Damage failure and ballistic performance of SiC ceramic-fiber reinforced resin-based composite armor with different thickness ratios

-

摘要:

陶瓷-纤维复合靶板是当前轻型防护工程中常用的装甲结构。对于复合装甲的弹道性能国内外学者已经进行了大量的研究,然而对于硬质弹芯和陶瓷-纤维复合靶板作用过程中的破碎特征研究相对较少。弹芯和陶瓷材料的破碎情况对整体复合装甲的防护性能存在较明显的相关性。本文利用12.7 mm的穿甲燃烧弹正侵彻SiC陶瓷-纤维复合靶板,在保证复合靶板面密度相近的情况下,设计了3种不同厚度比的Kevlar/SiC-碳纤维增强环氧树脂基复合材料(T300)-超高分子量聚乙烯(UHMWPE)复合靶板。通过观察回收的弹芯和陶瓷-纤维复合靶板的整体破坏形貌,分析了弹芯和纤维层合板的主要损伤模式。同时对回收的弹芯和陶瓷碎块进行多级筛分称重处理,得到了复合靶板在不同厚度比下弹芯和陶瓷的碎块质量分布符合幂律分布规律。实验结果表明:9 mm SiC+4 mm T300+10 mm UHMWPE的厚度组合在3种不同厚度比中的抗侵彻性能最优,将1 mm厚的SiC陶瓷替换成1 mm厚的碳纤维T300在降低质量的同时可以提高复合装甲的防护能力。复合靶板的失效破坏模式包括陶瓷在高速冲击下形成陶瓷锥和径向裂纹。UHMWPE层合板由拉伸波造成的层间分离现象,背部凸起永久塑性变形及主要为剪切力导致穿孔失效。碳纤维T300层合板损伤形式主要是剪切力导致的十字型脆性断裂,同时伴随冲塞碎块的脱落。弹芯头部主要呈现粉碎性磨蚀破碎,对于较大的弹芯碎块主要是由剪切应力和拉伸应力共同作用下的拉剪失效断裂。陶瓷-纤维复合装甲理想模型是在陶瓷后加入较高刚度的弹性材料同时背板应选择具有高抗拉强度及良好冲击韧性的材料。

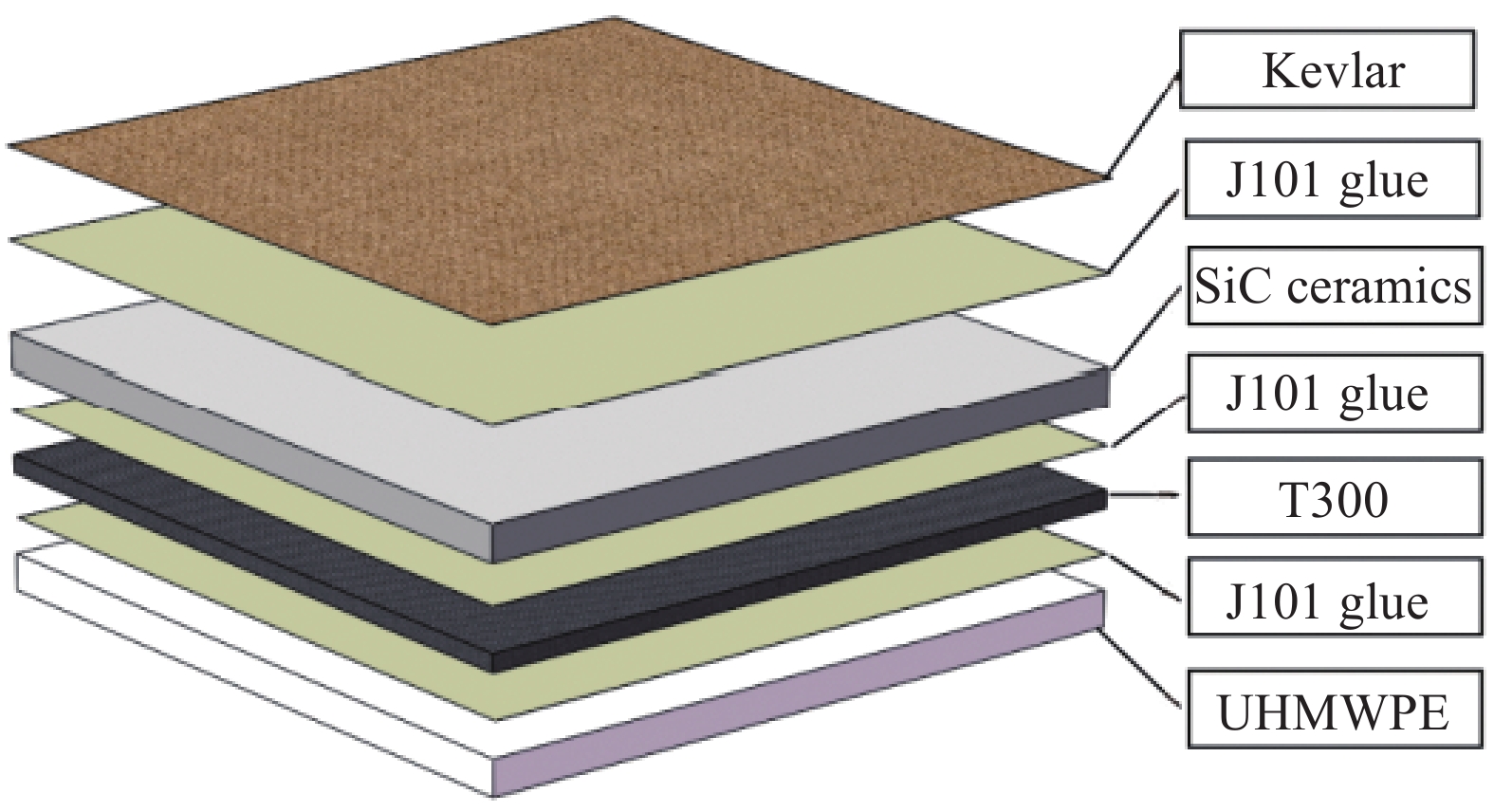

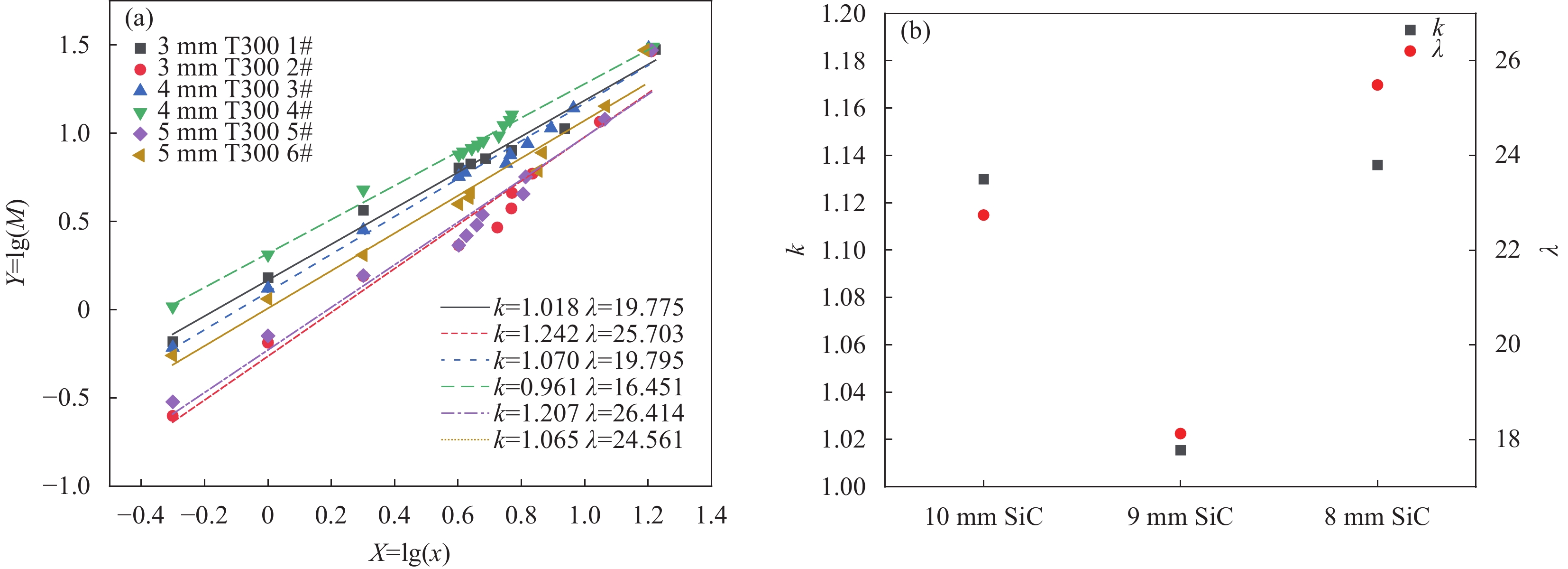

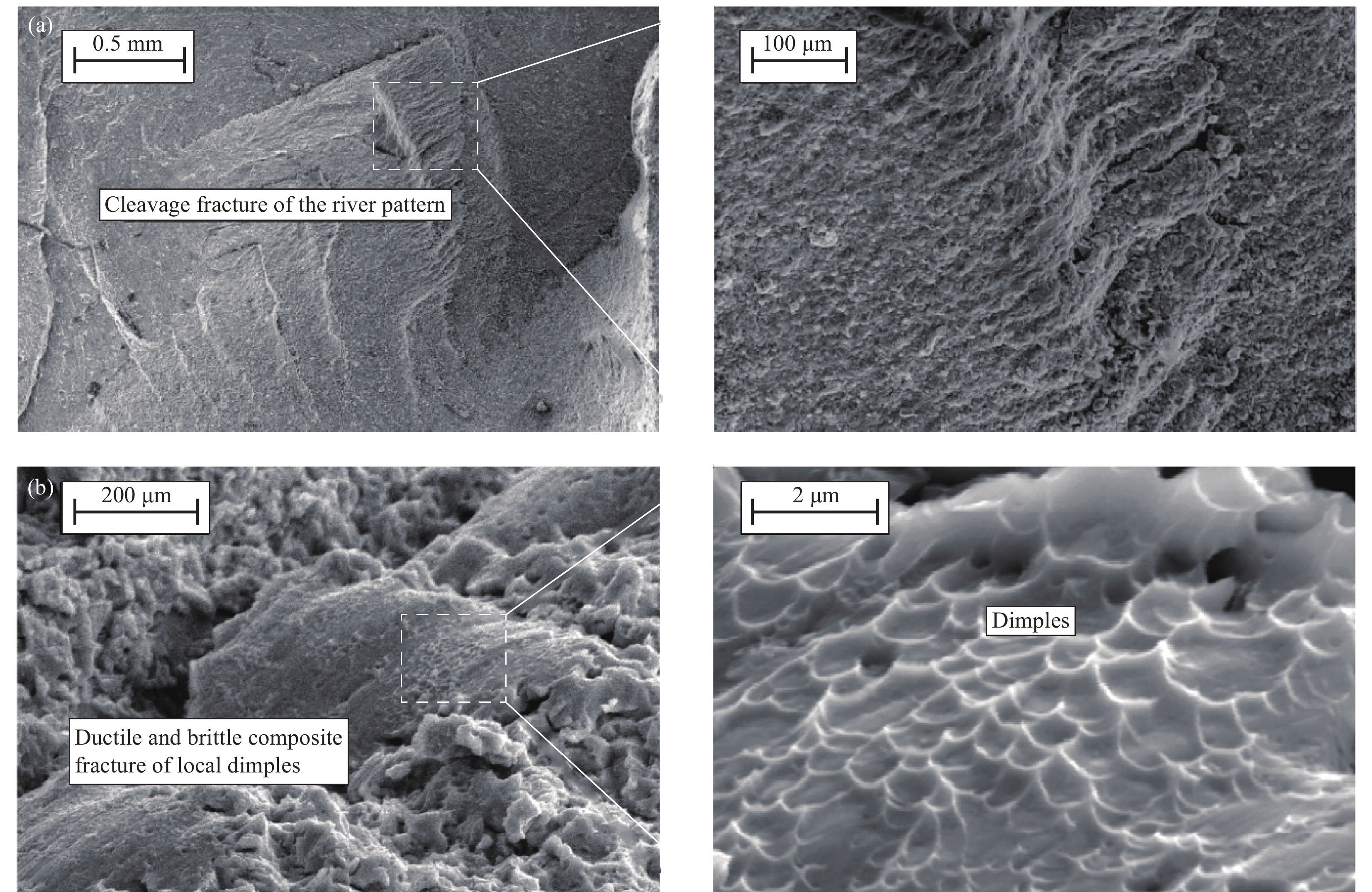

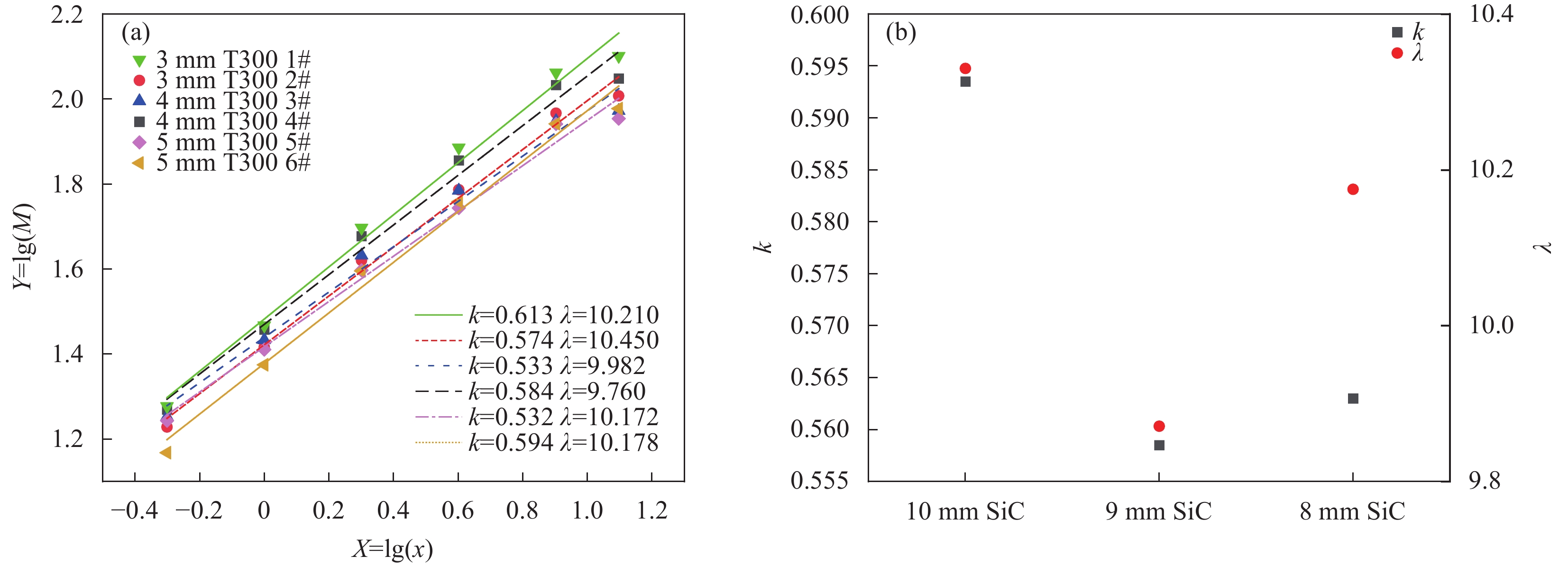

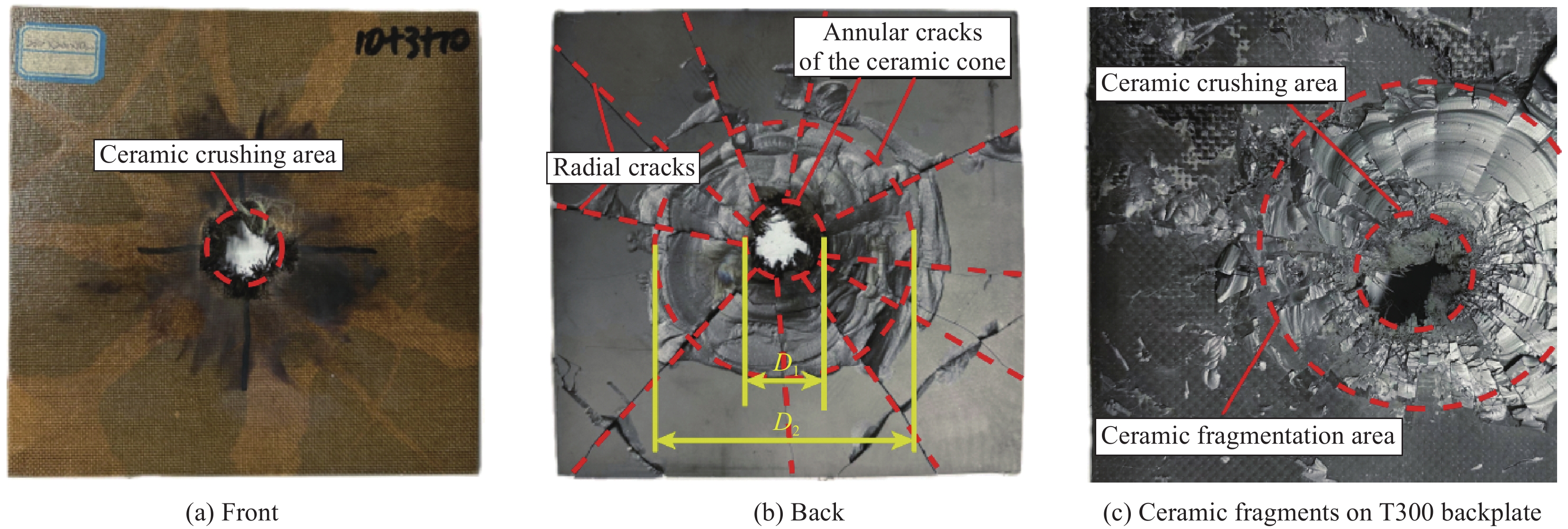

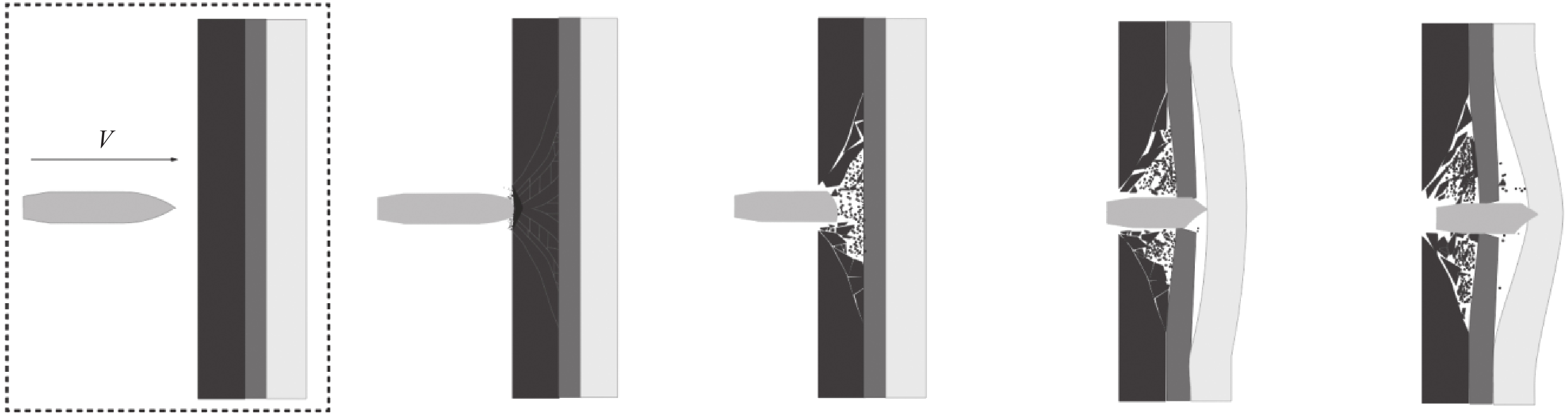

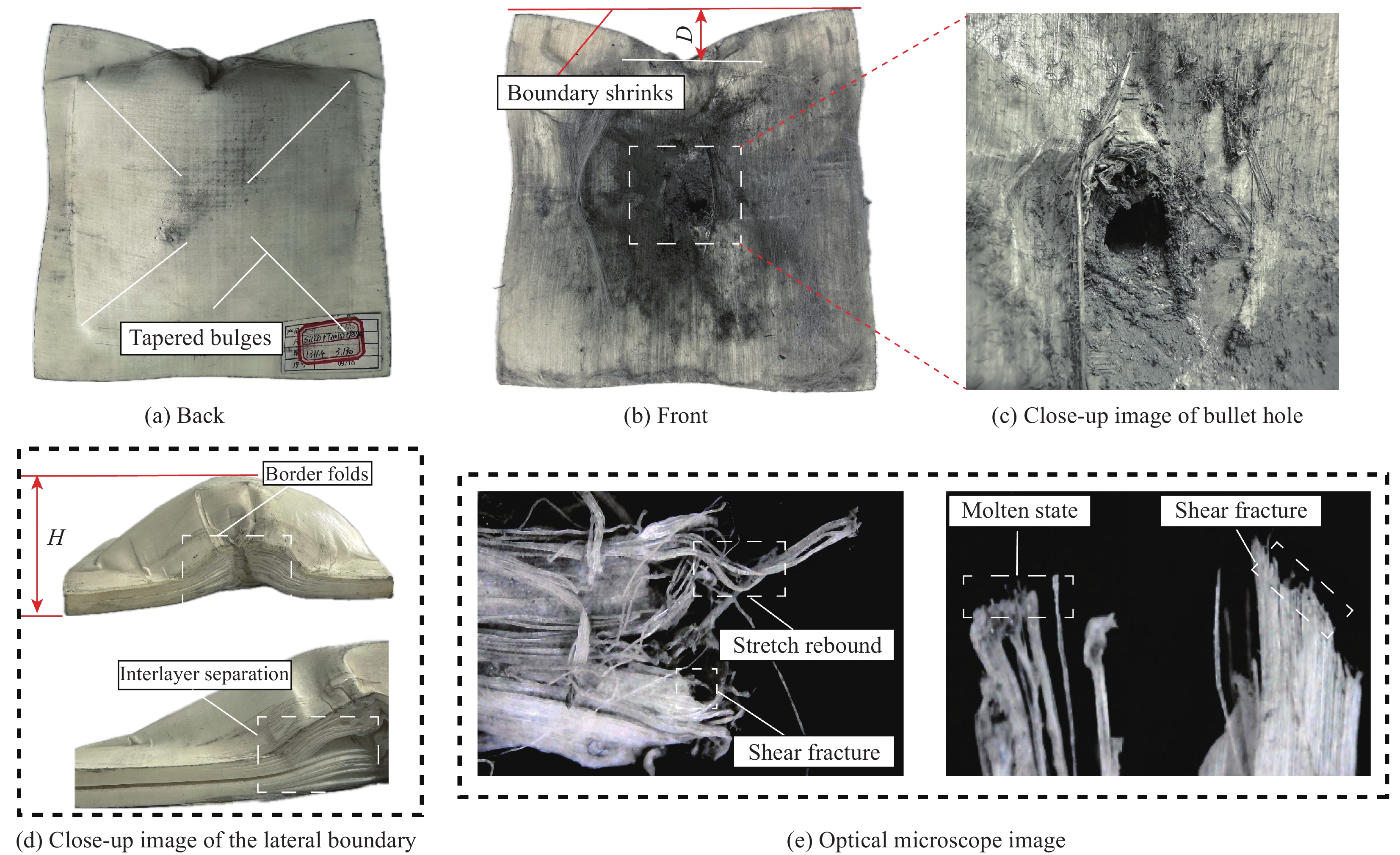

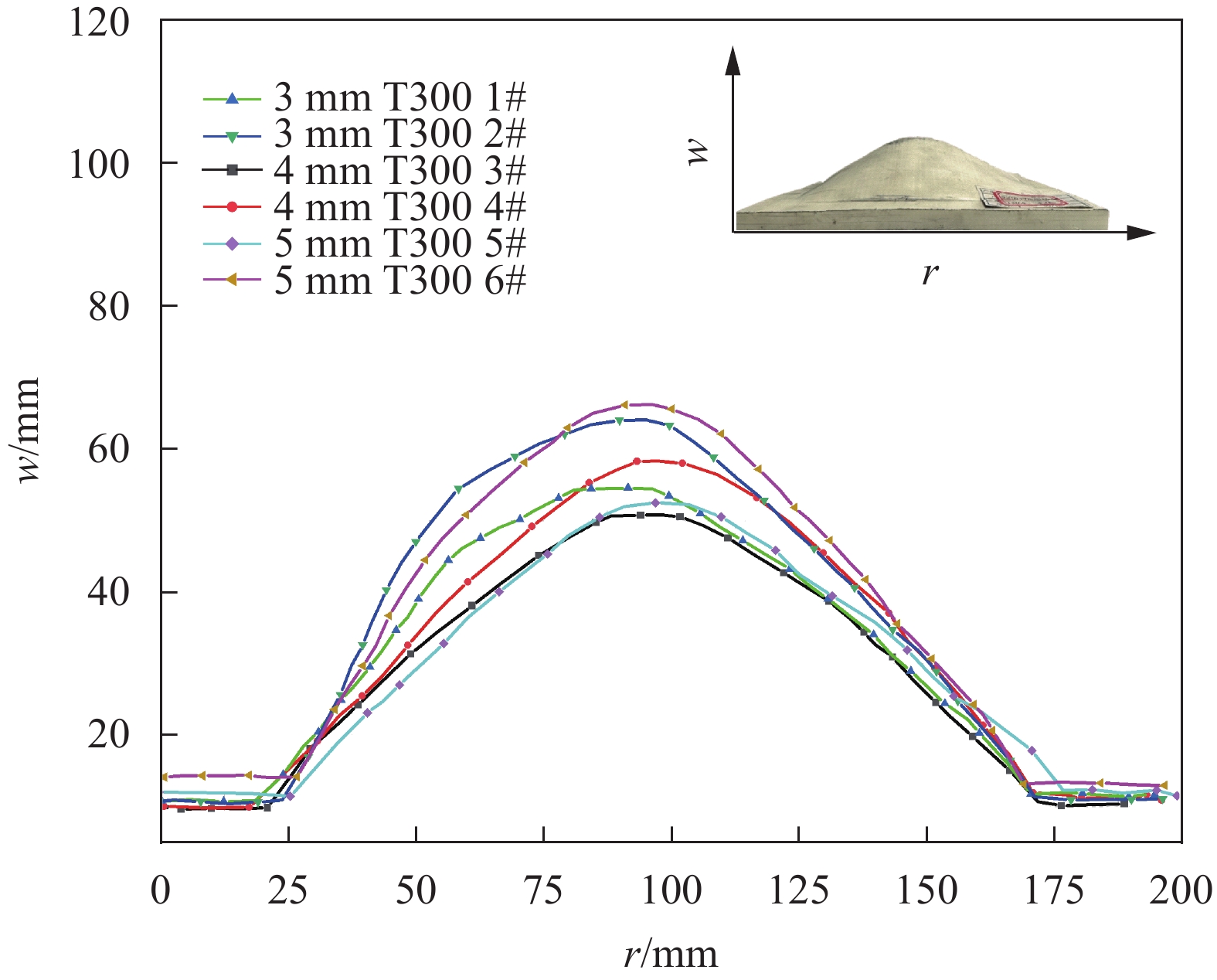

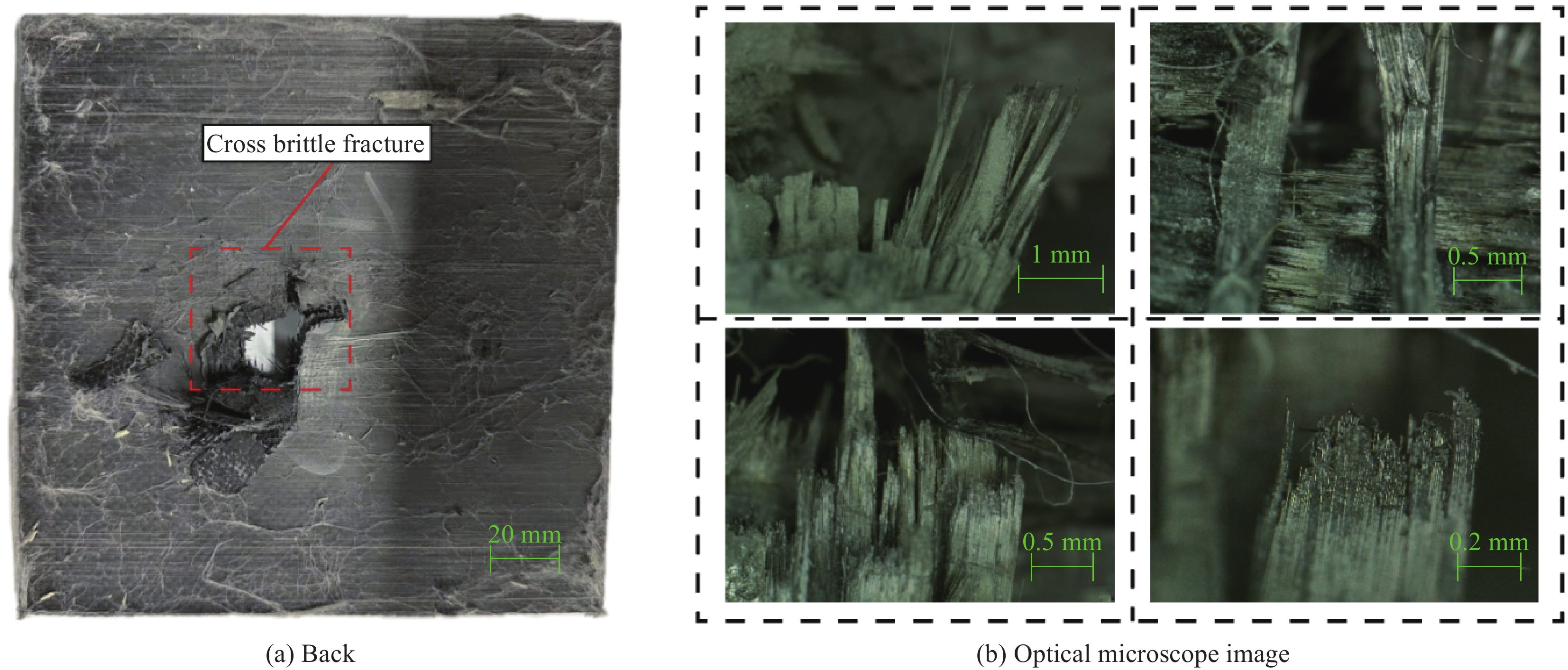

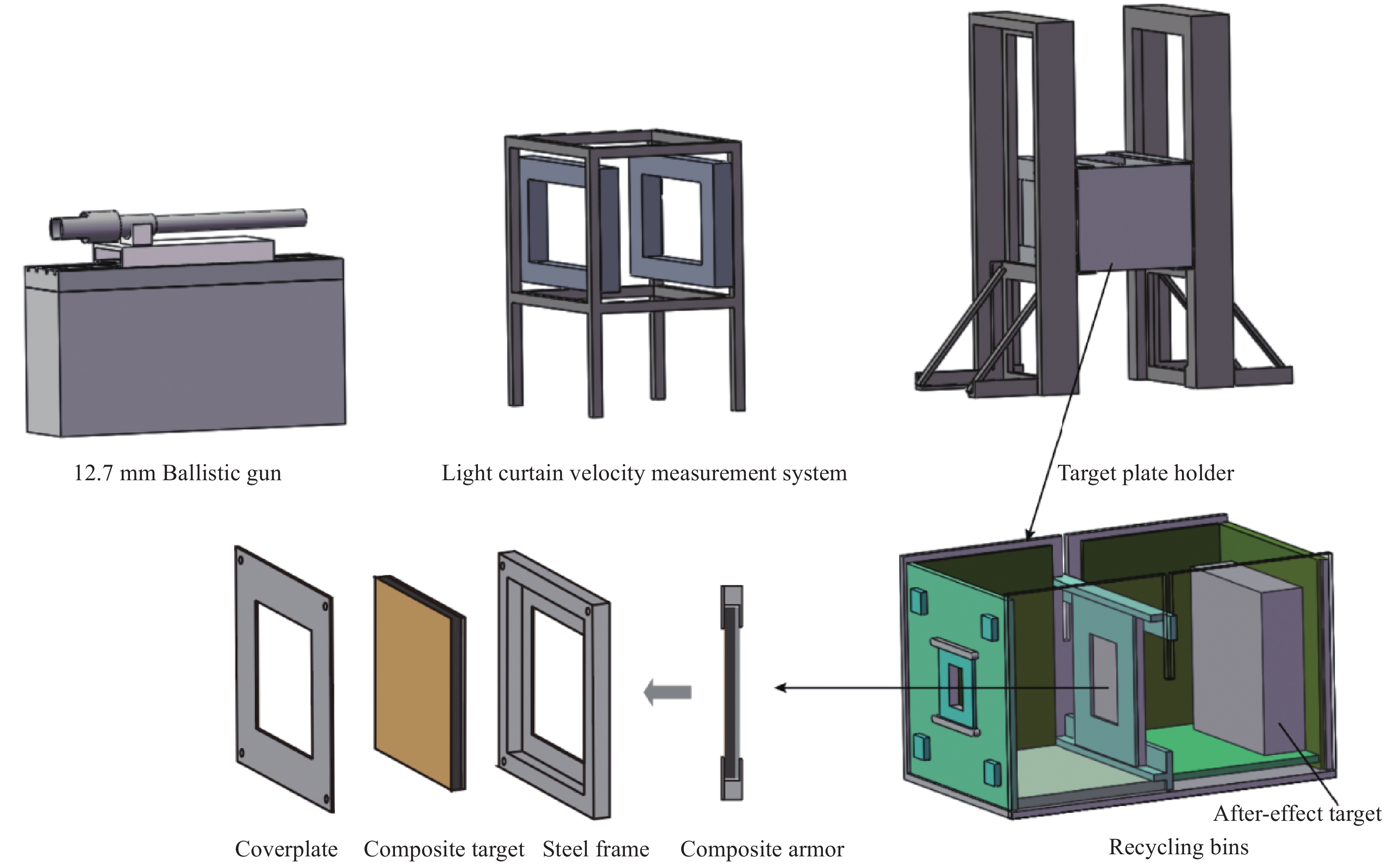

Abstract:Ceramic-fiber composite target plates are commonly used armored structures in current lightweight protection engineering. While a substantial amount of research has been conducted by scholars worldwide on the ballistic performance of composite armor, there has been relatively little study on the fracture characteristics during the interaction process between hard core projectiles and ceramic-fiber composite target plates. The fragmentation patterns of the core and ceramic materials have a significant correlation with the protective performance of the overall composite armor. In this study, 12.7 mm armor-piercing incendiary rounds were fired to penetrate SiC ceramic-fiber composite target plates. Under similar areal density conditions of the composite target plates, three different thickness ratios of Kevlar/SiC-carbon fiber reinforced epoxy resin-based composites (T300) and ultra-high molecular weight polyethylene (UHMWPE) composite target plates were designed. By observing the overall failure morphology of the recovered core and ceramic-fiber composite target plates, the primary damage modes of the core and fiber laminates were analyzed. Moreover, multi-stage sieving and weighing processes were performed on the recovered core and ceramic fragments to investigate the mass distribution of core and ceramics in accordance with power-law distribution under different thickness ratios. The experimental results indicate that the combination of 9 mm SiC+4 mm T300+10 mm UHMWPE exhibits optimal resistance to penetration among the three different thickness ratios tested. Replacing 1 mm thick SiC ceramic with 1 mm thick carbon fiber T300 not only reduces weight but also enhances the protective capability of the composite armor. The failure and fracture modes of the composite target plates include the formation of ceramic cones and radial cracks in ceramics under high-speed impact. The UHMWPE laminate experiences interlayer separation induced by tensile waves, permanent plastic deformation at the backside protrusion, and perforation failure primarily due to shear forces. The damage form of the carbon fiber T300 laminate mainly comprises brittle cross-shaped fractures caused by shear forces, accompanied by the detachment of impacted fragments. The head of the core predominantly exhibits crushing abrasion fractures, while larger core fragments experience combined shear and tensile stresses resulting in shear failure fractures. An ideal model for ceramic-fiber composite armor involves incorporating highly rigid elastic materials behind ceramics, while selecting backplates with high tensile strength and good impact toughness.

-

-

表 1 T12 A和SiC主要力学性能

Table 1 Mechanical properties of T12 A and SiC

Density/(g·cm−3) Young's modulus E/GPa Poisson's ratio γ Static yield strength A/GPa T12 A 7.830 197 0.30 1.65 SiC 3.196 430 0.22 – 表 2 纤维层合板的力学性能

Table 2 Mechanical properties of fiber laminates

Density/

(g·cm−3)Young's

modulus-

longitudinal

direction

E11/GPaYoung's

modulus-

transverse

direction

E22/GPaYoung's

modulus-

normal

direction

E33/GPaPoisson's

ratio

γ12/GPaPoisson's

ratio

γ13/GPaPoisson's

ratio

γ23/GPaShear

modulus

G12/GPaShear

modulus

G31/GPaShear

modulus

G23/GPaCarbon 1.65 33 33 6.27 0.22 0.30 0.30 8.77 6.94 6.94 UHMWPE 0.97 87.72 3.21 3.21 0.20 0.20 0.20 2.47 2.47 0.60 Note: UHMWPE—Ultra-high molecular weight polyethylene. 表 3 实验靶板设计尺寸配置

Table 3 Design size configuration of experimental backplane

Experiment

numberThickness of SiC ceramics/mm Configuration of composite backing plate Areal density/(kg·m−2) Thickness of T300/mm Thickness of UHMWPE/mm 1# 10 3 10 46.57 2# 10 3 10 46.57 3# 9 4 10 45.03 4# 9 4 10 45.03 5# 8 5 12 45.41 6# 8 5 12 45.41 表 4 超高分子量聚乙烯(UHMWPE)层合板的侵彻深度和变形凸起高度

Table 4 Penetration depth and deformation height of ultra-high molecular weight polyethylene (UHMWPE) laminates

Experiment

numberImpact velocity/

(m·s−1)Penetration depth of

UHMWPE/mmAverage penetration

depth of UHMWPE/mmProtrusion height of

UHMWPE/mmAverage protrusion height of

UHMWPE/mm1# 477.4 7.05 12.810 53 48.5 2# 483.2 18.57 44 3# 508.8 3.23 3.955 41 44.0 4# 492.0 4.68 47 5# 491.6 19.61 16.450 41 47.5 6# 514.6 13.29 54 表 5 多级筛分后的弹芯碎片质量

Table 5 Mass of bullet core fragments after multistage screening

Experiment number Mass of core fragments/g Total >8 mm 4-8 mm 2-4 mm 1-2 mm 0.5-1 mm 0-0.5 mm 1# 29.85 19.20 4.54 2.45 2.14 0.86 0.66 2# 29.14 23.24 3.59 0.76 0.90 0.40 0.25 3# 30.42 16.52 8.47 2.60 1.51 0.71 0.61 4# 30.89 18.17 5.29 2.65 2.73 1.01 1.04 5# 29.61 23.95 3.34 0.76 0.85 0.41 0.30 6# 29.58 21.82 3.79 1.93 0.89 0.60 0.55 -

[1] WU C, XIE S, SUN M, et al. Microstructural evolution of amorphous nano carbon reinforced TiB2-SiC-B4C composite ceramics derived from absorbent cotton[J]. Ceramics International, 2022, 48(17): 25637-25641. DOI: 10.1016/j.ceramint.2022.05.020

[2] CHEN Y L, HUANG W K, YEH J N. Theoretical analysis of bulletproof capability of multilayer ceramic composites subjected to impact by an armor piercing projectile[J]. Advances in Materials Science and Engineering, 2021, 2021: 1-13.

[3] YU W, LI W, SHANGGUAN Y, et al. Relationships between distribution characteristics of ceramic fragments and anti-penetration performance of ceramic composite bulletproof insert plates[J]. Defence Technology, 2023, 19: 103-110. DOI: 10.1016/j.dt.2021.10.003

[4] LIU W, CHEN Z, CHENG X, et al. Design and ballistic penetration of the ceramic composite armor[J]. Composites Part B: Engineering, 2016, 84: 33-40. DOI: 10.1016/j.compositesb.2015.08.071

[5] REN K, FENG S, CHEN Z, et al. Study on the penetration performance of a 5.8 mm ceramic composite projectile[J]. Materials, 2021, 14(4): 721. DOI: 10.3390/ma14040721

[6] WANG J H, SHI X M, WANG Q, et al. Study on ballistic performance of metal matrix ceramic ball composite[C]//Journal of Physics: Conference Series. Beijing: IOP Publishing, 2023, 2478(11): 112005.

[7] WILKINS M L. Mechanics of penetration and perforation[J]. International Journal of Engineering Science, 1978, 16(11): 793-807. DOI: 10.1016/0020-7225(78)90066-6

[8] TIAN C, SUN Q, AN X, et al. Influences of ceramic constraint on protection performances of ceramic-metal hybrid structures under impact loads[J]. International Journal of Mechanical Sciences, 2019, 159: 81-90. DOI: 10.1016/j.ijmecsci.2019.05.042

[9] ZHANG Y, DONG H, LIANG K, et al. Impact simulation and ballistic analysis of B4C composite armour based on target plate tests[J]. Ceramics International, 2021, 47(7): 10035-10049. DOI: 10.1016/j.ceramint.2020.12.150

[10] WU Y, WANG X, MA M, et al. Research on theanti-penetration behavior and failure mode analysis of different ceramics[J]. Ceramics International, 2023, 49(24): 39800-39814. DOI: 10.1016/j.ceramint.2023.08.300

[11] 余毅磊, 王晓东, 任文科, 等. 三层组合陶瓷复合装甲的抗侵彻性能及其损伤机制[J]. 兵工学报, 2024, 45(1): 44-57. YU Yilei, WANG Xiaodong, REN Wenke, et al. Anti-penetration performance and damage mechanism of three-layer composite ceramic armor[J]. Acta Armamentarii, 2024, 45(1): 44-57(in Chinese).

[12] 何业茂, 焦亚男, 周庆, 等. 弹道防护用先进复合材料弹道响应的研究进展[J]. 复合材料学报, 2022, 38(5): 1331-1347. HE Yemao, JIAO Yanan, ZHOU Qing, et al. Tensile mechanical behavior of ultra-high molecular weight polyethylene reinforced thermoplastic resin matrix composites for ballistic application[J]. Acta Materiae Compositae Sinica, 2022, 38(5): 1331-1347(in Chinese).

[13] AYDIN M, SOYDEMIR M. Ballistic protection performance of a free ceramic particle armor system: An experimental investigation[J]. Ceramics International, 2021, 47(8): 11628-11636. DOI: 10.1016/j.ceramint.2020.12.295

[14] TAN M, ZHANG X, XIONG W, et al. Influence of layered back plate on the ballistic performance of ceramic armor[J]. Composite Structures, 2023, 308: 116688. DOI: 10.1016/j.compstruct.2023.116688

[15] 贾楠, 焦亚男, 周庆, 等. 碳化硅-超高分子量聚乙烯纤维增强树脂基复合材料复合装甲板的抗穿甲弹侵彻性能及其损伤机制[J]. 复合材料学报, 2022, 39(10): 4908-4917. JIA Nan, JIAO Yanan, ZHOU Qing, et al. Anti-penetration performance of SiC-ultra-high molecular weight polyethylene fiber reinforced resin matrix composite armor plate against armor piercing projectile and its damage mechanism[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4908-4917(in Chinese).

[16] CHOCRON S, CARPENTER A J, SCOTT N L, et al. Impact on carbon fiber composite: Ballistic tests, material tests, and computer simulations[J]. International Journal of Impact Engineering, 2019, 131: 39-56. DOI: 10.1016/j.ijimpeng.2019.05.002

[17] BAO J, WANG Y, AN R, et al. Investigation of the mechanical and ballistic properties of hybrid carbon/aramid woven laminates[J]. Defence Technology, 2022, 18(10): 1822-1833. DOI: 10.1016/j.dt.2021.09.009

[18] YANG S, WANG Y, ZHANG Y, et al. Theoretical analysis for the enhanced mechanism and optimal design of the backing layer on improving the ballistic resistance of the ceramic composite armor[J]. Acta Mechanica Sinica, 2024, 40(3): 123216. DOI: 10.1007/s10409-023-23216-x

[19] HU D, ZHANG Y, SHEN Z, et al. Investigation on the ballistic behavior of mosaic SiC/UHMWPE composite armor systems[J]. Ceramics International, 2017, 43(13): 10368-10376. DOI: 10.1016/j.ceramint.2017.05.071

[20] HE L, ZHONG W, ZHANG F, et al. Bullet-resistant performance of spruce in a sandwich structure[J]. International Journal of Impact Engineering, 2023, 178: 104600. DOI: 10.1016/j.ijimpeng.2023.104600

[21] ZHUANG W, WANG P, AO W, et al. Experiment and simulation of impact response of woven CFRP laminates with different stacking angles[J]. Journal of Shanghai Jiaotong University (Science), 2021, 26: 218-230. DOI: 10.1007/s12204-021-2271-y

[22] XIE Y, WANG T, WANG L, et al. Numerical investigation of ballistic performance of SiC/TC4/UHMWPE composite armor against 7.62 mm AP projectile[J]. Ceramics International, 2022, 48(16): 24079-24090. DOI: 10.1016/j.ceramint.2022.05.088

[23] LI Z, XUE Y, SUN B, et al. Ballistic penetration damages of hybrid plain-woven laminates with carbon, Kevlar and UHMWPE fibers in different stacking sequences[J]. Defence Technology, 2023, 26: 23-38. DOI: 10.1016/j.dt.2022.07.006

[24] 武一丁, 王晓东, 余毅磊, 等. 纤维背板结构对B4C陶瓷复合装甲抗侵彻破碎特性的影响[J]. 爆炸与冲击, 2023, 43(9): 181-193. WU Yiding, WANG Xiaodong, YU Yilei, et al. Affection of fiber backboard structure on the penetration and crushing resistance of B4C ceramic composite armor[J]. Explosion and Shock Waves, 2023, 43(9): 181-193(in Chinese).

[25] LEVY S, MOLINARI J F. Dynamic fragmentation of ceramics, signature of defects and scaling of fragment sizes[J]. Journal of the Mechanics and Physics of Solids, 2010, 58(1): 12-26. DOI: 10.1016/j.jmps.2009.09.002

[26] ZHOU F, MOLINARI J F, RAMESH K T. Effects of material properties on the fragmentation of brittle materials[J]. International Journal of Fracture, 2006, 139(2): 169-196. DOI: 10.1007/s10704-006-7135-9

[27] GONZALEZ-TELLO P, CAMACHO F, VICARIA J M, et al. A modified Nukiyama-Tanasawa distribution function and a Rosin-Rammler model for the particle-size-distribution analysis[J]. Powder Technology, 2008, 186(3): 278-281. DOI: 10.1016/j.powtec.2007.12.011

[28] WU Y, WANG X, MA M, et al. Breaking behavior and stress distribution of T12A hard steel core penetrating ceramic/aluminum alloy lightweight composite armor[J]. Materials Today Communications, 2023, 37: 107115. DOI: 10.1016/j.mtcomm.2023.107115

[29] SUN M, BAI Y, LI M, et al. Structural design and energy absorption mechanism of laminated SiC/BN ceramics[J]. Journal of the European Ceramic Society, 2018, 38(11): 3742-3751. DOI: 10.1016/j.jeurceramsoc.2018.04.052

[30] 余毅磊, 蒋招绣, 王晓东, 等. 轻型陶瓷/金属复合装甲抗垂直侵彻过程中陶瓷碎裂行为研究[J]. 爆炸与冲击, 2021, 41(11): 82-91. DOI: 10.11883/bzycj-2021-0134 YU Yilei, JIANG Zhaoxiu, WANG Xiaodong, et al. Research on ceramic fragmentation behavior of lightweight ceramic/metal composite armor during vertical penetration[J]. Explosion and Shock Waves, 2021, 41(11): 82-91(in Chinese). DOI: 10.11883/bzycj-2021-0134

[31] BENLOULO I S C, SANCHEZ-GALVEZ V. A new analytical model to simulate impact onto ceramic/composite armors[J]. International Journal of Impact Engineering, 1998, 21(6): 461-471. DOI: 10.1016/S0734-743X(98)00006-2

[32] WANG X, YU Y, ZHONG K, et al. Effects of impact velocity on the dynamic fragmentation of rigid-brittle projectiles and ceramic composite armors[J]. Latin American Journal of Solids and Structures, 2021, 18(8): e410.

[33] GAO Y, ZHANG W, XU P, et al. Influence of epoxy adhesive layer on impact performance of TiB2-B4C composites armor backed by aluminum plate[J]. International Journal of Impact Engineering, 2018, 122: 60-72. DOI: 10.1016/j.ijimpeng.2018.07.017

[34] NAIK N K, KUMAR S, RATNAVEER D, et al. An energy-based model for ballistic impact analysis of ceramic-composite armors[J]. International Journal of Damage Mechanics, 2013, 22(2): 145-187. DOI: 10.1177/1056789511435346

-

其他相关附件

-

-

陶瓷-纤维复合靶板是当前轻型防护工程中常用的装甲结构。对于复合装甲的弹道性能国内外学者已经进行了大量的研究,然而对于硬质弹芯和陶瓷-纤维复合靶板作用过程中的破碎特征研究相对较少。弹芯和陶瓷材料的破碎情况对整体复合装甲的防护性能存在较为明显的相关性。

本文利用12.7 mm的穿甲燃烧弹正侵彻三种不同厚度比的Kevlar/SiC-碳纤维增强环氧树脂基复合材料(T300)-超高分子量聚乙烯(UHMWPE)复合靶板。通过观察回收的弹芯和陶瓷-纤维复合靶板的整体破坏形貌,分析了弹芯和纤维层合板的主要损伤模式。同时对回收的弹芯和陶瓷碎块进行多级筛分称重处理,得到了复合靶板在不同厚度比下弹芯和陶瓷的碎块质量分布符合幂律分布规律。实验结果表明9 mmSiC+4 mmT300+10 mm UHMWPE的厚度组合在三种不同厚度比中的抗侵彻性能最优,将1 mm厚的SiC陶瓷替换成1 mm厚的碳纤维T300在降低质量的同时可以提高复合装甲的防护能力。

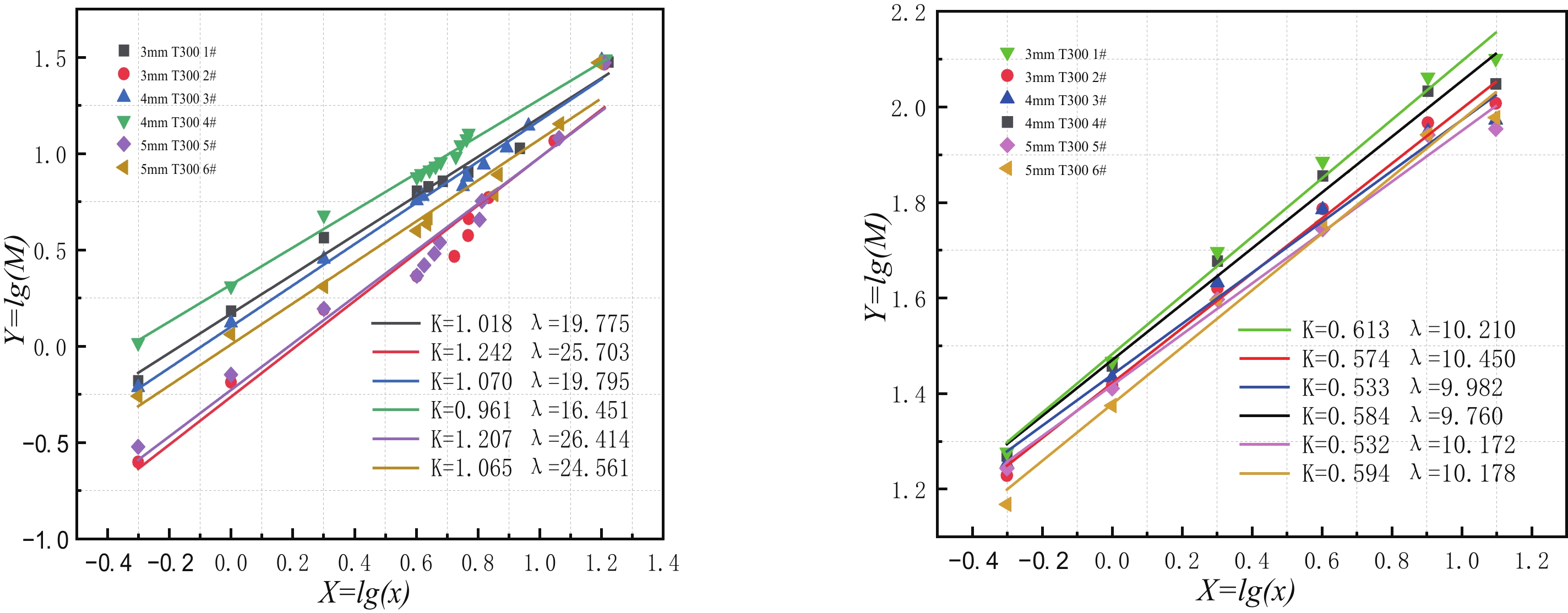

弹芯和陶瓷碎块累积质量的对数与弹芯和陶瓷碎块粒径对数的拟合

下载:

下载: