Properties and flame retardant mechanism of sulfuretted DOPO derivative in epoxy resin

-

摘要: 为了获得综合性能好的阻燃环氧树脂(EP)复合材料,将9,10-二氢-9-氧杂-10-磷杂菲-10-硫化物(DOPS)的衍生物应用于EP。首先,通过DOPS和马来酸酐(MAH)反应合成磷杂菲衍生物马来酸酐-9,10-二氢-9-氧杂-10-磷杂菲-10-硫化物(MAH-DOPS),采用FTIR、1H NMR、31P NMR等手段确定其结构;其次,分别将DOPS和MAH-DOPS添加到EP中,通过共混制备复合材料DOPS/EP和MAH-DOPS/EP;再次,对比了DOPS/EP和MAH-DOPS/EP的热稳定性、阻燃性能和力学性能;最后,探讨了MAH-DOPS对EP的燃烧性能和热降解行为的影响,深入分析其阻燃机制。通过对比发现:阻燃剂DOPS的初始分解温度(T5%,205.4℃)低于MAH-DOPS(235.2℃),在添加相同质量分数的阻燃剂时,复合材料DOPS/EP的热稳定性也低于MAH-DOPS/EP,与阻燃剂热稳定性一致;阻燃剂DOPS和MAH-DOPS均能改善EP的阻燃性能,MAH-DOPS/EP具有更优异的阻燃效果。当阻燃剂添加量为15wt%时,MAH-DOPS/EP和DOPS/EP的极限氧指数(LOI) 值分别为28.6%和29.1%,分别达到UL-94 V-0级和V-1级。力学测试结果表明,与EP相比,MAH-DOPS/EP的弯曲强度提高了45.8%,而DOPS/EP下降了62.5%,DOPS/EP体系的力学性能下降明显,几乎失去使用价值。锥形量热测试表明,复合材料MAH-DOPS/EP的平均热释放速率(av-HRR)和总热释放量(THR)显著降低。TG-IR结果表明,MAH-DOPS/EP热解产生的含磷自由基捕捉了H•、O•或HO•等自由基,起到了自由基淬灭作用;SEM-EDS结果表明,MAH-DOPS/EP能够形成更加完整致密的炭层,炭层中P含量较高。研究表明,MAH-DOPS通过抑制火焰和成炭分别在气相和凝聚相发挥阻燃作用,并以气相阻燃机制为主。

-

关键词:

- 阻燃性能 /

- 环氧树脂 /

- 马来酸酐-9,10-二氢-9-氧杂-10-磷杂菲-10-硫化物(MAH-DOPS) /

- 热降解 /

- 成炭

Abstract: In order to obtain the flame retardant epoxy resin (EP) composites with good comprehensive properties, the 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (DOPS) derivative was applied to EP. First, maleic anhydride-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (MAH-DOPS) was synthesized by the reaction of DOPS and maleic anhydride (MAH). The structure was determined by FTIR, 1H NMR and 31P NMR. Secondly, DOPS and MAH-DOPS were added to EP respectively, to prepare composites DOPS/EP and MAH-DOPS/EP by blending. Thirdly, the thermal stability, flame retardancy and mechanical properties of DOPS/EP and MAH-DOPS/EP were compared. Finally, the effects of MAH-DOPS on the combustion performance and thermal degradation behavior of EP were discussed, and its flame retardant mechanism was analyzed in depth. The results show that the initial decomposition temperature of flame retardant DOPS (205.4℃) is lower than that of MAH-DOPS (235.2℃), and the thermal stability of DOPS/EP is lower than that of MAH-DOPS/EP when the same mass fraction of flame retardants is added, which is consistent with the thermal stability of flame retardants. Both flame retardants DOPS and MAH-DOPS can improve the flame retardancy of EP, and MAH-DOPS/EP has better flame retardant effect. When the amount of flame retardant is 15wt%, limit oxygen index (LOI) values of MAH-DOPS/EP and DOPS/EP are 28.6% and 29.1%, reaching UL-94 V-0 and V-1 rating, respectively. The mechanical test results show that compared with EP, the bending strength of MAH-DOPS/EP increases by 45.8%, while DOPS/EP decreases by 62.5%. The mechanical properties of DOPS/EP system decrease obviously, and almost lose the use value. Cone calorimeter tests show that the average heat release rate (av-HRR) and total heat release (THR) of the composite MAH-DOPS/EP decrease significantly. The results of TG-IR show that the H•, O• or HO• free radicals are captured by the phosphorus-containing free radicals generated by the pyrolysis of MAH-DOPS/EP, and the free radicals are quenched. SEM-EDS results show that MAH-DOPS/EP can form a more complete and compact char layer, and the content of P in the char layer is higher. The study shows that MAH-DOPS plays a flame retardant role in gas phase and condensed phase through flame suppression and char formation respectively, and the gas phase flame retardant mechanism is the main one. -

环氧树脂(EP)是三大通用型热固性树脂之一,因其具有优异的粘结性能、电绝缘性能、耐磨性能和化学稳定性,固化收缩率低,易于成型加工,而广泛应用于粘合剂、电子封装材料、航空航天及工程复合材料等领域[1-3]。然而,EP的阻燃性能差,极限氧指数(LOI)低(19.8%左右),在空气中就能燃烧,燃烧时热释放量大、火焰传播速度快,并产生大量有毒烟雾,且离火后持续燃烧,易引发火灾,极大地限制了其在军工、航空、电子元器件等领域的应用[4]。因此,对 EP 进行阻燃改性,已成为拓宽其应用范围的有效途径。

9,10-二氢-9-氧杂-10-磷杂菲-10-氧化物(DOPO)是一种有机磷阻燃剂中间体,DOPO及其衍生物由于具有环境友好、含碳量高、相容性好、阻燃性持久等优点被广泛应用于EP[5-7]、尼龙6(PA6)[8]、聚乳酸(PLA)[9]等聚合物基材中,均表现出较好的阻燃效果。DOPO分子结构中的P—H键具有很高的反应活性,能够与环氧基[5,10]、碳氮双键[6,11]、碳碳双键[12-13]、醛酮[14]、醌[15]等不饱和基团发生加成反应制得DOPO衍生物。此外,在DOPO的结构中引入硫元素,即可获得硫磷复合化合物9,10-二氢-9-氧杂-10-磷杂菲-10-硫化物(DOPS)。研究表明:首先,硫元素作为一种阻燃元素,将其引入DOPO结构中,可以增进磷的阻燃效果,在凝聚相发挥出优异的阻燃作用[16];其次,硫元素有助于抑制阻燃改性基材的熔滴行为;再次,在DOPO结构中引入硫元素后,P—H键的反应活性增加,更容易与不饱和基团发生加成反应,便于生成各种DOPS衍生物[17]。

马来酸酐(MAH)是一种含有不饱和双键的杂环化合物,可与DOPO中的P—H键发生加成反应。目前,关于MAH-DOPO的阻燃应用研究已有文献报道[18-19],王昱等[20]用DOPO与马来酸反应合成马来酸-9,10-二氢-9-氧杂-10-磷杂菲-10-氧化物(MA-DOPO),再将MA-DOPO进一步脱水闭环合成MAH-DOPO。研究不同含磷量下,MAH-DOPO对EP阻燃性能的影响。研究发现,当含磷量为2wt% 时,EP阻燃复合材料的LOI值为33.4%,达到UL-94 V-0级。此外,MAH-DOPO不仅可以提高材料的阻燃性能,还能保持其力学性能[19-20],而关于其衍生物MAH-DOPS的研究鲜有报道。因此,本研究合成了MAH-DOPS,并将其应用于EP,以期获得阻燃性能和力学性能较好的EP复合材料。首先,以MAH与DOPS为原料合成了新型阻燃剂MAH-DOPS,将其按照一定比例添加到EP中;其次,通过热重(TG)、LOI、垂直燃烧(UL-94)等测试手段,对比了复合材料DOPS/EP和MAH-DOPS/EP的热稳定性、阻燃性能和力学性能;最后,通过锥形量热(CONE)、热重-红外光谱联用(TG-IR)、扫描电镜-能量色散X射线谱(SEM-EDS)等测试手段,探讨了MAH-DOPS对EP的燃烧性能和热降解行为的影响,深入分析其阻燃机制。

1. 实验部分

1.1 原材料

DOPS,实验室自制;马来酸酐(AR),上海麦克林生化科技有限公司;环氧树脂E51(工业级),湖南岳阳巴陵石化有限公司;甲基四氢苯酐(工业级),昆山久力美电子材料有限公司;四氢呋喃、三乙胺、无水乙醇、N,N-二甲基苄胺,均为国产分析纯试剂。

1.2 阻燃剂MAH-DOPS的合成

首先,根据文献[21]的方法合成DOPS。 MAH-DOPS的合成方法如下:在装有冷凝管、温度计、氮气进出口和磁力搅拌子的100 mL三口烧瓶中加入3.48 g (15 mmol) DOPS、0.026 mL三乙胺和15 mL四氢呋喃,开启搅拌,升温至65℃。待DOPS完全溶解后,将1.91 g (19.5 mmol) MAH在1 h内分多次加入到体系内,加料完毕后,升温至80℃反应8 h。反应结束后,冷却至室温,抽滤,用无水乙醇洗涤数次后,70℃干燥10 h,得到3.61 g白色粉末状产物,产率73%,产物熔点(m.p.)为199.2~200.0℃。DOPS: FTIR (KBr),ν (cm−1):3065.13,2371.02(C—H),2359.12(P—H),1582.43(P—Ph),1184.79(P—O—Ph),939.95(P=S),758.19(CAr—H)。1H NMR (CDCl3,400 MHz),δ(10-6):9.01 (s,1H);7.94(dd,J=7.6 Hz,1H);7.82~7.78(m,2H);7.68(s,1H);7.64(t,J=7.8 Hz,1H);7.49(dt,J1=7.5 Hz,J2=3.2 Hz,1H);7.33(m,1H);7.24~7.17(m,2H)。31P NMR (CDCl3,160 MHz),δ(10-6): 9.12。MAH-DOPS:FTIR (KBr) ,ν (cm−1):2926.47(CA—H),1856.51,1785.91(C=O),1579.41(P—Ph),1471.27~1426.74(C—CAr),1259.04(C—O),1185.56(P—O—Ph),936.80(P=S)。1H NMR (DMSO-d6,400 MHz),δ (10-6): 8.31~8.18 (m,2H);8.12~7.84 (m,2H);7.78~7.66 (m,1H);7.62~7.48 (m,1H);7.48~7.32 (m,2H);4.22 (m,1H);3.55~3.36 (m,1H);3.32~3.02 (m,1H)。31P NMR (DMSO-d6,160 MHz),δ(10-6):78.23。合成反应式如图1所示,DOPS和MAH-DOPS的红外图谱见图2。

1.3 阻燃环氧树脂的制备

取适量EP于烧杯中,加热至50~60℃,边加热边搅拌,将一定比例的MAH-DOPS或DOPS溶于四氢呋喃中,再加至已搅拌均匀的EP中,超声振荡使其分散均匀。旋蒸除去溶剂,冷却至室温后,向体系中加入适量固化剂甲基四氢苯酐(MTHPA)和少量固化促进剂N,N-二甲基苄胺(BDMA),室温下迅速搅拌使其混合均匀。然后倒入聚四氟乙烯模具中,于真空干燥箱中脱气后,加热固化,最后自然冷却至室温,脱模即可得到阻燃EP样条。具体配方如表1所示。

表 1 阻燃环氧树脂的配方Table 1. Formulation of flame retardant epoxy resinSample Composition/g EP MTHPA BDMA MAH-DOPS DOPS 5wt%MAH-DOPS/EP 100 85 1 9.79 — 5wt%DOPS/EP 100 85 1 — 9.79 10wt%MAH-DOPS/EP 100 85 1 20.67 — 10wt%DOPS/EP 100 85 1 — 20.67 15wt%MAH-DOPS/EP 100 85 1 32.82 — 15wt%DOPS/EP 100 85 1 — 32.82 Notes: EP—Epoxy resin; MTHPA—Methyl tetrahydrophthalic anhydride; BDMA—N,N-dimethylbenzylamine; MAH-DOPS—Maleic anhydride-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide; DOPS—9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide. 1.4 性能测试

热重分析(TG,TGA55,美国TA公司),样品质量5~10 mg,以10℃/min 的升温速率在氮气气氛下升温至800℃,气体流速为60 mL/min。

极限氧指数测试(LOI,JF-3型,南京江宁区分析仪器厂),按照GB/T 2406.1—2008 [22] 标准进行测试,样条尺寸80(±5)×6.5(±0.5)×3.0(±0.25) mm3。

垂直燃烧测试(UL-94,CZF-5型,江苏卓恒测控技术有限公司),按照GB/T 2408—2008[23]标准进行测试,样条尺寸125(±5)×13.0(±0.3)×3.0(±0.2) mm3。

锥形量热测试(CONE,VOUCH 6810型,苏州阳屹沃尔奇公司),按照ISO 5660-1—2002[24]标准进行测试,辐射功率为35 kW/m2,样条尺寸100(±5)×100(±5)×3(±0.5) mm3。

拉伸强度和弯曲强度测试(微机控制电子万能试验机,WDW-10C,上海华龙测试仪器公司),拉伸强度按照GB/T 1040.2—2006[25]标准进行测试,拉伸速率50 mm/min;弯曲强度按照GB/T 9341—2008[26]标准进行测试,弯曲速率2 mm/min。缺口冲击强度测试(液晶式摆锤冲击试验机,ZBC-4B,深圳市新三思计量技术有限公司),按 GB/T 1843—2008[27]进行测试,缺口深度为(2.0±0.2) mm,缺口底部半径r=(0.25±0.05) mm。

热重-红外光谱分析(TG-IR,Netzsch TG209F3 &Bruker TENSOR27),5~10 mg样品在氮气气氛下,20℃/min升温至700℃,气体流速为60 mL/min。红外气体池的波数范围为500~4000 cm−1。

扫描电镜-X射线能量色谱(SEM-EDS,FEI Scios 2型,美国FEI NanoPorts公司),对燃烧后的残炭断口表面进行真空喷金处理,加速电压为2 kV;并在相同的加速电压下分析燃烧后炭层表面的元素含量。

2. 结果与讨论

2.1 MAH-DOPS阻燃剂的热稳定性分析

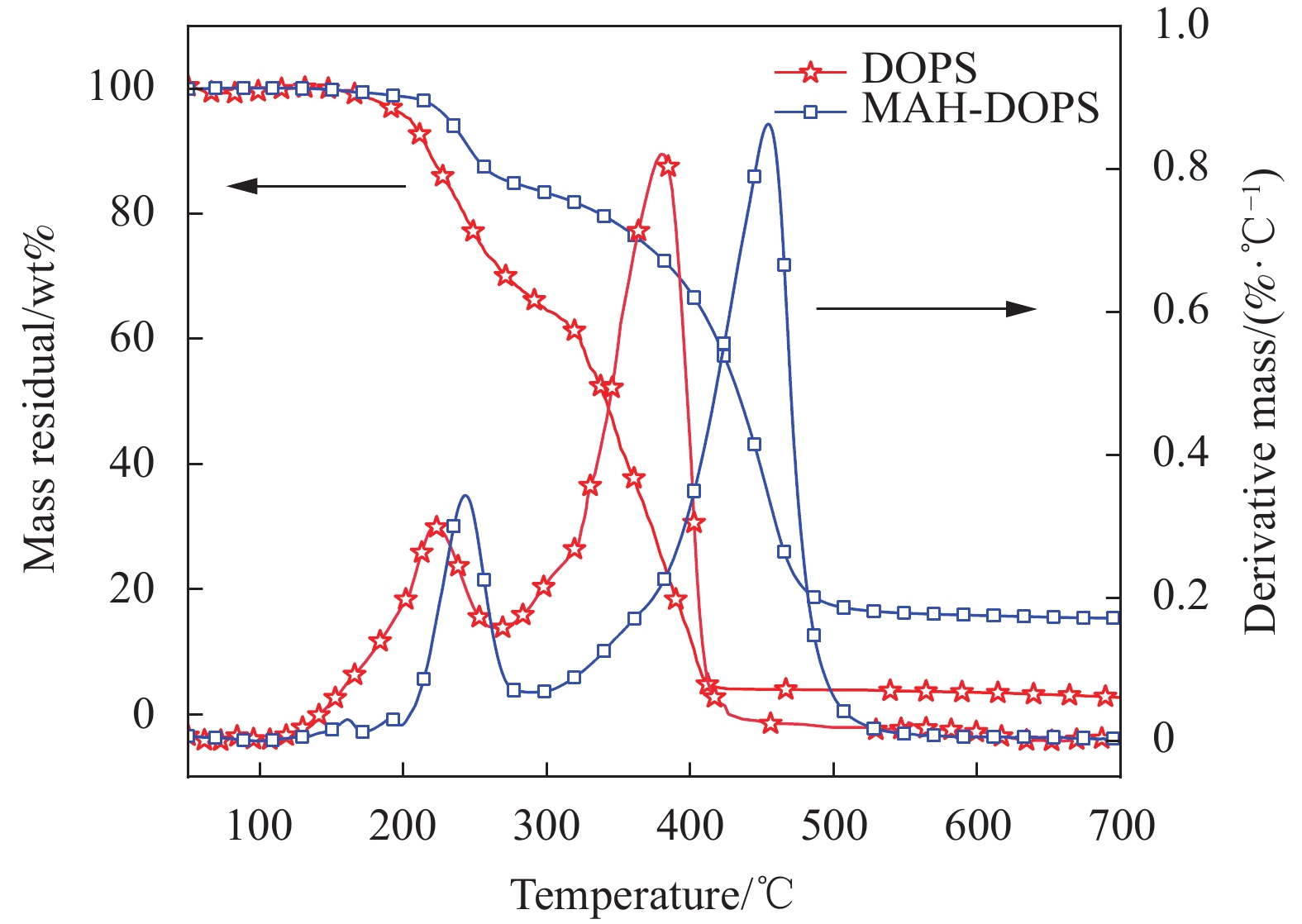

阻燃剂自身的热稳定性在一定程度上会影响基材的热稳定性和阻燃效果。图3是阻燃剂DOPS和MAH-DOPS在氮气气氛下的TG-DTG曲线,具体数据见表2。由此可知,DOPS和MAH-DOPS都有两个热降解阶段,主要以第2阶段为主。DOPS的初始分解温度(T5%)、失重10%、50%时的温度(T10%、T50%)、峰温(TP)、最大热失重速率(Rmax)及600℃的残炭量均低于MAH-DOPS。DOPS的T5%为205.4℃,TP1、TP2分别为225.5℃、381.5℃;MAH-DOPS的T5%提高至235.2℃,TP1、TP2分别达到245.1、469.7℃,两种阻燃剂的Rmax值相近。相比之下,MAH-DOPS具有更好的热稳定性,600℃下MAH-DOPS的残炭量为15.81%,高于DOPS(3.57%),这可能是由于DOPS含有活泼的P—H键,易发生断裂,而酸酐接枝使P=S结构的稳定性提高,分解温度升高,酸酐基团和磷硫元素共同作用促进成炭,导致MAH-DOPS的热稳定性提高,残炭量增大。

表 2 两种阻燃剂在氮气下的TG和DTG数据Table 2. TG and DTG data of two flame retardants in N2Sample T5%/℃ T10%/℃ T50%/℃ TP1/℃ TP2/℃ Rmax1 Rmax2 Char residue

at 600℃/%DOPS 205.4 216.9 341.6 225.5 381.5 0.31 0.83 3.57 MAH-DOPS 235.2 248.7 435.4 245.1 469.7 0.34 0.86 15.81 Notes: T5%, T10%, T50%—Temperature corresponding to weight loss 5%, 10% and 50% of material; TP—Temperature corresponding to maximum thermal degradation rate; Rmax—Maximum thermal degradation rate. 2.2 MAH-DOPS阻燃剂对EP热稳定性的影响

通过共混方式把质量分数为10wt%的阻燃剂DOPS和MAH-DOPS分别添加到EP中,对EP和阻燃EP复合材料进行热重分析,比较DOPS和MAH-DOPS对EP热稳定性的影响。EP及其复合材料DOPS/EP和MAH-DOPS/EP在N2气氛下的TG、DTG曲线见图4,具体的热失重数据见表3。由此可见,EP和MAH-DOPS/EP的热降解过程都只有1个阶段,DOPS/EP的热降解过程有2个阶段,第1阶段发生在200℃~350℃,第2阶段发生在350℃~500℃,热降解主要以第2阶段为主。EP的T5%为345.1℃,加入阻燃剂后,两个阻燃体系的T5%均降低。MAH-DOPS/EP的T5%为292.84℃,降低约52℃,而DOPS/EP的T5%进一步降低至230.17℃,约降低了115℃,主要是由于:首先,DOPS的热稳定性较差(T5%为205.4℃),阻燃剂发生降解;其次,DOPS的酸性促进了EP的降解,导致DOPS/EP的T5%大大提前。600℃时EP的残炭量为7.22%,DOPS/EP的残炭量为3.52%,降低了51.2%,说明DOPS/EP的成炭能力较差;MAH-DOPS/EP的残炭量为11.42%,比EP提高了58.2%。综合分析可知,DOPS的加入导致EP的热稳定性下降,而MAH-DOPS在一定程度上改善了EP的热稳定性,即与DOPS/EP相比,MAH-DOPS/EP表现出更好的热稳定性。

表 3 EP及其复合材料在氮气下的TG、DTG数据Table 3. TG and DTG data of EP and EP composites in N2Sample T5%/℃ T10%/℃ T50%/℃ TP1/℃ TP2/℃ Rmax1 Rmax2 Char residue at 600℃/% EP 345.1 369.7 410.1 407.6 — 1.61 — 7.22 5wt%MAH-DOPS/EP 271.2 326.5 400.8 402.6 — 1.50 — 8.90 10wt%MAH-DOPS/EP 292.8 342.8 393.2 395.1 — 1.53 — 11.42 10wt%DOPS/EP 230.2 276.5 409.8 308.1 449.7 0.37 0.79 3.52 15wt%MAH-DOPS/EP 319.2 357.1 402.8 392.5 — 1.49 — 11.93 通过改变阻燃剂添加量,进一步研究MAH-DOPS对EP热稳定性的影响。EP及不同添加量的MAH-DOPS/EP在N2气氛下的TG、DTG曲线如图5所示,具体数据见表3。由此可知,随着MAH-DOPS添加量的增大,MAH-DOPS/EP的T5%呈升高趋势,TP值逐渐降低;这主要是由于含P量随着MAH-DOPS添加量的增大而增大,含P基团的极性效应使分子间的相互作用力增大,故MAH-DOPS/EP的T5%呈升高趋势[28]。当MAH-DOPS的添加量为15wt%时,MAH-DOPS/EP的T5%大约提前了26℃,TP降低了约15℃,其原因是阻燃剂MAH-DOPS属于磷杂菲衍生物,而磷杂菲衍生物中的O—P—C键不如C—C键稳定,因此阻燃剂MAH-DOPS能在相对较低的温度下开始分解,从而促使EP树脂提前降解,导致其T5%降低[29,17]。此外,600℃时MAH-DOPS/EP的残炭量均比纯EP高,且随着阻燃剂含量的增加呈升高趋势。当阻燃剂添加量为15wt%时,残炭量为11.93%,比纯EP提高了4.71%。这可能是由于阻燃剂MAH-DOPS在高温下分解产生的物质促使EP脱水成炭,并抑制EP产生可燃性气体,因此残炭量有所增加。

2.3 MAH-DOPS/EP的阻燃性能

为了比较阻燃剂MAH-DOPS和DOPS对EP阻燃性能的影响,通过LOI和UL-94对样条进行测试,测试结果如表4所示。可知,纯EP的LOI值为19.5%,不能通过UL-94测试,阻燃性能较差。添加阻燃剂DOPS和MAH-DOPS均明显增大了EP的LOI值,提高了垂直燃烧等级。当MAH-DOPS的添加量为5wt%、10wt%和15wt%时,MAH-DOPS/EP的LOI值依次为24.9%、27.1%和28.6%,UL-94等级也从V-2级逐渐提高到V-0级。当DOPS的添加量分别为5wt%、10wt%和15wt%时,DOPS/EP的LOI值分别为26.2%、30.7%和29.1%,和MAH-DOPS/EP相比,虽然LOI值较高,但UL-94垂直燃烧等级均未达到V-0级,并且随着DOPS的添加量增大,LOI值呈现先升高后降低的趋势。即与DOPS/EP相比,MAH-DOPS/EP具有更优异的阻燃性能。同时,在后续的力学性能测试中发现,添加DOPS后,EP的力学性能下降明显。当添加量为15wt%时,其弯曲强度比纯EP下降了72.2%,拉伸强度下降了84.6%,DOPS/EP体系几乎失去使用价值,因此未对DOPS/EP体系做进一步深入研究。

表 4 EP及其复合材料的LOI和垂直燃烧测试(UL-94)数据Table 4. LOI and vertical combustion test (UL-94) data of EP an EP compositesSample LOI/% UL-94 t1/t2 Dripping Rating EP 19.5 — NO N.R. 5wt%DOPS/EP 26.2 >50/>50 NO N.R. 5wt%MAH-DOPS/EP 24.9 19.21/15.08 NO V-2 10wt%DOPS/EP 30.7 5.81/43.53 NO V-2 10wt%MAH-DOPS/EP 27.1 15.37/13.42 NO V-1 15wt%DOPS/EP 29.1 12.27/1.91 NO V-1 15wt%MAH-DOPS/EP 28.6 5.01/4.45 NO V-0 Notes: LOI—Limiting oxygen index; t1/t2—First and second combustion time in UL-94 test; N.R.—No rating. 2.4 MAH-DOPS/EP的燃烧性能

锥形量热分析是研究复合材料燃烧性能的常用手段。在35 kW/m2的辐射功率下,使用锥形量热仪研究了EP和MAH-DOPS/EP阻燃复合材料的燃烧性能。点燃时间(TTI)、最大热释放速率(PHRR)、平均热释放速率(av-HRR)、总热释放量(THR)、平均有效燃烧热(av-EHC)、总烟释放量(TSR)、CO生成量(COY)等数据如表5所示。

表 5 EP和MAH-DOPS/EP的锥形量热测试(CONE)数据Table 5. Cone calorimeter (CONE) data of EP and MAH-DOPS/EPSample TTI/s av-HRR/

(kW·m−2)PHRR/

(kW·m−2)THR/

(MJ·m−2)av-EHC/

(MJ·kg−1)TSR/

(m2·m−2)av-COY/

(kg·kg−1)EP 66 218.88 918.01 155.57 31.41 2251.69 0.21 5wt%MAH-DOPS/EP 55 129.55 697.83 96.98 28.31 2859.35 0.27 10wt%MAH-DOPS/EP 58 132.37 644.54 81.43 27.82 2873.67 0.33 15wt%MAH-DOPS/EP 52 137.43 603.67 71.37 28.75 3098.42 0.37 Notes: TTI—Time to ignition; av-HRR—Average heat release rate; PHRR—Peak heat release rate; THR—Total heat release; av-EHC—Average effective heat of combustion; TSR—Total smoke release; av-COY—Average carbon monoxide yield. 可知,纯EP的TTI值为66 s,阻燃复合材料的TTI值均降低,这与TG测试中阻燃复合材料的热稳定性下降基本一致。与纯EP相比,添加MAH-DOPS后,复合材料的av-HRR呈下降趋势。当添加量为5wt%时,av-HRR为129.55 kW/m2,降低了40.81%;15%MAH-DOPS/EP的av-HRR值下降为137.43 kW/m2。从表5和图6可知,纯EP的PHRR为918.01 kW/m2,THR为155.57 MJ/m2,MAH-DOPS/EP的PHRR、THR值都随着阻燃剂MAH-DOPS添加量的增加而逐渐降低。当MAH-DOPS添加量为15wt%时,PHRR为603.67 kW/m2,THR值为71.37 MJ/m2,与纯EP相比,分别下降34.24%和54.12%,这可能是由于MAH-DOPS在凝聚相发挥阻燃作用,随着阻燃剂添加量的增大,促进阻燃EP复合材料燃烧成炭,炭层起到了隔热隔氧的作用,在一定程度上阻止了火焰的燃烧,导致HRR和THR值下降,降低了材料的火灾危险性。与纯EP相比,阻燃复合材料MAH-DOPS/EP的av-EHC值均有所降低,分别下降9.87%、11.43%、8.47%,说明MAH-DOPS的加入使复合材料在气相中分解出的有效燃烧成分减少,燃烧强度降低[18]。

材料燃烧时会产生大量的烟雾,其中一些是有毒有害气体,因此TSR和av-COY也是评价材料潜在火灾危险性的重要指标[30]。从表5和图7可知,阻燃EP复合材料的TSR和av-COY均高于纯EP。随着阻燃剂MAH-DOPS添加量的增大,阻燃EP的TSR值呈现出上升趋势,可能是由于阻燃剂MAH-DOPS中含有硫元素,含硫量的增加使TSR值逐渐上升[17];阻燃EP复合材料的CO生成量也随着阻燃剂添加量的增加而增大,这可能由于在高温条件下分解产生的物质促使EP脱水成炭,并释放出不燃性气体,如N2、NH3、SO2等,稀释了局部的氧浓度,阻止了可燃气体与氧气的接触,氧浓度不足导致可燃性气体燃烧不充分,从而导致CO生成量增加。总之,av-EHC值的略微减小和TSR值的显著上升,说明MAH-DOPS/EP复合材料在燃烧过程中产生了更多的不可燃物质,发挥出较好的气相阻燃作用[18],其阻燃机制主要是MAH-DOPS热解产生的含磷自由基捕捉了H•、O•或HO•等自由基,起到了自由基淬灭作用,进而发挥气相阻燃作用[31-32]。

2.5 MAH-DOPS/EP的热降解行为

为了研究MAH-DOPS/EP阻燃复合材料的热解气体和阻燃机制,并验证气相中含磷自由基的存在,对EP及其复合材料进行了TG-IR分析。如图8(a)和8(b)所示,EP与MAH-DOPS/EP具有类似的吸收峰:3651 cm−1处是H2O的吸收峰;2833~3017 cm−1处为碳氢化合物的伸缩振动吸收峰;2370 cm−1为CO2的吸收峰;1807 cm−1为羰基化合物的吸收峰;1610 cm−1和1514 cm−1为苯环上C—C的伸缩振动吸收峰。不同的是,图8(b)中MAH-DOPS/EP在1267 cm−1处出现S=O伸缩振动吸收峰[33],1169 cm−1处为SO2的吸收峰[34],1058和923 cm−1为P—O的吸收峰[35],744 cm−1处为P—C的吸收峰[36]。随着温度升高,各种特征吸收峰的强度呈现出先增大后减小的趋势。MAH-DOPS/EP在220℃时未检测到吸收峰,说明此时复合材料未降解,在318℃时出现了CO2和羰基化合物的吸收峰,继续升高温度,吸收峰逐渐变得尖锐,当温度达到383℃时,出现较强的吸收峰,说明此时EP复合材料热降解速度加快,391℃时羰基化合物的吸收峰强度最大,这与TG测试中的Tp值392.5℃基本一致;升温至400℃时,各种吸收峰的强度开始减弱,表明热解反应的气相分解产物明显减少;500℃时热解气体的吸收峰基本消失,说明MAH-DOPS/EP复合材料基本降解完全。P—O、P—C等含磷官能团特征峰的出现表明气相中存在含磷自由基,因此推测阻燃剂MAH-DOPS起到了气相阻燃作用。

2.6 MAH-DOPS/EP 燃烧后残炭形貌和元素分析

为了进一步分析阻燃机制,对锥量测试后的炭层表面形貌进行分析,如图9所示。可以看出,添加MAH-DOPS后,阻燃EP复合材料的残炭量有所增加,而且残炭量随阻燃剂添加量的增大而增加。此外,采用SEM-EDS对炭层表面的微观形貌和结构进行分析。图10为阻燃复合材料MAH-DOPS/EP燃烧后残炭的SEM图像。可见,阻燃剂添加量为5wt%时,MAH-DOPS/EP阻燃复合材料形成的炭层疏松破碎,有很多不规则的开放式大小不一的孔洞,且孔洞之间互相连通,无法形成致密且连续的网状结构,很难起到隔热隔氧的作用,可能是由于在燃烧过程中释放出大量气体破坏了炭层的完整性;当添加量为10wt%时,燃烧后形成的炭层更加致密光滑,仍有部分孔状结构;当添加量为15wt%时,复合材料燃烧后形成的炭层气孔基本消失,炭层更加连续完整、光滑致密,能够很好地隔绝空气及热量向基材内部传递,阻止基材进一步燃烧,从而发挥凝聚相阻燃作用[37]。

阻燃复合材料残炭的EDS测试结果如表6所示,纯EP残炭中主要有C和O,而阻燃EP复合材料的残炭中除了C、O外,还有P和S的存在,不同添加量的阻燃EP复合材料的理论P含量分别为0.47wt%、0.94wt%和1.41wt%,而燃烧后残炭中的P含量分别为7.06wt%、5.32wt%和4.01wt%,均高于EP复合材料的理论P含量,说明阻燃复合材料燃烧后会生成含磷物质,促进基材脱水成炭,并在凝聚相中发挥一定的阻燃作用。可见,随着阻燃剂含量的增加,阻燃EP复合材料的C含量和P含量均逐渐减少;15wt%MAH-DOPS/EP阻燃复合材料的理论P含量最高,但残炭中的P含量却最低,这可能是由于随着阻燃剂添加量的增大,大量的含磷物质被传送到气相中,在气相发挥阻燃作用;残炭中S含量比较低,说明热降解过程中产生的含硫化合物也主要在气相发挥阻燃作用,在带走热量的同时,稀释可燃性气体的浓度[38]。

表 6 MAH-DOPS/EP残炭的EDS数据Table 6. EDS data of char residues of MAH-DOPS/EPSample Char residue Composites C/wt% O/wt% P/wt% S/wt% P/wt% S/wt% 5wt%MAH-DOPS/EP 67.70 24.17 7.06 1.07 0.47 0.48 10wt%MAH-DOPS/EP 64.45 29.57 5.32 0.28 0.94 0.97 15wt%MAH-DOPS/EP 66.01 29.18 4.01 0.81 1.41 1.46 2.7 阻燃EP的力学性能

力学性能是聚合物材料实际应用的重要指标。图11为EP及阻燃EP复合材料的力学性能随阻燃剂变化的柱状图。纯EP的弯曲强度、弯曲模量和拉伸强度分别为96.47、2326.68、75.19 MPa,缺口冲击强度为3.11 kJ/m2。可知,当阻燃剂的质量分数均为10wt%时,MAH-DOPS/EP的弯曲强度为140.66 MPa,比EP提高了45.8%,而DOPS/EP为36.2 MPa,下降了62.5%;两种阻燃EP复合材料的拉伸强度均下降,其中DOPS/EP仅为27.4 MPa,下降了63.6%,MAH-DOPS/EP为47.56 MPa,下降了36.7%;对于缺口冲击强度,MAH-DOPS/EP为2.89 kJ/m2,下降了7.1%,DOPS/EP为3.41 kJ/m2,提高了9.6%。综合分析可以看出,在阻燃剂的质量分数相同时,MAH-DOPS/EP比DOPS/EP具有更好的力学性能。

通过添加不同质量分数的阻燃剂MAH-DOPS,进一步研究阻燃剂MAH-DOPS对EP力学性能的影响。表7为MAH-DOPS/EP的力学性能数据。可知,当阻燃剂MAH-DOPS的添加量分别为5wt%、10wt%和15wt%时,MAH-DOPS/EP的弯曲强度均有所提高,其弯曲强度分别为 125.33、140.66和116.46 MPa,与纯EP相比,分别提高了29.9%、45.8%和20.7%。当MAH-DOPS添加量为10wt%时,弯曲强度和弯曲模量的升高幅度最大,MAH-DOPS/EP的拉伸强度和缺口冲击强度均有所下降,且随着MAH-DOPS添加量的增大呈下降趋势。当阻燃剂MAH-DOPS的添加量分别为5wt%、10wt%和15wt%时,MAH-DOPS/EP拉伸强度分别为52.39、47.56和30.63 MPa,与EP相比,分别下降了30.3%、36.7%和59.3%,这可能是由于随着MAH-DOPS添加量的增大,部分颗粒出现团聚现象造成应力集中导致的[39]。与拉伸强度相比,阻燃剂MAH-DOPS对EP缺口冲击强度的影响较小,当MAH-DOPS添加量分别为5wt%、10wt%和15wt%时,缺口冲击强度分别为2.94 kJ/m2、2.89 kJ/m2和2.67 kJ/m2,与EP相比分别下降了5.5%、7.1%和14.1%,即随着添加量的增大,缺口冲击强度下降幅度增大,这可能是由于阻燃剂MAH-DOPS与EP之间的相容性较差,两者之间形成分界面,阻碍EP分子链的运动,从而使材料的韧性有所下降。

表 7 EP和MAH-DOPS/EP的力学性能Table 7. Mechanical properties of EP and MAH-DOPS/EPSample Bending strength/MPa Bending modulus/MPa Tensile strength/MPa Notched izod impact strengh/(kJ·m−2) EP 96.47 2326.68 75.19 3.11 5wt%MAH-DOPS/EP 125.33 3224.83 52.39 2.94 10wt%MAH-DOPS/EP 140.66 4099.70 47.56 2.89 15wt%MAH-DOPS/EP 116.46 3258.97 30.63 2.67 3. 结 论

本研究合成了一种新型磷杂菲衍生物阻燃剂马来酸酐-9, 10-二氢-9-氧杂-10-磷杂菲-10-硫化物(MAH-DOPS),并将其添加到环氧树脂(EP)中,对比了阻燃剂DOPS和MAH-DOPS对EP的热稳定性、阻燃性能和力学性能的影响,探究了MAH-DOPS/EP的燃烧性能和热降解行为,深入分析其阻燃机制,结果如下:

(1)阻燃剂DOPS的初始分解温度(T5%)(205.4℃)低于MAH-DOPS(235.2℃),当两种阻燃剂的质量分数均为10wt%时,复合材料DOPS/EP的热稳定性也低于MAH-DOPS/EP,与阻燃剂热稳定性一致;

(2) 阻燃剂DOPS和MAH-DOPS均能提高EP的极限氧指数(LOI)值和垂直燃烧(UL-94)等级。当阻燃剂的添加量为15wt%时,MAH-DOPS/EP的LOI值提高到28.6%,达到UL-94 V-0级;DOPS/EP的LOI值为29.1%,达到UL-94 V-1级。力学测试结果表明:与纯EP相比,10wt%MAH-DOPS/EP的弯曲强度为140.66 MPa,提高了45.8%;而10wt%DOPS/EP的弯曲强度为36.2 MPa,下降了62.5%,其拉伸强度为27.4 MPa,下降了63.6%,DOPS/EP体系的力学性能下降明显,几乎失去使用价值。MAH-DOPS/EP的力学性能优于DOPS/EP;

(3) TG、SEM-EDS测试结果表明:MAH-DOPS/EP存在一定的凝聚相阻燃作用;锥形量热测试、TG-IR分析结果表明:在MAH-DOPS/EP阻燃体系中,MAH-DOPS以气相阻燃机制为主。

-

表 1 阻燃环氧树脂的配方

Table 1 Formulation of flame retardant epoxy resin

Sample Composition/g EP MTHPA BDMA MAH-DOPS DOPS 5wt%MAH-DOPS/EP 100 85 1 9.79 — 5wt%DOPS/EP 100 85 1 — 9.79 10wt%MAH-DOPS/EP 100 85 1 20.67 — 10wt%DOPS/EP 100 85 1 — 20.67 15wt%MAH-DOPS/EP 100 85 1 32.82 — 15wt%DOPS/EP 100 85 1 — 32.82 Notes: EP—Epoxy resin; MTHPA—Methyl tetrahydrophthalic anhydride; BDMA—N,N-dimethylbenzylamine; MAH-DOPS—Maleic anhydride-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide; DOPS—9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide. 表 2 两种阻燃剂在氮气下的TG和DTG数据

Table 2 TG and DTG data of two flame retardants in N2

Sample T5%/℃ T10%/℃ T50%/℃ TP1/℃ TP2/℃ Rmax1 Rmax2 Char residue

at 600℃/%DOPS 205.4 216.9 341.6 225.5 381.5 0.31 0.83 3.57 MAH-DOPS 235.2 248.7 435.4 245.1 469.7 0.34 0.86 15.81 Notes: T5%, T10%, T50%—Temperature corresponding to weight loss 5%, 10% and 50% of material; TP—Temperature corresponding to maximum thermal degradation rate; Rmax—Maximum thermal degradation rate. 表 3 EP及其复合材料在氮气下的TG、DTG数据

Table 3 TG and DTG data of EP and EP composites in N2

Sample T5%/℃ T10%/℃ T50%/℃ TP1/℃ TP2/℃ Rmax1 Rmax2 Char residue at 600℃/% EP 345.1 369.7 410.1 407.6 — 1.61 — 7.22 5wt%MAH-DOPS/EP 271.2 326.5 400.8 402.6 — 1.50 — 8.90 10wt%MAH-DOPS/EP 292.8 342.8 393.2 395.1 — 1.53 — 11.42 10wt%DOPS/EP 230.2 276.5 409.8 308.1 449.7 0.37 0.79 3.52 15wt%MAH-DOPS/EP 319.2 357.1 402.8 392.5 — 1.49 — 11.93 表 4 EP及其复合材料的LOI和垂直燃烧测试(UL-94)数据

Table 4 LOI and vertical combustion test (UL-94) data of EP an EP composites

Sample LOI/% UL-94 t1/t2 Dripping Rating EP 19.5 — NO N.R. 5wt%DOPS/EP 26.2 >50/>50 NO N.R. 5wt%MAH-DOPS/EP 24.9 19.21/15.08 NO V-2 10wt%DOPS/EP 30.7 5.81/43.53 NO V-2 10wt%MAH-DOPS/EP 27.1 15.37/13.42 NO V-1 15wt%DOPS/EP 29.1 12.27/1.91 NO V-1 15wt%MAH-DOPS/EP 28.6 5.01/4.45 NO V-0 Notes: LOI—Limiting oxygen index; t1/t2—First and second combustion time in UL-94 test; N.R.—No rating. 表 5 EP和MAH-DOPS/EP的锥形量热测试(CONE)数据

Table 5 Cone calorimeter (CONE) data of EP and MAH-DOPS/EP

Sample TTI/s av-HRR/

(kW·m−2)PHRR/

(kW·m−2)THR/

(MJ·m−2)av-EHC/

(MJ·kg−1)TSR/

(m2·m−2)av-COY/

(kg·kg−1)EP 66 218.88 918.01 155.57 31.41 2251.69 0.21 5wt%MAH-DOPS/EP 55 129.55 697.83 96.98 28.31 2859.35 0.27 10wt%MAH-DOPS/EP 58 132.37 644.54 81.43 27.82 2873.67 0.33 15wt%MAH-DOPS/EP 52 137.43 603.67 71.37 28.75 3098.42 0.37 Notes: TTI—Time to ignition; av-HRR—Average heat release rate; PHRR—Peak heat release rate; THR—Total heat release; av-EHC—Average effective heat of combustion; TSR—Total smoke release; av-COY—Average carbon monoxide yield. 表 6 MAH-DOPS/EP残炭的EDS数据

Table 6 EDS data of char residues of MAH-DOPS/EP

Sample Char residue Composites C/wt% O/wt% P/wt% S/wt% P/wt% S/wt% 5wt%MAH-DOPS/EP 67.70 24.17 7.06 1.07 0.47 0.48 10wt%MAH-DOPS/EP 64.45 29.57 5.32 0.28 0.94 0.97 15wt%MAH-DOPS/EP 66.01 29.18 4.01 0.81 1.41 1.46 表 7 EP和MAH-DOPS/EP的力学性能

Table 7 Mechanical properties of EP and MAH-DOPS/EP

Sample Bending strength/MPa Bending modulus/MPa Tensile strength/MPa Notched izod impact strengh/(kJ·m−2) EP 96.47 2326.68 75.19 3.11 5wt%MAH-DOPS/EP 125.33 3224.83 52.39 2.94 10wt%MAH-DOPS/EP 140.66 4099.70 47.56 2.89 15wt%MAH-DOPS/EP 116.46 3258.97 30.63 2.67 -

[1] GHARIEH A, SEYED M S. A systematic study on the synergistic effects of MWCNTs and core-shell particles on the physicomechanical properties of epoxy resin[J]. Scientific Reports,2021,11:20789.

[2] HUO S Q, SONG P A, YU B, et al. Phosphorus-containing flame retardant epoxy thermosets: Recent advances and future perspectives[J]. Progress in Polymer Science,2021,114:101366. DOI: 10.1016/j.progpolymsci.2021.101366.

[3] YANG S, HUO S Q, WANG J, et al. A highly fire-safe and smoke-suppressive single-component epoxy resin with switchable curing temperature and rapid curing rate[J]. Composites Part B: Engineering,2021,207:108601. DOI: 10.1016/j.compositesb.2020.108601.

[4] DENG J, SHI W F. Synthesis and effect of hyper-branched (3-hydroxyphenyl) phosphate as a curing agent on the thermal and combustion behaviours of novolac epoxy resin[J]. European Polymer Journal,2004,40(6):1137-1143. DOI: 10.1016/j.eurpolymj.2003.12.015.

[5] WANG J Y, QIAN L J, HUANG Z G, et al. Synergistic flame-retardant behavior and mechanisms of aluminum poly-hexamethylene-phosphinate and phosphaphenan-threne in epoxy resin[J]. Polymer Degradation and Stability,2016,130:173-181. DOI: 10.1016/j.polymdegradstab.2016.06.010.

[6] WANG P, CHEN L, XIAO H, et al. Nitrogen/sulfur-containing DOPO based oligomer for highly efficient flame-retardant epoxy resin[J]. Polymer Degradation and Stabi-lity, 2020, 171: 109023.

[7] SHI Y Q, YU B, ZHENG Y Y, et al. Design of reduced graphene oxide decorated with DOPO-phosphanomidate for enhanced fire safety of epoxy resin[J]. Journal of Colloid and Interface Science,2018,521:160-171. DOI: 10.1016/j.jcis.2018.02.054.

[8] ČOLOVIC M, VASILJEVIC J, ŠTIM Z, et al. New sustainable flame retardant DOPO-NH-functionalized polyamide 6 and filament yarn[J]. Chemical Engineering Journal,2021,426(7):130760.

[9] JIANG P, GU X Y, ZHANG S, et al. Synthesis, characterization, and utilization of a novel phosphorus/nitrogen-containing flame retardant[J]. Industrial & Engineering Chemistry Research,2015,54(11):2974-2982.

[10] QIAN L J, QIU Y, SUN N, et al. Pyrolysis route of a novel flame retardant constructed by phosphaphenanthrene and triazine-trione groups and its flame-retardant effect on epoxy resin[J]. Polymer Degradation and Stability,2014,107:98-105. DOI: 10.1016/j.polymdegradstab.2014.05.007.

[11] GU L Q, QIU J H. Effect of DOPO-containing flame retardants on poly(lactic acid): Non-flammability, mechanical properties and thermal behaviors[J]. Chemical Research in Chinese Universitie,2017,33(1):143-149. DOI: 10.1007/s40242-017-6196-9.

[12] YU T, TUERHONGJIANG T, SHENG C, et al. Phosphorus-containing diacid and its application in jute/poly(lactic acid) composites: Mechanical, thermal and flammability properties[J]. Composites Part A: Applied Science and Manufacturing,2017,97:60-66. DOI: 10.1016/j.compositesa.2017.03.004.

[13] YANG S, WANG J, HUO S Q, et al. Preparation and flame retardancy of an intumescent flame-retardant epoxy resin system constructed by multiple flame-retardant compositions containing phosphorus and nitrogen heterocycle[J]. Polymer Degradation and Stability,2015,119:251-259. DOI: 10.1016/j.polymdegradstab.2015.05.019.

[14] LIU Y L. Flame-retardant epoxy resins from novel phosphorus-containing novolac[J]. Polymer,2001,42(8):3445-3454. DOI: 10.1016/S0032-3861(00)00717-5.

[15] WANG X, HU Y, SONG L, et al. Flame retardancy and thermal degradation mechanism of epoxy resin composites based on DOPO substituted organophosphorus oligomer[J]. Polymer,2010,51(11):2435-2445. DOI: 10.1016/j.polymer.2010.03.053.

[16] 陈仕梅. 磷杂菲类阻燃剂的合成及在环氧树脂中的应用[D].贵阳: 贵州师范大学, 2018. CHEN Shimei. Synthesis of flame retardant based on phospha-phenanthrene and its application in epoxy resin[D]. Guiyang: Guizhou Normal University, 2018(in Chinese).

[17] 陈仕梅, 来方, 李霈, 等. 磷杂菲类阻燃剂的合成及其与聚磷酸铵复合膨胀体系对环氧树脂的阻燃性能研究[J]. 高分子学报, 2017(8):1358-1365. CHEN Shimei, LAI Fang, LI Pei, et al. Synthesis of flame retardant based on phosphaphenanthrene and flame retardancy study of epoxy resin modified by intumescent flame retardant system composed of ammonium polyphosphate[J]. Acta Polymerica Sinica,2017(8):1358-1365(in Chinese).

[18] 罗继永, 张道海, 周密, 等. PBT/TPU/DOPO-MA阻燃复合材料的制备及性能[J]. 化工进展, 2020, 39(8):3221-3229. LUO Jiyong, ZHANG Daohai, ZHOU Mi, et al. Preparation and properties of PBT/TPU/DOPO-MA flame retardant composites[J]. Chemical Industry and Engineering Progress,2020,39(8):3221-3229(in Chinese).

[19] LIU P, LIU M M, GAO C, et al. Preparation, characterization and properties of a halogen-free phosphorous flameretarded poly(butylene terephthalate) composite based on a DOPO derivative[J]. Journal of Applied Polymer Science,2013,130(2):1301-1307. DOI: 10.1002/app.39318.

[20] 王昱, 罗炎, 张桢. 阻燃型DOPO-马来酸酐改性的环氧树脂研究[J]. 绝缘材料, 2010, 43(3):20-23, 28. DOI: 10.3969/j.issn.1009-9239.2010.03.006. WANG Yu, LUO Yan, ZHANG Zhen. Study on epoxy resin modified with flame retardant DOPO-MA[J]. Insulating Materials,2010,43(3):20-23, 28(in Chinese). DOI: 10.3969/j.issn.1009-9239.2010.03.006.

[21] 王建航, 许志彦, 张玉鹏, 等. 磷杂菲/环氧树脂复合材料的热分解动力学研究[J]. 功能材料, 2020, 51(11):11152-11158. DOI: 10.3969/j.issn.1001-9731.2020.11.022. WANG Jianhang, XU Zhiyan, ZHANG Yupeng, et al. Thermal decomposition kinetics of phosphaphenanthrene/epoxy composites[J]. Journal of Functional Materials,2020,51(11):11152-11158(in Chinese). DOI: 10.3969/j.issn.1001-9731.2020.11.022.

[22] 中国国家标准化管理委员会. 塑料用氧指数法测定燃烧行为第1部分: 导则: GB/T 2406.1—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People's Republic of China. Plastics—Determination of burning behaviour by oxygen index—Part 1: Guidance: GB/T 2406.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[23] 中国国家标准化管理委员会. 塑料燃烧性能的测定: 水平法和垂直法: GB/T 2408—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People's Republic of China. Plastics—Determination of burning characteristics: Horizontal and vertical test: GB/T 2408—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[24] International Organization for Standardization. Reaction-to-fire tests—Heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method): ISO 5660-1—2002[S]. Switzerland: International Organization for Standardization, 2002.

[25] 中国国家标准化管理委员会. 塑料拉伸性能的测定第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2006. Standardization Administration of the People's Republic of China. Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics: GB/T 1040.2—2006[S]. Beijing: China Standards Press, 2006(in Chinese).

[26] 中国国家标准化管理委员会. 塑料弯曲性能的测定: GB/T 9341—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People's Republic of China. Plastics—Determination of flexural properties: GB/T 9341—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[27] 中国国家标准化管理委员会. 塑料悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People's Republic of China. Plastics—Determination of izod impact strength: GB/T 1843—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[28] 崔锦峰, 王心远, 郭永亮, 等. P元素杂化本征阻燃热塑性聚氨酯弹性体的制备及其性能研究[J]. 功能材料, 2015, 8(46):8050-8054. CUI Jinfeng, WANG Xinyuan, GUO Yongliang, et al. Study on preparation and properties of phosphorus hybrid intrinsic flame retardant thermoplastic polyurethane elastomer[J]. Journal of Functional Materials,2015,8(46):8050-8054(in Chinese).

[29] 魏振杰, 刘伟区, 李宏静, 等. 含磷有机硅杂化环氧树脂固化体系性能研究[J]. 高分子学报, 2012(2):148-153. WEI Zhenjie, LIU Weiqu, LI Hongjing, et al. Propeties of phosphorus-containing organic silicon/epoxy hybrid resin[J]. Acta Polymerica Sinica,2012(2):148-153(in Chinese).

[30] ZHAO Z, JIN Q, ZHANG N, et al. Preparation of a novel polysiloxane and its synergistic effect with ammonium polyphosphate on the flame retardancy of polypropylene[J]. Polymer Degradation and Stability,2018,150:73-85. DOI: 10.1016/j.polymdegradstab.2018.02.007.

[31] LONG L J, CHANG Q F, HE W T, et al. Effects of bridged DOPO derivatives on the thermal stability and flame retardant properties of poly(lactic acid)[J]. Polymer Degradation and Stability,2017,139:55-66. DOI: 10.1016/j.polymdegradstab.2017.03.016.

[32] LIU L, ZHU M H, MA Z W, et al. A reactive copper-organophosphate-MXene heterostructure enabled antibacterial, self-extinguishing and mechanically robust[J]. Chemical Engineering Journal,2022,430(1):132712. DOI: 10.1016/j.cej.2021.132712.

[33] YANG Y Y, LIU J, CAI X F, et al. Antagonistic flame retardancy between hexakis(4-nitrophenoxy) cyclotriphosphazene and potassium diphenylsulf-one sulfonate in the PC system[J]. Journal of Thermal Analysis Calorimetry,2016,126(2):571-583. DOI: 10.1007/s10973-016-5519-2.

[34] BATTIG A, MARKWARTT J, WURM F, et al. Sulfur's role in the flame retardancy of thio-ether-linked hyperbranched poly(phosphoesters) in epoxy resins[J]. European Polymer Journal,2019,122:109390.

[35] 张通, 龙丽娟, 何文涛, 等. 9, 10-二氢-9-氧杂-10-磷杂菲-10-氧化物衍生物阻燃聚乳酸的性能研究[J]. 高分子学报, 2019, 50(1): 71-81. ZHANG Tong, LONG Lijuan, HE Wentao, et al. Flame-retardant properties of 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivatives in poly(lactic acid)[J]. Acta Polymerica Sinica, 2019, 50(1): 71-81(in Chinese).

[36] 徐文静, 龙丽娟, 徐国敏, 等. DOPO衍生物/聚乳酸复合材料的热降解、阻燃及力学性能[J]. 复合材料学报, 2021, 38(9):2848-2861. XU Wenjing, LONG Lijuan, XU Guomin, et al. Thermal degradation, flame retardancy and mechanical properties of DOPO derivatives/poly(lactic acid) composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2848-2861(in Chinese).

[37] WANG P, XIA L, JIAN R K, et al. Flame-retarding epoxy resin with an efficient P/N/S-containing flame retardant: Preparation, thermal stability, and flame retardance[J]. Polymer Degradation and Stability,2018,149:69-77. DOI: 10.1016/j.polymdegradstab.2018.01.026.

[38] 张通. 桥链基团对双DOPO膦酸酯阻燃聚乳酸性能的影响[D]. 贵阳: 贵州大学, 2019. ZHANG Tong. Synthesis of DOPO phosphonates and their flame retardant mechanism on polylactic acid[D]. Guiyang: Guizhou University, 2019(in Chinese).

[39] 魏柯. 磷杂菲类阻燃剂的制备及其在聚乳酸中的应用研究[D]. 贵阳: 贵州大学, 2019. WEI Ke. Preparation of phosphorus phenanthrene flame retardant and its application in polylactic acid[D]. Guiyang: Guizhou University, 2019(in Chinese).

-

期刊类型引用(8)

1. 胥秋,侯泽明,宦宣英,祁钰昭,许松江,宝冬梅,高成涛,邹光龙,张玉鹏,文竹. 双基阻燃剂DOPS-TEAIC的合成及阻燃环氧树脂的性能. 高分子材料科学与工程. 2024(09): 74-85 .  百度学术

百度学术

2. 宦宣英,马仕凯,胥秋,叶小林,黄永菲,宝冬梅,杜海军,文竹,张玉鹏,侯学清. 复配阻燃剂MSB/DOPS在环氧树脂中的协同阻燃性能. 高分子材料科学与工程. 2024(12): 61-70 .  百度学术

百度学术

3. 许志彦,侯泽明,叶小林,祁钰昭,许松江,宝冬梅,张道海,周国永,蔡晓东,邹光龙,文竹. 双基协同阻燃环氧树脂HPCTP-DOPS/EP的性能研究. 复合材料学报. 2023(04): 2187-2198 .  本站查看

本站查看

4. 陆亦洲,耿海春,沈金荣,方园. 基于微流控技术的阻燃微胶囊的制备及其改性环氧树脂的性能与阻燃机制. 复合材料学报. 2023(04): 2119-2130 .  本站查看

本站查看

5. 张玲,任癸林,宿芃,张军华,房轶群. DOPO衍生物/八氨丙基POSS阻燃木塑复合材料的研究. 西南林业大学学报(自然科学). 2023(03): 136-144 .  百度学术

百度学术

6. 祁钰昭,许松江,侯泽明,叶小林,宝冬梅,张道海,秦舒浩,向宇姝,高成涛,邹光龙,周国永. 磷杂菲衍生物的合成及对环氧树脂阻燃性能与热降解行为的影响. 高分子材料科学与工程. 2023(05): 50-58 .  百度学术

百度学术

7. 许松江,许志彦,侯泽明,宝冬梅,周国永,邹光龙. 环氧树脂/DOPS衍生物复合材料的阻燃性能及热降解行为. 材料导报. 2023(22): 259-265 .  百度学术

百度学术

8. 吴于爽,龙佳朋,梁兵,班瀚雯,王晓楠,邢皓杨. 环氧树脂阻燃固化剂的研究进展. 塑料科技. 2022(03): 104-108 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: