Cyclic compression behavior of FRP-ECC confined concrete cylinder

-

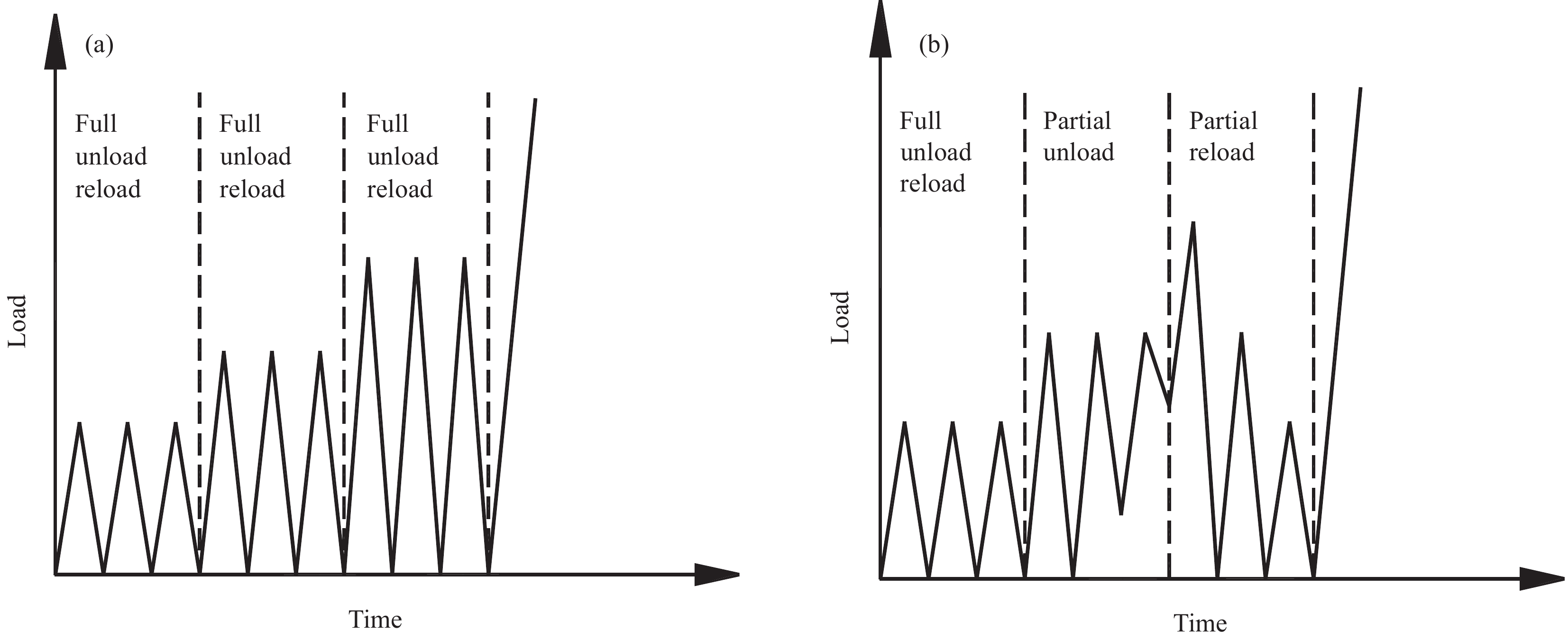

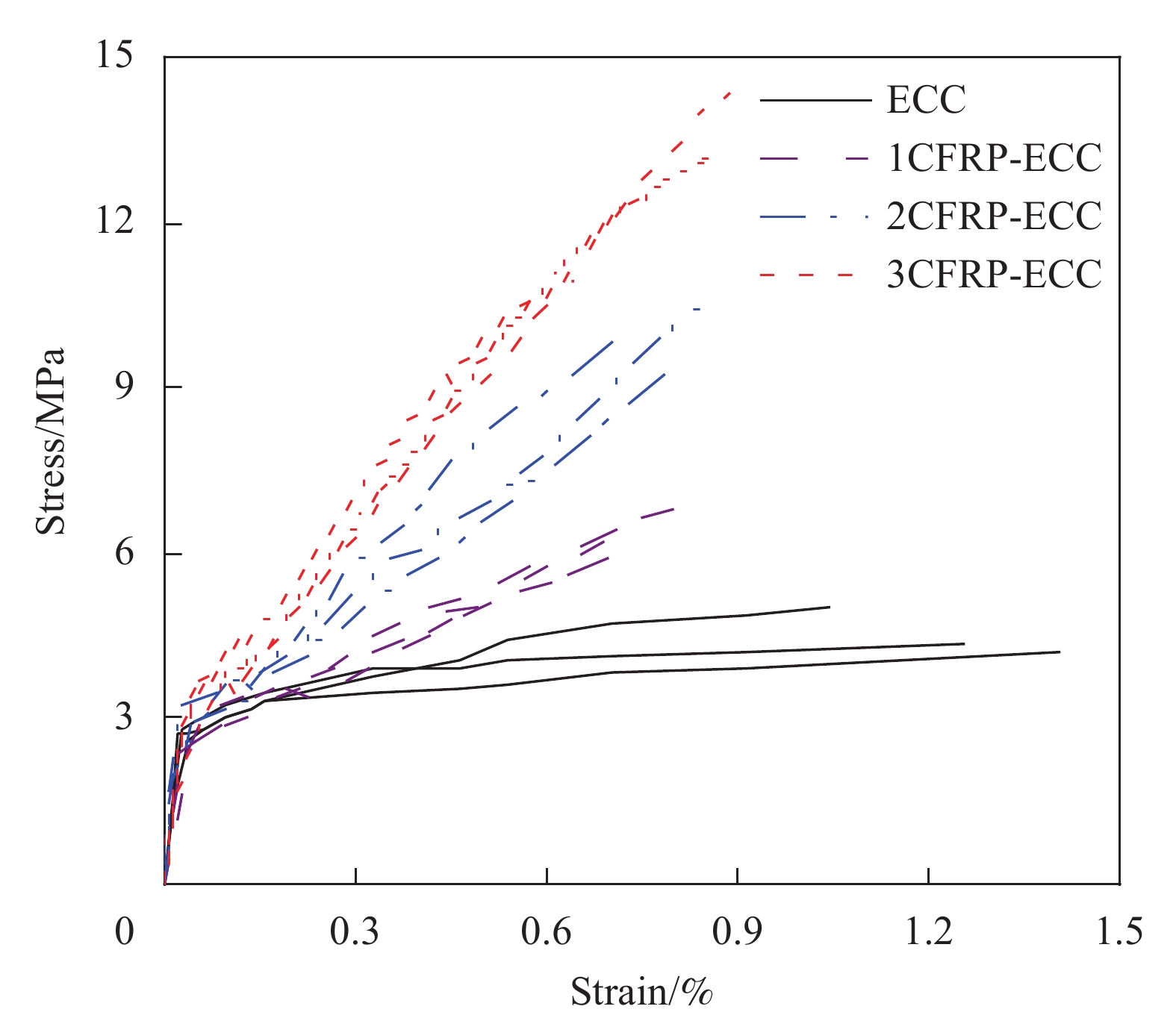

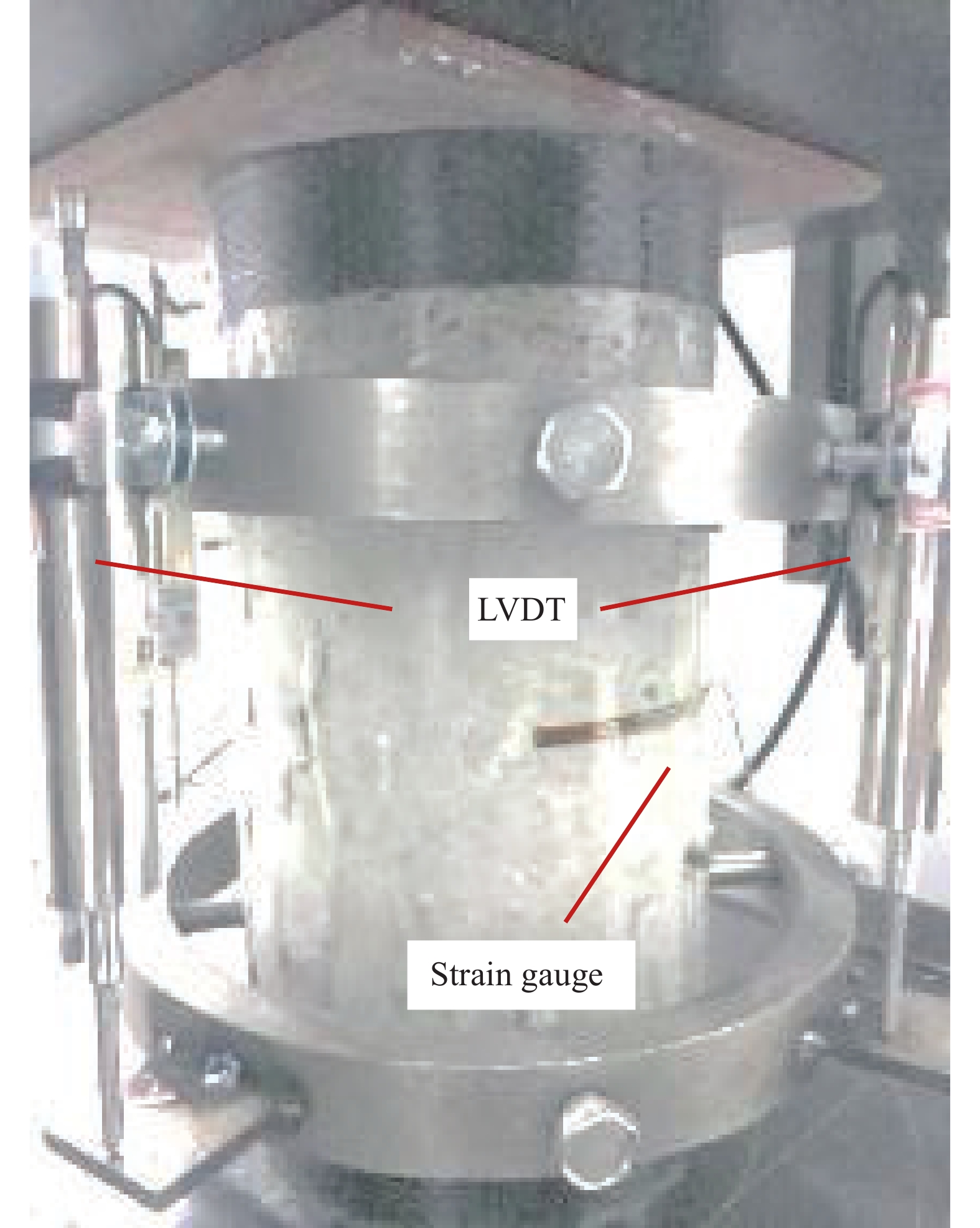

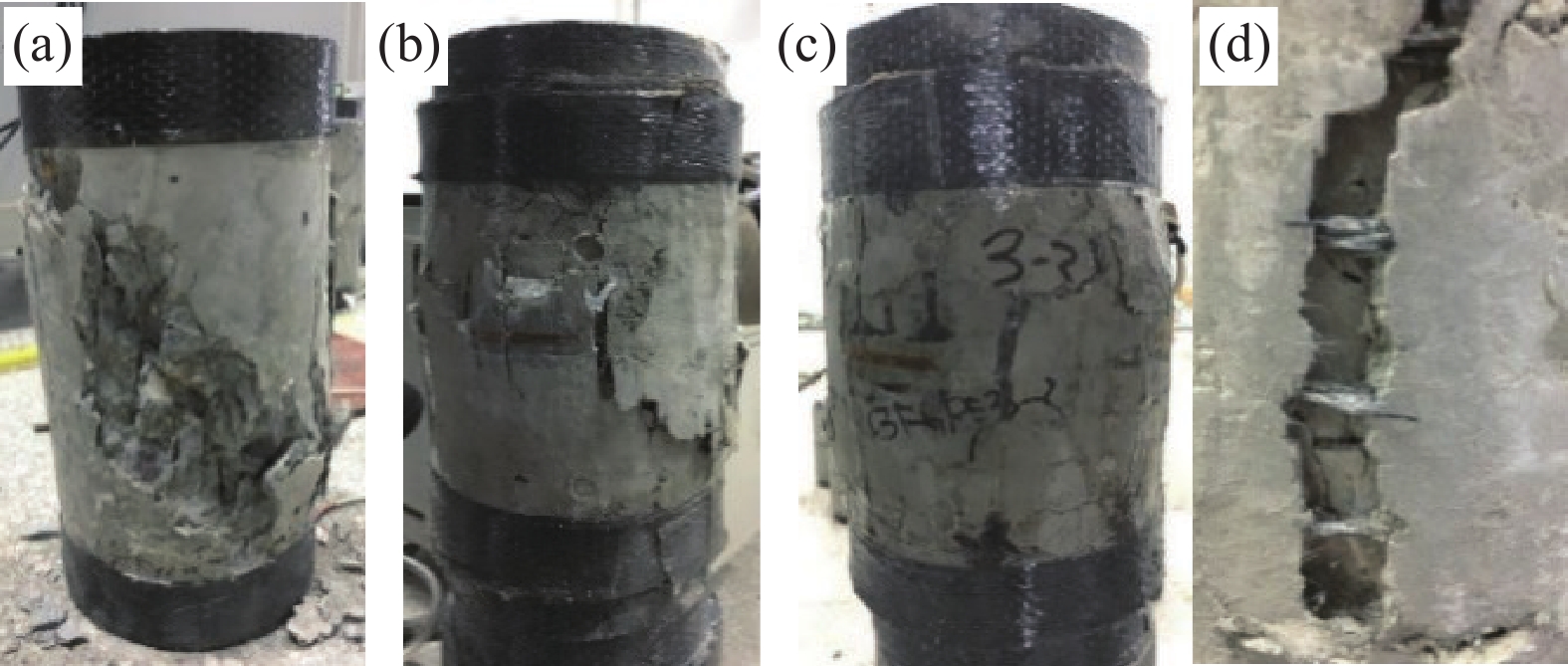

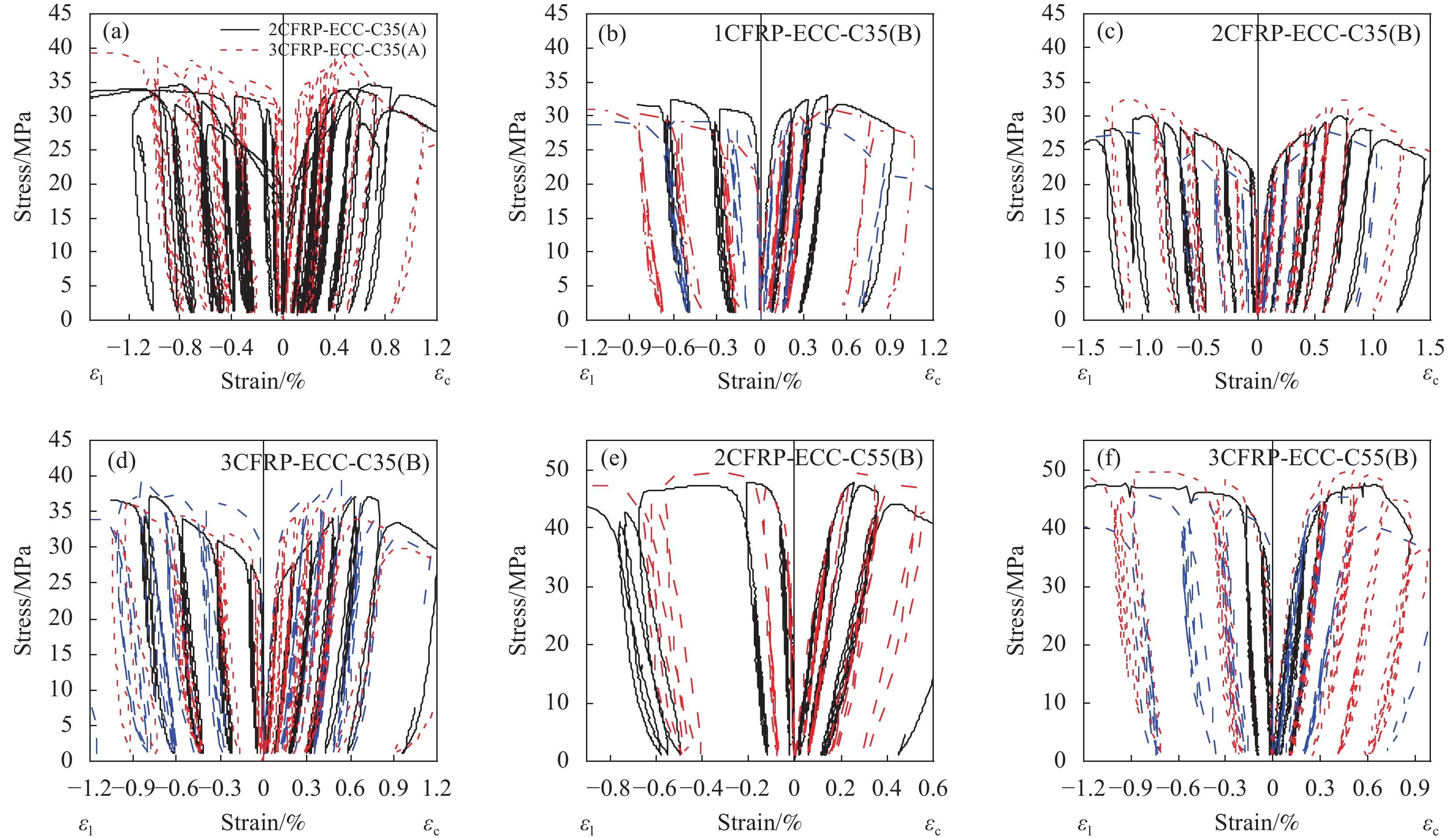

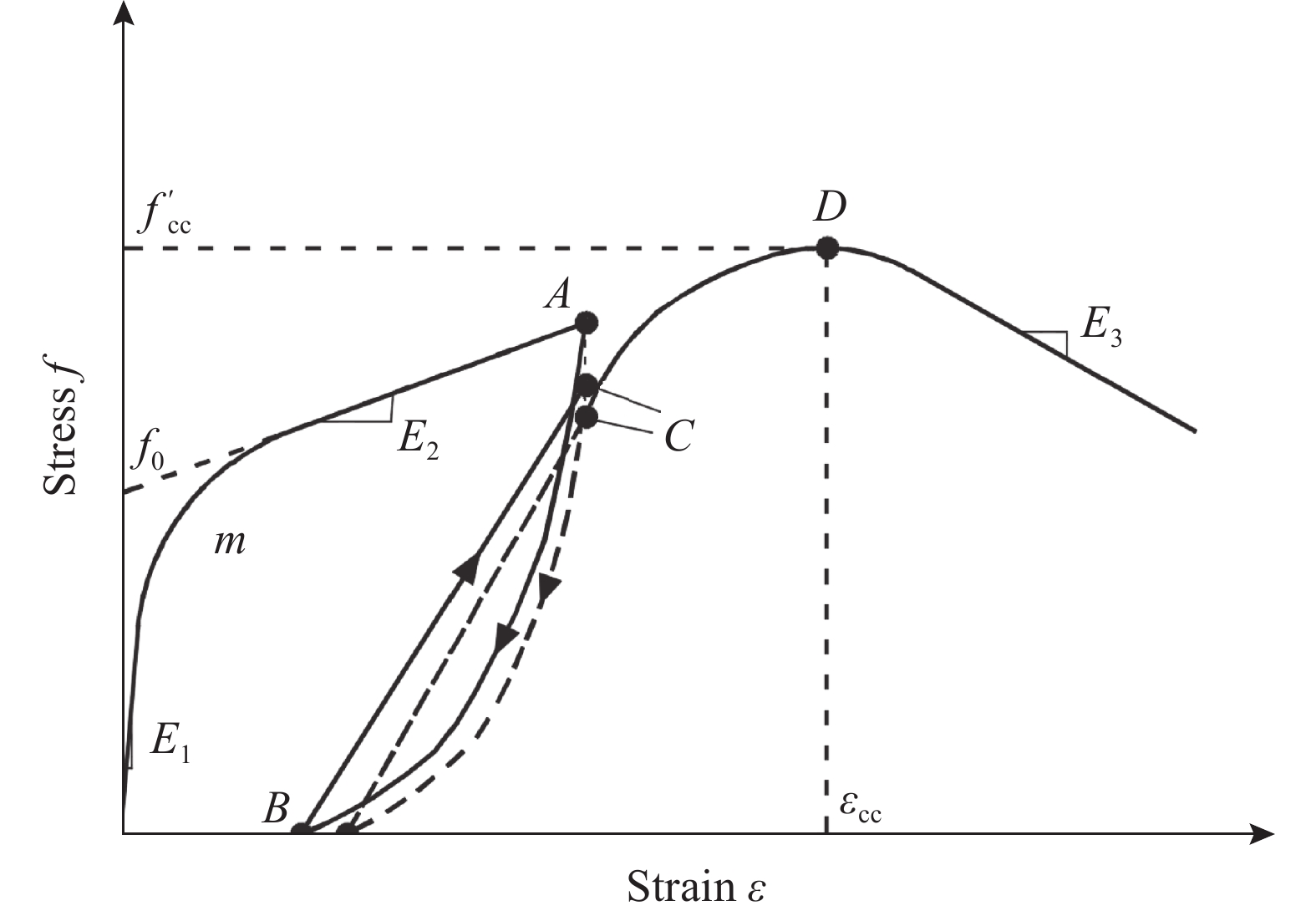

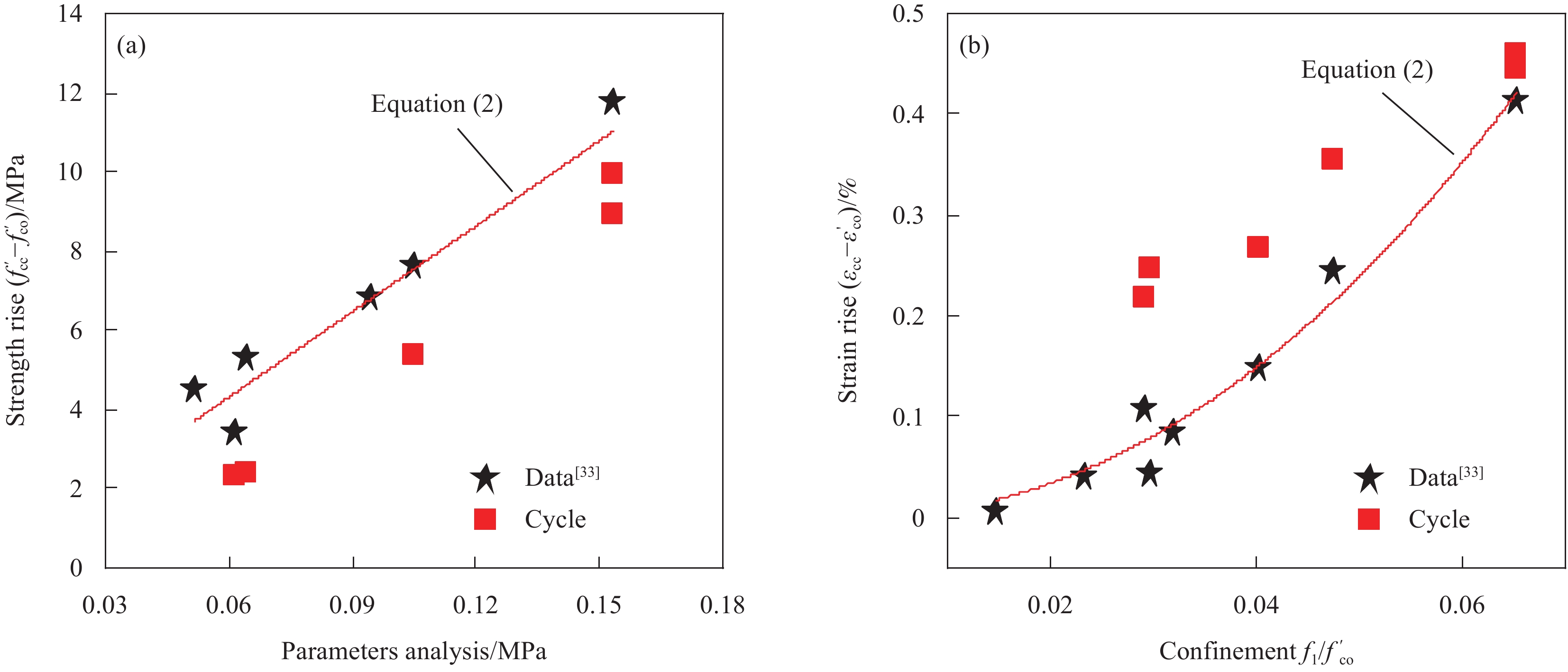

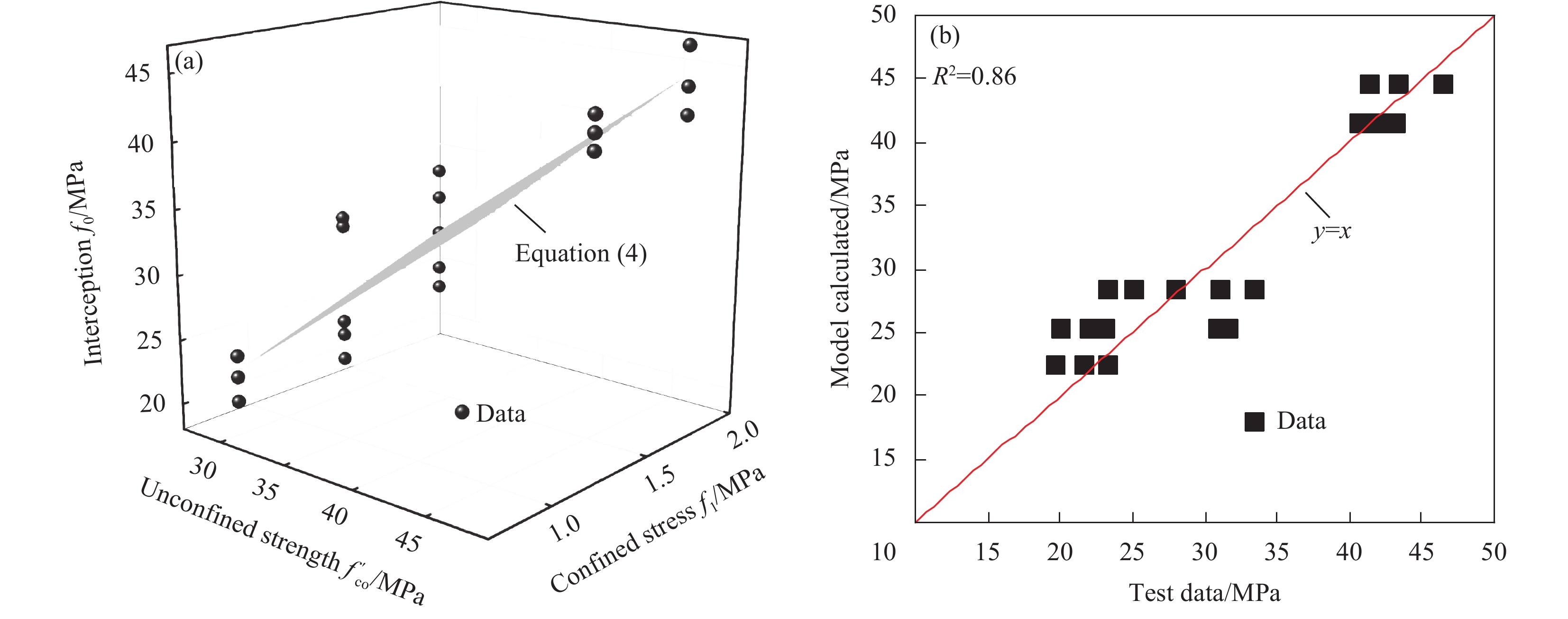

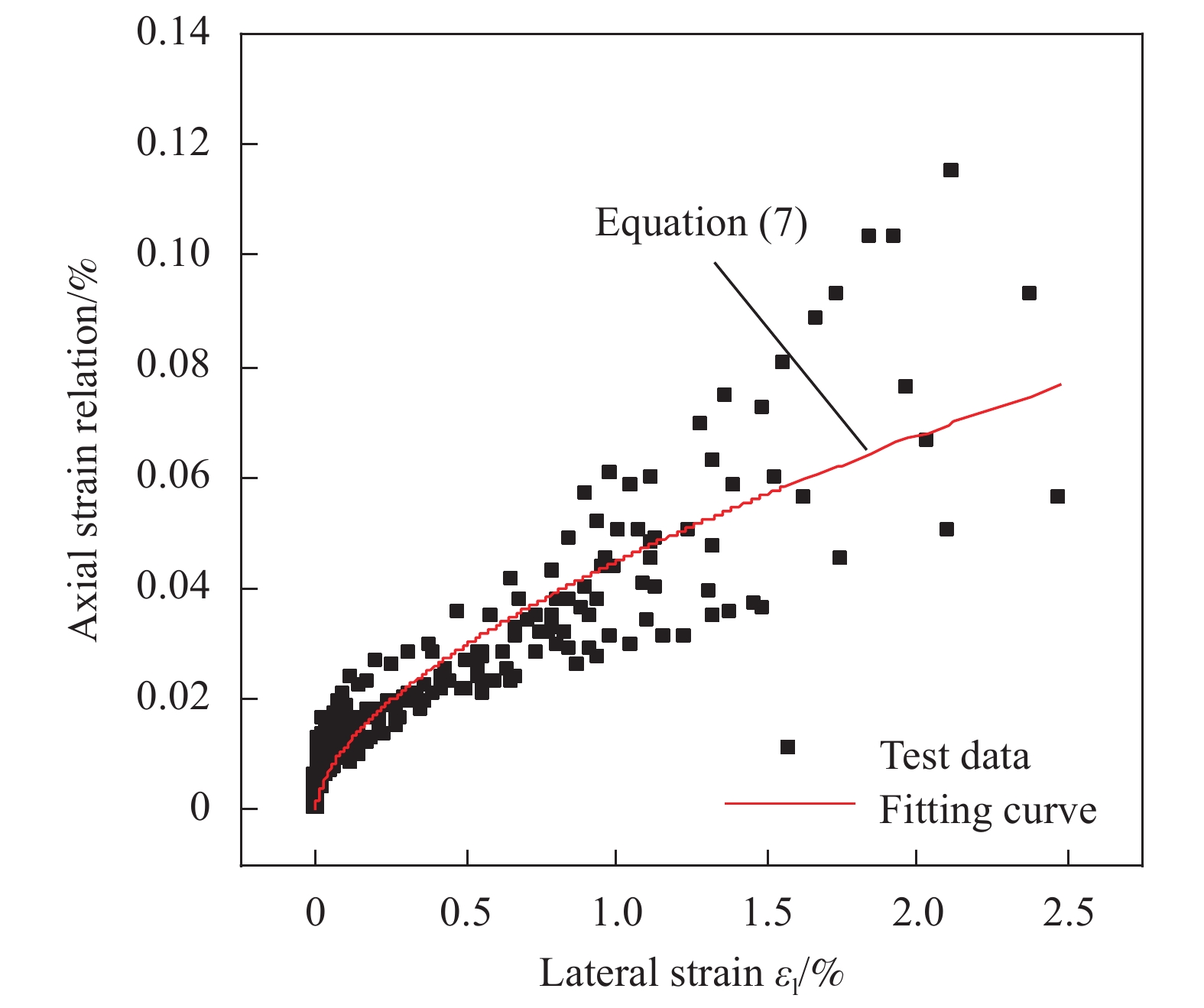

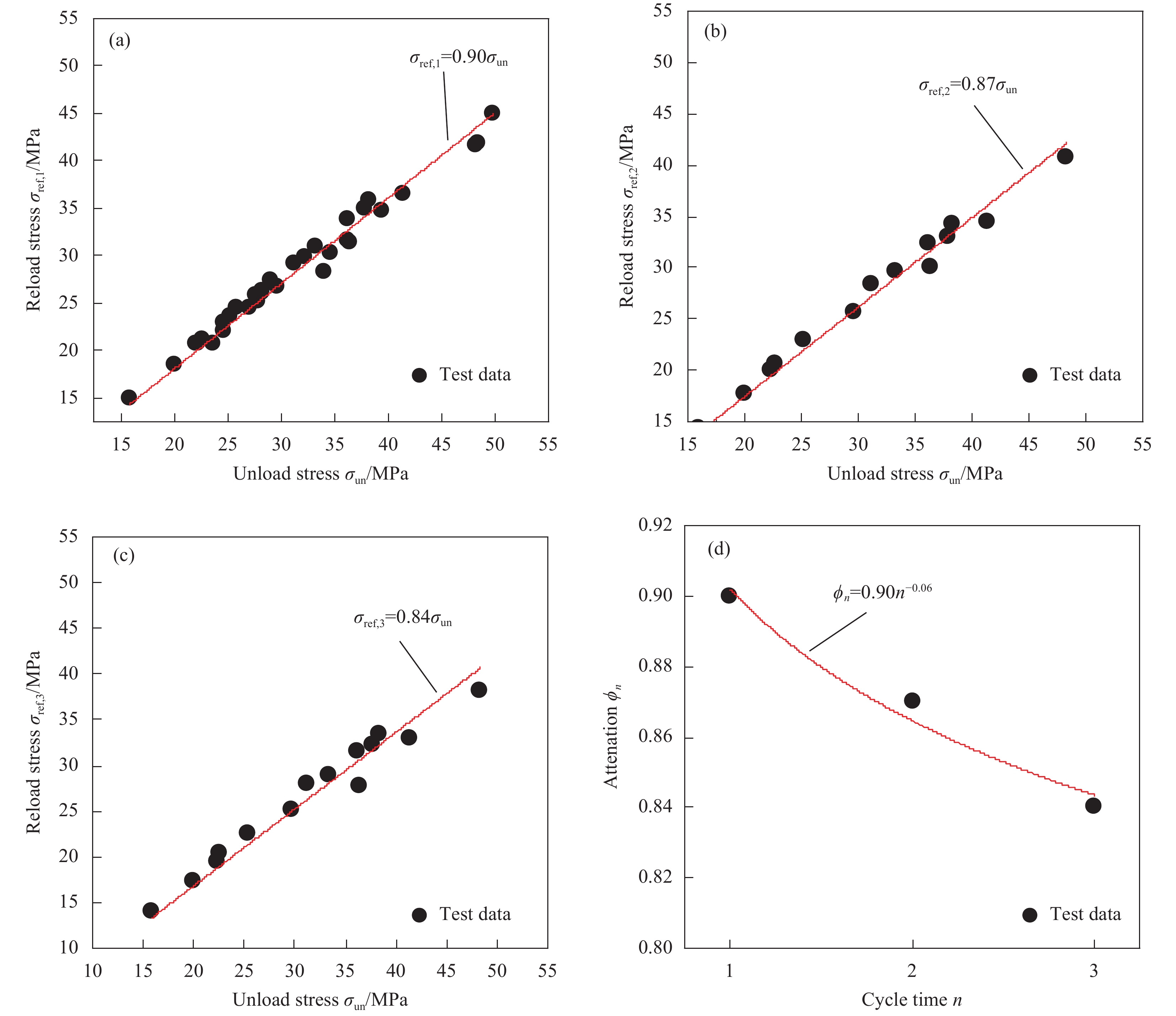

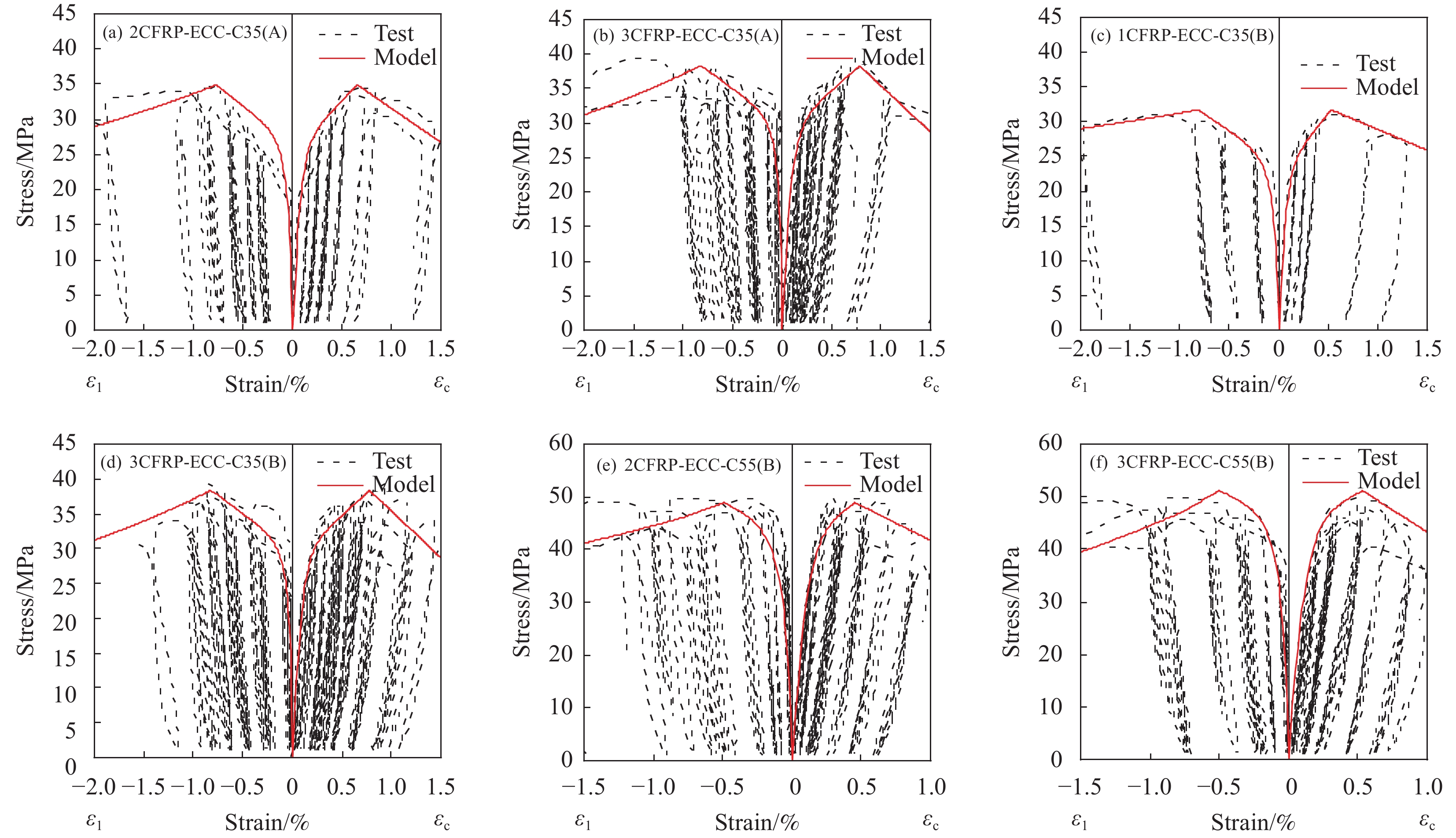

摘要: 考虑核心柱混凝土强度等级、碳纤维增强树脂复合材料(FRP)网格层数、反复荷载形式等因素,对FRP网格与工程水泥基复合材料(ECC)复合增强混凝土圆柱进行了轴向受压试验,研究约束圆柱的承载力和变形能力。试验结果表明,约束柱的破坏形态表现为FRP柔性网格断裂;随着网格层数的增加,约束柱的极限荷载和变形性能分别提高2%~35%和77%~145%;随着核心混凝土强度等级的提高,复合约束柱的极限承载力提高幅度降低。此外,根据试验结果并结合FRP约束混凝土的应力-应变关系模型,本文针对FRP-ECC复合约束圆柱在反复荷载作用下提出了相应的强度模型和应力-应变关系包络线模型。分析结果表明,模型所得轴向应力-轴向应变及轴向应力-环向应变关系曲线均与试验值吻合良好。Abstract: Considering the strength grade of core concrete, reinforcement layer of fiber-reinforced polymer (FRP) textile, the axial compressive tests of concrete cylinders strengthened with FRP textile and engineered cementitious composites (ECC) were carried out to study the bearing capacity and deformation performance of the FRP-ECC confined cylinder. The test results show that the failure mode of most strengthened cylinders is the rupture of embedded FRP flexible textile. With the increase of reinforcement FRP textile layers, the strengthened columns’ ultimate bearing capacity and deformation performance are improved by 2%-35% and 77%-145%, respectively. With the increase of the strength grade of the core concrete, the increase range of the ultimate bearing capacity is gradually reduced. In addition, according to the test results and the stress-strain model of FRP confined concrete, the corresponding strength model and envelope stress-strain models of FRP-ECC confined cylinder are given. The analysis results show that the stress-strain curves predicted by these models match well with test results.

-

Keywords:

- cyclic loading /

- FRP textile /

- ECC /

- confined cylinder /

- stress-strain model /

- concrete cylinder

-

碳纤维增强树脂复合材料(Carbon fiber reinforced plastics,CFRP)具有比金属更高的比刚度和比强度、优异的耐腐蚀和抗疲劳特性,但是其面外承载能力及抗冲击特性较弱[1-3],而金属延展性较好,抗冲击性能优良。为了结合二者的优点,常常将金属与CFRP复合材料复合,进行轻量化结构设计,如纤维-金属层合板(Fiber metal laminates, FMLs)超混杂结构[1,4],纤维-金属-泡沫夹层结构[5-7]等在航空航天、汽车工业、船舶和民用建设等领域的应用越来越广泛[8-16]。就汽车轻量化而言,发展车用CFRP-金属超混杂层合承载结构是一种既能满足高性能要求又同时兼顾一定成本的策略。在金属方面,单从材料的密度来看,铝合金、钛合金及镁合金等轻金属相比于钢的密度较小,但其更高的成本也在一定程度上限制了其在汽车轻量化方面的应用[17];而热成型钢因其成本较低、强度较高、碰撞吸能优良及成型性较好等优势已成为汽车轻量化的一种主要材料[18]。因此结合CFRP复合材料与热成型钢的优点,开发CFRP-热成型钢超混杂层合承载结构,在汽车工业具有非常良好的应用前景,目前宝马7系的B柱结构已经采用了这种混杂轻量化结构设计。然而,热成型钢和CFRP复合材料属于异种材料,两者之间必然存在物理性能的差异(如热膨胀系数、弹性模量等),导致钢与CFRP复合材料界面之间粘结强度较低,从而在界面上容易产生脱层,滋生裂纹。因此,对钢与CFRP复合材料界面连接进行增强增韧研究十分重要。

就改善FMLs层间断裂韧性而言,可以从两个方面分别入手:(1)可以通过改进金属与CFRP复合材料界面性能实现改善其层间断裂韧性的目的;(2)可以通过提高CFRP复合材料层的力学性能来改善其层间断裂韧性。对于改进FMLs界面性能,一般要对金属进行表面处理,如机械打磨[19]、激光刻蚀[20]、硅烷化处理[21]、喷砂[22-23]和等离子处理[24]等。对于改进CFRP复合材料层间力学性能,插层[25-27]、三维编织[28]、z-pinning[29]等技术被开发出来。目前,大部分学者的研究主要集中在金属表面处理方式或CFRP复合材料内部插层,而结合金属表面处理技术和CFRP-金属界面插层协同改善FMLs层间断裂韧性的研究还较少,对其增韧机制的研究还不够完善。

本文以热成型钢和CFRP复合材料为研究对象,采用金属表面处理和界面插层协同增韧方案,运用热压成型工艺制备出了6种不同界面强韧化方案的CFRP-热成型钢超混杂复合结构。并通过双悬臂梁试验(Double cantilever beam tests, DCB)和相关表征,讨论了表面处理和界面插层对CFRP-热成型钢超混杂复合结构层间断裂韧性的影响。另外,基于内聚区模型,对典型的界面增韧方案进行建模,并将其与实验结果进行了对比。

1. 试验方案

1.1 原材料

试验采用的钢板为连续变截面轧制热成型钢板(Tailor rolled blanks, TRB),厚度为1.2 mm,由北汽集团新技术研究院提供,其主要化学成分(按质量分数计算)为0.23wt%C、0.25wt%Si、1.35wt%Mn、0.19wt%Cr、0.04wt%Mo, 0.003wt%B, 经过加热并淬火后的拉伸强度可达1 500 MPa;单向T700碳纤维/树脂预浸料,中复神鹰碳纤维有限公司;环氧树脂(Epoxy,EP)为双酚F型树脂EPON 862,固化剂为EPIKURE 3140,均由广州市镐韵化工有限公司提供,其中环氧树脂与固化剂的质量比为2∶1;胶膜为艾联公司的L-F501,厚度约为0.3 mm;具体的材料参数见表1。其他原材料均由成都科隆化工有限公司提供。

表 1 碳纤维增强树脂复合材料(CFRP)及插层(L-F501胶膜和树脂)的物理参数Table 1. Physical parameters of carbon fiber reinforced plastics(CFRP) composite and interlayer (L-F501 and epoxy)Material Physical parameter Value CFRP Young’s modulus (Fiber direction)/GPa 138 Young’s modulus (Transverse direction)/GPa 10 Tensile strength (Fiber direction)/MPa 1 800 Class fiber volume fraction/vol% 67 L-F501 Young’s modulus/GPa 3.6 Tensile strength/MPa 40 Steel-to-steel joint (Untreated)/MPa 28 Epoxy Young’s modulus/GPa 3 Tensile strength/MPa 60 1.2 超混杂层合板制备流程

本文采用热压成型工艺,对CFRP和热成型钢进行有效地共固化粘结。具体制备CFRP-热成型钢超混杂层合板的流程和热压工艺如图1所示。

1.3 界面强韧化方案

1.3.1 金属表面脱脂处理

裁剪一定尺寸的热成型钢板,将其浸泡至酒精溶液中,超声清洗30 min,以做简单的脱脂处理,60℃干燥箱烘干。最后裁剪相应尺寸的CFRP复合材料预浸料,与热成型钢进行共固化热压成型。

1.3.2 金属表面打磨处理

选用600#型号砂纸对热成型钢表面进行有效打磨,随后将打磨处理后的钢板浸泡至酒精溶液中进行脱脂,其余过程同1.3.1节。

1.3.3 金属表面喷砂处理

选用36#金刚砂(SiC类型),利用吸入式喷砂机对热成型钢进行喷砂处理,喷砂作业时空气压力为0.8 MPa左右,喷砂距离约为9 cm,喷砂角度为70°~85°,随后将喷砂处理后的钢板浸泡至酒精溶液中,超声清洗30 min,以去除表面的油脂和残留的SiC颗粒,其余过程同1.3.1节。

1.3.4 界面插层处理

由于CFRP复合材料与金属之间容易存在电化学腐蚀问题,因此引入界面插层来隔绝电化学腐蚀。本文拟采用L-F501胶膜和纯树脂插层两种方案。

L-F501胶膜插层:直接将裁剪好的单层胶膜引入到CFRP复合材料与金属界面之间,进行叠层铺设,最后将试件放到热压机中,进行共固化热压成型(最终胶膜的厚度在0.2 mm左右)。

纯树脂插层:首先将环氧树脂与固化剂按质量2∶1进行混合,进行搅拌10 min,脱泡5 min,得到自制的纯树脂粘结剂。采用涂布机将配好的纯树脂粘结剂均匀敷在热成型钢与裁好的CFRP复合材料之间,保证环氧胶面密度为225 g/m2,最后将试件放到热压机中,进行共固化热压成型(最终的环氧胶厚度在30 μm左右)。

对上述金属表面处理方式和界面插层进行组合,得到了本文层间增韧的具体6种方案如表2所示。

表 2 试验方案Table 2. Experimental schemesGroup Scheme name Abbreviation scheme 1 Degreasing Degreasing 2 600# sandpaper grinding 600# 3 Sandblasting GB36# 4 Degreasing/adhesive film interleaves Degreasing/AF 5 Sandblasting/adhesive film interleaves GB36#/AF 6 Sandblasting/epoxy resin interleaves GB36#/EP 1.4 试验加载与测试

参照标准JIS K 7086[30]对CFRP-热成型钢超混杂层合板进行DCB实验,本文中的层合板结构为2/1结构(铺叠形式为钢/

[0∘]3 CFRP/钢)。由于试件不完全对称,在DCB测试中可能造成试件末端偏移影响测量精度[31],为此通过增大钢板厚度和减小CFRP复合材料层的厚度来近似使其上下板的弯曲刚度接近,以减小实验误差。试件尺寸及加载示意图如图2所示。其中,L、B、2H、t分别代表试件的长、宽、高和CFRP复合材料层的厚度。预制裂纹长度为af ;嵌入物尖端至力的加载点为初始裂纹,其初始分层长度为a ;分层增量Δa 由钢板两侧的刻度作为标记。实验的加载速度为1 mm/min,当分层增量达到50 mm时,停止加载。采用改进的柔度校准方法计算得到I型层间断裂韧性GIC (kJ/m2)[30]:GIC=32(2H)(PCB)(Bλ)23αI (1) a2H=αI(Bλ)13+α0 (2) 其中:

PC 为裂纹起始时的临界载荷;λ 为柔度;αI 为拟合直线的截距;α0 为拟合直线的斜率。2. 结果与讨论

2.1 CFRP-热成型钢超混杂层合板双悬臂梁实验测试结果

图3为通过静态DCB试验得到的各类型试件的I型载荷-位移曲线。可知:随着张开位移的增大,载荷也逐渐增大,载荷与张开位移初始阶段呈线性关系;随后曲线出现拐点,载荷非线性上升直到最大值;最后阶段,张开位移增大,载荷

P 逐渐减小,直到分层长度达到50 mm,结束实验。图4为所有方案试件的临界载荷PC 。可以看到,金属表面处理和界面插层对界面失效临界载荷PC 有着不同的影响。其中,对金属表面进行喷砂处理可以有效地提高临界载荷PC ,且效果明显优于其他类别的表面处理方式;对热成型钢和CFRP复合材料界面进行插层,如脱脂/界面插层胶膜试件,相比于单进行脱脂处理试件,其临界载荷PC 也得到了极大的提高,表明界面插层有利于层间力学性能的提高;在对金属表面进行喷砂处理的基础上,进一步在异种材料界面引入插层进行协同增强处理,如喷砂/界面胶膜插层试件,其临界载荷PC 相比于脱脂/界面胶膜插层试件有了更进一步地提高,证明了采用金属表面处理技术与界面插层协同改性层合板的有效性。其可以最大幅度地提高界面失效临界载荷。另外,对于协同改性层合板的试件,临界载荷值PC 均高于只进行金属表面处理的试件;纯树脂插层试件的临界载荷低于胶膜插层的临界载荷。通过载荷、张开位移和分层增量可以计算出不同位置处的断裂韧性值。图5为不同方案试件的R曲线,横坐标为分层增量Δα,纵坐标为I型层间断裂韧性。可以看出,随着裂纹的扩展,其层间断裂韧性值逐渐增大,主要是由于初始分层裂纹形成后会引起纤维桥接,随后层间断裂韧性趋于平稳状态。

不同方案对应的I型断裂韧性

GIC 和断裂阻抗GIR 如图6所示,其中GIC 为Δα=0 mm处的断裂韧性值,GIR 为Δα=25~45 mm处的平均断裂韧性值。可以看出,断裂韧性的变化规律与临界载荷的变化规律相同。其中,对于机械打磨的试件,GIC 和GIR 均比较低;喷砂试件的GIC 和GIR 均高于脱脂试件,分别提高了64%和81%(见图6),说明喷砂处理可以有效提高层间断裂韧性;在脱脂钢板与CFRP复合材料界面之间引入胶膜,其断裂韧性得到了极大的提高,相比于脱脂试件,GIC 和GIR 分别提高了214%和237%;对CFRP复合材料-热成型钢进行喷砂和界面胶膜插层协同改性,可以最大限度地提高层间断裂韧性,尤其GIC ,相比于脱脂试件提高了近343%,相比于喷砂试件提高了170%,相比脱脂/界面插层胶膜试件提高了41%;另外,纯树脂插层的试件,其层间断裂韧性相比于只进行金属表面处理的试件也有较大提高。2.2 CFRP-热成型钢超混杂层合板I型裂纹扩展有限元模拟

利用ABAQUS软件对层合板I型裂纹扩展进行有限元模拟。其中,CFRP复合材料和钢板采用二维平面应变单元,单元类型为CPE4RH。胶膜或纯树脂插层采用二维平面应变单元,单元类型为内聚单元COH2D4。由于胶膜固化后有实际厚度且不可忽略,因此对Degreasing/AF 和GB36#/AF样品采用有限厚度内聚单元建模来模拟界面脱粘;而其他类型试件,界面胶层较薄,故采用零厚度内聚单元进行建模。在模拟裂纹扩展阶段时,为了克服计算收敛问题,将内聚单元尺寸调到0.5 mm以下。最后根据试验测得的I型断裂韧性

GIC 等相关参数,得到I型加载模拟结果,并将其与实验结果进行对比,如图7所示,可见,计算结果和试验结果吻合程度较好。2.3 CFRP-热成型钢超混杂层合板界面增韧机制

有多种因素促成了CFRP-热成型钢超混杂层合板层间断裂韧性的提高。其中,钢板表面的物理化学性质(如钢板表面的微结构、粗糙度和表面润湿性等)起着重要的作用。

图8为不同金属表面处理方式下的钢板表面形貌。对脱脂钢板表面进行扫描电镜观察(见图8(a)),明显可见脱脂钢板表面有很多不规则的凹凸结构,相对粗糙;而钢板经过砂纸打磨处理之后(见图8(b)),原本粗糙的表面变得更光滑,表面出现了一些较细腻的划痕;对钢板表面进行喷砂处理后(见图8(c)),钢板表面出现了较大的起伏,相较脱脂钢板,其表现变得更粗糙,凹凸结构也更明显。从上述钢板表面微结构的变化可以看出,不同的表面处理方式可以得到不同的粗糙度和微结构,它们是影响层间断裂韧性的一个重要因素。图9为采用激光共聚焦扫描显微镜测试得到的钢板表面粗糙度。其中脱脂钢板表面的粗糙度

Ra 为2.55 μm,砂纸打磨处理后的钢板表面的粗糙度为0.79 μm,喷砂钢板表面的粗糙度为7.97 μm。粗糙度测试结果与SEM结果一致,同时也与相应金属表面处理试件的层间断裂韧性值的大小相互吻合,表现为粗糙程度越高,其层间断裂韧性也越大,这是由于粗糙的表面有利于提高金属与树脂之间的力学机械联锁作用,从而在一定程度上改善超混杂层合板的层间断裂韧性。图10为不同金属表面处理方式下钢板表面的接触角。可以得出以下结论:对脱脂钢板进行机械打磨,由于表面的凹凸结构被破坏,钢板表面的接触角从

77.5∘ 降到72.5∘ ,润湿性增强;喷砂处理的钢板,表面接触角较大,浸润性也较差,不利于树脂与金属之间的充分接触[17]。但从最终的DCB实验结果来看,虽然表面润湿性和粗糙度都对界面粘结性能有影响,但是两者存在竞争机制,本实验中,表面粗糙度对层间断裂韧性的提升占主导地位。图11为采用电子显微镜观察到的各组试件的钢板一侧破坏面。从图11(a)和图11(b)可以看到,对于脱脂试件和砂纸打磨的试件,其钢板表面只有微量的碳纤维和树脂附着,CFRP复合材料与热成型钢直接在界面发生失效,裂纹扩展时裂纹几乎不发生偏转(见图12(a)),导致其层间断裂韧性较低。当对热成型钢表面进行喷砂处理之后,如图11(c)GB36#样品,由于提高了热成型钢与树脂之间的机械联锁作用,界面脱粘的现象发生了改变,大量的纤维和树脂附着在钢板表面,界面破坏形式主要为内聚破坏,而内聚破坏主要由高分子基体失效引起,在裂纹扩展时会消耗更多的能量,因此GB36#样品的层间断裂韧性较脱脂和机械打磨试件要高,同时这也证明了改变界面破坏的形式,可以有效地提高金属纤维层合板的层间断裂韧性。进一步对GB36#试件破坏面的局部进行显微镜观察(见图11(c)右上角),可以看到有少部分的钢板直接暴露了出来,可能原因是喷砂会使钢板表面粗糙度急剧增加,润湿性下降,导致部分钢板与树脂粘接作用力不强而脱粘。如图11(e),在脱脂钢板与CFRP复合材料界面之间引入胶膜,其破坏模式比较特殊,除了裂纹起始这一小部分的破坏模式是界面失效外,其他区域均是内聚失效;而且可以清楚地看到破坏面比较粗糙同时伴有胶层中短切纤维拔出的现象,粗糙的表面说明了裂纹在扩展时,由于裂纹偏转和基体的塑性变形产生了更大的断裂面积,而纤维的桥接作用又有利于胶膜的增强增韧;另外胶膜与复合材料之间存在化学交联的作用,界面粘结性能较好,以上就是插层胶膜能够大幅度提高层间断裂韧性的主要原因。将Degreasing/AF和GB36#/AF试件进行对比(见图11(e)和图11(f)),GB36#/AF试件的钢板表面全部被断裂的胶膜所包覆,它在起裂和裂纹扩展位置的破坏模式都属于内聚破坏,而Degreasing/AF试件在起裂和裂纹扩展阶段发生的是界面破坏和内聚破坏,这就是两组样品

GIC 不同但GIR 相近的原因。再对GB36#/EP样品的破坏面进行观察(见图11(d)),不难看出其层间断裂的模式也是内聚破坏,但与GB36#试件的破坏面形貌稍有不同,出现差异的原因有:树脂层厚度的增加会扩大裂纹扩展的范围(见图12(b)和12(c)),延长裂纹扩展路径[25],这也是GB36#/EP试件层间断裂韧性比GB36#试件高的原因。将GB36#/EP与GB36#/AF两组试件进行对比,GB36#/AF层间断裂韧性比GB36#/EP试样高,可能原因有:胶膜中本身包含的短切纤维的桥接作用有利于裂纹的偏转和胶层的增强增韧;胶膜插层的厚度大于纯树脂插层的厚度,意味着容许裂纹扩展的范围增大(见图12(f));胶膜基体与环氧树脂基体本身的力学性能差异等。3. 结 论

(1)通过双悬臂梁(DCB)试验结果,可以得知采用金属表面处理和界面插层协同增韧的方案,能最大限度地提高纤维-金属层合板的层间断裂韧性。其中喷砂/界面胶膜插层(GB36#/AF)试件的I型断裂韧性

GIC 和断裂阻抗GIR 相比于脱脂试件提高了343%和254%;GB36#/EP试件的GIC 和GIR 相比于脱脂试件提高了129%和100%。(2)根据内聚单元建立的有限元模型及临界载荷

PC 和I型断裂韧性GIC 等相关参数,得到了I型加载模拟结果,且与实验曲线对比拟合程度较好。(3)通过断裂面形貌观测,可以发现各组试件的失效破坏特征有所差异。对于脱脂和金属打磨的试件,其失效模式主要是界面失效;对于喷砂和插层试件,破坏模式主要为内聚失效。

(4)基于以上表征和观测,揭示了碳纤维增强树脂复合材料(CFRP)-热成型钢界面的增强增韧机制。提高钢板表面的粗糙度,可以有效地提高钢板与聚合物基体的机械联锁作用;在金属-CFRP复合材料界面之间插层胶膜或树脂,可以有效地扩大裂纹扩展的范围,延长裂纹扩展路径;另外胶膜内部含有很多短切纤维,短切纤维的桥接作用使裂纹在扩展时发生偏转,从而导致基体的塑性破坏,吸收更多的能量。

-

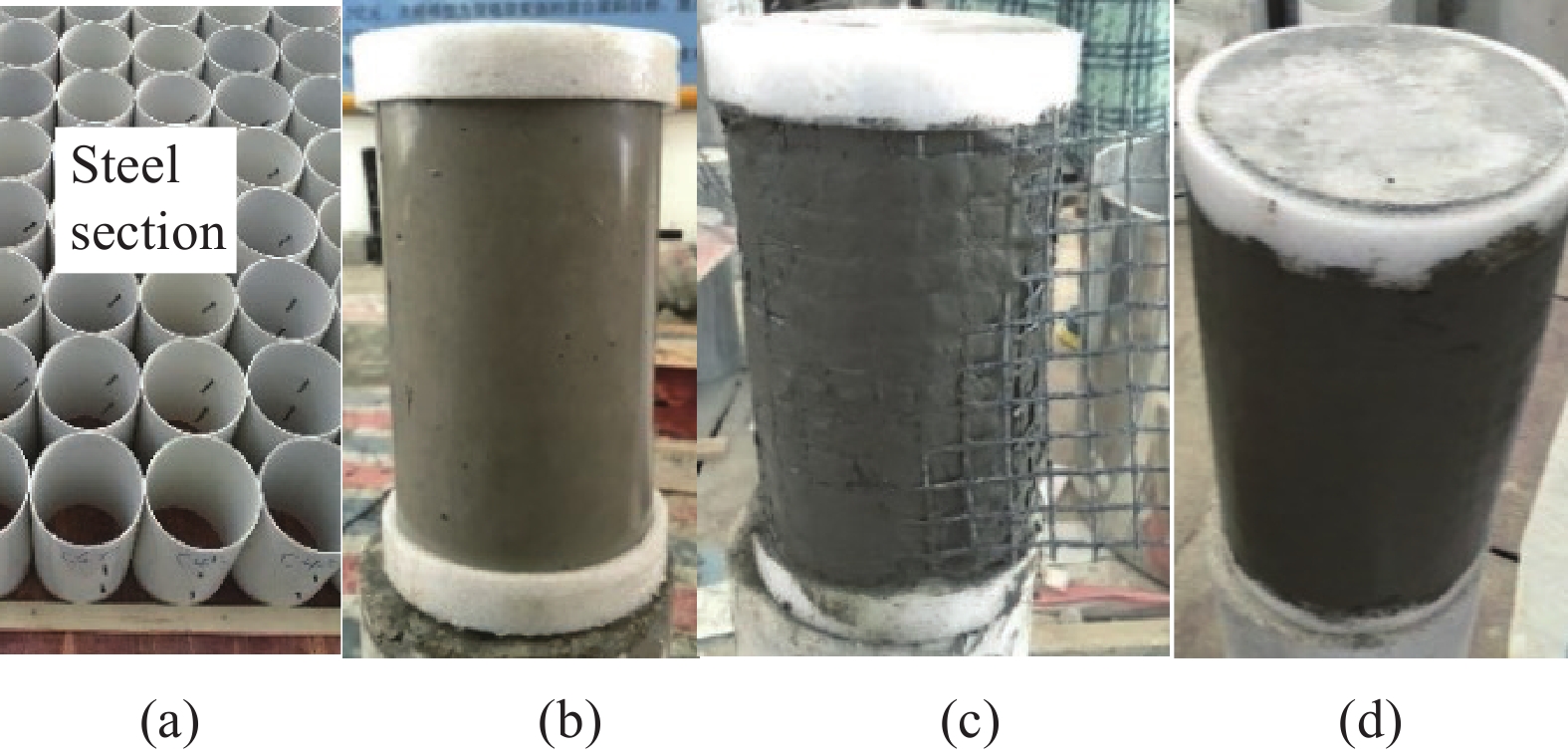

表 1 工程水泥基复合材料(ECC)配合比

Table 1 Mix proportion of engineered cementitous composites (ECC)

kg/m3 Water Cement Sand Water reducer Fly ash Fiber Silica fume 330 351 317 4.5 1052 26 40 表 2 试验方案

Table 2 Experimental program

Sample Number in

each groupCFRP

layerThickness of ECC/mm 2CFRP-ECC-C35(A) 3 2 10 3CFRP-ECC-C35(A) 3 3 1CFRP-ECC-C35(B) 3 1 2CFRP-ECC-C35(B) 3 2 3CFRP-ECC-C35(B) 3 3 1CFRP-ECC-C55(B) 3 1 2CFRP-ECC-C55(B) 3 2 3CFRP-ECC-C55(B) 3 3 Notes:For the sample, the first number represents the layer of CFRP textile; CFRP—Carbon fiber reinforced polymer; CFRP-ECC—Strengthening CFRP-ECC composite layer; C35, C55—Strength grade of core concrete; A, B—Loading scheme. 表 3 素混凝土强度

Table 3 Compressive strength of plain concrete

ID ε′co/% f′co/MPa Average 150 mm cube strength ε′co/% f′co/MPa C35 0.35 25.75 0.32 28.74 36.38 0.28 31.44 0.32 29.03 C55 0.24 48.41 0.24 46.67 59.08 0.28 44.61 0.21 46.99 Notes:ε′co, f′co—Peak strain and stress of plain concrete; Conversion ratio between cylinder and cube is 0.79[43]. 表 4 CFRP-ECC复合约束混凝土圆柱试验数据

Table 4 Test results of CFRP-ECC confined columns

Sample εl/% εcc/% f′cc/MPa Average εcc/ε′co f′cc/f′co εl

/%εcc/% f′cc/MPa 1CFRP-ECC-C35(B)-1 1.06 0.70 33.1 1.07 0.56 31.1 1.77 1.08 1CFRP-ECC-C35(B)-2 1.01 0.39 29.1 1CFRP-ECC-C35(B)-3 1.13 0.60 31.0 2CFRP-ECC-C35(B)-1 0.96 0.71 30.1 1.06 0.67 31.2 2.12 1.09 2CFRP-ECC-C35(B)-2 1.16 0.63 32.3 3CFRP-ECC-C35(B)-1 0.78 0.73 37.2 0.86 0.76 37.7 2.40 1.31 3CFRP-ECC-C35(B)-2 0.95 0.60 36.4 3CFRP-ECC-C35(B)-3 0.85 0.95 39.5 2CFRP-ECC-C55(B)-1 – 0.25 47.8 0.97 0.46 49.1 1.89 1.05 2CFRP-ECC-C55(B)-2 1.15 0.67 49.8 2CFRP-ECC-C55(B)-3 0.78 0.46 49.6 3CFRP-ECC-C55(B)-1 0.88 0.51 47.3 0.88 0.51 47.5 2.10 1.02 3CFRP-ECC-C55(B)-2 – 0.29 45.4 3CFRP-ECC-C55(B)-3 0.88 0.51 49.8 2CFRP-ECC-C35(A)-1 0.80 0.70 34.6 1.01 0.58 34.1 1.83 1.19 2CFRP-ECC-C35(A)-2 1.09 0.56 34.1 2CFRP-ECC-C35(A)-3 1.15 0.48 33.8 3CFRP-ECC-C35(A)-1 0.71 0.79 38.1 1.01 0.78 38.7 2.45 1.35 3CFRP-ECC-C35(A)-2 1.30 0.76 39.3 Notes: εcc and f′cc—Ultimate axial strain and ultimate strength of confined cylinders. 表 5 CFRP-ECC复合约束混凝土圆柱模型和试验结果对比

Table 5 Comparison of model and test results of CFRP-ECC confined cylinders

Sample Test Prediction Prediction/Test εcc

/%f′cc

/MPaεcc

/%f′cc

/MPaεcc f′cc 1CFRP-ECC-C35(B) 0.56 31.06 0.53 31.72 0.94 1.02 2CFRP-ECC-C35(B) 0.67 31.19 0.65 34.84 0.97 1.12 3CFRP-ECC-C35(B) 0.76 37.68 0.78 38.33 1.03 1.02 2CFRP-ECC-C55(B) 0.46 49.07 0.45 48.98 0.98 1.00 3CFRP-ECC-C55(B) 0.51 47.50 0.53 51.13 1.04 1.08 2CFRP-ECC-C35(A) 0.58 34.13 0.65 34.84 1.13 1.02 3CFRP-ECC-C35(A) 0.78 38.70 0.78 38.33 1.01 0.99 Mean 1.01 1.04 SD 0.06 0.03 CV 0.055 0.034 Notes: Mean—Average value; SD—Standard deviation; CV—Coefficient of variation. -

[1] TAELJSTEN B, BLANKSVAERD T. Mineral-based bonding of carbon FRP to strengthen concrete structures[J]. Jour-nal of Composites for Construction,2007,11(2):120-128. DOI: 10.1061/(ASCE)1090-0268(2007)11:2(120)

[2] YU K Q, YU J T, DAI J G, et al. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers[J]. Construction Building Materials,2018,158:217-227. DOI: 10.1016/j.conbuildmat.2017.10.040

[3] POURFALAH S. Behaviour of engineered cementitious composites and hybrid engineered cementitious compo-sites at high temperatures[J]. Construction Building Materials,2018,158(15):921-937.

[4] ZHOU Y W, XI B, YU K Q, et al. Mechanical properties of hybrid ultra-high performance engineered cementitous composites incorporating steel and polyethylene fibers[J]. Materials (Basel),2018,11(8):1448. DOI: 10.3390/ma11081448

[5] ZHOU Y, ZHENG Y, SUI L, et al. Behavior and modeling of FRP-confined ultra-lightweight cement composites under monotonic axial compression[J]. Composites Part B: Engineering,2019,162:289-302. DOI: 10.1016/j.compositesb.2018.10.087

[6] 徐世烺, 蔡新华. 超高韧性水泥基复合材料碳化与渗透性能试验研究[J]. 复合材料学报, 2010, 27(3):177-183. XU Shilang, CAI Xinhua. Experimental studies on permeability and carbonation properties of ultra high toughness cementitious composites[J]. Acta Materiae Compositae Sinica,2010,27(3):177-183(in Chinese).

[7] MA H, ZHANG Z G. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance[J]. Construction and Building Materials,2020,252:119048. DOI: 10.1016/j.conbuildmat.2020.119048

[8] LIU Y M, ZHANG Q H, BAO Y, et al. Static and fatigue push-out tests of short headed shear studs embedded in engi-neered cementitious composites (ECC)[J]. Engineering Structures,2019,182:29-38. DOI: 10.1016/j.engstruct.2018.12.068

[9] LIU H Z, ZHANG Q, LI V, et al. Durability study on engi-neered cementitious composites (ECC) under sulfate and chloride environment[J]. Construction and Building Materials,2017,133:171-181. DOI: 10.1016/j.conbuildmat.2016.12.074

[10] QIU J S, YANG E H. Micromechanics-based investigation of fatigue deterioration of engineered cementitious compo-site (ECC)[J]. Cement and Concrete Research,2017,95:65-74. DOI: 10.1016/j.cemconres.2017.02.029

[11] SINGH M, SAINI B, CHALAK H D. Performance and composition analysis of engineered cementitious composite (ECC)—A review[J]. Journal of Building Engineering,2019,26:100851. DOI: 10.1016/j.jobe.2019.100851

[12] ZHANG D, YU J, WU H, et al. Discontinuous microfibers as intrinsic reinforcement for ductile engineered cementitious composites (ECC)[J]. Composites Part B:Engineering,2020,184:107741. DOI: 10.1016/j.compositesb.2020.107741

[13] 刘少龙. 级配复合水泥基 ECC 的设计制备及其微观力学与拉伸行为的研究[D]. 广州: 华南理工大学, 2020. LIU Shaolong. On the design and preparation, microstructure and tensile behaviors of gap-graded cement-based engineered cementitious composite[D]. Guangzhou: South China University of Technology, 2020(in Chinese).

[14] 徐世烺, 刘问. 超高韧性水泥基复合材料疲劳损伤模型试验[J]. 中国公路学报, 2011, 24(6): 1-8. XU Shilang, LIU Wen. Fatigue damage model test of ultra-high toughness cmentitious composites[J]. China Journal of Highway and Transport, 2011, 24(6): 1-8(in Chinese).

[15] CHEN Y, YAO J, LU Z, et al. Experimental study on the shrinkage reduction of high strength strain-hardening cementitious composites[J]. Cement and Concrete Composites,2019,104:103416. DOI: 10.1016/j.cemconcomp.2019.103416

[16] DING Y, YU J T, YU K Q, et al. Basic mechanical properties of ultra-high ductility cementitious composites: From 40 MPa to 120 MPa[J]. Composite Structures,2018,185:634-645. DOI: 10.1016/j.compstruct.2017.11.034

[17] DING Y, YU K Q, YU J T, et al. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study[J]. Construction and Building Materials,2018,177:102-115. DOI: 10.1016/j.conbuildmat.2018.05.122

[18] GUO M H, ZHONG Q L, ZHOU Y W, et al. Influence of flexural loading and chloride exposure on the fatigue behavior of high-performance lightweight engineered cementitious composites[J]. Construction and Building Materials,2020,249:118512. DOI: 10.1016/j.conbuildmat.2020.118512

[19] HUANG B T, LI Q H, XU S L, et al. Fatigue deformation behavior and fiber failure mechanism of ultra-high toughness cementitious composites in compression[J]. Materials & Design,2018,157:457-468.

[20] LI X, ZHOU X, TIAN Y, et al. A modified cyclic constitutive model for engineered cementitious composites[J]. Engi-neering Structures,2019,179:398-411. DOI: 10.1016/j.engstruct.2018.09.030

[21] ZHANG Z G, YANG F, LIU J C, et al. Eco-friendly high strength, high ductility engineered cementitious compo-sites (ECC) with substitution of fly ash by rice husk ash[J]. Cement and Concrete Research,2020:137: 106200.

[22] TIAN J, WU X, ZHENG Y, et al. Investigation of damage behaviors of ECC-to-concrete interface and damage prediction model under salt freeze-thaw cycles[J]. Construction and Building Materials,2019,226:238-249. DOI: 10.1016/j.conbuildmat.2019.07.237

[23] TIAN J, WU X, ZHENG Y, et al. Investigation of interface shear properties and mechanical model between ECC and concrete[J]. Construction and Building Materials,2019,223:12-27. DOI: 10.1016/j.conbuildmat.2019.06.188

[24] BOSHOFF W P, NIEUWOUDT P D. Tensile crack widths of strain hardening cement-based composites[C]//2nd International RILEM Conference on Strain Hardening Cementitious Composites (SHCC2-Rio). Rio de Brazil: RILEM Publications SARL, 2011: 199-206.

[25] 朱忠锋, 王文炜. 玄武岩格栅增强水泥基复合材料单轴拉伸力学性能试验及本构关系模型[J]. 复合材料学报, 2017, 34(10):2367-2374. ZHU Zhongfeng, WANG Wenwei. Experiment on the uniaxial tensile mechanical behavior of basalt grid reinforced engineered cementitious composites and its constitutive model[J]. Acta Materiae Compositae Sinica,2017,34(10):2367-2374(in Chinese).

[26] CHEN C, CAI H Y, LI J J, et al. One-dimensional extended FEM based approach for predicting the tensile behavior of SHCC-FRP composites[J]. Engineering Fracture Mecha-nics,2020,225:106775. DOI: 10.1016/j.engfracmech.2019.106775

[27] 朱忠锋, 王文炜, 郑宇宙, 等. 基于非接触式观测技术的FRP/ECC复合材料反复受拉本构关系模型[J]. 土木工程学报, 2019, 52(10):36-45, 55. ZHU Zhongfeng, WANG Wenwei, ZHENG Yuzhou, et al. The constitutive model of FRP/ECC composite materials under uniaxial cyclic tensile loading based on the digital image correlation technique[J]. China Civil Engineering Journal,2019,52(10):36-45, 55(in Chinese).

[28] ZHU Z F, WANG W W, HARRIES K A, et al. Uniaxial tensile stress-strain behavior of carbon-fiber grid-reinforced engineered cementitious composites[J]. Journal of Composites for Construction, 2018, 22(6): 04018057.

[29] 王新玲, 杨广华, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料受拉应力-应变关系[J]. 复合材料学报, 2020, 37(12):3220-3228. WANG Xinling, YANG Guanghua, QIAN Wenwen, et al. Tensile stress-strain relationship of engineered cementitious composites reinforced by high-strength stainless steel wire mesh[J]. Acta Materiae Compositae Sinica,2020,37(12):3220-3228(in Chinese).

[30] 夏立鹏, 张黎飞, 郑愚. CFRP增强工程水泥基复合材料桥面连接板的结构和性能[J]. 复合材料学报, 2019, 36(4):848-859. XIA Lipeng, ZHANG Lifei, ZHENG Yu. Structural perfor-mance of CFRP reinforced ECC link slabs in jointless bridge decks[J]. Acta Materiae Compositae Sinica,2019,36(4):848-859(in Chinese).

[31] 朱忠锋, 王文炜. FRP编织网/ECC复合加固钢筋混凝土圆柱力学性能的试验[J]. 东南大学学报(自然科学版), 2016, 46(5):1082-1087. ZHU Zhongfeng, WANG Wenwei. Experimental study on mechanical behaviour of circular reinforced concrete columns strengthened with FRP textile and ECC[J]. Journal of Southeast University (Natural Science Edition),2016,46(5):1082-1087(in Chinese).

[32] YUAN F, CHEN M C, PAN J L. Experimental study on seismic behaviours of hybrid FRP-steel-reinforced ECC-concrete composite columns[J]. Composites Part B: Engineering,2019,176:107272.

[33] ZHU Z F, WANG W W, HUI Y X, et al. Mechanical behavior of concrete columns confined with CFRP grid-reinforced engineered cementitious composites[J]. Journal of Composites for Construction, 2022, 26(1): 4021060.

[34] 江佳斐, 隋凯. 纤维网格增强超高韧性水泥复合材料加固混凝土圆柱受压性能试验[J]. 复合材料学报, 2019, 36(8):1957-1967. JIANG Jiafei, SUI Kai. Experimental study of compression performance of concrete cylinder strengthened by extile reinforced engineering cement composites[J]. Acta Materiae Compositae Sinica,2019,36(8):1957-1967(in Chinese).

[35] HUANG B T, LI Q H, XU S L, et al. Development of reinforced ultra-high toughness cementitious composite permanent formwork: Experimental study and digital image correlation analysis[J]. Composite Structures,2017,180:892-903. DOI: 10.1016/j.compstruct.2017.08.016

[36] ZHENG Y Z, WANG W W, BRIGHAM J C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC[J]. Construction Building Materials,2016,115(15):424-437.

[37] ZHENG Y Z, WANG W W, MOSALAM K M, et al. Mechani-cal behavior of ultra-high toughness cementitious compo-site strengthened with fiber reinforced polymer grid[J]. Composite Structures,2018,184:1-10. DOI: 10.1016/j.compstruct.2017.09.073

[38] HU B, ZHOU Y W, XING F, et al. Experimental and theoretical investigation on the hybrid CFRP-ECC flexural strengthening of RC beams with corroded longitudinal reinforcement[J]. Engineering Structures,2019,200:109717. DOI: 10.1016/j.engstruct.2019.109717

[39] QIN F J, ZHANG Z G, YIN Z W, et al. Use of high strength, high ductility engineered cementitious composites (ECC) to enhance the flexural performance of reinforced concrete beams[J]. Journal of Building Engineering,2020,32:101746. DOI: 10.1016/j.jobe.2020.101746

[40] YUAN F, CHEN M C, PAN J L. Flexural strengthening of reinforced concrete beams with high-strength steel wire and engineered cementitious composites[J]. Construction and Building Materials,2020,254:119284. DOI: 10.1016/j.conbuildmat.2020.119284

[41] LIN Y W, WOTHERSPOON L, SCOTT A, et al. In-plane strengthening of clay brick unreinforced masonry wallettes using ECC shotcrete[J]. Engineering Structures,2014,66(5):57-65.

[42] DENG M K, DONG Z F, MA P. Cyclic loading tests of flexural-failure dominant URM walls strengthened with engineered cementitious composite[J]. Engineering Structures,2019,194:173-182. DOI: 10.1016/j.engstruct.2019.05.073

[43] 中华人民共和国住房和城乡建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2002[S]. Beijing: China Architecture & Publishing Press, 2003(in Chinese).

[44] ZHOU Y W, WU Y F. General model for constitutive relationships of concrete and its composite structures[J]. Composite Structures,2012,94(2):580-592. DOI: 10.1016/j.compstruct.2011.08.022

[45] ZHOU Y, LIU X, XING F, et al. Axial compressive behavior of FRP-confined lightweight aggregate concrete: An experimental study and stress-strain relation model[J]. Construction and Building Materials,2016,119:1-15. DOI: 10.1016/j.conbuildmat.2016.02.180

[46] LI P D, WU Y F, ZHOU Y W, et al. Stress-strain model for FRP-confined concrete subject to arbitrary load path[J]. Composites Part B: Engineering,2019,163:9-25. DOI: 10.1016/j.compositesb.2018.11.002

[47] LI P D, SUI L L, XING F, et al. Stress-strain relation of FRP-confined predamaged concrete prisms with square sections of different corner radii subjected to monotonic axial compression[J]. Journal of Composites for Construction,2019,23(2):04019001. DOI: 10.1061/(ASCE)CC.1943-5614.0000921

[48] LAM L, TENG J. Design-oriented stress-strain model for FRP-confined concrete in rectangular columns[J]. Journal of Reinforced Plastics Composites in Construction,2003,22(13):1149-1186. DOI: 10.1177/0731684403035429

[49] WU Y F, YUN Y C, WEI Y Y, et al. Effect of predamage on the stress-strain relationship of confined concrete under monotonic loading[J]. Journal of Structural Engineering,2014,140(12):04014093. DOI: 10.1061/(ASCE)ST.1943-541X.0001015

[50] TENG J G, HUANG Y L, LAM L, et al. Theoretical model for fiber-reinforced polymer-confined concrete[J]. Journal of Composites for Construction, 2007, 11(2): 201-210.

[51] DAI J, BAI Y, TENG J G. Behavior and modeling of concrete confined with FRP composites of large deformability[J]. Journal of Composites for Construction,2011,15(6):963-973. DOI: 10.1061/(ASCE)CC.1943-5614.0000230

[52] SHAO Y, ZHU Z, MIRMIRAN A. Cyclic modeling of FRP-confined concrete with improved ductility[J]. Cement and Concrete Composites,2006,28(10):959-968. DOI: 10.1016/j.cemconcomp.2006.07.009

-

期刊类型引用(1)

1. 李登高,刘成霞. 有限元分析技术在织物力学性能领域的应用. 现代纺织技术. 2024(06): 129-141 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: