Experimental study on the pre-tightened tooth connection of carbon fiber reinforced polymer

-

摘要: 为探明桥梁用碳纤维增强树脂复合材料(CFRP)预紧力齿连接破坏模式和承载性能,以预紧力(23 MPa、34.6 MPa、53 MPa、64.5 MPa)、齿深(0.5 mm、1 mm、2 mm)、齿长(8 mm、16 mm、24 mm)和齿数(1道齿、3道齿和6道齿)为变化参数, 进行了共计68个预紧力齿连接接头拉伸试验。根据荷载-位移曲线、应变及破坏模式的测试结果,分析了各参数变化对复合材料预紧力齿连接接头力学性能的影响。研究结果表明:CFRP预紧力齿连接接头存在4种破坏模式−剪切破坏、压溃破坏、纵向劈裂和纤维拉断;接头荷载-位移曲线有两种特征,荷载在达到极值后突然下降及荷载在达到极值后缓慢下降,前者接头发生剪切或纤维拉断破坏,后者接头发生压溃或劈裂破坏;预紧力多齿接头荷载分配不均匀,发生压溃破坏的接头比发生剪切破坏的接头内力分配更均匀,不管接头发生压溃破坏还是剪切破坏,第一道齿承担的载荷分配比最大,齿数越多,接头的最大载荷分配比越小,当预紧力超过53 MPa时,预紧力变化对接头破坏时第一道齿的影响不明显;当预紧力、齿深和齿长分别小于53 MPa、2 mm和16 mm时,接头连接强度分别随预紧力、齿深和齿长的增加而增加,当预紧力和齿长分别超过53 MPa和16 mm时,接头连接强度变化不大,在6齿范围内,接头连接强度随齿数的增加而增加。

-

关键词:

- 桥梁工程 /

- 预紧力齿连接 /

- 试验 /

- 承载性能 /

- 碳纤维增强树脂复合材料

Abstract: To investigate the failure modes and load-bearing performance of pre-tightened tooth connections of carbon fiber reinforced polymer (CFRP) in the bridge engineering, a total of 68 tensile specimens were carried out with transverse pre-tightened force (23 MPa, 34.6 MPa, 53 MPa, 64.5 MPa), tooth depth (0.5 mm, 1 mm, 2 mm), tooth length (8 mm, 16 mm, 24 mm) and tooth number (one tooth, three teeth and six teeth) as variable parameters. According to the test results of load displacement curve, strain and failure mode, the effects of various parameters on the mechanical properties of the joint were analyzed. The results show that there are four failure modes for CFRP pre-tightened tooth joints: Shear failure, crushing failure, longitudinal splitting failure and fiber breaking failure. There are two characteristics of the load-displacement curves of the joint: The load drops suddenly after reaching the extreme value and the load decreases slowly after reaching the extreme value. The former joints are subjected to shear failure or fiber breaking failure, while the latter joint is subjected to crushing failure or splitting failure. The load distribution ratio of pre-tightened multi-tooth joints is uneven, the load distribution ratio of the joint with crushing failure is more uniform than that of joint with shear failure. Whether the joint is crushing or shear failure, the load distribution ratio of the first tooth is the largest. The more the number of joint teeth, the smaller the maximum load distribution ratio of the joint. When the pre-tightened force, tooth depth and tooth length are less than 53 MPa, 2 mm and 16 mm respectively, the joint strength increases with the increase of pre-tightened force, tooth depth and tooth length. When the pre-tightened force and tooth length exceed a certain value of 53 MPa and 16mm respectively, the joint connection strength changes little. In the range of 6 teeth, the joint strength increases with the increase of the number of teeth. -

纤维增强树脂复合材料(FRP)由于比强度、比刚度高、耐腐蚀和设计性强等特点,已经在桥梁工程中得到广泛的应用[1-6]。Teixeira等[7]研制的可拆拆卸式桁架桥、Sedlacek等[8]提出的玻璃纤维增强树脂复合材料(GFRP)桁架应急桥、Kostopoulos等[9]设计的FRP空间桁架交通桥、重庆的茅以升公益桥[10]和南京工业大学的拼装式徒步桥等[11]都采用了FRP作为桥梁结构的主承力构件。然而,FRP构件连接部分通常是FRP桥梁结构中的薄弱环节,限制了FRP作为主承力构件在大跨度和大承载桥梁结构中的应用,因此FRP连接部分的设计一直是研究者关注的重点和难点。

目前,针对FRP构件的连接方式主要采用胶连接、螺栓连接和胶螺混合连接[12-17]。Li等[18]研究了胶连接几何构型对接头强度的影响,发现胶接长度、胶接厚度、胶接宽度、胶接角等参数与接头强度之间不存在直接的正比关系;Palmieri等[19]研究了胶层属性对接头强度的影响,介绍了一种基于商用结构胶膜的自愈增韧环氧胶粘剂,提升了胶连接的断裂性能;蒋正文[20]通过试验确定了胶连接临界应力、临界应变及对应的6种基本破坏模式,进一步得到了半经验半理论的胶连接强度计算公式。尽管目前针对胶连接有大量的研究,但无法改变胶粘剂本身强度不高和胶层应力分布不均的事实,因此无法充分发挥构件强度。Giannopoulos等[21]通过试验发现对螺栓施加一定的扭矩对接头静强度和疲劳强度有明显的提高;Romanov等[22]对胶螺混合连接进行了参数化研究,发现板的搭接长度对接头强度有很大的影响;Zhao等[23]、Liu等[24-25]、房子昂等[26]、龚潇[27]、赵美英[28]、谢宗蕻等[29]和李想等[30]对复合材料多螺栓连接的荷载分配试验、计算方法和优化分配等进行了研究,结果表明多螺栓连接荷载平均分配难以在工程中实现。螺栓连接需要在构件上开孔,破坏了纤维的连续性,并且孔边缘与螺栓接触位置存在较大的应力集中,导致接头承载力较低。现有的复合材料连接技术无法充分发挥构件的强度,是限制FRP在大承载桥梁结构中应用的重要原因。

为了充分发挥FRP构件的强度,赵启林等[31-32]提出了一种主要适用于拉挤型FRP构件的新型连接技术—复合材料预紧力齿连接技术。该连接技术在连接处能提供很大的承载力,对于厚壁构件,能充分发挥构件的强度。该技术主要通过复合材料的层间抗剪传递荷载,而施加的径向预紧力提高了复合材料的层间剪切强度,因此具有很高的承载力。目前,该技术已经应用于大承载的复合材料空间桁架桥,Zhang等[33-36]对该桥的抗弯和抗扭性能进行了大量的研究,接头处的承载均满足试验和设计要求。

前期,研究者已经针对复合材料预紧力齿连接接头开展了大量的研究。李飞等[37-40]对GFRP预紧力单齿接头进行了大量的试验研究,发现接头具有剪切和压溃两种典型的破坏模式,提出了接头设计计算方法并通过改变齿形的方法提高了接头的强度;Gao等[41-43]分析了接头的传力机制,对单齿接头进行了强度预测,并简要分析了多齿接头荷载分配规律;高建岗[44]和柳锦春等[45-46]研究了接头的疲劳性能,发现预紧力齿连接具有很好的疲劳性能。尽管研究者已经针对复合材料预紧力齿连接的破坏模式、传力机制、设计计算方法和疲劳性能等方面进行了研究,但主要是针对GFRP进行的,较少研究碳纤维增强树脂复合材料(CFRP)接头,并且大多数研究对象都是单齿接头,尚未开展系统的针对CFRP预紧力齿连接单齿和多齿的试验研究。

为此,本文以预紧力、齿深、齿长和齿数为变化参数,对CFRP预紧力齿连接单齿和多齿接头进行系统的试验研究。根据荷载-位移曲线、应变及破坏模式的测试结果,比较分析各参数变化对复合材料预紧力齿连接接头力学性能的影响。最后分析了复合材料预紧力齿连接接头的连接强度。本文的研究为CFRP预紧力齿连接接头在桥梁工程中的应用提供了试验支撑和设计指导。

1. 试验设置

1.1 试件材料

试件主要有复合材料平板、金属板和螺栓3种材料。复合材料平板选用拉挤型碳纤维T700环氧复合材料,纤维走向以0°为主(纤维含量近70vol%),材料来源于深圳航宇碳纤维科技有限公司,型号为YT-200。复合材料板厚度13 mm,宽度17 mm,材料参数见表1。金属板采用钢板 Q345,厚度为10 mm,宽度取43 mm,材料参数见表2。螺栓:螺栓为全牙不锈钢12.9级M6的高强螺栓,螺栓的抗拉强度700 MPa,屈服强度450 MPa。

表 1 碳纤维增强树脂复合材料(CFRP)板力学参数Table 1. Mechanical parameters of carbon fiber reinforced polymer (CFRP) plateEa/GPa Eb/GPa Ec/GPa Gab/GPa υab Xt/MPa Xc/MPa Yt/MPa Yc/MPa Sab/MPa 108.9 8.8 8.8 3 0.33 1480 613.4 65 205 54 Notes: a—Fiber direction, whereas b and c are perpendicular to a. For example, Gab—Shear modulus in the plane a–b; Sab—Shear strength in the plane a–b; Xt and Xc—Tensile and compressive strengths, respectively, along the fiber direction; Yt and Yc—Tensile and compressive strengths perpendicular to the fiber direction; Ea, Eb, Ec—Elastic modulus in a, b and c directions, respectively; νab—Poisson's ratio in the plane a–b. 表 2 Q345钢板力学参数Table 2. Mechanical parameters of Q345 plateMaterial Young’s modulus/GPa Yield strength/MPa Poisson’s ratio Q345 210 345 0.3 1.2 试件分组

预紧力齿连接试件分组见表3。变化参数为预紧力、齿深、齿长和齿数,共计10组,每个试件编号设置2个试件,合计68个试件。试件的编号设置为nT-L-H-P,其中n表示齿数,L表示齿长,H表示齿深,P表示预紧力,比如6T-16-2-53表示6齿、齿长16 mm、齿深2 mm和53 MPa预紧力的试件。A组为预紧力变化试件组。B~J组所有试件预紧力相同,每组的各试件齿深和齿长相同而齿数变化。B~D组所有试件齿长8 mm,E~G组所有试件齿长16 mm,H~J组所有试件齿长24 mm,以上每3组试件齿深变化。

表 3 CFRP预紧力齿连接试件分组Table 3. Grouping of CFRP pre-tightened tooth specimensMaterial type Group Serial number Tooth

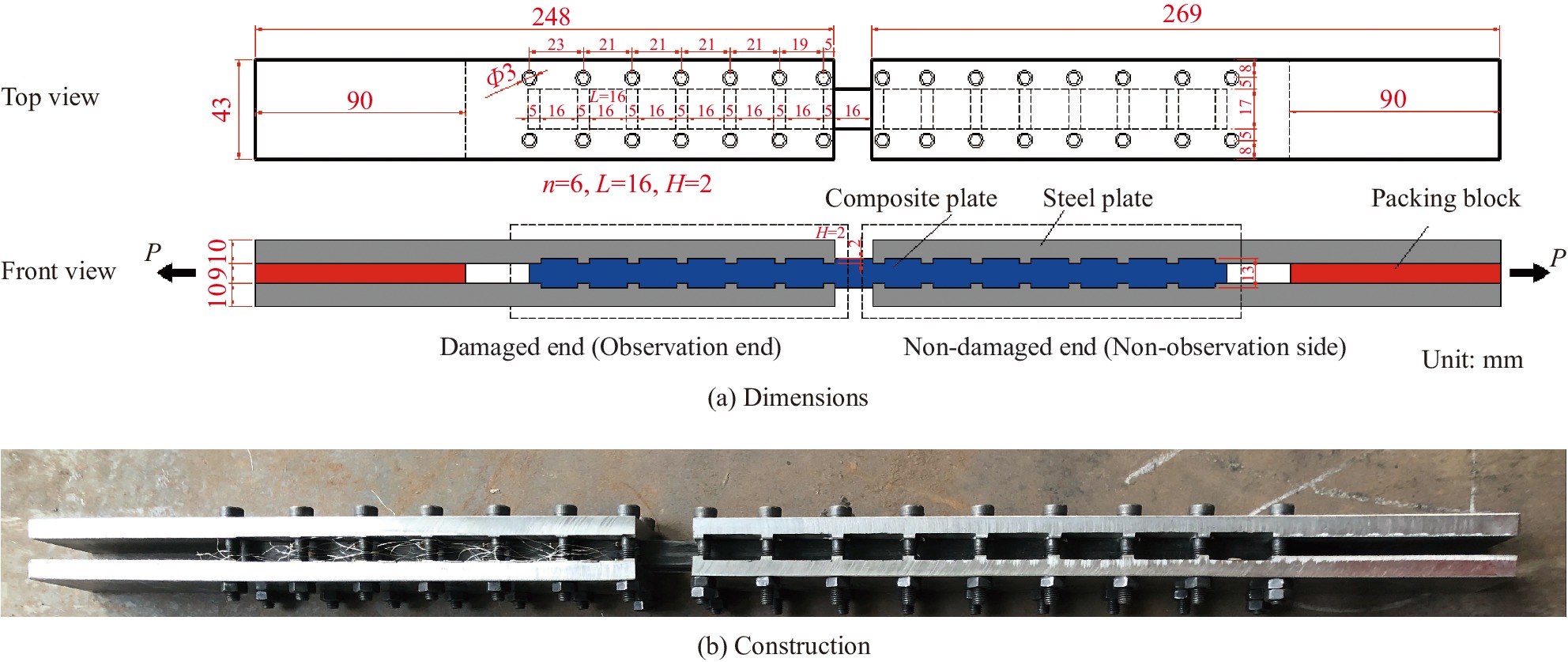

depth/mmTooth

length/mmPre-tightened

force/MPaTorque of

single bolt/(N·m)Number of

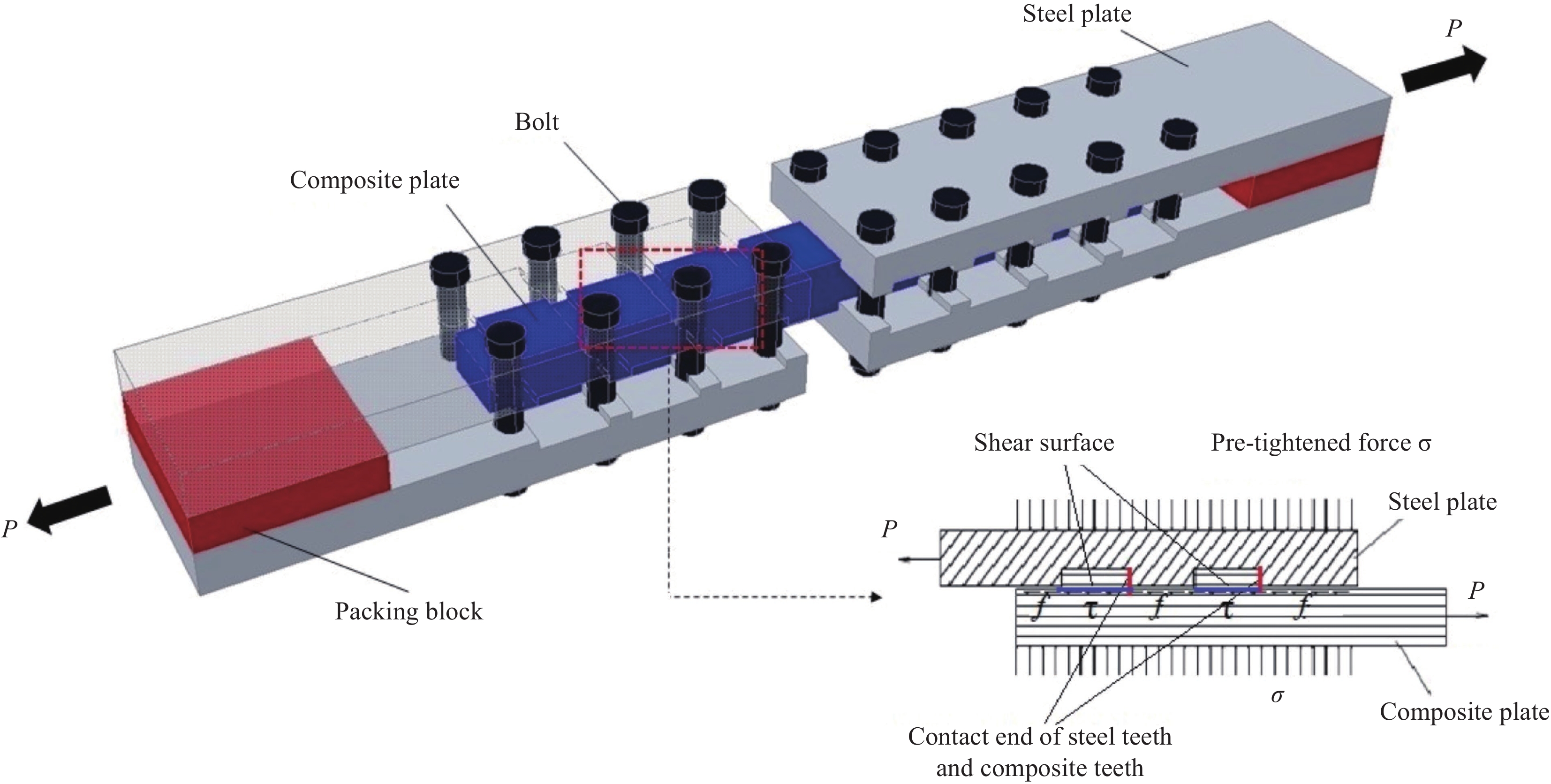

specimensCFRP A 6T-16-2-23 2 16 23 10 6 6T-16-2-34.6 34.6 15 6T-16-2-53 53 23 6T-16-2-64.5 64.5 28 B 1T-8-0.5-53 0.5 8 53 11.1 1 3T-8-0.5-53 13.5 3 6T-8-0.5-53 14.6 6 C 1T-8-1-53 1 11.1 1 3T-8-1-53 13.5 3 6T-8-1-53 14.6 6 D 1T-8-2-53 2 11.1 1 3T-8-2-53 13.5 3 6T-8-2-53 14.6 6 E 1T-16-0.5-53 0.5 16 53 16 1 3T-16-0.5-53 20.9 3 6T-16-0.5-53 23 6 F 1T-16-1-53 1 16 1 3T-16-1-53 20.9 3 6T-16-1-53 23 6 G 1T-16-2-53 2 16 1 2T-16-2-53 19.3 2 3T-16-2-53 20.9 3 4T-16-2-53 21.9 4 5T-16-2-53 22.5 5 6T-16-2-53 23 6 H 1T-24-0.5-53 0.5 24 53 20.9 1 3T-24-0.5-53 28.3 3 6T-24-0.5-53 31.4 6 I 1T-24-1-53 1 20.9 1 3T-24-1-53 28.3 3 6T-24-1-53 31.4 6 J 1T-24-2-53 2 20.9 1 3T-24-2-53 28.3 3 6T-24-2-53 31.4 6 Notes: Serial number nT-L-H-P, where n—Number of teeth; L—Tooth length; H—Tooth depth; P—Preloading force. 以6齿试件6T-16-2-53为例,试件的尺寸及构造如图1所示。为方便观察复合材料齿的破坏过程,将试件的其中一端作为破坏端(即观测端),而在接头的另一端多设置一道齿作为非破坏端(即非观测端),以确保试件破坏发生在观测端。图1(a)显示的是齿数为6、齿长16 mm、齿深2 mm的试件,其余试件的尺寸变化相应的齿数、齿深或齿长即可。预紧力齿连接接头是通过铣床加工而成。首先在复合材料板表面切割条状齿,之后在钢板上加工相匹配的齿形成。复合材料齿和金属齿必须要有较高的精度才能使复合材料板和钢板装配后紧密接触,而复合材料齿接触端与钢齿接触端是否紧密接触对接头力学性能有较大影响,6齿接头构造如图1(b)所示。复合材料预紧力齿连接通过复合材料板与钢板之间的摩擦及复合材料齿的层间抗剪传递荷载,而施加的径向预紧力提高了摩擦力和复合材料的层间剪切强度,因此具有很高的承载力,其传递荷载示意图如图2所示。

1.3 扭矩-预紧力转换

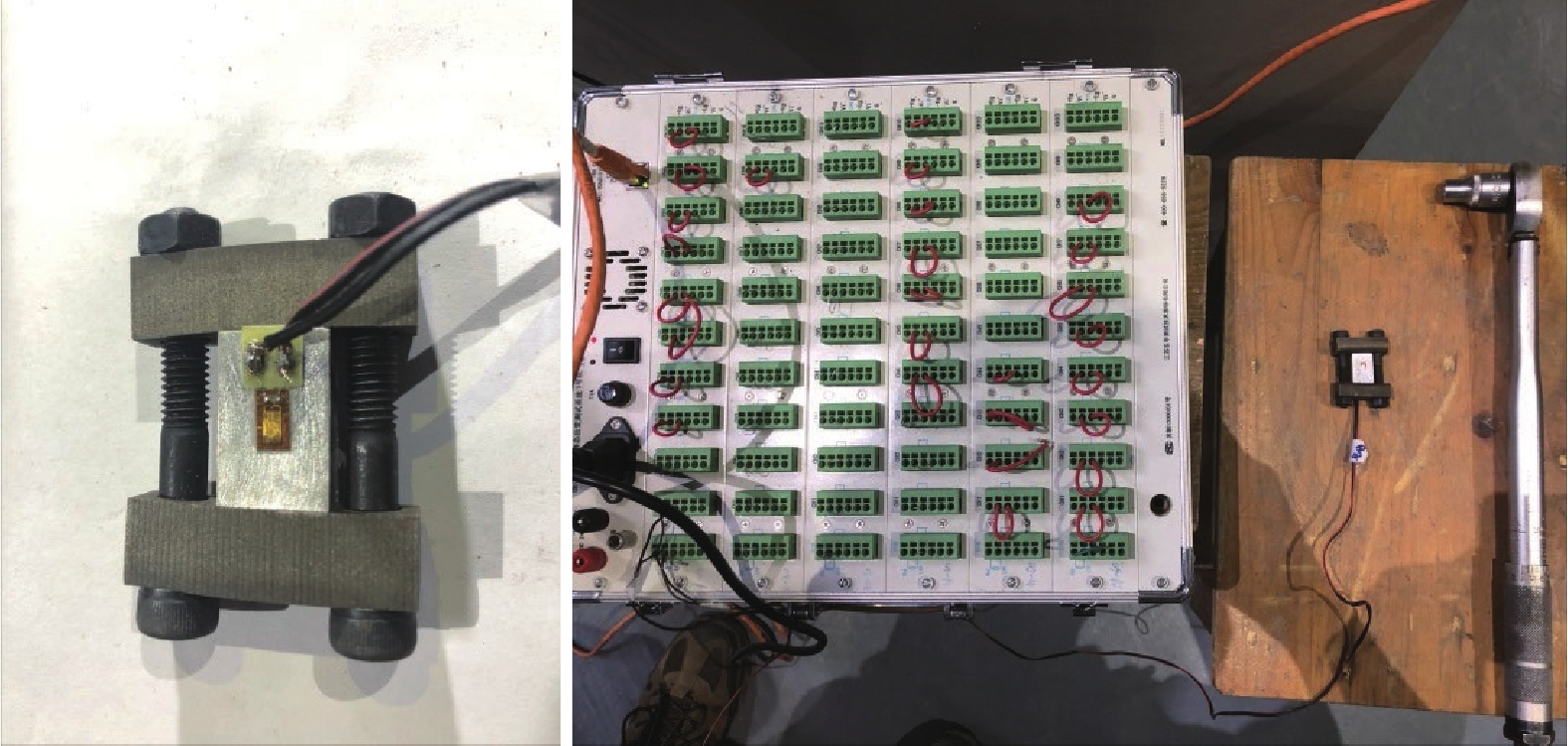

施加到复合材料齿上的预紧力是由螺杆的拉力提供,螺杆的拉力是由扭力扳手施加到螺栓上的扭矩提供。为得到施加到单个螺栓上的扭矩和试件所受预紧力之间的转换关系,设计了一个含铝合金块的夹具装置和试验,如图3所示。通过测量施加到螺栓上不同扭矩作用下铝合金块的应变,得到单个螺栓上的扭矩与单根螺杆拉力之间的关系。应变片正反两片纵向贴在铝合金中间,计算结果取平均应变值,测试了扭矩从12~26 N·m之间的应变,扭矩-平均应变和扭矩-螺杆拉力之间的关系见图4。

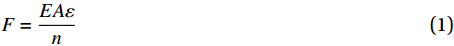

单根螺栓拉力为

F=EAεn (1) 式中:E为铝合金弹性模量,取72 GPa;A为铝合金截面积;

ε 为平均应变值;n为螺栓数量,取2。图4结果显示,单根螺栓拉力与扭矩之间呈线性关系,这表明在该扭矩范围内,铝合金尚未进入塑性阶段,因此,所得结果是可靠的。得到了单个螺栓上的扭矩与单根螺杆拉力之间的关系后,根据复合材料预紧力齿连接螺栓数量、复合材料板和钢板的接触面积,进一步得到施加到单个螺栓上的扭矩和试件所受预紧力之间的转换关系。各试件所施加到单个螺栓上的扭矩和试件所受预紧力大小见表3。

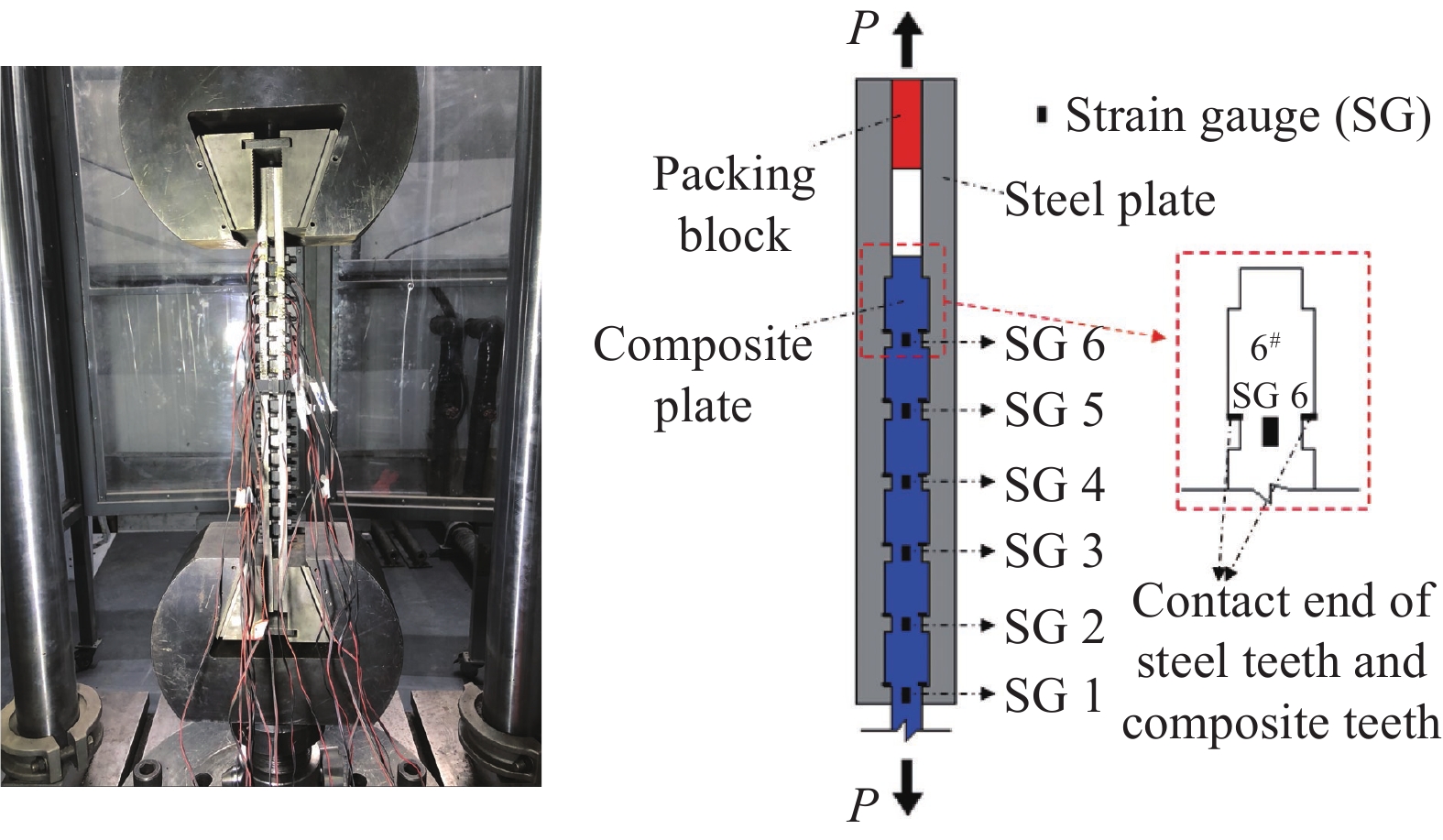

1.4 加载及测试

试验测试在200 t MTS上进行,位移控制,加载速率为2 mm/min,荷载-位移曲线由试验机自动记录,采集频率为1 Hz。应变片测点布置如图5所示(以6齿试件为例)。测量各复合材料齿齿槽位置的纵向应变(具体位置见图5),将测点位置的应变作为横截面上的平均应变,通过相邻应变片所测应变的差值计算各齿的荷载分配比。应变片采集频率为1 Hz,与荷载-位移曲线采集频率一致。每道齿承担的荷载为

pi=EA(εi−εi + 1) (2) 式中:

pi 是第i 道齿承担的荷载;εi 是第i 处的应变。各齿的荷载分配比为

n1=p1p,n2=p2p,n3=p3p,n4 = p4p,n5 = p5p,n6 = p6p (3) 式中,

p 是总的荷载值:p=EAε1 (4) 2. 试验结果及讨论

2.1 CFRP复合材料预紧力齿连接接头破坏模式

CFRP复合材料预紧力齿连接接头存在4种典型的破坏模式:(1) 复合材料齿的剪切破坏;(2) 复合材料齿的压溃破坏;(3) 复合材料板的纵向劈裂破坏;(4) 复合材料板的纤维断裂。4种破坏模式如图6所示。剪切和压溃破坏是复合材料预紧力齿连接最典型的两种破坏形式,纵向劈裂破坏和纤维断裂仅在多齿发生。劈裂破坏通常与压溃破坏同时发生,纤维拉断通常与压溃破坏或剪切破坏同时发生。

劈裂破坏的主要特征是沿复合材料板长度方向存在纵向裂纹。裂纹位于板的中部,垂直于剪切面。在试验过程中很难观察到裂纹的形成。从试件荷载-位移曲线的特征可以发现,纵向劈裂破坏不会导致荷载的突然降低。纤维断裂的主要特征是沿受力方向的纵向纤维拉伸断裂。纤维断裂后,接头不能承受载荷。纤维断裂一般发生在齿数较多、承载力较大的接头。

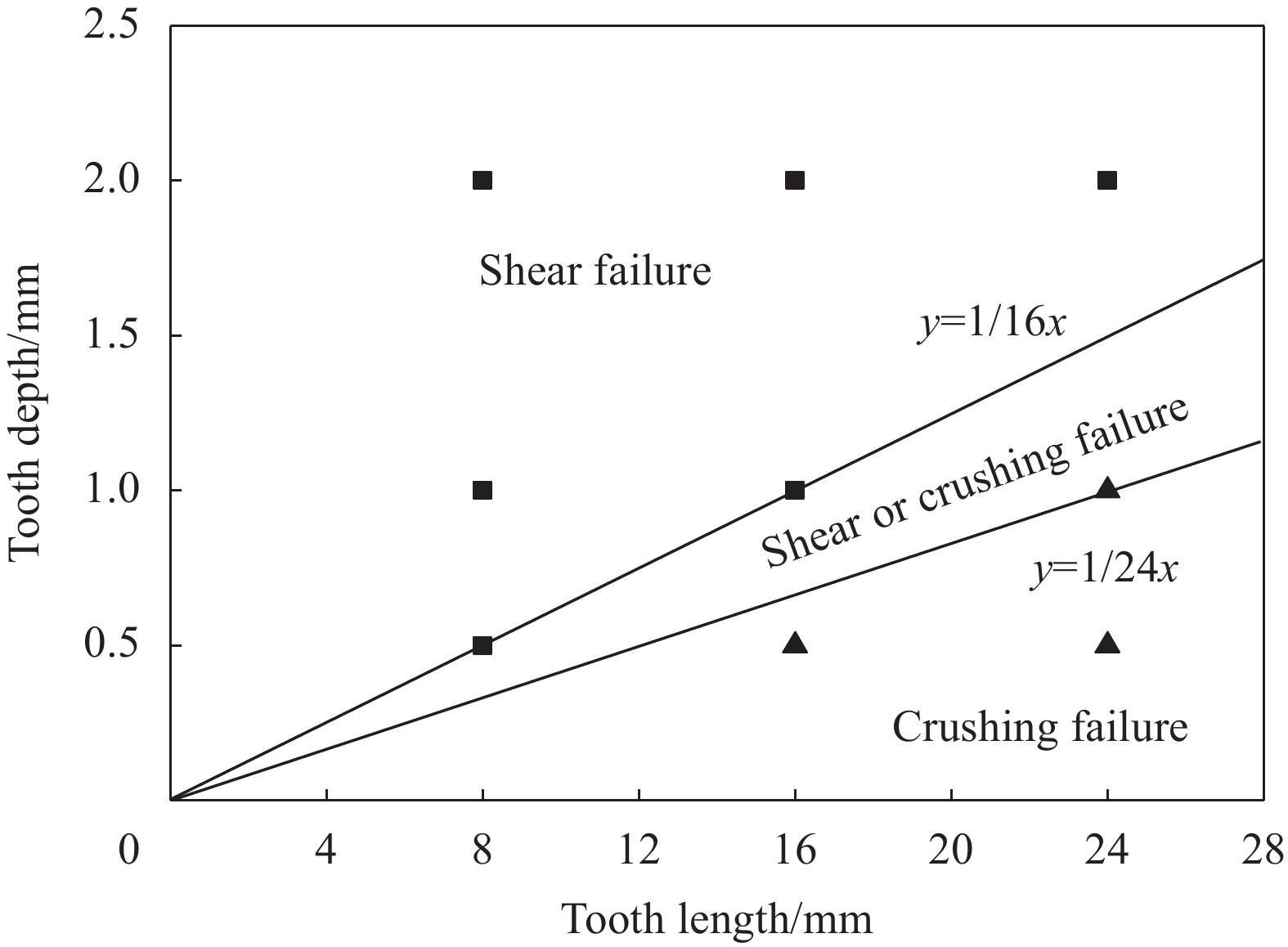

结果表明,预紧力变化对破坏模式没有影响,齿数增多可能导致接头发生劈裂或者纤维拉断破坏。齿深与齿长之比会影响接头发生剪切或者压溃破坏:当齿深/齿长小于1/24时,接头发生压溃破坏;当齿深/齿长大于1/16时,接头发生剪切破坏;当齿深/齿长介于1/24~1/16之间时,压溃破坏和剪切破坏都有可能发生,如图7所示。

2.2 CFRP复合材料预紧力齿连接接头荷载-位移曲线

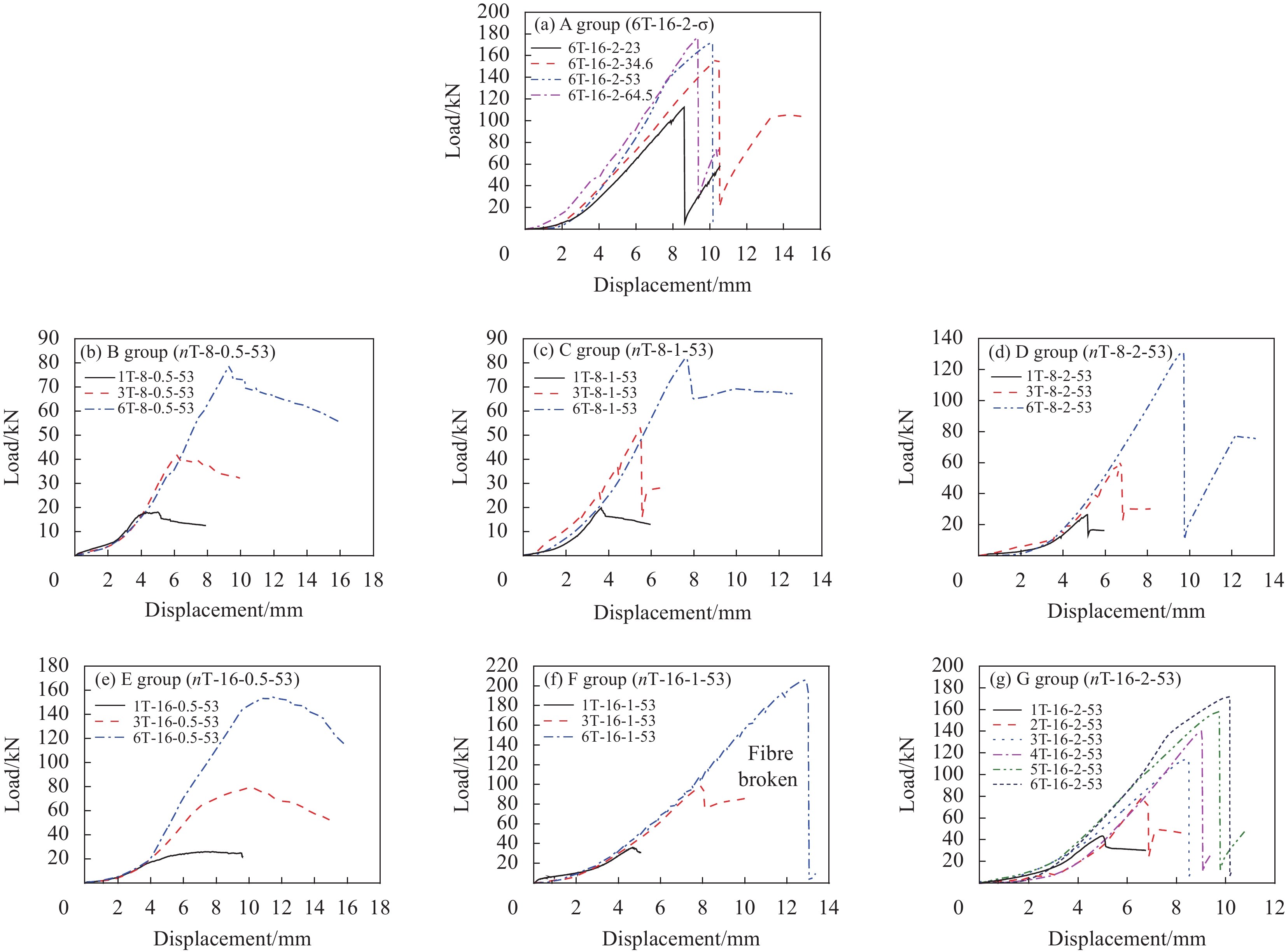

所有试件的荷载-位移曲线如图8所示(取每个试件编号的一个典型试件)。所有试件的荷载-位移曲线初期都存在明显的非线性特征,这是由于试件与夹具的滑移产生。从结果可知,预紧力齿连接荷载-位移曲线有两种特征,一种是荷载达到极限值后突然下降,此时试件主要发生剪切破坏或纤维拉断破坏;另一种是荷载达到极限值前后缓慢变化,此时试件发生压溃破坏或劈裂破坏。预紧力变化和齿数变化不会影响荷载-位移特征。齿深和齿长变化会影响试件的破坏模式,进一步影响荷载-位移特征。

2.3 CFRP复合材料预紧力齿连接接头内力分配规律

之所以复合材料预紧力齿连接接头能承担较大的外荷载,是因为接头的每道齿都承担了一定比例的荷载。为了探明预紧力齿连接的荷载分配规律,本文选取了发生压溃破坏的3齿接头3T-16-0.5-53,发生剪切破坏的3齿接头3T-16-2-53及发生剪切破坏的6齿接头6T-16-2-53和6T-16-2-64.5为研究对象,分析破坏模式、齿数和预紧力变化对荷载分配规律的影响。

3组试件的内力分配规律如图9所示,接头破坏时,接头各个齿的荷载分配比如表4所示。结果表明:(1) 无论何种失效模式,各齿的载荷分配比都是不均匀的;(2) 破坏模式影响载荷分布规律:对于多齿接头,压溃破坏的内力分配比剪切破坏的内力分配更均匀;(3) 不管接头发生压溃破坏还是剪切破坏,接头破坏时第一道齿承受最大的载荷分配比;(4) 齿数越多,接头的最大载荷分配比越小;(5) 当预紧力超过53 MPa时,预紧力变化对接头破坏时第一道齿的荷载分配比影响不明显。

表 4 CFRP复合材料预紧力齿连接接头破坏时各个齿的荷载分配比Table 4. Load distribution ratio of each tooth when CFRP pre-tightened tooth connection failureSerial

numberTooth

numberFailure

modesLoad distribution ratio 1# 2# 3# 4# 5# 6# 3T-16-0.5-53 3 Crushing 0.367 0.328 0.305 — — — 3T-16-2-53 3 Shear 0.426 0.232 0.342 — — — 6T-16-2-53 6 Shear 0.201 0.198 0.191 0.170 0.138 0.102 6T-16-2-64.5 6 Shear 0.198 0.120 0.196 0.172 0.171 0.143 2.4 CFRP复合材料预紧力齿连接接头极限承载力

表5为试验得到的复合材料预紧力齿连接承载力Pu平均值、连接强度σ和破坏模式。连接强度σ为

表 5 CFRP复合材料预紧力齿连接接头承载力Table 5. Bearing capacities of CFRP pre-tightened tooth connectionGroup Serial number Bearing capacity

P/kNAverage value of

bearing capacity Pu/kNConnection

strength σ/MPaFailure mode A 6T-16-2-23 112.48/130.53 121.51 549.82 Shear 6T-16-2-34.6 157.6/153.21 155.41 703.21 Shear 6T-16-2-53 171.6/180.54 176.07 796.70 Shear 6T-16-2-64.5 174/177.15 175.58 794.48 Shear B 1T-8-0.5-53 18.1/19 18.55 83.94 Shear 3T-8-0.5-53 41.57/45.72 43.65 197.51 Shear 6T-8-0.5-53 78.72/103.31 91.02 411.86 Shear C 1T-8-1-53 19.86/20 19.93 90.18 Shear 3T-8-1-53 53.47/55 54.24 245.43 Shear 6T-8-1-53 82.14/102.4 92.27 417.51 Shear D 1T-8-2-53 26.49/24 25.25 114.25 Shear 3T-8-2-53 52.52/60.96 56.74 256.74 Shear 6T-8-2-53 131.55/130 130.78 591.76 Shear E 1T-16-0.5-53 25.99/27.57 26.78 121.18 Crushing 3T-16-0.5-53 79.11/77.82 78.47 355.07 Crushing, spitting 6T-16-0.5-53 154.36/166.33 160.35 725.57 Crushing, spitting F 1T-16-1-53 34.9/37.05 35.98 162.81 Shear 3T-16-1-53 98.8/106.18 102.5 463.80 Shear 6T-16-1-53 172/205.8 188.9 854.75 Shear, fiber broken G 1T-16-2-53 43.3/43.95 43.63 197.42 Shear 2T-16-2-53 79.62/82.44 81.03 366.65 Shear 3T-16-2-53 99.3/114.08 106.69 482.76 Shear 4T-16-2-53 140/138.86 139.43 630.90 Shear 5T-16-2-53 157.85/170.66 164.26 743.26 Shear 6T-16-2-53 171.6/180.54 176.07 796.70 Shear H 1T-24-0.5-53 38.15/39 38.58 174.57 Crushing, spitting 3T-24-0.5-53 97.85/98 97.93 443.12 Crushing, spitting 6T-24-0.5-53 158.65/173.3 165.98 751.04 Crushing, fiber broken I 1T-24-1-53 41.65/42.9 42.28 191.31 Crushing 3T-24-1-53 127.98/125 126.49 572.35 Crushing 6T-24-1-53 186.58/192.06 189.32 856.65 Crushing, fiber broken J 1T-24-2-53 42.53/44 43.27 195.79 Shear 3T-24-2-53 115.25/86 100.62 455.29 Shear 6T-24-2-53 191/205.16 198.08 896.29 Shear σ = pudt (5) 式中:d是复合材料板宽,取17 mm;t是复合材料板厚,取13 mm。

3. CFRP复合材料预紧力齿连接接头承载力影响因素

3.1 CFRP复合材料的预紧力

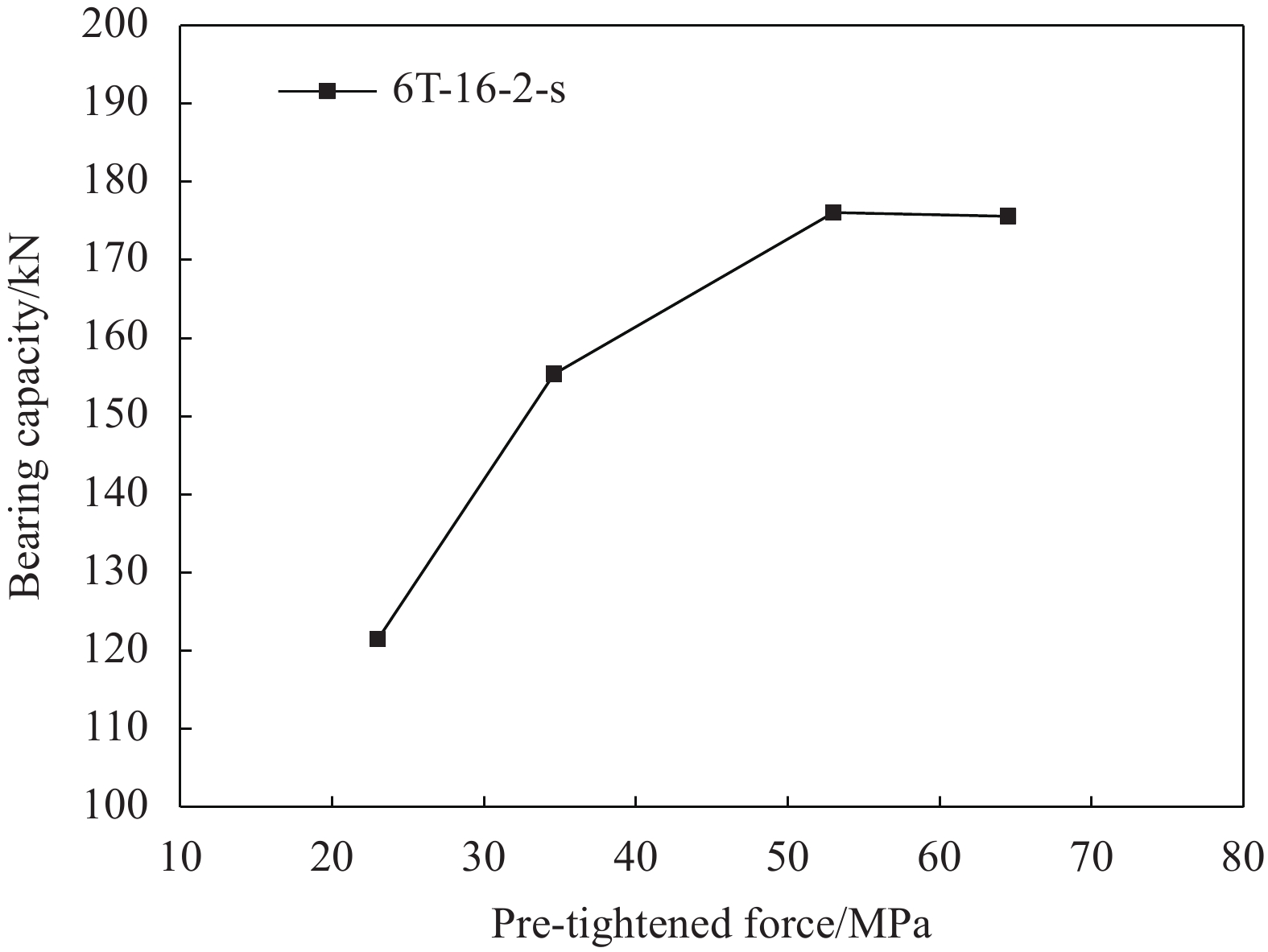

图10显示A组试件接头极限承载力随预紧力的变化规律。结果表明,在预紧力为53 MPa范围内,多齿接头极限承载力随预紧力增加而增加,当预紧力达到53 MPa之后,承载力基本保持稳定。

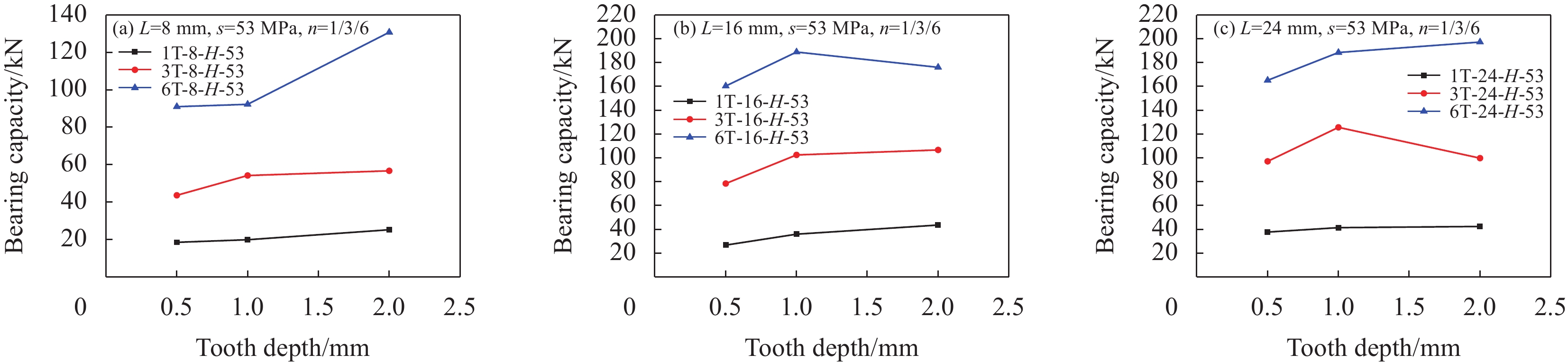

3.2 CFRP复合材料的齿深

图11(a)~11(c)分别显示了齿长8 mm、16 mm和24 mm的接头极限承载力随齿深的变化规律。结果表明,大多数接头承载力随齿深的增加而增加。这是由于齿深与齿长大小的相互关系会影响接头破坏模式(图7)与接头承载力:当齿深较小而齿长相对较长时,接头更容易发生压溃破坏,此时接头承载力主要受压溃破坏的影响;当齿深较大而齿长相对较短时,接头更容易发生剪切破坏,此时接头承载力主要受剪切破坏的影响。接头通过复合材料齿抗剪相对齿的压溃能传递更大的荷载,但接头承载力不会随着齿深的继续增加而明显增加,这是由于齿深较大的接头都发生剪切破坏。因此,大多数接头承载力随齿深的增加而增加,但是承载力会在齿深增大到某个值时其增幅会变缓,这是由于破坏模式从压溃破坏逐渐趋向于发生剪切破坏导致,典型的就是齿长16 mm的接头。

3.3 CFRP复合材料的齿长

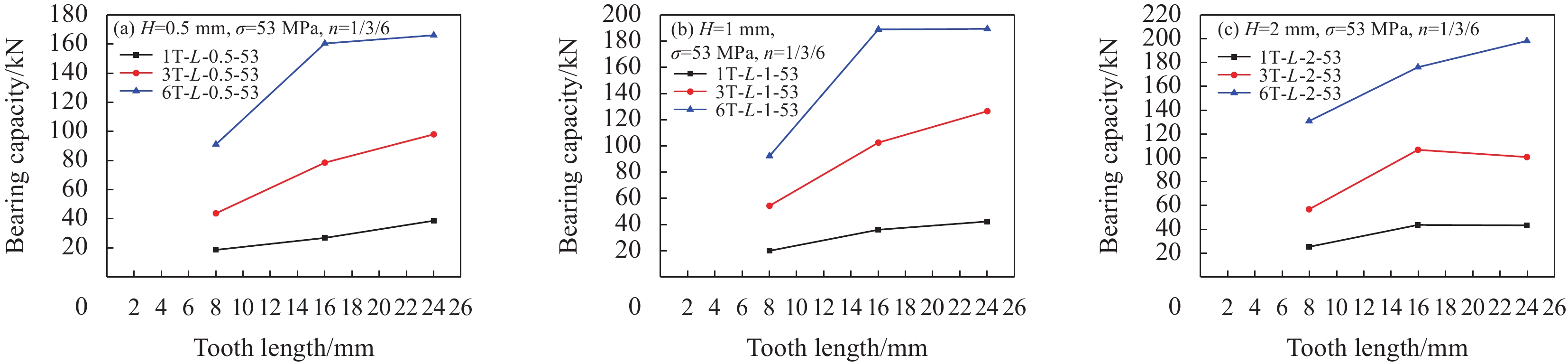

图12(a)~12(c)分别显示了齿深0.5 mm、1 mm和2 mm的接头极限承载力随齿长的变化规律。结果表明,接头承载力随齿长的增加而增加,但是当齿长大于16 mm时,接头承载力增加的幅度变缓。其原因在于在外荷载作用下,复合材料预紧力齿属于双向受剪状态,剪切面的抗剪应力两端大中间小,当齿长较大时,复合材料齿中间部分基本不受剪力,即复合材料齿存在有效齿长。在有效齿长内,接头承载力随齿长增加而增加,当齿长超过有效齿长时,接头承载力随齿长变化的趋势不明显。

3.4 齿数

图13(a)~13(c)分别显示了齿长8 mm、16 mm和24 mm的接头极限承载力随齿数的变化规律。结果表明,在6齿范围内,接头承载力随齿数的增加而增加,即每道齿都承担了一定比例的外荷载;从各曲线的变化趋势可以发现,接头承载力随齿数的增加并非呈线性关系,并且多齿接头承载力与单齿接头承载力的比值小于齿的数量,这表明多齿接头的各道齿并非承担相同比例的荷载。实际上,多齿接头的破坏取决于承担荷载比例最大的第一道齿的破坏,如图8所示。

4. CFRP复合材料预紧力齿连接接头连接强度

图14显示了CFRP预紧力多齿接头在6齿范围内所有试件的连接强度。结果表明,复合材料预紧力齿连接接头具有较高的连接强度,最大连接强度达896.29 MPa。结合表5可知,接头的连接强度受预紧力、齿深、齿长和齿数的影响较大:当预紧力在53 MPa范围内时,接头连接强度随预紧力的增加而增加,当预紧力超过53 MPa时,接头连接强度变化不大;当齿深在一定范围内时,接头连接强度随齿深增加而增加,当齿深超过一定值时,接头连接强度变化不大;当齿长在16 mm范围内时,接头连接强度随齿长增加而增加,当齿长超过16 mm时,接头连接强度变化不大;在6齿范围内,接头连接强度随齿数的增加而增加。尽管复合材料预紧力多齿连接强度较高,但仍然与复合材料板的抗拉强度存在一定的差距,如何提高预紧力齿连接的连接强度,是以后需要继续进行的研究。

5. 结 论

针对碳纤维增强树脂复合材料(CFRP)预紧力齿连接接头进行了系统的试验研究,得到以下结论:

(1) CFRP复合材料预紧力齿连接接头存在4种典型的破坏模式:复合材料齿的剪切破坏、复合材料齿的压溃破坏、复合材料板的纵向劈裂破坏和复合材料板的纤维断裂。

(2) 预紧力齿连接接头荷载-位移曲线有两种特征,即荷载达到极值后突然下降和达到极限值后缓慢下降,前者接头发生剪切或纤维拉断破坏,后者发生压溃破坏或劈裂破坏。

(3) 预紧力多齿接头的各齿荷载分配比是不均匀的。发生压溃破坏的各齿内力分配比发生剪切破坏的内力分配更均匀。不管接头发生压溃破坏还是剪切破坏,接头破坏时第一道齿承担的载荷分配比最大。在6齿范围内,接头齿数越多,接头的最大载荷分配比越小。当预紧力超过53 MPa时,预紧力变化对接头破坏时第一道齿的荷载分配比影响不明显。

(4) 复合材料预紧力齿连接接头具有较高的连接强度,最大连接强度达896.2 MPa。接头的连接强度受预紧力、齿深、齿长和齿数的影响较大:当预紧力在53 MPa范围内时,接头连接强度随预紧力的增加而增加,当预紧力超过53 MPa时,接头连接强度变化不大;当齿深在一定范围内时,接头连接强度随齿深增加而增加,当齿深超过一定值时,接头连接强度变化不大;当齿长在16 mm范围内时,接头连接强度随齿长增加而增加,当齿长超过16 mm时,接头连接强度变化不大;在6齿范围内,接头连接强度随齿数的增加而增加。

(5) CFRP预紧力齿连接接头在桥梁工程中的应用提供了试验支撑,但桥梁用接头影响因素复杂,仍需开展更多的损伤分析、多尺度有限元模拟和疲劳研究,为CFRP预紧力齿连接接头在桥梁中的应用提供更多的理论支撑。

-

表 1 碳纤维增强树脂复合材料(CFRP)板力学参数

Table 1 Mechanical parameters of carbon fiber reinforced polymer (CFRP) plate

Ea/GPa Eb/GPa Ec/GPa Gab/GPa υab Xt/MPa Xc/MPa Yt/MPa Yc/MPa Sab/MPa 108.9 8.8 8.8 3 0.33 1480 613.4 65 205 54 Notes: a—Fiber direction, whereas b and c are perpendicular to a. For example, Gab—Shear modulus in the plane a–b; Sab—Shear strength in the plane a–b; Xt and Xc—Tensile and compressive strengths, respectively, along the fiber direction; Yt and Yc—Tensile and compressive strengths perpendicular to the fiber direction; Ea, Eb, Ec—Elastic modulus in a, b and c directions, respectively; νab—Poisson's ratio in the plane a–b. 表 2 Q345钢板力学参数

Table 2 Mechanical parameters of Q345 plate

Material Young’s modulus/GPa Yield strength/MPa Poisson’s ratio Q345 210 345 0.3 表 3 CFRP预紧力齿连接试件分组

Table 3 Grouping of CFRP pre-tightened tooth specimens

Material type Group Serial number Tooth

depth/mmTooth

length/mmPre-tightened

force/MPaTorque of

single bolt/(N·m)Number of

specimensCFRP A 6T-16-2-23 2 16 23 10 6 6T-16-2-34.6 34.6 15 6T-16-2-53 53 23 6T-16-2-64.5 64.5 28 B 1T-8-0.5-53 0.5 8 53 11.1 1 3T-8-0.5-53 13.5 3 6T-8-0.5-53 14.6 6 C 1T-8-1-53 1 11.1 1 3T-8-1-53 13.5 3 6T-8-1-53 14.6 6 D 1T-8-2-53 2 11.1 1 3T-8-2-53 13.5 3 6T-8-2-53 14.6 6 E 1T-16-0.5-53 0.5 16 53 16 1 3T-16-0.5-53 20.9 3 6T-16-0.5-53 23 6 F 1T-16-1-53 1 16 1 3T-16-1-53 20.9 3 6T-16-1-53 23 6 G 1T-16-2-53 2 16 1 2T-16-2-53 19.3 2 3T-16-2-53 20.9 3 4T-16-2-53 21.9 4 5T-16-2-53 22.5 5 6T-16-2-53 23 6 H 1T-24-0.5-53 0.5 24 53 20.9 1 3T-24-0.5-53 28.3 3 6T-24-0.5-53 31.4 6 I 1T-24-1-53 1 20.9 1 3T-24-1-53 28.3 3 6T-24-1-53 31.4 6 J 1T-24-2-53 2 20.9 1 3T-24-2-53 28.3 3 6T-24-2-53 31.4 6 Notes: Serial number nT-L-H-P, where n—Number of teeth; L—Tooth length; H—Tooth depth; P—Preloading force. 表 4 CFRP复合材料预紧力齿连接接头破坏时各个齿的荷载分配比

Table 4 Load distribution ratio of each tooth when CFRP pre-tightened tooth connection failure

Serial

numberTooth

numberFailure

modesLoad distribution ratio 1# 2# 3# 4# 5# 6# 3T-16-0.5-53 3 Crushing 0.367 0.328 0.305 — — — 3T-16-2-53 3 Shear 0.426 0.232 0.342 — — — 6T-16-2-53 6 Shear 0.201 0.198 0.191 0.170 0.138 0.102 6T-16-2-64.5 6 Shear 0.198 0.120 0.196 0.172 0.171 0.143 表 5 CFRP复合材料预紧力齿连接接头承载力

Table 5 Bearing capacities of CFRP pre-tightened tooth connection

Group Serial number Bearing capacity

P/kNAverage value of

bearing capacity Pu/kNConnection

strength σ/MPaFailure mode A 6T-16-2-23 112.48/130.53 121.51 549.82 Shear 6T-16-2-34.6 157.6/153.21 155.41 703.21 Shear 6T-16-2-53 171.6/180.54 176.07 796.70 Shear 6T-16-2-64.5 174/177.15 175.58 794.48 Shear B 1T-8-0.5-53 18.1/19 18.55 83.94 Shear 3T-8-0.5-53 41.57/45.72 43.65 197.51 Shear 6T-8-0.5-53 78.72/103.31 91.02 411.86 Shear C 1T-8-1-53 19.86/20 19.93 90.18 Shear 3T-8-1-53 53.47/55 54.24 245.43 Shear 6T-8-1-53 82.14/102.4 92.27 417.51 Shear D 1T-8-2-53 26.49/24 25.25 114.25 Shear 3T-8-2-53 52.52/60.96 56.74 256.74 Shear 6T-8-2-53 131.55/130 130.78 591.76 Shear E 1T-16-0.5-53 25.99/27.57 26.78 121.18 Crushing 3T-16-0.5-53 79.11/77.82 78.47 355.07 Crushing, spitting 6T-16-0.5-53 154.36/166.33 160.35 725.57 Crushing, spitting F 1T-16-1-53 34.9/37.05 35.98 162.81 Shear 3T-16-1-53 98.8/106.18 102.5 463.80 Shear 6T-16-1-53 172/205.8 188.9 854.75 Shear, fiber broken G 1T-16-2-53 43.3/43.95 43.63 197.42 Shear 2T-16-2-53 79.62/82.44 81.03 366.65 Shear 3T-16-2-53 99.3/114.08 106.69 482.76 Shear 4T-16-2-53 140/138.86 139.43 630.90 Shear 5T-16-2-53 157.85/170.66 164.26 743.26 Shear 6T-16-2-53 171.6/180.54 176.07 796.70 Shear H 1T-24-0.5-53 38.15/39 38.58 174.57 Crushing, spitting 3T-24-0.5-53 97.85/98 97.93 443.12 Crushing, spitting 6T-24-0.5-53 158.65/173.3 165.98 751.04 Crushing, fiber broken I 1T-24-1-53 41.65/42.9 42.28 191.31 Crushing 3T-24-1-53 127.98/125 126.49 572.35 Crushing 6T-24-1-53 186.58/192.06 189.32 856.65 Crushing, fiber broken J 1T-24-2-53 42.53/44 43.27 195.79 Shear 3T-24-2-53 115.25/86 100.62 455.29 Shear 6T-24-2-53 191/205.16 198.08 896.29 Shear -

[1] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006(3):24-36. DOI: 10.3321/j.issn:1000-131X.2006.03.004 YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006(3):24-36(in Chinese). DOI: 10.3321/j.issn:1000-131X.2006.03.004

[2] WANG X, PENG Z Q, WU Z S, et al. High-performance composite bridge deck with prestressed basalt fiber-reinforced polymer shell and concrete[J]. Engineering Structures,2019,201:109852. DOI: 10.1016/j.engstruct.2019.109852

[3] 刘路路, 汪昕, 吴智深. 基于构件-节点一体化设计纤维增强复合材料桁架结构节点性能研究[J]. 工业建筑, 2019, 49(9):109-112, 172. LIU Lulu, WANG Xin, WU Zhishen, et al. Research on connection performance of FRP truss structure based on integrated performance of member and connection[J]. Industrial Construction,2019,49(9):109-112, 172(in Chinese).

[4] 徐以扬, 方海, 刘伟庆. 复合材料拉挤型材在桁架桥梁结构中的应用与发展[J]. 世界桥梁, 2010(4):32-34, 38. XU Yiyang, FANG Hai, LIU Weiqing. Application and de-velopment of composite pultruded profiles in truss bridge structures[J]. World Bridges,2010(4):32-34, 38(in Chinese).

[5] 白玉磊, 梅世杰, 张玉峰, 等. 基于刚度的大应变 FRP 约束混凝土模型及其在桥梁抗震加固中的应用[J]. 中国公路学报, 2022, 35(2):115-123. DOI: 10.3969/j.issn.1001-7372.2021.01.001 BAI Yulei, MEI Shijie, ZHANG Yufeng, et al. Stiffness-based design-oriented model for large-rupture-strain (LRS) FRP-confined concrete and its application in seismic analysis of bridge retrofitting[J]. China Journal of Highway and Transport,2022,35(2):115-123(in Chinese). DOI: 10.3969/j.issn.1001-7372.2021.01.001

[6] 滕锦光. 新材料组合结构[J]. 土木工程学报, 2018, 51(12):1-11. TENG Jinguang. New-material hybrid structures[J]. China Civil Engineering Journal,2018,51(12):1-11(in Chinese).

[7] TEIXEIRA A, PFEIL M S, BATTISTA R C. Structural evaluation of a GFRP truss girder for a deployable bridge[J]. Composite Structures,2014,110(4):29-38.

[8] SEDLACEK G, TRUMPF H, CASTRISCHER U. Development of a light-weight emergency bridge[J]. Structural Engineering International,2004,14(4):282-287. DOI: 10.2749/101686604777963702

[9] KOSTOPOULOS V, MARKOPOULOS Y P, VLACHOS D E, et al. Design and construction of a vehicular bridge made of glass/polyester pultruded box beams[J]. Plastics Rubber and Composites,2005,34(4):201-207. DOI: 10.1179/174328905X55641

[10] 冯鹏, 田野, 覃兆平. 纤维增强复合材料拉挤型材桁架桥静动力性能研究[J]. 工业建筑, 2013, 43(6):36-41. FENG peng, TIAN Ye, QIN Zhaoping. Static and dynamic behevior of a truss bridge made of pultruded profiles[J]. Industrial Construction,2013,43(6):36-41(in Chinese).

[11] FANG H, BAI Y, LIU W Q, et al. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments[J]. Composites Part B: Engineering,2019,164:129-143. DOI: 10.1016/j.compositesb.2018.11.047

[12] ZHANG T, LUO W, XIAO W, et al. Numerical simulation of single-lap adhesive joint of composite laminates[J]. Jour-nal of Reinforced Plastics and Composites,2018,37(8):520-532. DOI: 10.1177/0731684418754358

[13] SHANG X, MARQUES E, CARBAS R, et al. Fracture mechanism of adhesive single-lap joints with composite adherends under quasi-static tension[J]. Composite Structures,2020,251:112639.

[14] 刘玉擎, 都骜, 辛灏辉, 等. 拉挤GFRP型材层合板螺栓连接试验[J]. 中国公路学报, 2017, 30(6):223-229. DOI: 10.3969/j.issn.1001-7372.2017.06.005 LIU Yuqing, DU Ao, XIN Haohui, et al. Experiment on bolted joints of pultruded GFRP laminates[J]. China Jour-nal of Highway and Transport,2017,30(6):223-229(in Chinese). DOI: 10.3969/j.issn.1001-7372.2017.06.005

[15] 毛振刚, 侯玉亮, 李成, 等. 搭接长度和铺层方式对CFRP复合材料层合板胶接结构连接性能和损伤行为的影响[J]. 复合材料学报, 2020, 37(1):121-131. MAO Zhen'gang, HOU Yuliang, LI Cheng, et al. Effect of lap length and stacking sequence on strength and damage behaviors of adhesively bonded CFRP composite laminates[J]. Acta Materiae Compositae Sinica,2020,37(1):121-131(in Chinese).

[16] CHENG X, WANG S, ZHANG J, et al. Effect of damage on failure mode of multi-bolt composite joints using failure envelope method[J]. Composite Structures,2017,160:8-15. DOI: 10.1016/j.compstruct.2016.10.042

[17] 赵丽滨, 徐吉峰. 先进复合材料连接结构分析方法[M]. 北京: 北京航空航天大学出版社, 2015. ZHAO Libin, XU Jifeng. Analytical methods for advanced composite joint structures[M]. Beijing: Beihang University Press, 2015(in Chinese).

[18] LI J, YAN Y, ZHANG T, et al. Experimental study of adhesively bonded CFRP joints subjected to tensile loads[J]. International Journal of Adhesion and Adhesives,2015,57:95-104. DOI: 10.1016/j.ijadhadh.2014.11.001

[19] PALMIERI F L, BELCHER M A, WOHL C J, et al. Laser ablation surface preparation for adhesive bonding of carbon fiber reinforced epoxy composites[J]. International Jour-nal of Adhesion and Adhesives,2016,68:95-101. DOI: 10.1016/j.ijadhadh.2016.02.007

[20] 蒋正文. GFRP桥面板胶接界面力学性能研究[D]. 南京: 东南大学, 2018. JIANG Zhengwen. Research of mechanical properties for adhesively bonded joint in gfrp bridge deck[D]. Nanjing: Southeast University, 2018(in Chinese).

[21] GIANNOPOULOS I K, DORONIDAWES D, KOUROUSIS K I, et al. Effects of bolt torque tightening on the strength and fatigue life of airframe FRP laminate bolted joints[J]. Composites Part B: Engineering,2017,125(12):19-26.

[22] ROMANOV V S, HEIDARI RARANI M, LESSARD L. A parametric study on static behavior and load sharing of multi-bolt hybrid bonded/bolted composite joints[J]. Compo-sites Part B: Engineering,2021,217:108897. DOI: 10.1016/j.compositesb.2021.108897

[23] ZHAO L B, FANG Z, LIU F R, et al. A modified stiffness method considering effects of hole tensile deformation on bolt load distribution in multi-bolt composite joints[J]. Composite Part B: Engineering,2019,171:264-271. DOI: 10.1016/j.compositesb.2019.05.010

[24] LIU F, LU X, ZHAO L, et al. Investigation of bolt load redistribution and ts effect on failure prediction in double-lap, multi-bolt composite joints[J]. Composite Structures,2018,202(10):397-405.

[25] LIU F, FANG Z, ZHAO L, et al. A failure-envelope-based method for the probabilistic failure prediction of compo-site multi-bolt double-lap joints[J]. Composites Part B: Engineering,2019,172:593-602. DOI: 10.1016/j.compositesb.2019.05.034

[26] 房子昂, 赵丽滨, 刘丰睿, 等. 碳纤维/树脂复合材料多钉连接钉载系数测试方法[J]. 复合材料学报, 2019, 36(12):2795-2804. FANG Ziang, ZHAO Libin, LIU Fengrui, et al. Tesing method of bolt load distribution in carbon fiber/resin compo-site multi-bolt joints[J]. Acta Materiae Compositae Sinica,2019,36(12):2795-2804(in Chinese).

[27] 龚潇. 碳纤维复合材料机械连接载荷分配均匀化研究[D]. 上海: 上海交通大学, 2015. GONG Xiao. Research on the equalization of load distribution of carbon fibre composite bolt joints[D]. Shanghai: Shanghai Jiao Tong University, 2015(in Chinese).

[28] 赵美英. 复合材料机械连接失效分析及强度影响因素研究[D]. 西安: 西北工业大学, 2006. ZHAO Meiying. Study on the failure analysis and strength influencing factors of composite mechanical connec-tions[D]. Xi’an: Northwestern Polytechnical University, 2006(in Chinese).

[29] 谢宗蕻, 李想, 郭家平, 等. 考虑间隙配合的复合材料钉载分配均匀化方法[J]. 复合材料学报, 2016, 33(4):806-813. XIE Zonghong, LI Xiang, GUO Jiaping, et al. Load distribution homogenization method of multi-bolt composite joint with consideration of bolt-hole clearance[J]. Acta Materiae Composite Sinica,2016,33(4):806-813(in Chinese).

[30] 李想, 谢宗蕻. 复合材料多钉连接钉载分配均匀化的泰勒展开方法[J]. 哈尔滨工业大学学报, 2019, 51(11):108-115. DOI: 10.11918/j.issn.0367-6234.201811201 LI Xiang, XIE Zonghong. A taylor expansion algorithm for the load distribution homogenization of multi-bolt composite joints[J]. Journal of Harbin Institute of Technology,2019,51(11):108-115(in Chinese). DOI: 10.11918/j.issn.0367-6234.201811201

[31] 赵启林, 高一峰, 李飞. 复合材料预紧力齿连接技术研究现状与进展[J]. 玻璃钢/复合材料, 2014(12):52-56. ZHAO Qilin, GAO Yifeng, LI Fei. Current research and development of the application of the pre-tightened tooth connection[J]. Fiber Reinforced Plastics/Composites,2014(12):52-56(in Chinese).

[32] ZHAO Q L, LI F, GAO Y F, et al. Research on the shear failure load of composite pre-tightened tooth connections by the characteristic lengths[J]. Journal of Reinforced Plastics and Composites,2015,34(14):1153-1166. DOI: 10.1177/0731684415588935

[33] ZHANG D D, ZHAO Q L, HUANG Y X, et al. Flexural properties of a lightweight hybrid FRP-aluminum modular space truss bridge system[J]. Composite Structures,2014,108:600-615.

[34] ZHANG D D, ZHAO Q L, LI F, et al. Torsional behavior of a hybrid FRP-aluminum space truss bridge: Experimental and numerical study[J]. Engineering Structures,2018,157:132-143.

[35] ZHANG D D, LV Y R, ZHAO Q L, et al. Development of lightweight emergency bridge using GFRP-metal composite plate-truss girder[J]. Engineering Structures,2019,196:109291.

[36] ZHANG D D, YUAN J X, ZHAO Q L, et al. Static perfor-mance of a new GFRP-metal string truss bridge subjected to unsymmetrical loads[J]. Steel and Composite Structures,2020,35(5):641-657.

[37] 李飞. 复合材料新型连接技术及在桁架中的应用研究[D]. 南京: 解放军理工大学, 2012. LI Fei. Research on new type of pultruded composite connection and application in the truss [D]. Nanjing: PLA University of Science and Technology, 2012(in Chinese).

[38] LI F, ZHAO Q L, GAO Y F, et al. A prediction method of the failure load and failure mode for composite pre-tightened tooth connections based on the characteristic lengths[J]. Composite Structures,2016,154:684-693. DOI: 10.1016/j.compstruct.2016.06.036

[39] LI F, ZHAO Q L, CHEN H S, et al. Experimental investigation of novel pre-tightened teeth connection technique for composite tube[J]. Steel and Composite Structures,2017,23(2):161-172. DOI: 10.12989/scs.2017.23.2.161

[40] LI F, LIU Z, DUAN J H, et al. Research on failure mode and load distribution pattern of composite pretightened tooth connections under different tooth shapes[J]. Engineering Failure Analysis,2020,118:104801. DOI: 10.1016/j.engfailanal.2020.104801

[41] GAO Y F, LI F, ZHAO Q L, et al. Failure modes and failure mechanisms of single tooth bound to composite pre-tightened tooth connection[J]. Journal of Reinforced Plastics and Composites,2018,37(4):267-283. DOI: 10.1177/0731684417741205

[42] GAO Y F, LI F, ZHAO Q L, et al. Strength prediction of a single tooth bound to composite pre-tightened tooth connection (PTTC) joints based on different failure criteria[J]. KSCE Journal of Civil Engineering,2019,23(8):3547-3559. DOI: 10.1007/s12205-019-1988-8

[43] 高一峰. 基于剪切非线性的复合材料预紧力齿连接强度与失效分析[D]. 南京: 陆军工程大学, 2019. GAO Yifeng. Strength and failure analysis of composite pre-tightened teeth connection based on shear nonlinearity[D]. Nanjing: Army Engineering University of PLA, 2019(in Chinese).

[44] 高建岗. 拉挤型复合材料预紧力齿连接件疲劳失效机理及寿命预测方法研究[D]. 南京: 陆军工程大学, 2020. GAO Jiangang. Study on fatigue failure mechanism and life prediction method of pultruded composite pre-tightened teeth connection[D]. Nanjing: Army Engineering University of PLA, 2020(in Chinese).

[45] 柳锦春, 高建岗, 赵启林, 等. 碳纤维增强树脂基复合材料预紧力单齿接头的静态及疲劳性能试验[J]. 复合材料学报, 2016, 33(10):2215-2222. LIU Jinchun, GAO Jiangang, ZHAO Qilin, et al. Tests for static and fatigue performances of carbon fiber reinforced plastics pre-tightened single tooth connector[J]. Acta Materiae Compositae Sinica,2016,33(10):2215-2222(in Chinese).

[46] LIU J C, GAO J G, ZHAO Q L. Failure modes of CFRP pre-tightened single tooth joints under axial cyclic tensile loading[J]. Construction and Building Materials,2019,222:786-795. DOI: 10.1016/j.conbuildmat.2019.06.206

-

期刊类型引用(2)

1. 《中国公路学报》编辑部. 中国桥梁工程学术研究综述·2024. 中国公路学报. 2024(12): 1-160 .  百度学术

百度学术

2. 李飞,高训鹏,赵启林,王正兴,施霖. 弯压耦合作用下的复合材料预紧力齿连接力学性能研究. 复合材料科学与工程. 2023(08): 5-13 .  百度学术

百度学术

其他类型引用(3)

-

下载:

下载: