Thermodynamic and electrochemical properties of co-spun polyvinyl-vinyl alcohol lithium-thermoplastic polyurethane lithium ion battery separator

-

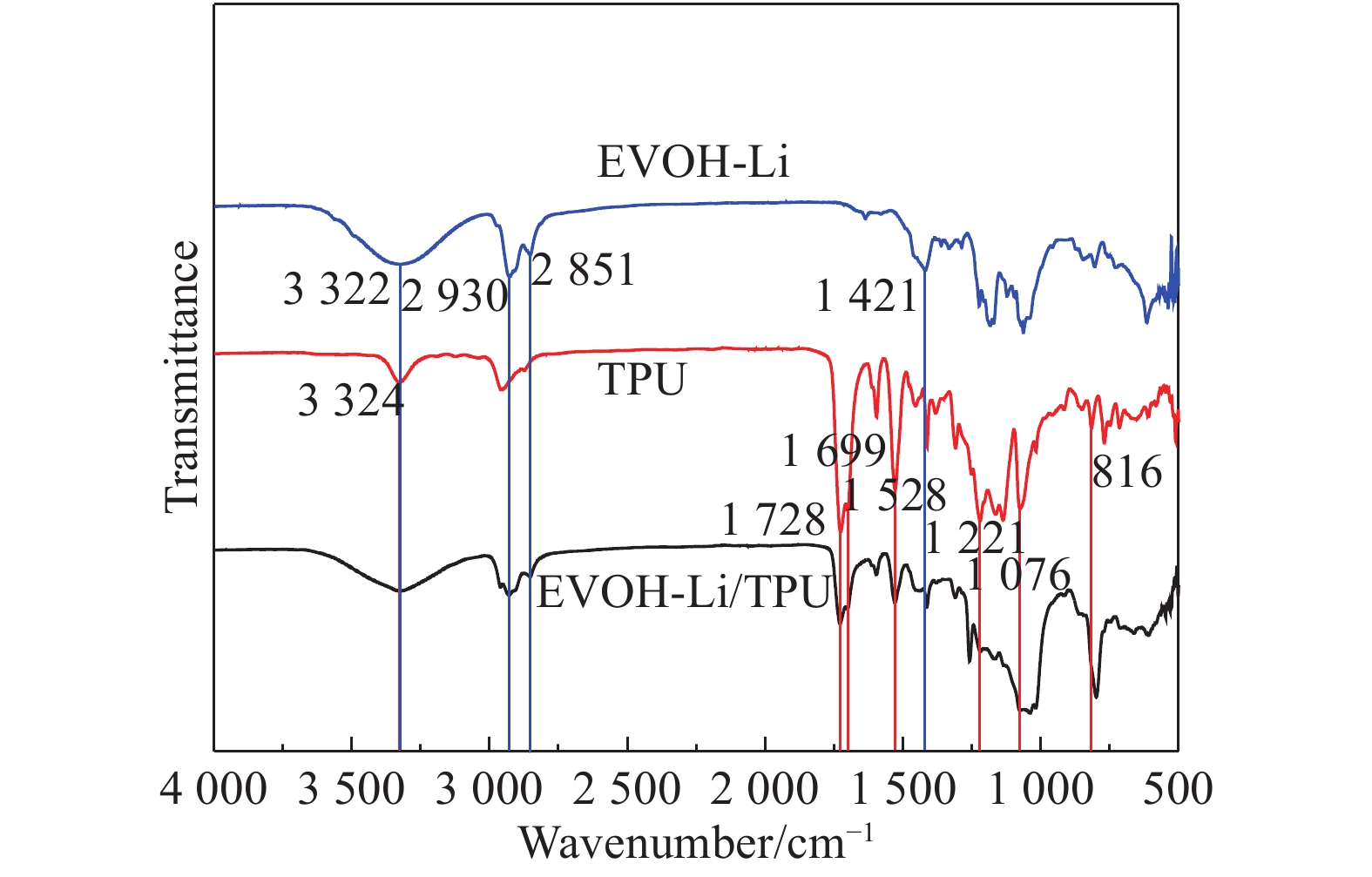

摘要: 为了改善锂离子电池隔膜的热力学和电化学等性能,以聚乙烯-乙烯醇锂(EVOH-Li)和热塑性聚氨酯(TPU)为原料,利用高压静电纺丝法进行双针头同时纺丝,制备了两种不同纤维丝相互缠结的EVOH-Li-TPU共纺膜。其中,EVOH-Li具有自由脱嵌的锂离子,可以增加电池隔膜的离子导电性;TPU具有良好的力学性能和韧性,可以增加锂离子电池隔膜的抗穿刺性,从而提高其安全性。研究了EVOH-Li-TPU共纺膜的微观形貌、力学性能、吸液率、孔隙率、热学性能及电化学性能,并与EVOH-Li和TPU单纺膜的相关性能进行对比。结果表明,EVOH-Li-TPU共纺膜的拉伸强度和断裂伸长率分别达到6.09 MPa和79.26%,孔隙率和吸液率分别达到84%和321%,室温离子电导率为4.41×10–4 S/cm,界面阻抗相比EVOH-Li和TPU单纺膜显著降低,电化学窗口为5.0 V,EVOH-Li-TPU共纺膜相比于EVOH-Li和TPU单纺膜,各种性能均有所增强。Abstract: In order to improve the thermodynamic and electrochemical properties of lithium ion battery separators, polyvinyl-vinyl alcohol lithium(EVOH-Li) and thermoplastic polyurethane (TPU) were used as the raw materials. High voltage electrospinning was used to spin two needles simultaneously. The EVOH-Li-TPU co-spinning separators for lithium ion batteries were prepared. The EVOH-Li has free de-intercalation lithium ions. The ionic conductivity of battery separator is increased. The TPU has good mechanical properties and toughness. The puncture resistance of lithium ion battery separator is increased, and its security is improved. The morphology, mechanical properties, liquid absorption, porosity, thermal properties and electrochemical properties of the EVOH-Li-TPU co-spinning separators were studied, and compared with EVOH-Li and TPU mono-spun membranes. The results show that the tensile strength and elongation at break of the EVOH-Li-TPU co-spinning separator reach to 6.09 MPa and 79.26%, the porosity and liquid absorption reach to 84% and 321%, the ionic conductivity at room temperature is 4.41×10−4 S/cm, the interfacial impedance is reduced compared with the EVOH-Li and TPU mono-spun membranes, and the electrochemical window is 5.0 V. Comparing with EVOH-Li and TPU single spinning, the properties of EVOH-Li-TPU co-spinning separators is improved.

-

表 1 EVOH-Li隔膜、TPU隔膜及EVOH-Li-TPU共纺膜的孔隙率和吸液率

Table 1. Porosity and electrolyte uptake of EVOH-Li separators, TPU separators and EVOH-Li-TPU co-spinning separators

Porosity/% Electrolyte uptake/% EVOH-Li 68 244 TPU 70 265 EVOH-Li-TPU 84 321 -

[1] MANTHIRAM A. An outlook on lithium ion battery technology[J]. ACS Central Science,2017,3(10):1063-1069. doi: 10.1021/acscentsci.7b00288 [2] FRIEß B , SOCZKA-GUTH T, HOFBECK F, et al. Challenges in battery development basics and optimization strategy[J]. ATZ Worldwide,2018,120:48-53. [3] BLOMGREN G E. The development and future of lithium ion batteries[J]. Journal of The Electrochemical Society,2017,164(1):5019-5025. doi: 10.1149/2.0251701jes [4] 杨文秀. 基于分形原理的静电纺丝技术研究和锂电池隔膜研发[D]. 天津: 天津工业大学, 2016.YANG Wenxiu. Research on electrospinning technology based on fractal principle and development of lithium battery separator[D]. Tianjin: Tianjin Polytechnic University, 2016(in Chinese). [5] 刘宏宇, 徐军, 郭宝华, 等. 二氧化硅/聚乙烯醇多孔层对锂离子电池用聚丙烯隔膜性能的影响[J]. 高分子学报, 2015(11):1307-1312.LIU Hongyu, XU Jun, GUO Baohua, et al. Effect of silica/polyvinyl alcohol porous layers on performance of polypropylene separators for lithium-ion batteries[J]. Acta Polymerica Sinica,2015(11):1307-1312(in Chinese). [6] NITTA N, WU F, LEE J, et al. Li-ion battery materials: present and future[J]. Materialstoday,2015,18(5):252-264. [7] FENG X, OUYANG M, LIU X, et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review[J]. Energy Storage Materials,2018,10:246-267. doi: 10.1016/j.ensm.2017.05.013 [8] AHMED F E, LALIA B S, HASHAIKEH R. A review on electrospinning for membrane fabrication: Challenges and applications[J]. Desalination,2015,356:15-30. doi: 10.1016/j.desal.2014.09.033 [9] WANG H, GAO H. A sandwich-like composite nonwoven separator for Li-ion batteries[J]. Electrochim Acta,2016,215:525-534. doi: 10.1016/j.electacta.2016.08.039 [10] DING B, WANG X, YU J. Electrospinning: Nanofabrication and applications[M]. England: Matthew Dean, 2019. [11] LUO K, ZHU G, ZHAO Y, et al. Enhanced cycling stability of Li-O2 batteries by using a polyurethane/SiO2/glass fiber nanocomposite separator[J]. Journal of Materials Chemistry A,2018,6(17):7770-7776. doi: 10.1039/C8TA00879E [12] SHEN X, LI C, SHI C, et al. Core-shell structured ceramic nonwoven separators by atomic layer deposition for safe lithium-ion batteries[J]. Applied Surface Science,2018,441:165-173. doi: 10.1016/j.apsusc.2018.01.222 [13] ZHANG T, QU H, SUN K. Development of polydopamine coated electrospun PAN/PMMA nanofibrous membrane as composite separator for lithium-ion batteries[J]. Materials Letters,2019,245:10-13. doi: 10.1016/j.matlet.2019.02.079 [14] GONG W, WEI S, RUAN S,et al. Electrospun coaxial PPESK/PVDF fibrous membranes with thermal shutdown property used for lithium-ion batteries[J]. Materials Letters,2019,244:126-129. doi: 10.1016/j.matlet.2019.02.009 [15] LI L, LIU P, FU Q, et al. Study on preparation of polyacrylonitrile/polyimide composite lithium-ion battery separator by electrospinning[J]. Journal of Materials Research,2019,34(4):642-651. doi: 10.1557/jmr.2019.8 [16] CAI M, ZHU J, YANG C, et al. A parallel bicomponent TPU/PI membrane with mechanical strength enhanced isotropic interfaces used as polymer electrolyte for lithium-ion battery[J]. Polymers,2019,11(1):185-196. doi: 10.3390/polym11010185 [17] 巩桂芬, 王磊, 徐阿文. 静电纺PMMA/EVOH-SO3Li锂离子电池隔膜复合材料的制备及性能[J]. 复合材料学报, 2018, 35(3):477-484.GONG Guifen, WANG Lei, XU Awen. Preparation and properties of PMMA/EVOH-SO3Li Li-ion battery separator composite by electrospinning[J]. Acta Materiae Compositae Sinica,2018,35(3):477-484(in Chinese). [18] LU Q W, MACOSKO C W. Comparing the compatibility of various functionalized polypropylenes with thermoplastic polyurethane (TPU)[J]. Polymer,2004,45(6):1981-1991. doi: 10.1016/j.polymer.2003.12.077 [19] 中国国家标准化管理委员会. 锂离子电池用聚烯烃隔膜: GB/T 36363—2018[S]. 北京: 中国标准出版社, 2018.Standardization Administration of the People’s Republic of China. Polyolefin separator for lithium-ion battery: GB/T 36363—2018[S]. Beijing: China Standards Press, 2018(in Chinese). [20] ZHAI Y Y, XIAO K, YU J Y, et al. Fabrication of hierarchical structured SiO2/ polyetherimide-polyurethane nanofibrous separators with high performance for lithium ion batteries[J]. Electrochim Acta,2015,154:219-226. doi: 10.1016/j.electacta.2014.12.102 [21] KIM K J, KWON Y K, YIM T, et al. Functional separator with lower resistance toward lithium ion transport for enhancing the electrochemical performance of lithium ion batteries[J]. Journal of Industrial and Engineering Chemistry,2019,71:228-233. doi: 10.1016/j.jiec.2018.11.029 -

下载:

下载: