Study on the impact of fibre wrinkle on the compression of composite laminates

-

摘要:

纤维褶皱是纤维增强复合材料难以避免的制造缺陷,致使复合材料层合板的力学性能尤其是压缩强度大幅下降。深入研究纤维褶皱对压缩失效的影响规律对于复合材料压缩强度的定量评估至关重要。本文采用数值分析和试验测试方法,探讨褶皱特征参数与压缩失效的关联规律。利用MATLAB和Python脚本在ABAQUS中创建具有可控褶皱几何形貌的几何模型,考虑基体塑性屈服,建立了包含纤维、基体和分层等多种损伤形式的分析模型。在此基础上分析纤维褶皱参数对层合板的压缩失效模式和压缩强度的影响效应。研究结果表明,无论是单向抑或多向层合板,其主控失效模式随着褶皱程度的增大从纤维扭结转变为分层损伤。对于所研究的单向层合板,失效模式转换的纤维褶皱角阈值介于4°~6°之间,而多向层合板的转变阈值则介于8°~9°之间。纤维褶皱角和褶皱区高度占比对单向层板压缩强度的影响存在敏感区和非敏感区。当层合板横截面上存在多个褶皱区时,分层损伤不一定发生在褶皱最严重的区域。当铺层褶皱角超过45o,由于铺层失稳导致承担的峰值纵向应力下降,由此所传递的层间剪切作用减弱,分层损伤不易发生。

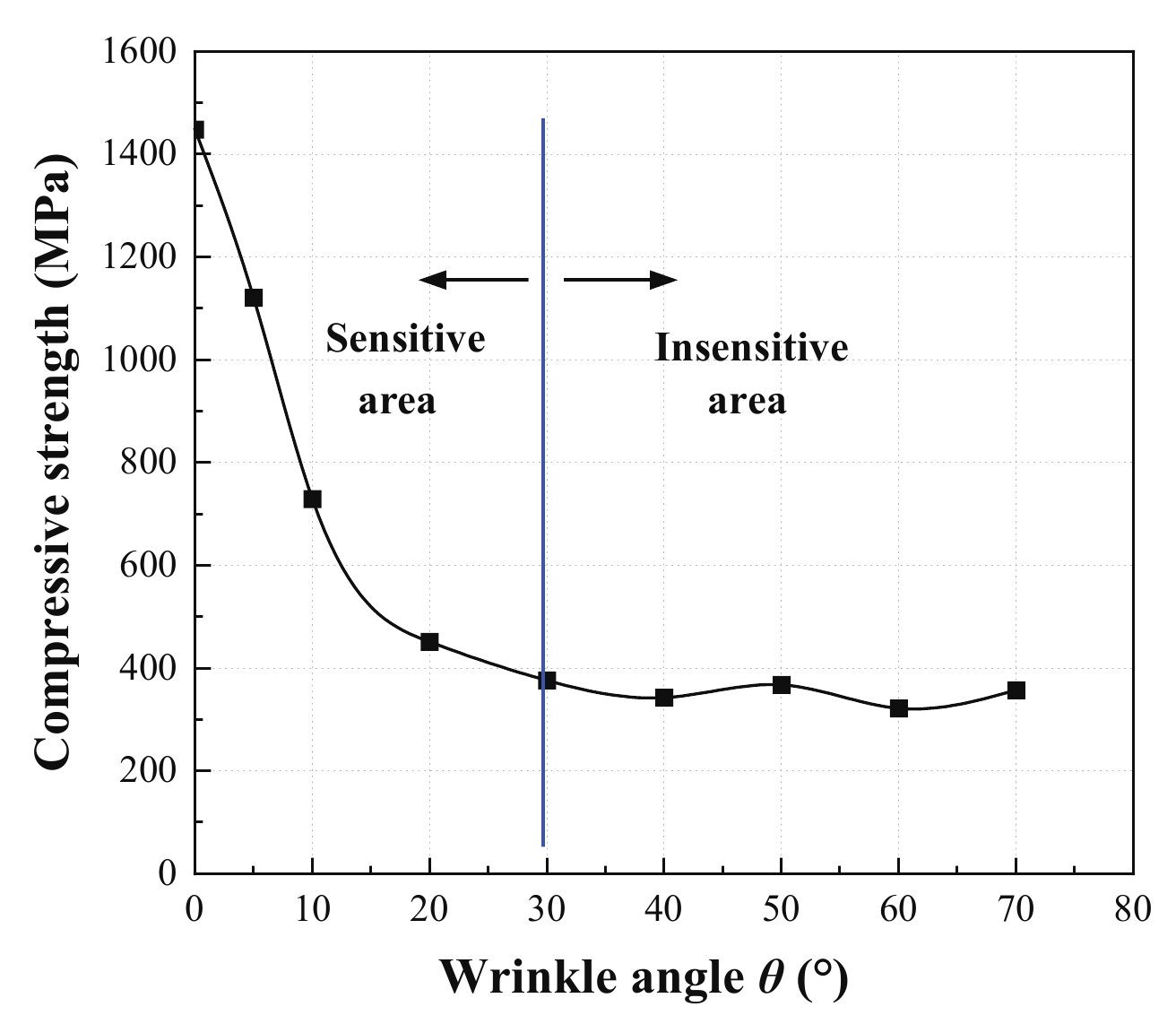

Abstract:Fibre wrinkle is an unavoidable manufacturing defect of fibre reinforced composites, which leads to a significant decrease in the mechanical properties, especially in the compressive strength of composite laminates. It is very important to study the effect of fibre wrinkle on compression failure for quantitative evaluation of compressive strength of composite materials. In this paper, the correlation between wrinkle characteristic parameters and compression failure was studied by numerical and experimental analysis. MATLAB and Python scripts were used to create the geometric model with controllable wrinkle geometry in ABAQUS. The damage model with multi-damage mode such as fibre kinking, matrix damage and delamination was established. The effects of fibre wrinkle parameters on compression failure mode and compressive strength of unidirectional and multidirectional laminates were analyzed based on the damage model. The results show that the dominant failure mode changes from fibre kinking to delamination with the increase of wrinkle severity, for either unidirectional or multidirectional laminates. For the unidirectional laminates studied, the threshold of fibre wrinkle angle for failure mode shift lies between 4° and 6°, while that for multidirectional laminates is between 8° and 9°. There exist sensitive and non-sensitive zones for the influence of fibre wrinkle angle and wrinkle area height ratio on compressive strength of unidirectional laminates. When there are multiple wrinkle areas in the cross-section of laminates, delamination does not necessarily occur in the most severely wrinkle area. For maximum ply wrinkle angle greater than 45o, delamination is less likely to occur because the peak longitudinal stresses carried by the ply decrease due to ply instability, resulting in a weak interlaminar shearing.

-

Keywords:

- fibre wrinkle /

- compressive strength /

- failure mode /

- fibre kinking /

- delamination

-

光子晶体[1-3]是一种介电常数周期排列且可调控的高度有序材料。光波在光子晶体中传播时,会受到这种周期性的影响而被调制,产生“禁带”(光子带隙,PBG,同半导体中的电子带隙原理类似)。当光波长处在光子带隙范围内,该波长的光会被反射而不能在材料内传播,从而产生许多新的物理现象,如结构色[4-8]现象和超棱镜现象[9]等。除此之外,光子晶体还具有慢光子效应[10-11]、多重散射效应[12]等特性。

光子晶体具有两种典型的空间结构构型—蛋白石结构和反蛋白石结构。蛋白石结构是一种通常由胶体粒子以立方堆积的形式堆叠而成的、具有周期性排列的结构。反蛋白石结构则是以蛋白石结构为模板,再通过去除蛋白石模板而制得的具有高度有序大孔结构 [13-14]。由于是以蛋白石结构为模板,反蛋白结构光子晶体不仅具有孔结构规整有序、孔径均匀、比表面积大、易传质等特点,而且具有孔径大小易调控的特点。这些特点使反蛋白石结构光子晶体较蛋白石结构光子晶体而言具有一定的优势:当反蛋白石结构材料与周边介质的折射率的比值大于2.8时,反蛋白石光子晶体可产生完全光子带隙;材料中的介电常数差距可调整的幅度更大;可选择的材料类型更多。因此,反蛋白石结构光子晶体的应用范围更广。

功能性薄膜材料是一种物理化学性质特殊、厚度可从纳米级到微米级的材料。通过以功能性物质为原材料[15-18]、赋予薄膜材料特殊的孔结构[19-20]、在基膜中加入功能性的微粒[21-25]或注入功能性液体[26-33]、进行化学改性等多种途径,薄膜材料可以实现物质分离(分离膜)、能量转化(如燃料电池膜、光转化膜、发光膜等)、物质转化(如膜生物反应器等)、控制释放、电荷传导(如导电膜)和物质识别(如膜生物感应器)等功能。因此,功能性薄膜材料是当前材料领域的热点研究材料之一[34-35]。

通过构筑反蛋白石结构的方法而制得的薄膜材料(反蛋白石结构膜),不仅具有分布均匀且排列规整的孔结构、更高的比表面积,而且还具备光子晶体特有的光学性能,如结构色和对光的调控作用,从而使膜材多功能化,在众多领域具有广阔的发展前景。本文简要介绍了反蛋白石结构膜的特点,总结了反蛋白石结构膜的制备方法,并将其归纳为三步法和两步法两大类,综述了反蛋白石结构膜在结构色、传感器、电致变色、光催化和医学载体领域的应用现状和前景,为反蛋白石结构膜的研究提供一定的参考。

1. 反蛋白石结构膜的结构特点和光学特性

1.1 反蛋白石结构膜的结构特点

与通过传统的制多孔膜法(如相转化法)所制得的膜材料相比,反蛋白石结构膜具有孔径大小均匀且孔结构规整有序的特点,如图1所示。这是由于反蛋白石结构是在蛋白石结构的基础上去除其中的胶体微球所制得的一种多孔结构,蛋白石结构的三维周期性赋予了反蛋白石结构膜材料的孔结构三维规整性。反蛋白石结构膜的孔排列紧密,孔多且间隙小,从而其孔隙率高,比表面积大。通过改变蛋白石结构的胶体微球模板的大小,可轻易实现对孔径大小的调控[36-37]。

1.2 反蛋白石结构膜的光学特性

反蛋白结构膜的三维周期性有序多孔结构使其可对光具有调控能力,是一种典型的光子晶体。三维周期性结构使材料的折射率具有周期性,当光波射入反蛋白石结构中后,某些特定波长的光会被禁止传播而发生反射,进而在结构表面形成衍射效应,产生结构色。衍射波长与结构周期性之间的关系可用Bragg-Snell公式解释[38-39]:

mλBragg=2D√n2neff−sin2θ (1) 其中:

λBragg 为衍射波长;m为衍射级数;D为垂直于薄膜的(111)方向上的面间间距(晶面间距);θ 为入射角;neff 为有效折射率。对于蛋白石结构,neff 可根据Lorentz-Lorenz公式计算:n2eff−1n2eff+2=fn2sphere−1n2sphere+2+(1−f)n2void−1n2void+2 (2) 其中:

nsphere 和nvoid 分别为胶体微球与空隙的折射率;f 为微球在结构中所占的体积分数。当材料为反蛋白石结构膜时,由于原胶体微球已被空气替代(空气折射率

n =1),而空隙被填充材料所替代,有效折射率neff 可进一步简化为n2eff−1n2eff+2=(1−f)n2m−1n2m+2 (3) 其中,

nm 为填充材料的折射率。结合式(1)和式(3)可知,在入射角

θ 一定时,调整晶面间距D或填充材料的折射率nm 使衍射波长λBragg 处在可见光波段(380~760 nm)时,反蛋白石结构膜可呈现出结构色现象。当反蛋白石材料内有缺陷时可以发生多重散射;处在光子带隙的边缘时,由于非线性色散的影响,光的群速度会大幅度地降低,从而形成慢光子效应[40]。利用光的反射、多重散射和慢光子效应调控光在反蛋白石结构中的传播,能显著增强光与反蛋白石材料的相互作用[41-42],进而提高光的利用效率。

2. 反蛋白石结构膜的制备方法

目前,反蛋白石结构膜的制备根据步骤的不同,可大致分为三步法和两步法,示意图如图2所示。

2.1 三步法

三步法的具体制备步骤可以概括为[43]:(1) 胶体微球组装成蛋白石结构模板;(2) 在模板间隙中填充膜材料并固化;(3) 去除模板以制得反蛋白石结构膜。

2.1.1 模板的制备

组装蛋白石模板常用的微球有SiO2、聚苯乙烯(PS)、聚甲基丙烯酸甲酯(PMMA)等。组装的模板是否规整决定着反蛋白石结构膜中孔的均匀性。常用组装方法如下:

(1)重力沉积法

重力沉积法是指单分散的胶体微球在重力作用下随溶剂的蒸发缓慢沉降在基板上而自组装成周期性排列的蛋白石结构模板,自组装过程如图3所示。该方法制备工艺和设备简单,无需特殊实验装置,但组装的模板厚度不易控制,缺陷较多,不易形成单一均匀的蛋白石结构[45]。

(2)垂直沉积法

将基板垂直放入单分散胶体微球组装液中,胶体微球在毛细管力和静电斥力等作用下随溶剂蒸发在基板两侧堆积形成周期性排列的蛋白石模板,组装过程如图4所示。该方法操作简单且制得的模板较均匀,厚度容易调节,但耗时较长,对温度、湿度和设备的防震性要求较高。

(3)旋涂法

将胶体微球分散液滴在基板上,然后放置在旋转台中心。胶体微球在向心力作用下随溶剂的蒸发沉积在基板上形成蛋白石模板,如图5所示[46]。该方法制备流程简单且耗时短,但对分散液浓度及旋涂参数的选择要求较高。Zhang等[47]通过旋涂法和提拉法相结合的二次组装法制备了大尺寸的致密聚苯乙烯(PS)单层胶体晶体模板。首先采用旋涂法将PS胶体微球组装在玻璃基底上;然后将样品缓慢浸入去离子水中,再加入适量的十二甲基磺酸钠(SDS)溶液,一段时间后将玻璃基底缓慢提出水面,制备流程如图6所示。该方法充分利用了SDS可降低表面张力的性质。PS微球模板在浸入含SDS的水中后排列得更加紧密,旋涂过程中产生的裂纹得到修复,更易获得均匀致密的晶体模板。Galle等[46]对旋涂法中微球浓度、旋转速度、旋转加速度等参数进行优化以获得均匀的晶体模板,结果如图7所示。实验发现,当这些参数使旋涂过程中组装模板的三个关键性作用力(内力,如熵,由微球的单分散性决定;外长程力,即离心力;短程力,如范德华力和表面吸引力,由微球浓度控制)的合力越接近于零,单层晶体模板越均匀,为旋涂法组装均匀的晶体模板提供了一定的理论基础。

(4)喷涂法

胶体微球溶液在一定压力作用下经过喷枪口被细化成雾状,随后微球叠加在基材上形成周期性的蛋白石结构。该方法操作简单,成本低,不限基材的形状与大小,可快速制备大面积的蛋白石模板。Fan等[48]直接将SnO2乙醇分散液喷涂到氟掺杂的氧化锡(FTO)基底上制得均匀规整的SnO2微球层,如图8所示。高雅芳等[49]通过喷涂法在纺织基材上成功快速制备了聚(苯乙烯-甲基丙烯酸)(P(St-MAA))蛋白石光子晶体,并对微球浓度等参数进行了优化(图9)。喷涂法与旋涂法均可快速制备大面积的晶体模板,但与旋涂法相比,喷涂过程中没有离心力的作用,胶体微球更易黏附在基材上,晶体模板不易从基材上脱落。

2.1.2 模板的填充

在三步法制备反蛋白石结构膜的过程中,模板填充是至关重要的一步,填充率的大小直接影响了反蛋白石结构膜的性能。常用的填充方法如下。

(1)溶剂蒸发法

溶剂蒸发法是指将膜材料溶解到溶剂中形成溶液并添加到模板上,待模板被溶液完全渗透后,蒸发溶剂以得到固体填充物。该方法操作简单,对设备要求低。按照溶液添加方式的不同,又可分为浸涂法、滴涂法和喷印填充法等。

Kim等[38]将质量分数为8wt%的丝素蛋白溶液直接添加到PMMA模板上对其进行填充,后在室温下干燥24 h使溶剂挥发,再去除模板,得到膜孔均匀且带结构色的丝素蛋白反蛋白石结构膜,如图10所示。Yao等[50]在倾斜的SiO2模板的一侧滴加65 mg/mL 聚偏氟乙烯(PVDF)溶液,使其依靠重力和毛细管力缓慢渗入到SiO2微球空隙之间,待填充完成后,将样品置于80℃空气烘箱中4 h以蒸发溶剂使PVDF固化,制得可通过温度调节光子带隙的PVDF反蛋白石结构膜。热处理温度改变,反蛋白石结构膜的折光指数和晶面参数发生变化,从而光子带隙改变,膜呈现出的颜色也会不同,如图11所示。虽然溶剂蒸发法操作简单,但在实际填充过程中,膜材料的自发渗透和固化是不受控制的,容易造成膜上小面积的缺陷。在较多情况下,即使填充材料足够多,也不能将模板底部完全填充。此外,填充材料过量会完全覆盖住蛋白石模板,在顶部形成膜,从而导致膜上层无孔,且在后续工艺中很难去除模板;填充材料不足则会导致反蛋白石结构膜顶部形态结构不均匀。

(2)溶胶-凝胶法

溶胶-凝胶法是以含有高化学活性成分的原料为前驱体,混合后对模板进行填充,经过水解和缩合反应在模板空隙中形成稳定透明的溶胶或凝胶,然后去除模板即可得到反蛋白石薄膜[51]。Kyujin等[52]通过溶胶-凝胶法制备了BaTiO3反蛋白石结构膜,海绵状三维网络结构赋予了BaTiO3反蛋白石结构膜优异的压电性能。Mcnulty等[53]以SnCl2·2H2O与Ge(OC2H5)4为前驱体,通过溶胶-凝胶法制备了SnO2/GeO2复合反蛋白石结构膜并应用于锂离子电池。结果表明,SnO2/GeO2复合反蛋白石结构膜作为锂离子电池负极材料时,具有循环寿命长、容量保持能力优异等特点。溶胶-凝胶填充法具有产品纯度高、均匀性好、合成温度低(即使在室温下也可合成)、化学计量比和反应条件易控制等优点,特别是制备过程相对简单,不需要特殊昂贵的仪器,常用于制备无机反蛋白石结构膜。

(3)化学气相沉积法

化学气相沉积(CVD)法是通过气态前驱体渗透到蛋白石缝隙间并发生化学反应而完成填充。Li等[54]通过CVD将SiH4气相前驱体渗透到SiO2蛋白石中,得到Si/SiO2复合材料,再通过2wt%的HF腐蚀掉其中的SiO2,得到高折射率的反蛋白石硅膜。所得的硅膜在3319 nm存在明显的反射峰,说明其在中红外波长范围内具有较完整的光子带隙,可应用于大气中的中红外光电探测领域。Song等[55]先在不锈钢集流器上制备SiO2蛋白石模板,然后以GeH4为气相前驱体,通过化学气相沉积法(350~370℃)在蛋白石模板间隙中形成Ge纳米层,最后采用HF进行腐蚀,得到具有反蛋白石结构的Ge电极。该电极微孔多、比表面积大,大大改善了电极的电化学性能。CVD填充速率可控,可制备出均匀的薄膜,但工艺温度高且所需设备复杂。

(4)原子层沉积法

原子层沉积(ALD)是一种新开发的气相沉积法,气相前驱体脉冲交替地进入反应器,在蛋白石模板微球表面被化学吸附并顺次发生化学反应而完成填充。Birnal等[56]先通过旋涂法在硅片上组装单层PS微球,后通过原子沉积法在硅片上形成致密的TiO2薄膜,最后经过退火工序去除PS模板并诱导TiO2在锐钛矿相中结晶,获得TiO2反蛋白石结构膜并将其应用于染料降解。Bakos等[57]以碳纳米球为模板,通过原子层沉积法制备了TiO2反蛋白石结构膜,并将其与以PS为模板通过ALD技术获得的TiO2反蛋白石结构膜进行了对比,结果如图12所示。碳纳米球温度耐受性较PS高且其表面具有含氧官能团,使其比PS微球更适合作为原子层沉积的模板,获得的反蛋白石结构膜质量更高。Waleczek等[58]同样采用了原子层沉积法制备了TiO2反蛋白石结构膜。其在沉积TiO2薄膜过程中掺杂了Al2O3,从而可在退火去除模板时控制TiO2的相变并稳定晶相。掺杂Al2O3后,TiO2反蛋白石结构的热稳定性提高,即使在900℃热处理后仍能保持其光子带隙,保证了其特殊的光学性能。与传统的化学气相沉积(CVD)相比,ALD技术中可通过控制反应周期来精确调控薄膜的厚度;气相前驱体可完全覆盖基底,从而获得三维均匀的沉积膜;而且ALD的操作温度更低,因此也适用于低降解温度的基材,如聚合物。

(5)电化学沉积法

电化学沉积法(ED)是电解液中的离子前驱体在一定条件下发生电化学反应而沉积到起电极作用的蛋白石光子晶体间隙的填充方法[51]。Ma等[59]先在镍合金基底上组装PS蛋白石,然后将基底浸入到含NiCl2和NiSO4的电解液中,通过电化学沉积法将镍沉积到PS蛋白石模板内,然后采用甲苯将PS模板去除,即可得到反蛋白石多孔镍膜。Mohammad等[60]以含有苯的1-己基-3-甲基咪唑三(五氟乙基)三氟磷酸盐溶液([HMIm]FAP)为电解质溶液,含氧化铟锡(FTO)涂层的玻璃板(表层为PS蛋白石光子晶体)为阳极,利用电化学聚合反应将聚对苯撑(PPP)填充到PS模板间隙中,然后采用四氢呋喃(THF)将PS微球溶胀掉,得到具有多孔结构的聚对苯撑。与化学气相沉积法和原子层沉积法相比较,采用电化学沉积法来填充具有可完全填充的优势,这是由于在电化学沉积过程中,填充材料是从蛋白石模板的底部开始生长的,而后向顶部延展。

(6)其他方法

除了上述介绍的方法之外,三步法制备反蛋白膜还有一些其他的方法。Kim等[61]和Lee等[62]采用了一种新型填充法,以膜为基材,先将蛋白石模板组装到膜上,再在一定条件推动下(提高温度或使用紫外光照射)使蛋白石模板嵌入到膜材中,最后去除模板分别得到聚乳酸-羟基乙酸共聚物(PLGA)反蛋白结构膜和SU-8(一种负性光刻胶)反蛋白石结构膜,分别如图13(a)和图13(b)所示。这种方法可实现完全填充,得到结构均匀的反蛋白石膜,但也存在明显的限制条件,只适用于一些热塑性聚合物或光敏材料。Pan等[63]将一定量的聚乙二醇二丙烯酸酯(PEGDA,数均分子量(Mn)=200)和少量的光引发剂加入到SiO2的乙醇分散液中形成均匀混合物,然后蒸发溶剂乙醇诱导SiO2在液态中自组装,形成SiO2-PEGDA光子悬浮液,再通过紫外光照射固化,形成SiO2-PEGDA薄膜,最后将薄膜浸入HF溶液中,得到反蛋白石结构PEGDA薄膜。

2.1.3 模板的去除

去除模板常用的方法有:(1) 加热法,将填充好的模板加热到一定温度使模板发生热分解;(2) 溶解腐蚀法,选择合适的试剂将模板溶解或腐蚀而达到去除的效果。

在制备TiO2及SiO2等金属氧化物类反蛋白石结构膜时,通常选用加热法来去除模板,这是由于热处理不仅可以去除模板,而且还可以使金属氧化物前驱体转化为对应的氧化物,从而获得反蛋白石结构膜。对于溶胶-凝胶法填充的复合蛋白石结构,加热还可浓缩模板结构,并促进膜生长。但对于在热处理过程中,反蛋白结构容易发生坍塌或模板容易熔融而黏附在膜上的材料,应慎用加热法。

对于不耐高温的反蛋白石结构膜,例如聚合物膜,常采用溶解腐蚀法去除模板。SiO2模板常用HF去除;PMMA可用丙酮溶解去除;PS可用四氢呋喃或甲苯去除。

SiO2和PMMA模板也可采用紫外光辐射去除。

2.2 两步法

两步法制备反蛋白石结构膜通常是将三步法中连续的两步合并成一步,即将模板组装和模板填充合成一步,或使模板填充和模板去除同时进行。Phillips等[64]先将PS微球分散液、TiO2前驱体、SiO2前驱体混合,再通过“蒸发诱导共组装”的方式在硅片上进行组装,原理如图14所示。最后在500℃条件下煅烧去除PS模板,制得TiO2/SiO2杂化反蛋白石结构膜。结果表明TiO2和SiO2在反蛋白石结构中分散良好。通过改变混合物中TiO2前驱体和SiO2前驱体的比例,可以调整膜的折射率,同时减少反蛋白石结构中的裂纹并保持结构有序,如图15所示。Luo等[65]通过热聚合的方式制备了含大孔结构的掺氟SnO2(mac-FTO)反蛋白石薄膜。以SnCl4·5H2O和NH4F的乙醇溶液为前驱体,将PS模板浸泡在乙醇中0.5 h,然后再转移到前驱体溶液中浸泡1 h,最后将模板放置在坩埚中450℃烧结2 h,在前驱体转化成SnO2的同时,高温去除PS模板,获得mac-FTO反蛋白石薄膜。与三步法相比,两步法制备反蛋白石结构膜制备工艺简单,且制备的样品效果无明显差距,但适用范围受限。若将模板组装与模板填充合成一步,则需要合适的溶剂;要使模板填充和模板去除同时进行,则所用的膜材料须是可以通过加热前驱体便可直接获得的材料。

3. 反蛋白石结构膜的应用研究进展

3.1 反蛋白石结构膜的结构生色

反蛋白石结构因其三维周期性结构而具有光子带隙,能量处于光子带隙中的光在其中会被禁止传播。当光子带隙处于可见光波段时,与之波长相当的电磁波在该结构中不能传播,而被选择性反射,进而在周期性排列的反蛋白石结构膜表面形成相干衍射。相长干涉的反射光刺激人的视觉系统,从而产生明亮的结构色视觉反映[66]。Meng等[67]以掺杂了少量碳黑(CB)的SiO2乙醇分散液为组装液,采用垂直沉积法进行模板组装,后采用聚偏氟乙烯/六甲基磷酰胺(PVDF/HMPA)溶液对模板进行填充,去除模板后,获得彩色PVDF反蛋白石结构膜,制备过程如图16所示。制得的PVDF反蛋白石结构膜具有丰富的色彩状态,在无外部设备辅助的条件下直接分辨出纸币的真伪(如图17所示),且PVDF固有的优异机械性能赋予了反蛋白石结构膜优良的结构耐久性。Liu等[68]使用三步法制备了SnO2反蛋白石结构膜,然后将其嵌入聚二甲基硅氧烷(PDMS)中,得到复合反蛋白石结构生色膜。由于光散射及SnO2的高折射率,所制得的复合膜在观测角度较小时,呈现出的结构色几乎保持不变,如图18所示。同时PDMS良好的机械强度给予了SnO2反蛋白石结构有效的保护,在拉伸过程中,结构色无明显变化,表现出优异的结构色稳定性。与传统的化学色相比,结构色亮度高、饱和度高、不褪色,且具有虹彩效应,对环境友好,优势明显,应用前景更好。

3.2 传感器

反蛋白石结构膜具有特殊的光学性质。通过调控折射率或膜孔大小(晶格间距),反蛋白石结构膜的光子禁带位置及呈现出的结构色发生改变,从而实现对外部环境变化的检测,例如温度、湿度、pH、溶剂、光、机械应力及生物分子等。Guo等[69]采用经聚乙二醇二丙烯酸酯(PEGDA)和2-丙烯酰胺-2-甲基丙基磺酸(AMPS)改性过的聚丙烯酰胺基水凝胶对TiO2反蛋白石进行封装,得到一种有机-无机复合响应型水凝胶(SRPH)薄膜。当SRPH薄膜置于有机溶剂环境中时,一方面,其在不同溶剂中的溶胀程度不同,从而反蛋白石结构中的晶格间距大小发生变化(薄膜体积也相应地改变);另一方面,不同的溶剂渗入到SRPH薄膜中使其有效折射率也发生一定的改变。这两大方面使得SRPH薄膜能够积极响应溶剂种类的改变,如图19所示。Liu等[70]将聚(甲基丙烯酸2-羟乙酯-丙烯酸甲酯)(P(HEMA-co-MA))作为功能性成分注入到SiO2反蛋白石中实现对挥发性醇类的检测。反蛋白石结构的周期性大孔结构及P(HEMA-co-MA)与醇之间的强氢键作用使挥发性醇类可以快速有效地扩散到整个结构并被吸附,增加了反蛋白石传感器的有效折射率,使传感器的反射峰红移,颜色发生改变,达到检测效果。反蛋白石传感器最大的优势在于简便直观,在没有复杂昂贵设备的前提下便可以对复杂的环境信号产生直观可视化的响应信号。因此,其在传感领域具有一定的推广应用价值。

3.3 电致变色

电致变色是指在外界电场的作用下,材料发生氧化或还原反应,从而导致其光学性质(透射或反射)发生可逆变化—在宏观上体现为颜色变化的一种可逆变化现象。一般来说,电致变色材料需要具有良好的离子和电子导电性及高对比度(对比度:电致变色材料在一定波长下透过率变化的百分数)等性能[71]。将反蛋白石光子晶体结构引入到电致变色材料中可提高其电致变色性能。反蛋白石光子晶体结构的有序孔结构提高可离子、电子的扩散性,使电致变色材料具有更快的响应时间;且反蛋白光子晶体本身具有电响应性,在氧化或还原过程中会发生结构色变化。因为结构色的饱和度更高,所以材料在电致变色过程中的颜色饱和度也随之提高。Zhan等[72]将PS蛋白石模板浸入含(NH4)6H2W12O40 ·xH2O、Er2O3和Yb2O3的混合溶液中,在480℃下煅烧,得到WO3:Er3+, Yb3+反蛋白石结构膜。在负偏压刺激下,WO3:Er3+, Yb3+反蛋白石结构膜的颜色从浅黄色变为黑色;在正偏压刺激下,颜色又可恢复,在多个循环后仍具有优异的可恢复性,表明WO3:Er3+, Yb3+反蛋白石结构膜的电致变色性能较好。Ling等[73]通过电沉积法将三氧化钨(WO3)沉积到TiO2反蛋白石上,制得了TiO2@WO3核壳结构反蛋白石膜并探讨了其在近红外区域的电致变色性能。研究发现在0.3 V的低电压条件下,与电沉积所得的WO3薄膜相比,TiO2@WO3核壳反蛋白石结构膜近红外区的对比度提高了60%。这是由于反蛋白石结构的高比表面积提高了材料与离子大的接触面积而增加了氧化还原反应的活性位点,从而改善了电荷的转移性,提高了近红外对比度。结构规整有序、比表面积高及结构本身的特殊光学性质是反蛋白石结构电致变色材料性能好的关键原因。

3.4 光催化

反蛋白石结构膜特有的光学性质及三维网络结构赋予其优异的光催化活性:(1) 反蛋白石结构具有多重光散射效应和慢光子效应,使得入射光在材料中的光程显著增加,进而增强光催化剂与入射光的相互作用,提高光的吸收利用效率;(2) 大面积周期性的三维孔洞结构使反蛋白石结构膜的比表面积较大,为光催化反应提供足够的活性点位,有利于光催化过程的传质和载流子传输[74-75]。Chen等[76]先通过三步法制备了苯胺黑-聚偏氟乙烯(AB-PVDF)反蛋白石结构膜,后采用等离子体辉光放电技术将ZnO纳米颗粒沉积在膜上,制得ZnO/AB-PVDF复合反蛋白石结构膜并应用于光热催化水净化领域,如图20所示。其中,PVDF反蛋白石结构膜作为光催化剂的载体,柔韧性好且在250~2500 nm波段有良好的透射率,有利于光热催化剂加强对近红外辐射的吸收从而产生更多的热量以加快催化水净化进程。Le等[37]采用两步法制备了TiO2反蛋白石薄膜,并通过光还原法将Ag纳米粒沉积在膜上对其进行修饰,得到Ag/TiO2反蛋白石结构膜,如图21所示。结果表明,具有蜂窝结构的TiO2反蛋白石结构膜大幅度吸收400~500 nm波段的可见光,有利于提高TiO2的可见光催化活性。同时,Ag纳米粒子的存在不仅增强了TiO2对可见光的吸收,而且减少了光电子和空穴的复合。这两个因素之间的协同效应增强了Ag/TiO2反蛋白石结构膜的光催化性能。以反蛋白石结构膜作为光催化剂的载体或直接将光催化剂制备成反蛋白石结构,光催化效果均比其同种非反蛋白结构的材料要好,这是由于反蛋白石结构使光程增加,从而光与光催化材料之间的相互作用增强,进而光催化效率提高。

![]() 图 20 三步法制备ZnO/苯胺黑(AB)-PVDF复合反蛋白石结构膜 (a);SiO2光子晶体模板 (b)、填充AB-PVDF后的SiO2光子晶体模板 (c)、0.5%AB-PVDF反蛋白石结构膜 (d) 和ZnO/0.5%AB-PVDF反蛋白石结构膜 (e) 的SEM图像[76]Figure 20. Preparation process illustration of the ZnO/aniline black (AB)-PVDF inverse opal film by three-step method (a); SEM images of the silica photonic crystal template(b), silica photonic crystal template after AB-PVDF infiltration(c), 0.5%AB-PVDF inverse opal film(d)and ZnO/0.5%AB-PVDF inverse opal film (e)[76]

图 20 三步法制备ZnO/苯胺黑(AB)-PVDF复合反蛋白石结构膜 (a);SiO2光子晶体模板 (b)、填充AB-PVDF后的SiO2光子晶体模板 (c)、0.5%AB-PVDF反蛋白石结构膜 (d) 和ZnO/0.5%AB-PVDF反蛋白石结构膜 (e) 的SEM图像[76]Figure 20. Preparation process illustration of the ZnO/aniline black (AB)-PVDF inverse opal film by three-step method (a); SEM images of the silica photonic crystal template(b), silica photonic crystal template after AB-PVDF infiltration(c), 0.5%AB-PVDF inverse opal film(d)and ZnO/0.5%AB-PVDF inverse opal film (e)[76]3.5 医学载体

具有相互连通、排列规整、大小均一的孔使反蛋白结构膜在医学载体(尤其是生物支架)方面具有很大的应用优势。排列规整且相互连通的孔为接种的细胞提供足够大的比表面积来黏附及连接良好的空间来增殖,并促进氧气、营养物质和废物等的有效扩散,有利于组织的生成。孔的均匀性使反蛋白结构医学载体的每个孔隙中的微环境都受到严格控制,为细胞提供了一致的生长微环境。同时,反蛋白石结构膜的均匀性还使不同批次制造的载体具有出色的重现性,保证了不同局部组织之间的均匀性[77]。且通过调整模板微球的粒径可灵活调控其微纳结构,从而获得理想的生物医学仿生骨架。此外,反蛋白石结构特有的光学性质使其能够响应外界环境信号的变化,可将具有自驱动特性的细胞整合到反蛋白石结构膜基底上制备复合型仿生驱动器。以上优点使反蛋白石结构膜在生物医学领域具有巨大的应用潜力[78]。Xia等[44]通过三步法制备了PVDF反蛋白石薄膜,后对膜进行机械拉伸,获得各向异性的PVDF反蛋白石薄膜(图22),并将其作为神经干细胞形成及分化的基材,结果如图23所示。各向异性PVDF反蛋白石结构膜具有良好的柔性及周期性的孔结构,为神经球状体的形成、神经干细胞的排列、神经干细胞的分化、衍生神经元的定向生长和新生神经元的树突复杂化提供了良好的指导,是一种理想的调控细胞生长的生物材料。Weng等[79]先通过三步法制备了聚乳酸-羟基乙酸共聚物(PLGA)反蛋白石结构膜,然后将羧甲基壳聚糖和血管内皮生长因子(VEGF)负载在膜孔内,形成多功能复合膜,并将其应用于愈合创伤方面。结果表明,该复合膜可有效抑菌并促进伤口愈合。同时由于反蛋白石结构膜特有的光学性质,在装载和释放药物期间,膜表面呈现出的结构色会有所变化,从而可从视觉上监测药物是否成功装载和释放(图24),使该PLGA膜成为一种理想的慢性伤口愈合智能医学材料,具有良好的应用前景。与其他用于细胞生长的基材膜相比,反蛋白石结构膜超高的比表面积更利于细胞生长,且规整的孔结构可定向调控细胞生长,应用范围更广。

4. 结束语

反蛋白石结构膜因其独特的三维网络状孔结构、光学性能及良好的力学性能,在结构生色、传感器、电致变色、光催化和生物医药领域应用广泛,除这些领域外,其在太阳电池[80-81]和辐射发射器[82-83]等方面也展现出巨大的应用潜力。反蛋白结构膜有望成为膜材料中必不可少的一部分。随着研究者对反蛋白石结构膜的关注与研究,越来越多的材料被应用于制备反蛋白石结构膜,制备工艺也不断优化和创新,反蛋白石结构膜的质量更加优异,但仍有需改进的地方:

(1) 模板材料的选择。目前制备反蛋白石结构膜常用的模板微球有SiO2、聚苯乙烯(PS)和聚甲基丙烯酸甲酯(PMMA)。SiO2模板常采用HF溶解腐蚀去除,HF具有强腐蚀性,会对膜材料本体造成一定的影响;而PS模板常采用450~550℃煅烧去除,大多数聚合物膜材料是不耐高温的,高温容易导致反蛋白石结构崩塌;PMMA模板常采用丙酮溶解去除,丙酮作为一种有机溶剂,容易对膜材料造成一定的影响。因此需要寻求一种能在较温和条件下便可去除的模板材料;

(2) 大面积制备反蛋白石结构膜。难以实现大面积的反蛋白石结构膜的制备主要是由于难以组装大面积的模板。模板面积越大,越容易产生缺陷。若能实现大面积、无缺陷的蛋白石模板组装,便能制备大面积的反蛋白石结构膜;

(3) 理论上,反蛋白石结构膜的高孔隙率及膜孔均匀性和易调控性使其可以实现高精度、高截留、高通量的过滤。但实际上,目前在膜分离技术方面,反蛋白结构膜的研究与应用较匮乏。这可能是由于组装的晶体模板厚度较小,导致填充后的膜材料较薄,从而机械强度不足以承受过滤过程中的机械压力,具体原因还待研究。

以上问题若能够得到解决,有望进一步推广反蛋白石结构膜的应用。

-

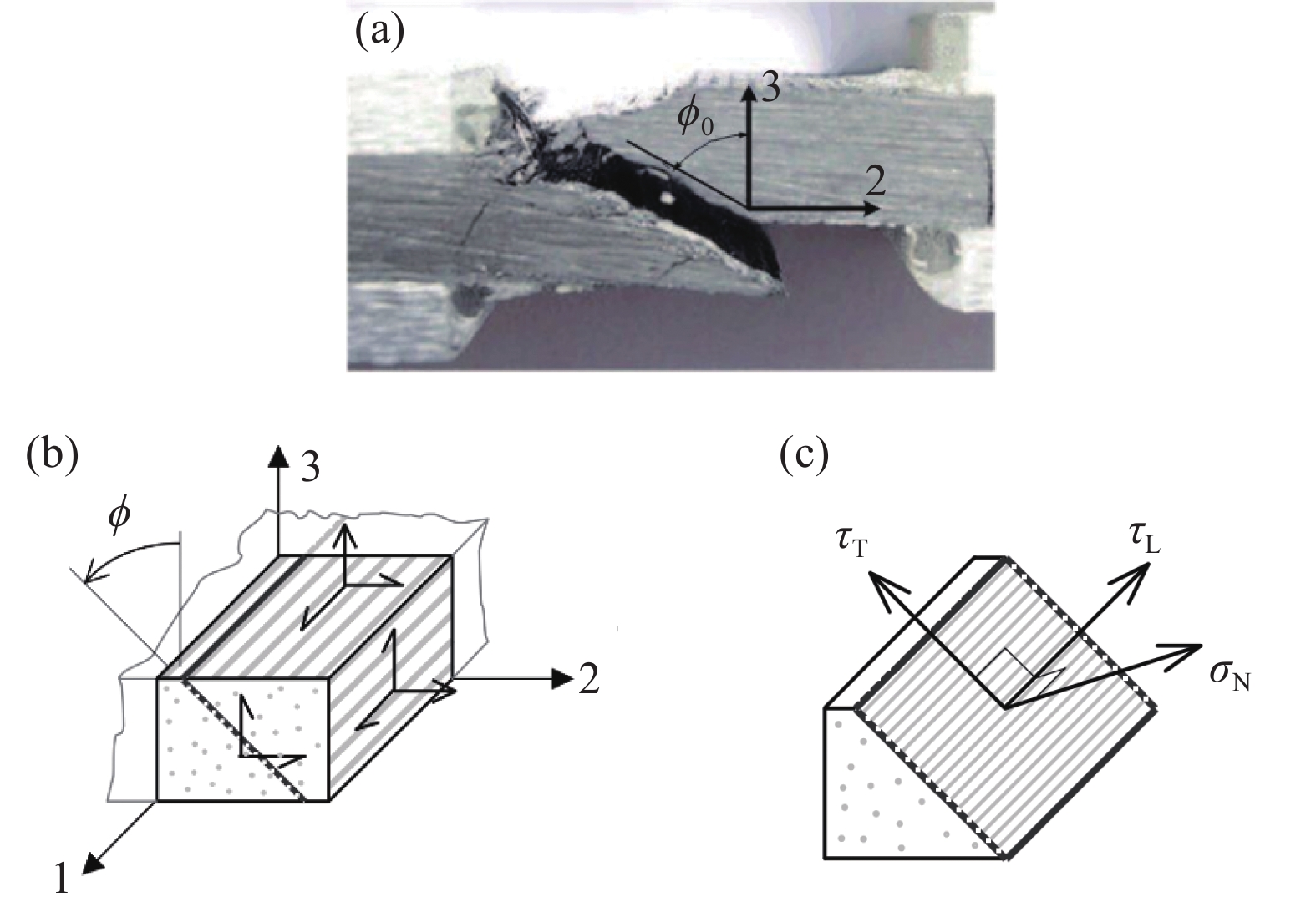

图 1 层合板基体断裂面[29]:(a) CFRP试件的纯横向压缩破坏;(b) 三维应力状态下的断裂面;(c) 断裂面的应力

Figure 1. Laminates fracture surface [29]: (a) Pure transverse compression failure, for a CFRP specimen; (b) Fracture plane for a 3 D stress state; (c) Stresses in the fracture plane

ϕ0—Fracture angle of the material under pure compression; ϕ—Fracture angle; τT, τL—Shear stress; σN—Normal stress

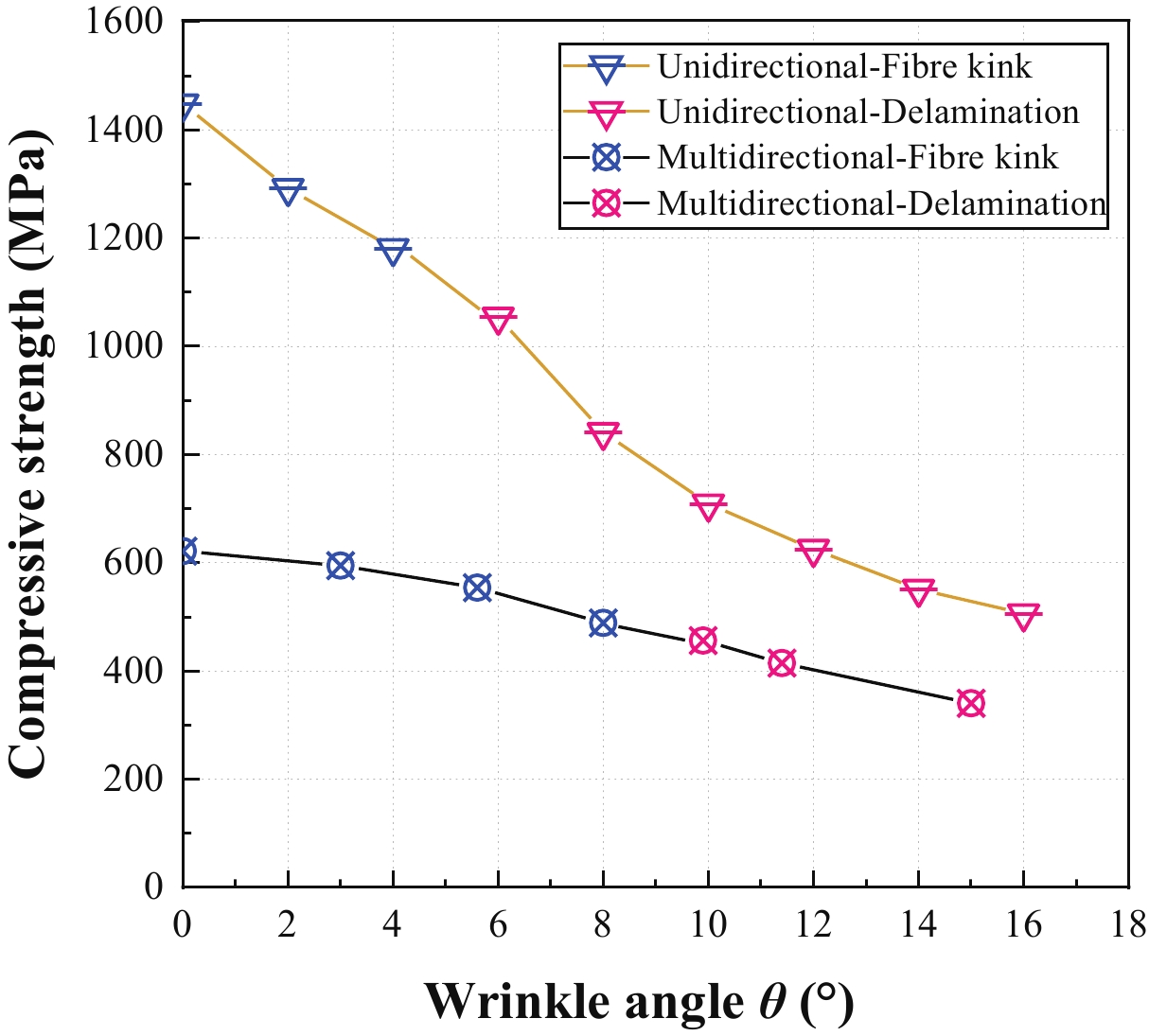

图 17 IM7/8552 单向和多向铺设层合板预测结果对比:(a) 压缩强度折减率与最大褶皱角的关系; (b) 压缩强度和主控失效模式随最大褶皱角的变化

Figure 17. Prediction comparison of IM7/8552 unidirectional and multidirectional laminates:(a) Discount rate of compressive strength vs. maximum wrinkle angle; (b) Compressive strength and dominant failure mode variation with maximum wrinkle angle

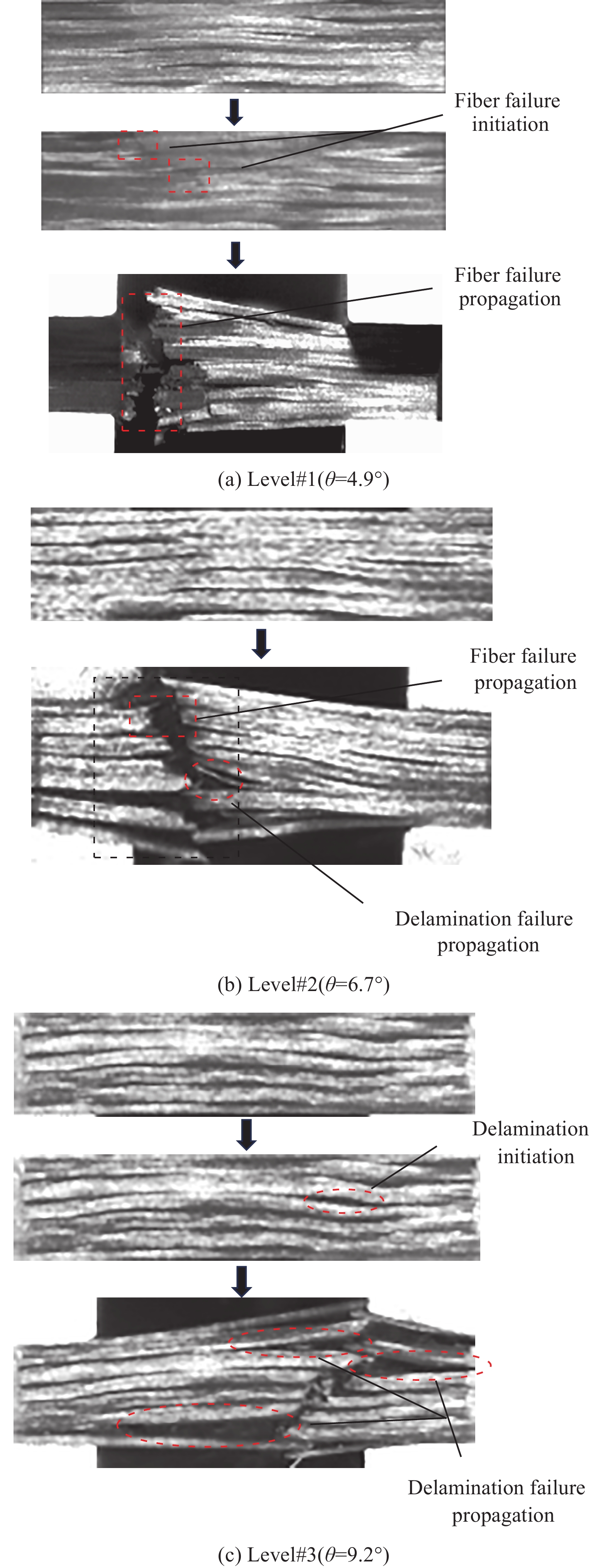

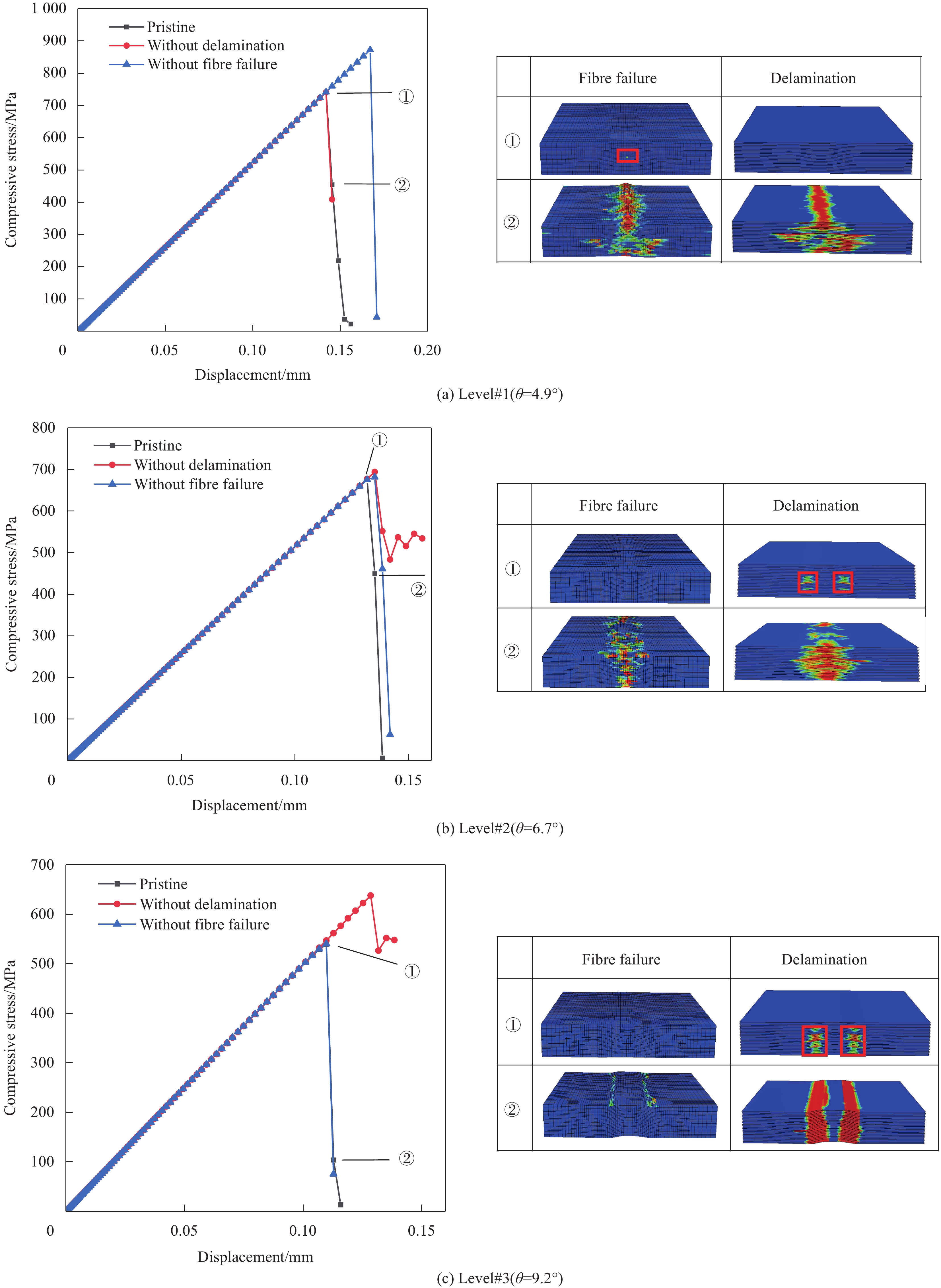

图 31 三种褶皱程度的T300/7901层合板有限元模型预测结果(①表示曲线最高点,②表示曲线下降点,其中红色区域表明单元已失效)

Figure 31. Prediction results of finite element model with three wrinkle degrees of T300/7901 laminates (① indicates the highest point of the curve, ② indicates the point of the curve decline, red areas indicate that the element has failed)

E1/MPa E2/MPa E3/MPa G12/MPa G13/MPa G23/MPa 161000 11380 11380 5170 5170 3980 XT/MPa XC/MPa YT/MPa YC/MPa SL/MPa μ12 2560 1590 73 250 91.4 0.34 μ13 μ23 β n α66 GIC/(N·mm-1) 0.34 0.5 1059.955 0.2041 2.6 0.21 GIIC/(N·mm-1) GⅢC/(N·mm-1) Gkink/(N·mm-1) Gsplit/(N·mm-1) 0.8 0.8 80 80 Notes: Ei—Lamina modulus in i direction; Gij—Lamina shear modulus in ij direction; μij—Poisson’s ratio in ij direction; XT—Longitudinal tensile strength; XC—Longitudinal compressive strength; YT—Transverse tensile strength; YC—Transverse compressive strength; SL—Inplane shear; GIC, GIIC, GⅢC—Fracture toughness for mode I and II; Gkink, Gsplit—Fiber compressive fracture energy; β,n,α66 —Plastic parameter. Kn/(N·mm−3) Ks= Kt/(N·mm−3) σn/MPa σs =σt/MPa Gn/(N·mm−1) Gs = Gt/(N·mm−1) α 105 105 60 90 0.26 1.002 1 Notes: Kn—Normal separation stiffness; Ks, Kt —Shear stiffness;σn —Normal interface strength; σs, σt— Shear interface strength; Gn —Normal fracture energy; Gs, Gt—Shear fracture energy; α—Damage coefficient. 表 3 8种梯度褶皱的IM7/8552单向层板模型的损伤萌生位置

Table 3 Damage initiation location of IM7/8552 unidirectional laminates with eight wrinkle levels

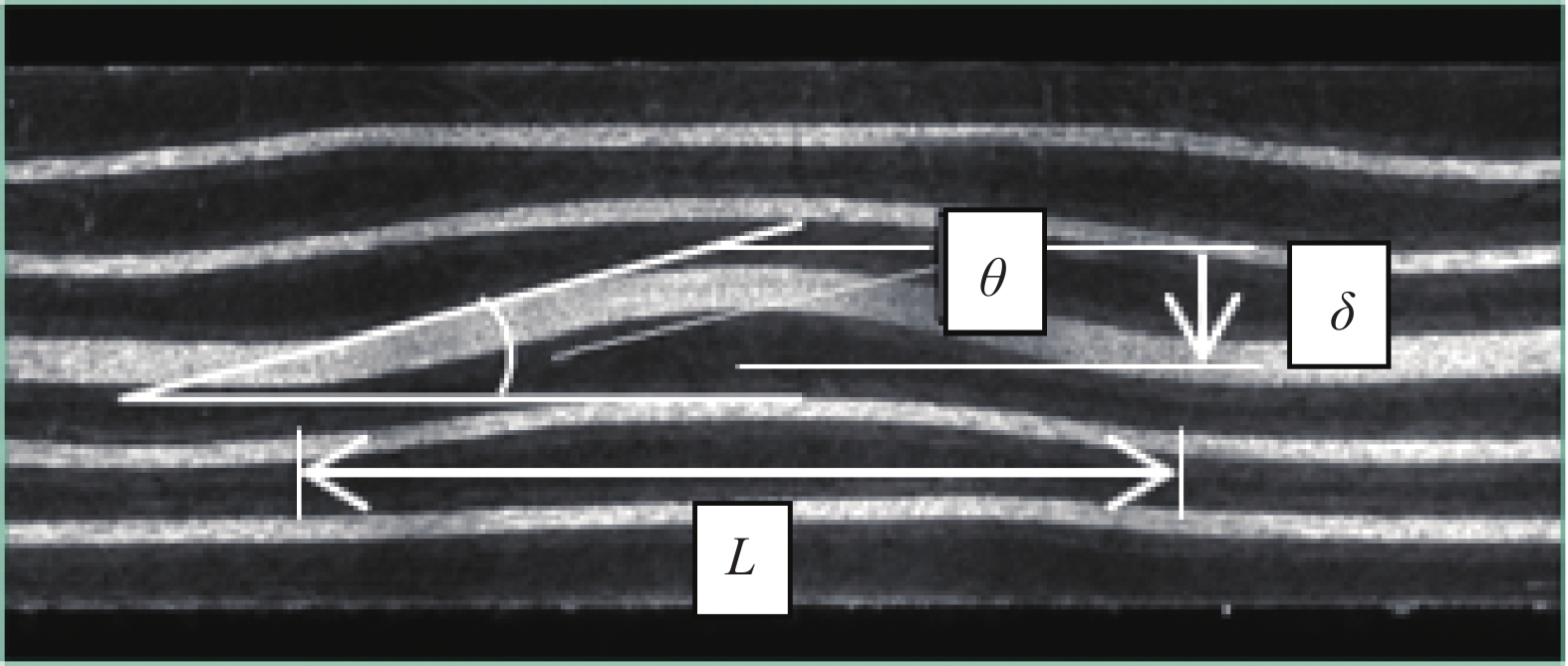

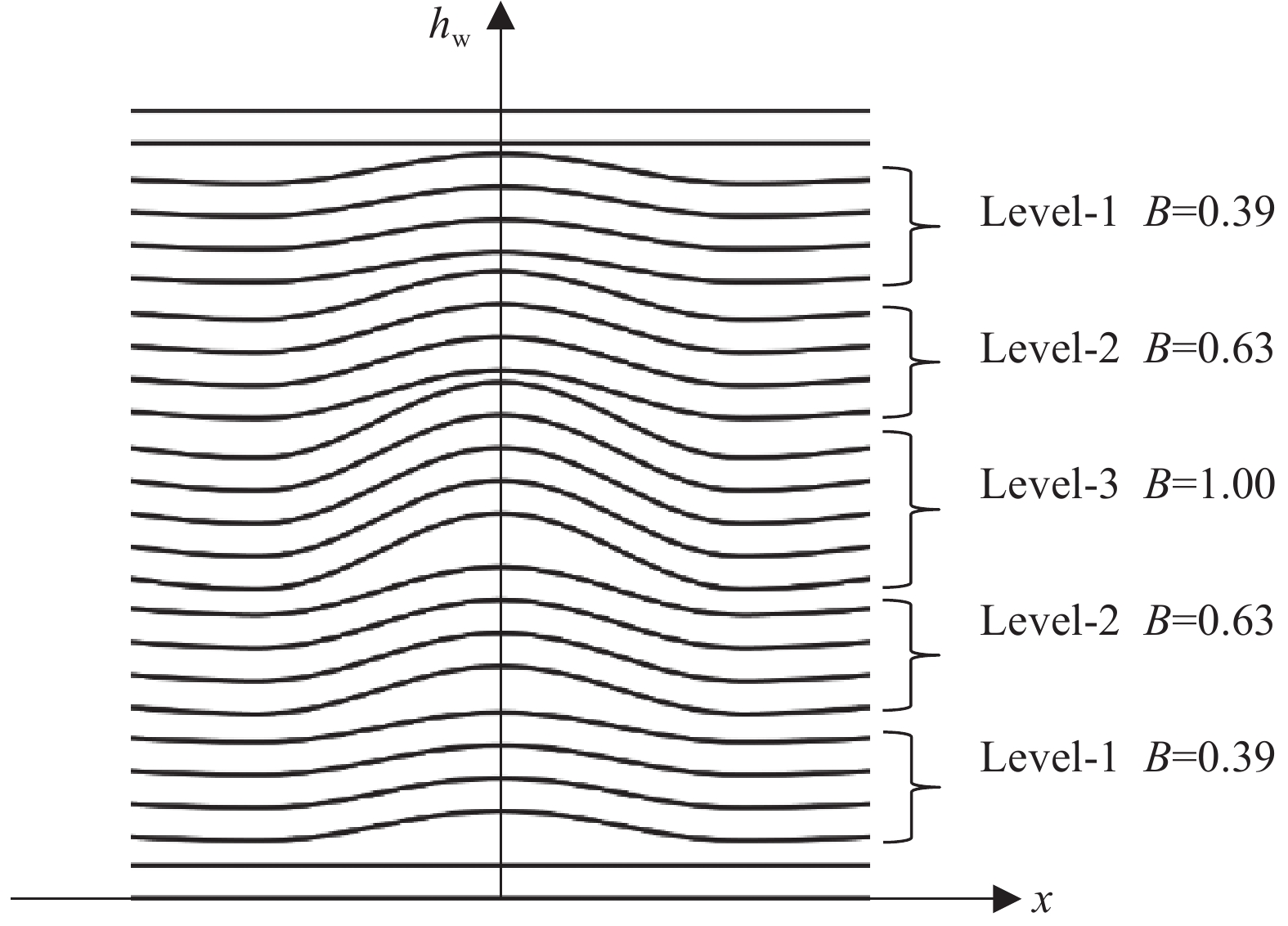

Maximum wrinkle angle θ/(°) Level-1/(°) Level-2/(°) Level-3/(°) Wrinkle angle of layer where wrinkle

initiation position is located θi/(°)5 1.95 3.15 5 5 10 3.93 6.34 10 10 20 8.08 12.91 20 20 30 12.69 19.99 30 30 40 18.12 27.86 40 40 50 24.93 36.9 50 36.9 60 34.04 47.5 60 47.5 70 46.98 59.99 70 46.98 表 4 T300/7901试件制备设计参数和最大褶皱角测量值

Table 4 T300/7901 specimen preparation design parameters and maximum wrinkle angle measurement values

Wrinkle

severitySpecimen

quantity /pcsStrip

Thickness/mmStrip width/

mmWrinkle thickness

ratio/%Molded specimen

thickness/mmAngle/(°) Pristine 4 5.0 0.4 Level#1 4 0.15 5 100 5.4 4.9 Level#2 4 0.3 5 100 4.6 6.7 Level#3 4 0.45 5 100 4.4 9.2 表 5 T300/7901材料参数测试结果

Table 5 Material parameter measurement results of T300/7901

E1/MPa E2 = E3/MPa G12/MPa μ12=μ13/MPa 131629 11440 11440 4395 XC/MPa YC/MPa SL/MPa 958 188 94 表 6 T300/7901材料力学参数和模型参数[43,44]

Table 6 Material properties of T300/7901 and model parameters[43,44]

G13/MPa G23/MPa XT/MPa YT/MPa μ23 β 3980 3980 2000 80 0.42 1059.955 n α66 Gft,c/(N·mm−1) Gfc,c/(N·mm−1) GⅠC/(N·mm−1) GⅡC = GⅢC/(N·mm−1) 0.2041 2.6 91.6 79.9 0.3 0.899 NotesGft,c, Gfc,c— Tensile and compressive fracture toughnesses in the fiber direction. -

[1] POTTER K, KHAN B, WISNOM M, et al. Variability, fiber waviness and misalignment in the determination of the properties of composite materials and structures[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(9): 1343-1354. DOI: 10.1016/j.compositesa.2008.04.016

[2] FU Y, YAO X. A review on manufacturing defects and their detection of fiber reinforced resin matrix composites[J]. Composites Part C: Open Access, 2022, 8: 100276. DOI: 10.1016/j.jcomc.2022.100276

[3] ALVES M P, CIMINI JUNIOR C A, HA S K. Fiber waviness and its effect on the mechanical performance of fiber reinforced polymer composites: An enhanced review[J]. Composites: Part A, 2021, 149: 106526. DOI: 10.1016/j.compositesa.2021.106526

[4] BELNOUE J P, et al. Consolidation-Driven Defect Generation in Thick Composite Parts[J]. Journal of Manufacturing Science and Engineering, 2018, 140: 071006. DOI: 10.1115/1.4039555

[5] SEBAEY T A, CATALANOTTI G, O'DOWD N P. A microscale integrated approach to measure and model fibre misalignment in fibre-reinforced composites[J]. Composites Science and Technology, 2019, 183: 107793. DOI: 10.1016/j.compscitech.2019.107793

[6] WILHELMSSON D, RIKEMANSON D, BRU T, et al. Compressive strength assessment of a CFRP aero-engine component–An approach based on measured fibre misalignment angles[J]. Composite Structures, 2020, 233: 111632. DOI: 10.1016/j.compstruct.2019.111632

[7] CIMOLAI G, YASAEE M. Numerical simulations of embedded wrinkle defects geometry on the strength knockdown of FRP composites[J]. Composite Structures, 2023, 305: 116541. DOI: 10.1016/j.compstruct.2022.116541

[8] MECHIN P Y, KERYVIN V, GRANDIDIER J C, et al. An experimental protocol to measure the parameters affecting the compressive strength of CFRP with a fibre micro-buckling failure criterion[J]. Composite Structures, 2019, 211: 154-162. DOI: 10.1016/j.compstruct.2018.12.026

[9] WILHELMSSON D, GUTKIN R, EDGREN F, et al. An experimental study of fibre waviness and its effects on compressive properties of unidirectional NCF composites[J]. Composites Part A: Applied Science & Manufacturing, 2018, 107: 665-674.

[10] HSIAO H M, DANIEL I M. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading[J]. Composites Science and Technology, 1996, 56(5): 581-593. DOI: 10.1016/0266-3538(96)00045-0

[11] ADAMS D O H, HYER M W. Effects of layer waviness on the compression strength of thermoplastic composite laminates[J]. Journal of Reinforced Plastics and Composites, 1993, 12(4): 414-429. DOI: 10.1177/073168449301200404

[12] MUKHOPADHYAY S, JONES M I, HALLETT S R. Tensile failure of laminates containing an embedded wrinkle; numerical and experimental study[J]. Composites Part A: Applied Science and Manufacturing, 2015, 77: 219-228. DOI: 10.1016/j.compositesa.2015.07.007

[13] MUKHOPADHYAY S, JONES M, HALLETT S. Compressive failure of laminates containing an embedded wrinkle; Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing, 2015, 73: 132-142. DOI: 10.1016/j.compositesa.2015.03.012

[14] 叶梯, 曾昭炜, 马铭泽. 褶皱对碳纤维复合材料层合板压缩性能的影响[J]. 宇航材料工艺, 2022, 52(05): 48- 53. YE T, ZENG Z W, MA M, Effect of fiber waviness on compressive properties of carbon fiber composite laminates[J]. Aerospace Materials & Technology, 2022, 52(05): 48- 53(in Chinese).

[15] XIE N, SMITH R A, MUKHOPADHYAY S, et al. A numerical study on the influence of composite wrinkle defect geometry on compressive strength[J]. Materials & Design, 2018, 140: 7-20.

[16] SITOHANG R D R, GROUVE W J B, WARNET L L, et al. Effect of in-plane fiber waviness defects on the compressive properties of quasi-isotropic thermoplastic composites[J]. Composite Structures, 2021, 272: 114-166.

[17] SITOHANG R D R, GROUVE W J B, WARNET L L, et al. The relation between in-plane fiber waviness severity and first ply failure in thermoplastic composite laminates[J]. Composite Structures, 2022, 289: 115374. DOI: 10.1016/j.compstruct.2022.115374

[18] 朱俊, 吴维清, 欧阳佳斯, 等. 面外波纹对复合材料层合板弹性性能的影响[J]. 复合材料学报, 2016, 33(9): 1981-1988. ZHU J, WU W Q, OUYANG J S, et al. Influence of out-of-plane waviness on elastic properties of composite laminates[J]. Acta Materiae Compositae Sinica, 2016, 33(9): 1981-1988( in Chinese).

[19] 叶梯. 含纤维错位复合材料层压板压缩性能研究[C]//第三届中国国际复合材料科技大会摘要集-分会场. 杭州: 中国复合材料学, 2017: 10-16. YE T. Research on compression Properties of Fiber misaligned Composite Laminates [C]// The Third China International Composite Science and Technology Conference Abstracts - Sub-conference. Hangzhou: Composites Science in China, 2017: 10-16(in Chinese).

[20] 张弥, 关志东, 黎增山, 等. 考虑纤维初始位错的复合材料轴向压缩性能[J]. 复合材料学报, 2017, 34(8): 1754-1763. ZHANG M, GUAN Z D, LI Z S, et al. Longitudinal compressive properties of composites considering fiber initial misalignment[J]. Acta Materiae Compositae Sinica, 2017, 34(8): 1754-1763(in Chinese).

[21] NIMBAL S S, BANKER M M, ROOPA A, et al. Effect of gap induced waviness on compressive strength of laminated composites[J]. International Conference on Advancement of Aeromechanical Materials for Manufacturing, 26-28th June, 2016, Hyderabad: India.

[22] SUN Q, GUO H, ZHOU G, et al. Experimental and computational analysis of failure mechanisms in unidirectional carbon fiber reinforced polymer laminates under longitudinal compression loading[J]. Composite Structures, 2018, 203: 335-48. DOI: 10.1016/j.compstruct.2018.06.028

[23] SUN Q, ZHOU G, MENG Z, et al. Failure criteria of unidirectional carbon fiber reinforced polymer composites informed by a computational micromechanics model[J]. Composite Science and Technology, 2019, 172: 81-95. DOI: 10.1016/j.compscitech.2019.01.012

[24] 凌圣博, 姚启, 王乐蓬, 等. 褶皱缺陷对复合材料拉伸性能的影响规律: 试验及数值模型[J]. 力学学报, 2024, 56(6): 1740-1751 Ling S B, Yao Q, Wang L P, et al. Influence of wrinkle on the tensile properties of composite laminates: experiments and numerical model[J]. Chinese Journal of Theoretical and Applied Mechanics, 2024, 56(6): 1740-1751 (in Chinese).

[25] WANG J, CALLUS P J, BANNISTER M K. Experimental and numerical investigation of the tension and compression strength of un-notched and notched quasi-isotropic laminates[J]. Composite Structures, 2004, 64(3/4): 297-306.

[26] VOGLER T J, KYRIAKIDES S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part I: experiments[J]. Internation al Journal of Plasticity, 1999, 15(8): 783-806. DOI: 10.1016/S0749-6419(99)00011-X

[27] WANG J, XIAO Y. Some improvements on Sun-Chen’s one-parameter plasticity model for fibrous composites Part I: Constitutive modelling for tension–compression asymmetry response[J]. Journal of Composite Materials, 2016, 51(3): 405-418.

[28] C T, SUN, J L, et al. A Simple Flow Rule for Characterizing Nonlinear Behavior of Fiber Composites[J]. Journal of Composite Materials, 1989, 23(10): 1009-1020. DOI: 10.1177/002199838902301004

[29] PINHO S T, DARVIZEH R, ROBINSON P, et al. Material and structural response of polymer-matrix fibre-reinforced composites[J]. Journal of Composite Materials, 2012, 46(19-20): 2313-2341. DOI: 10.1177/0021998312454478

[30] PUCK A, SCHÜRMANN H. Failure analysis of FRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology, 1998, 58: 1045-1067. DOI: 10.1016/S0266-3538(96)00140-6

[31] ARGON A S. Fracture of composites[J]. Treatise on Materials Science and Technology vol1: Academic Press, 1972, 79-114.

[32] MANNIGEL M. Influence of shear stresses on the fibre failure behaviour in carbon fibre reinforced plastics. [D]. Technischen Hochschule Aachen, 2007.

[33] BAZANT Z P, OH B H. Crack band theory for fracture of concrete[J]. Materials and Structures, 1983, 16(93): 155-77.

[34] 刘志明, 陈静芬, 毛欢, 等. 基于率相关三维弹塑性损伤模型的复合材料渐进失效分析[J]. 复合材料学报, 2022, 39(5): 2482-2494 LIU Z M, CHEN J F, MAO H, et al. Progressive failure analysis of composite materials based on rate-dependent three-dimensional elastoplastic damage model[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2482-2494(in Chinese).

[35] Camanho P, Dávila C, De Moura M. Numerical simulation of mixed-mode progressive delamination in composite materials[J]. Journal of Composite Materials, 2003, 37(16): 1415-1438. DOI: 10.1177/0021998303034505

[36] PIMENTA S, GUTKIN R, PINHO ST, et al. A micromechanical model for kink-band formation: Part I-Experimental study and numerical modelling[J]. Composites Science and Technology, 2009, 69(7-8): 948-55. DOI: 10.1016/j.compscitech.2009.02.010

[37] NICHOLAS R. PILATO A, RICHARD BUTLER, et al. An experimental and numerical study of industrially representative wrinkles in carbon fiber composite laminates[J]. Materials & Design, 2022, 222: 111055.

[38] 薛康, 肖毅, 王杰, 等. 单向纤维增强聚合物复合材料压缩渐进破坏[J]. 复合材料学报, 2019, 36(6): 1398-1412. XUE K, XIAO Y, WANG J, et al. Compression progressive failure of unidirectional fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica, 2019, 36(6): 1398-1412(in Chinese).

[39] XIE N, SMITH R A, MUKHOPADHYAY S, et al. Modelling the mechanical properties of wrinkled composites from NDT data. [C]//20th International Conference on Composite Materials, Copenhagen, 2015.

[40] SITOHANG R D R, GROUVE W J B, WARNET L L, et al. An experimental approach to reproduce in-plane fiber waviness in thermoplastic composites test coupons using a reverse forming method[J]. Journal of Composite Materials, 2021, 56(4): 561-574.

[41] WILHELMSSON D, TALREJA R, GUTKIN R, et al. Compressive strength assessment of fibre composites based on a defect severity model[J]. Composites Science and Technology, 2019, 181: 107685. DOI: 10.1016/j.compscitech.2019.107685

[42] An American National Standard, Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture1, Designation: ASTM D6641/D6641M-16E01[S]. Annual Book of ASTM Standards, 2016.

[43] TIE Y, ZHANG, et al. Impact damage assessment in orthotropic CFRP laminates using nonlinear Lamb wave: Experimental and numerical investigations[J]. Composite Structures, 2020, 236: 111869. DOI: 10.1016/j.compstruct.2020.111869

[44] ZHAO Y Q, JIANG F, HUANG Z M, et al. Micromechanical progressive damage analysis of inter- and intra-layer failures in fiber-reinforced composite laminates[J]. Journal of Composite Materials, 2020, 54(21): 2913-2942. DOI: 10.1177/0021998319900300

[45] Sun Q, Zhou G, Tang H, et al. A combined experimental and computational analysis of failure mechanisms in open-hole cross-ply laminates under flexural loading[J]. Composites Part B Engineering, 2021, (S2): 108803.

-

目的

纤维褶皱是纤维增强复合材料难以避免的制造缺陷,致使复合材料层合板的力学性能尤其是压缩强度大幅下降。探讨纤维褶皱参数对复合材料层合板的压缩失效模式和压缩强度的关联规律,为复合材料压缩性能的定量评估以及建立合理的错误容忍标准提供科学依据。

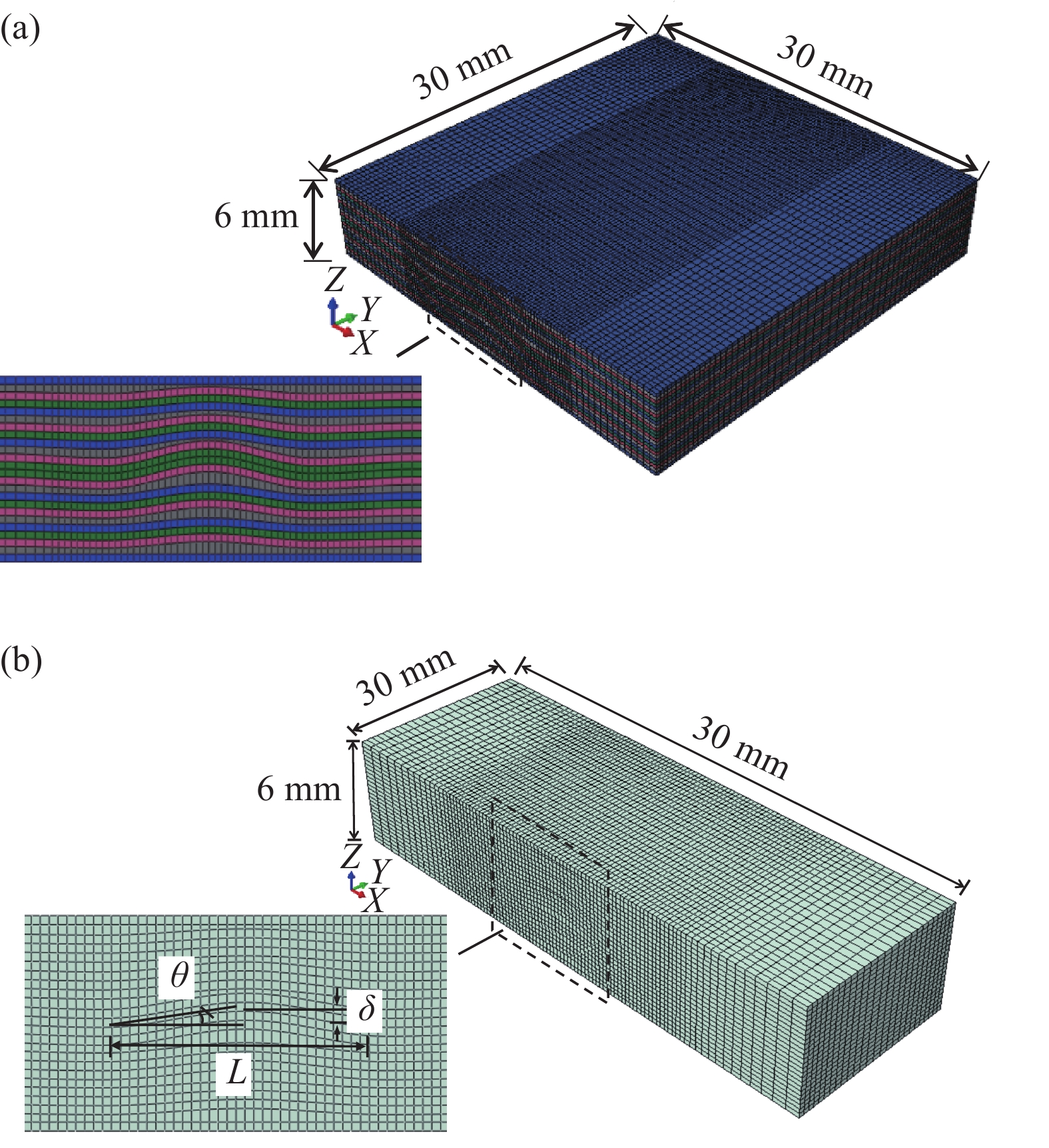

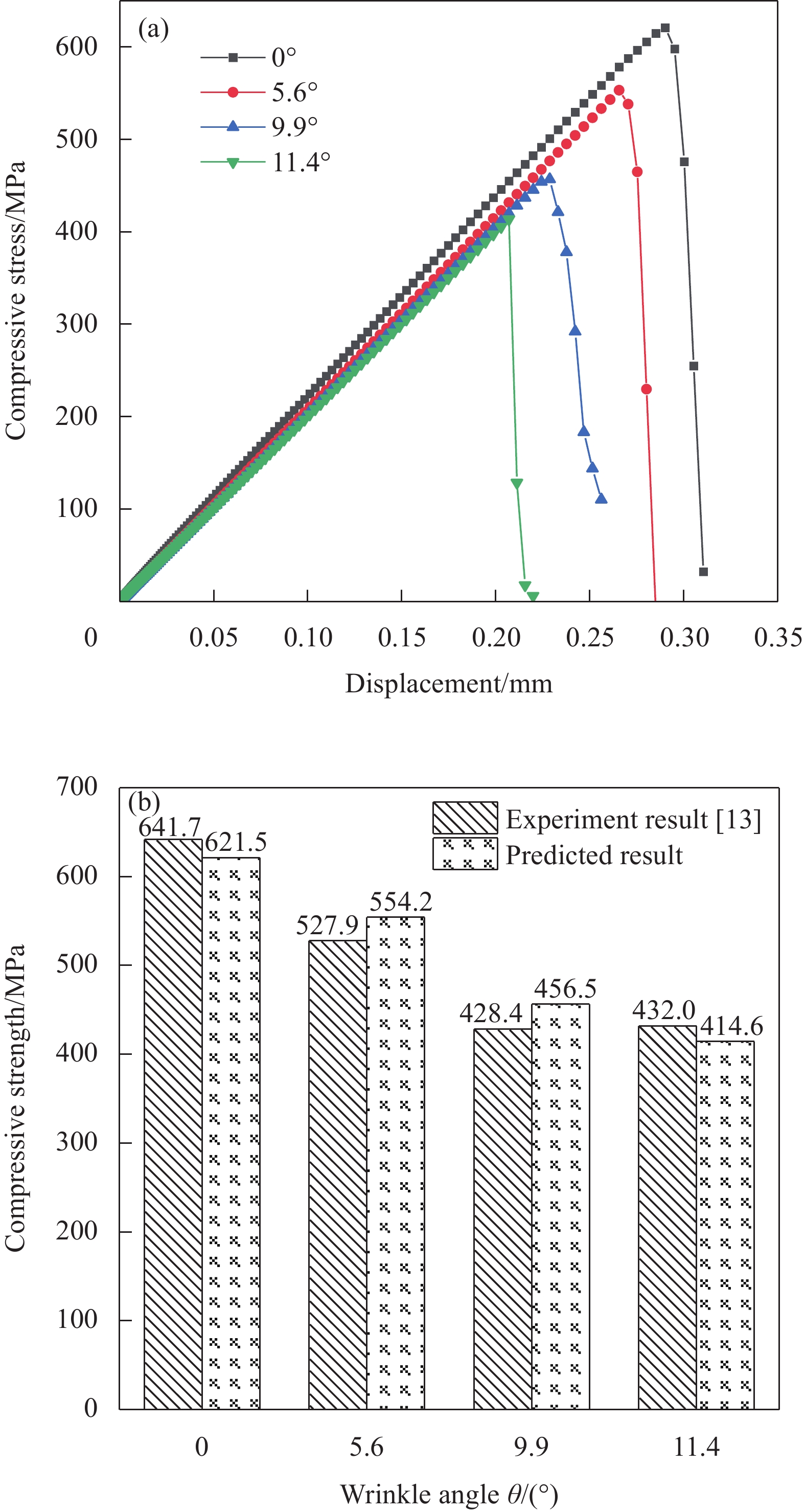

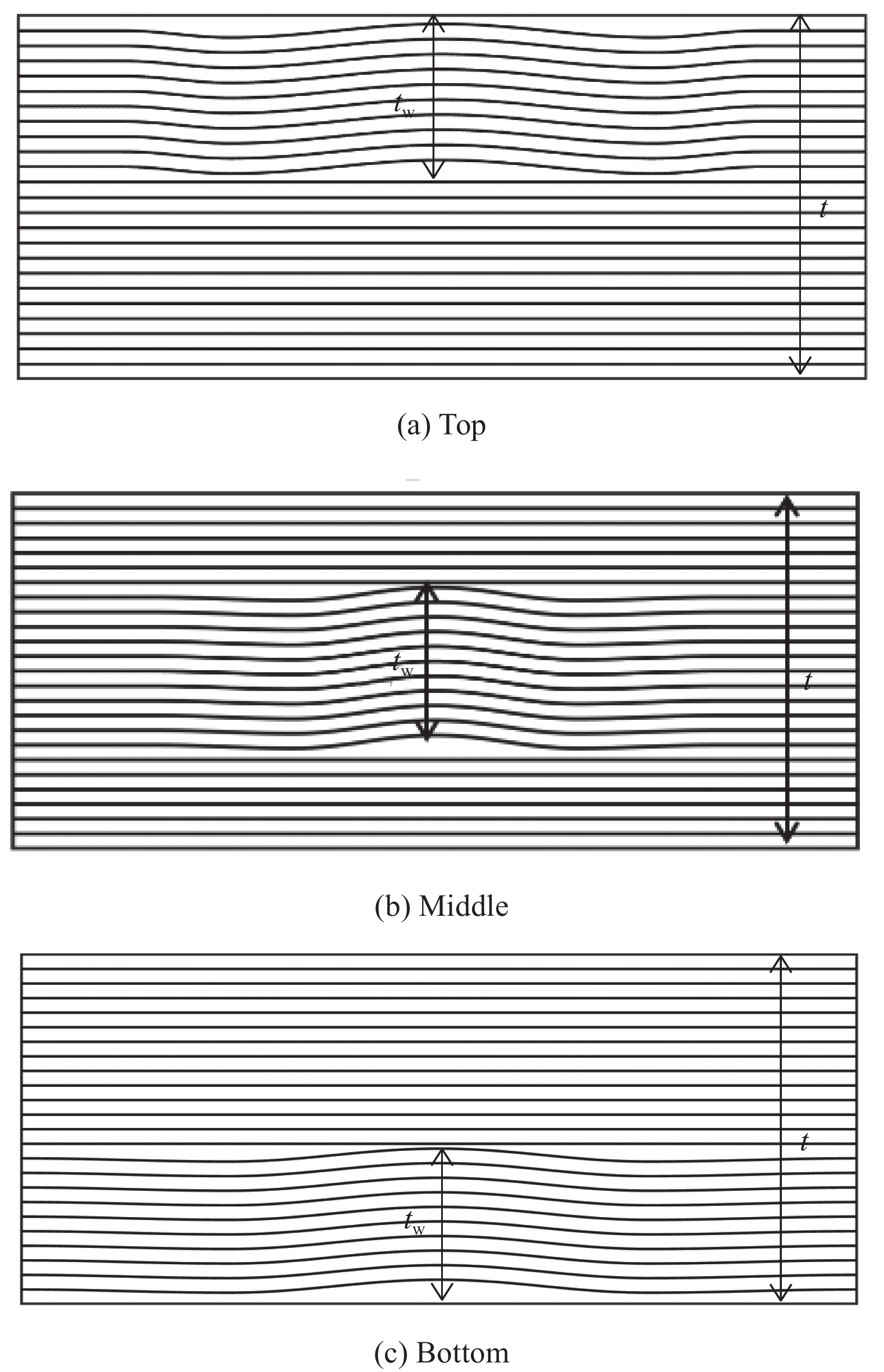

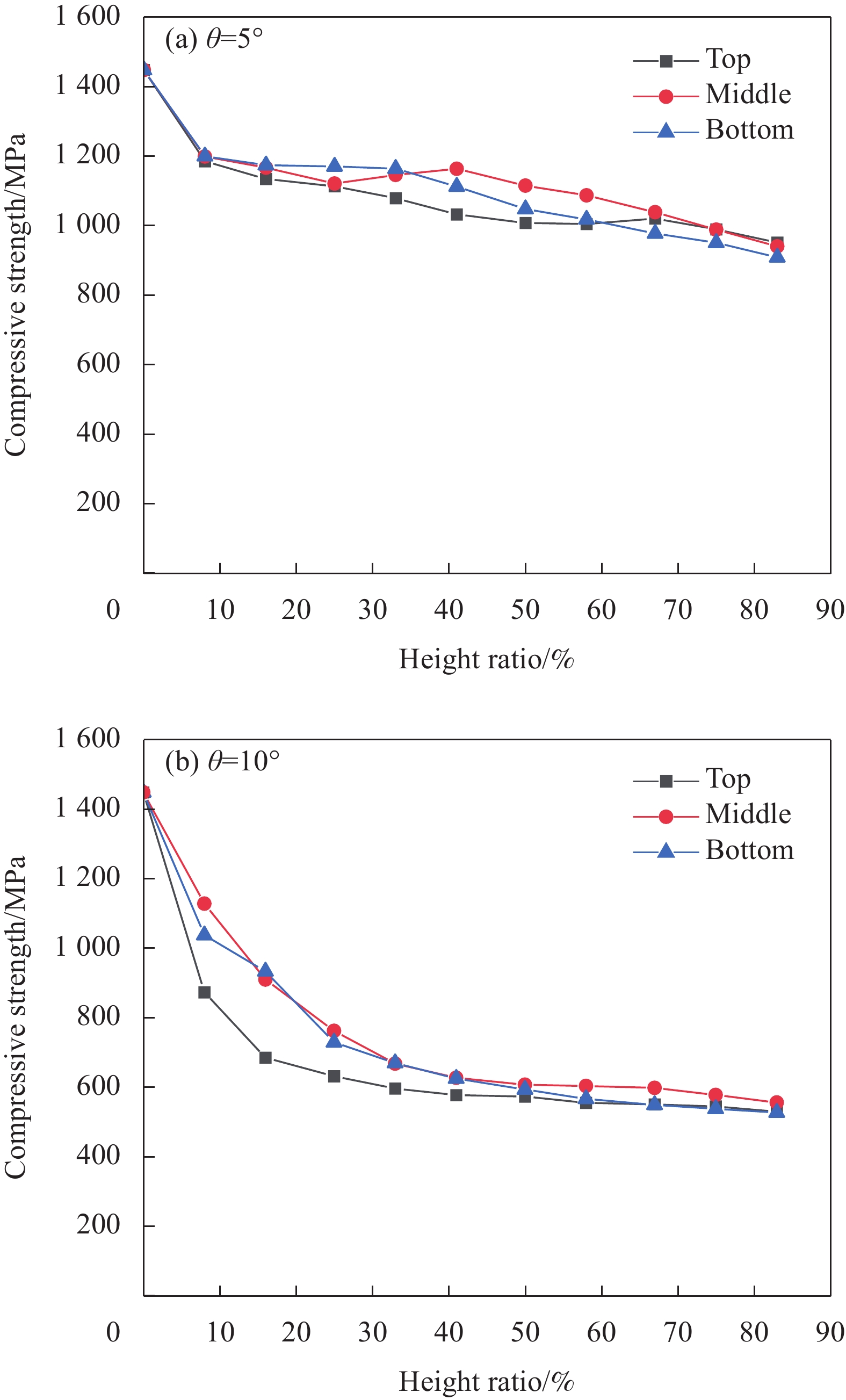

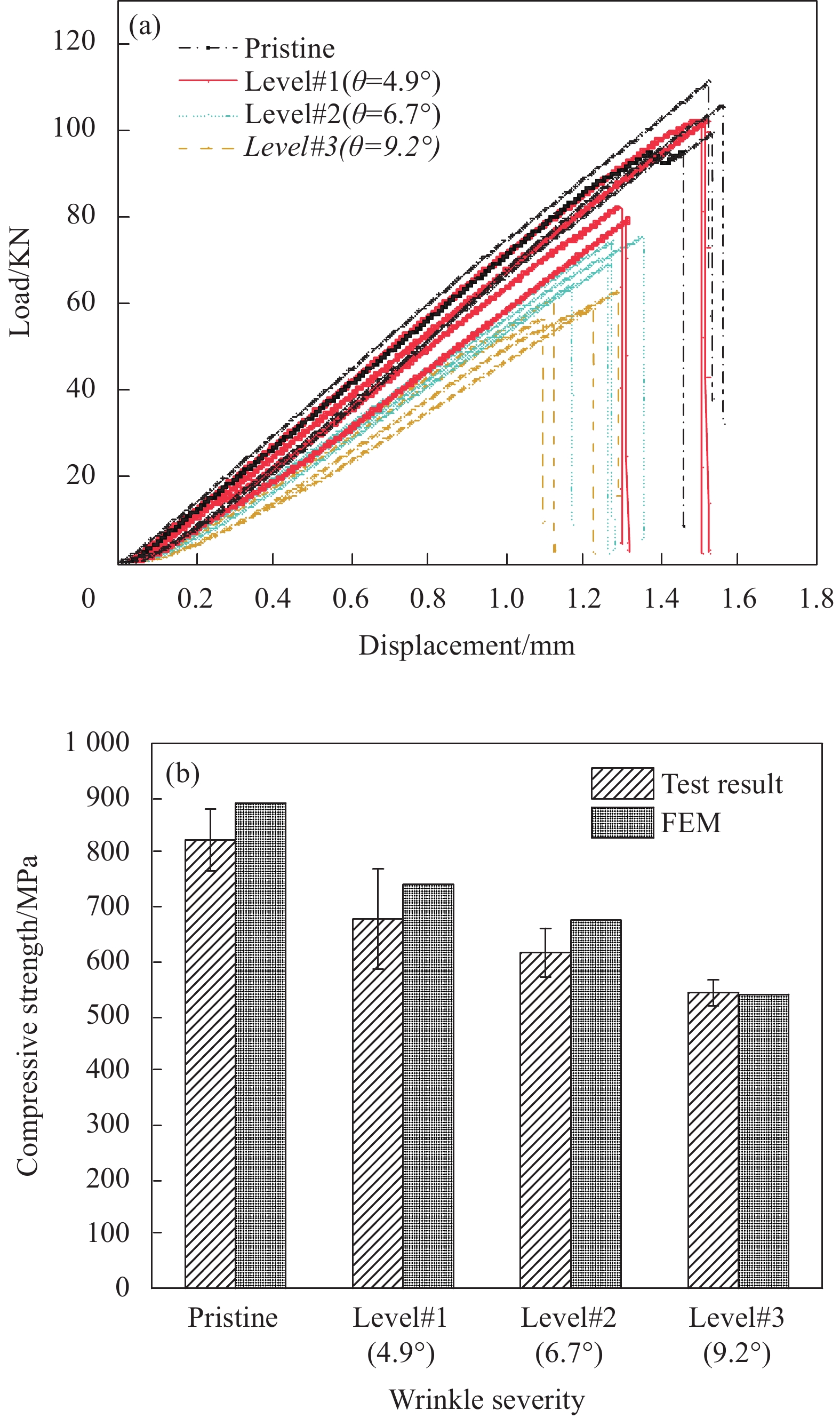

方法借助MATLAB和Python脚本实现可控褶皱几何形貌的数值建模,构建包含多种损伤形式的复合材料三维弹塑性损伤模型。利用数值模拟结果,将无褶皱和最大褶皱角分别为5.6°、9.9°、11.4°的层合板压缩失效预测结果与文献的试验数据进行对比,揭示多向层合板的压缩强度、损伤演化和主控失效模式与纤维褶皱之间的关联规律;建立25组不同褶皱程度的单向层合板模型,分析单向铺设层合板的褶皱参数对压缩强度折减率及主控失效模式的影响效应,并将单向铺设和多向铺设层合板的预测结果进行对比;选取最大褶皱角在0°~70°(间隔为10°)范围内,探讨层合板压缩强度随铺层最大褶皱角的变化的敏感性关系;改变褶皱区域宽度、高度比和位置,研究单向铺设层合板的轴向压缩强度与纤维褶皱区域大小之间的敏感性规律。制作含有纤维褶皱的层合板试件,开展含铺层褶皱层合板的压缩破坏试验研究,验证数值模型对纤维褶皱影响效应预测的有效性。

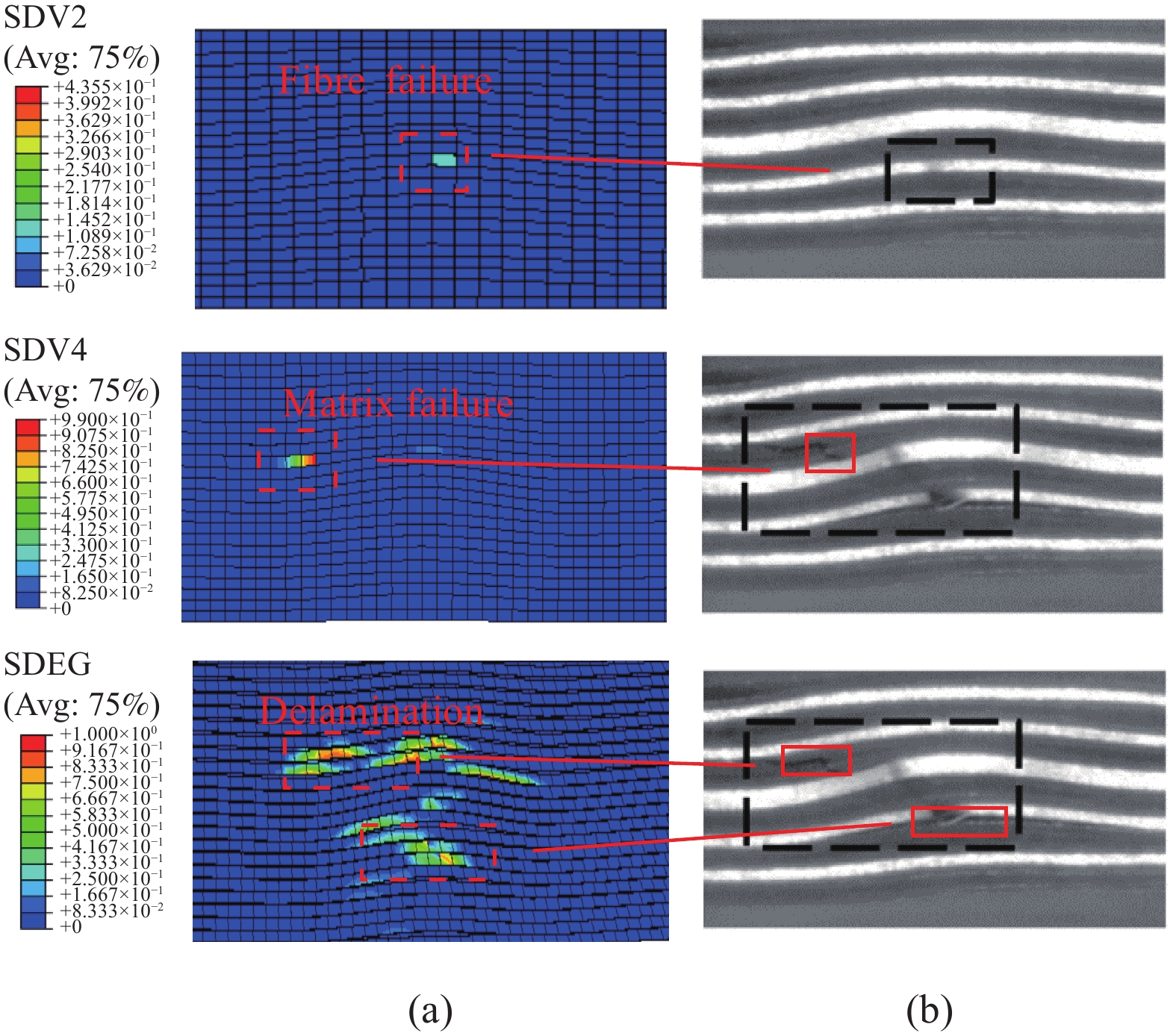

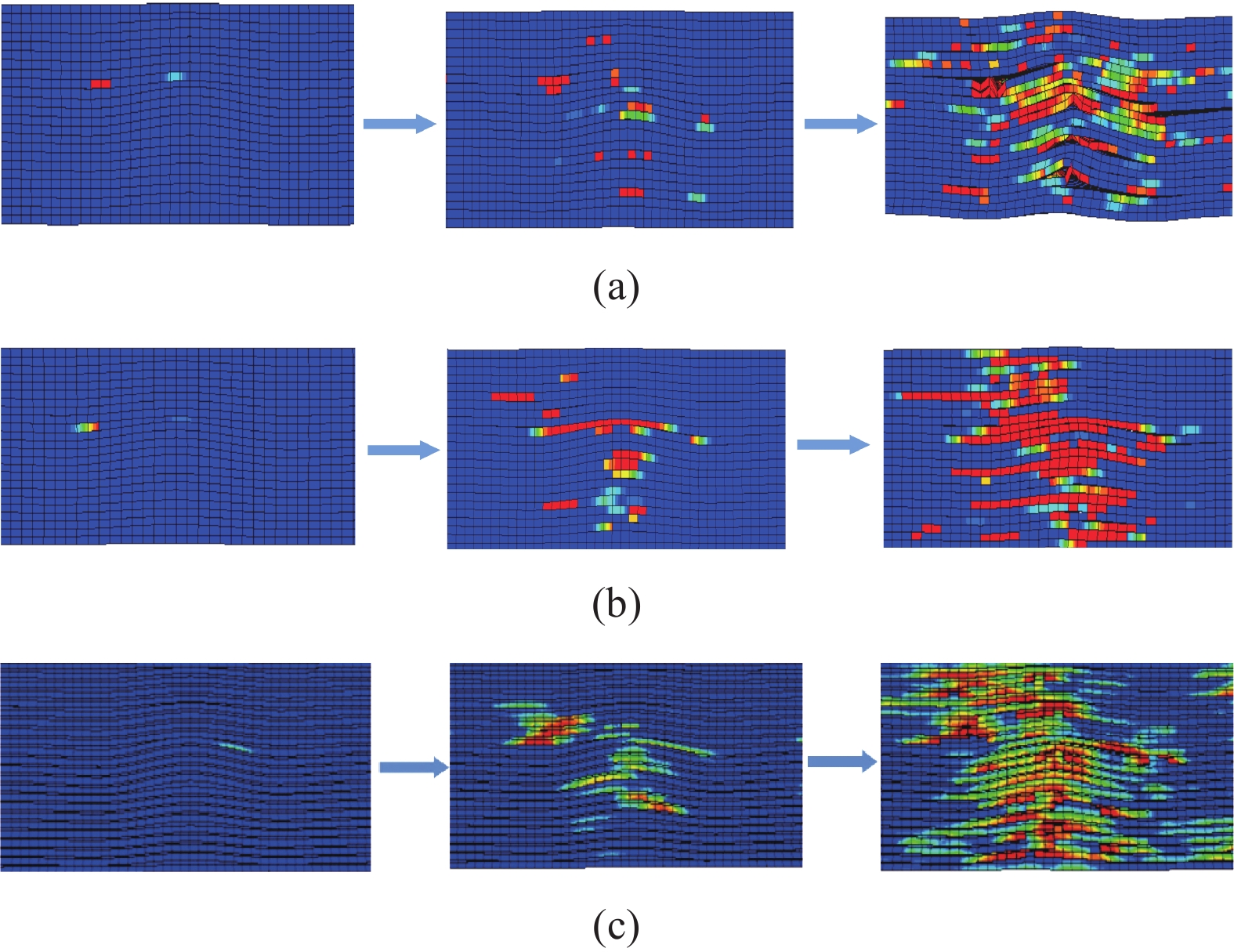

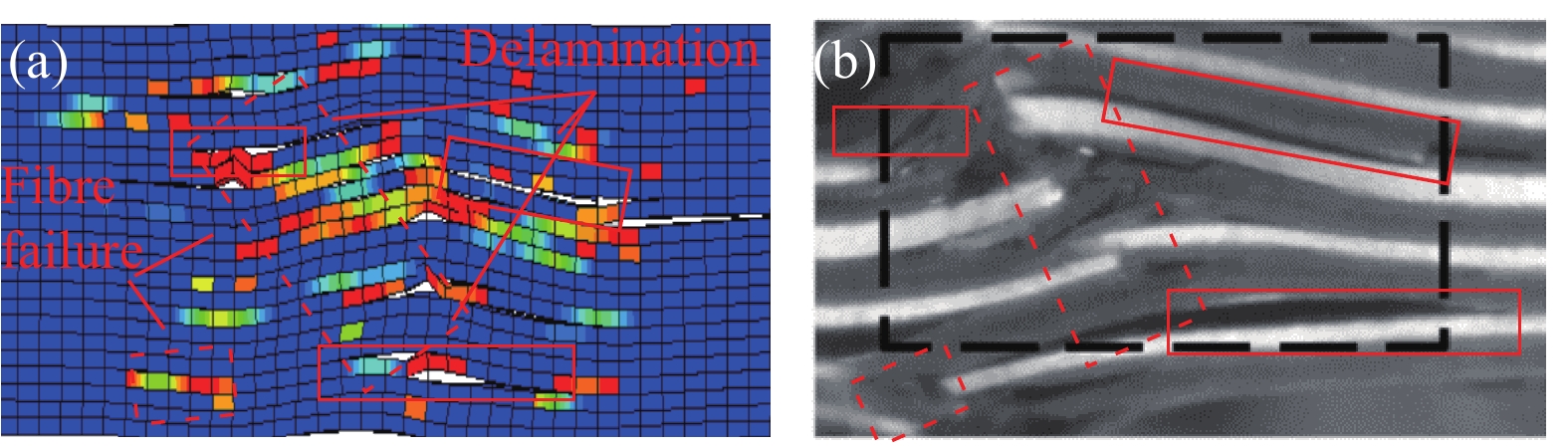

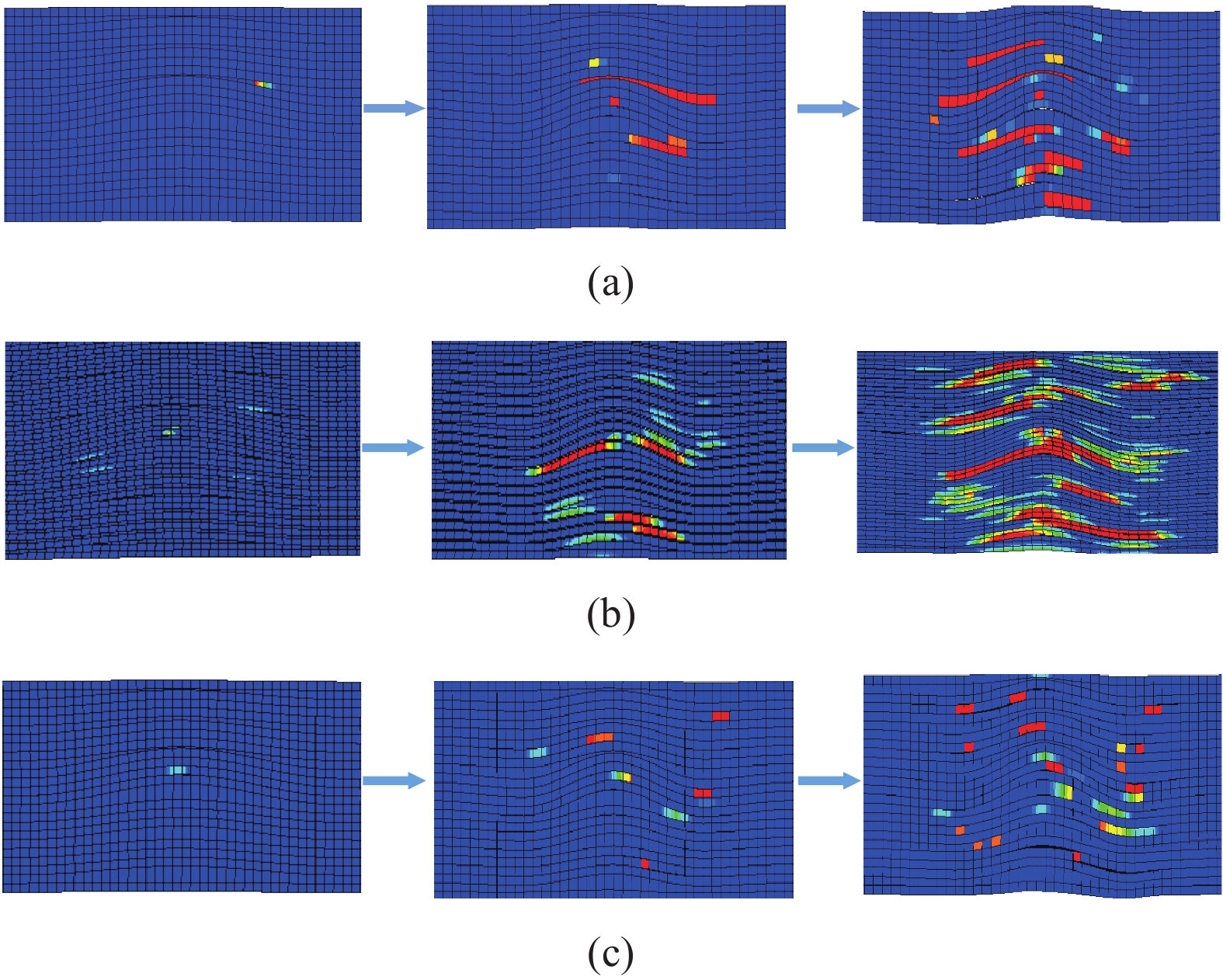

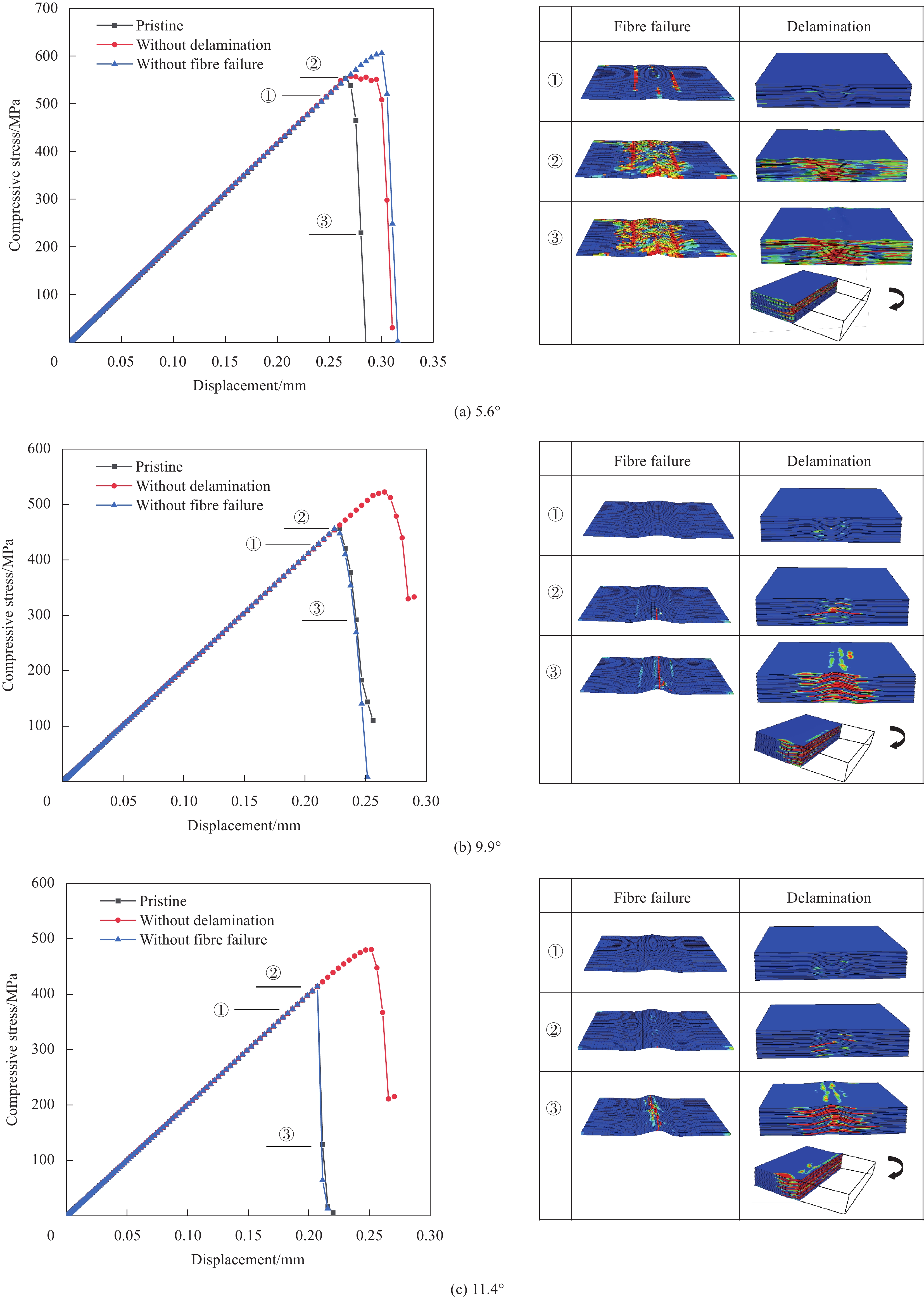

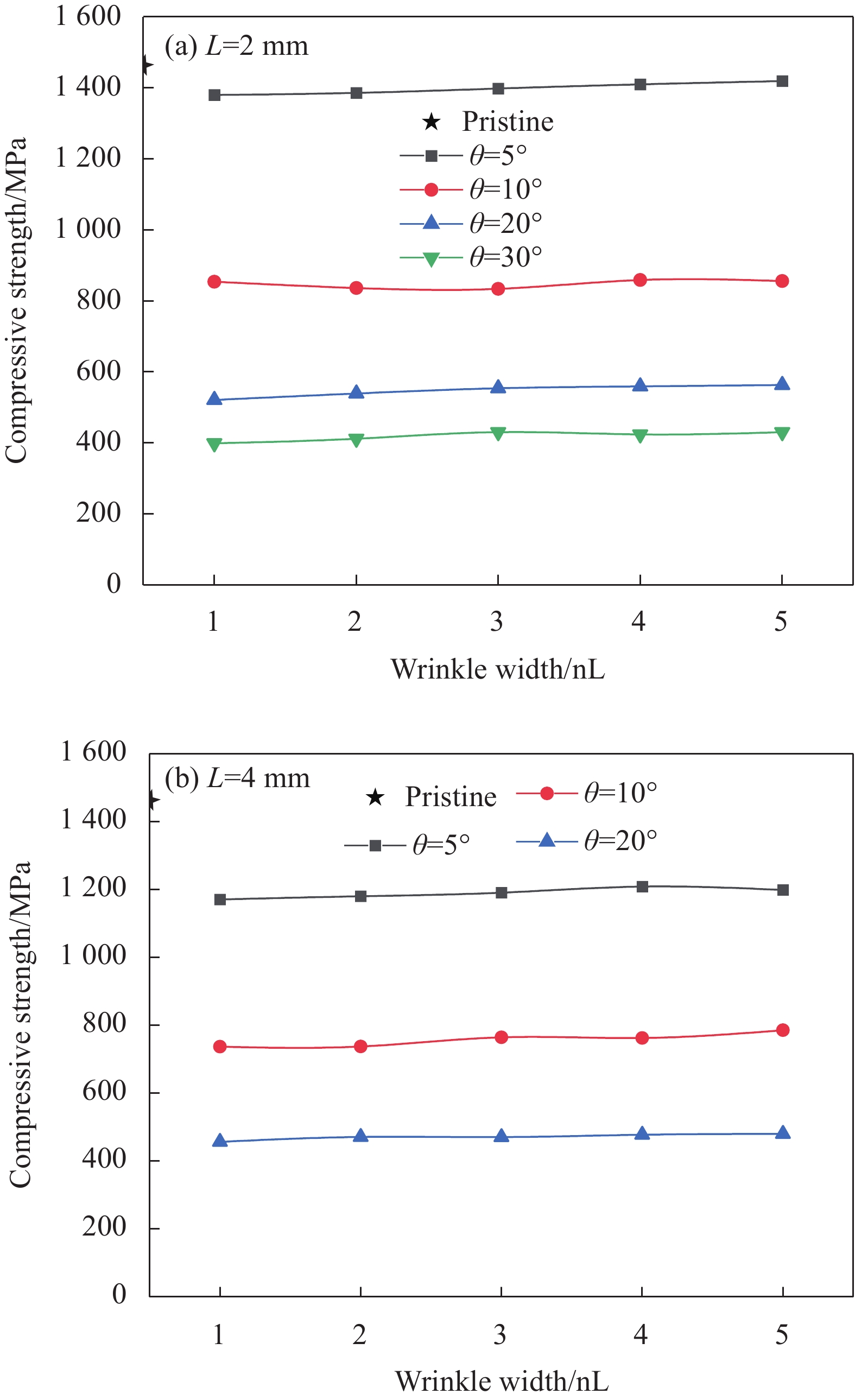

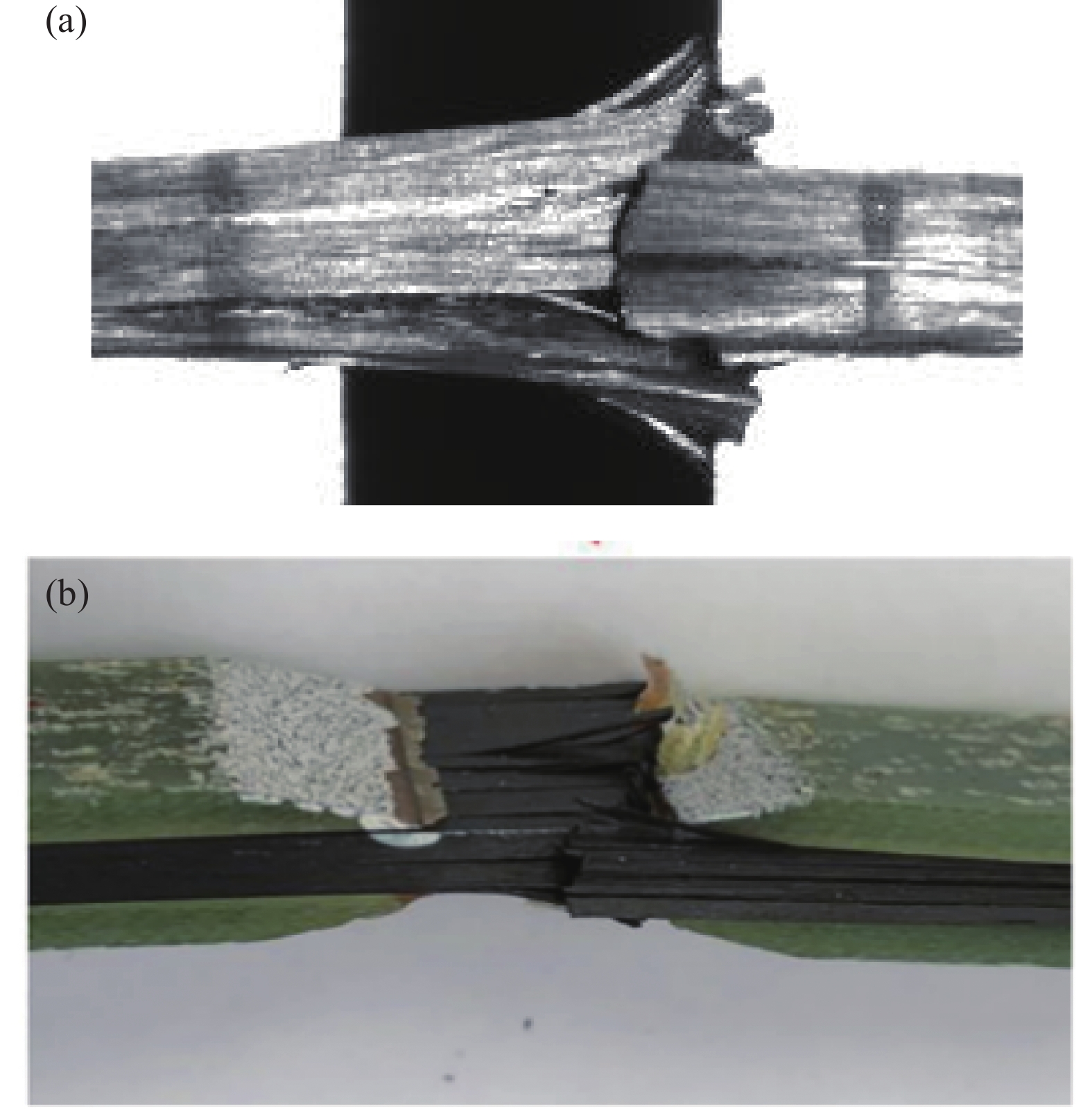

结果关于碳纤维复合材料IM7/8552多向层合板的研究结果表明:①多铺设层合板的刚度和压缩强度随着最大褶皱角的增大而降低。5.6°和11.4°层合板模型损伤发生顺序和损伤位置都与试验结果基本一致。②当最大褶皱角介于0°~15°时,最大褶皱角与压缩强度之间的关系近似于线性关系,压缩强度随着最大褶皱角的增大而降低。当最大褶皱角为15°时,与无褶皱的情形相比,压缩强度下降了45.29%。随着褶皱程度的提高,层合板的主控失效模式会发生转变,褶皱程度低于8°时,层合板的主控失效模式为纤维扭结,高于9.9°时,层合板的主控失效模式为分层损伤。关于单向层合板压缩失效的褶皱参数敏感性分析结果发现:①压缩强度折减率与最大褶皱角和幅值成正比、与波长成反比。对于褶皱波长(幅值)较小的情形,最大褶皱角和波长(幅值)共同影响压缩强度;②随着最大褶皱角的增大,主控失效模式由纤维扭结转变为分层损伤,失效模式发生转换的最大褶皱角阈值约为5°;③当最大褶皱角为20°、30°、40°时,分层损伤先发生在厚度中间褶皱程度最大区域的-45°和90°铺层之间;当最大褶皱角为50°、60°和70°时,损伤并非首先发生在褶皱最大区域,而是发生在相邻的褶皱角较低的区域;④当其他参数保持不变、只通过改变褶皱波数来改变褶皱区域大小时,层合板压缩强度基本保持不变。⑤当褶皱角为5°时,三种褶皱位置的压缩强度差异在10%以内;当褶皱角为10°时,褶皱区域位于顶部的压缩强度低于中部和底部的情形。压缩破坏试验和有限元模型结果表明,无褶皱和三种褶皱程度层合板的模型计算结果与试验结果的误差分别为7.8%、9.42%、9.71%、-0.26%。对于较低褶皱程度(=4.9°),主控损伤模式为纤维扭结,对于较高褶皱程度(=6.7°)和(=9.2°)层合板,主控失效模式为分层损伤。

结论最大褶皱角为影响单向层合板压缩强度的关键特征参数,层合板压缩强度随最大褶皱角的变化存在敏感和非敏感区间。相较于多向层合板,单向层合板压缩强度受褶皱程度影响更大。层合板的压缩失效模式随着褶皱程度的增大从纤维扭结转变为分层损伤。[45/90/-45/0]层合板的主控失效模式发生转变的褶皱角阈值高于单向层合板。当褶皱形貌参数不变时,纤维褶皱区域的大小对层合板压缩强度的影响主要体现在褶皱区域的高度占比上,高度占比越大,压缩强度越低。当层合板横截面上存在多个褶皱区时,分层损伤不一定发生在褶皱最严重的区域。

-

纤维褶皱是纤维增强聚合物复合材料及其结构常见的制造缺陷,导致层合板压缩强度大幅降低。针对这一问题,论文围绕纤维褶皱参数对复合材料层合板压缩破坏的影响效应开展研究,为保障复合材料及其结构的安全服役提供科学指导。

本文通过提出一种纤维褶皱几何模型的参数化建模方法,建立了含铺层褶皱复合材料的三维弹塑性损伤分析模型。该模型实现了对失效过程中不同形式的损伤萌生和演化规律的预测,揭示了纤维褶皱对多向和单向层合板压缩强度及失效模式的影响规律。其主控失效模式随着褶皱程度的增大从纤维扭结转变为分层损伤。对于所研究的单向层合板,失效模式转换的纤维褶皱角阈值介于4°~6°之间,而多向层合板的转变阈值则介于8°~9°之间。纤维褶皱角和褶皱区高度占比对单向层板压缩强度的影响存在敏感区和非敏感区。当层合板横截面上存在多个褶皱区时,分层损伤不一定发生在褶皱最严重的区域。当铺层褶皱程度超过45o,由于铺层失稳导致承担的峰值纵向应力下降,由此所传递的层间剪切作用也减弱,分层损伤不易发生。

单向和多向铺设层合板的压缩强度和主控失效模式与最大褶皱角的关系

单向板压缩强度与最大褶皱角的关系

下载:

下载: