Axial compressive behavior of CFRP uniformly wrapped coal in circular columns

-

摘要: 为扩大纤维增强树脂复合材料(FRP)加固组合结构的应用范围,改善煤矿采空区煤柱的承载能力和变形能力,对碳纤维增强树脂复合材料(CFRP)均匀约束煤圆柱的轴压性能进行了研究。试验结果表明:因CFRP的均匀约束,致使煤圆柱破坏时基本保持原状,断口位置约为0.25~0.5倍煤样高度范围,轴向变形能力至少提高1.5倍;单、双层CFRP约束煤圆柱的峰值强度分别提高了3.56~6.34倍、6.33~11.21倍;相同CFRP布层数时,随加载速率的增大,CFRP约束煤圆柱的强度增强比则逐渐降低,且CFRP层数越多,降低趋势越显著;CFRP层数对峰值强度的影响要比加载速率对峰值强度的影响更显著,加载速率对破坏时间的影响要比CFRP层数对破坏时间的影响更显著。获得了兼顾加载速率与CFRP层数的强度增强比三维可视化映射函数;建立了CFRP布约束煤圆柱的修正Richart强度分析模型,整体绝对误差评价指标表明模型性能优越,精度较高。Abstract: To facilitate the practical application of fiber-reinforced polymer (FRP) strengthened structures and improve the bearing capacity and deformation capacity of coal pillar in goaf, the mechanical performance of carbon fiber-reinforced polymer (CFRP) uniformly wrapped coal columns under axial compression was explored. Test results show that its state is basically unchanged and the fracture position is about 0.25-0.5 times the height of CFRP confined coal columns, and the axial deformation capacity is increased by at least 1.5 times when the coal columns are damaged since the uniform confinement of CFRP. The peak strength of single and double CFRP confined coal columns is increased by 3.56-6.34 times and 6.33-11.21 times, respectively. When the number of CFRP layers is the same, the strength enhancement ratio of CFRP confined coal columns decreases gradually with the increase of loading rate, and the decrease trend becomes more significant with the increase of the number of CFRP layers. The effect of CFRP layers on peak strength is more significant than that of loading rate, but it is obviously the opposite as for the failure time. It has been obtained that the 3D visualized mapping function of strength enhancement ratio considering loading rate and number of CFRP layers. The modified Richart strength model of CFRP confined coal columns has been established, and the index of integral absolute error shows that the model has good performance and higher precision.

-

Keywords:

- CFRP /

- uniform confinement /

- confined coal columns /

- strength enhancement ratio /

- strength model

-

碳纤维增强聚合物(Carbon fiber-reinforced polymer,CFRP)作为一种复合材料,具有质量轻、力学性能优越、耐腐蚀和易施工等优点,被广泛用于工程中结构或构件的加固和修复等方面[1],如钢[2-5]、混凝土[6-7]、木[8-9]、冰[10-11]、砌体[12-13]及钢筋混凝土[14-16]等结构。CFRP通过提供侧向约束力,从而改善工程结构梁[17-19]、板[20-22]、柱[23-33]的受力状态,达到加固的效果,其中柱加固方面的研究成果较多。

在煤炭资源开采过程中,采场周围留设了大量煤柱,与煤层顶底板形成组合结构。煤柱作为因煤矿采掘活动而后天人为形成的一种地下空间承载组合结构,它的稳定问题决定着整个采场及覆岩乃至地表的安全,一旦发生失稳,将导致众多灾难性后果。国内外学者对煤柱的加固进行了研究,取得了一定的研究成果。Zhang等[34]提出了一种混凝土包裹煤柱的加固方法,加固煤柱的应力应变曲线呈现双峰特点,发现最大承载力与半径比、弹性模量比密切相关;陈绍杰等[35]、张洪伟等[36]利用大流动性充填膏体作为充填墙加固条带煤柱,有效改善了煤柱的受力状态;赵国贞等[37]采用注浆加固煤柱的方法,发现煤柱的承载力提高了4倍;王波等[38]针对沿空掘巷留设的煤柱,提出了对穿锚索双向加固新技术。由此可见,现阶段煤柱加固主要采用锚索、注浆、喷射混凝土、充填墙等方法,但在缩小煤柱尺寸提高煤炭资源回采率方面,提高的效果不显著。而Das等[39]首次采用纤维增强树脂复合材料(FRP)加固煤柱的新方法,开展了室内试验与数值模拟验证,研究结果表明,FRP能有效减小煤柱留设尺寸,显著提高煤样的承载能力与变形能力,提高了回采率且加固效果显著。目前刘洪林等[40]、李庆文等[41]也已开展了FRP加固煤柱相关方面的研究,但在此方面系统的研究成果仍比较少见。

为此,本文将以CFRP布均匀约束煤圆柱为研究对象,着重探究其在轴向受压状态下的力学行为,详细探讨加载速率与CFRP布缠绕层数试验因素对破坏形态、轴向应力应变行为、环向应变及峰值强度增强比的影响,基于试验数据验证现有强度模型对于煤的适用性并进行改进。

1. 试验概况

1.1 试验设计

试验所用煤样取自红庆梁煤矿某工作面煤柱,根据国际岩石力学学会(ISRM)推荐的方法[42]和中国《煤和岩石物理力学性质测定方法》( GB/T 23561—2010)的规定[43],本试验制备了28个尺寸为Φ50 mm×100 mm的CFRP均匀约束煤圆柱试件,考虑不同加载速率(0.01、0.1、1.0 和10 mm·min−1)分成4组,每组分未约束、一层和两层碳纤维布约束3种工况,每种工况中未约束含3个试件,其他工况各含2个试件,具体参数详见表1。

表 1 碳纤维增强聚合物(CFRP) 加固煤圆柱的主要试验结果Table 1. Main test results of coal columns strengthened with carbon fiber-reinforced polymer (CFRP)Group Specimen D/mm H/mm v/(mm·min−1) n/layers fpu/MPa fpc/MPa nf tf/s 1 A-CC-1 49.60 100.19 0.01 0 15.79 — — 2010.50 A-CC-2 49.70 100.32 0.01 0 16.14 — — — A-CC-3 49.70 100.48 0.01 0 25.20 — — — A-1CFRP-CC-1 49.44 100.37 0.01 1 — 118.12 6.203 12360.45 A-1CFRP-CC-2 49.62 100.52 0.01 1 — 123.28 6.474 — A-2CFRP-CC-1 49.63 100.40 0.01 2 — 207.08 10.874 29193.37 A-2CFRP-CC-2 49.64 100.50 0.01 2 — 220.00 11.553 — 2 B-CC-1 49.59 100.37 0.1 0 19.03 — — 259.73 B-CC-2 49.84 100.44 0.1 0 27.52 — — — B-CC-3 49.68 100.28 0.1 0 26.29 — — — B-1CFRP-CC-1 49.67 100.42 0.1 1 — 133.90 5.515 1110.39 B-1CFRP-CC-2 49.57 100.40 0.1 1 — 127.70 5.259 — B-2CFRP-CC-1 49.70 100.37 0.1 2 — 181.73 7.485 1852.65 B-2CFRP-CC-2 49.40 100.32 0.1 2 — 200.86 8.273 — 3 C-CC-1 49.55 100.54 1.0 0 20.95 — — 23.99 C-CC-2 49.63 100.39 1.0 0 23.99 — — — C-CC-3 49.61 100.24 1.0 0 31.94 — — — C-1CFRP-CC-1 49.64 100.29 1.0 1 — 163.25 6.370 105.44 C-1CFRP-CC-2 49.68 100.32 1.0 1 — 136.76 5.337 — C-2CFRP-CC-1 49.81 100.40 1.0 2 — 187.18 7.304 146.59 C-2CFRP-CC-2 49.83 100.32 1.0 2 — 186.96 7.296 — 4 D-CC-1 49.42 100.36 10.0 0 30.81 — — 2.98 D-CC-2 49.86 100.38 10.0 0 34.81 — — — D-CC-3 49.55 100.39 10.0 0 32.07 — — — D-1CFRP-CC-1 49.62 100.33 10.0 1 — 121.35 3.727 7.88 D-1CFRP-CC-2 49.64 100.47 10.0 1 — 110.40 3.390 — D-2CFRP-CC-1 49.89 100.37 10.0 2 — 189.72 5.826 12.36 D-2CFRP-CC-2 49.74 100.51 10.0 2 — 222.41 6.830 — Notes:In the specimen, A, B, C, D—Loading rates of 0.01, 0.1, 1.0 and 10 mm·min−1, respectively; Number before CFRP—CFRP layer number; CC—Coal column; The last number—Specimen number with the same parameters. D—Diameter of coal; H—Height of coal; v—Loading rate; n—Number of CFRP layers; fpu—Peak strength of unconfined coal columns; fpc—Peak strength of CFRP-confined coal columns; nf—Strength enhancement ratio of CFRP-confined coal columns; tf—Average failure time. 借鉴混凝土粘贴的CFRP布方式,煤圆柱体表面粘贴CFRP布采用传统的湿法工艺,主要流程:(1) 按照CFRP布缠绕层数及煤样高度计算CFRP布使用长度和宽度,并裁剪备用;(2) 用风枪将煤样表面吹净,同时在煤样表面均匀涂抹薄薄一层浸渍胶;(3) 将已裁剪待粘贴的CFRP布,用刷子蘸取适量浸渍胶均匀涂抹在CFRP的正反两面,并使整个CFRP布被胶水浸透;(4) 把CFRP布平铺在操作台上,一端对准煤样起点并固定,用手顺着包裹方向轻压抹平CFRP布,使CFRP布与煤样侧壁紧密贴合,沿着缠绕方向慢慢旋转使其缠绕在煤样上,保持纤维端部与煤样端部平齐,用力按压试件使煤样侧壁与CFRP布之间的胶水渗出,并用刮板反复刮压CFRP包裹煤样直至胶水渗完,以此来去除气泡,使CFRP布与煤样充分紧密贴合;(5) 待CFRP布粘贴完毕后,将包裹后的煤样置于阴凉通风处放置,在实验室环境下继续养护直至试验开始。CFRP布缠绕煤圆柱的过程如图1所示。

裁剪CFRP布的长度按照nπD+L计算,其中,n为CFRP层数,D为煤样直径,L为搭接长度,为避免约束煤圆柱因CFRP布脱粘导致的预先破坏,搭接长度L取为50 mm,故1层CFRP布长度为207.08 mm,2层CFRP布为364.16 mm。

为便于后续讨论,准确区分每个试件,根据试件参数不同对试件进行命名,其命名方式则是由字母与数字构成,如表1所示。第一个字母表示加载速率,即A、B、C、D分别代表0.01 、0.1、1.0和10 mm·min−1的加载速率;第一个数字表示表面粘贴CFRP布的层数(1层和2层);字母CC表示煤圆柱;最后,连字符后的数字则用来区分相同的试件,粘贴CFRP布的相同参数试件分别制备了2个,未粘贴CFRP布的相同参数试件分别制备了3个。以“A-2CFRP-CC-2”为例,A-2CFRP-CC-2表示加载速率为0.01 mm·min−1、包裹2层CFRP布的煤圆柱2号试件;以“A-CC-3”为例,A-CC-3表示加载速率为0.01 mm·min−1、未包裹CFRP布的煤圆柱3号试件。

1.2 CFRP材料性能

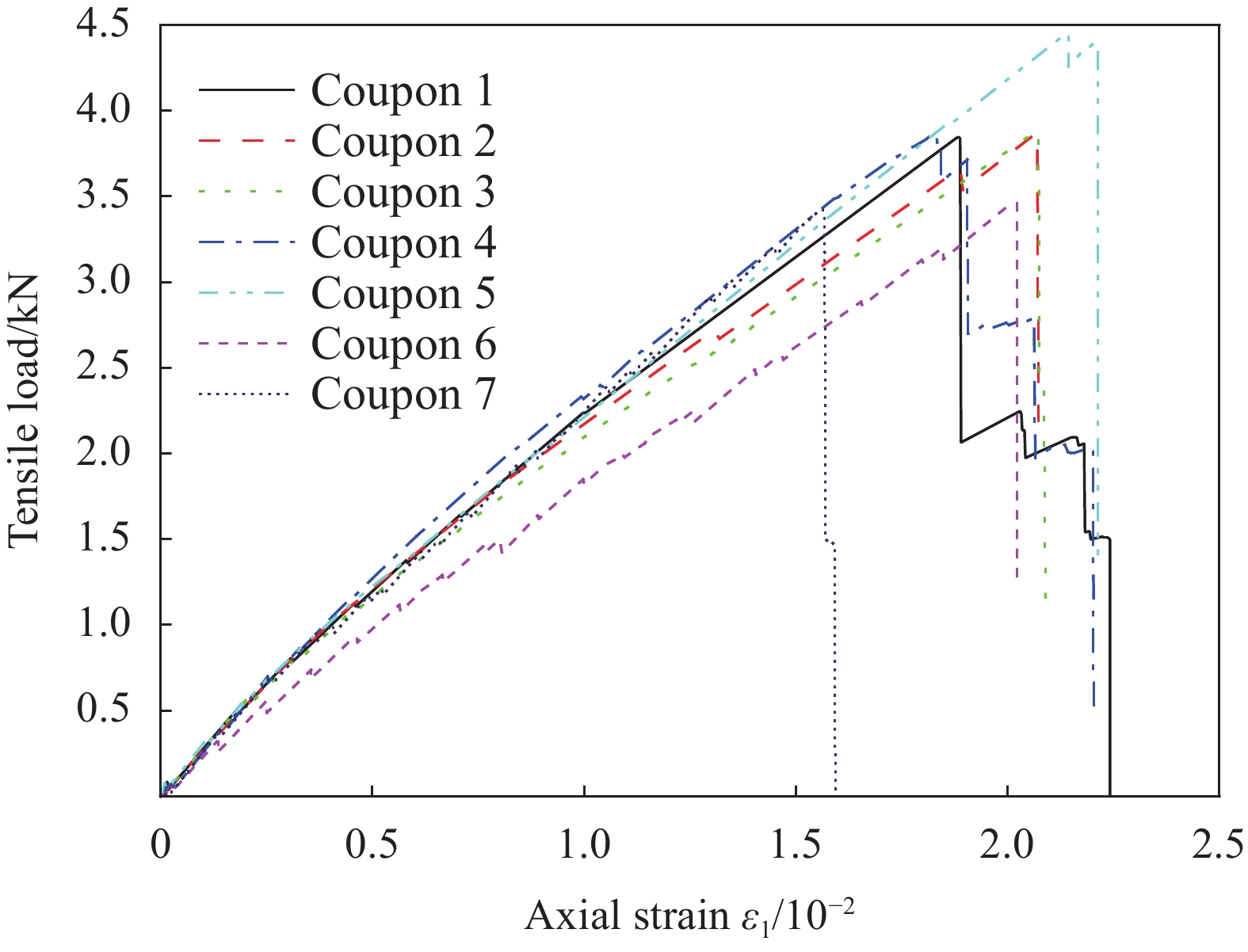

CFRP 布的材料性能依据《定向纤维增强聚合物基复合材料拉伸性能试验方法》(GBT 3354—2014)[44]检测,制作7个标准规格为250 mm(长)×25 mm(宽)×0.167 mm(厚)的CFRP布,利用长春科新试验仪器有限公司生产的WDW-300微机控制电子式万能试验机,设备如图2所示,以加载速率2 mm/min进行标准拉伸试验,试验结果如图3所示,CFRP材料性能参数详见表2所示。

表 2 CFRP平均力学性能指标Table 2. Average mechanical properties of CFRP sheetsThickness/

(mm·ply−1)Tensile

strength/MPaUltimate

tensile strain/%Elastic

modulus/GPa0.167 918.07 1.94 47.54 1.3 试验装置与测点布置

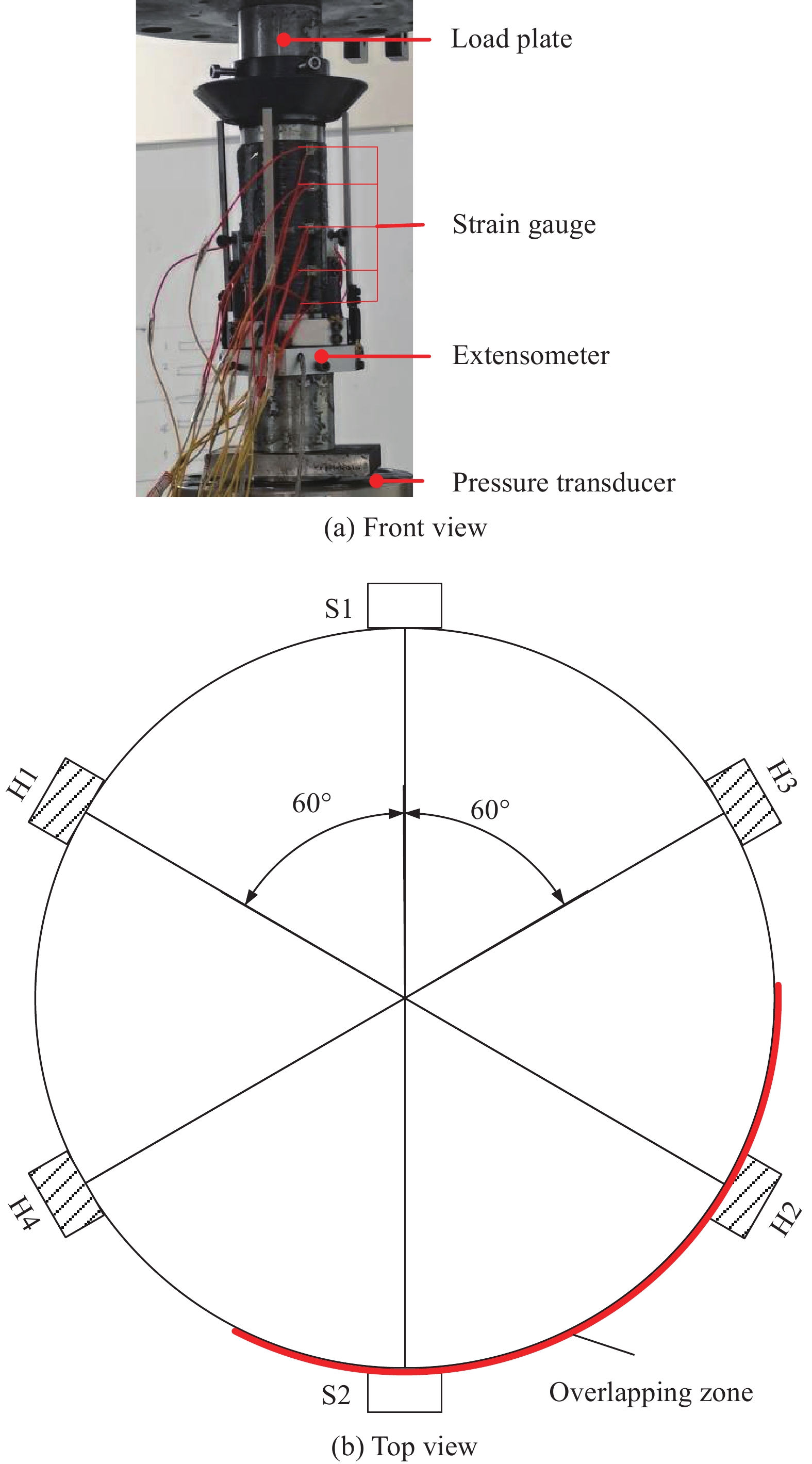

采用的试验加载装置为长春科新试验仪器有限公司生产的SAM-2000型微机控制电液伺服岩石试验机,同时采用东华测试的DH3816静态应变测试仪(100 Hz)进行采集试验应变、应力及位移等数据,试验加载及测量装置如图4所示。试件周围有一套岩石试验机自带的引伸计,可测环向应变和轴向应变。同时又在试件局部(中间位置)布设了4个环向应变片(H1、H2、H3、H4)、2个轴向应变片(S1、S2),其中H2和S2在搭接区域内,沿试件高度均匀布置5个环向应变片,监测沿试件高度的环向应变分布情况。为保证应变片与应力同步采集,在试件下部放置一个压力传感器(最大量程500 kN)。试验加载采用位移控制方式,详见表1。

2. 试验结果与分析

2.1 试验现象及CFRP布均匀约束煤圆柱破坏形态

表3给出了代表性煤样破坏形态。不同加载速率下煤样单轴压缩变形过程中,对于未约束煤样,随着加载速率的增加煤样破损程度更加严重,煤碎屑飞溅更加猛烈,煤样的完整性越差,表明加载速率显著地影响煤样的断裂损伤演化过程,主要是由于加载速率(0.01、1.0 mm/min)较小时,在渐进性破坏过程中煤样内部裂隙有足够的时间去扩展和贯穿,反之亦然;对于CFRP约束煤样,随着加载速率逐渐递增,仅从破坏表面观察可知,似乎CFRP层数(1、2层)对于煤样的影响不显著,CFRP布材断口位置均在0.25~0.5倍煤样高度范围,但破坏时的声音逐渐增强,伴有一定量煤粉碎屑物从CFRP布材断口位置飞溅出,煤样的完整性均较好。至于煤样的破坏形态,随着加载速率增长,未约束煤样从单一的劈裂破坏(拉伸破坏)过渡到复杂的拉-剪复合破坏;CFRP约束煤样则是沿着煤样原生主裂隙进行扩展、融合贯穿,直至在0.25~0.5倍煤样高度内某处CFRP布材薄弱断口,产生X状共轭斜面剪切破坏。

表 3 代表性CFRP约束煤圆柱试样破坏Table 3. Typical failure of CFRP confined coal column specimensn/layer Loading rate v/(mm·min−1) 0.01 0.1 1.0 10.0 0

1

2

2.2 CFRP布均匀约束煤圆柱应力-应变关系

图5给出了不同加载速率下未约束煤样的应力-应变曲线,图6为CFRP约束煤样的应力-应变曲线,A-2CFRP-CC-2应变数据缺失,荷载值正常,A-2CFRP-CC-1与B-2CFRP-CC-2来源于应变片和荷载传感器,其他数据均来源于引伸计和岩石试验机本身。

从图5与图6观察可知,煤样变形是一个渐进性破坏的过程,主要分为压密、弹性、屈服和破坏4个过渡阶段。不同加载速率下未约束煤样应力-应变曲线的离散性高于约束煤样的应力-应变曲线的离散性,主要由于煤是一种天然的非均质体,致使其力学性质也表现出离散性,煤样在加载变形过程中,其内部随机分布的原生裂隙压密并产生新的随机次生微裂隙,当加载到某一特定阶段,随机分布的原生裂隙与次生裂隙扩展、汇聚到一个或多个成规模主裂隙带上继续扩展,形成微裂纹局部化,致使煤样近似均匀的变形过程产生了极不均匀的破坏现象。不同加载速率下未约束煤样的轴向形变均小于0.01,CFRP布约束煤样的轴向形变均大于0.015,轴向变形能力至少提高1.5倍以上,当加载速率≥0.1 mm/min时,随着CFRP布缠绕层数增加,轴向变形与峰值强度均显著增长;当加载速率<0.1 mm/min时,随着CFRP缠绕层数增加,轴向变形与峰值强度均增长不显著。由此可见,通过CFRP布缠绕煤圆柱试件能显著提高变形能力和承载能力,这将有助于缩小煤柱的尺寸,提高煤炭资源的回采率,增强采空区煤柱上覆岩层的稳定性,进而有效控制采空区地表沉降,改善地表生态环境。

2.3 CFRP布约束煤圆柱轴压性能参数分析

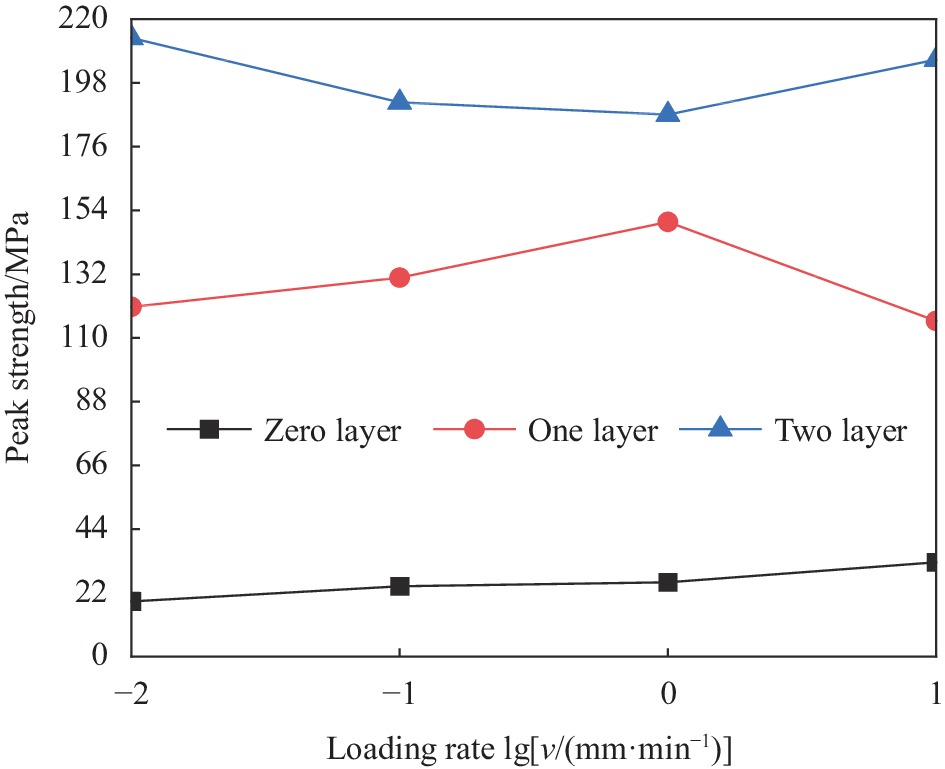

2.3.1 峰值强度

图7给出了不同CFRP布缠绕层数下煤样峰值强度与加载速率的关系。可知,未约束煤样的峰值强度随着加载速率的增加而增加,这与文献[45]的研究成果相一致,但在加载速率0.1~1.0 mm/min范围内,峰值强度增长速率放缓,没有加载速率0.01~0.1 mm/min与1.0~10 mm/min范围内峰值强度增长速率高;对于单层CFRP布约束煤样,在加载速率为0.01~1.0 mm/min时,峰值强度增长率随加载速率增加而增加,在加载速率为1.0~10 mm/min时,峰值强度增长率随加载速率增加而降低;对于双层CFRP布约束煤样,正好与单层CFRP布约束煤样的峰值强度增长率发展趋势相反。加载速率一定时,随着CFRP布缠绕层数的增加,峰值强度也逐渐增加;双层CFRP布相对于单层约束煤样所带来的峰值强度增长率(最大增长率为77.83%),显著低于单层CFRP布相对于未约束煤样所带来的峰值应力增长率(最小增长率为255.91%),这表明对于煤这种非均质材料而言,随着CFRP布缠绕层数的增加,这种相对峰值强度增长率的增加趋势逐渐减小;换而言之,不是CFRP布缠绕层数越多,煤样的峰值强度增长越显著,兼顾考虑到经济成本,在某种条件下存在最优缠绕层数的问题。

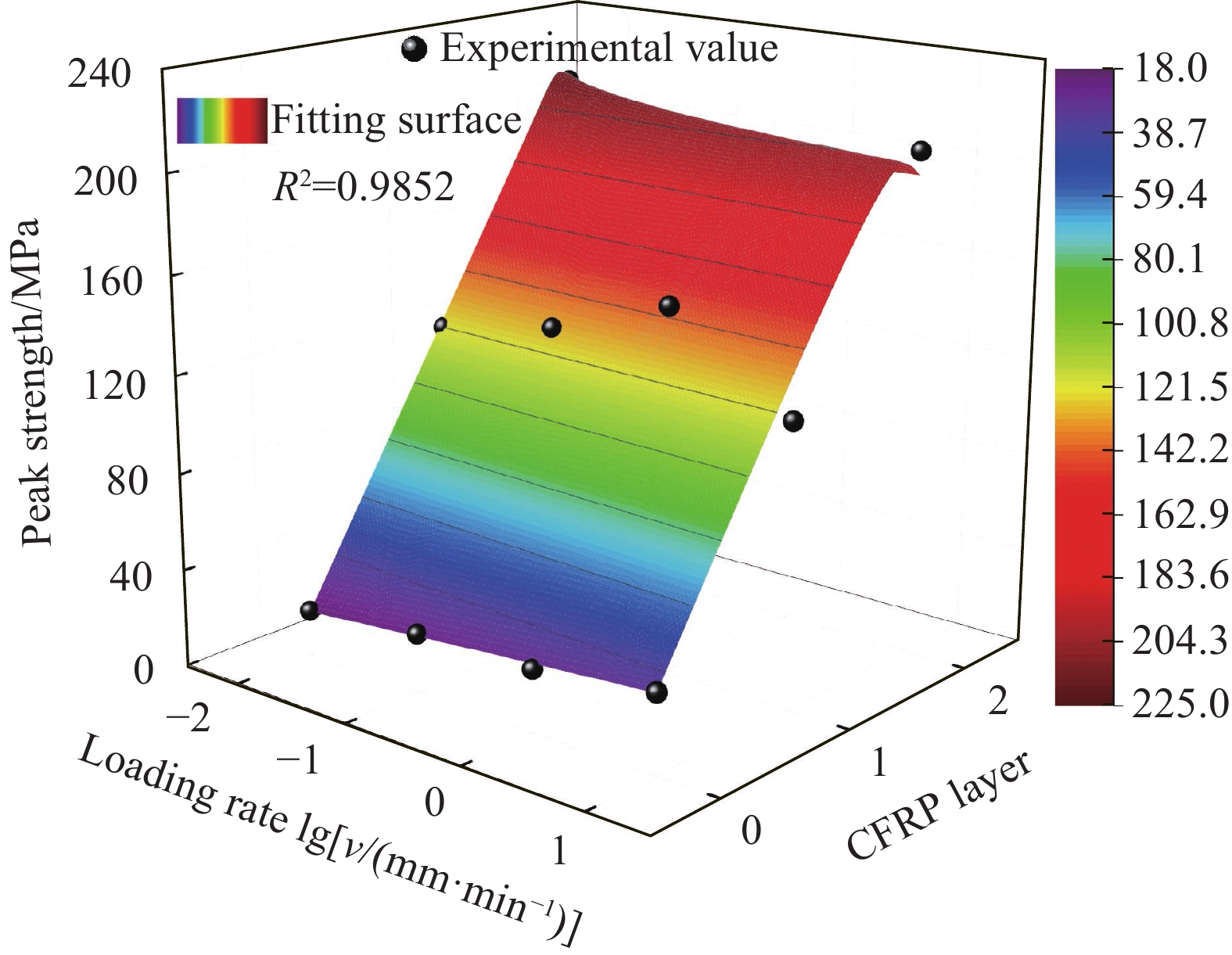

为了进一步探究峰值强度、加载速率及CFRP布缠绕层数三者之间的映射关系,通过非线性拟合分析,得到不同加载速率下不同CFRP层数约束煤样的峰值强度三维函数关系,如下式:

fp=27.81+5.16lgv+91.52n−50.0n21+0.027lgv−0.47n (1) 式中:fp为煤样峰值强度(MPa);v与n分别为加载速率和CFRP层数。

可视化后的峰值强度三维曲面如图8所示,曲面与试验数据的相关性很高(R2=0.9852),并与图7可以相互验证,这表明CFRP布缠绕层数对煤样峰值强度的影响要比加载速率对煤样峰值强度的影响更加显著。

2.3.2 破坏时间

图9给出了不同加载速率下CFRP约束煤样破坏时间与CFRP层数的关系。可知,当加载速率一定时,煤样变形破坏的时间随着CFRP布缠绕层数的增加而增加,但从未约束向单层CFRP约束煤样过渡过程中煤样变形破坏时间增长率(最小破坏时间增长率为0.42),显著高于从单层向双层CFRP约束煤样过渡过程中煤样变形破坏时间的增长率(最大破坏时间增长率为0.37),约为至少1.14倍的破坏时间增长率,简而言之,随着CFRP布缠绕层数的增加,相对于不同CFRP层数间的增加所带来的变形破坏时间增长率则在逐渐减小。当CFRP布的缠绕层数一定时,随着加载速率的增加,CFRP布约束煤样变形破坏所需时间则在骤减,反之亦然。

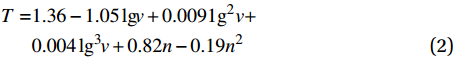

为了进一步探究破坏时间、加载速率及CFRP布缠绕层数三者之间的映射关系,通过非线性拟合分析,得到不同加载速率下不同CFRP层数约束煤样的破坏时间三维函数关系,如下式:

T=1.36−1.05lgv+0.0091g2v+0.004lg3v+0.82n−0.19n2 (2) 式中,T为lgtf变换破坏时间(s)。

可视化后的破坏时间三维函数曲面如图10所示,曲面与试验数据的相关性很高(R2=0.9953),并与图9可以相互验证,这表明加载速率对煤样破坏时间的影响要比CFRP布缠绕层数对煤样峰值强度的影响更加显著。

2.3.3 环向应变

为了更加直观地比较不同加载速率下CFRP布缠绕煤样不同高度处的环向应变大小,取了峰值应力点对应的环向应变进行分析,以煤样顶部为1位置并沿着煤样轴向进行四等分,五个不同位置处的环向应变分布如图11和图12所示。由图11可知,未约束煤样中部3位置不是环向应变最大,而是2位置取得最大环向应变,这说明未约束煤样在2位置处存在局部弱化的裂隙发育带,加载速率0.01 mm/min时环向应变最大,加载速率0.1 mm/min时次之,但二者的环向应变大小相近,加载速率1.0 mm/min时环向应变最小,并与10 mm/min时的环向应变大小相近。未约束煤样不同高度范围内的环向应变均在0.3×10−3~3.0×10−3区间,均小于图5中未约束煤样轴向应变的0.005~0.01区间,这与煤的非均质属性相吻合。

比较图11与图12可知,不同加载速率下单层、双层CFRP布缠绕煤样不同位置的最大环向应变分别为0.004~0.015区间、0.010~0.015区间,未约束煤样不同位置的最大环向应变为0.0018~0.003区间,CFRP布能显著提高煤样破坏时的最大环向应变,表明CFRP布能提供有效的侧向约束作用,进而改善煤样的轴向变形及承载力。当加载速率一定时,随着CFRP布缠绕层数增加,不同位置处的最大环向应变逐渐增加,尤其表现在只缠绕单层时候这种趋势更加显著。当CFRP布缠绕层数一定时,未约束煤样均在2位置首先发生破坏,加载速率越小,不同位置处的最大环向应变越大;对于单层CFRP约束煤样,加载速率10 mm/min时煤样在3位置率先破坏,其次为加载速率0.1 mm/min时煤样在1位置率先破坏,最后加载速率最小0.01 mm/min时煤样在2位置首先破坏;对于双层CFRP约束煤样,加载速率0.1 mm/min时煤样在1位置率先破坏,其次加载速率1.0 mm/min时煤样在2位置率先发生破坏,其他两个加载速率(0.01 mm/min和10 mm/min)时煤样分别在1位置和3位置首先发生破坏。由此可见,不同加载速率下不同CFRP缠绕层数煤样不同位置的最大环向应变分布极其各异,主要由于煤是一种非均质性、渐进性的材料,自身内部拥有大量原生裂隙,在荷载作用下易产生非均匀局部裂隙发育带,导致煤样不同高度位置的环应变处于形变大小各异状态,与此同时,表3中煤样代表性破坏形态也验证了不同加载速率下不同CFRP缠绕层数煤样不同高度最大环向应变分布各异现象。

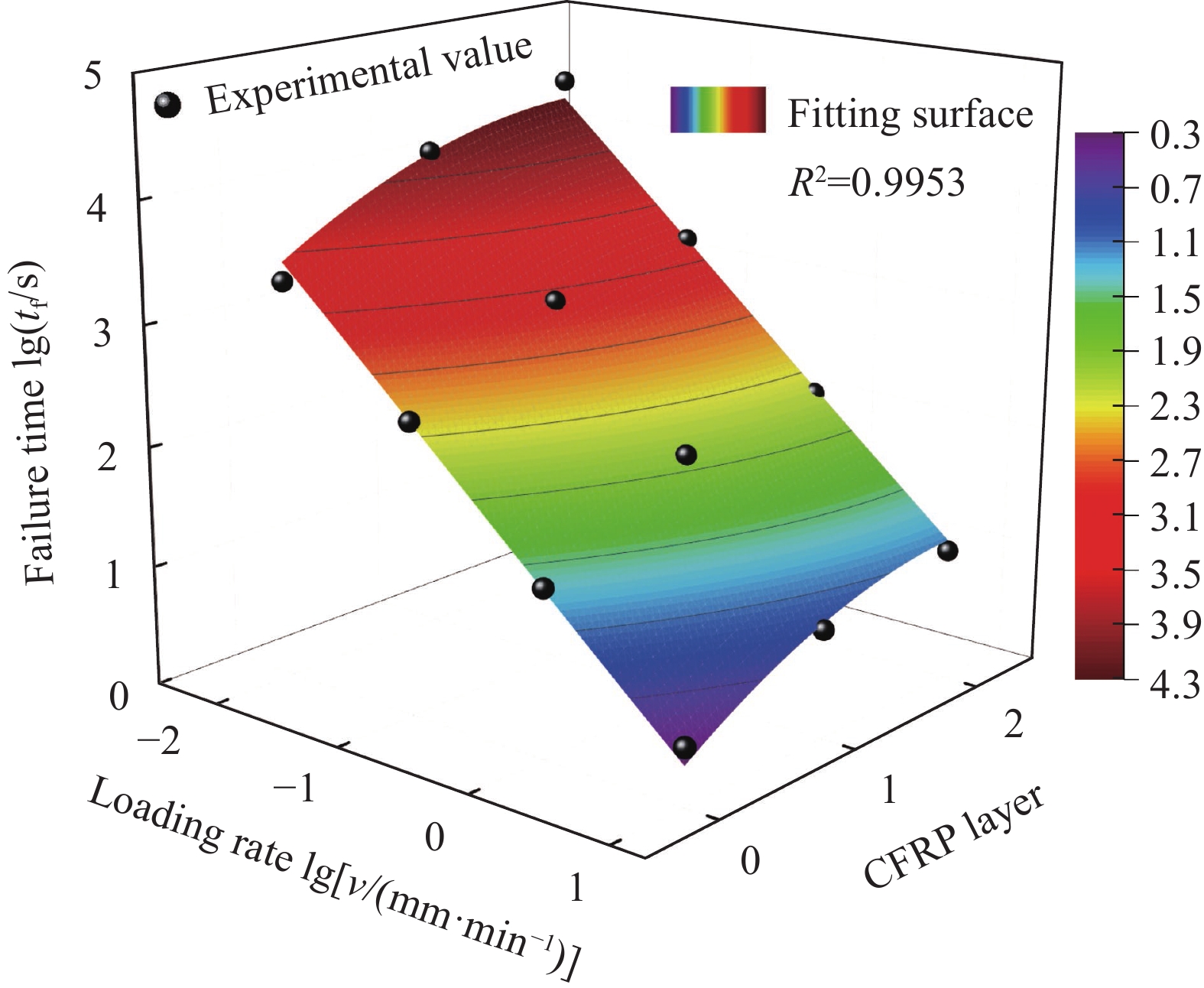

2.3.4 强度增强比

图13给出了不同CFRP布缠绕层数下煤样峰值强度增强比与加载速率的关系,强度增强比的定义为不同层数CFRP约束煤样的峰值应力与未约束煤样的峰值强度之比。可知,当CFRP布缠绕层数一定时,随着加载速率的增大,约束煤样的峰值强度增强比则逐渐降低,而且CFRP布缠绕层数越多,此种现象越显著,单、双层CFRP约束煤样的峰值应力增强比分别为3.56~6.34范围、6.33~11.21范围,强度提高显著。这表明CFRP布材提供了有效侧向约束力。同加载速率下,随CFRP布层数增加,强度增强比也逐渐增加,加载速率为0.01 mm/min时,双层CFRP布的强度增强比最大,约为11.21;加载速率为10 mm/min时,单层CFRP布的强度增强比最小,约为3.56。

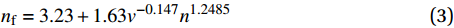

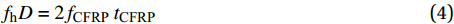

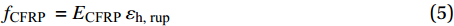

为了进一步探究强度增强比、加载速率及CFRP布缠绕层数三者之间的映射关系,通过非线性拟合分析,得到不同加载速率下不同CFRP层数约束煤样的峰值强度增强比三维函数关系,如下式:

nf=3.23+1.63v−0.147n1.2485 (3) 式中,nf为CFRP约束煤圆柱的强度增强比。

可视化后的峰值强度增强比三维函数曲面如图14所示,曲面与试验数据的相关性很高(R2=0.90),并与图13可以相互验证。从图14三维曲面可知,加载速率越小,CFRP布缠绕层数越多,CFRP布约束煤样的峰值强度增强比越大,这表明通过CFRP布缠绕加固煤柱可有效提高煤柱的极限承载能力,式(3)的函数表达式也验证了该点。

2.4 CFRP布约束煤圆柱轴压强度分析模型

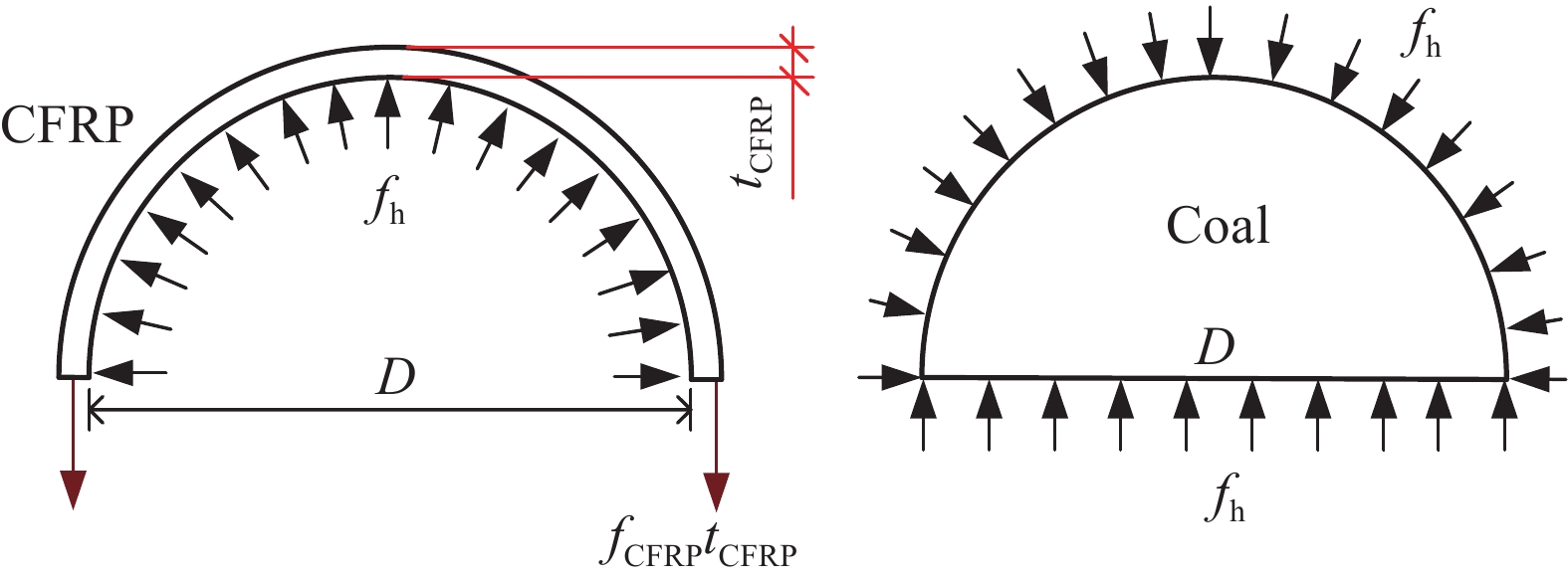

2.4.1 约束原理

借鉴FRP约束混凝土的约束原理[46],给出了CFRP约束煤圆柱体临界破坏时刻的受力平衡关系,如图15所示。

煤圆柱体的侧向力均由CFRP提供,依据图15的静力平衡条件可得:

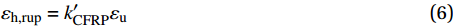

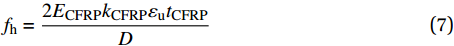

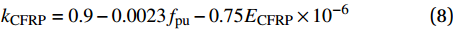

fhD=2fCFRP tCFRP (4) fCFRP =ECFRP εh, rup (5) εh,rup=k′CFRPεu (6) 式中:

fCFRP 为环向CFRP抗拉强度(MPa);ECFRP 为CFRP弹性模量(GPa);εh,rup 为环向CFRP断裂应变;εu 为CFRP拉伸试验的极限拉应变;k′CFRP 为环向应变折减系数;fh 为CFRP提供的环向约束力(MPa);tCFRP 为CFRP缠绕厚度(mm)。将式(5)、式(6)代入式(4)可得:

fh=2ECFRPkCFRPεutCFRPD (7) kCFRP=0.9−0.0023fpu−0.75ECFRP×10−6 (8) 式中,

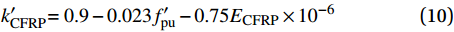

fpu 为未约束煤样峰值强度(MPa)。由于本试验考虑了不同加载速率因素,故对其进行修正可得:

f′pu=25.63+2.56lgv+2.79lg2v+1.581g3v (9) 式中,

f′pu 为修正的未约束煤样峰值强度(MPa)。将式(9)代入式(8),可得:

k′CFRP=0.9−0.023f′pu−0.75ECFRP×10−6 (10) 为得到CFRP约束煤样强度与CFRP层数n的关系,对CFRP缠绕厚度进行变换:

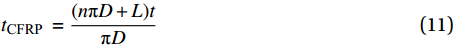

tCFRP =(nπD+L)tπD (11) 式中,t为CFRP布单层厚度,取0.167 mm/层。

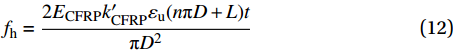

将式(10)、式(11)代入式(7)可得:

fh=2ECFRPk′CFRPεu(nπD+L)tπD2 (12) 将式(10)与式(12)进行组合,最终得到CFRP布对煤样的侧向约束力计算公式。

2.4.2 修正强度模型与评价

对文献[49-50]推荐的Richart模型和Hoek-Brown模型进行修正,来表征不同加载速率下CFRP约束煤样的强度分析模型:

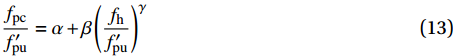

(1) 修正的Richart模型:

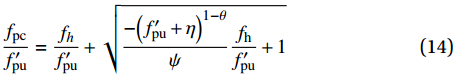

fpcf′pu=α+β(fhf′pu)γ (13) (2) 修正的Hoek-Brown模型:

fpcf′pu=fhf′pu+√−(f′pu+η)1−θψfhf′pu+1 (14) 式中:α、β、γ、η、θ、ψ均为待定参数;fpc为CFRP布约束煤圆柱的峰值强度。

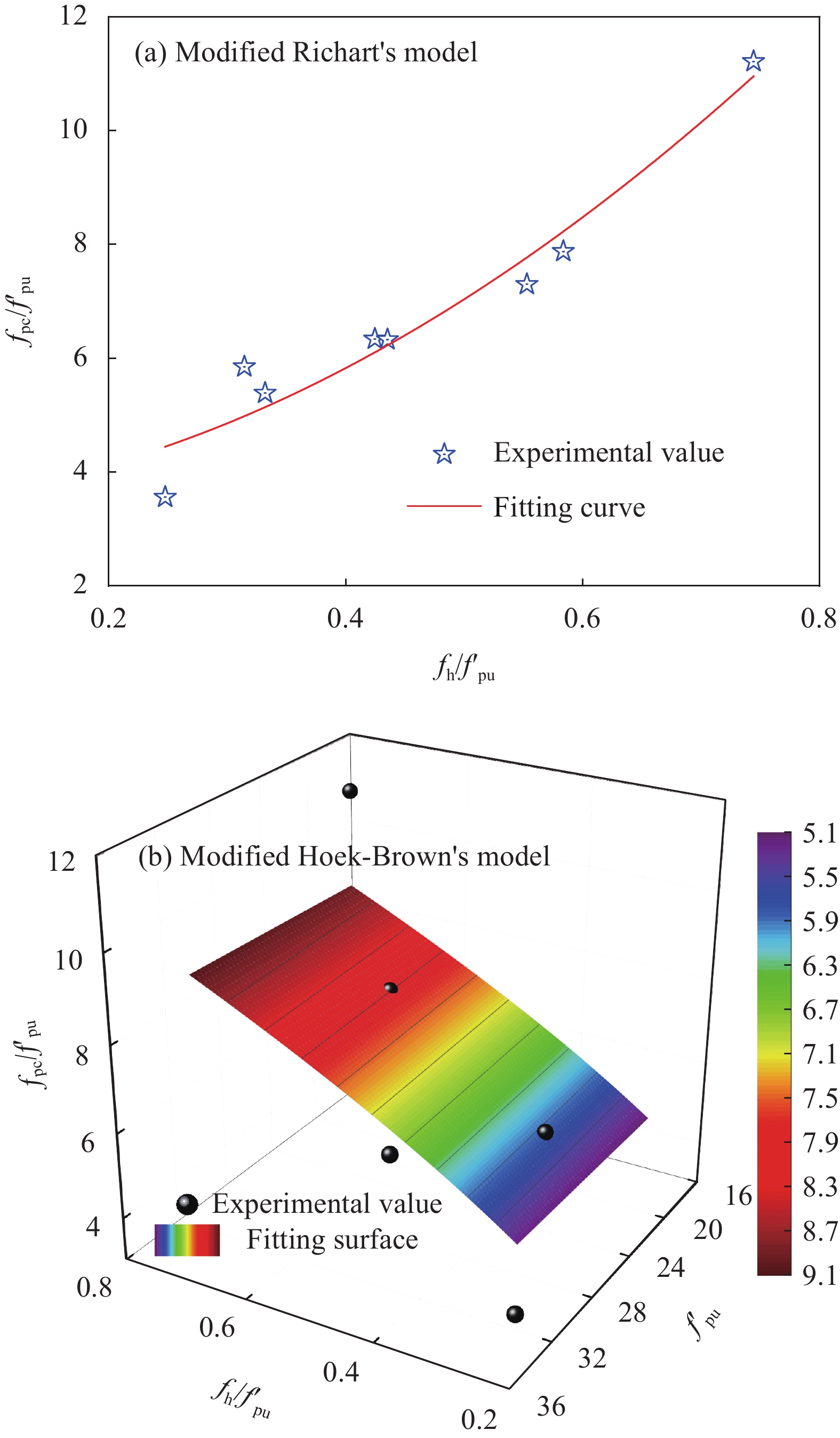

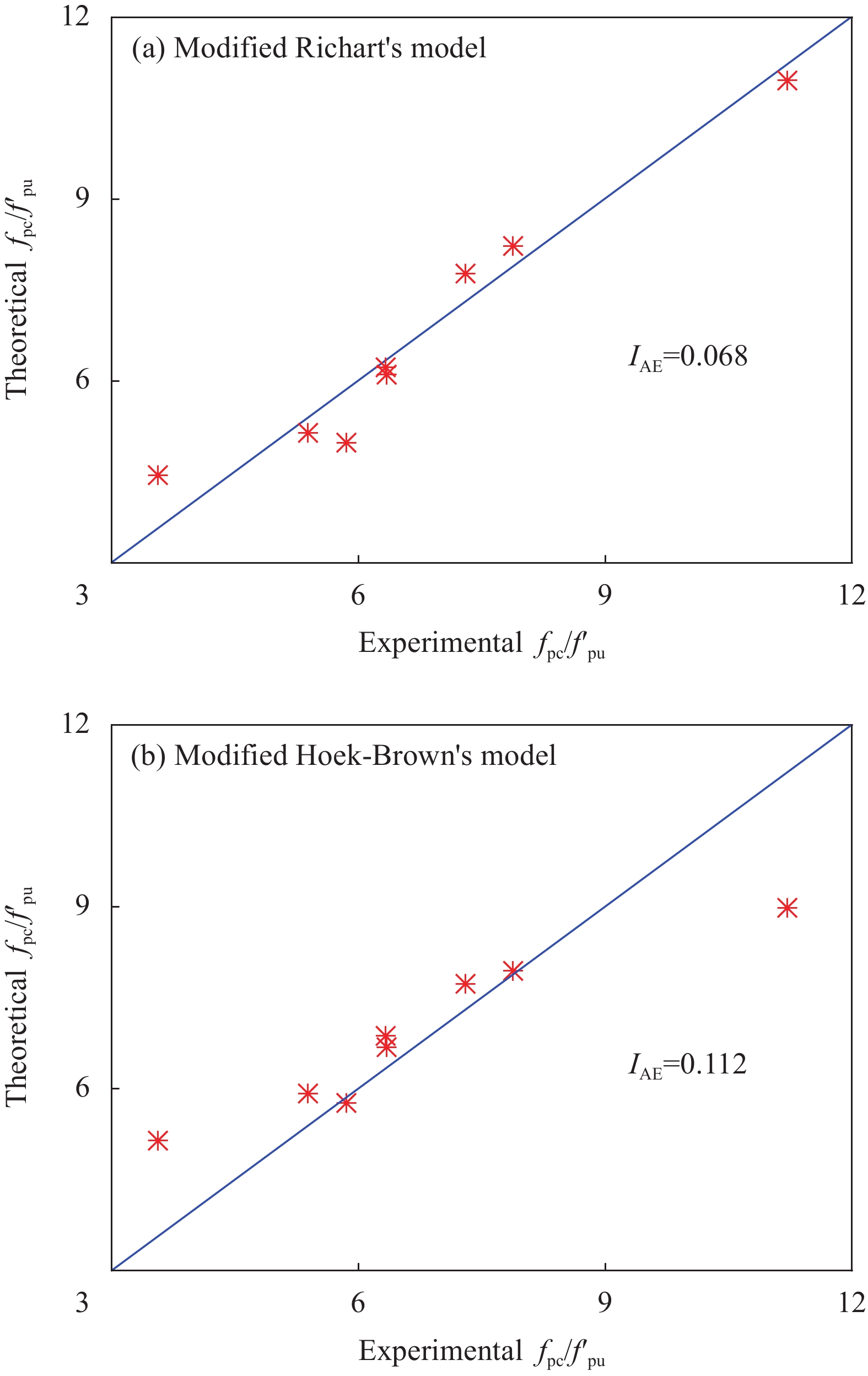

基于表1与表2试验数据,利用Levenberg-Marquardt+通用全局优化的组合算法,对式(13)与式(14)进行非线性拟合分析,得到修正Richart模型与修正Hoek-Brown模型拟合结果如图16所示,修正的模型参数如表4所示。

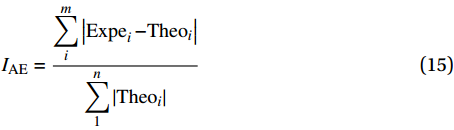

采用整体绝对误差(Integral absolute error,IAE)来评价模型的优越性[50]。IAE是一种对预测精度非常敏感的指标,其值越小,表明模型优越性能越好,IAE的表达式为

IAE=m∑i|Expei−Theoi|n∑1|Theoi| (15) 式中:Theoi为理论值;Expei为试验值;m、n为试验数据个数。

用式(15)计算可得修正Richart模型与修正Hoek-Brown模型的IAE,如图17所示。由表4与图17综合分析可知,修正Richart模型的R2与IAE值分别为0.94与0.068,修正Hoek-Brown模型的R2与IAE值分别为0.7与0.112,R2越接近1,拟合度越高,IAE越小,拟合效果越显著。

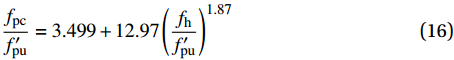

表 4 CFRP布约束煤圆柱强度修正模型参数Table 4. Parameters of strength modified models of CFRP confined coal columnsParameters Modified Richart Modified Hoek-Brown α β γ Ψ η θ Value 3.499 12.97 1.87 −1 292.77 0.22 R2 0.94 0.70 Note: α, β, γ, η, θ, Ψ—Undetermined parameter. 由此可见,选用修正Richart模型来表征CFRP约束煤样强度分析模型,具体模型见式(16)所示。

fpcf′pu=3.499+12.97(fhf′pu)1.87 (16) 3. 结 论

(1) 随着加载速率增加,未约束煤样的碎片化程度越来越高,而碳纤维增强树脂复合材料(CFRP)约束煤样基本上维持原状,CFRP约束煤样断口位置在0.25~0.5倍煤样高度范围,且随CFRP布层数和加载速率增加,约束煤样破坏时声响更大,CFRP布约束煤样的轴向变形能力至少提高1.5倍。

(2) CFRP布缠绕层数对煤样峰值强度的影响要比加载速率对煤样峰值强度的影响更加显著;加载速率对煤样破坏时间的影响要比CFRP布缠绕层数对煤样破坏时间的影响更加显著。

(3) 建立了同时考虑加载速率与CFRP层数的强度增强比三维可视化映射函数;相同CFRP布缠绕层数时,随加载速率的增大,CFRP约束煤样的峰值强度增强比则逐渐降低,且CFRP层数越多降低趋势越显著;单、双层CFRP约束煤样的峰值应力增强比分别为3.56~6.34范围、6.33~11.21范围,CFRP布显著提高了煤样的承载能力。

(4) 建立了CFRP布约束煤样的修正Richart强度分析模型,决定系数R2与整体绝对误差评价指标表明,修正的Richart模型能够表征出不同加载速率下CFRP约束煤样的强度属性。

-

表 1 碳纤维增强聚合物(CFRP) 加固煤圆柱的主要试验结果

Table 1 Main test results of coal columns strengthened with carbon fiber-reinforced polymer (CFRP)

Group Specimen D/mm H/mm v/(mm·min−1) n/layers fpu/MPa fpc/MPa nf tf/s 1 A-CC-1 49.60 100.19 0.01 0 15.79 — — 2010.50 A-CC-2 49.70 100.32 0.01 0 16.14 — — — A-CC-3 49.70 100.48 0.01 0 25.20 — — — A-1CFRP-CC-1 49.44 100.37 0.01 1 — 118.12 6.203 12360.45 A-1CFRP-CC-2 49.62 100.52 0.01 1 — 123.28 6.474 — A-2CFRP-CC-1 49.63 100.40 0.01 2 — 207.08 10.874 29193.37 A-2CFRP-CC-2 49.64 100.50 0.01 2 — 220.00 11.553 — 2 B-CC-1 49.59 100.37 0.1 0 19.03 — — 259.73 B-CC-2 49.84 100.44 0.1 0 27.52 — — — B-CC-3 49.68 100.28 0.1 0 26.29 — — — B-1CFRP-CC-1 49.67 100.42 0.1 1 — 133.90 5.515 1110.39 B-1CFRP-CC-2 49.57 100.40 0.1 1 — 127.70 5.259 — B-2CFRP-CC-1 49.70 100.37 0.1 2 — 181.73 7.485 1852.65 B-2CFRP-CC-2 49.40 100.32 0.1 2 — 200.86 8.273 — 3 C-CC-1 49.55 100.54 1.0 0 20.95 — — 23.99 C-CC-2 49.63 100.39 1.0 0 23.99 — — — C-CC-3 49.61 100.24 1.0 0 31.94 — — — C-1CFRP-CC-1 49.64 100.29 1.0 1 — 163.25 6.370 105.44 C-1CFRP-CC-2 49.68 100.32 1.0 1 — 136.76 5.337 — C-2CFRP-CC-1 49.81 100.40 1.0 2 — 187.18 7.304 146.59 C-2CFRP-CC-2 49.83 100.32 1.0 2 — 186.96 7.296 — 4 D-CC-1 49.42 100.36 10.0 0 30.81 — — 2.98 D-CC-2 49.86 100.38 10.0 0 34.81 — — — D-CC-3 49.55 100.39 10.0 0 32.07 — — — D-1CFRP-CC-1 49.62 100.33 10.0 1 — 121.35 3.727 7.88 D-1CFRP-CC-2 49.64 100.47 10.0 1 — 110.40 3.390 — D-2CFRP-CC-1 49.89 100.37 10.0 2 — 189.72 5.826 12.36 D-2CFRP-CC-2 49.74 100.51 10.0 2 — 222.41 6.830 — Notes:In the specimen, A, B, C, D—Loading rates of 0.01, 0.1, 1.0 and 10 mm·min−1, respectively; Number before CFRP—CFRP layer number; CC—Coal column; The last number—Specimen number with the same parameters. D—Diameter of coal; H—Height of coal; v—Loading rate; n—Number of CFRP layers; fpu—Peak strength of unconfined coal columns; fpc—Peak strength of CFRP-confined coal columns; nf—Strength enhancement ratio of CFRP-confined coal columns; tf—Average failure time. 表 2 CFRP平均力学性能指标

Table 2 Average mechanical properties of CFRP sheets

Thickness/

(mm·ply−1)Tensile

strength/MPaUltimate

tensile strain/%Elastic

modulus/GPa0.167 918.07 1.94 47.54 表 3 代表性CFRP约束煤圆柱试样破坏

Table 3 Typical failure of CFRP confined coal column specimens

n/layer Loading rate v/(mm·min−1) 0.01 0.1 1.0 10.0 0

1

2

表 4 CFRP布约束煤圆柱强度修正模型参数

Table 4 Parameters of strength modified models of CFRP confined coal columns

Parameters Modified Richart Modified Hoek-Brown α β γ Ψ η θ Value 3.499 12.97 1.87 −1 292.77 0.22 R2 0.94 0.70 Note: α, β, γ, η, θ, Ψ—Undetermined parameter. -

[1] 纪孙航, 王文达, 鲜威. CFRP加固火灾作用后圆钢管混凝土构件的侧向撞击性能研究[J]. 工程力学, 2021, 38(8):178-191. DOI: 10.6052/j.issn.1000-4750.2020.08.0586 JI Sunhang, WANG Wenda, XIAN Wei. Lateral impact behavior of CFRP-reinforced circular concrete-filled steel tubular members[J]. Engineering Mechanics,2021,38(8):178-191(in Chinese). DOI: 10.6052/j.issn.1000-4750.2020.08.0586

[2] YOUSEFI O, NARMASHIRI K, HEDAYAT A A, et al. Strengthening of corroded steel CHS columns under axial compressive loads using CFRP[J]. Journal of Constructional Steel Research,2021,178:106496. DOI: 10.1016/j.jcsr.2020.106496

[3] ALTAEE M, CUNNINGHAM L S, GILLIE M. Practical application of CFRP strengthening to steel floor beams with web openings: A numerical investigation[J]. Journal of Constructional Steel Research,2019,155(4):395-408.

[4] LI C X, KE L, HE J, et al. Effects of mechanical properties of adhesive and CFRP on the bond behavior in CFRP-strengthened steel structures[J]. Composite Structures,2019,211:163-174. DOI: 10.1016/j.compstruct.2018.12.020

[5] LI J R, LU Y, LEE Y F. Debonding detection in CFRP-reinforced steel structures using anti-symmetrical guided waves[J]. Composite Structures,2020,253:112813.

[6] YANG J Q, FENG P. Analysis-oriented models for FRP-confined concrete: 3D interpretation and general methodology[J]. Engineering Structures,2020,216:110749. DOI: 10.1016/j.engstruct.2020.110749

[7] JAVAD S, JOAQUIM A O B, MOHAMMADALI R. Genera-lized analysis-oriented model of FRP confined concrete circular columns[J]. Composite Structures,2021,270:114026. DOI: 10.1016/j.compstruct.2021.114026

[8] SCHOBER K U, HARTE A M, KLIGER R, et al. FRP reinforcement of timber structures[J]. Construction and Building Materials,2015,97:106-118. DOI: 10.1016/j.conbuildmat.2015.06.020

[9] CORRADI M, VEMURY C M, EDMONDSON V, et al. Local FRP reinforcement of existing timber beams[J]. Compo-site Structures,2021,258:113263.

[10] WANG Y L, CHEN G P, WAN B L, et al. Behavior and modeling of circular large rupture strain FRP-confined ice under axial compression[J]. Journal of Composites for Construction,2021,25(1):04020076. DOI: 10.1061/(ASCE)CC.1943-5614.0001094

[11] WANG Y L, CHEN G P, WAN B L, et al. Behavior of circular ice-filled self-luminous FRP tubular stub columns under axial compression[J]. Construction and Building Materials,2020,232:117287. DOI: 10.1016/j.conbuildmat.2019.117287

[12] ESTEVAN L, BAEZA F J, BRU D, et al. Stone masonry confinement with FRP and FRCM composites[J]. Construction and Building Materials,2020,237:117612. DOI: 10.1016/j.conbuildmat.2019.117612

[13] THAMBOO J L. Performance of masonry columns confined with composites under axial compression: A state-of-the-art review[J]. Construction and Building Materials,2021,274:121791. DOI: 10.1016/j.conbuildmat.2020.121791

[14] WANG Y, CAI G, LI Y, et al. Behavior of circular fiber-reinforced polymer-steel-confined concrete columns subjected to reversed cyclic loads: Experimental studies and finite-element analysis[J]. Journal of Structural Engineering,2019,145(9):04019085.

[15] HUANG L, YU T, WANG Z Y, et al. Compressive behaviour of slender FRP-confined concrete-encased cross-shaped steel columns[J]. Construction and Building Materials,2020,258:120356. DOI: 10.1016/j.conbuildmat.2020.120356

[16] WANG Y, CAI G, LARBI A S, et al. Monotonic axial compressive behaviour and confinement mechanism of square CFRP-steel tube confined concrete[J]. Engineering Structures,2020,217:110802. DOI: 10.1016/j.engstruct.2020.110802

[17] KOTYNIA R, OLLER E, MARI A, et al. Efficiency of shear strengthening of RC beams with externally bonded FRP materials-State-of-the-art in the experimental tests[J]. Composite Structures,2021,267:113891. DOI: 10.1016/j.compstruct.2021.113891

[18] GODAT A, HAMMAD F, CHAALLAL O, et al. State-of-the-art review of anchored FRP shear-strengthened RC beams: A study of influencing factors[J]. Composite Structures,2020,254:112767. DOI: 10.1016/j.compstruct.2020.112767

[19] 姚未来, 江世永, 蔡涛, 等. 粘贴纤维增强复合材料加固混凝土梁的蠕变特性研究进展[J]. 材料导报, 2019, 33(17):2890-2901. DOI: 10.11896/cldb.18100193 YAO Weilai, JIANG Shiyong, CAI Tao, et al. Research progress on creep response of FRP-strengthened reinforced concrete beams[J]. Materials Reports,2019,33(17):2890-2901(in Chinese). DOI: 10.11896/cldb.18100193

[20] 黄丽华, 董媛媛. CFRP加固混凝土板动力性能有限元分析[J]. 建筑结构学报, 2015, 36(S2):183-187. HUANG Lihua, DONG Yuanyuan. Finite element analysis on dynamic properties of CFRP reinforced RC slabs[J]. Journal of Building Structures,2015,36(S2):183-187(in Chinese).

[21] THACKER H, VORA T P. State-of-the-art review of FRP strengthened RC slabs[J]. International Journal for Scientific Research and Development,2015,3(10):78-85.

[22] ALMUSTAFA M K, NEHDI M L. Machine learning prediction of structural response for FRP retrofitted RC slabs subjected to blast loading[J]. Engineering Structures,2021,244:112752. DOI: 10.1016/j.engstruct.2021.112752

[23] KHUSRU S, FAWZIA S, THAMBIRATNAM D P, et al. Confined rubberised concrete tubular column for high-performance structures-Review[J]. Construction and Building Materials,2021,276:122216. DOI: 10.1016/j.conbuildmat.2020.122216

[24] LAI M H, SONG W, QU X L, et al. A path dependent stress-strain model for concrete-filled-steel-tube column[J]. Engineering Structures,2020,211:110312. DOI: 10.1016/j.engstruct.2020.110312

[25] SUN J Z, WEI Y M, WAGN Z Y, et al. A new composite column of FRP-steel-FRP clad tube filled with seawater sea-sand coral aggregate concrete: Concept and compressive behavior[J]. Construction and Building Materials,2021,301:124096. DOI: 10.1016/j.conbuildmat.2021.124096

[26] 杨俊龙, 王吉忠, 卢世伟, 等. FRP非均匀约束海水海砂混凝土方柱轴压性能[J]. 复合材料学报, 2022, 39(6): 2801-2809. YANG Junlong, WANG Jizhong, LU Shiwei, et al. Axial compressive behavior of FRP nonuniformly wrapped seawater sea-sand concrete in square columns[J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2801-2809(in Chinese).

[27] ADAFER S, YOUCEF Y S, AMZIANE S. Cyclic behaviour of CFRP confined concrete under axial compression[J]. Construction and Building Materials,2022,340:127793. DOI: 10.1016/j.conbuildmat.2022.127793

[28] 马超, 王作虎, 路德春, 等. CFRP加固地铁车站结构中柱地震损伤评价研究[J]. 岩土工程学报, 2020, 42(12):2249-2256. MA Chao, WANG Zuohu, LU Dechun, et al. Seismic damage evaluation of CFRP-strengthened columns in subway stations[J]. Chinese Journal of Geotechnical Engineering,2020,42(12):2249-2256(in Chinese).

[29] 焦楚杰, 李松, 崔力仕, 等. CFRP约束钢管-活性粉末混凝土短柱轴压性能[J]. 复合材料学报, 2021, 38(2):439-448. JIAO Chujie, LI Song, CUI Lishi, et al. Axial compression behaviour of CFRP confined reactive power concrete filled steel tube stub columns[J]. Acta Materiae Compositae Sinica,2021,38(2):439-448(in Chinese).

[30] 张景杭, 夏樟华, 姜绍飞, 等. BFRP模壳加固混凝土墩柱抗震性能试验研究[J]. 建筑结构学报, 2021, 42(8):84-94. ZHANG Jinghang, XIA Zhanghua, JIANG Shaofei, et al. Experimental study on seismic behavior of concrete pier columns strengthened with BFRP mould shell[J]. Journal of Building Structures,2021,42(8):84-94(in Chinese).

[31] 王作虎, 杨菊, 崔宇强, 等. 碳纤维增强树脂复合材料加固钢筋混凝土柱抗震性能的尺寸效应试验[J]. 复合材料学报, 2020, 37(10):2645-2655. WANG Zuohu, YANG Ju, CUI Yuqiang, et al. Experiment on the size effect of seismic behavior for reinforced concrete columns strengthened by carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2020,37(10):2645-2655(in Chinese).

[32] 张冰, 魏威, 冯贵森, 等. 纤维缠绕角度对GFRP约束混凝土短柱轴压性能的影响[J]. 建筑结构学报, 2019, 40(S1):192-199. ZHANG Bing, WEI Wei, FENG Guisen, et al. Influences of fiber angles on axial compressive behavior of GFRP-confined concrete stub column[J]. Journal of Building Structures,2019,40(S1):192-199(in Chinese).

[33] 欧阳利军, 许峰, 高皖扬, 等. 玄武岩纤维布约束高温损伤混凝土方柱轴压力学性能试验[J]. 复合材料学报, 2019, 36(2):469-481. OUYANG Lijun, XU Feng, GAO Wanyang, et al. Axial compressive behavior of post-heated square concrete columns wrapped by BFRP sheets: An experimental investigation[J]. Acta Materiae Compositae Sinica,2019,36(2):469-481(in Chinese).

[34] ZHANG C W, JIN Z X, FENG G R, et al. Double peaked stress-strain behavior and progressive failure mechanism of encased coal pillars under uniaxial compression[J]. Rock Mechanics and Rock Engineering,2020,53:3253-3266. DOI: 10.1007/s00603-020-02101-7

[35] 陈绍杰, 张俊文, 尹大伟, 等. 充填墙提升煤柱性能机理与数值模拟研究[J]. 采矿与安全工程学报, 2017, 34(2):268-275. CHEN Shaojie, ZHANG Junwen, YIN Dawei, et al. Mecha-nism and numerical simulation of filling walls improving performance of coal pillar[J]. Journal of Mining and Safety Engineering,2017,34(2):268-275(in Chinese).

[36] 张洪伟, 万志军, 张源, 等. 工作面顺序接续下综放沿空掘巷窄煤柱稳定性控制[J]. 煤炭学报, 2021, 46(4):1211-1219. ZHANG Hongwei, WAN Zhijun, ZHANG Yuan, et al. Stability control of narrow coal pillars in the fully-mecha-nized gob-side entry during sequenced top coal caving mining[J]. Journal of China Coal Society,2021,46(4):1211-1219(in Chinese).

[37] 赵国贞, 马占国, 孙凯, 等. 小煤柱沿空掘巷围岩变形控制机理研究[J]. 采矿与安全工程学报, 2010, 27(4):517-521. DOI: 10.3969/j.issn.1673-3363.2010.04.013 ZHAO Guozhen, MA Zhanguo, SUN Kai, et al. Research on deformation controlling mechanism of the narrow pillar of roadway driving along next goaf[J]. Journal of Mining and Safety Engineering,2010,27(4):517-521(in Chinese). DOI: 10.3969/j.issn.1673-3363.2010.04.013

[38] 王波, 谷长宛, 王军, 等. 对穿锚索加固作用下沿空掘巷留设煤柱承压性能试验研究[J]. 中国矿业大学学报, 2020, 49(2):262-270. WANG Bo, GU Changwan, WANG Jun, et al. Bearing capacity experimental study of coal pillar in the gob-side entry driving under the reinforcement of inflatable lock-type anchor[J]. Journal of China University of Mining and Technology,2020,49(2):262-270(in Chinese).

[39] DAS A J, MANDAL P K, GHOSH C N, et al. Extraction of locked-up coal by strengthening of rib pillars with FRP-A comparative study through numerical modelling[J]. International Journal of Mining Science and Technology,2017,27(2):261-267. DOI: 10.1016/j.ijmst.2017.01.024

[40] 刘洪林, 赵红超, 陈辉, 等. 预应力纤维布加固房柱式采煤工作面遗留煤柱的方法: 中国, ZL 201910632413.4[P]. 2021-07-09. LIU Honglin, ZHAO Hongchao, CHEN Hui, et al. Method of reinforcing residual coal pillars of room and pillar type coal face by prestressed fiber cloth: China, ZL 201910632413.4[P]. 2021-07-09(in Chinese).

[41] 李庆文, 杨浩, 董芳红, 等. 一种快速加固小煤柱的FRP装置: 中国, ZL 201921478839.0[P]. 2020-04-28. LI Qingwen, YANG Hao, DONG Fanghong, et al. FRP device for quickly reinforcing small coal pillar: China, ZL 201921478839.0[P]. 2020-04-28(in Chinese).

[42] International Society for Rock Mechanics. Suggested methods for determining tensile strength of rock materials[J]. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts,1978,15(1):99-103.

[43] 中华人民共和国国家标准编写组. 煤和岩石物理力学性质测定方法: GB/T 23561—2010[S]. 北京: 中国标准出版社, 2010. National Standards Compilation Group of People's Republic of China. Methods for determining the physical and mechanical properties of coal and rock: GB/T 23561—2010[S]. Beijing: Standards Press of China, 2010(in Chinese).

[44] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014. Standardization Administration of the People's Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: Standards Press of China, 2014(in Chinese).

[45] XIAO W J, ZHANG D M, CAI Y, et al. Study on loading rate dependence of the coal failure process based on uniaxial compression test[J]. Pure and Applied Geophysics,2020,177:4925-4941. DOI: 10.1007/s00024-020-02513-0

[46] 敬登虎. FRP约束混凝土的应力—应变模型及其在加固中的应用研究[D]. 南京: 东南大学, 2006. JING Denghu. Researches on model of stress-strain and applications in rehabilitation for concrete confined by FRP[D]. Nanjing: Southeast University, 2006(in Chinese).

[47] LIM J C, OZBAKKALOGLU T. Lateral strain-to-axial strain relationship of confined concrete[J]. Journal of Structural Engineering,2015,141(5):04014141. DOI: 10.1061/(ASCE)ST.1943-541X.0001094

[48] FERROTTO M F, FISCHER O, CAVALERI L. Analysis-oriented stress-strain model of CRFP-confined circular concrete columns with applied preload[J]. Materials and Structures,2018,51(2):1-16.

[49] WU Y F, ZHOU Y W. Unified strength model based on Hoek-Brown failure criterion for circular and square concrete columns confined by FRP[J]. Journal of Composites for Construction,2010,14(2):175-184. DOI: 10.1061/(ASCE)CC.1943-5614.0000062

[50] ZHANG Y, LU Z F, CAO Y G. Unified strength model based on the Hoek-Brown failure criterion for fibre-reinforced polymer-confined pre-damaged concrete columns with circular and square cross sections[J]. Journal of Central South University,2020,27(12):3807-3820. DOI: 10.1007/s11771-020-4563-z

-

期刊类型引用(12)

1. 李庆文,高翔,谭正林,张帅帅,徐康康,才诗婷. 不同数量碳纤维布条带约束煤样的轴压蠕变特性细观模拟研究. 高压物理学报. 2025(02): 52-64 .  百度学术

百度学术

2. 李庆文,高翔,谭正林,张帅帅,徐康康,才诗婷. 不同数量碳纤维布条带约束煤样的轴压蠕变特性细观模拟研究. 高压物理学报. 2025(03): 52-64 .  百度学术

百度学术

3. 张学磊,杨明,李庆文,柳亚南,郝代龙,钟宇奇,高安梁. 替代率对CFRP布约束煤矸石混凝土轴压性能的影响. 山西建筑. 2025(07): 12-17+54 .  百度学术

百度学术

4. 梁志威,张庆贺. CFRP约束多裂隙岩体轴压性能研究. 重庆科技学院学报(自然科学版). 2024(01): 109-114 .  百度学术

百度学术

5. 李庆文,李莹,曾杏钢,徐康康,张向东. 不同尺寸下CFRP约束煤圆柱细观模拟研究. 煤矿安全. 2024(08): 133-145 .  百度学术

百度学术

6. 李庆文,禹萌萌,高森林,刘艺伟,曹行,曾杏钢,黄筱. 加载速率对碳纤维布被动约束煤能量演化的影响. 煤炭学报. 2024(S1): 236-247 .  百度学术

百度学术

7. 白锦文,杨欣宇,史旭东,冯国瑞,崔博强,宋诚,王凯,李剑. FRP包裹对煤充结构体劈裂破坏特征的影响. 岩石力学与工程学报. 2023(S1): 3541-3557 .  百度学术

百度学术

8. 李庆文,禹萌萌,刘艺伟,曹行,高森林,聂帆帆,李玲. GFRP布被动约束标准煤矸石混凝土圆柱轴压性能细观模拟. 硅酸盐通报. 2023(07): 2458-2471 .  百度学术

百度学术

9. 李庆文,曾杏钢,张向东,禹萌萌,刘艺伟,曹行. 碳纤维布层数对煤圆柱力学特性影响的细观研究. 煤炭科学技术. 2023(08): 73-85 .  百度学术

百度学术

10. 李庆文,高森林,黄筱. 基于加载速率效应的煤样损伤演化研究. 煤矿安全. 2023(11): 105-115 .  百度学术

百度学术

11. 赵兵朝,王京滨,张晴,赵阳,韦启蒙. 侧限条件下充填体-煤柱耦合承载协同作用机理. 煤炭学报. 2023(12): 4380-4392 .  百度学术

百度学术

12. 李庆文,高森林,胡露露,禹萌萌,刘艺伟,曾杏钢,祝青云,曹行,黄筱. 不同加载速率下非均质煤样能量耗散损伤本构关系. 煤炭学报. 2022(S1): 90-102 .  百度学术

百度学术

其他类型引用(4)

-

下载:

下载: