Damage identification and scanning imaging of glass fiber reinforced polymer composite plates based on empirical mode decomposition and correlation coefficient

-

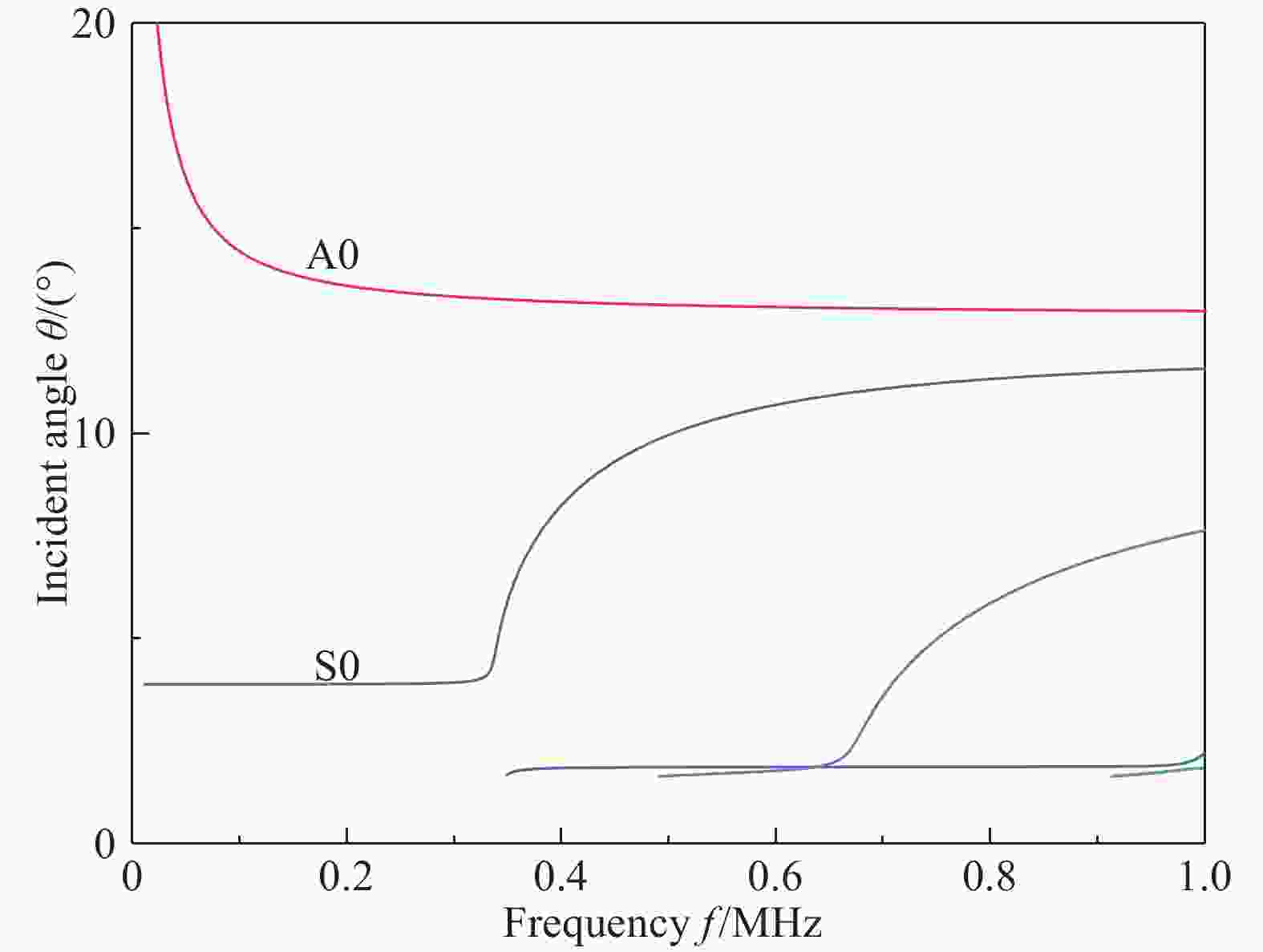

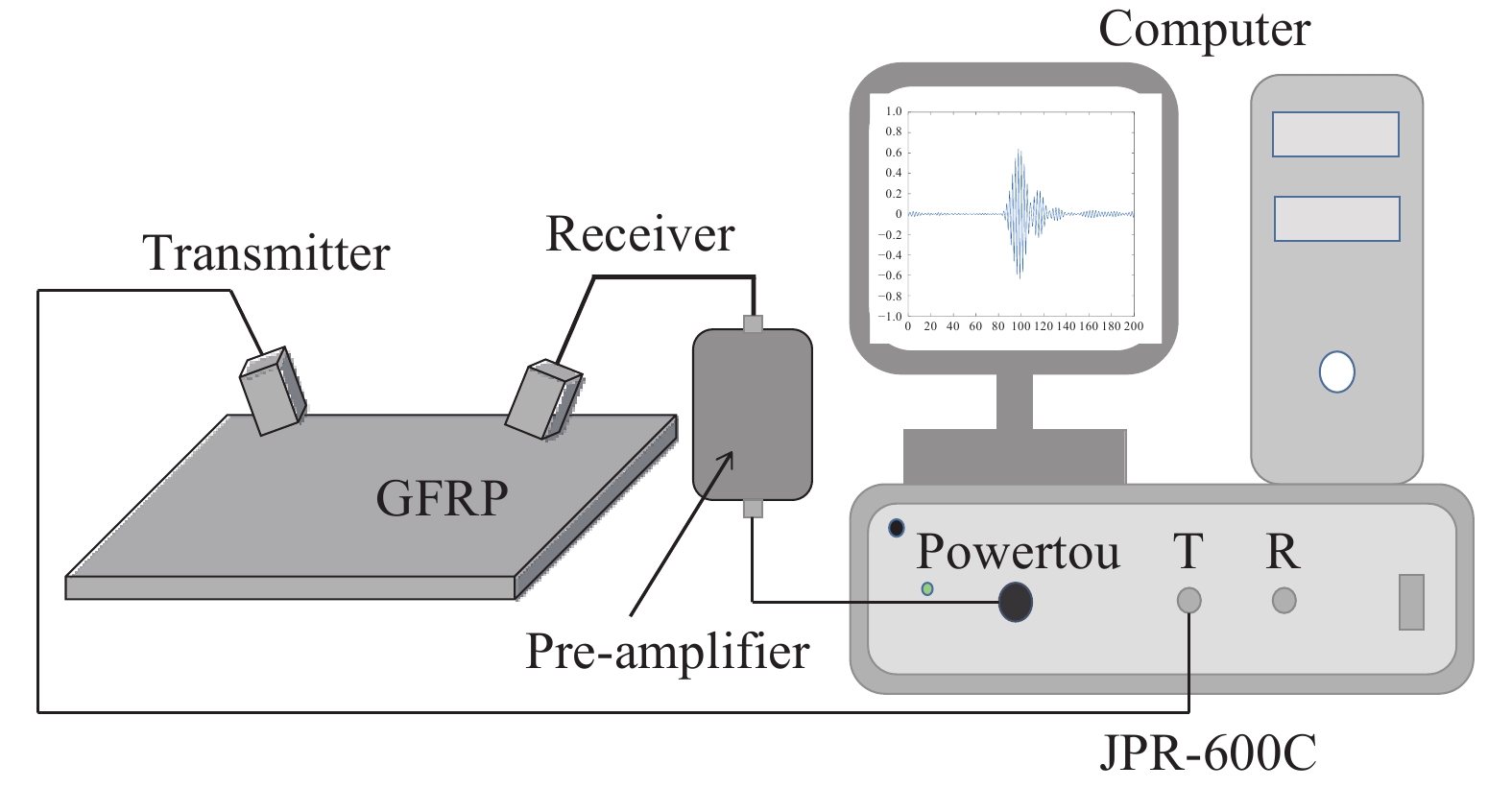

摘要: 针对外界环境噪声等因素造成损伤因子不敏感,导致复合材料损伤识别困难和成像误差大等问题,提出了一种基于经验模态分解(Empirical mode decomposition, EMD)和相关系数的损伤因子。用空气耦合探头采集损伤前后的Lamb波信号进行EMD分解获取多个本征模态分量(Intrinsic mode function, IMF)。根据相关系数获取与信号相关性最大的IMF分量,并定义其能量值的相对变化为损伤因子。在模拟噪声环境前后,分别对玻璃纤维增强聚合物复合材料(GFRP)板中的分层缺陷进行识别和扫查成像,验证了该损伤因子的有效性。结果表明:信号经过EMD分解后,与其相关性最大的IMF分量对损伤最敏感,能够定义为识别损伤的损伤因子。将该损伤因子结合概率成像方法进行空耦Lamb波扫查,不仅能够有效对复合材料中的缺陷进行成像,而且在模拟强噪声环境中具有良好的抗噪性。Abstract: Aiming at the problem that the influence of environmental noise and insensitive damage factor make damage identification difficult and imaging error large for composite plate, a damage factor based on empirical mode decomposition(EMD) and correlation coefficient was proposed. The air-couple probe was used to obtain Lamb wave signal before and after the damage, and a group of intrinsic mode function (IMF) components of signal was obtained by EMD. According to the correlation coefficient, the IMF component which has the greatest correlation with the signal was obtained, and the relative change of its energy value was defined as the damage factor. The validity of the proposed algorithm was assessed by identifying damage and scaning imaging at composite plate. The results show that after EMD, the IMF component with the greatest correlation with the original signal is most sensitive to damage, and can be used as a damage factor to identify damage. Combining this damage factor with probability imaging algorithm for the air-coupled Lamb wave scanning can not only effectively image the defect in composite plate, but also has good noise resistance in simulated strong noise environment.

-

表 1 GFRP不同损伤因子的对比结果

Table 1. Comparison results of different damage factors of GFRP

Noise level Box counting-dimension BDI IMF energy IEDI No damage Damage No damage Damage No noise 1.14 1.53 0.057 25.85 2.62 0.90 9 dB 1.55 1.60 0.03 19.55 1.15 0.94 5 dB 1.58 1.63 0.03 21.39 1.09 0.94 1 dB 1.62 1.66 0.02 19.61 1.52 0.92 0.1 dB 1.63 1.66 0.01 15.77 1.92 0.87 表 2 GFRP成像定位结果

Table 2. Imaging location results of GFRP

Noise level Actual position IEDI position Error/mm BDI position Error/mm (x,y) (x,y) (x,y) No noise (92,98) (92,99) 1.00 (92,100) 2.00 9 dB (92,98) (93,98) 1.00 (92,100) 2.00 5 dB (92,98) (93,98) 1.00 (91,100) 2.23 1 dB (92,98) (93,99) 1.41 (90,100) 2.82 0.1 dB (92,98) (93,99) 1.41 (90,101) 3.60 表 3 GFRP不同损伤因子成像后在x和y方向上的定量结果

Table 3. Imaging results of different damage factors in the x and y directions of GFRP

Noise level Autal size IEDI size Error/mm BDI size Error /mm x/mm y/mm x/mm y/mm x/mm y/mm x/mm y/mm x/mm y/mm No noise 35.00 35.00 38.40 37.20 3.40 2.20 30.20 31.50 4.80 3.50 9 dB 35.00 35.00 38.70 39.70 3.70 4.70 27.90 29.60 7.10 5.40 5 dB 35.00 35.00 39.10 39.90 4.10 4.90 27.70 30.40 7.30 4.60 1 dB 35.00 35.00 38.90 40.30 3.90 5.30 30.00 98.20 5.00 63.20 0.1 dB 35.00 35.00 38.20 38.40 3.20 3.40 52.60 98.80 17.60 63.80 -

[1] FENG P, WANG J, WANG Y, et al. Effects of corrosive environments on properties of pultruded GFRP plates[J]. Composites Part B: Engineering,2014,67:427-433. doi: 10.1016/j.compositesb.2014.08.021 [2] OPRISAN G, TARANU N, MUNTEANU V, et al. Application of modern polymer composite materials in industrial construction[J]. Bulletin of the Polytechnic Institute of Jassy Constructions Architechture,2010,3(3):1-20. [3] 代礼葵,孙耀宁,王国建. 玻璃纤维/环氧乙烯基酯树脂复合材料环境综合因素下的冲蚀行为及机制[J]. 复合材料学报, 2019, 36(9):2059-2066.DAI Likui, SUN Yaoning, WANG Guojian. Erosion behavior and mechanism of glass fiber/epoxy vinlester compo-sites under multiple environmental[J]. Acta Materiae Compositae Sinica,2019,36(9):2059-2066(in Chinese). [4] 刘增华, 樊军伟, 何存富, 等. 基于概率损伤算法的复合材料板空气耦合Lamb波扫描成像[J]. 复合材料学报, 2015, 32(1):227-235.LIU Zenghua, FAN Junwei, HE Cunfu, et al. Scanning im-aging of composite plate using air-coupled Lamb waves based on probabilistic damage algorithm[J]. Acta Materiae Composite Sinica,2015,32(1):227-235(in Chinese). [5] 张倩昀, 张华, 赵银燕. 复合材料冲击损伤监测的概率成像方法[J]. 应用声学, 2016, 35(5):426-430.ZHANG Qianyun, ZHANG Hua, ZHAO Yinyan. A probability imaging method of composite impact damage monitoring[J]. Applied Acoustics,2016,35(5):426-430(in Chinese). [6] 刘小峰, 夏宇峰, 蔡雨洋. 基于关联维数的超声Lamb波损伤成像[J]. 压电与声光, 2018, 40(1):115-118.LIU Xiaofeng, XIA Yufeng, CAI Yuyang. Ultrasonic lamb wave damage imaging based on correlation dimension[J]. Piezo Electrics and Acousto Optics,2018,40(1):115-118(in Chinese). [7] 常俊杰, 卢超, 川嶋紘一郎. 非接触空气耦合超声波的材料无损评价与检测[J]. 浙江理工大学学报, 2015, 33(7):532-536, 542.CHANG Junjie, LU Chao, KAWASHIMA. Nondestructive material evaluation and testing basedon noncontact air-coupled ultrasonics[J]. Journal of Zhejiang Sci-Tech University,2015,33(7):532-536, 542(in Chinese). [8] 常俊杰, 杨凯, 李光亚, 等. 空耦超声波技术用于锂离子电池缺陷检测[J]. 电池, 2017, 47(5):315-317.CHANG Junjie, YANG Kai, LI Guangya, et al. Application of air-coupled ultrasonic technology in Lion battery defect detection[J]. Battery Bimonthly,2017,47(5):315-317(in Chinese). [9] 常俊杰, 李媛媛, 胡宸, 等.钢轨踏面的空气耦合超声检测方法[J]. 应用声学, 2019(3): 1-6.CHANG Junjie, LI Yuanyuan, HU Chen, et al. Air coupled ultrasonic testing method for railtread[J]. Applied Acoustics, 2019(3): 1-6(in Chinese). [10] 刘国强, 肖迎春, 张华, 等. 复合材料加筋壁板损伤识别的概率成像方法[J]. 复合材料学报, 2018, 35(2):311-319.LIU Guoqiang, XIAO Yingchun, ZHANG Hua, et al. Probability based diagnostic imaging for damage identification of stiffened composite panel[J]. Acta Materiae Compositae Sinica,2018,35(2):311-319(in Chinese). [11] 刘彬, 邱雷, 袁慎芳, 等. 复合材料T型接头损伤监测的概率成像方法[J]. 振动.测试与诊断, 2015, 35(3):519-524,593-594.LIU Bin, QIU Lei, YUAN Shenfang, et al. Probabilistic imaging method of composite T-joint damage monitoring[J]. Journal of Vibration, Mearsurement, Diagnosis,2015,35(3):519-524,593-594(in Chinese). [12] 刘国强, 孙侠生, 肖迎春, 等. 基于Lamb波和Hilbert变换的复合材料T型加筋损伤监测[J]. 复合材料学报, 2014, 31(3):818-823.LIU Guoqiang, SUN Xiasheng, XIAO Yingchun, et al. Damage monitoring of composite T-joint using Lamb wave and Hilbert transform[J]. Acta Materiae Compositae Sinica,2014,31(3):818-823(in Chinese). [13] IHN J B, CHANG F K. Detection and monitoring of hidden fatigue crack growth using a built in piezoelectric sen-sor/actuator netork: I. Diagnostics[J]. Smart Materials and Structures,2004,13(3):609-620. doi: 10.1088/0964-1726/13/3/020 [14] 苏晨辉,姜明顺,梁建英, 等. 强噪声下碳纤维增强树脂复合材料结构Lamb波层析损伤成像方法[J]. 复合材料学报, 2020, 37(4):886-895.SU Chenghui, JIANG Mingshun, LIANG Jianying, et al. Lamb wave tomography damage imaging of composite structuresin strong noise environment[J]. Acta Materiae Compositae Sinica,2020,37(4):886-895(in Chinese). [15] QIAO Nan, WANG Lihui, LIU Qingya, et al. Multi-scale eigenvalues empirical mode decomposition for geomagnetic signal filtering[J]. Measurement,2019,146:885-891. [16] 池永为, 杨世锡, 焦卫东, 等. 基于EMD-DCS的滚动轴承伪故障特征识别方法[J]. 振动与冲击, 2020, 39(9):9-16.CHI Yongwei, YANG Shixi, JIAO Weidong, et al. EMD-DCS based pseudo-fault feature identification method for rolling bearings[J]. Journal of Vibration and Shock,2020,39(9):9-16(in Chinese). [17] 陈闯, 俞鹏, 王银辉. 基于马氏距离累积量和EMD的结构损伤识别两步法[J]. 振动与冲击, 2019, 38(13):142-150.CHEN Chuang, YU Peng, WANG Yinhui. A two-step method for structural damage identification based on Mahalanobis distance accumulation and EMD[J]. ] Journal of Vibration and Shock,2019,38(13):142-150(in Chinese). [18] 余腾, 胡伍生, 吴杰, 等. 基于小波阈值去噪与EMD分解方法提取润扬大桥振动信息[J]. 振动与冲击, 2019, 38(12):264-270.YU Teng, HU Wusheng, WU Jie, et al. Extraction of Runyang bridge vibration information based on a fusion method of wavelet threshold denoising and EMD decomposition[J]. Journal of Vibration and Shock,2019,38(12):264-270(in Chinese). [19] 李秋锋, 黄攀, 施倩, 等. 基于经验模态分解去噪的粗晶材料超声检测[J]. 应用基础与工程科学学报, 2014, 22(3):566-573.LI Qiufeng, HUANG Pan, SHI Qian, et al. Ultrasonic test-ing of coarse grained materials based on EMD denoising method[J]. Journal of Basic Science and Engineering,2014,22(3):566-573(in Chinese). [20] IMIELINSKA K, CASTAINGS M, WOJTYRA R, et al. Air-coupled ultrasonic C-scan technique in impact response testing of carbon fibre and hybrid: Glass, carbon and Kevlar/epoxy composites[J]. Journal of Materials Processing Technology,2004,157-158:513-522. doi: 10.1016/j.jmatprotec.2004.07.143 [21] CASTAINGS M, CAWLEY P. The generation, propagation, and detection of Lamb waves in plates using air-coupled ultrasonic transducers[J]. Journal of the Acoustical Society of America,1996,100(5):3070-3077. doi: 10.1121/1.417193 [22] CASTAINGS M, HOSTEN B. Lamb and SH waves generatedand detected by air coupled ultrasonic transducers in composite material plates[J]. NDT <italic>&</italic> E International,2001,34(4):249-258. [23] 何存富, 刘岳鹏, 刘增华. 空气耦合Lamb波在单晶硅中的传播特性和缺陷检测研究[J]. 机械工程学报, 2015, 51(12):1-7. doi: 10.3901/JME.2015.12.001HE Cunfu, LIU Yuepeng, LIU Zenghua. Air-coupled Lamb waves propagation characteristics and defect detection in monocrystalline silicon[J]. Journal of Mechanical Engi-neering,2015,51(12):1-7(in Chinese). doi: 10.3901/JME.2015.12.001 -

下载:

下载: