Synergistic toughening of thermoplastic particles-inorganic particles to carbon fiber reinforced epoxy resin composites

-

摘要: 针对碳纤维增强环氧树脂(CF/EP)复合材料层间断裂韧性进行研究,通过在CF/EP复合材料层间添加四种无机纳米粒子和三种热塑性颗粒对其进行II型层间断裂韧性(GIIC)研究,选择工艺性和增韧性效果好的两种无机纳米粒子和热塑性颗粒进行协同增韧研究。结果表明,CF/EP复合材料的GIIC在适当的无机纳米粒子含量下都得到提高,这主要是由于无机纳米粒子在层间形成了有效吸收断裂能的微结构,纳米羟基氧化铝(AlOOH)的工艺性及增韧性等综合性能最好,AlOOH质量分数为1wt%时,CF/EP复合材料的GIIC达到931 J/m2,提高了29.3%;热塑性颗粒中,改性聚芳醚酮颗粒(PAEK)的综合性能最好,添加10wt% PAEK,CF/EP复合材料的GIIC可以提高32%,这是由于预制在层间的热塑性颗粒随着基体流动而得到扩散,形成了独特的跨层间连续结构,从而使裂纹扩展的阻力增加,有效提高了CF/EP复合材料的GIIC;10wt%PAEK和1wt%AlOOH共同增韧CF/EP复合材料的GIIC达到1 368 J/m2,相对于未增韧的CF/EP复合材料提高了90%,增韧效果比PAEK和AlOOH对CF/EP复合材料的增韧效果之和大,这表明,PAEK和AlOOH同时加入CF/EP复合材料层间,对CF/EP复合材料具有协同增韧效应。Abstract: The interlaminar fracture toughness of carbon fiber reinforced epoxy resin (CF/EP) composites was studied. The type II interlaminar fracture toughness (GIIC) was studied by adding four kinds of inorganic nano-particles and three kinds of thermoplastic particles into the interlaminar of CF/EP composites . One kind of inorganic nano-particle and one kind of thermoplastic particles with good operability and tougheness effect were selected to study the synergistic toughening property. The results show that the GIIC of CF/EP composites is improved with appropriate inorganic nano-particle, which is mainly due to the micro-structure formation between layers and fracture energy absorbed effectively. The comprehensive properties of nano sheet boehmite (AlOOH) are the best. When the content of AlOOH nano particles is 1wt%, the GIIC of CF/EP composites reaches 931 J/m2, which increases by 29.3%. Among the thermoplastic particles, the modified poly (aryl ether ketone) (PAEK) has the best comprehensive properties. Adding 10 wt%PAEK in the layers, the GIIC of the CF/EP composite can be increased by 32%. This is due to the diffusion of thermoplastic particles between layers along with the flow of EP matrix, forming a unique interlaminar continuous structure, which increases the resistance of crack propagation and effectively improves GIIC of the CF/EP composites. The GIIC of the CF/EP composites toughened by both 10wt%PAEK and 1wt%AlOOH reaches 1 368 J/m2, compared with the non-toughened CF/EP composites , which is increased by 90%. The toughening effect is greater than the sum of adding PAEK and AlOOH. This shows that the addition of both PAEK and AlOOH into the interlayer of CF/EP composites has a synergistic toughening effect.

-

表 1 T700-12k碳纤维(T700-CF)和TDE85环氧树脂(TDE85-EP)的性能

Table 1. Properties of T700-12k carbon fiber (T700-CF) and TDE85 epoxy resin (TDE85-EP)

Strength/MPa Modulus/GPa Elongation at break/% Density/(g·cm−3) T700-CF 4 800 235 2.0 1.78 TDE85-EP 70 4.0 1.89 1.22 表 2 各种增韧粒子尺寸及含量

Table 2. Size and content of various toughening particles

AlOOH Fe2O3 MMT MWCNTs PAEK, PA6, PES Size/nm 22 40 2.13 8-15 25×103 Mass fraction/wt% 0,0.5,1.0,1.5,2.0 0,0.5,1.0,1.5,2.0 0,0.5,1.0,1.5,2.0 0,0.5,1.0,1.5,2.0 10 Notes:AlOOH—Nano sheet boehmite; MMT—Nano montmorillonite; MWCNTs—Multi-walled carbon nanotubes; PAEK—Modified poly(aryl ether ketone); PA6—Polyamide 6; PES—Polyethersulfone. -

[1] 张辰威, 张博明. 复合材料贮箱在航天飞行器低温推进系统上的应用与关键技术[J]. 航空学报, 2014, 5(10):2747-2755.ZHANG Chenwei, ZHANG Boming. Application and key technology of composites tank in space cryogenic propulsion system[J]. Acta Aeronautica et Astronautica Sinica,2014,5(10):2747-2755(in Chinese). [2] KIM M G, KANG S G, KIM C G, et al. Tensile response of graphite/epoxy composites at low temperatures[J]. Composite Structures,2007,79(1):84-89. doi: 10.1016/j.compstruct.2005.11.031 [3] 马兴瑞, 韩增尧, 邹元杰, 等. 航天器力学环境分析与条件设计研究进展[J]. 宇航学报, 2012, 33(1):1-12. doi: 10.3873/j.issn.1000-1328.2012.01.001MA Xingrui, HAN Zengyao, ZOU Yuanjie, et al. Review and assessment of spacecraft mechanical environment analy-sis and specification determination[J]. Journal of Astronautics,2012,33(1):1-12(in Chinese). doi: 10.3873/j.issn.1000-1328.2012.01.001 [4] 宋盛菊, 杨法杰, 褚庭亮, 等. 环氧树脂增韧方法及增韧剂的研究进展[J]. 中国印刷与包装研究, 2013(5):9-24.SONG Shengju, YANG Fajie, CHU Tingliang, et al. Research progress of epoxy resin toughening method and toughening agent[J]. China Printing and Packaging Study,2013(5):9-24(in Chinese). [5] GARDNER N, GUPTA S, SHUKLA A, et al. Dynamic response of nanoscale core-shell rubber toughened sandwich composites[J]. Strain,2014,50(6):501-516. doi: 10.1111/str.12104 [6] 邓火英, 梁馨, 顾轶卓, 等. MWCNTs对环氧树脂及多尺度MWCNTs-碳纤维/环氧树脂复合材料力学性能的影响[J]. 复合材料学报, 2018, 35(11):3073-3080.DENG Huoying, LIANG Xin, GU Yizhuo, et al. Effect of MWCNTs on mechanical properties of epoxy and multi-scale MWCNTs carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2018,35(11):3073-3080(in Chinese). [7] BAGHERI R, MAROUF B T, PEARSON R A. Rubber-toughened epoxies: A critical review[J]. Journal of Macromolecular Science®, Part C: Polymer Reviews,2009,49(3):201-225. [8] 卢少杰. 橡胶增韧环氧树脂低温韧性的研究[J]. 中国胶粘剂, 2003, 12(6):5-7. doi: 10.3969/j.issn.1004-2849.2003.06.002LU Shaojie. Study on the low-temperature toughness of rubber-modified epoxy resin[J]. China Adhesives,2003,12(6):5-7(in Chinese). doi: 10.3969/j.issn.1004-2849.2003.06.002 [9] NASH N H, YOUNG T M, MCGRAIL P T, et al. Inclusion of a thermoplastic phase to improve impact and post-impact performances of carbon fibre reinforced thermosetting composites: A review[J]. Materials <italic>&</italic> Design,2015,85:582-597. [10] DUARTE A, HERSZBERG I, PATON R. Impact resistance and tolerance of interleaved tape laminates[J]. Composite Structures,1999,47(1-4):753-758. doi: 10.1016/S0263-8223(00)00049-0 [11] LI G, LI P, ZHANG C, et al. Inhomogeneous toughening of carbon fiber/epoxy composite using electrospun polysulfone nanofibrous membranes by in situ phase separation[J]. Composites Science and Technology,2008,68(3-4):987-994. doi: 10.1016/j.compscitech.2007.07.010 [12] LI G, LI P, YU Y, et al. Novel carbon fiber/epoxy composite toughened by electrospun polysulfone nanofibers[J]. Materials Letters,2008,62(3):511-514. doi: 10.1016/j.matlet.2007.05.080 [13] 陈宇飞, 楚洪月, 汪波涛. 改性蒙脱土/双马来酰亚胺复合材料微观形貌及力学性能[J]. 复合材料学报, 2018, 35(6):1407-1413.CHEN Yufei, CHU Hongyue, WANG Botao. Micro-morphology and mechanical properties of modified montmorillo-nite/bismaleimide composite[J]. Acta Materiae Composi-tae Sinica,2018,35(6):1407-1413(in Chinese). [14] 胡小雨, 蒋秋冉, 魏毅, 等. 碳纤维-氧化石墨烯/环氧树脂复合材料的制备及表征[J]. 复合材料学报, 2018, 35(7):1691-1699.HU Xiaoyu, JIANG Qiuran, WEI Yi, et al. Preparation and characterization of carbon fiber-graphene oxide/epoxy composites[J]. Acta Materiae Compositae Sinica,2018,35(7):1691-1699(in Chinese). [15] PARK B Y, KIM S C, JUNG B. Interlaminar fracture toughness of carbon fiber/epoxy composites using short Kevlar fiber and/or nylon-6 powder reinforcement[J]. Polymers for Advanced Technologies,1997,8(6):371-377. doi: 10.1002/(SICI)1099-1581(199706)8:6<371::AID-PAT658>3.0.CO;2-I [16] KINLOCH A J, YUEN M L, JENKINS S D. Thermoplastic-toughened epoxy polymers[J]. Journal of Materials Science,1994,29(14):3781-3790. doi: 10.1007/BF00357349 [17] LOBANOV M V, GULYAEV A I, BABIN A N. Improvement of the impact and crack resistance of epoxy thermosets and thermoset-based composites with the use of thermoplastics as modifiers[J]. Polymer Science Series B,2016,58(1):1-12. doi: 10.1134/S1560090416010048 [18] 税荣森, 初增泽, 黄鹏程. 聚醚砜对环氧树脂在低温下韧性和力学性能的影响[J]. 宇航材料工艺, 2006(3):33-35. doi: 10.3969/j.issn.1007-2330.2006.03.009SHUI Rongsen, CHU Zengze, HUANG Pengcheng. Toughness and mechanical properties of epoxy modified with poly (ether sulphone) at cryogenic temperature[J]. Aerospace Materials & Technology,2006(3):33-35(in Chinese). doi: 10.3969/j.issn.1007-2330.2006.03.009 [19] 周建刚, 曾黎明, 周亚洲, 等. 环氧树脂/聚芳醚酮共混物的制备研究[J]. 粘接, 2011, 32(8):61-63. doi: 10.3969/j.issn.1001-5922.2011.08.028ZHOU Jian'gang, ZENG Liming, ZHOU Yazhou, et al. Study on preparation of epoxy resins/poly (aryl ether ketone) blends[J]. Adhesion,2011,32(8):61-63(in Chinese). doi: 10.3969/j.issn.1001-5922.2011.08.028 [20] 朱孙欣. 聚醚酰亚胺/热固性树脂体系的研究[D]. 苏州: 苏州大学, 2011.ZHU Sunxin. Modification of thermosetting resins by polyetherimide[D]. Suzhou: Soochow University, 2011(in Chinese). [21] HAYES B S, SEFERIS J C. Influence of particle size distribution of preformed rubber on the structure and properties of composite systems[J]. Journal of Composite Materials,2002,36(3):299-312. doi: 10.1177/0021998302036003552 [22] NGUYEN L D, LOWRY M A, STONE D L, et al. Epoxy resin toughened with a polyether sulfone and polyarylsulfidesulfone: USA, 5, 434, 226[P]. 1995-7-18. [23] MUJIKA F, VARGAS G, IBARRETXE J, et al. Influence of the modification with MWCNT on the interlinear fracture properties of long carbon fiber composites[J]. Composites Part B: Engineering,2012,43(3):1336-1340. doi: 10.1016/j.compositesb.2011.11.020 [24] 邱昆, 姜云鹏, 史雪萍, 等. 新型金属玻璃复合材料的拉伸增韧机制[J]. 复合材料学报, 2018, 35(1):124-131.QIU Kun, JIANG Yunpeng, SHI Xueping, et al. Tensile toughening mechanism of new particle reinforced metallic glass composites[J]. Acta Materiae Compositae Sinica,2018,35(1):124-131(in Chinese). [25] 董平, 孙文磊, 樊军, 等. GFRP复合材料叶片摆振运动表面位移与层间断裂韧性响应[J]. 复合材料学报, 2018, 35(11):3088-3096.DONG Ping, SUN Wenlei, FAN Jun, et al. Response of surface displacement and interlayer fracture toughness of GFRP composite blades shimmy[J]. Acta Materiae Compositae Sinica,2018,35(11):3088-3096(in Chinese). [26] JOSHI S C, DIKSHIT V. Enhancing interlinear fracture characteristics of woven CFRP prepreg composites through CNT dispersion[J]. Journal of Composite Materials,2012,46(6):665-675. doi: 10.1177/0021998311410472 [27] WILLIAMS J, GRADDAGE N, RAHATEKAR S. Effects of plasma modified carbon nanotube interlinear coating on crack propagation in glass epoxy composites[J]. Compo-sites Part A: Applied Science and Manufacturing,2013,54:173-181. doi: 10.1016/j.compositesa.2013.07.018 [28] 张明艳, 王晨, 吴子剑. 碳纳米管-有机化蒙脱土多维纳米界面构筑及其对环氧树脂的增韧机制[J]. 复合材料学报, 2018, 35(7):1841-1849.ZHANG Mingyan, WANG Chen, WU Zijian. Formation of interface and toughening mechanism of carbon nanotubes-organic montmorillonite/epoxy resin composites[J]. Acta Materiae Compositae Sinica,2018,35(7):1841-1849(in Chinese). [29] ASTM. Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905/D7905M—14[S]. West Conshohocken: ASTM International, 2014. [30] 郭壮壮, 徐武, 余音. 低温环境下测试复合材料Ⅰ型层间断裂韧性的简易方法[J]. 复合材料学报, 2019, 36(5):1210-1215.GUO Zhuangzhuang, XU Wu, YU Yin. A simple method for determining model I interlaminar fracture toughness of composite at low temperature[J]. Acta Materiae Composi-tae Sinica,2019,36(5):1210-1215(in Chinese). [31] SHINDO Y, NARITA F, SATO T. Analysis of mode II interlaminar fracture and damage behavior in end notched flexure testing of GFRP woven laminates at cryogenic temperatures[J]. Acta Mechanica,2006,187(1-4):231-240. doi: 10.1007/s00707-006-0357-0 -

下载:

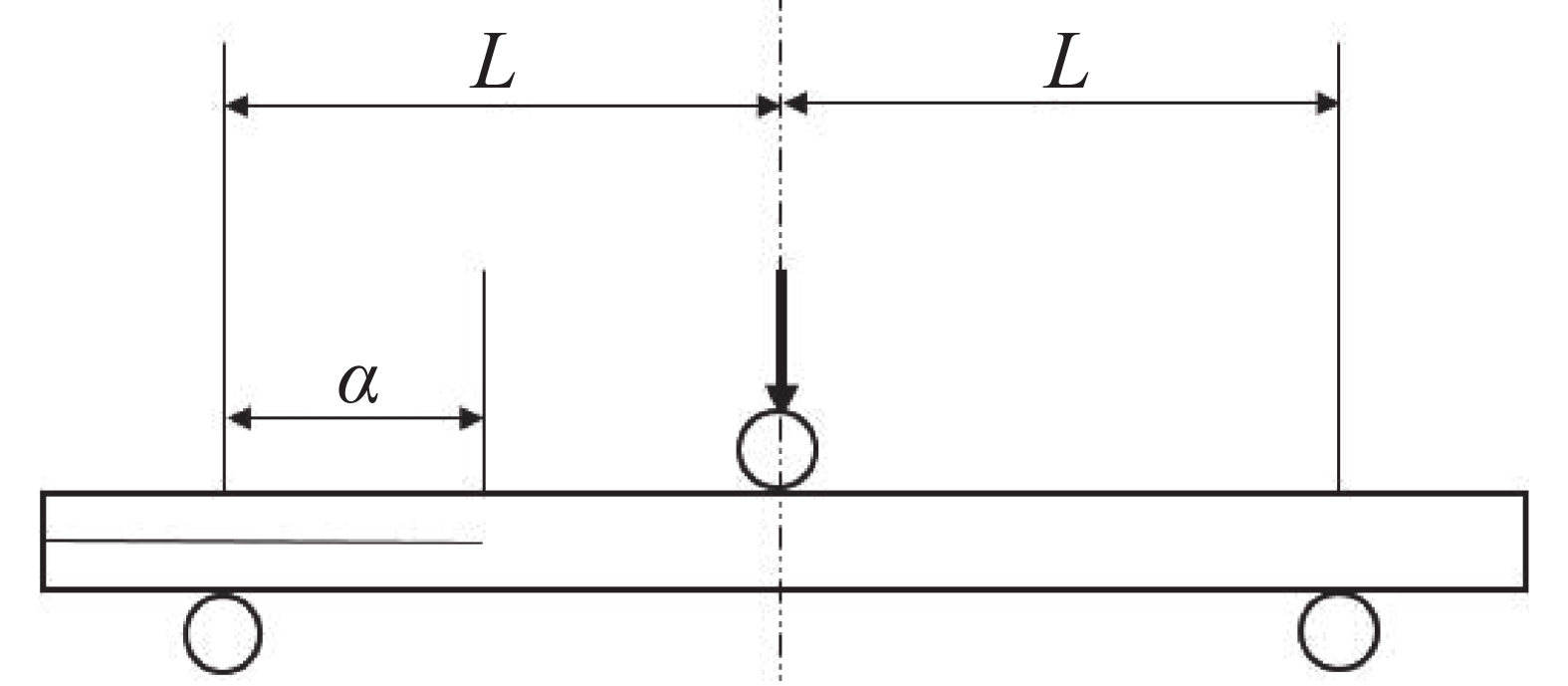

下载: