Effect of aramid bundling yarn types on interlaminar properties of multilayered biaxial weft knitted fabric reinforced epoxy composites

-

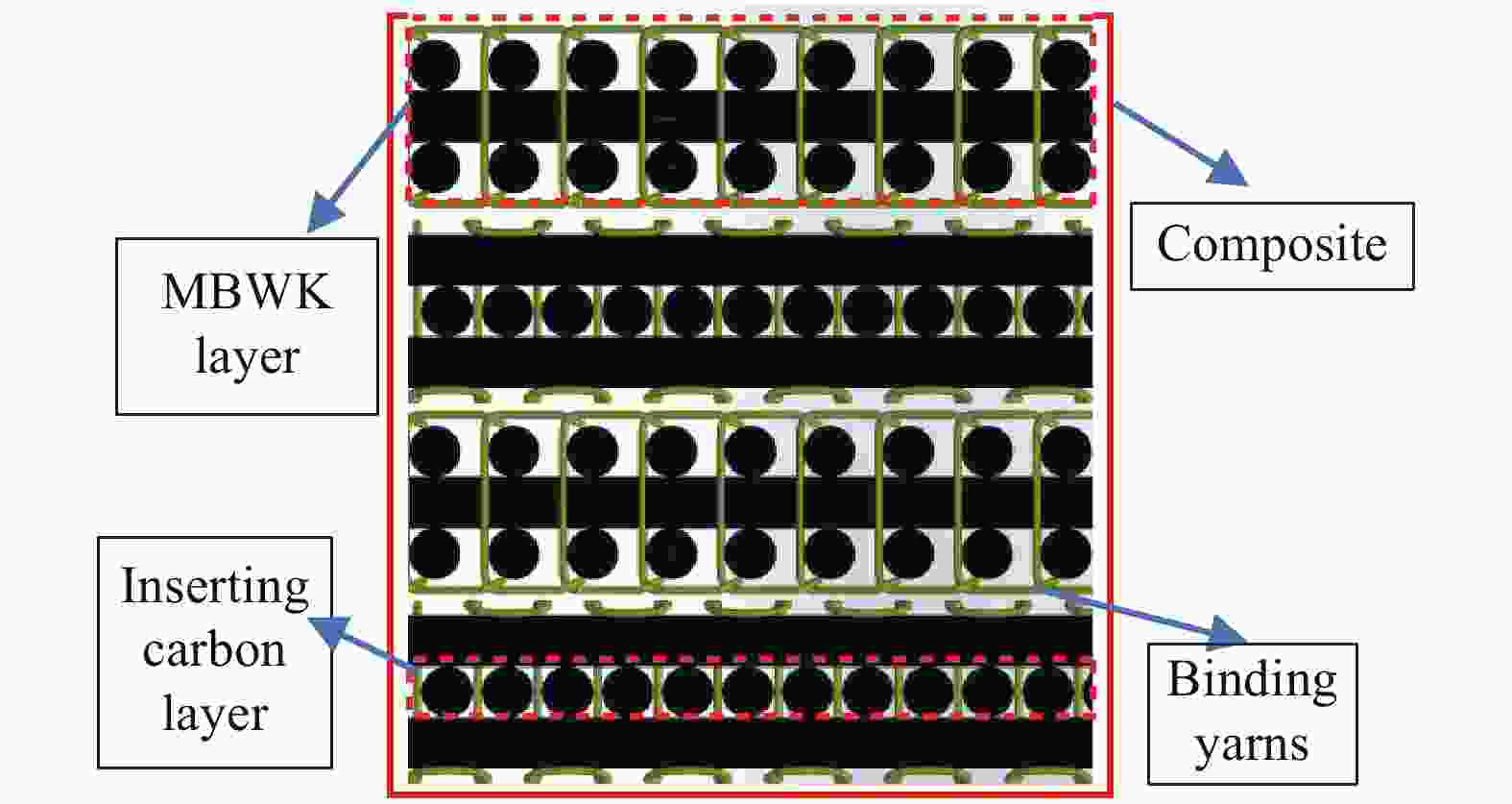

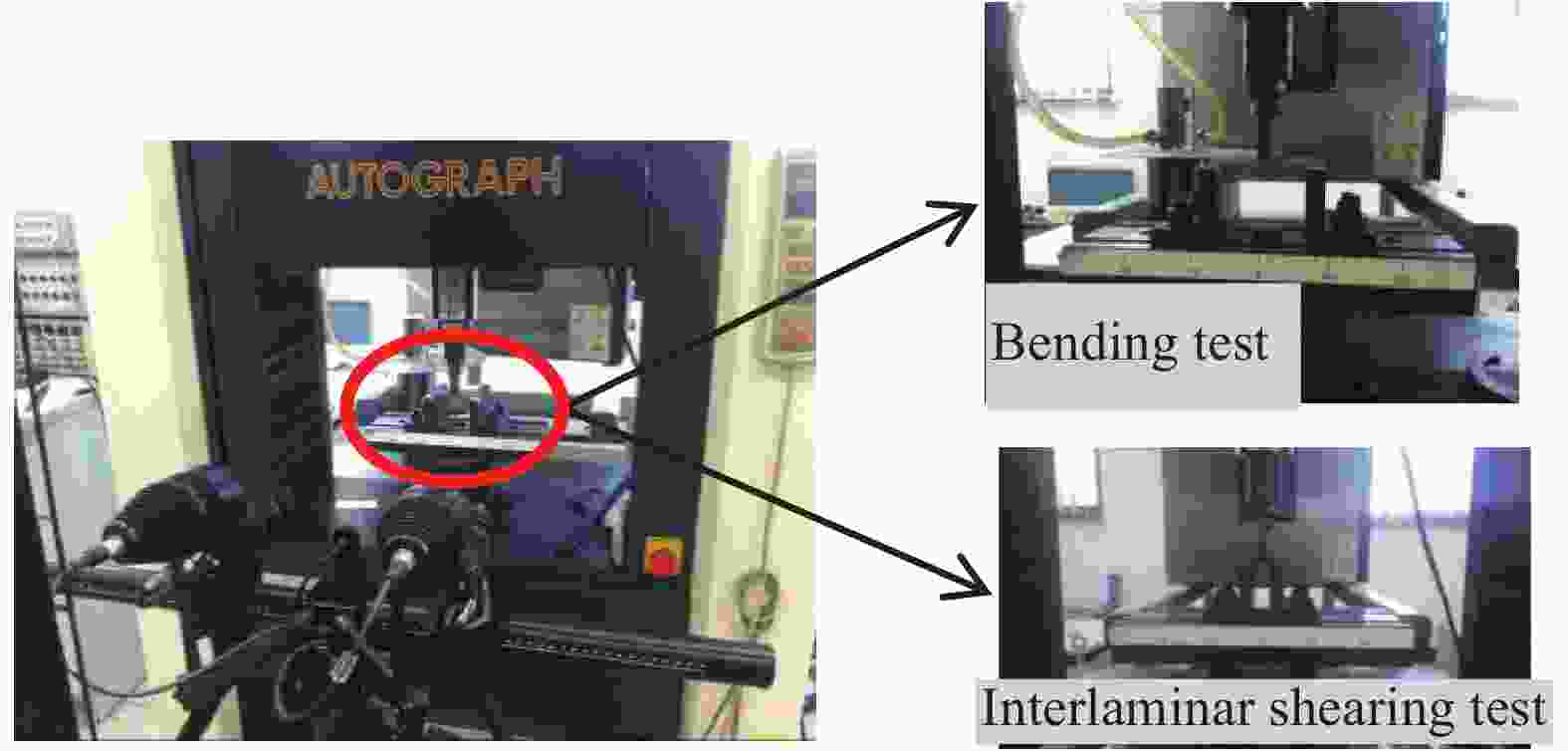

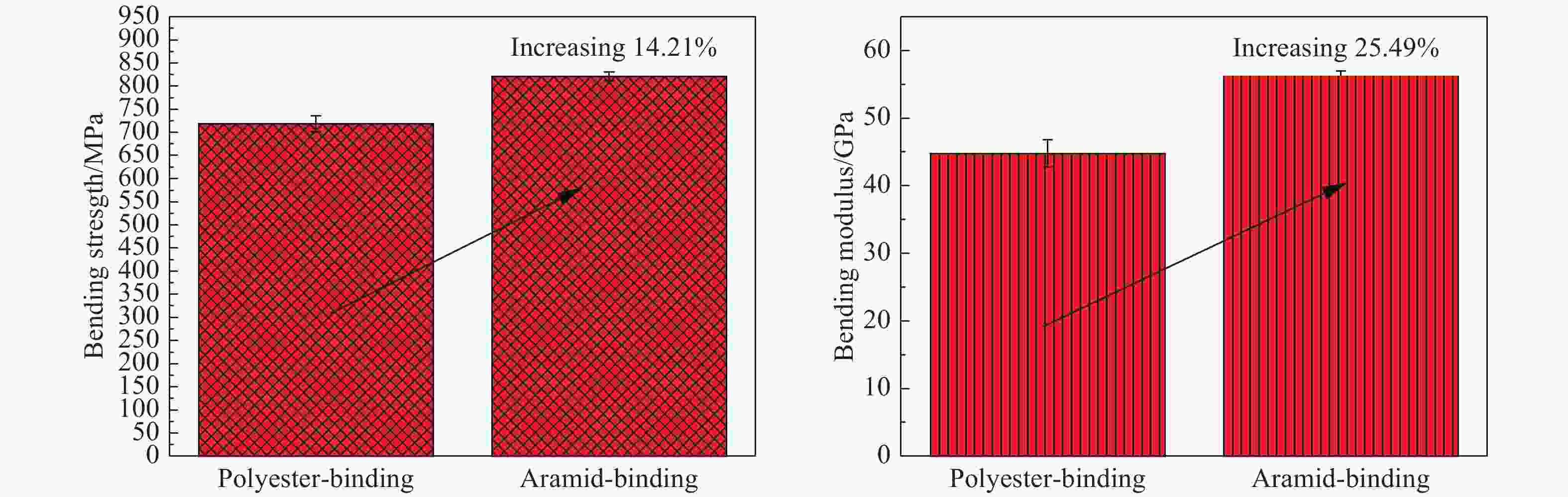

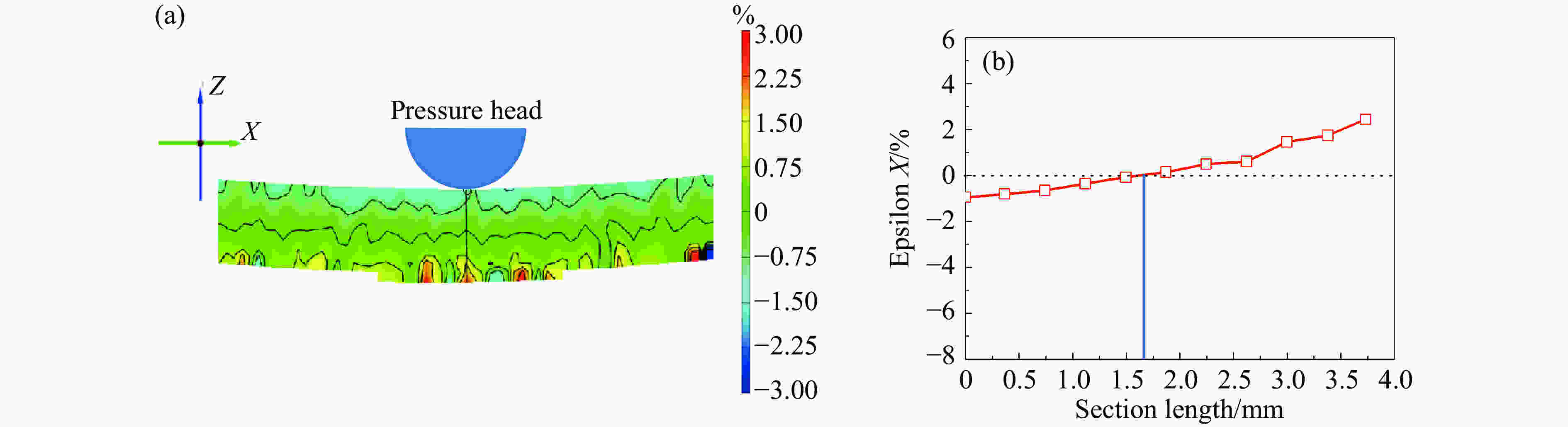

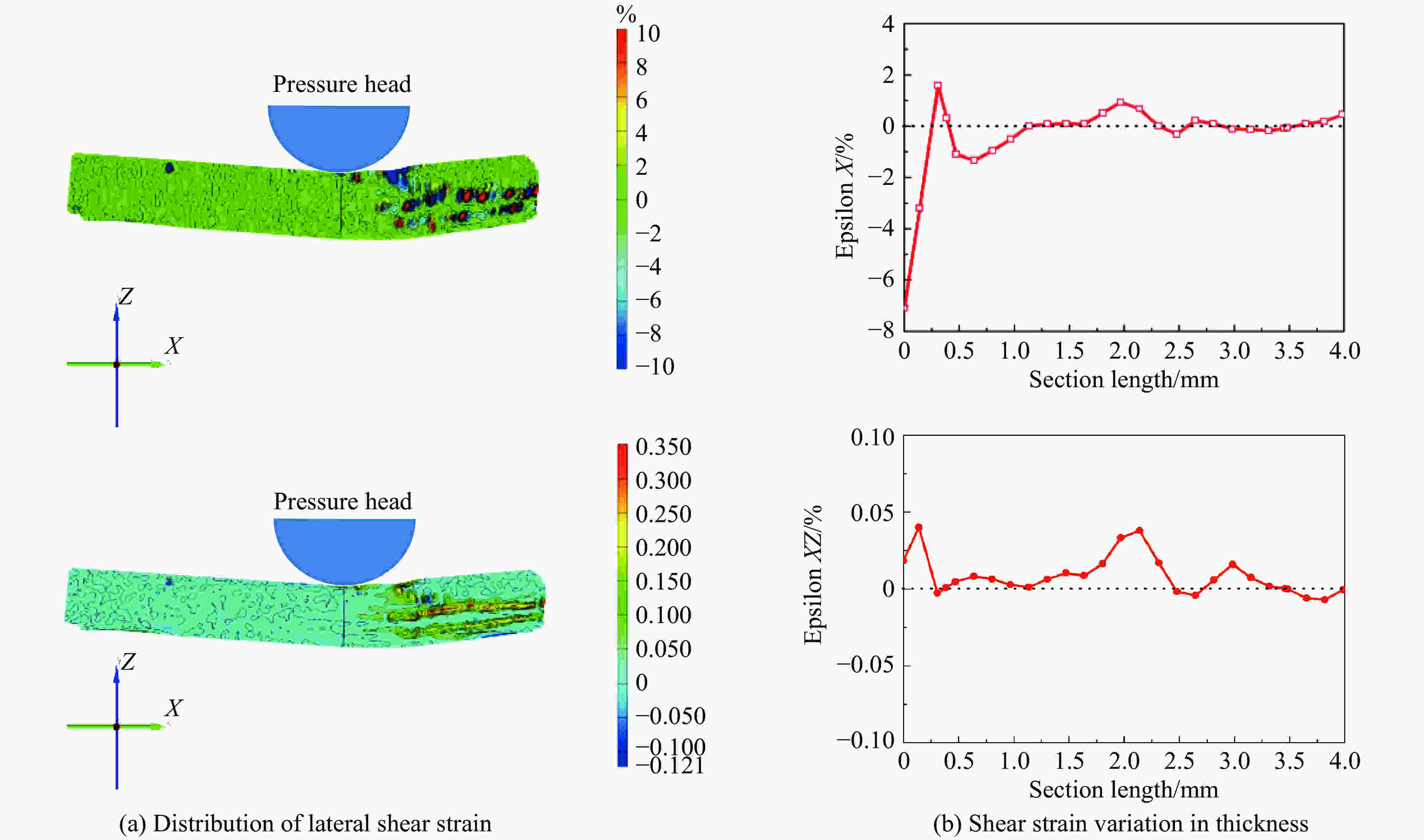

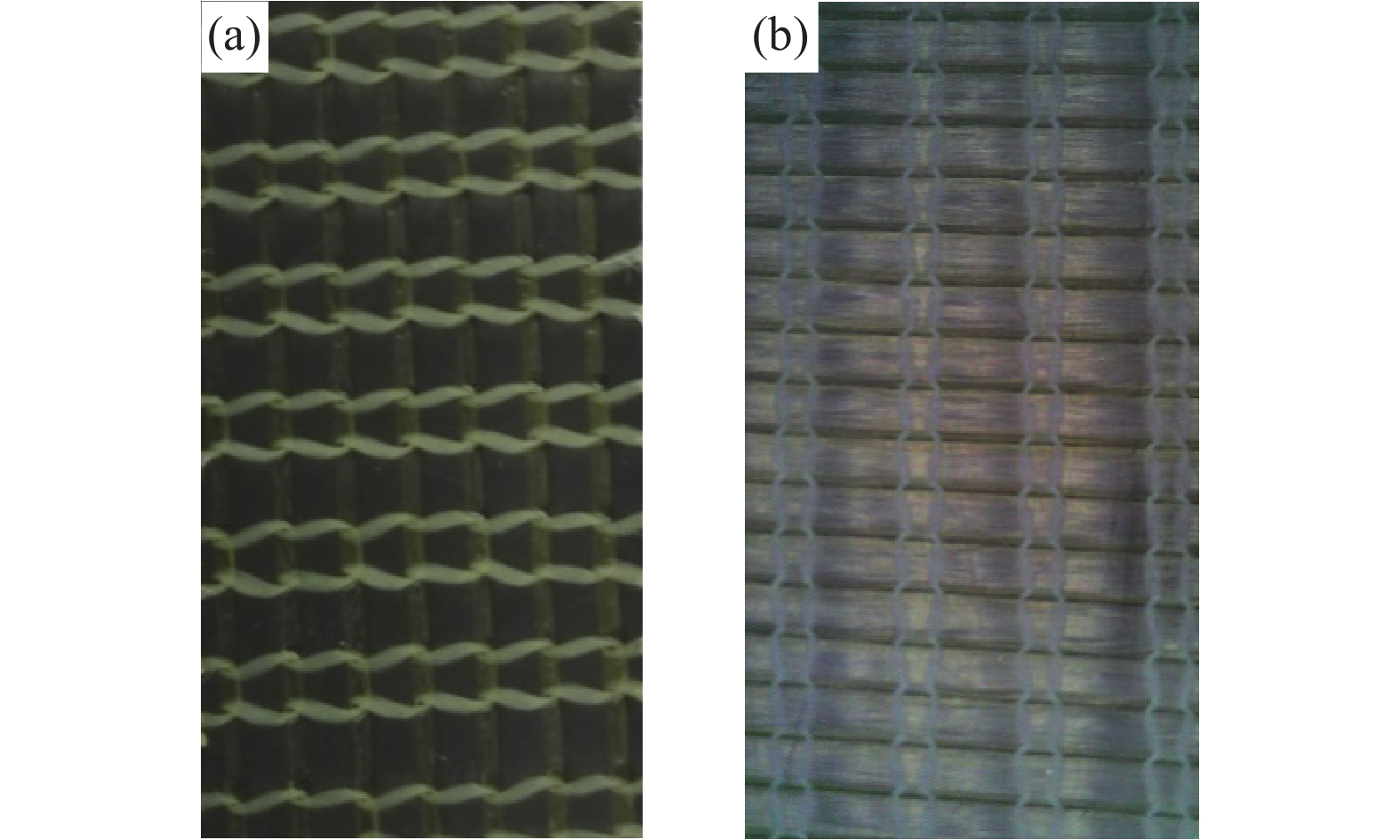

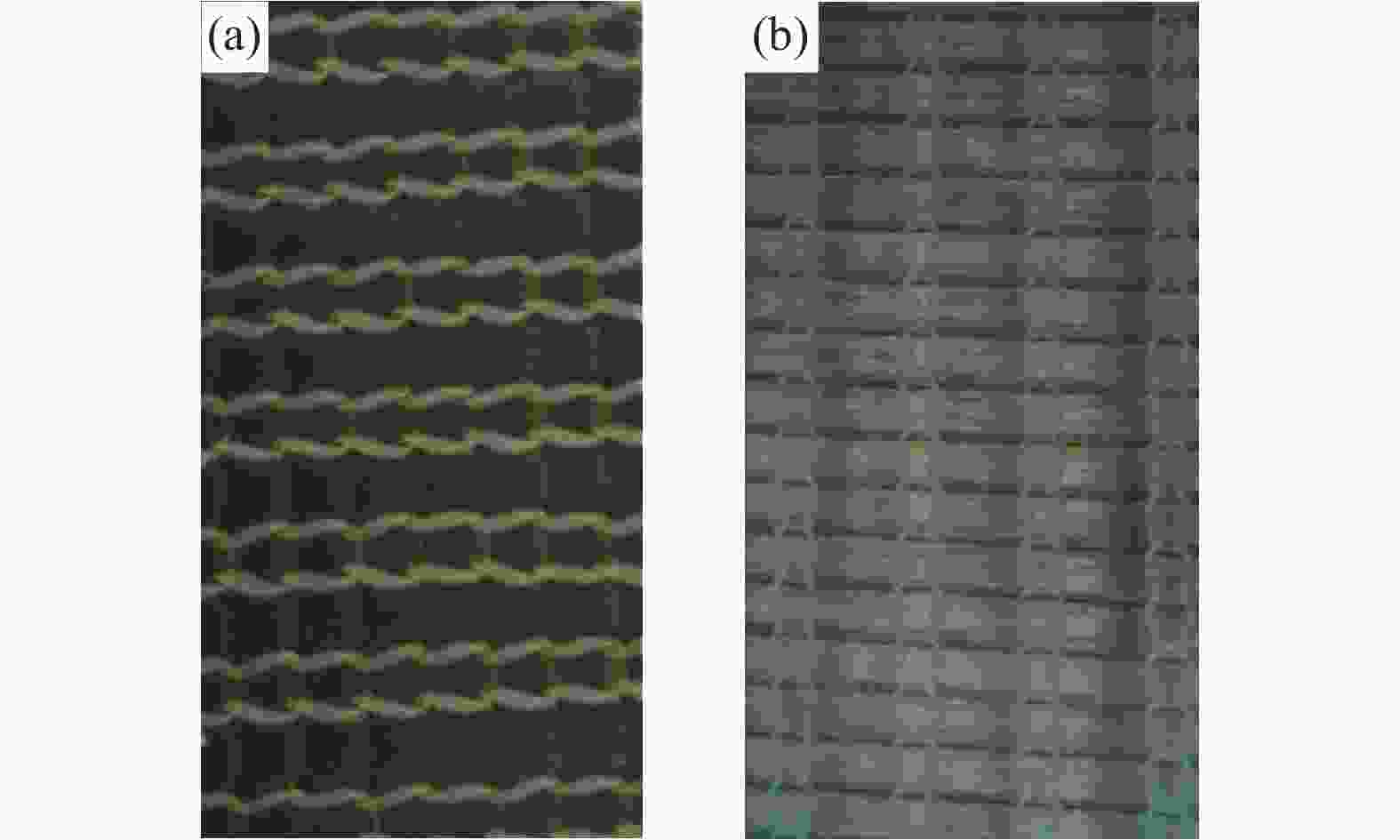

摘要: 将芳纶作为捆绑纱制备纬编双轴向多层衬纱(MBWK)织物增强环氧树脂复合材料,研究了MBWK织物增强环氧树脂复合材料层间性能及芳纶捆绑纱对其层间性能的影响。通过三点弯曲和短梁剪切测试,得到MBWK织物增强环氧树脂复合材料的弯曲性能和层间剪切性能,并通过Aramis V6三维场应变测量系统观察实验过程中层间应变变化。与传统涤纶低弹丝捆绑的MBWK织物增强环氧树脂复合材料相比,芳纶捆绑MBWK织物增强环氧树脂复合材料的弯曲性能和层间剪切性能明显提升,弯曲强度和层间剪切强度分别提高了14.21%和12.70%;弯曲模量提高了25.49%。芳纶捆绑MBWK织物增强环氧树脂复合材料在受到面外载荷时,纵向应变(Epsilon X)和层间剪切应变(Epsilon XZ)在中性面区域内较大,且在受到面外载荷时,芳纶捆绑纱起到有效抑制复合材料分层的作用。Abstract: The interlaminar properties of multilayered biaxial weft knitted (MBWK) fabric reinforced epoxy composites were studied by using aramid yarns as bundling yarns. The interlaminar properties of MBWK fabric reinforced epoxy composites and the effects of aramid bundling yarn on the interlaminar properties were analyzed. The bending and interlaminar shear properties of the MBWK fabric reinforced epoxy composites were obtained by three-point bending and short-beam shear tests. The interlaminar strain changes were observed by Aramis V6 digital image correlation system. Compared with the traditional MBWK fabric reinforced epoxy composites bonded with polyester filaments, the bending and interlaminar shear properties of the MBWK fabric reinforced epoxy composites bonded with aramid fibers are improved significantly with the bending strength, interlaminar shear strength and the bending modulus increment of 14.21%, 12.70% and 25.49%, respectively. The longitudinal strain (Epsilon X) and interlaminar shear strain (Epsilon XZ) of MBWK fabric reinforced epoxy composites bound with aramid fibers are larger in the neutral location when the composites are subjected to the out-of-plane loads. And aramid yarns play an effective role in restraining the delamination of composites when subjected to out-of-plane loads.

-

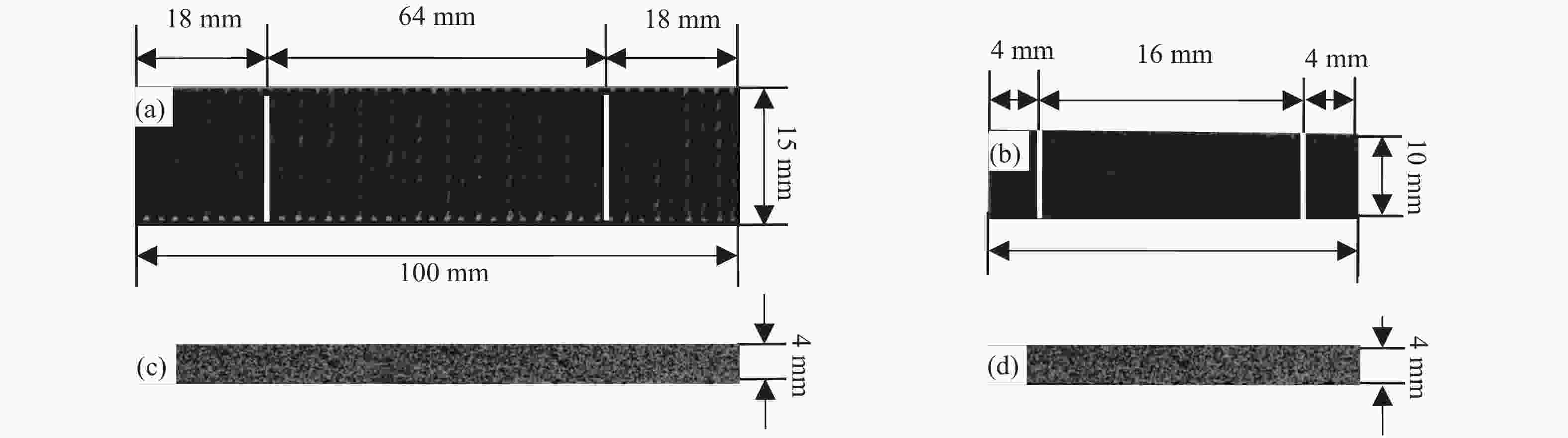

图 3 MBWK织物增强环氧树脂复合材料弯曲和层间剪切试样尺寸及形状

Figure 3. Size and shape of bending and interlaminar shear specimens of MBWK fabric reinforced epoxy composites((a) Front view of bending specimen; (b) Front view of interlaminar shearing specimen; (c) Side view of bending specimen; (d) Side view of interlaminar shearing specimen)

表 1 纬编双轴向多层衬纱(MBWK)织物增强树脂复合材料的原材料基本性能

Table 1. Basic materials properties of multilayered biaxial weft knitted (MBWK) fabric reinforced epoxy composites

Materials Tensile

property/MPaTensile

modulus/GPaDensity/

(g•m−2)Carbon 3 530 230 1.76 Polyester 767 14 1.37 Aramid 2 923 70 1.44 TDE-85 epoxy 100 3.38 1.17 -

[1] LOMOV S V. Non-crimp fabric composites: Manufacturing, properties and applications[M]. Cambridge: Woodhead Publishing, 2011. [2] LI X K, BAI S L. Tensile properties of multilayered biaxial weft knitted fabric reinforced composite material[J]. Plastics Rubber and Composites,2010,39(2):91-98. doi: 10.1179/174328910X12608851832696 [3] QI Y X, LI J L, LIU L S. Tensile properties of multilayer-connected biaxial weft knitted fabric reinforced composites for carbon fibers[J]. Materials & Design,2014,54:678-685. [4] QI Y X, LI J L, LIU L S. The stiffness prediction of multilayer-connected biaxial weft knitted fabrics reinforced composites[J]. Journal of Reinforced Plastics & Composites,2015,34(14):1113-1125. [5] HU J L, JIANG Y M, KO F. Modeling uniaxial tensile properties of multiaxial warp knitted fabrics[J]. Textile Research Journal,1998,68(11):828-834. doi: 10.1177/004051759806801107 [6] MENG M, LE H R, RIZVI M J, et al. 3D FEA modelling of laminated composites in bending and their failure mechanisms[J]. Composite Structures,2015,119:693-708. doi: 10.1016/j.compstruct.2014.09.048 [7] QI Y X, LI J L, LIU L S. Bending properties of the multilayer-connected biaxial weft knitted fabrics-reinforced composites made with carbon fibers[J]. Polymer Composites,2015,36:2291-2302. doi: 10.1002/pc.23142 [8] 马芳武, 杨猛, 蒲永锋, 等. 混杂比对碳纤维-玄武岩纤维混杂增强环氧树脂基复合材料弯曲性能的影响[J]. 复合材料学报, 2019, 36(2):362-369.MA F W, YANG M, PU Y F, et al. Effect of hybrid ratio on the flexural properties of carbon and basalt hybrid fibers reinforced epoxyres in composites[J]. Acta Materiae Compositae Sinica,2019,36(2):362-369(in Chinese). [9] LIU D. Delamination resistance in stitched and unstitched composite plates subjected to impact loading[J]. Journal of Reinforced Plastics & Composites,1990,9(1):59-69. [10] KOISSINA V, KUSTERMANSA J, LOMOVA S V. Structurally stitched NCF preforms: Quasi- static response[J]. Composites Science and Technology,2009,69(15-16):2701-2710. doi: 10.1016/j.compscitech.2009.08.015 [11] HEß H, HIMMEL N. Structurally stitched NCF CFRP laminates Part 1: Experimental characterization of in-plane and out-of-plane properties[J]. Composite Science and Technology,2011,71(5):549-568. doi: 10.1016/j.compscitech.2010.11.012 [12] CRAMMOND G, BOYD S W, DULIEU- BARTON J M. Evaluating the localised through-thickness load transfer and damage initiation in a composite joint using digital image correlation[J]. Composites Part A: Applied Science and Manufacturing,2014,61:224-234. doi: 10.1016/j.compositesa.2014.03.002 [13] 王裕龙, 许希武, 毛春见. 缝合复合材料层板低速冲击损伤数值模拟[J]. 复合材料学报, 2014, 31(3):715-724.WANG Y L, XU X W, MAO C J. Numberical simulation of low-velocity impact damage on wtitched composite laminates[J]. Acta Materiae Composite Sinica,2014,31(3):715-724(in Chinese). [14] 毛春见, 许希武. 含冲击损伤缝合层合板剩余压缩强度[J]. 复合材料学报, 2013, 30(3):247-252.MAO C J, XU X W. Residual compression strength of stitched composite panels with impact damage[J]. Acta Materiae Composite Sinica,2013,30(3):247-252(in Chinese). [15] JIANG Y M, HU J L, KO F. Characterizing and modeling bending properties of multiaxial warp knitted fabrics[J]. Textile Research Journal,1999,69(9):691-697. doi: 10.1177/004051759906900910 [16] 张卓. 纬编双轴向多层衬纱织物增强复合材料面内力学性能研究[D]. 天津: 天津工业大学, 2003.ZHANG Z. The analysis of in-plane mechanical properties of multilared biaxial weft-knitted fabric reinforced composite[D]. Tianjin: Tianjin Polythecnic University, 2003(in Chinese). [17] 张艳明. 纬编双轴向多层衬纱织物的成型性研究[D]. 天津: 天津工业大学, 2005.ZHANF Y M. The study of formability of multi-layered biaxial weft knitted fabrics[D]. Tianjin: Tianjin Polythecnic University, 2005(in Chinese). [18] PEI X Y, SHANG B, CHEN L, et al. Compression properties of multilayer-connected biaxial weft knitted carbon fiber fabric reinforced composites[J]. Composites Part B: Engineering,2016,91:296-305. doi: 10.1016/j.compositesb.2015.12.041 [19] DAI S, CUNNINGHAM P R, MARSHALL S, et al. Influence of fibre architecture on the tensile, compressive and flexural behaviour of 3D woven composites[J]. Composites Part A: Applied Science and Manufacturing,2015,69:195-207. doi: 10.1016/j.compositesa.2014.11.012 [20] ULLAH H, HARLAND A R, SILBESCHMIT V V. Experimental and numerical analysis of damage in woven GFRP composites under large-deflection bending[J]. Appllied Composite Materials,2012,19(5):769-783. doi: 10.1007/s10443-011-9242-7 [21] 中华人民共和国工业和信息化部. 纤维增强塑料短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国建材工业出版社, 2010.Ministry of Industry and Information Technology of the People’s Republic of China . Fibre-reinforced plastics composites: Determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Building Materials Press, 2010(in Chinese). [22] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fibre-reinforced plastic composites: Determaination of flexural properites: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). -

下载:

下载: