforcement and toughening of UHPC[J]. Journal of Building Materials,2016,19(6):1013-1018(in Chinese). doi: 10.3969/j.issn.1007-9629.2016.06.010 [11] WASIM A M, IQBAL K, SHEHAB M. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete[J]. Construction and Building Materials,2018,168:556-569. doi: 10.1016/j.conbuildmat.2018.02.164 [12] 丁一宁, 李林泽, 曾伟. 纤维对混凝土的损伤、裂缝曲折度及裂缝恢复的影响[J]. 复合材料学报, 2019, 36(10):2439-2447.DING Yining, LI Linze, ZENG Wei. Influence of fiber on damage, crack curvature and crack recovery of concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2439-2447(in Chinese). [13] HANNAWI K, BIAN H, PRINCE-AGBODJAN W, et al. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes[J]. Composites Part B: Engineering,2016,86:214-220. doi: 10.1016/j.compositesb.2015.09.059 [14] 卢安琪, 祝烨然, 李克亮, 等. 聚丙烯纤维混凝土试验研究[J]. 水利水运工程学报, 2002(4):14-19. doi: 10.3969/j.issn.1009-640X.2002.04.003LU Anqi, ZHU Yeran, LI Keliang, et al. Experimental study on polypropylene fiber concrete[J]. Journal of Water Resources and Water Transportation Engineering,2002(4):14-19(in Chinese). doi: 10.3969/j.issn.1009-640X.2002.04.003 [15] YUAN C, CHEN W, PHAM T M, et al. Bond behavior between basalt fibres reinforced polymer sheets and steel fibres reinforced concrete[J]. Engineering Structures,2018,176:812-824. doi: 10.1016/j.engstruct.2018.09.052 [16] 刘世明, 刘永健, 李晓克, 等. 开孔钢板加劲的矩形钢管钢纤维高强混凝土柱轴压试验研究[J]. 建筑结构学报, 2018, 39(12):22-28.LIU Shiming, LIU Yongjian, LI Xiaoke, et al. Axial compression test of rectangular steel tube reinforced high-strength concrete columns strengthened with steel plate with openings[J]. Journal of Architectural Structures,2018,39(12):22-28(in Chinese). [17] 唐佳军, 裴长春. 撒布式混杂钢纤维再生混凝土力学性能[J]. 科学技术与工程, 2019, 19(18):265-270. doi: 10.3969/j.issn.1671-1815.2019.18.040TANG Jiajun, PEI Changchun. Mechanical properties of spread hybrid steel fiber recycled concrete[J]. Science and Technology and Engineering,2019,19(18):265-270(in Chinese). doi: 10.3969/j.issn.1671-1815.2019.18.040 [18] ALBERTI M G, ENFEDAQUE A, GALVEZ J. C. Fracture mechanics of polyolefin fibre reinforced concrete: Study of the influence of the concrete properties, casting procedures, the fibre length and specimen size[J]. Engineering Fracture Mechanics,2016,154:225-244. doi: 10.1016/j.engfracmech.2015.12.032 [19] 吴隆. 高速铣床树脂混凝土床身制造的研究[J]. 现代制造工程, 2004(2):77-78. doi: 10.3969/j.issn.1671-3133.2004.02.028WU Long. Research on manufacturing of resin concrete bed for high speed milling machine[J]. Modern Manufacturing Engineering,2004(2):77-78(in Chinese). doi: 10.3969/j.issn.1671-3133.2004.02.028 [20] 李鹏, 季忠, 刘韧, 等. 矿物复合材料及其在机床上的应用[J]. 机床与液压, 2013, 41(19):159-163. doi: 10.3969/j.issn.1001-3881.2013.19.045LI Peng, JI Zhong, LIU Ren, et al. Mineral composite materials and their applications in machine tools[J]. Machine Tools and Hydraulic Pressures,2013,41(19):159-163(in Chinese). doi: 10.3969/j.issn.1001-3881.2013.19.045 [21] 赵惠英, 于贺春, 赵则祥, 等. 机床基础件应用人造花岗岩的发展和现状[J]. 制造技术与机床, 2012(12):64-67. doi: 10.3969/j.issn.1005-2402.2012.12.019ZHAO Huiying, YU Hechun, ZHAO Zexiang, et al. The development and present situation of artificial granite applied to machine tool foundations[J]. Manufacturing Technology and Machine Tools,2012(12):64-67(in Chinese). doi: 10.3969/j.issn.1005-2402.2012.12.019 [22] 许华威. 超精密外圆磨床床身用人造花岗岩材料试验研究[D]. 郑州: 中原工学院, 2017.XU Huawei. Experimental study on artificial granite material for ultra-precision cylindrical grinder bed[D]. Zhengzhou: Zhongyuan Institute of Technology, 2017(in Chinese). [23] 周仕学. 粉体工程导论[M]. 北京: 科学出版社, 2010.ZHOU Shixue. Introduction to powder engineering[M]. Beijing: Science Press, 2010(in Chinese). [24] 郝培文, 徐金枝, 周怀治. 应用贝雷法进行级配组成设计的关键技术[J]. 长安大学学报(自然科学版), 2004(6):1-6.HAO Peiwen, XU Jinzhi, ZHOU Huaizhi. Key technology of gradation composition design using Bayley method[J]. Journal of Chang'an University (Natural Science Edition),2004(6):1-6(in Chinese). [25] 中华人民共和国交通部. 公路工程集料试验规程: JTJ058—2000[S]. 北京: 人民交通出版社, 2000.Ministry of Communications of the People's Republic of China. Highway engineering aggregate test rules: JTJ058-2000[S]. Beijing: People's Communications Publishing House, 2000(in Chinese). [26] 中华人民共和国建设部. 普通混凝土力学性能试验方法标准: . GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003.Ministry of Construction of the People's Republic of China. Standard for testing method of mechanical properties of ordinary concrete: GB/T 50081-2002[S]. Beijing: China Construction Industry Press, 2003(in Chinese). -

下载:

下载: