Advances in Micro-CT aided numerical simulation of fabric-reinforced composites

-

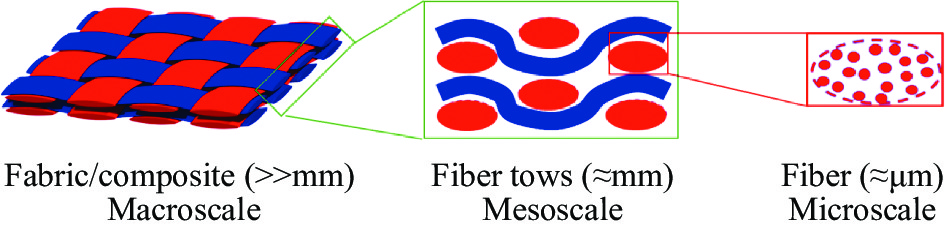

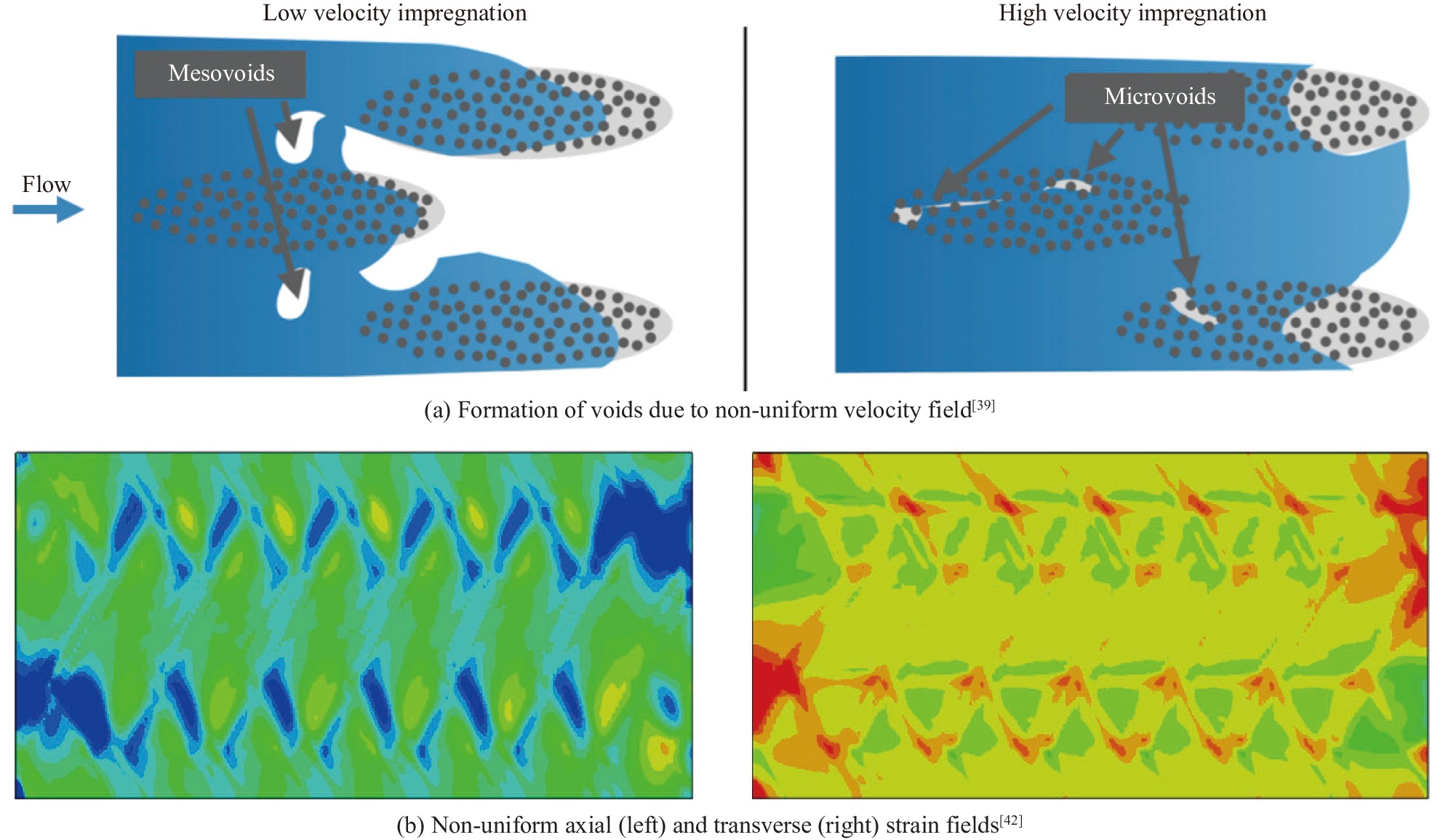

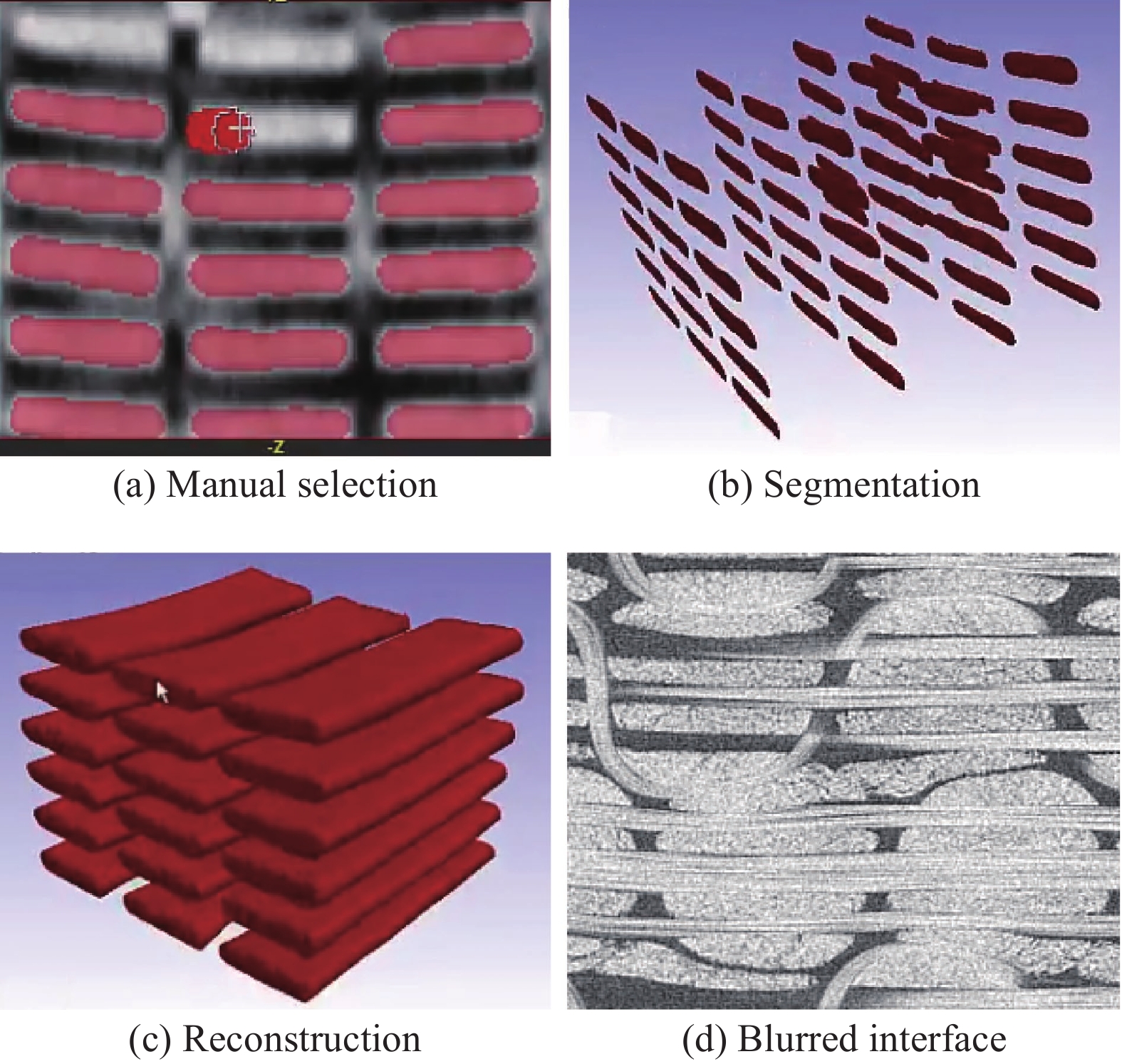

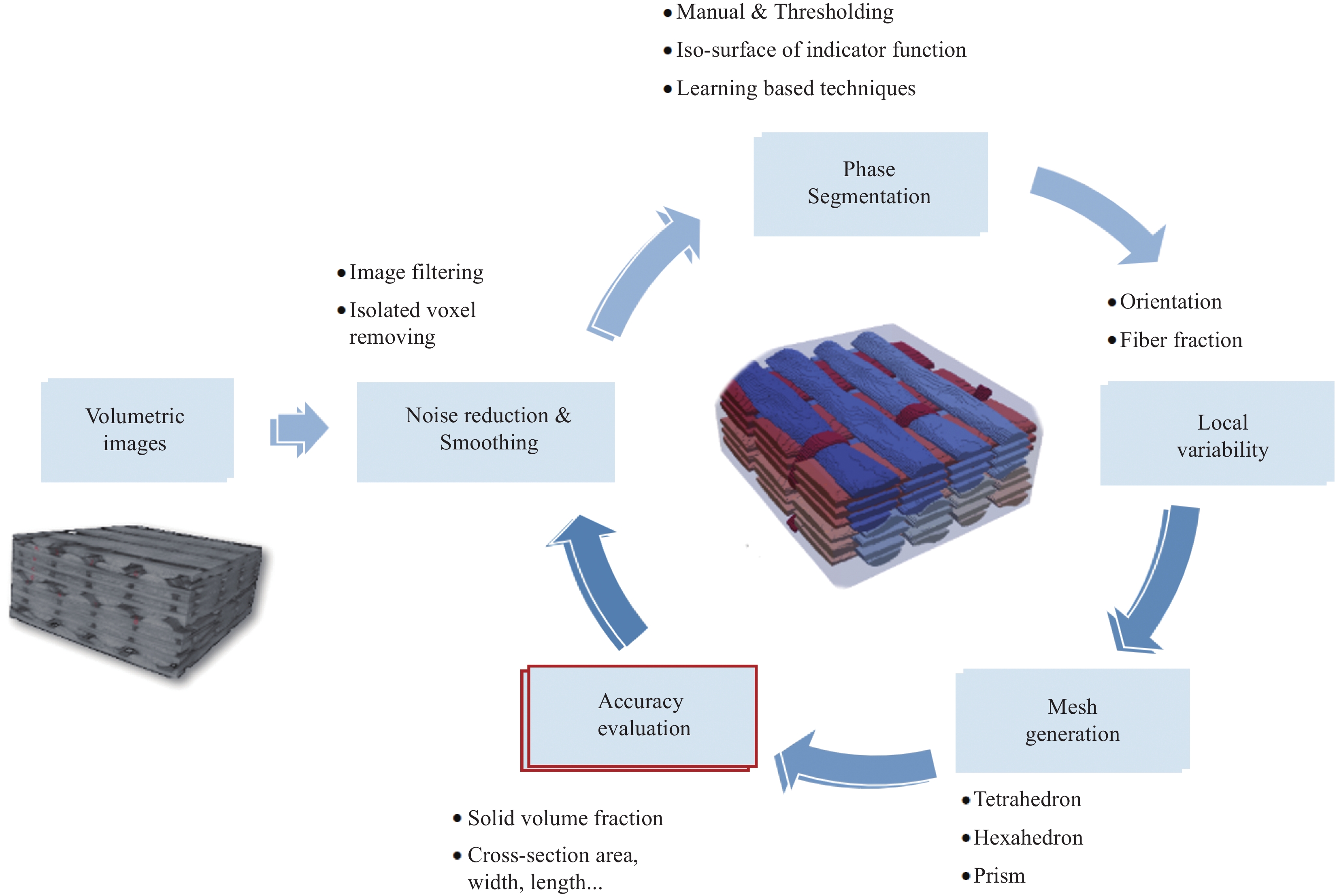

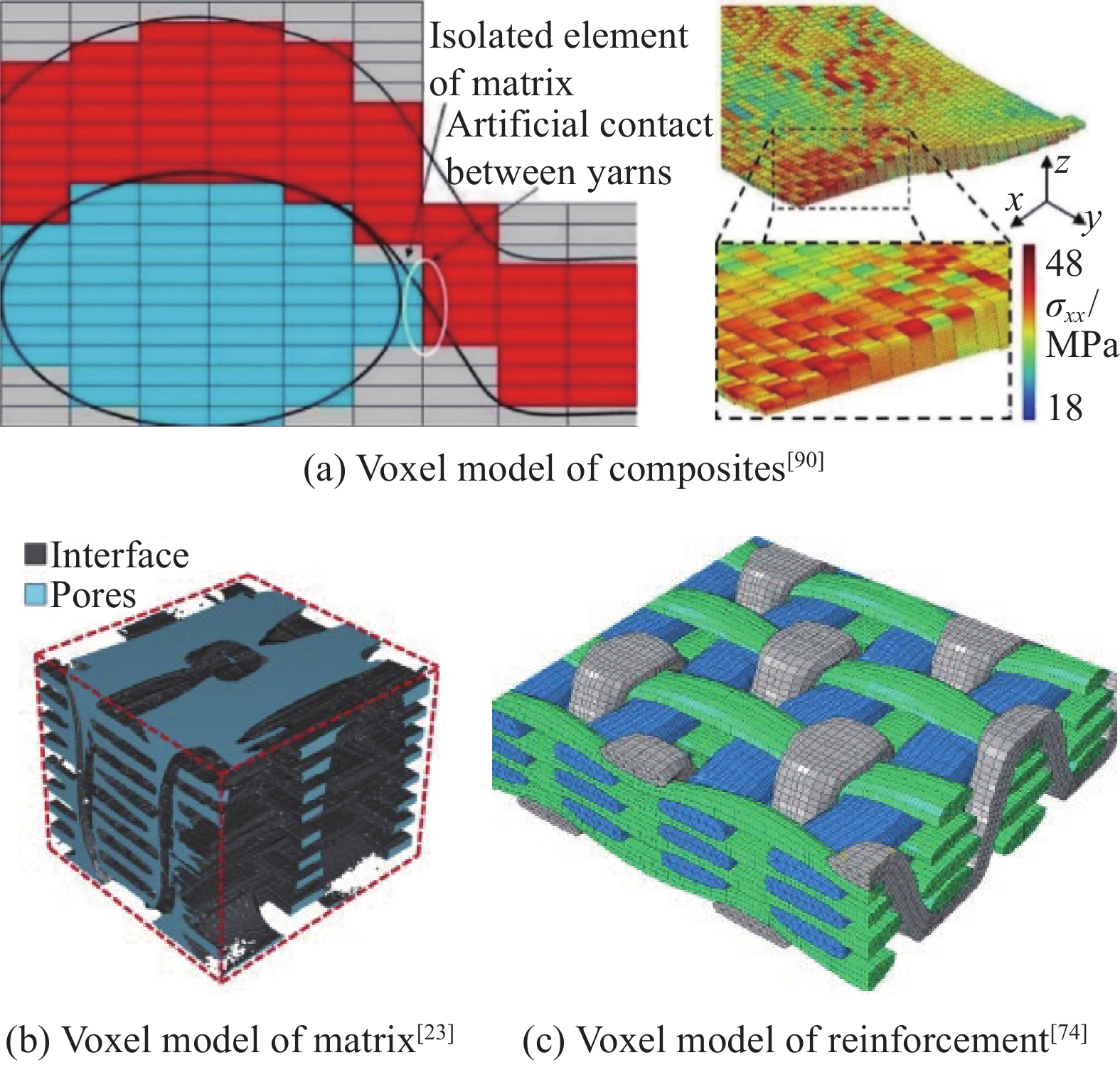

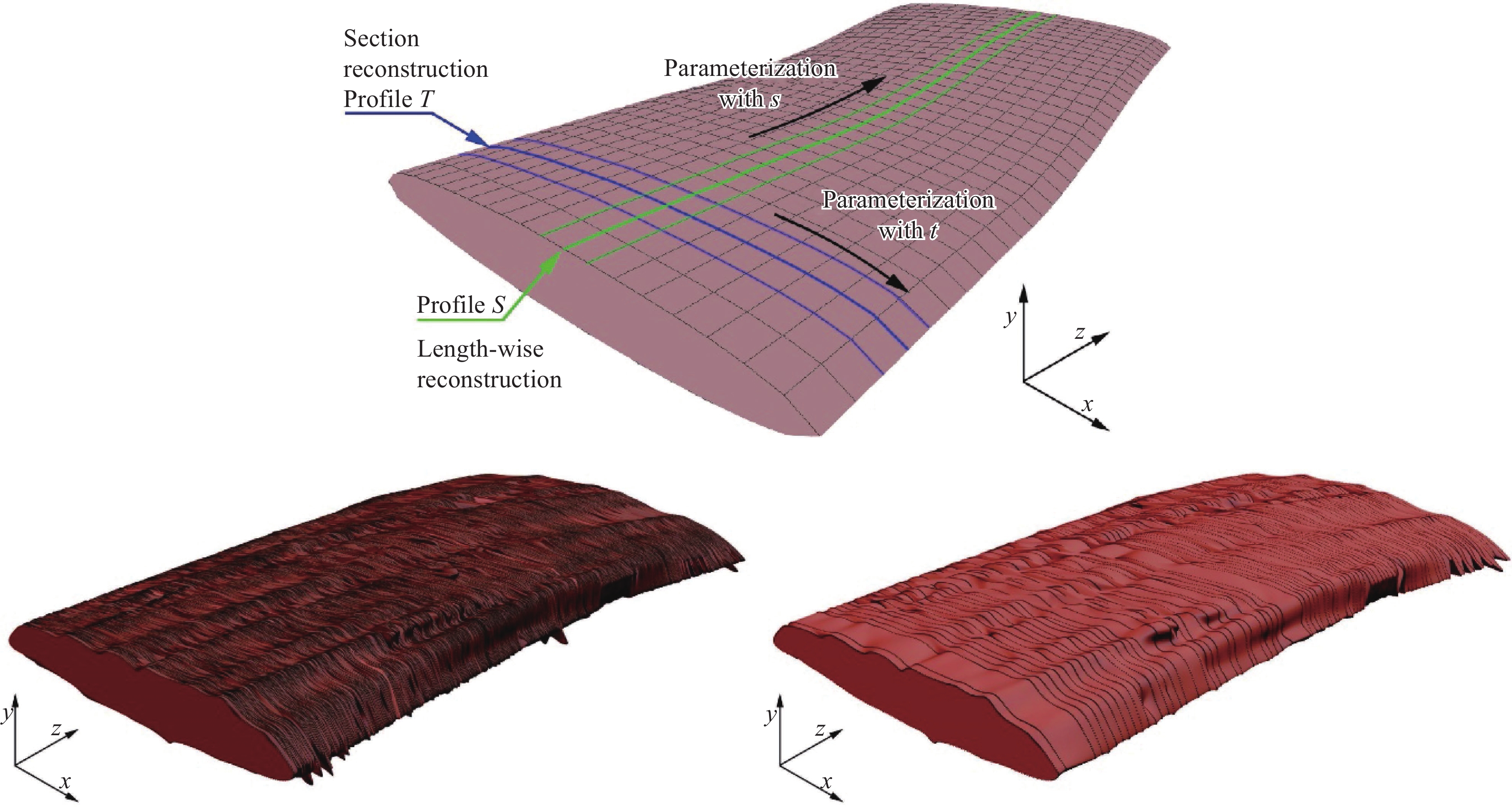

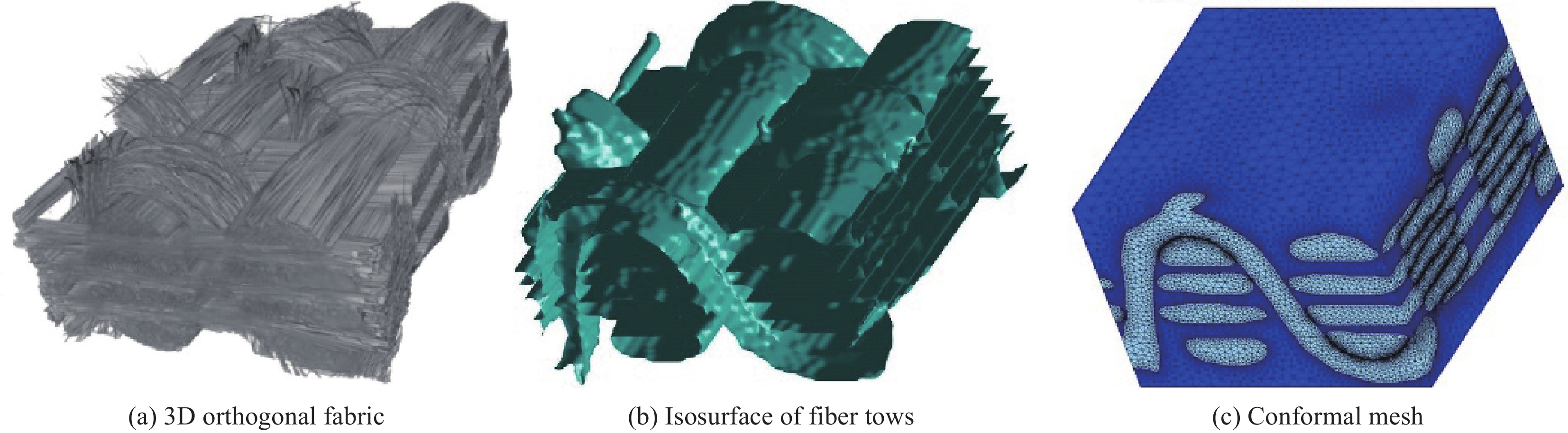

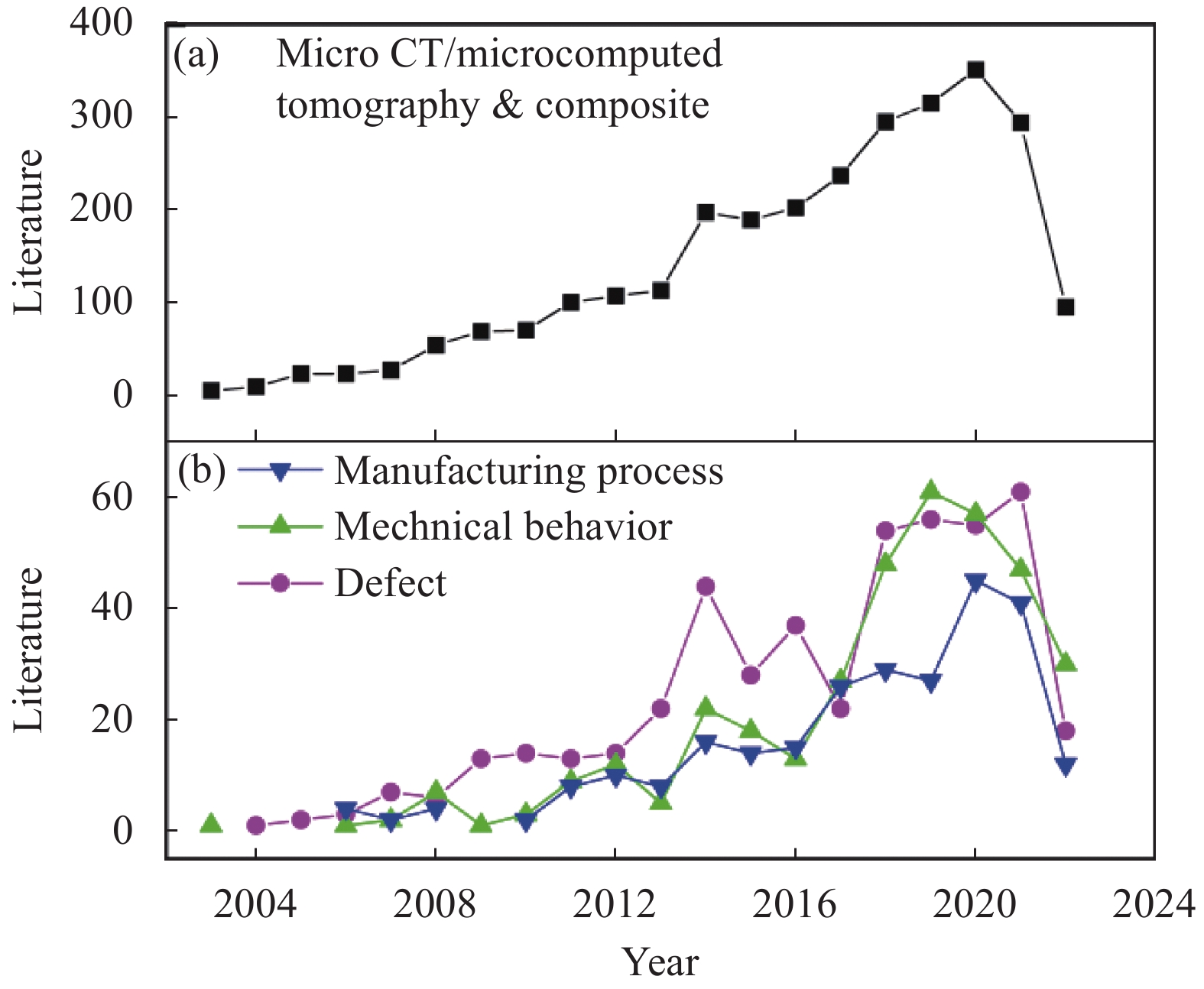

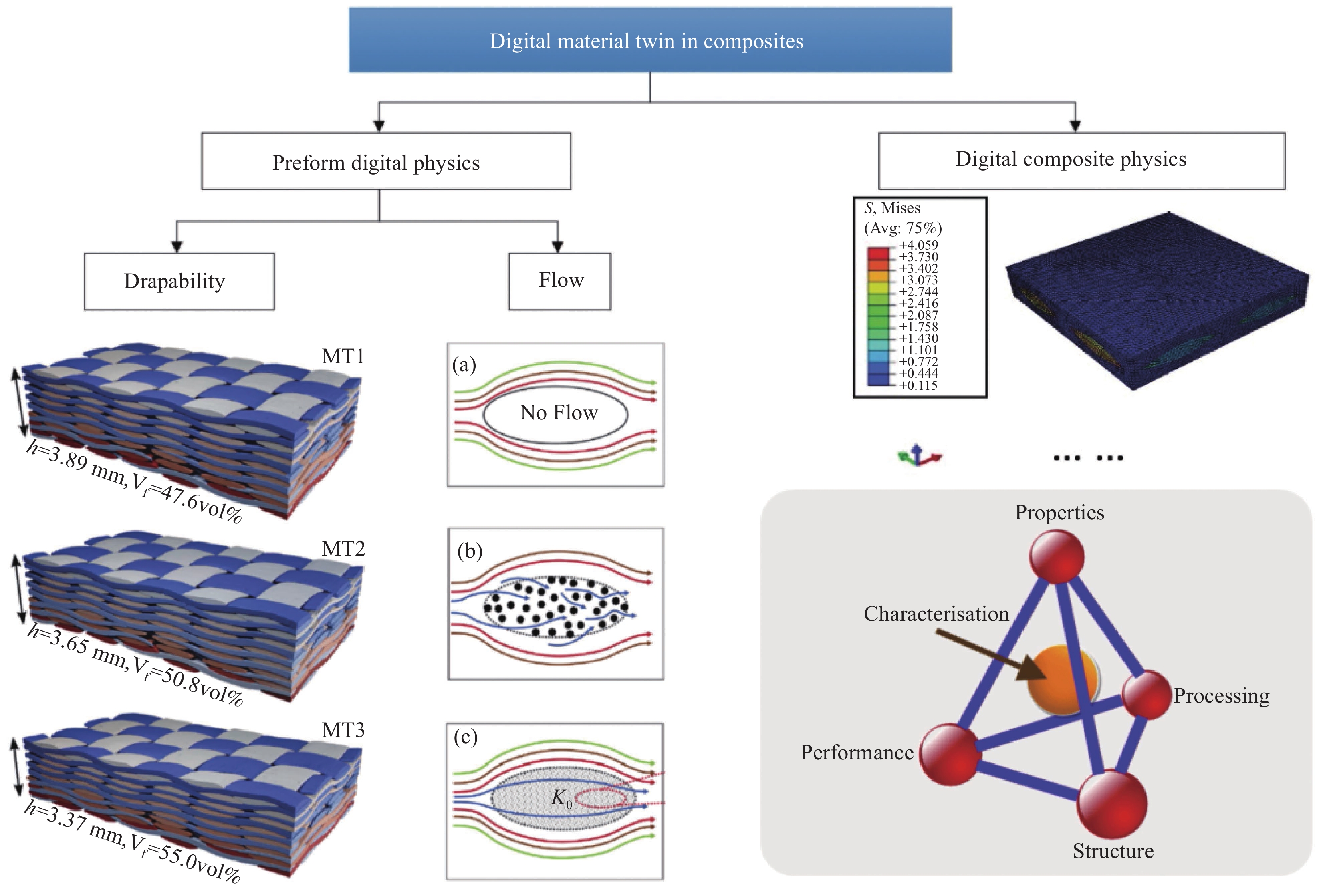

摘要: 精确的数值模型是获得可靠的数值仿真结果的前提。显微计算机断层扫描(Micro-CT)技术可无损成像复合材料的内部结构,据此建立的数值模型比理想化模型更具代表性。本文综述了基于Micro-CT图像的复合材料介观模型构建方法及其在材料虚拟测试中的应用,提出了Micro-CT辅助数值仿真的概念。首先,对Micro-CT成像原理、设备特点和织物增强复合材料的成像难点进行了讨论。其次,梳理了现有的Micro-CT辅助建模技术的特点,将其建立的模型划分为间接模型、体素模型和数字材料孪生模型,重点介绍了构建各类模型的理论基础和技术途径,指出了各自的优势和局限性。然后对Micro-CT辅助数值仿真技术在织物增强复合材料的成型工艺和力学性能预测等方面的应用进行了总结,表明了该技术的重要价值。最后,对Micro-CT辅助数值仿真技术的未来发展进行了展望。Abstract: Reliable numerical simulation results depend on the use of accurate numerical models. Micro-computed tomography (Micro-CT) technology is capable of non-destructively imaging the internal structure of composite materials, hence, numerical models reconstructed from it are more representative than the idealized ones. Here, a review is presented for constructing mesoscopic models of composite materials based on Micro-CT images and its application in virtual testing. A novel concept, Micro-CT aided numerical simulation, is proposed. First, the principle of Micro-CT imaging, the characteristics of equipment, and the difficulties with scanning fabric-reinforced composites are discussed. Second, the characteristics of existing Micro-CT aided modeling techniques are analyzed and compared. The models are divided into three types including indirect, voxel, and digital material twin ones. The theoretical basis and technical approaches for constructing each type of model are highlighted, and the advantages and limitations of each are analyzed. Then recent applications of Micro-CT aided numerical simulation in composite molding process and mechanical property prediction of fabric reinforced composites are summarized, showing the potential and importance of the technology. Finally, the future of Micro-CT aided numerical simulation technology is anticipated.

-

Keywords:

- fabric-reinforced composites /

- Micro-CT /

- numerical simulation /

- image reconstruction /

- digital twin

-

金属的腐蚀过程本质上是化学腐蚀和电化学腐蚀,其中又以金属暴露在潮湿环境提供的腐蚀性介质(H2O,Cl−,O2−等)中,而引发的电化学腐蚀为最主要影响因素[1-3],因此采用涂层将金属基底与环境隔离,减少腐蚀性介质与金属的接触是避免腐蚀发生的关键。为了提升涂层的防腐性能,主要有以下两种主要策略:(1)提升涂层对腐蚀性介质的阻隔能力,石墨烯复合材料即具备优异的阻隔能力,这一策略为生产石墨烯复合材料及其衍生物提供了良好的环境基础[4];(2)赋予功能涂料优异的疏水特性[5]。

石墨烯因其超薄均匀的二维形貌、优良的抗压强度等理化性质、极高的载流子迁移率等,对小分子优越的阻隔能力[6-7],在科学研究和技术应用中备受关注。随着其在复合涂层中的广泛应用,表面功能化[8-9]及其产物的研究开始受到关注。Qiu等[10]以原位聚合法制备了一种聚吡咯插层石墨烯复合涂层,发现当石墨烯添加量达到0.5%时,涂层的防腐性能最佳,腐蚀电流仅为7.728×10−9 A/cm2。在OU等[11]的研究中,通过1,3-偶极环加成反应,将石墨烯与苯酚基团共价功能化,结果表明,通过该方法,石墨烯可以用聚甲基丙烯酸甲酯共价功能化,且不降低石墨烯的电学性质。一些摩擦学研究工作还报道了石墨烯、碳纳米管、纳米二氧化硅等纳米粒子的加入,往往能使复合涂层材料具备减摩和抗磨性能[12-14]。

另有研究表明,氟改性石墨烯材料由于氟的存在,导致表面能降低在水环境中表现出高度疏水性[15-16],同时材料的耐化学性也有所提高。因此,氟化石墨烯及含氟聚合物接枝改性石墨烯复合材料作为一种耐腐蚀、超疏水的纳米材料与有机涂层相结合后,在防腐防污领域具备一定的应用潜力[17-19]。并且,聚合物改性石墨烯材料由于其导电性和分子隔离能力,具备一定阴极保护能力,结合其优异的阻隔效应和超疏水特性,能使氟改性石墨烯/有机复合涂层的防腐性能进一步提高[20-21]。Li等[22]通过将多壁碳纳米管分散在热塑性弹性体溶液后喷涂,又用乙醇处理,制备了一种高度柔性的多功能涂层,接触角在各种材质表面均达到150°。Guo等[23]以含氟石墨烯和γ-oxo-1-苯乙烯丁酸为原料,通过溶液浸涂法制备出一种含氟石墨烯涂层材料,接触角达到163.7°。然而氟改性石墨烯材料也存在明显的不足之处。例如,石墨烯材料因其巨大的比表面积,在有机涂层基体中难以形成稳定分散状态[24-25],经过氟化改性后该问题仍无法得到解决。另一方面,由于氟化石墨烯及含氟聚合物接枝改性石墨烯复合材料的制备过程存在工艺复杂、化学方法收率低等因素,也使其实际应用受到极大限制。

本文报道了一种含氟聚合物共价功能化石墨烯复合材料,该材料以共价键方式将含氟丙烯酸酯与苯乙烯的共聚物接枝在氧化石墨烯表面,赋予氧化石墨烯超疏水性的同时,由于共聚反应中苯乙烯的参与,导致最终产物含氟聚合物共价功能化石墨烯在有机涂层基体中的分散性得到改善,从而解决石墨烯在涂层材料基质中容易团聚的问题,使涂层具备良好的粘接性能和高稳定性。结合OU等[11,26]的研究发现,经过聚合物改性后的石墨烯往往可以同时保留石墨烯与聚合物两种材料的优点。基于含氟聚合物改性的石墨烯复合材料不仅保持了石墨烯的潜力,而且具有类似聚合物的特性,两种优势特性得到进一步放大[27]。采用环氧树脂作为用于成膜的涂层材料基体,添加含氟丙烯酸酯聚合物共价功能化石墨烯,在有机无机协同作用下,复合涂层的防腐性能显著提高,且成膜过程中未观察到含氟聚合物共价功能化石墨烯团聚的现象。该含氟聚合物共价功能化石墨烯复合材料具有优异的超疏水性和抗腐蚀性能,其制备方法简单、经济,在做到超疏水的同时,保证了超疏水改性石墨烯在涂层基体中稳定的分散性。作为涂层中的防腐增强型填料,可以便捷地应用于船舰船身、机翼、风电叶片等长期面临恶劣环境的结构表面。

1. 实验材料及方法

1.1 原材料

鳞片石墨(>99%,中国青岛海达石墨有限公司);苯乙烯(St)、甲基丙烯酸十三氟辛酯(PFOMA)、三氟甲基磺酸(TfOH)、偶氮二异丁腈(AIBN)、四氢呋喃(THF)、甲醇、N,N-二甲基甲酰胺(DMF)、丙炔胺、十二烷基硫酸钠(C12H25SO4Na)、二氯甲烷,分析纯,上海阿拉丁生化科技有限公司;EP CYD-127环氧树脂、T31固化剂,中国石油化工股份有限公司巴陵分公司。

1.2 含氟丙烯酸酯共聚物(PFOMA-co-St)的合成

分别称取St和PFOMA单体,置于100 mL三颈烧瓶中,向体系中加入引发剂AIBN。反应温度为70℃,反应体系持续12 h,反应产物取出。首先将所得共聚物溶于适量的THF中,选择甲醇作为沉淀剂反复漂洗,沉淀。在恒温真空干燥箱(60℃)中干燥至恒重。

1.3 氧化石墨烯(GO)的制备

原料预处理:用稀盐酸(5%)洗涤鳞片石墨,过滤,用大量去离子水洗涤至中性,在100℃真空下干燥24 h。在250 mL四颈烧瓶中加入1.0 g预成型鳞片石墨、1.2 g硝酸钾和46 mL浓硫酸,在超声波条件下均匀混合,然后缓慢加入6.0 g高锰酸钾并在冰水浴中搅拌。随后,将温度提高到40℃,并高速搅拌反应6 h。缓慢向反应体系中加入80 mL蒸馏水,升温至70℃,反应进行0.5 h。加入6 mL过氧化氢(30%)和100 mL蒸馏水,3 min后,停止反应,得到亮黄色的初级产品液体。

初始产品后处理:首先以低速取上层液体(下层为未反应石墨);然后高速离心取下层液体;最后,用大量蒸馏水多次洗涤至体系中性,加入1 g十二烷基硫酸钠,得到深黄色GO凝胶。

1.4 炔基化氧化石墨烯(AGO)的制备

称取60.0 mg GO,与120 mL蒸馏水一起加入250 mL三颈烧瓶中,经超声波均匀分散,得到亮黄色分散体。将0.14 g KOH和34.0 mg丙炔胺依次添加到分散体系中,搅拌并均匀混合混合物。反应在室温下进行30 min,并在油浴(80℃)中连续搅拌反应24 h。反应完成后,用0.22 μm聚四氟乙烯膜过滤,用大量蒸馏水洗涤至中性。最终,真空干燥得到AGO。

1.5 超疏水改性石墨烯(FAGO)的制备

FAGO的制备如图1所示,将20 mg AGO和3.0 g PFOMA-co-St超声溶解于3 mL二氯甲烷中均匀分散,称为分散液a。将PFOMA-co-St超声溶解于5 mL二氯甲烷中至分散均匀,溶液为白色粘稠透明液体。此时,迅速向溶液中加入约0.3 mL TfOH。将酸和超声波均匀分散,得到深红色液体,称为分散液b,然后在冰浴下将上述分散液b缓慢滴加到分散液a中。最后,滴加完毕,在冰浴中继续搅拌,使系统反应15 min,然后移除冰浴,使反应在室温下进行24 h。反应停止后,溶解反应体系,用20 mL DMF稀释,低速离心至上层液体澄清。该操作重复5次以去除未反应的聚合物。最后用旋转蒸发器除去少量残留溶剂,真空干燥至恒重,得到最终目标产物。

1.6 表征与分析

采用美国 Thermo Fisher公司的NICOLET 6700 FTIR傅里叶红外光谱仪测定GO、AGO、FAGO各组分特征官能团,以干燥的KBr压片法进行测试。采用瑞士Bruker公司AVANCE-500 MHz型核磁共振光谱仪,以氘代氯仿为溶剂,四甲基硅烷为内标,对PFOMA-co-St的分子结构进行表征分析。采用美国 Thermo Fisher公司的Thermo Scientific K-Alpha XPS对FAGO的元素含量进行表征。采用捷克 TESCAN公司的TESCAN-MIRA3型场发射扫描电子显微镜观察所制备的FAGO复合材料的形貌结构。采用德国耐驰公司NETZSCH TG 209F1型热重分析仪进行热失重分析,在N2气氛下,以10℃/min的升温速率加热至800℃。采用承德市成惠试验机有限公司JGW-360A型接触角测定仪表征了涂层材料在室温下的疏水性能。采用上海辰华仪器有限公司CHI660E型电化学工作站,通过Tafel曲线和电化学阻抗谱(EIS)评价了FAGO/环氧树脂的腐蚀防护性能。电化学测量采用常规的三电极体系,以饱和甘汞电极为参比电极,以铂为辅助电极,以涂覆复合涂层的钢样为工作电极。进行EIS分析时电化学工作站工作频率为10−2~105 Hz,正弦电压振幅设置为5 mV,工作电极的接触面积被限制在2 cm2,试样在3.5wt% NaCl溶液中分别浸泡5天、25天及55天。

2. 结果与讨论

2.1 结构分析

为验证氟化丙烯酸酯共聚物的成功制备,进行核磁共振氢谱(1HNMR)波谱分析,用于确定氟化丙烯酸酯共聚物的分子结构。在图2中,7.06 ppm和6.61 ppm处的峰值对应苯环上—H(a)的共振信号;3.95 ppm处的峰值来自于—OCH2—上氢原子(b)的贡献;2.55 ppm处的峰值对应于叔碳上的氢(c);1.50 ppm处的峰值对应于—CH2CF2中的—CH2上的氢(d);1.18 ppm处为聚合物主链上仲碳氢(e)贡献的共振信号;0.79 ppm处为伯碳氢(g)对应的共振信号[28]。GO表面存在大量羟基、环氧基、羧基等表面活性基团[29],可充当活性位点与改性剂反应,形成稳定化学键。本文首先利用丙炔胺中的氨基与GO表面的活性基团反应,在C原子与N原子间形成稳定的σ键,从而实现GO的炔基化;然后利用AGO表面接枝的炔基与 PFOMA-co-St中由偶氮二异丁腈提供的氰基(—CN)进行环加成反应,得到目标产物FAGO。

图3为GO、AGO和FAGO改性前后的FTIR图谱。可以看出,GO的FTIR光谱在3480 cm−1和1230 cm−1处的强谱带是由于—OH的伸缩振动吸收峰,1710 cm−1处的强谱带来源于羧基的C=O键的伸缩振动吸收峰;AGO的FTIR光谱与GO的FTIR光谱相比,在3480 cm−1、1230 cm−1和1710 cm−1处存在相同的吸收峰,而1020 cm−1处有非常明显的C—H伸缩振动吸收峰,2975 cm−1处是酰胺的N—H伸缩振动吸收峰,在2930 cm−1处观察到C—H伸缩振动吸收峰,这是炔丙基基团的特征,结果表明GO的炔基化反应成功;FAGO的FTIR光谱与AGO的FTIR图谱相比,1643 cm−1处有明显的C=N伸缩振动吸收峰,1215 cm−1处也有明显的C—F伸缩振动吸收峰,并且1020 cm−1处原本非常明显的C—H伸缩振动吸收峰消失,这证明AGO表面的炔基已反应完全,表明共聚物成功与石墨烯发生反应。上述分析结果可以证明共聚物与石墨烯发生了反应,成功制备含氟丙烯酸酯共聚物改性石墨烯复合材料。一系列实验结果和分析表明,采用传统自由基共聚合成氟化丙烯酸酯共聚物并采用点击化学反应将共聚物接枝到石墨烯表面,此方法具有简单、经济和高效等优势。

图4为GO、AGO和FAGO的热失重(TGA)曲线。可以看出,GO、AGO和FAGO曲线都在70℃左右开始失重,持续到100℃时稳定,这是由于样品表面物理吸附的水分及未干燥的水分蒸发所致。在GO的TGA曲线可以看到,在100~500℃之间,GO的质量从92wt%下降为61wt%,质量损失为31%,最终剩余质量为59wt%,TGA结果可能与石墨烯的内部结构崩塌和逐渐碳化有关,符合氧化石墨烯的热重曲线规律[30];与AGO的TGA曲线相比,在上述温度范围内AGO的质量从92wt%下降为45wt%,质量损失为47%,说明AGO表面接枝率达到16%;与FAGO的TGA曲线相比,在上述温度范围内FAGO的质量从92wt%下降为28wt%,质量损失为64%,FAGO的接枝率达到33%。随着接枝率的增加,质量损失率也随之增加。三种曲线间的质量损失率差异反映了共聚物的接枝率,证明了含氟丙烯酸酯共聚物在石墨烯表面形成复合材料,共聚物的加入改变了石墨烯复合材料的各种物理参数。

图5为FAGO样品的XPS能谱图。可以明显看到,FAGO样品中显示出F、O、N和C信号;其中,氮信号来源于氧化石墨烯炔基化改性及含氟共聚物(含—CN)接枝过程;其中,氟的信号来源于含氟共聚物中的氟元素。此外,图5中在结合能为160 eV和230 eV处还存在两个信号,这两个信号归因于样品中残留的少量表面活性剂(SDS)。由XPS分析结果再次验证FAGO表面成功接枝含氟丙烯酸酯共聚物,它们为FAGO具备超疏水性,并能在有机涂层基体中维持稳定分散提供物理化学基础。

图6为鳞片石墨、GO、AGO和FAGO样品的SEM图像。由图6(a)可以看出鳞片石墨呈现典型的鳞片状颗粒结构;图6(b)显示具有明显边缘的片状GO纳米薄片,证明通过Hummers法成功制备出具备二维结构的GO纳米粒子,二维片状结构为之后的炔基化改性提供足够大的比表面积;从图6(c)右图可以观察到材料表面形貌浓度与其未改性石墨烯相比的显著变化。在炔基化石墨烯表面生长了300~600 nm的半球状接枝部分。在模板效应的影响下,当复合材料浓度较高时,生长部分均匀且具有良好的平面性。充分证明了石墨烯的改性是成功的;图6(d)为最终目标产物FAGO复合材料,相比于AGO,FAGO复合材料表面存在大量附着的300~600 nm的半球状接枝部分,FAGO粒子表面被连续的聚合物覆盖,边缘转化为典型的高分材料的形貌特征,这证明含氟丙烯酸酯共聚物已经通过AGO表面的炔基接枝在AGO表面,产物纳米颗粒和层状尺寸仍在微纳米范围内且保持非团聚状态,这种表面形貌和尺寸有助于超疏水表面的形成,且有助于FAGO在有机涂层基体中维持稳定的分散状态。

2.2 FAGO的疏水性能

图7为通过控制含氟丙烯酸酯共聚物中含氟单体(PFOMA)的量,制备出具有不同FAGO材料涂敷在45#碳钢表面后,涂层疏水性能测试的最终结果。从中找到规律,制备出超疏水FAGO。其中采用不同配比(PFOMA∶St=1∶9、3∶7、5∶5、7∶3、9∶1)时,所制备的FAGO其CA值分别为(101.3±2.3)°、(113.9±1.9)°、(129.4±2.8)°、(153.1±2.5)°和(130.5±1.7)°。在PFOMA少量引入的情况下,CA值随PFOMA引入量的增加而不断增加,当PFOMA的加入量为70%时达到峰值,之后CA值有一定程度的下降,这可能是由于PFOMA的用量大导致GO表面空间位阻增大,导致进一步接枝反应难以进行。实验表明,当含氟单体掺杂量为70%时,效果最好。

图8为FAGO复合材料在不同表面的超疏水性能。可以看出,对于玻片、SiC、SiO2、棉涤纶织物和环氧树脂板等不同的基材,水接触角没有明显变化均保持在150°以上。当以钢板为基板时,其水接触角增加到(171.3±2.2)°,其原因在于45#碳钢经过抛光、丙酮等预处理后,钢板表面产生不规则的细小磨削凹痕,产生的微表面粗糙结构显著提升了FAGO材料的表面超疏水性能[31]。

2.3 FAGO在环氧树脂中的分散性能

为了研究FAGO复合材料在环氧树脂中的稳定性及对复合材料疏水性的影响,以45#碳钢作为基底,环氧树脂(EP)作为涂层基体,FAGO作为填料,制备出FAGO/EP复合涂层。其中环氧树脂与固化剂的质量比为3∶1,FAGO为填料,质量分数分别为0.5wt%、1.0wt%和1.5wt%,所制备的样品分别记为FAGO0.5wt%/EP,FAGO1.0wt%/EP和FAGO1.5wt%/EP。

图9为样品FAGO0.5wt%/EP、FAGO1.0wt%/EP和FAGO1.5wt%/EP在液氮环境中淬断后拍摄的SEM图像。由图9(a)、图9(b)、图9(c)可知FAGO/环氧树脂复合涂层的厚度在450 μm左右;如图9(d)、图9(g)所示,含0.5wt% FAGO的复合涂层显示断裂表面有稀疏光滑的裂纹,FAGO总体呈现出均匀分布;图9(e)和图9(h)为含1.0wt% FAGO的复合涂层的SEM图像,由于FAGO的含量升高,复合涂层的横截面表现出更短的裂纹长度和更密集的裂纹;图9(f)、图9(i)为含1.5wt% FAGO的复合涂层的SEM图像,由于所添加的FAGO含量进一步升高,导致涂层出现更粗糙的断裂表面并且形成更多的孔隙和裂纹;总体而言SEM图像显示FAGO在环氧涂层中具备较好的分散性。

2.4 FAGO/环氧树脂复合涂层的疏水性能

图10为纯环氧树脂涂层及FAGO含量不同的FAGO/环氧树脂复合涂层的水接触角。可知,当环氧树脂中不添加FAGO时,纯环氧树脂涂层的水接触角为(54.9±2.1)°表现为亲水性;当FAGO的质量分数达到0.5wt%时FAGO0.5wt%/EP的水接触角上升至(88.1±1.6)°,FAGO1.0wt%/EP的水接触角为(92.3±1.9)°,FAGO1.5wt%/EP的水接触角为(97.8±2.3)°,这说明FAGO的加入能够明显提升环氧树脂的疏水性,但是由于FAGO的添加量仅在1.0wt%左右,因此仍旧难以使涂层具备超疏水性。

2.5 FAGO/环氧树脂复合涂层的防腐性能

采用电化学工作站分别采集样品FAGO0.5wt%/EP、FAGO1.0wt%/EP、FAGO1.5wt%/EP及空白对照组(45#碳钢表面涂腊wax)在3.5wt% NaCl溶液中浸泡后的Tafel极化曲线与EIS阻抗数据,以判断FAGO/环氧树脂复合涂层材料防腐性能的优劣。Tafel极化曲线如图11所示,利用电化学分析仪测量结果见表1,其中Ecorr代表腐蚀电位、Icorr代表腐蚀电流密度、ba

为阳极Tafel斜率、bc为阴极Tafel斜率、vcorr为腐蚀速率。 表 1 涂覆涂层的45#碳钢在3.5wt% NaCl溶液中通过Tafel极化曲线拟合得到的腐蚀参数Table 1. Fitting corrosion data of coated 45# carbon steel samples in 3.5wt% NaCl solution by Tafel polarization curvesSample Ecorr/V Icorr/(a·cm−2) ba/(V·dec−1) bc /(V·dec−1) vcorr/(mm·year−1) Wax −0.284 1.665×10−6 7.801 −11.732 1.932×10−2 FAGO0.5wt%/EP −0.206 8.872×10−9 16.890 −13.401 1.032×10−4 FAGO1.0wt%/EP −0.226 1.999×10−8 12.817 −13.913 2.327×10−4 FAGO1.5wt%/EP −0.231 2.111×10−7 4.583 −4.905 2.454×10−3 Notes: Corrosion current density (Icorr), anodic Tafel slope (ba ), corrosion potential (Ecorr), corrosion rate (vcorr) and cathodic Tafel slope (bc) were calculated via electrochemical analyzer instrument. 表面涂蜡的45#碳钢试样腐蚀电位为0.284 V,而表面涂有FAGO/环氧树脂复合涂层的45#碳钢试样的腐蚀电位明显向更高的值移动,表明环氧树脂体系有助于填料达到耐腐蚀性能。随着FAGO的加入,ba值可以证明阳极的溶解速度逐渐减慢,当FAGO的添加量为0.5wt%时FAGO0.5wt%/EP的腐蚀电位最高,达到0.206 V,FAGO1.0wt%/EP的腐蚀电位为−0.226 V,FAGO1.5wt%/EP的腐蚀电位为−0.231V,表明FAGO的引入可以提高涂层的阻隔性能。与FAGO0.5wt%/EP相比,FAGO1.0wt%/EP和FAGO1.5wt%/EP的腐蚀电位较低。从Icorr来看,FAGO0.5wt%/EP的电流密度最低(8.872×10−9 A/cm2),与wax和FAGO1.5wt%/EP的腐蚀电流相比减小二到三个数量级。腐蚀速率规律与腐蚀电流规律相同,这是由于FAGO的加入最初可以起到优异的阻隔作用,显著延长腐蚀介质进入金属基底的路径,但随着FAGO继续不断增加,则会导致涂层缺陷增多,反而导致腐蚀介质渗透到金属基底的路径变短,从而加速了涂层下金属材料的腐蚀[5]。

为了进一步研究FAGO0.5wt%/EP在腐蚀环境下的防腐历程,对涂敷FAGO0.5wt%/EP的45#碳钢试样进行EIS阻抗测试。图12和图13分别显示了涂敷有FAGO0.5wt%/EP的45#碳钢在3.5%NaCl溶液中浸泡了2天、20天和40天后测得的Nyquist图与Bode图。其中Z'代表阻抗实部,Z''代表阻抗虚部,|Z|代表阻抗的模,其大小代表电化学体系的极化电阻,因此曲线中曲线直径越大,表示涂层材料对金属的耐腐蚀保护性能越好。在所有样品的Nyquist图中只有一个弛豫时间,这表明腐蚀过程主要以电荷转移控制之下为主。

在Bode图中,通常最低频率区(10−2 Hz)处的阻抗数值可被用作涂层防腐性能的半定量指标[32]。图13中45#碳钢涂覆FAGO0.5wt%/EP试样,前20天的|Z|值下降很少,20天到40天时|Z|值下降增速,这是腐蚀介质逐渐深入复合涂层所导致。随着浸泡时间的延长,涂层阻隔性能下降。浸泡40天后,Nyquist图中没有出现两个时间常数[10]。这一观察表明,涂层降解导致涂层的阻隔性能下降,但腐蚀电解液没有到达金属基体。FAGO的加入一方面延长了腐蚀性介质到达金属基底的路径;另一方面腐蚀性介质沿涂层内部缝隙缺陷进入金属基底时,由于FAGO的超疏水作用,腐蚀介质在空隙中产生向外的表面张力,也在一定程度上减缓其在涂层中的扩散速度,从而延缓了电解质溶液的侵蚀,起到了阻隔作用。为了验证FAGO/环氧树脂复合涂层在实际应用下的防腐性能,采用人工模拟海水的方法进行浸泡实验。

图14为涂覆FAGO0.5%/EP的45#碳钢试样在人工模拟海水中浸泡1天、25天和55天及在酸液中浸泡25天、70天后的光学照片。其中图14(a)、图14(b)与图14(c)分别为涂覆FAGO0.5wt%/EP的45#碳钢在人工模拟海水中浸泡1天、25天和55天后的光学照片;图14(e)、图14(f)与图14(g)分别对应涂覆FAGO0.5wt%/EP的45#碳钢在人工模拟海水中浸泡1天、25天和55天后再去除表面涂层的金属底板的照片。图14(a)、图14(e)为涂板浸泡第一天时拍摄的照片,边缘少量锈迹是由于单面涂膜导致腐蚀介质沿涂层与金属基底结合处边缘渗入所致。当涂板浸泡时间达到25天时(见图14(b)、图14(f)),边缘出现的少量锈迹略微增多,逐渐向内部扩展,金属基底内部并无锈迹产生,这是由于金属样品单面涂层会在侧面产生间隙,但中央部位仍然未呈现出锈蚀迹象,说明此时FAGO0.5wt%/EP仍然为45#碳钢提供优良的防腐效果。当涂膜板浸泡时间达到55天时(见图14(c)、图14(g)),涂层之下金属材料中间部位开始出现明显的锈蚀迹象,说明涂层在人工海水环境中浸泡55天后逐渐失效,这与之前由Nyquist图与Bode图中得出的结论相匹配。图14(d)、图14(h)分别为酸浸实验中浸泡25天及70天的样本图片,除表面泛黄程度有所加深外,没有其他变化,证明FAGO0.5wt%/EP对酸性环境也有一定的防护能力,这展现出FAGO纳米粒子在对抗酸性环境时所具备的应用价值。

2.6 FAGO/EP复合涂层的防腐机制

通过以上测试,FAGO/EP复合涂层防腐性能提升的工作机制如下:(1) 当涂有FAGO/EP复合涂层的样品浸入腐蚀介质(3.5wt%NaCl溶液)时,腐蚀介质通过涂层中的裂缝及毛细管以毛细相的形式渗入涂层。由于石墨烯具有优越的阻隔性能;并且在FAGO的改性过程中通过St引入苯环,使其能够在EP中稳定分散;裂缝及毛细管等腐蚀介质的扩散路径被延长延迟了腐蚀的发生。(2) FAGO表面接枝的氟元素赋予FAGO/EP复合涂层较低的表面能,使涂层表现出疏水的性质;而裂缝及毛细管由于其直径小的特点,使其产生疏水毛细现象,凸液面对腐蚀介质施以压力,导致腐蚀介质沿涂层中裂缝与毛细管渗透的过程更难以进行,从而贡献了FAGO/EP复合涂层的防腐性能。FAGO/环EP复合涂层的防腐机制模型如图15所示。

3. 结 论

(1) 石墨烯表面成功地接枝了含氟丙烯酸酯共聚物,完成了氧化石墨烯的炔化反应,确定了超疏水改性石墨烯 (FAGO)纳米复合材料的合成方法。

(2) 通过一种简单有效的方法通过共价键接枝制备的含氟共聚物实现了石墨烯复合材料的超疏水性能,并使其具有可控性。

(3) 与非功能化石墨烯相比,FAGO复合材料不仅具有超疏水性能,而且具有优异的耐腐蚀性能。

(4) FAGO的加入使FAGO/环氧树脂复合涂层延长腐蚀介质扩散路径的同时,因其超疏水性也减缓腐蚀介质沿裂缝及毛细管扩散的过程。

-

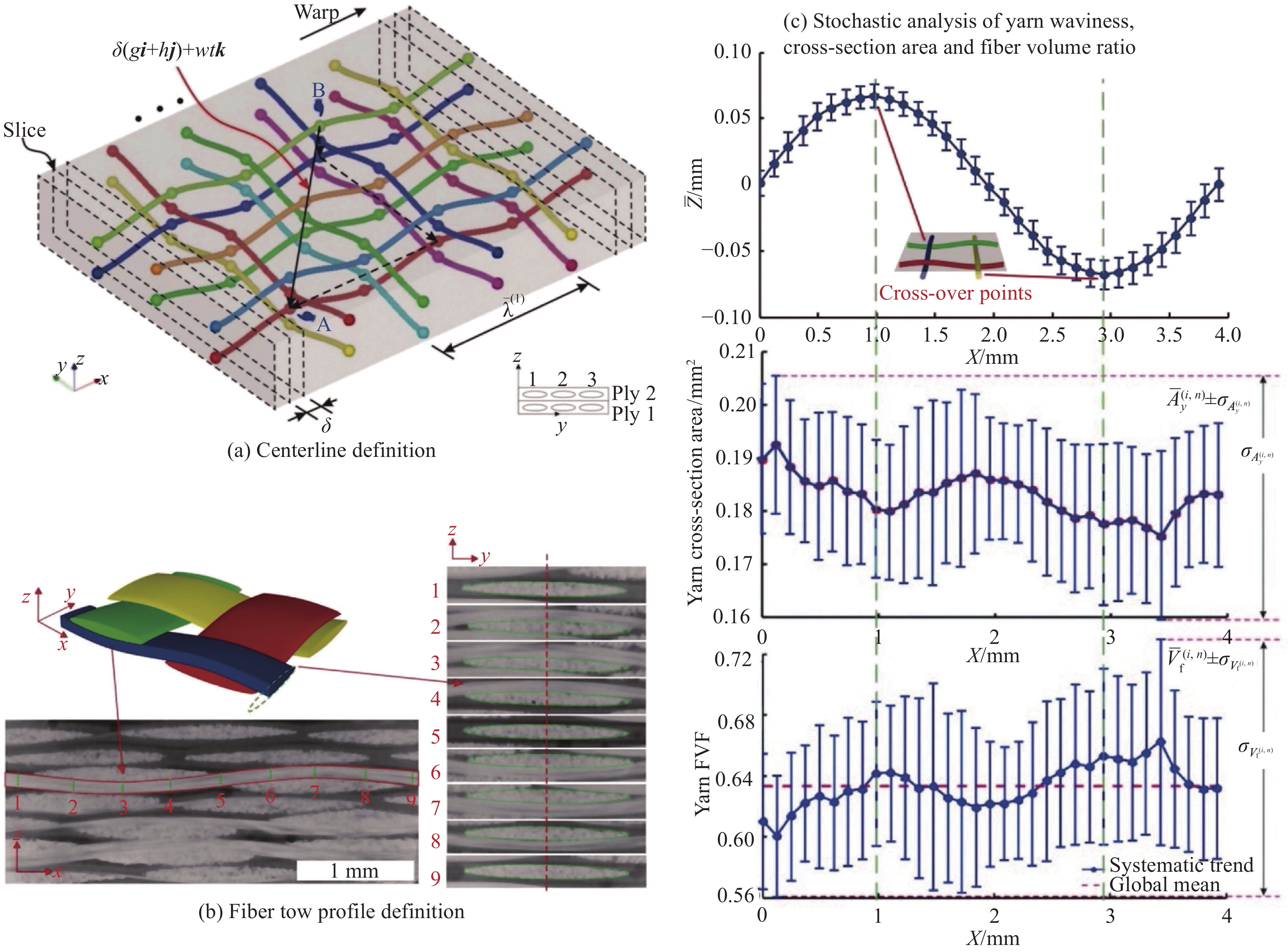

图 5 间接建模技术的纤维束路径、轮廓特征定义和尺寸数据分析[67]

Figure 5. Fiber yarn paths, profile definition and dimensional analysis for indirect modeling techniques [67]

(i, j, k)—Unit vectors in Cartesian coordinate systems; (g, h, w)—Periodicity parameters; δ—Image slice interval; t—Average thickness of ply; ˉA(i,n)y—Systematic yarn cross-sectional area; ˉV(i,n)f—Fiber volume fraction; σA(i,n)y—Standard deviation of ˉA(i,n)y; σV(i,n)f—Standard deviation of ˉV(i,n)f; Z—Ply thickness; ˉλ(1)—Mean period length of warp tow; FVF—Fiber volume fraction

表 1 Micro-CT 图像预处理和图像分割方法

Table 1 Micro-CT image pre-processing and image segmentation methods

Textile Resolution/μm Denosing Smoothing Segmentation Software Ref. Plain weave 10.4 – – Manual segmentation VGStudio [67] 25 Pixel intensity averaged with neighbors Sobel operator & Structure tensor MATLAB [77] 1-10 Median filter Threshold-texture feature-morphology – [78] 5 A 1D uniform filter Morphological gradient & Deep learning ImageJ & SciPy [82] 18.6 Non-local mean filter Thresholding based on seed

region growingAvizo [83] 5-directional braided composite 22.1 √ √ √ VGStudio/ImageJ [65] Fiber tow 9.3 – Nugget effect Implicit kriging & Indicator function In-house Python code [84] 3D fabric 2 Median filter Texture analysis – [74] – Gaussian smoothing Structure tensor & Signed distances MATLAB [64] Notes: "–" means information of the item was not given by authors, while "√" means the item was done but the method was not given. 表 2 5种常用的多孔介质渗流力学求解器

Table 2 Five commonly used solvers for percolation mechanics in porous media

Category Governing equation Meshing Software Ref. Computational fluid dynamic (CFD) Stokes and Navier-Stokes equations on discretized grid mesh Yes Fluent, OpenFOAM, et al [92, 110-111] Lattice-Boltzmann method (LBM) Boltzmann equation on voxel mesh No OpenLB, et al [112-113] Voxel based direct Navier-Stokes

solvers (VBS)Stokes and Navier-Stokes equations on segmented Micro-CT images No VGStudio, Avizo, et al [73, 105, 107-108, 114] Semi-analytical solvers (SAS) Analytical up-scaling solutions No — [115] Empirical Kozeny-Carman type

model (EMP)Pore size distribution extracted from No — [5, 88] -

[1] LLORCA J, GONZÁLEZ C, MOLINA-ALDAREGUÍA J M, et al. Multiscale modeling of composite materials: A roadmap towards virtual testing[J]. Advanced Materials,2011,23(44):5130-5147. DOI: 10.1002/adma.201101683

[2] HENNING F, KÄRGER L, DÖRR D, et al. Fast processing and continuous simulation of automotive structural composite components[J]. Composites Science and Technology,2019,171:261-279. DOI: 10.1016/j.compscitech.2018.12.007

[3] GRIEVES M, VICKERS J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems[M]//Transdisciplinary perspectives on complex systems. Cham: Springer, 2017: 85-113.

[4] 张霖. 关于数字孪生的冷思考及其背后的建模和仿真技术[J]. 系统仿真学报, 2020, 32(4):1-10. ZHANG Lin. Cool thoughts on digital twins and modeling and simulation technologies behind[J]. Journal of System Simulation,2020,32(4):1-10(in Chinese).

[5] ENDRUWEIT A, ZENG X, MATVEEV M, et al. Effect of yarn cross-sectional shape on resin flow through inter-yarn gaps in textile reinforcements[J]. Composites Part A: Applied Science and Manufacturing,2018,104:139-150. DOI: 10.1016/j.compositesa.2017.10.020

[6] MADRA A, BREITKOPF P, RASSINEUX A, et al. Image-based model reconstruction and meshing of woven reinforcements in composites[J]. International Journal for Numerical Methods in Engineering,2017,112(9):1235-1252. DOI: 10.1002/nme.5555

[7] ZENG X, ENDRUWEIT A, BROWN L P, et al. Numerical prediction of in-plane permeability for multilayer woven fabrics with manufacture-induced deformation[J]. Composites Part A: Applied Science and Manufacturing,2015,77:266-274. DOI: 10.1016/j.compositesa.2015.03.027

[8] LONG A C, BROWN L P. Modelling the geometry of textile reinforcements for composites[M]//Composite Reinforcements for Optimum Performance. Cambridge: Woodhead Publishing, 2011: 239-264.

[9] SHERBURN M. Geometric and mechanical modelling of textiles[D]. Nottingham: University of Nottingham, 2007.

[10] WENDLING A, DANIEL J, HIVET G, et al. Meshing preprocessor for the mesoscopic 3D finite element simulation of 2D and interlock fabric deformation[J]. Applied Composite Materials,2015,22(6):869-886. DOI: 10.1007/s10443-015-9441-8

[11] ISART N, MAYUGO J A, BLANCO N, et al. Geometric model for 3D through-thickness orthogonal interlock composites[J]. Composite Structures,2015,119:787-798. DOI: 10.1016/j.compstruct.2014.09.044

[12] 倪爱清, 王继辉, 朱以文. 复合材料液体模塑成型工艺中预成型体渗透率张量的数值预测[J]. 复合材料学报, 2007, 24(6):50-56. DOI: 10.3321/j.issn:1000-3851.2007.06.009 NI Aiqing, WANG Jihui, ZHU Yiwen. Numerical prediction of saturated permeability tensor of a woven fabric for use in the fluid simulation of liquid composite molding[J]. Acta Materiae Compositae Sinica,2007,24(6):50-56(in Chinese). DOI: 10.3321/j.issn:1000-3851.2007.06.009

[13] 王旭. 基于3ds Max软件的机织物结构三维建模研究[J]. 安徽工程大学学报, 2013, 28(3):27-29, 65. DOI: 10.3969/j.issn.2095-0977.2013.03.008 WANG Xu. 3D modeling on woven fabric structure by 3ds Max[J]. Journal of Anhui Polytechnic University,2013,28(3):27-29, 65(in Chinese). DOI: 10.3969/j.issn.2095-0977.2013.03.008

[14] 惠新育, 许英杰, 张卫红, 等. 平纹编织 SiC/SiC 复合材料多尺度建模及强度预测[J]. 复合材料学报, 2019, 36(10):2380-2388. HUI Xinyu, XU Yingjie, ZHANG Weihong, et al. Multi-scale modeling and strength prediction of plain woven SiC/SiC composites[J]. Acta Materiae Compositae Sinica,2019,36(10):2380-2388(in Chinese).

[15] YANG B, WANG S, TANG Q. Geometry modeling and permeability prediction for textile preforms with nesting in laminates[J]. Polymer Composites,2018,39(12):4408-4415. DOI: 10.1002/pc.24526

[16] SWERY E E, MEIER R, LOMOV S V, et al. Predicting permeability based on flow simulations and textile modelling techniques: Comparison with experimental values and verification of FlowTex solver using Ansys CFX[J]. Journal of Composite Materials,2016,50(5):601-615. DOI: 10.1177/0021998315579927

[17] VERPOEST I, LOMOV S V. Virtual textile composites software WiseTex: Integration with micro-mechanical, permeability and structural analysis[J]. Composites Science and Technology,2005,65(15-16):2563-2574. DOI: 10.1016/j.compscitech.2005.05.031

[18] 金天国, 魏雅君, 杨波, 等. 预成型体渗透率预测及其受压缩变形的影响[J]. 复合材料学报, 2015, 32(3):840-847. DOI: 10.13801/j.cnki.fhclxb.201503.009 JIN Tianguo, WEI Yajun, YANG Bo, et al. Permeability prediction of preform and influence of compression deformation[J]. Acta Materiae Compositae Sinica,2015,32(3):840-847(in Chinese). DOI: 10.13801/j.cnki.fhclxb.201503.009

[19] STUMP D, FRASER W. A simplified model of fabric drape based on ring theory[J]. Textile Research Journal,1996,66(8):506-514. DOI: 10.1177/004051759606600804

[20] WADEKAR P, GOEL P, AMANATIDES C, et al. Geometric modeling of knitted fabrics using helicoid scaffolds[J]. Journal of Engineered Fibers & Fabrics,2021,16:1-15. DOI: 10.1177/1558925020913871

[21] HUANG W, CAUSSE P, BRAILOVSKI V, et al. Reconstruction of mesostructural material twin models of engineering textiles based on Micro-CT aided geometric modeling[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105481. DOI: 10.1016/j.compositesa.2019.105481

[22] ZENG X, BROWN L P, ENDRUWEIT A, et al. Geometrical modelling of 3D woven reinforcements for polymer composites: Prediction of fabric permeability and composite mechanical properties[J]. Composites Part A: Applied Science and Manufacturing,2014,56:150-160. DOI: 10.1016/j.compositesa.2013.10.004

[23] ALI M A, UMER R, KHAN K A. A virtual permeability measurement framework for fiber reinforcements using micro CT generated digital twins[J]. International Journal of Lightweight Materials and Manufacture,2020,3(3):204-216. DOI: 10.1016/j.ijlmm.2019.12.002

[24] BODAGHI M, LOMOV S V, SIMACEK P, et al. On the variability of permeability induced by reinforcement distortions and dual scale flow in liquid composite moulding: A review[J]. Composites Part A: Applied Science and Manufacturing,2019,120:188-210.

[25] GEREKE T, CHERIF C. A review of numerical models for 3D woven composite reinforcements[J]. Composite Structures,2019,209:60-66. DOI: 10.1016/j.compstruct.2018.10.085

[26] ORHAN K. Micro-computed tomography (Micro-CT) in medicine and engineering[M]. Cham: Springer, 2020: 27-33.

[27] MADRA A, CAUSSE P, TROCHU F, et al. Stochastic characterization of textile reinforcements in composites based on X-ray microtomographic scans[J]. Composite Structures,2019,224:111031. DOI: 10.1016/j.compstruct.2019.111031

[28] 许承海, 徐凯, 宋乐颖, 等. 多向轴编碳/碳材料炭基体微结构 Micro-CT 原位扫描及其等效力[J]. 复合材料学报, 2013, 30(S1): 193-198. XU Chenghai, XU Kai, SONG Leying, et al. Microstructure characterization from X-ray micro-tomography and equivalent mechanical properties of carbon matrix of 4D in-plane carbon/carbon composites[J]. Acta Materiae Compositae Sinica, 2013, 30(S1): 193-198(in Chinese).

[29] NGUYEN N Q, MEHDIKHANI M, STRAUMIT I, et al. Micro-CT measurement of fibre misalignment: Application to carbon/epoxy laminates manufactured in autoclave and by vacuum assisted resin transfer moulding[J]. Composites Part A: Applied Science and Manufacturing,2018,104:14-23. DOI: 10.1016/j.compositesa.2017.10.018

[30] ALI M A, GUAN Q, UMER R, et al. Efficient processing of μCT images using deep learning tools for generating digital material twins of woven fabrics[J]. Composites Science and Technology,2022,217:109091. DOI: 10.1016/j.compscitech.2021.109091

[31] PENG P, GAO M, GUO E, et al. Deformation behavior and damage in B4Cp/6061Al composites: An actual 3D microstructure-based modeling[J]. Materials Science and Engineering: A,2020,781:139169. DOI: 10.1016/j.msea.2020.139169

[32] WILLIAMS J, FLOM Z, AMELL A, et al. Damage evolution in SiC particle reinforced Al alloy matrix composites by X-ray synchrotron tomography[J]. Acta Materialia,2010,58(18):6194-6205. DOI: 10.1016/j.actamat.2010.07.039

[33] MADRA A, ADRIEN J, BREITKOPF P, et al. A clustering method for analysis of morphology of short natural fibers in composites based on X-ray microtomography[J]. Composites Part A: Applied Science and Manufacturing,2017,102:184-195. DOI: 10.1016/j.compositesa.2017.07.028

[34] AGYEI R F, SANGID M D. A supervised iterative approach to 3D microstructure reconstruction from acquired tomographic data of heterogeneous fibrous systems[J]. Composite Structures,2018,206:234-246. DOI: 10.1016/j.compstruct.2018.08.029

[35] PATIÑO I D, POWER H, NIETO-LONDOÑO C, et al. Stokes-Brinkman formulation for prediction of void formation in dual-scale fibrous reinforcements: A BEM/DR-BEM simulation[J]. Computational Mechanics,2017,59(4):555-577. DOI: 10.1007/s00466-016-1360-5

[36] YANG B, HUANG W, CAUSSE P, et al. On the design of test molds based on unidirectional saturated flows to measure transverse permeability in liquid composite molding[J]. Polymer Composites,2022,43(4):2234-2251. DOI: 10.1002/pc.26536

[37] KANG M K, LEE W I, HAHN H T. Formation of microvoids during resin-transfer molding process[J]. Composites Science and Technology,2000,60(12):2427-2434.

[38] RUIZ E, ACHIM V, SOUKANE S, et al. Optimization of injection flow rate to minimize micro/macro-voids formation in resin transfer molded composites[J]. Composites Science and Technology,2006,66(3-4):475-486. DOI: 10.1016/j.compscitech.2005.06.013

[39] HUANG W. Analysis of through-thickness injection in liquid composite molding based on digital material twins[D]. Montréal: Polytechnique Montréal, 2020.

[40] YUAN Z, WANG Y, YANG G, et al. Evolution of curing residual stresses in composite using multi-scale method[J]. Composites Part B: Engineering,2018,155:49-61. DOI: 10.1016/j.compositesb.2018.08.012

[41] 王晓霞, 贾玉玺, 董抒华. 基于 Morris 方法的纤维复合材料结构件固化均匀性的全局灵敏度分析[J]. 复合材料学报, 2015, 32(4):1211-1217. WANG Xiaoxia, JIA Yuxi, DONG Shuhua. Global sensitivity analysis of curing uniformity of fiber composite structures based on Morris method[J]. Acta Materiae Compositae Sinica,2015,32(4):1211-1217(in Chinese).

[42] ZHANG C, LI N, WANG W, et al. Progressive damage simulation of triaxially braided composite using a 3D meso-scale finite element model[J]. Composite Structures,2015,125:104-116. DOI: 10.1016/j.compstruct.2015.01.034

[43] 屈鹏. 纤维/树脂复合材料多尺度结构对力学性能的影响[D]. 济南: 山东大学, 2012. QU Peng. Influence of multiscale structure of fiber/resin composites on mechanical properties[D]. Ji'nan: Shandong University, 2012(in Chinese).

[44] WELLINGTON S L, VINEGAR H J. X-ray computerized tomography[J]. Journal of Petroleum Technology,1987,39(8):885-898. DOI: 10.2118/16983-PA

[45] MAYERHÖFER T G, PAHLOW S, POPP J. The Bouguer-Beer-Lambert law: Shining light on the obscure[J]. ChemPhysChem,2020,21(18):2029-2046. DOI: 10.1002/cphc.202000464

[46] GARCEA S C, WANG Y, WITHERS P J. X-ray computed tomography of polymer composites[J]. Composites Science and Technology,2018,156:305-319. DOI: 10.1016/j.compscitech.2017.10.023

[47] NIKISHKOV Y, AIROLDI L, MAKEEV A. Measurement of voids in composites by X-ray computed tomography[J]. Composites Science and Technology,2013,89:89-97. DOI: 10.1016/j.compscitech.2013.09.019

[48] FELDKAMP L A, DAVIS L C, KRESS J W. Practical cone-beam algorithm[J]. Journal of the Optical Society of America A,1984,1(6):612. DOI: 10.1364/JOSAA.1.000612

[49] GORDON R, BENDER R, HERMAN G T. Algebraic reconstruction techniques (ART) for three-dimensional electron microscopy and X-ray photography[J]. Journal of Theoretical Biology,1970,29(3):471-481. DOI: 10.1016/0022-5193(70)90109-8

[50] HAIDE R, FEST-SANTINI S, SANTINI M. Use of X-ray micro-computed tomography for the investigation of drying processes in porous media: A review[J]. Drying Technology,2021,40(9):1-14.

[51] ELBAKRI I A, FESSLER J A. Statistical image reconstruction for polyenergetic X-ray computed tomography[J]. IEEE Transactions on Medical Imaging,2002,21(2):89-99. DOI: 10.1109/42.993128

[52] WIELHORSKI Y, MENDOZA A, RUBINO M, et al. Numerical modeling of 3D woven composite reinforcements: A review[J]. Composites Part A: Applied Science and Manufacturing,2022,154:106729. DOI: 10.1016/j.compositesa.2021.106729

[53] GAO Y, HU W, XIN S, et al. A review of applications of CT imaging on fiber reinforced composites[J]. Journal of Composite Materials,2022,56(1):133-164. DOI: 10.1177/00219983211050705

[54] RASHIDI A, OLFATBAKHSH T, CRAWFORD B, et al. A review of current challenges and case study toward optimizing micro-computed X-ray tomography of carbon fabric composites[J]. Materials,2020,13(16):3606. DOI: 10.3390/ma13163606

[55] FLAY N, BROWN S, SUN W, et al. Effects of off-focal radiation on dimensional measurements in industrial cone-beam micro-focus X-ray computed tomography systems[J]. Precision Engineering,2020,66:472-481. DOI: 10.1016/j.precisioneng.2020.08.014

[56] HE P, ZHAO W, YANG B, et al. Void content reduction of composites with sensor-aided injection strategy in liquid composite molding process[J]. Materials Research Express,2021,8(7):075309. DOI: 10.1088/2053-1591/ac1532

[57] MADRA A, HAJJ N E, BENZEGGAGH M. X-ray microtomography applications for quantitative and qualitative analysis of porosity in woven glass fiber reinforced thermoplastic[J]. Composites Science and Technology,2014,95:50-58. DOI: 10.1016/j.compscitech.2014.02.009

[58] ALIYEVA S, ALABBAD A, DAZA J P, et al. Elasticity, electrical conductivity and permeability in digital rocks: A comparative study using simpleware, NIST, comsol multiphysics and lattice-boltzmann algorithms[C]//51st US Rock Mechanics/Geomechanics Symposium. California: ARMA, 2017.

[59] MILAN J L, PLANELL J A, LACROIX D. Computational modelling of the mechanical environment of osteogenesis within a polylactic acid-calcium phosphate glass scaffold[J]. Biomaterials,2009,30(25):4219-4226. DOI: 10.1016/j.biomaterials.2009.04.026

[60] 张于北, 王倩妮. VGStudio MAX 2.0软件在CT图像三维重建中的应用[J]. 计测技术, 2011, 31(5): 30-32. ZHANG Yubei, WANG Qianni. Application of software VGStudio MAX 2.0 in 3D reconstruction of industrial computed tomography images[J]. Metrology & Measurement Technology, 2011, 31(5): 30-32(in Chinese).

[61] KIKINIS R, PIEPER S D, VOSBURGH K G. 3D slicer: A platform for subject-specific image analysis, visualization, and clinical support[M]. Cham: Springer, 2014: 277-289.

[62] BIRD M B, BUTLER S L, HAWKES C D, et al. Numerical modeling of fluid and electrical currents through geometries based on synchrotron X-ray tomographic images of reservoir rocks using Avizo and COMSOL[J]. Computers & Geosciences,2014,73:6-16.

[63] RASSINEUX A. Robust conformal adaptive meshing of complex textile composites unit cells[J]. Composite Structures,2022,279:114740. DOI: 10.1016/j.compstruct.2021.114740

[64] WINTIBA B, VASIUKOV D, PANIER S, et al. Automated reconstruction and conformal discretization of 3D woven composite CT scans with local fiber volume fraction control[J]. Composite Structures,2020,248:112438. DOI: 10.1016/j.compstruct.2020.112438

[65] LIU X, ZHANG D, SUN J, et al. Refine reconstruction and verification of meso-scale modeling of three-dimensional five-directional braided composites from X-ray computed tomography data[J]. Composite Structures,2020,245:112347. DOI: 10.1016/j.compstruct.2020.112347

[66] ABRÀMOFF M D, MAGALHÃES P J, RAM S J. Image processing with ImageJ[J]. Biophotonics International,2004,11(7):36-42.

[67] YU X W, WANG H, WANG Z W. Analysis of yarn fiber volume fraction in textile composites using scanning electron microscopy and X-ray micro-computed tomography[J]. Journal of Reinforced Plastics and Composites,2018,38(5):199-210. DOI: 10.1177/0731684418811943

[68] TAO W, ZHU P, XU C, et al. Uncertainty quantification of mechanical properties for three-dimensional orthogonal woven composites. Part II: Multiscale simulation[J]. Composite Structures,2020,235:111764. DOI: 10.1016/j.compstruct.2019.111764

[69] TAO W, ZHU P, XU C, et al. Uncertainty quantification of mechanical properties for three-dimensional orthogonal woven composites. Part I: Stochastic reinforcement geometry reconstruction[J]. Composite Structures,2020,235:111763. DOI: 10.1016/j.compstruct.2019.111763

[70] 曹欣怡, 彭秀钟, 范进, 等. 一种改进的基于两单胞模型的三维角联锁机织复合材料弹性性能数值预测方法及实验验证[J]. 复合材料学报, 2021, 38(11):3704-3713. DOI: 10.13801/j.cnki.fhclxb.20210122.003 CAO Xinyi, PENG Xiuzhong, FAN Jin, et al. An improved numerical prediction method of elastic properties based on two unit-cells models for 3D angle-interlock woven composites and experimental verification[J]. Acta Materiae Compositae Sinica,2021,38(11):3704-3713(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210122.003

[71] 王童童. 三维编织复合材料的制备及面内拉伸和剪切性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019. WANG Tongtong. The fabrication and in-plane tensile and shear performance of 3D woven composites[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese).

[72] ISART N, EL SAID B, IVANOV D S, et al. Internal geometric modelling of 3D woven composites: A comparison between different approaches[J]. Composite Structures,2015,132:1219-1230. DOI: 10.1016/j.compstruct.2015.07.007

[73] AZIZ A R, ALI M A, ZENG X, et al. Transverse permeability of dry fiber preforms manufactured by automated fiber placement[J]. Composites Science and Technology,2017,152:57-67. DOI: 10.1016/j.compscitech.2017.09.011

[74] NAOUAR N, VIDAL-SALLE E, SCHNEIDER J, et al. 3D composite reinforcement meso F.E. analyses based on X-ray computed tomography[J]. Composite Structures,2015,132:1094-1104. DOI: 10.1016/j.compstruct.2015.07.005

[75] IWATA A, INOUE T, NAOUAR N, et al. Coupled meso-macro simulation of woven fabric local deformation during draping[J]. Composites Part A: Applied Science and Manufacturing,2019,118:267-280.

[76] NAOUAR N, VASIUKOV D, PARK C H, et al. Meso-FE modelling of textile composites and X-ray tomography[J]. Journal of Materials Science,2020,55(36):16969-16989. DOI: 10.1007/s10853-020-05225-x

[77] WIJAYA W, ALI M A, UMER R, et al. An automatic methodology to CT-scans of 2D woven textile fabrics to structured finite element and voxel meshes[J]. Composites Part A: Applied Science and Manufacturing,2019,125:105561. DOI: 10.1016/j.compositesa.2019.105561

[78] 钱浩. 平纹编织复合材料Micro CT成像试验与纤维束识别方法研究[D]. 长沙: 国防科学技术大学, 2015. QIAN Hao. Micro CT experiment and the method of yarn segmentation in plain-weave composites of Micro CT images[D]. Changsha: National University of Defense Technology, 2015(in Chinese).

[79] 宋永忠, 王俊山, 傅健. 多向编织C/C复合材料显微结构的µ-CT研究[J]. 宇航材料工艺, 2011, 41(2):105-109. SONG Yongzhong, WANG Junshan, FU Jian. Microstructure of 3D carbon/carbon composites measured with Micro-CT[J]. Aerospace Science and Technology,2011,41(2):105-109(in Chinese).

[80] BADRAN A, MARSHALL D, LEGAULT Z, et al. Automated segmentation of computed tomography images of fiber-reinforced composites by deep learning[J]. Journal of Materials Science,2020,55(34):16273-16289. DOI: 10.1007/s10853-020-05148-7

[81] STRAUMIT I, LOMOV S V, WEVERS M. Quantification of the internal structure and automatic generation of voxel models of textile composites from X-ray computed tomography data[J]. Composites Part A: Applied Science and Manufacturing,2015,69:150-158. DOI: 10.1016/j.compositesa.2014.11.016

[82] SINCHUK Y, KIBLEUR P, AELTERMAN J, et al. Variational and deep learning segmentation of very-low-contrast X-ray computed tomography images of carbon/epoxy woven composites[J]. Materials,2020,13(4):936. DOI: 10.3390/ma13040936

[83] YOUSAF Z, WITHERS P J, POTLURI P. Compaction, nesting and image based permeability analysis of multi-layer dry preforms by computed tomography (CT)[J]. Composite Structures,2021,263:113676. DOI: 10.1016/j.compstruct.2021.113676

[84] MADRA A, TROCHU F, BREITKOPF P. Implicit kriging model of fibrous reinforcements in composites based on X-ray microtomography[C]//13e Colloque National en Calcul des Structures. Giens: CSMA, 2017: 1-4.

[85] SAXENA N, HOFMANN R, ALPAK F O, et al. References and benchmarks for pore-scale flow simulated using Micro-CT images of porous media and digital rocks[J]. Advances in Water Resources,2017,109:211-235. DOI: 10.1016/j.advwatres.2017.09.007

[86] LIU Y, STRAUMIT I, VASIUKOV D, et al. Prediction of linear and non-linear behavior of 3D woven composite using mesoscopic voxel models reconstructed from X-ray micro-tomography[J]. Composite Structures,2017,179:568-579. DOI: 10.1016/j.compstruct.2017.07.066

[87] RINALDI R G, BLACKLOCK M, BALE H, et al. Generating virtual textile composite specimens using statistical data from micro-computed tomography: 3D tow representations[J]. Journal of the Mechanics and Physics of Solids,2012,60(8):1561-1581. DOI: 10.1016/j.jmps.2012.02.008

[88] ALI M A, UMER R, KHAN K A, et al. Application of X-ray computed tomography for the virtual permeability prediction of fiber reinforcements for liquid composite molding processes: A review[J]. Composites Science and Technology,2019,184:107828.

[89] SINCHUK Y, PANNIER Y, ANTORANZ-GONZALEZ R, et al. Analysis of moisture diffusion induced stress in carbon/epoxy 3D textile composite materials with voids by µ-CT based finite element models[J]. Composite Structures,2019,212:561-570. DOI: 10.1016/j.compstruct.2018.12.041

[90] DOITRAND A, FAGIANO C, IRISARRI F X, et al. Comparison between voxel and consistent meso-scale models of woven composites[J]. Composites Part A: Applied Science and Manufacturing,2015,73:143-154. DOI: 10.1016/j.compositesa.2015.02.022

[91] NAGAI Y, OHTAKE Y, SUZUKI H. Tomographic surface reconstruction from point cloud[J]. Computers & Graphics,2015,46:55-63.

[92] ZHAO Y, ZHU G, ZHANG C, et al. Pore-scale reconstruction and simulation of non-darcy flow in synthetic porous rocks[J]. Journal of Geophysical Research: Solid Earth,2018,123(4):2770-2786. DOI: 10.1002/2017JB015296

[93] TROCHU F. A contouring program based on dual kriging interpolation[J]. Engineering with Computers,1993,9(3):160-177. DOI: 10.1007/BF01206346

[94] MADRA A, BREITKOPF P, RAGHAVAN B, et al. Diffuse manifold learning of the geometry of woven reinforcements in composites[J]. Comptes Rendus Mécanique,2018,346(7):532-538.

[95] HUANG W, CAUSSE P, HU H, et al. Transverse compaction of 2D glass woven fabrics based on material twins—Part I: Geometric analysis[J]. Composite Structures,2020,237:111929. DOI: 10.1016/j.compstruct.2020.111929

[96] HUANG W, CAUSSE P, HU H, et al. Transverse compaction of 2D glass woven fabrics based on material twins—Part II: Tow and fabric deformations[J]. Composite Structures,2020,237:111963. DOI: 10.1016/j.compstruct.2020.111963

[97] BERGER M, TAGLIASACCHI A, SEVERSKY L, et al . State of the art in surface reconstruction from point clouds[C]// 35th Annual Conference of the European Association for Computer Graphics. Strasbourg: Eurographics, 2014: 161-185.

[98] KAMEL K E M, SONON B, MASSART T J. An integrated approach for the conformal discretization of complex inclusion-based microstructures[J]. Computational Mechanics,2019,64(4):1049-1071. DOI: 10.1007/s00466-019-01693-4

[99] SI H. TetGen, a Delaunay-based quality tetrahedral mesh generator[J]. ACM Transactions on Mathematical Software (TOMS),2015,41(2):1-36.

[100] SOLTANI P, JOHARI M S, ZARREBINI M. 3D fiber orientation characterization of nonwoven fabrics using X-ray micro-computed tomography[J]. World Journal of Textile Engineering and Technolog,2015,1:41-47.

[101] ARBTER R, BERAUD J M, BINETRUY C, et al. Experimental determination of the permeability of textiles: A benchmark exercise[J]. Composites Part A: Applied Science and Manufacturing,2011,42(9):1157-1168. DOI: 10.1016/j.compositesa.2011.04.021

[102] VERNET N, RUIZ E, ADVANI S, et al. Experimental determination of the permeability of engineering textiles: Benchmark II[J]. Composites Part A: Applied Science and Manufacturing,2014,61:172-184. DOI: 10.1016/j.compositesa.2014.02.010

[103] MAY D, AKTAS A, ADVANI S G, et al. In-plane permeability characterization of engineering textiles based on radial flow experiments: A benchmark exercise[J]. Composites Part A: Applied Science and Manufacturing,2019,121:100-114.

[104] SOLTANI P, JOHARI M S, ZARREBINI M. Effect of 3D fiber orientation on permeability of realistic fibrous porous networks[J]. Powder Technology,2014,254:44-56. DOI: 10.1016/j.powtec.2014.01.001

[105] ALI M A, UMER R, KHAN K A, et al. Non-destructive evaluation of through-thickness permeability in 3D woven fabrics for composite fan blade applications[J]. Aerospace Science and Technology,2018,82-83:520-533.

[106] TAHIR M W, HALLSTRÖM S, ÅKERMO M. Effect of dual scale porosity on the overall permeability of fibrous structures[J]. Composites Science and Technology,2014,103:56-62. DOI: 10.1016/j.compscitech.2014.08.008

[107] 曹鹏军, 赵文斌, 杨斌, 等. 基于Micro-CT图像的缎纹织物细观结构分析及渗透率预测[J]. 复合材料学报, 2023, 40(3):1751-1763. DOI: 10.13801/j.cnki.fhclxb.20220420.002 CAO Pengjun, ZHAO Wenbin, YANG Bin, et al. Meso-structure analysis and permeability prediction of satin fabric based on Micro-CT[J]. Acta Materiae Compositae Sinica,2023,40(3):1751-1763(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220420.002

[108] ALI M A, UMER R, KHAN K A, et al. In-plane virtual permeability characterization of 3D woven fabrics using a hybrid experimental and numerical approach[J]. Composites Science and Technology,2019,173:99-109.

[109] ALI M A, UMER R, KHAN K A, et al. XCT-scan assisted flow path analysis and permeability prediction of a 3D woven fabric[J]. Composites Part B: Engineering,2019,176:107320.

[110] SOULAINE C, GJETVAJ F, GARING C, et al. The impact of sub-resolution porosity of X-ray microtomography images on the permeability[J]. Transport in Porous Media,2016,113(1):227-243. DOI: 10.1007/s11242-016-0690-2

[111] RAEINI A Q, BIJELJIC B, BLUNT M J. Modelling capillary trapping using finite-volume simulation of two-phase flow directly on Micro-CT images[J]. Advances in Water Resources,2015,83:102-110. DOI: 10.1016/j.advwatres.2015.05.008

[112] NABOVATI A, SOUSA A C M. Fluid flow simulation at open-porous medium interface using the lattice Boltzmann method[J]. International Journal for Numerical Methods in Fluids,2008,56(8):1449-1456. DOI: 10.1002/fld.1614

[113] BELOV E B, LOMOV S V, VERPOEST I, et al. Modelling of permeability of textile reinforcements: Lattice Boltzmann method[J]. Composites Science and Technology,2004,64(7-8):1069-1080. DOI: 10.1016/j.compscitech.2003.09.015

[114] HUANG W, CAUSSE P, HU H, et al. Numerical and experimental investigation of saturated transverse permeability of 2D woven glass fabrics based on material twins[J]. Polymer Composites,2020,41(4):1341-1355. DOI: 10.1002/pc.25458

[115] DONG H, BLUNT M J. Pore-network extraction from micro-computerized-tomography images[J]. Physical Review E,2009,80(3):036307. DOI: 10.1103/PhysRevE.80.036307

[116] MAY D, AKTAS A, YONG A. International benchmark exercises of textile permeability and compressibility characterization[C]//18th European Conference on Composite Materials, Athens: ECCM, 2018: 24-28.

[117] ZHU J, WANG J, ZU L. Influence of out-of-plane ply waviness on elastic properties of composite laminates under uniaxial loading[J]. Composite Structures,2015,132:440-450. DOI: 10.1016/j.compstruct.2015.05.062

[118] CHEN B, CHOU T W. Compaction of woven-fabric preforms: Nesting and multi-layer deformation[J]. Composites Science and Technology,2000,60(12-13):2223-2231. DOI: 10.1016/S0266-3538(00)00017-8

[119] 吕青泉, 赵振强, 李超, 等. 2.5D 机织复合材料的渐进损伤与失效模拟[J]. 复合材料学报, 2021, 38(8):2747-2757. LYU Qingquan, ZHAO Zhenqiang, LI Chao, et al. Progressive damage and failure simulation of 2.5D woven composites[J]. Acta Materiae Compositae Sinica,2021,38(8):2747-2757(in Chinese).

[120] 曹勇, 张超. 薄层复合材料冲击损伤行为研究进展[J]. 航空学报, 2022, 43(6):147-163. CAO Yong, ZHANG Chao. Impact damage behavior of thin-ply composites: A review[J]. Acta Aeronautica et Astronautica Sinica,2022,43(6):147-163(in Chinese).

[121] ZHAO Z Q, LIU P, CHEN C Y. Modeling the transverse tensile and compressive failure behavior of triaxially braided composite[J]. Composites Science and Technology,2019,172:96-107. DOI: 10.1016/j.compscitech.2019.01.008

[122] PAN Q. Multi-scale modelling and material characterisation of textile composites for aerospace applications[J]. Computer Methods in Applied Mechanics and Engineering,2016,310:906-934. DOI: 10.1016/j.cma.2016.08.007

[123] ZHAO Z Q, LIU P, DANG H Y. Understanding the critical role of boundary conditions in meso-scale finite element simulation of braided composites[J]. Advanced Composites and Hybrid Materials,2022,5:39-49. DOI: 10.1007/s42114-021-00284-3

[124] AKPOYOMARE A I, OKEREKE M I, BINGLEY M S. Virtual testing of composites: Imposing periodic boundary conditions on general finite element meshes[J]. Composite Structures,2017,160:983-994. DOI: 10.1016/j.compstruct.2016.10.114

-

期刊类型引用(1)

1. 李登高,刘成霞. 有限元分析技术在织物力学性能领域的应用. 现代纺织技术. 2024(06): 129-141 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: