Dynamic response and damage of fiber metal interpenetrating composite plate under low-velocity impact

-

摘要:

纤维增强金属复合材料受到冲击时容易发生金属与纤维分层从而影响力学性能,为了缓解此类现象,将金属板冲孔,使用碳纤维和芳纶纤维交替穿编,制备了一种三维复合材料纤维金属互穿式复合板(Fiber Metal Interpenetrating Composite Plate,FMICP)。进行了低速冲击试验,研究了FMICP在不同冲击速度、冲击面积和冲孔样式下的力学性能。研究表明:当冲击速度在35.19~78.08 m/s之间时,FMICP发生了贯穿破坏,吸收了39.78~70.67 J的冲击能量;受到恒定49 J冲击能量时,冲击面积为491 mm2的FMICP最高能够吸收42.77 J能量;随着冲击面积的增大,FMICP中受到拉伸的纤维数量增多,冲击造成的冲切破坏和局部损伤减小;冲孔类型改变了FMICP中金属基的占比和应力传递方式,椭圆冲孔FMICP (41.11 J)相对矩型冲孔FMICP (34.08 J)能够起到更好的吸收能量的作用。本研究结果可为FMICP的推广应用提供参考。

-

关键词:

- 低速冲击 /

- 能量吸收 /

- 三维穿编 /

- 纤维金属互穿式复合板 /

- 动力响应

Abstract:Fiber reinforced metal composites are prone to delamination of metal and fibre when subjected to impact, thus affecting the mechanical properties, in order to alleviate such phenomena, a three-dimensional composite Fiber Metal Interpenetrating Composite Plate (FMICP) was prepared by punching the metal plate and alternately threading it with carbon fibres and aramid fibres. Low-speed impact tests were conducted to investigate the mechanical properties of FMICP at different impact velocities, impact areas and punching styles. The study shows that: when the impact velocity is between 35.19 and 78.08 m/s, the FMICP undergoes penetration damage and absorbs 39.78 J to 70.67 J of impact energy; when subjected to a constant 49 J of impact energy, the FMICP with an impact area of 491 mm2 is able to absorb a maximum of 42.77 J of energy; as the impact area increases, the number of fibers subjected to stretching in the FMICP increases, which decreases the punching damage and local damage caused by the impact; the type of punching changes the percentage of metal base in the FMICP and the mode of stress transfer, the elliptical punched FMICP (41.11 J) is able to absorb energy more effectively compared to the rectangular punched FMICP (34.08 J). The results of this study can provide a reference for the promotion and application of FMICP.

-

复合材料具有高比强度和高比模量、优异的抗疲劳性能、良好的耐热性能和独特的可设计性的优势,通过对其进行二次设计能够达到更好的拉伸冲击等性能,可用于飞行结构材料以及新能源电池保护结构[1-5]。随着科技现代化的发展,轻量化兼容防冲击性能逐步成为衡量结构的重要指标,传统的金属树脂基复合材料已经难以满足轻量化防冲击结构的发展需求。纤维增强金属层合板是有轻质金属薄板和树脂基纤维层进行交替铺设后,在高温和高压固化后形成的混杂复合材料。纤维增强金属层合板在复合材料优势的基础上,还兼顾了金属和纤维两种材料的性能优势,具有更高的抗疲劳性、抗冲击性和损伤容度[6-7],因此受到广泛的关注和研究。

在近几年来,研究人员对纤维增强金属层合板在冲击和爆炸等动荷载下的性能做了大量研究。崔岸[8]研究了玄武岩纤维增强铝合金层合板的低速冲击性能,结果发现相较于纯纤维层合板,纤维增强金属层合板可以吸收更多的冲击能量且冲击能量耗散更快,并且当铝合金板位于最顶部时,纤维增强金属层合板吸收的能量最多。赵艺桥等[9]研究了界面结合度对亚麻纤维增强复合材料抗冲击性能的影响,结果发现对金属层表面进行改性处理能够使材料整体的最大冲击荷载和能量吸收率分别提升136%和58%。碳纤维与芳纶纤维作为纤维增强金属层合板中的主要纤维材料,具有轻质高强的特点[10-12],被广泛应用到航空航天、船舶制造等领域。相关研究表明,碳纤维有良好的拉伸性能,使得碳纤维增强复合板在冲击作用下有更高的刚度[13],芳纶纤维在反复冲击作用下表现出良好的抗疲劳性能和抗损伤性能[14],同时还具有较大的断裂伸长率。Bresciani等[15]研究了芳纶纤维层压板的抗冲击性,研究发现芳纶纤维在冲击能量吸收方面发挥了重要作用,吸收了50%以上的冲击能量。也有研究表明[16-20],使用纤维杂化的方式可以有效提高复合材料在冲击荷载下的表现,Aswani[21]研究了二维平纹纤维层和三维正交织物纤维层增强的复合材料层压板在低速冲击下的失效行为,研究发现三维纤维提高了层压板峰值荷载14.21%~30.25%,提高了能量耗散12.7%~26.2%,并与层合板内部有相似面密度,减少了15.64%的损伤面积。纤维增强金属板在其使用期间,经常在受到冲击载荷后发生损坏,Zhu等[22-24]对纤维增强金属层合板在动态载荷下的失效模式进行了详细的研究,发现纤维增强金属层合板的失效模式表现在纤维断裂、基体断裂、树脂脱落、金属延展性损伤、花瓣撕裂和各种类型的层间分层。Pang等[25]研究了不同冲头形状和冲击能量下纤维金属板的破坏模式,研究发现纤维金属板在低速冲击下的损伤主要是由于纤维层和金属层之间的分层脱胶致使能量传递率大幅下降。Li[26-27]通过冲击试验研究了不同纤维类型的纤维增强金属层合板在冲击破坏性能,研究发现尽管纤维类型不同,但纤维增强金属层合板在试验中表现出相似的变形破坏和失效模式。Dhaliwal[28]研究发现在相同的冲击荷载下,随着层间强度的增强,纤维金属板的分层面积会减少40%~50%。因此,只要纤维层和金属层之间有较好地界面粘结强度,即纤维增强金属层合板的整体性保持在合理的区间范围内,就可以大幅减小在冲击过程中因界面剥离产生的能量耗散的影响。

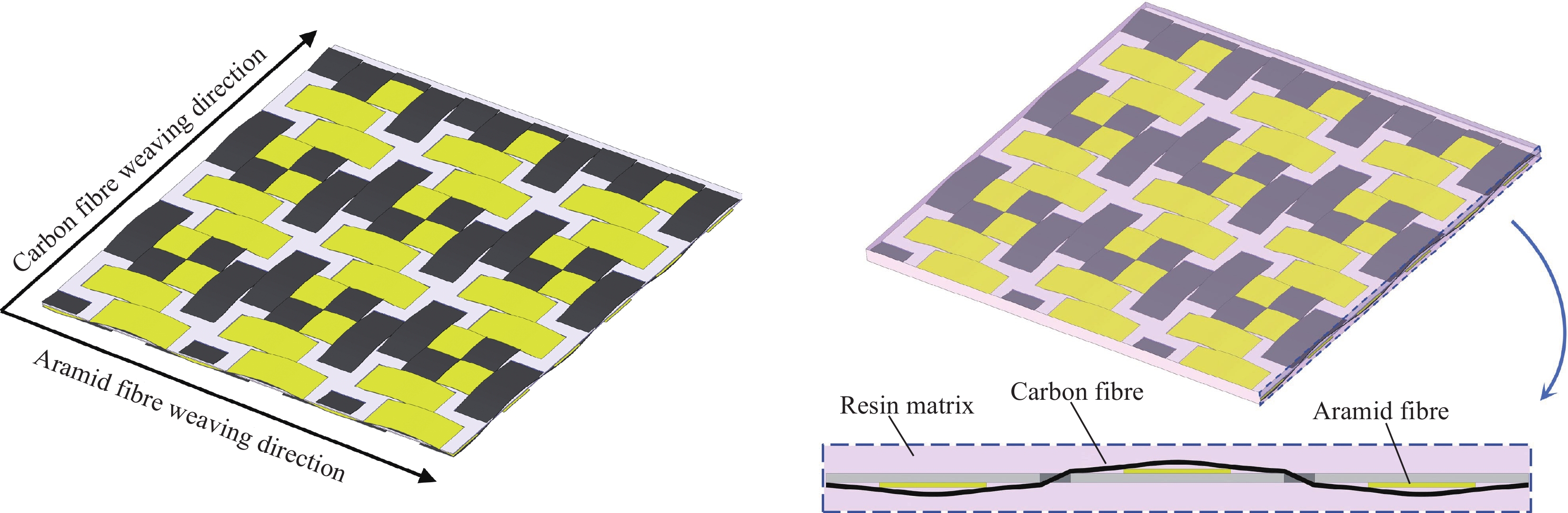

为解决冲击过程中纤维增强金属层合板的整体性不足的问题,本研究通过将碳纤维和芳纶纤维作为增强材料穿编至冲孔铝合金板,形成三维织物结构[29-32],使纤维在固化前与金属板形成“自锁”,制备了纤维金属互穿式复合板(Fiber-Metal Interpenetrating Composite Plate,FMICP)。能够缓解纤维层和金属层之间出现大面积脱胶,延缓材料内部的裂纹发展,增强材料整体性能[33-35]。本研究采用一级轻气炮冲击装置,研究了低速冲击下的冲击速度、孔洞形状和冲击面积对纤维金属互穿式复合板的冲击行为和吸能性能的影响,采用高速摄像机记录了FMICP的冲击响应过程,采集计算了弹体的冲击速度与残余速度,并测量了冲击区域的最大面外位移,对比研究了不同工况下FMICP的动态响应与能量吸收能力。本研究是有助于进一步拓展纤维增强复合材料在工程中的应用场景,为纤维增强复合材料的物理力学性能的提升提供参考思路。

1. 试验方法

1.1 FMICP制备材料

FMICP采用铝合金、碳纤维、芳纶纤维以及环氧树脂制备而成,其中金属板选用厚度为1 mm的5052铝合金板材,纤维选用的型号为T300-3k的碳纤维(日本东丽工业有限公司)以及型号为K29-3000D的芳纶纤维(美国杜邦公司),基体材料选取西卡Eploam2040/2042环氧树脂,金属表面使用偶联剂进行化学处理[36],以提高与树脂基体的粘结程度,试验材料的力学性能参数如表1所示。

表 1 纤维金属互穿式复合板(FMICP)制备材料力学性能Table 1. Mechanical properties of Fiber-Metal Interpenetrating Composite Plate(FMICP) prepared materialsMaterial Density/

(g·cm−3)Tensile

strength/MPaYield

strength/MPaElastic

modulus/GPaFiber

diameter/μmElongation

at break/%Aluminium alloy 2.68 230 170 70 — 14 Carbon fibre 1.76 3530 — 230 7 1.5 Aramid fiber 1.45 1750 — 440 15 3.1 Epoxy resin 0.95 75 — 2.0 — 8.7 1.2 FMICP试件制备

FMICP试件的结构示意图如图1所示,制备过程如图2所示。首先,将尺寸为200 mm×200 mm×1 mm的铝合金金属板进行砂磨机械预处理,按照设计点阵式孔洞样式对金属板进行冲孔处理,按照经向与纬向将碳纤维与芳纶纤维垂直交替穿编至冲孔金属板形成复合板。同时,将环氧树脂与固化剂按照体积比3∶1进行混合搅拌后,置于真空箱中抽除树脂中的多余空气。将复合板放置于模具中,将树脂混合液通过真空抽取填充至模具。在0.5 MPa的施加压力和在80℃高温下进行粘合,为使复合板固化受热均匀,温度先以1℃/min的速率从室温升至50℃,保持30 min确保热固性树脂充分渗透至纤维和层间粘结处并去除复合板中的气泡,再以1℃/min的升温速率再次升温至80℃,保持120 min使树脂再次进行固化。最后,将复合板试件冷却至室温得到固化后的FMICP,进行高压水射流加工技术制备成100×100 mm尺寸试件,环氧树脂填充过程以及试件成品如图3所示。

本文研究制备了19个FMICP试件,试件详细参数见表2。A1-1(1)、A1-2、A1-3、A1-4、A1-5为第一组对比组,改变了弹体冲击速度,对比研究弹体冲击前后的速度变化。A1-1(1-3)、A2-1(1-3)、A3-1(1-3)为第二组对比组,在保持冲击能量不变时,改变冲击弹体的尺寸大小,即改变了冲击面积;A1-1(1-3)、B1-1(1-3)、C1-1(1-3)为第三组对比组,改变了试件中金属板的孔洞类型。第二组与第三组研究相同能量下试件的变形与破坏,为了避免试验结果的偶然性,对两组试件进行三次重复冲击试验。

表 2 FMICP试件参数Table 2. FMICP specimen parametersNumber Thickness/mm Quality/g Punch type Punch shape/mm AC/AL-A1-1(1) 2.93±0.10 41.0 Elliptical

Elliptical

Circular-rectangular

RectangularAC/AL-A1-1(2) 2.90±0.10 40.7 AC/AL-A1-1(3) 2.94±0.10 41.2 AC/AL-A1-2 3.32±0.10 48.4 AC/AL-A1-3 2.78±0.10 40.2 AC/AL-A1-4 3.16±0.10 47.0 AC/AL-A1-5 2.91±0.10 40.9 AC/AL-A2-1(1) 2.99±0.10 43.8 AC/AL-A2-1(2) 2.95±0.10 42.9 AC/AL-A2-1(3) 2.97±0.10 43.1 AC/AL-A3-1(1) 2.94±0.10 42.9 AC/AL-A3-1(2) 2.89±0.10 42.0 AC/AL-A3-1(3) 2.97±0.10 43.1 AC/AL-B1-1(1) 2.84±0.10 39.7 Circular-rectangular AC/AL-B1-1(2) 2.91±0.10 40.1 AC/AL-B1-1(3) 2.93±0.10 40.3 AC/AL-C1-1(1) 3.09±0.10 43.3 Rectangular AC/AL-C1-1(2) 2.98±0.10 42.1 AC/AL-C1-1(3) 3.04±0.10 42.9 Notes:AC/AL is an aramid fibre (A) and carbon fibre (C) reinforced aluminum based (AL) FMICP; The three numbers in A1-1 differentiate between the type of punch, the impact area, and the impact velocity of the specimen, the specimen numbers in the article are abbreviated versions. 1.3 试验设备

本试验研究进行了动态冲击试验,冲击试验装置如图4所示。试验装置由压缩氮气瓶,空气压缩机,一级轻气炮发射装置(阿基米德工业科技有限公司),红外线激光测速仪,高速摄像机以及靶室组成,弹体材质为SKD11合金钢平头弹体,弹体及弹托力学性能参数见表3。试验所用夹具由前后夹板以及固定螺杆连接件组成,前后夹板的尺寸为300 mm×300 mm×10 mm。夹板与试件之间用橡胶垫夹紧固定防止试件在冲击过程中发生偏移。

表 3 弹体及弹托力学性能Table 3. Mechanical properties of Bullet and Shell casingParts Material Density/(g·cm−3) Tensile

strength/MPaCompressive

strength/MPaYield

strength/MPaElastic

modulus/GPaBullet Alloy Steel SKD11 7.80 2000 2800 1700 210 Shell casing Nylon 1.15 75 90 70 2.9 2. 结果与讨论

对FMICP进行轻气炮冲击试验,研究了其在不同冲击速度、不同冲孔样式、不同冲击面积情况下的变形效果和失效机制。冲击速度区间为35.19~78.08 m/s。使用高速摄像机捕获FMICP在受到冲击时的变形过程,冲击试验结果见表1。试验结果包括对FMICP变形失效模式和整体结构的定性观察以及对FMICP变形挠度、弹道极限、变形面积和能量吸收等方面的定量研究计算。

2.1 FMICP的冲击损伤过程

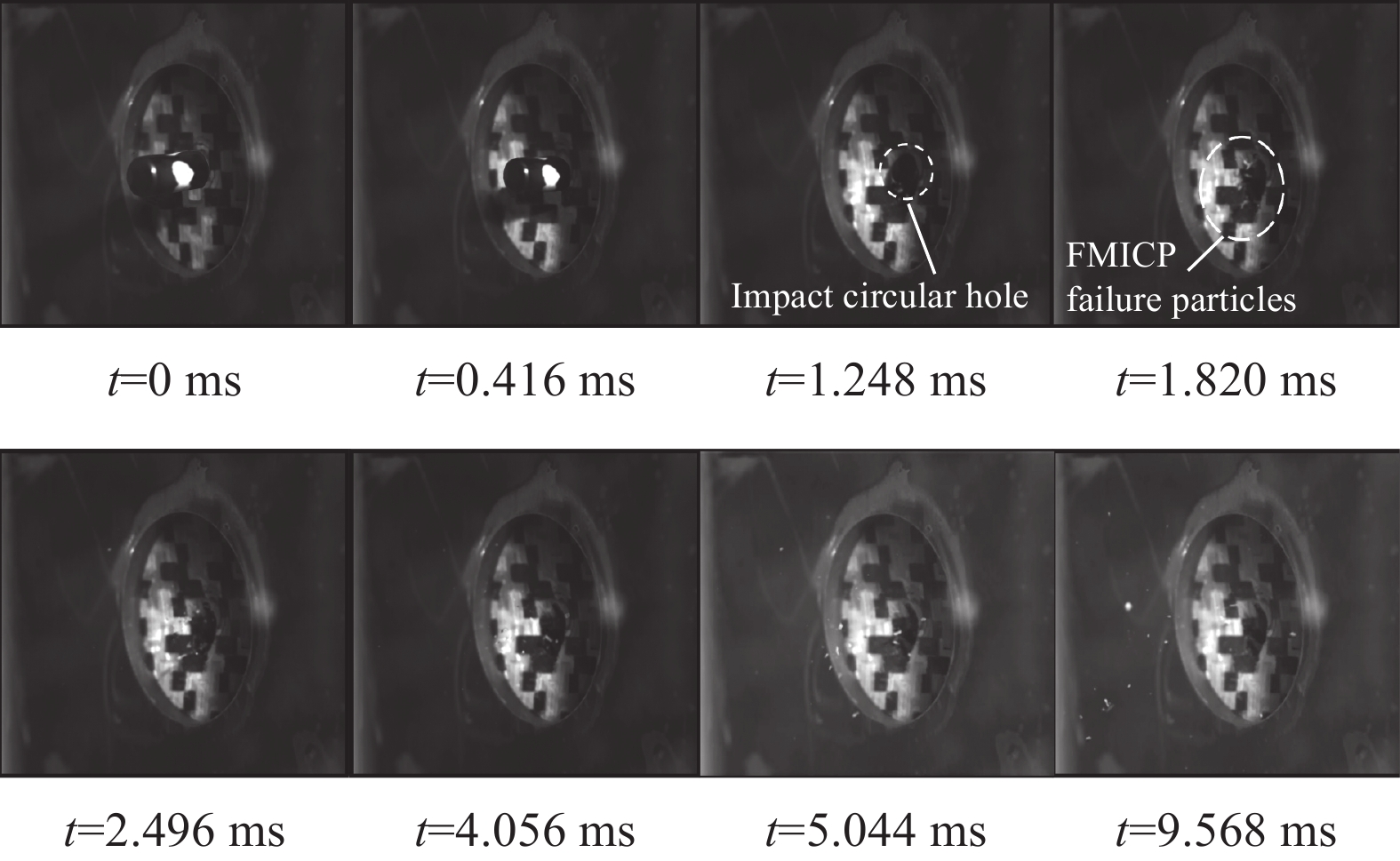

高速摄像机捕捉到的FMICP在受到弹体冲击时的变形发展情况,对于FMICP在冲击过程中有相似的变形过程,因此,本文在此只展示以37.55 m/s速度冲击FMICP的冲击过程,如图5所示。在FMICP受到冲击后,冲击正面冲击点处发生凹陷(t=0.416 ms),此时FMICP出现变形与裂纹且面板挠度变形达到最大,之后变形逐渐扩展到面外以及传播至圆形夹具周边。弹体完全穿透后(t=1~820 ms),可以观察到已失效的FMICP细小颗粒,这是由于FMICP具有一定的脆性导致,弹体在试件中心处产生一个冲击圆孔,说明在冲击过程中,发生了冲塞剪切现象,冲塞剪切只在弹体冲击区域发生,没有扩展至整个FMICP面板。弹体穿过后,试件从1.820 ms持续发生小幅度激振直到9.569 ms,变形挠度逐渐回弹后停止变化。

图6展示了冲击前后弹体的运动形态变化情况,冲击前,弹体的冲击路径为直线型冲击路径,以基本垂直于试件的方向射入;在冲击过程中,试件发生冲塞剪切破坏,冲塞碎片随弹体穿透试件而冲出。冲击弹体在冲击试件后发生路径的轻微偏转与自身整体偏转,弹体从横向直线冲击转变成横向冲击与纵向偏移的混合叠加,结合图1研究发现产生偏转的原因有两点,一是弹体冲击FMICP产生冲击裂纹,裂纹在进一步扩展的过程中使弹面与冲击面产生微小的冲击偏转角,使弹体发生整体偏转;二是弹体前端穿过试件后,试件发生激振而改变弹体后端的运动形态,从而影响弹体的冲击路径。

2.2 FMICP的变形失效模式

本文根据FMICP冲击面和横截面的破坏特征细节,分析研究了FMICP在冲击破坏下的典型变形和破坏模式。破坏模式包括树脂基体开裂、剥落、纤维单元断裂、金属板塑性变形和断裂、孔洞撕裂。

研究中发现树脂基体包括两种变形破坏模式,一是由冲击产生的脆性裂纹,二是裂缝进一步产生破坏发生的树脂剥落。FMICP正面和背面的裂缝分布情况如图7所示。可知尽管试件正面和背面的挠度基本相同,但在冲击正面出现数量多,长度较长的环向扩展裂纹,基本没有基体剥落破坏;而冲击背面产生裂纹数量较少,长度较短,呈分散型径向分布,在冲击点附近出现树脂基体剥落,说明裂纹的产生不是因为FMICP弯曲变形而产生,而是由于在弹体冲击试件时,试件正面产生较大的面内径向拉应力,产生大量的环向破坏裂纹。而部分能量在传递过程中由于试件的塑性变形和破坏、纤维断裂以及环向长裂纹出现而被吸收耗散,传递至FMICP背面的冲击能量较少,所以FMICP背面基本没有产生环向裂纹,而是由于局部变形和纤维局部拉伸产生的径向裂纹较多。

不同冲击速度下FMICP横截面的变形结果如图8所示。在35.19~78.08 m/s的冲击中不同速度下横截面的变形破坏情况发现,随着冲击速度的增加,试件的整体变形也逐渐增加,试件变形失效基本集中在冲击中心点周围。碳纤维的断裂方式为脆性断裂,断裂面较为平整,而芳纶纤维有较好的韧性,断裂后断面参差不齐,出现“抽丝”现象。值得注意的是,树脂与金属层之间只有微小的树脂剥落,没有产生大面积的脱胶现象,而且树脂剥落集中在冲击区域周围。试件背面出现“花瓣状”椭圆穿孔,产生原因为发生剪切冲塞,而且冲塞面积随着冲击速度的增加而增加。冲击点处的金属板的变形最开始以局部屈曲变形以及孔洞的变形、撕裂破坏为主,而远离冲击点的金属板的变形为整体弯曲变形以及孔洞的微小变形。

图9为相同能量、不同尺寸弹体冲击下FMICP横截面的变形破坏情况。对比可以发现弹体直径越小,冲击造成的试件背面板“花瓣状”破坏效果越明显,造成的局部冲塞破坏效果越显著,直径25 mm尺寸弹体冲击产生的变形表现为面板的整体屈曲,没有严重的局部变形破坏,最大变形挠度也相对较小。不同冲孔样式试件的破坏模式区别主要在金属板孔洞的破坏上,矩型孔洞的孔洞变形撕裂发生在孔洞边角端,撕裂呈斜线型撕裂,而椭圆型和圆矩型孔洞的变形撕裂沿着长轴与短轴方向,撕裂呈直线型撕裂。不同孔洞的变形破坏情况如图10所示。

2.3 FMICP的耗散能量结果分析

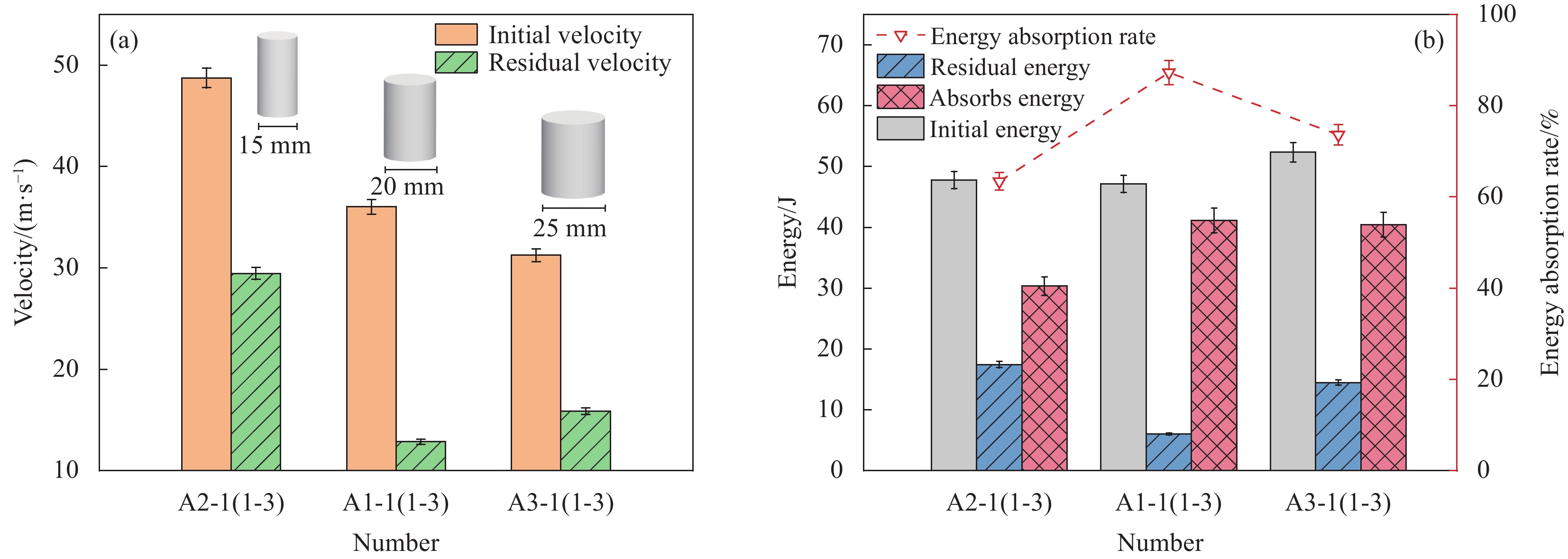

冲击试验结果如表4所示,从A1-1(1)至A1-5的试验结果可以看出,冲击速度大于35.19 m/s时,试件均发生了贯穿破坏现象。当冲击速度从35.19 m/s增加至78.08 m/s时,FMICP吸收的能量从39.78 J增加至70.67 J,吸收的能量得到有效提高,可见随着冲击速度增加,纤维的拉伸性能和金属板的塑性抗弯性能能够较好地发挥作用。冲击速度增大的过程中,即使FMICP吸收的能量增多,但能量吸收率从88.49%降低至31.93%。低速冲击时,能量能够进行较好的传播与耗散,随着冲击速度的增大,能量传递的时间大大缩减,产生的局部损伤和失效也更明显,此时试件的抗冲击能力因严重的局部损伤而未达到极限。由此可知,FMICP在低速冲击荷载下的抗冲击性能更优。图11(a)、图11(b)分别为A1-1(1)至A1-5冲击前后速度与能量的对比图。

表 4 FMICP冲击试验结果汇总Table 4. Summary of FMICP impact test resultsNumber Initial

velocity/(m·s−1)Residual

velocity/(m·s−1)Impact

area/mm2Initial

energy/JResidual

energy/JAbsorbs

energy/JEnergy absorption rate/% AC/AL-A1-1(1) 35.19 11.94 314 44.96 5.18 39.78 88.49 AC/AL-A1-1(2) 36.94 13.76 49.55 6.88 42.68 86.12 AC/AL-A1-1(3) 35.93 12.86 46.89 6.01 40.88 87.19 AC/AL-A1-2 49.95 35.28 90.58 45.19 45.39 50.11 AC/AL-A1-3 65.15 51.93 154.13 97.90 56.22 36.48 AC/AL-A1-4 68.86 56.52 172.15 115.98 56.17 32.63 AC/AL-A1-5 78.08 64.42 221.34 150.67 70.67 31.93 AC/AL-A2-1(1) 47.54 29.64 177 45.43 17.67 27.77 61.11 AC/AL-A2-1(2) 49.67 28.77 49.58 16.64 32.94 66.44 AC/AL-A2-1(3) 49.02 29.94 48.30 18.02 30.28 62.70 AC/AL-A3-1(1) 30.62 15.59 491 53.85 13.97 39.89 74.07 AC/AL-A3-1(2) 29.74 16.19 50.80 15.05 42.77 73.96 AC/AL-A3-1(3) 30.18 15.84 52.32 14.41 38.58 72.81 AC/AL-B1-1(1) 37.55 23.42 314 51.21 15.15 36.06 70.42 AC/AL-B1-1(2) 36.96 21.33 49.59 16.51 33.08 66.70 AC/AL-B1-1(3) 37.89 20.97 52.11 15.96 36.16 69.39 AC/AL-C1-1(1) 36.81 21.36 49.20 16.57 32.63 66.32 AC/AL-C1-1(2) 38.42 22.87 53.58 18.99 34.60 64.57 AC/AL-C1-1(3) 37.99 21.89 52.39 17.39 35.00 66.80 对A1-1(1-3)、A2-1(1-3)、A3-1(1-3)使用不同直径的弹体进行相同能量的冲击,试验结果如图12所示,由图12(b)可知不同冲击面积对FMICP能量吸收能力有影响。在49 J左右能量的冲击下,A2-1组平均吸收能量仅有30.33 J,平均能量吸收率为61.11%,冲击弹体尺寸最小,导致弹体与纤维的接触面积最小,而较快的冲击速度也造成FMICP产生局部破坏更明显。A1-1组(41.11 J)与A3-1组(40.42 J)吸收的能量基本相同,是A2-1吸收能量的144%,这是由于这是由于A1-1组的冲击速度36.02 m/s与弹道极限速度33.85 m/s(详细内容见2.4节)较为接近,此时A1-1组吸收冲击能量较多。此外,A1-1组能量吸收率高于A3-1组,这主要是由于试验设备不能保证不能保证每次冲击试件的总能量完全相同,导致A3-1组的总冲击能量偏大,最终使其能量吸收率偏小。

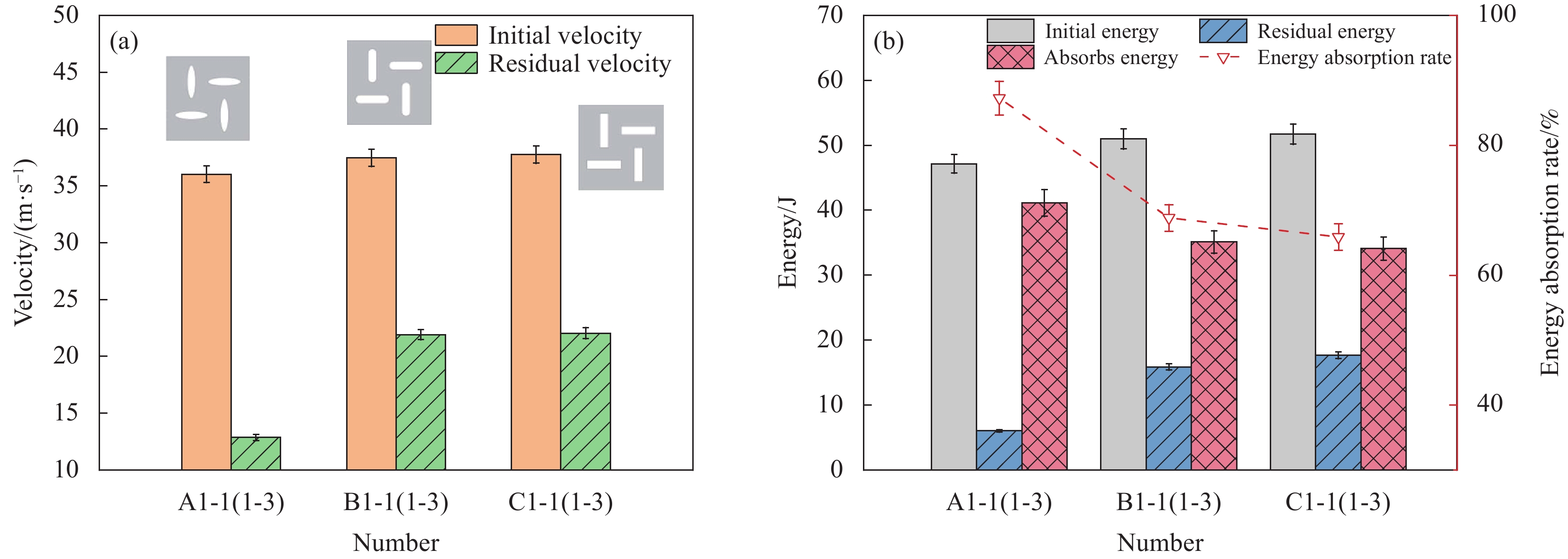

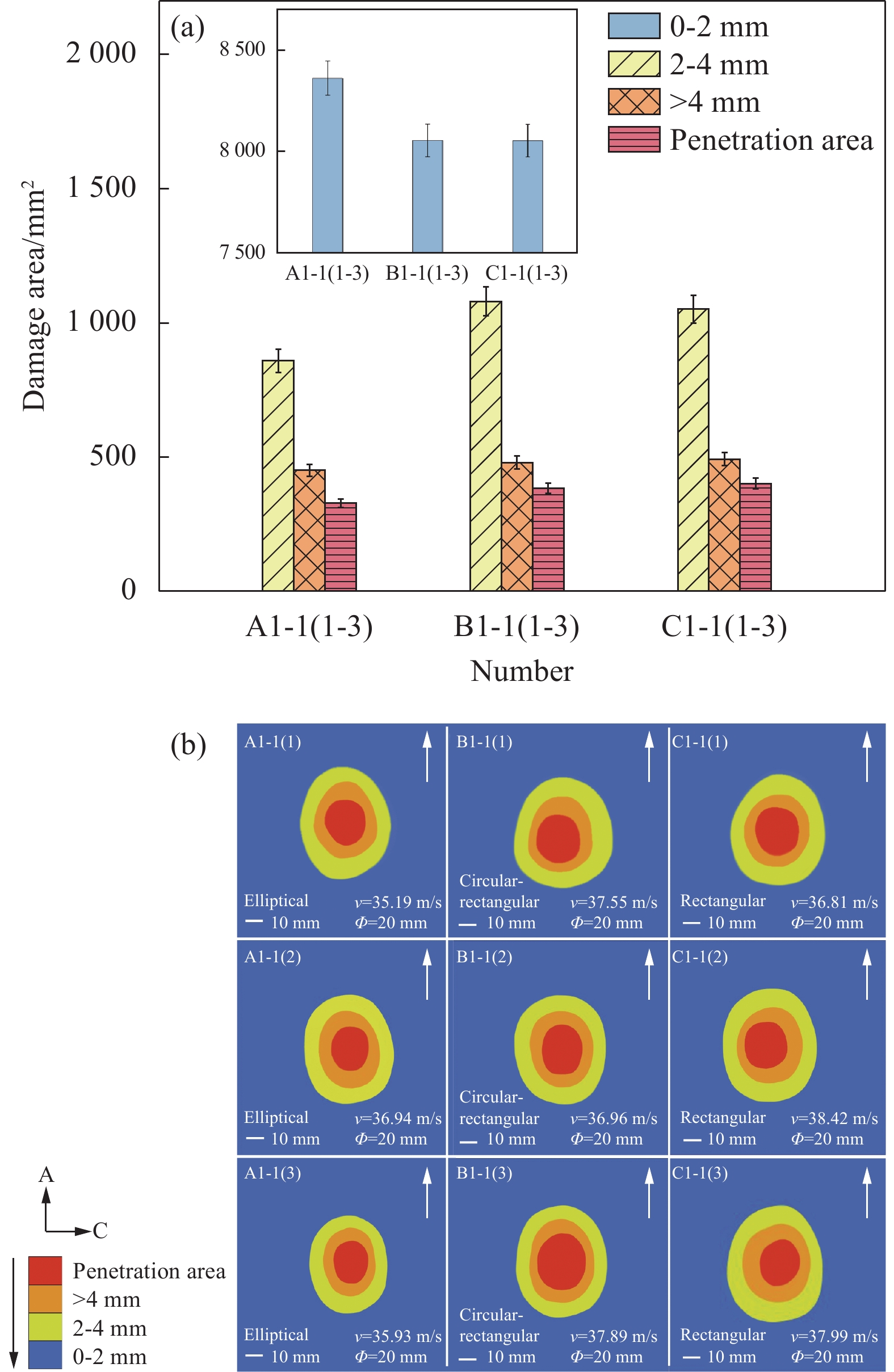

不同冲孔FMICP的冲击试验结果如图13所示,冲孔金属板详细参数见表5。对比试验结果可知,在49 J冲击能量下,A1-1组试件平均吸收能量高于B1-1组试件6.01 J,高于C1-1组试件7.03 J,平均能量吸收率高18.43%~21.37%。结合图10中不同孔洞的变形破坏分析,试件变形后,部分应力沿着孔洞边缘传递。相较于圆矩型与椭圆型,矩型孔洞的边角处更容易产生应力集中,出现较大程度的变形与撕裂,这也使得矩型孔洞FMICP能量吸收能力最弱。圆矩型与椭圆型孔洞的边缘较为平滑,使应力分布更加均匀,减少了裂纹的产生。此外,不同孔洞类型使金属板中孔洞所占比例发生变化,进而影响试件吸能能力。A1-1组中金属板中孔洞体积占比为18.09%,分别比圆矩型和矩型孔洞占比少3.72%、4.95%,使A1-1组中金属基占比比例较大,增强了试件的抵抗塑形变形能力和能量吸收能力。

表 5 不同冲孔FMICP参数Table 5. Different punching FMICP parametersNumber Punch type Single punching area/mm2 Metal based ratio/% Metal based quality/g AC/AL-A1-1(1-3) Elliptical 12.56 81.91 22.12 AC/AL-B1-1(1-3) Circular-rectangular 15.14 78.19 21.11 AC/AL-C1-1(1-3) Rectangular 16 76.96 20.78 Notes: Metal based ratio is the proportion of base metal after punching to the mass of base metal before punching. 2.4 FMICP的弹道极限速度

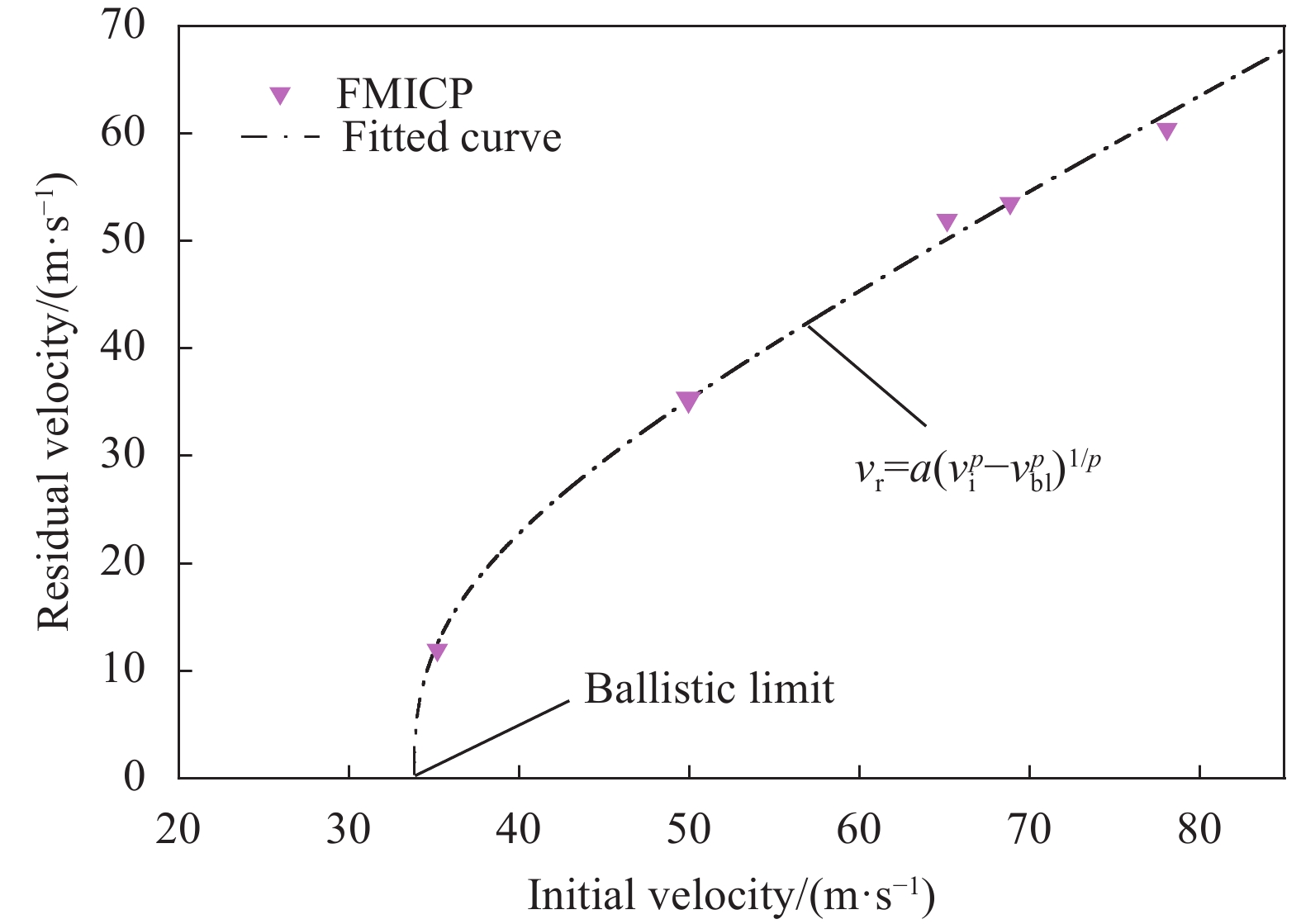

冲击速度大于35.19 m/s时,试件A1-1(1) ~ A1-5均发生完全贯穿,试件冲击速度-残余速度关系如图14所示。贯穿后FMICP的回弹激振和弹体偏转摩擦耗散的能量占吸收能量的相对较少的部分,因此,弹体动能的损失可以归因于FMICP试件的失效。基于能量和动量守恒定律,使用Recht-Ipson模型来拟合弹道极限速度曲线[37],Recht-Ipson模型表达式如下所示:

vr=a(vpi−vpbl)1/p 式中,a、p为无量纲模型参数,通过最小二乘法确定;vi为初始冲击速度;vr为剩余速度;vbl为弹道极限速度。

拟合结果见图14,可知FMICP的弹道极限估计值为33.85 m/s,拟合参数见表6。曲线显示冲击速度在弹道极限速度附近时,曲线曲率较大,此时由于试件被贯穿导致试件的刚度发生改变;冲击速度达到一定阈值后,冲击速度与残余速度基本呈现线性关系增长。由于试验样本数量的限制,对A2-1至C1-1的FMICP样本不进行弹道极限的研究。

表 6 Recht-Ipson模型拟合参数Table 6. Recht-Ipson model fitting parametersa p FMICP 0.823 2.726 2.5 FMICP的变形损伤分布

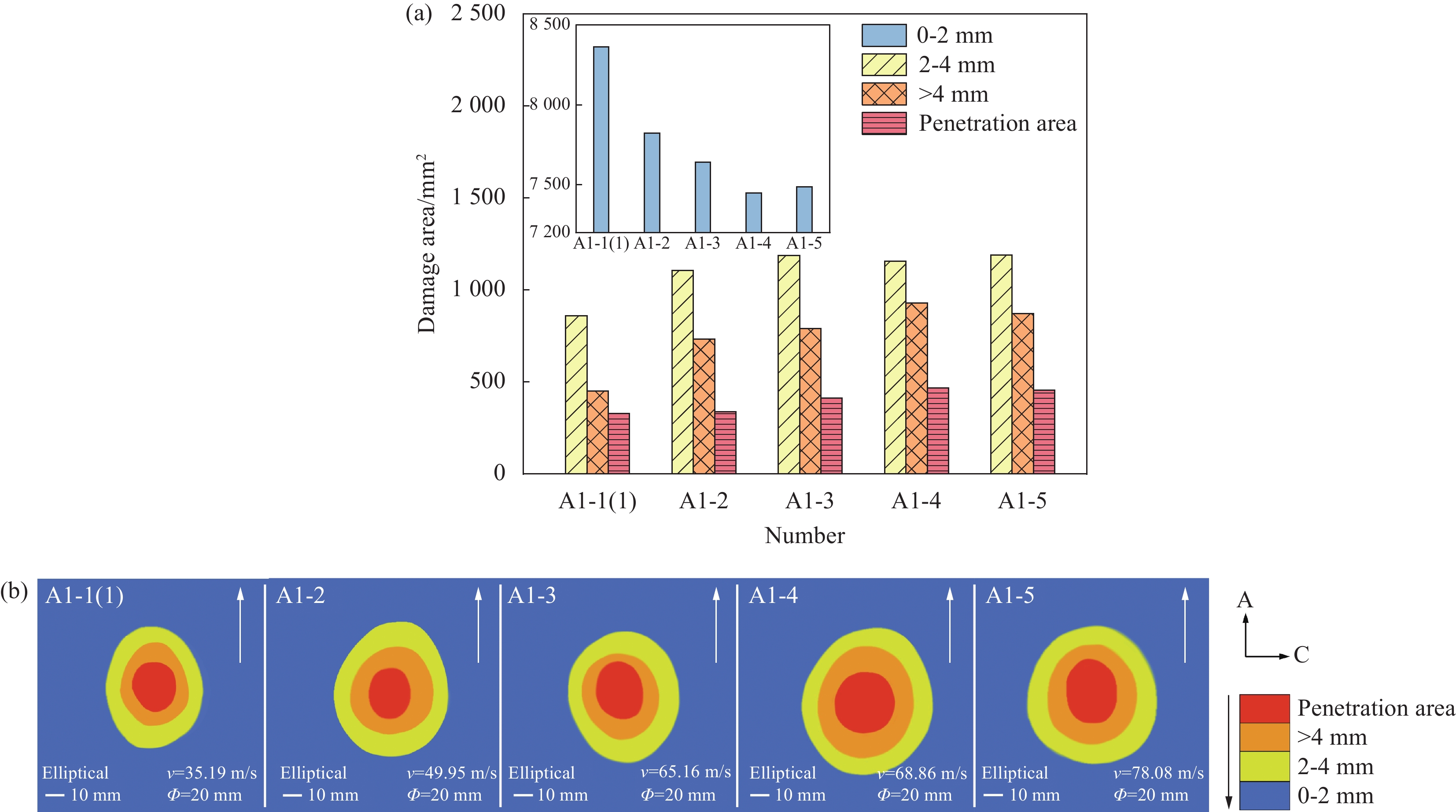

以冲击点处为中心,均匀选取12个等高点位后使用平滑曲线依次连接得到封闭轮廓图,通过测量图形内部像素点个数计算损伤区域面积,等效变形图与试件实际变形之间存在一定的误差,误差保持在合理范围之内。A1-1(1)~A1-5试件背面板的等效变形轮廓图和不同变形损伤区域面积对比如图15所示。通过对比不同冲击速度下FMICP的等效变形轮廓图,发现随着冲击速度的增加,产生大于2 mm的挠度的区域不断增加,但不同挠度阶段的增长规律不尽相同。对比发现,贯穿面积从328.17 mm2增长至455.11 mm2,仅仅增加了126.94 mm2,这表明即使在78.08 m/s的冲击速度下,弹体冲击FMICP并没有造成大面积的贯穿破坏,产生大于4 mm的区域面积增长较为明显,当冲击速度大于49.95 m/s后,2~4 mm挠度区域的面积增长基本趋于平稳,基本保持在

1160 mm2左右,说明冲击速度对FMICP整体性屈曲影响较小,对贯穿破坏的边界处的影响较大。同时,从图15(b)可以发现FMICP被冲击后产生挠度变化的区域呈现椭圆型变形,长轴方向(A轴)为芳纶纤维(Aramid fiber)穿编的方向,短轴方向(C轴)为碳纤维(Carbon fibre)穿编方向,等效变形轮廓图在C轴方向较为密集,在A轴方向较稀疏,这说明FMICP在芳纶纤维方向的挠度增加较为缓慢。而随着冲击速度的增加,AC轴方向变形长度比逐渐趋于1∶1,这是由于在较低速冲击时,两种纤维的冲击响应差异较大,芳纶纤维因更好的拉伸韧性能够将冲击能量传递至距离冲击点较远的纤维、金属板和树脂基体处,从而使FMICP在芳纶纤维方向产生较大变形面积和较小的屈曲度。在低中速冲击下,由于冲击速度已经远大于弹道极限速度,试件中纤维的响应时间大幅减少,使芳纶纤维的拉伸韧性发挥不完全,致使破坏面趋于正圆形。

A2-1(1-3)~A3-1(1-3)试件试件背面板的等效变形轮廓图和不同变形损伤区域面积对比如图16所示。可以发现,即使冲击能量相同,FMICP的冲击响应还是会受冲击弹体尺寸的影响。A2-1组、A1-1组、A3-1组的平均冲击速度分别是48.74 m/s、36.02 m/s、30.91 m/s,冲击能量均在49 J左右,而产生2 mm以上变形的区域面积分别为平均

1329.49 mm2、1636.65 mm2、2074.22 mm2,A2-1组和A3-1组变形面积为A1-1组的81.23%和126.74%,值得注意的是,A2-1中2 mm以上变形面积最小,但其等挠度云图较为密集,说明小尺寸弹体冲击产生的整体破坏占比较小,局部破坏占比较大,而A3-1则反之。图17为在49 J能量冲击下不同冲孔试件的不同变形损伤区域面积对比图和等效变形轮廓图。可以看出A1-1组试件产生的冲击变形都小于B1-1组圆矩型和C1-1组矩型,具有较优的抗冲击性能。其中2~4 mm挠度区域面积相差最显著,分别为858.22 mm2、

1079.76 mm2、1061.03 mm2,而大于4 mm区域和贯穿区域的面积差别较小,说明在矩型孔洞撕裂对复合板试件整体变形部分的影响较大。从孔型形状角度分析,试件整体破坏主要归因为金属板的塑形变形,而矩型孔洞因应力集中产生的撕裂效果最为明显,降低了金属板抵抗变形的能力;从试件组成占比角度分析,金属板孔型的变化直接影响所冲孔洞的体积,进而改变了FMICP中金属板所占比例,致使抗冲击性能发生变化,影响试件的整体变形。2.6 FMICP的冲击变形挠度分析

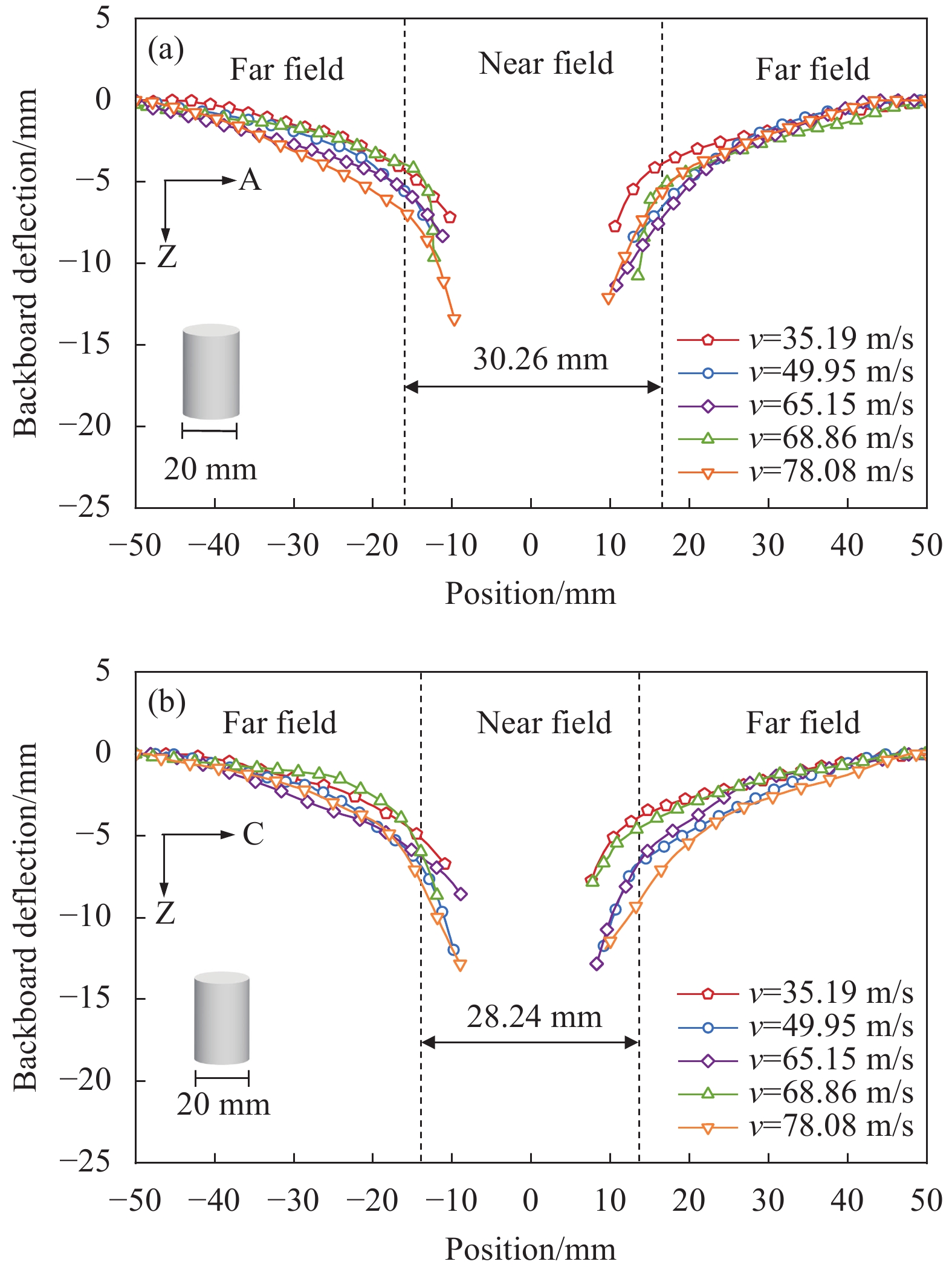

沿试件冲击点中心的A轴方向和C轴方向做水刀切割处理,得到A截面和C截面的挠曲线图如图18所示。可知,试件的挠度变形基本关于试件的中轴线对称,随着冲击速度的增加,试件挠度也随之增加,距离中轴线距离越远,各曲线之间的差异越小,挠度曲线重合度越高。挠度曲线可以根据挠曲率变化节点分成2个部分,分别为冲击远场区和冲击近场区。在冲击远场区各曲线之间的差异表现在挠度大小的不同,挠度变化率没有产生大幅变化,在冲击近场区各曲线之间不仅在挠度大小有差异,在挠度变化率有明显的增加。

当冲击速度从35.19 m/s增加至65.15 m/s时,FMICP的A截面挠度从7.47 mm增加至10.92 mm,C截面挠度从7.72 mm增加至10.44 mm,即速度差为29.96 m/s,A截面挠度差为3.45 mm,C截面挠度差为2.72 mm;而冲击速度增加至78.08 m/s时,FMICP的A截面挠度增加至13.38 mm,C截面挠度增加至12.74 mm,即速度差为12.93 m/s,A截面挠度差为2.46 mm,C截面挠度差为2.30 mm。可以看出FMICP在抗低速冲击时,不论在A截面还是C截面,挠曲率相较于低中速挠曲率都相对较小,可见FMICP在低速冲击下有更好的抗冲击性能,这也和3.3节中得出的研究结果一致。

通过对比A、C面挠度差和近场区长度发现,A截面的近场区长度比C截面长2.02 mm,这说明在相同冲击工况下,C截面产生大程度屈曲的区域更小,但其屈曲变化率高于A截面,这是由于A轴方向芳纶纤维在受到冲击时,能够更好地发挥拉伸性能,将冲击点处的能量传递至相邻区域,虽然产生了较大挠度变形,但其局部破坏程度较轻。碳纤维较于芳纶纤维其更容易发生脆性断裂,使得C截面产生更明显的局部破坏,从而降低C轴方向的抗冲击能力,在局部破坏的边界处会造成显著的弯曲和剪切破坏,进一步导致FMICP变形失效。

图19展示了在49 J能量和不同尺寸弹体冲击作用下A横截面和C横截面的挠度曲线图,由于在远场区的截面挠度变化较小,故主要展示各组近场区的挠度情况。从图19可以看出,直径15 mm弹体造成的远场区冲击挠度较小,在近场区却有较大的挠曲率;直径25 mm弹体冲击造成的挠度较大,但其挠曲线整体相对平滑,没有明显的挠曲率突变节点。随着弹体直径的增加,A截面和C截面挠度也逐渐增加,但挠曲率却逐渐减小,同时,近场区平均长度与弹体直径比值从1.61减少至1.39和1.25。原因有两点,第一,如表1所示,在保持冲击能量恒定时,大尺寸弹体的冲击速度小,试件的冲击响应时间长,能量传递整体性较好,冲击造成的局部破坏;第二。大尺寸弹体与FMICP试件的冲击接触面积大,有较多的纤维受到冲击作用从而产生拉伸,吸收了更多的能量,减缓了FMICP局部屈曲程度。

图20为为不同冲孔金属板的FMICP在49 J冲击能量作用下A横截面和C横截面的挠曲线图。可以看出,A1-1组试件的挠度和挠曲线曲率略小于试件B1-1组、C1-1组,B1-1与C1-1两组试件挠度和挠曲率都较大,且曲率增加点都距离中性轴较远,对比表6可知,两者孔洞体积分别比A1-1大20.54%和27.39%,这使得FMICP中金属板的占比减少,因塑形变形吸收耗散的能量减少,致使抵抗冲击破坏的能力减弱。试件C1-1有略大的挠曲率,其原因是矩型孔洞之间在节点处容易产生应力集中现象从而产生更大的破坏应力导致。

3. 结 论

为了减少纤维增强金属复合材料中的分层脱胶现象,本研究通过将纤维穿编至冲孔金属板上形成三维织物结构,制备了互穿式纤维金属复合板(Fiber Metal Interpenetrating Composite Plate,FMICP),通过高速摄影冲击试验研究了不同冲击速度、不同冲击面积、不同孔洞类型FMICP的冲击响应过程和变形损伤,分析了FMICP的变形损伤过程,详细量化了FMICP的能量吸收能力。本文的主要结论如下:

(1) FMICP在低速冲击下的破坏模式可分为整体面板塑形变形和冲击中心区域的局部变形,主要包括金属板的剪切破坏,纤维的拉伸断裂,树脂基体的损伤裂缝、断裂和剥落。未出现穿透前,能量吸收方式主要为整体塑形变形和树脂基体裂缝的开展;穿透后,能量耗散的方式为局部剪切冲塞破坏和试件的反复振动;

(2)冲击速度从35.19 m/s增加至78.08 m/s时,纤维发挥桥接拉伸作用逐渐显著,吸收能量从30.78 J增加至70.67 J,发生贯穿的面积仅仅增加126.94 mm2,通过对比和分析变形损伤面积可知,FMICP整体变形对速度敏感性较低,贯穿边界处的局部变形受速度影响较大;

(3)在相同能量49 J冲击作用下,弹体冲击面积对能量吸收的影响较大,冲击面积从177 mm2增加至491 mm2,吸收能量增加了10.08 J。此外,冲击面积较小时,等效变形轮廓图较为密集,FMICP产生的局部破坏较明显。分析可知,随着冲击面积的减小,FMICP冲切破坏逐渐明显,纤维拉伸耗能逐渐减小;

(4)当金属板孔洞为矩型和圆矩型孔洞时,由于胞元孔洞面积为15.14 mm2和16 mm2,高于椭圆型孔洞20.54%和27.39%,使椭圆型孔洞FMICP有较高的金属板质量占比,椭圆型(41.11 J)相比于圆矩型(35.10 J)和矩型(34.08 J)因此有较好的吸能能力。除了金属板占比较低外,矩型孔洞FMICP吸能能力最差与孔洞边角易出现应力集中现象有关。

-

表 1 纤维金属互穿式复合板(FMICP)制备材料力学性能

Table 1 Mechanical properties of Fiber-Metal Interpenetrating Composite Plate(FMICP) prepared materials

Material Density/

(g·cm−3)Tensile

strength/MPaYield

strength/MPaElastic

modulus/GPaFiber

diameter/μmElongation

at break/%Aluminium alloy 2.68 230 170 70 — 14 Carbon fibre 1.76 3530 — 230 7 1.5 Aramid fiber 1.45 1750 — 440 15 3.1 Epoxy resin 0.95 75 — 2.0 — 8.7 表 2 FMICP试件参数

Table 2 FMICP specimen parameters

Number Thickness/mm Quality/g Punch type Punch shape/mm AC/AL-A1-1(1) 2.93±0.10 41.0 Elliptical

Elliptical

Circular-rectangular

RectangularAC/AL-A1-1(2) 2.90±0.10 40.7 AC/AL-A1-1(3) 2.94±0.10 41.2 AC/AL-A1-2 3.32±0.10 48.4 AC/AL-A1-3 2.78±0.10 40.2 AC/AL-A1-4 3.16±0.10 47.0 AC/AL-A1-5 2.91±0.10 40.9 AC/AL-A2-1(1) 2.99±0.10 43.8 AC/AL-A2-1(2) 2.95±0.10 42.9 AC/AL-A2-1(3) 2.97±0.10 43.1 AC/AL-A3-1(1) 2.94±0.10 42.9 AC/AL-A3-1(2) 2.89±0.10 42.0 AC/AL-A3-1(3) 2.97±0.10 43.1 AC/AL-B1-1(1) 2.84±0.10 39.7 Circular-rectangular AC/AL-B1-1(2) 2.91±0.10 40.1 AC/AL-B1-1(3) 2.93±0.10 40.3 AC/AL-C1-1(1) 3.09±0.10 43.3 Rectangular AC/AL-C1-1(2) 2.98±0.10 42.1 AC/AL-C1-1(3) 3.04±0.10 42.9 Notes:AC/AL is an aramid fibre (A) and carbon fibre (C) reinforced aluminum based (AL) FMICP; The three numbers in A1-1 differentiate between the type of punch, the impact area, and the impact velocity of the specimen, the specimen numbers in the article are abbreviated versions. 表 3 弹体及弹托力学性能

Table 3 Mechanical properties of Bullet and Shell casing

Parts Material Density/(g·cm−3) Tensile

strength/MPaCompressive

strength/MPaYield

strength/MPaElastic

modulus/GPaBullet Alloy Steel SKD11 7.80 2000 2800 1700 210 Shell casing Nylon 1.15 75 90 70 2.9 表 4 FMICP冲击试验结果汇总

Table 4 Summary of FMICP impact test results

Number Initial

velocity/(m·s−1)Residual

velocity/(m·s−1)Impact

area/mm2Initial

energy/JResidual

energy/JAbsorbs

energy/JEnergy absorption rate/% AC/AL-A1-1(1) 35.19 11.94 314 44.96 5.18 39.78 88.49 AC/AL-A1-1(2) 36.94 13.76 49.55 6.88 42.68 86.12 AC/AL-A1-1(3) 35.93 12.86 46.89 6.01 40.88 87.19 AC/AL-A1-2 49.95 35.28 90.58 45.19 45.39 50.11 AC/AL-A1-3 65.15 51.93 154.13 97.90 56.22 36.48 AC/AL-A1-4 68.86 56.52 172.15 115.98 56.17 32.63 AC/AL-A1-5 78.08 64.42 221.34 150.67 70.67 31.93 AC/AL-A2-1(1) 47.54 29.64 177 45.43 17.67 27.77 61.11 AC/AL-A2-1(2) 49.67 28.77 49.58 16.64 32.94 66.44 AC/AL-A2-1(3) 49.02 29.94 48.30 18.02 30.28 62.70 AC/AL-A3-1(1) 30.62 15.59 491 53.85 13.97 39.89 74.07 AC/AL-A3-1(2) 29.74 16.19 50.80 15.05 42.77 73.96 AC/AL-A3-1(3) 30.18 15.84 52.32 14.41 38.58 72.81 AC/AL-B1-1(1) 37.55 23.42 314 51.21 15.15 36.06 70.42 AC/AL-B1-1(2) 36.96 21.33 49.59 16.51 33.08 66.70 AC/AL-B1-1(3) 37.89 20.97 52.11 15.96 36.16 69.39 AC/AL-C1-1(1) 36.81 21.36 49.20 16.57 32.63 66.32 AC/AL-C1-1(2) 38.42 22.87 53.58 18.99 34.60 64.57 AC/AL-C1-1(3) 37.99 21.89 52.39 17.39 35.00 66.80 表 5 不同冲孔FMICP参数

Table 5 Different punching FMICP parameters

Number Punch type Single punching area/mm2 Metal based ratio/% Metal based quality/g AC/AL-A1-1(1-3) Elliptical 12.56 81.91 22.12 AC/AL-B1-1(1-3) Circular-rectangular 15.14 78.19 21.11 AC/AL-C1-1(1-3) Rectangular 16 76.96 20.78 Notes: Metal based ratio is the proportion of base metal after punching to the mass of base metal before punching. 表 6 Recht-Ipson模型拟合参数

Table 6 Recht-Ipson model fitting parameters

a p FMICP 0.823 2.726 -

[1] SUN J, XU S, Lu G, et al. Ballistic impact experiments of titanium based carbon-fibre/epoxy laminates[J]. Thin-Walled Structures, 2022, 179: 109709. DOI: 10.1016/j.tws.2022.109709

[2] XU L Y, LU J R, LI K M, et al. Experimental study of CFRP laser surface modification and bonding characteristics of CFRP/Al6061 heterogeneous joints[J]. Composite Structures, 2022, 283: 115030. DOI: 10.1016/j.compstruct.2021.115030

[3] SUN G Y, YU H, WANG Z, et al. Energy absorption mechanics and design optimization of CFRP/aluminum hybrid structures for transverse loading[J]. International Journal of Mechanical Sciences, 2019, 150: 767-783. DOI: 10.1016/j.ijmecsci.2018.10.043

[4] LIU G, XIONG Y, ZHOU L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications[J]. Composites Communications, 2021, 27: 100907. DOI: 10.1016/j.coco.2021.100907

[5] DING Z, WEEGER O, QI H J, et al. 4D rods: 3D structures via programmable 1D composite rods[J]. Materials & Design, 2018, 137: 256-265.

[6] KULKARNI P, DHOBLE A, PADOLE P. A review of research and recent trends in analysis of composite plates[J]. Sadhana Academy Proceedings in Engineering Sciences, 2018, 43(6): 1-20.

[7] 陈勇, 庞宝君, 郑伟, 等. 纤维金属层板低速冲击实验和数值仿真[J]. 复合材料学报, 2014, 31(3): 733-740. CHEN Y, PANG B, ZHENG W, et al. Tests and numerical simulation on low velocity impact performance of fiber metal laminates[J]. Acta Materiae Compositae Sinica, 2014, 31(3): 733-740(in Chinese).

[8] 崔岸, 杨伟丽, 程普, 等. 玄武岩纤维/铝合金层合板低速冲击性能及应用研究[J]. 汽车工程, 2020, 42(5): 694-699+708. CUI A, YANG W, CHENG P, et al. Study on Low-speed Impact Performance and Application of Basalt Fiber/Aluminum Alloy Laminates[J]. Automotive Engineering, 2020, 42(5): 694-699+708(in Chinese).

[9] 赵艺桥, 于涛, 郭逸纯, 等. 植物纤维金属层合板的抗低速冲击性能[J]. 建筑材料学报, 2022, 25(8): 830-835. DOI: 10.3969/j.issn.1007-9629.2022.08.009 ZHAO Y, YU T, GUO Y, et al. Low Velocity Impact Performance of Plant Fiber Metal Laminates[J]. Journal of Building Materials, 2022, 25(8): 830-835(in Chinese). DOI: 10.3969/j.issn.1007-9629.2022.08.009

[10] Zhang J, Lin G, UDAY V, et al. present and future prospective of global carbon fibre composite developments and applications[J]. Composites Part B: Engineering, 2023, 250: 110463. DOI: 10.1016/j.compositesb.2022.110463

[11] PRIYANKA P. High-Strength Hybrid Textile Composites with Carbon, Kevlar, and E-Glass Fibers for Impact-Resistant Structures. A Review[J]. Mechanics of Composite Materials, 2017, 53: 685-704. DOI: 10.1007/s11029-017-9696-2

[12] SUN Z, HU X, CHEN H. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate[J]. International Journal of Adhesion and Adhesives, 2014, 48: 288-294. DOI: 10.1016/j.ijadhadh.2013.09.023

[13] K K, D R, A M. Evaluation of tensile properties on Glass/Carbon/Kevlar fiber reinforced hybrid composites[J]. Materials Today: Proceedings, 2021, 39: 1655-1660. DOI: 10.1016/j.matpr.2020.06.049

[14] TAMER S, EGEMEN A, MUSTAFA , et al. A review: Fibre metal laminates, background, bonding types and applied test methods, Materials & Design, 2011, 32, 3671-3685.

[15] BRESCIANI L, MANES A, GIGLIOM. An analytical model for ballistic impacts against plain woven fabrics with a polymeric matrix[J]. International Journal of Impact Engineering, 2015, 78: 138-149. DOI: 10.1016/j.ijimpeng.2015.01.001

[16] YENTL S, LARISSA G, IGNAAS V. Fibre hybridisation in polymer composites: A review[J]. Composites Part A: Applied Science and Manufacturing, 2014, 67: 181-200. DOI: 10.1016/j.compositesa.2014.08.027

[17] SYAFIQAH N, MOHAMED T, MOHAMMAD J, et al. Impact behaviour of hybrid composites for structural applications: A review[J]. Composites Part B: Engineering, 2018, 133: 112-121. DOI: 10.1016/j.compositesb.2017.09.008

[18] 曹俊超, 孙建波, 曹勇, 等. 混杂纤维增强环氧树脂复合材料高速冲击损伤行为[J]. 复合材料学报, 2022, 39(10): 4935-4948. CAO J, SUN J, CAO Y, et al. High-velocity impact damage behavior of hybrid fiber reinforced epoxy composites[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4935-4948 (in Chinese).

[19] KIM D, KIM H. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle[J]. Composite Structures, 2015, 131: 742-752. DOI: 10.1016/j.compstruct.2015.06.028

[20] HASHIM N, MAJID D, MAHDI E, et al. Effect of fiber loading directions on the low cycle fatigue of intraply carbon-kevlar reinforced epoxy hybrid composites[J]. Composite Structures, 2019, 212: 476-483. DOI: 10.1016/j.compstruct.2019.01.036

[21] BANDARU A, CHAVAN V, AHMAD S. Low velocity impact response of 2D and 3D Kevlar/polypropylene composites[J]. International Journal of Impact Engineering, 2016, 93: 136-143, DOI: 10.1016/j.ijimpeng.2016.02.016

[22] QIAN Z, CHAO Z. Finite element simulation of damage in fiber metal laminates under high velocity impact by projectiles with different shapes[J]. Composite Structures, 2019, 214: 73-82. DOI: 10.1016/j.compstruct.2019.02.009

[23] ZHANG C, ZHU Q. Ballistic performance and damage simulation of fiber metal laminates under high-velocity oblique impact[J]. International Journal of Damage Mechanics, 2020, 29(7): 1011-1034. DOI: 10.1177/1056789519900784

[24] XU M, Yang Y, LEI H, et al. Dynamic response of fiber metal laminates subjected to localized high impulse blast loading[J]. Composite Structures, 2020, 243: 112216. DOI: 10.1016/j.compstruct.2020.112216

[25] PANG Y, YAN X, WU L, et al. Experiment study of basalt fiber/steel hybrid laminates under high-velocity impact performance by projectiles[J]. Composite Structures, 2022, 280: 114848. DOI: 10.1016/j.compstruct.2021.114848

[26] Li X, ZHANG X, GUO Y. Influence of fiber type on the impact response of titanium based fiber-metal laminates[J]. International Journal of Impact Engineering, 2018, 114: 32-42. DOI: 10.1016/j.ijimpeng.2017.12.011

[27] Li X, YAHYA M, NIA A, et al. Dynamic failure of basalt/epoxy laminates under blast—Experimental observation[J]. International Journal of Impact Engineering, 2017, 102: 16-26. DOI: 10.1016/j.ijimpeng.2016.12.001

[28] DHALIWAL G, NEWAZ G. Compression after impact characteristics of carbon fiber reinforced aluminum laminates[J]. Composite Structures, 2017, 160: 1212-1224. DOI: 10.1016/j.compstruct.2016.11.015

[29] 沈玲燕, 李永池, 王志海, 等. 三维正交机织玻璃纤维/环氧树脂复合材料动态力学性能的实验和理论研究[J]. 复合材料学报, 2012, 29(4): 157-162. SHEN L, LI Y, WANG Z, et al. Experimental and theoretical research, dynamic mechanical properties, properties, three dimensions, methodology, woven glass fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2012, 29(4): 157-162 (in Chinese).

[30] 汪金花, 方芳, 杨格, 等. 三维正交机织复合材料低周弯曲疲劳力学性能有限元模拟[J]. 复合材料学报, 2014, 31(3): 797-802. WANG J, FANG F, YAN G, et al. Finite element simulation of 3D orthogonal woven composites under low cycle bending fatigue loading[J]. Acta Materia Compositae Sinica, 2014, 31(3): 797-802 (in Chinese)

[31] 王聪, 竺铝涛, 高晓平. 纳米增韧三维正交玻璃纤维机织物增强环氧树脂复合材料的力学性能[J]. 复合材料学报, 2020, 37(2): 252-259. WANG C, ZHU L, GAO X. Mechanical properties of 3d orthogonal glass fiber woven fabric reinforced epoxy resin composites with nano clay modification[J]. Acta Materia Compositae Sinica, 2020, 37(2): 252-259 (in Chinese).

[32] ELIAS A, LAURIN F, KAMINSKI M, et al. Experimental and numerical investigations of low energy/velocity impact damage generated in 3D woven composite with polymer matrix[J]. Composite Structures, 2017, 159: 228-239. DOI: 10.1016/j.compstruct.2016.09.077

[33] YU B, BRADLEY R, SOUTIS C, et al. 2D and 3D imaging of fatigue failure mechanisms of 3D woven composites[J]. Composites Part A: Applied Science and Manufacturing, 2015, 77: 37-49. DOI: 10.1016/j.compositesa.2015.06.013

[34] ZHOU W, WENTE T, LIU D, et al. A comparative study of a quasi 3D woven composite with UD and 2D woven laminates[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: 106139. DOI: 10.1016/j.compositesa.2020.106139

[35] MUOZ R, HERGUETA F, GLVEZ F, et al. Ballistic performance of hybrid 3D woven composites: Experiments and simulations[J]. Composite Structures, 2015, 127: 141-151. DOI: 10.1016/j.compstruct.2015.03.021

[36] 郭妙才, 李亚锋, 张杜鹃, 等. 偶联剂表面富集对高强玻纤复合材料界面和层间断裂韧性的影响[J]. 复合材料学报, 2023, 40(4): 2066-2074. GUO M, LI Y, ZHANG D, et al. Effect of the surface enrichment of coupling agent on the interfacial properties and interlaminar fracture toughness of GFRPs[J]. Acta Materia Compositae Sinica, 2023, 40(4): 2066-2074 (in Chinese).

[37] RECHT R, IPSON T. Ballistic perforation dynamics[J]. Journal Of Applied Mechanics, 1963, 30(3): 384-390. DOI: 10.1115/1.3636566

-

目的

纤维增强金属复合材料在冲击作用下往往会出现冲击损伤及破坏,主要表现在纤维断裂、树脂基体碎裂脱落、金属基延性损伤以及层间的分层脱胶等,进而导致材料宏观力学性能及抗冲击性能下降。为了减小材料层间开裂脱胶程度从而增强材料的抗冲击性能,本研究通过将金属板冲孔,使用碳纤维和芳纶纤维交替穿编后在真空高温下与环氧树脂基体进行浸润固化,制备了一种三维复合材料纤维金属互穿式复合板(FMICP)。本研究利用轻气炮冲击设备进行冲击试验研究FMICP在低速冲击下的力学响应过程。

方法本研究首先利用真空辅助成型工艺对试验材料进行加工处理,得到了制备成型的FWMIP,之后通过轻气炮冲击设备、速度测量设备、高速图像采集设备进行了试件的冲击试验,基于高速图像采集设备得到了不同冲击速度下的试件冲击变形过程以及弹体的冲击路径变化情况;采用高速水流切割的方法得到了试件变形破坏横截面图像;使用在试件同等变形处取点位后平滑连接的方法得到了试件在不同变形程度的变形区域;利用图像处理软件,提取不同变形区域的像素点后计算出各相应区域的变形面积;通过测量试件横截面的变形得到不同截面的挠度曲线,研究分析了FMICP在不同冲击速度、不同冲击面积和冲孔样式下的宏观力学性能。

结果通过研究分析不同冲击速度、不同冲击面积和冲孔样式下FWMIP试件的冲击响应过程、试件不同变形区域与试件横截面变形效果图可以发现:(1)FMICP在低速冲击下的破坏模式可分为整体面板塑形变形和冲击中心区域的局部变形,主要包括金属板的剪切破坏,纤维的拉伸断裂,树脂基体的损伤裂缝、断裂和剥落。试件未出现穿透前,能量吸收方式主要为整体塑形变形和树脂基体裂缝的开展;穿透后,能量耗散的方式为局部剪切冲塞破坏和试件的反复振动。(2)通过拟合计算得出FWMIP试件的理论弹道极限速度在33.85m/s,冲击速度增大后试件被贯穿导致试件的刚度会急剧下降。冲击速度从35.19m/s增加至78.08m/s时,纤维发挥桥接拉伸作用逐渐显著,吸收能量从30.78J增加至70.67J,发生贯穿的面积仅仅增加126.94mm,通过对比和分析变形损伤面积可知,FMICP整体变形对速度敏感性较低,贯穿边界处的局部变形受速度影响较大。(3)弹体冲击面积对能量吸收的影响较大,随着冲击面积的减小,FMICP冲切破坏逐渐明显,纤维拉伸耗能逐渐减小。在相同能量49J冲击作用下,当冲击面积较小时,等效变形轮廓图较为密集,FMICP产生的局部破坏较明显。冲击面积从177mm增加至491mm后,吸收能量增加了10.08J。(4)金属板冲孔类型对试件吸能能力有较大的影响,冲孔类型改变了应力传播路径和金属基所占比例。圆矩型和椭圆型的孔洞边缘较为平滑,矩型的孔洞边角容易发生应力集中,因而矩型的吸能能力较差;矩型和圆矩型的胞元孔洞面积为15.14mm和16mm,高于椭圆型孔洞20.54%和27.39%,使椭圆型孔洞FMICP有较高的金属板质量占比,椭圆型(41.11J)相比于圆矩型(35.10J)和矩型(34.08J)因此有较好的吸能能力。

结论三维复合材料纤维金属互穿式复合板是将使用穿编后固化的方法,使得纤维之间首先形成初步自锁,在固化之前与金属基互锁进一步增强纤维-金属整体性,最终通过固化的方式再次加强材料的整体连接性,减小复合材料在冲击作用下的分层脱胶程度,从而增强其抗冲击性能;纤维金属互穿式复合板具有轻质、耐腐蚀以及抗冲击整体性能较好的特点,可以通过改变材料类型、冲孔数量等应用于不同的场景。

-

纤维增强金属复合材料除了有高比强度和高比模量、良好的耐热性能以外还具有良好的抗疲劳性、抗冲击性和损伤容度,受到广泛的关注和研究。然而由于纤维层和金属层之间的界面粘结强度受不同材料的影响,在冲击荷载作用下容易发生金属层和纤维层分层从而严重影响复合材料的力学性能。

本研究的创新点和亮点主要有三点:(1)试件设计:碳纤维在荷载作用下裂纹增长率较低,芳纶纤维抗疲劳损伤性能较好,铝合金板轻质高强,通过将铝合金板冲孔,碳纤维和芳纶纤维双向交替穿编的方法,制备了一种三维复合材料纤维金属互穿式复合板(FMICP),使纤维与金属两种材料形成互锁,增强FMICP整体性和抗冲击性能。(2)试件制备:纤维通过平纹穿编成型,穿编过程中能够通过纤维预应力张拉进行纤维应力调控;铝基合金板为纤维提供了穿编基体,能够进行二次加工冲孔,可控调节冲孔尺寸、样式以及数量。(3)研究方法:利用轻气炮冲击系统进行了低速冲击试验,研究了FMICP在不同冲击速度、不同冲击面积、不同金属板冲孔类型变量下的动态力学响应。通过研究发现,FMICP在不同冲击速度下都没有出现大面积的脱胶现象,仅在冲击点附近出现微小的树脂剥落;冲击面积的增大使参与拉伸作用的纤维数量增多,降低了FMICP的局部变形程度,吸收了更多的冲击能量;椭圆形孔洞FMICP的吸收能量的能力更优。

不同冲击速度下FMICP的能量吸收能力

不同冲孔类型FMICP的截面挠曲线

下载:

下载: