Research progress of plant-derived porous carbon materials in supercapacitors

-

摘要:

超级电容器是一种功率密度高、充放电速率快、使用寿命长、应用范围广的储能装置。影响其性能的主要因素是电极材料,故导电性好、原料易得、成本低、环境友好的电极材料的开发是当今超级电容器的研究重点。植物衍生多孔碳材料因其满足上述要求而受到广泛关注。本文按照前驱体的来源对植物衍生多孔碳材料进行了分类,介绍了近年来国内外植物衍生多孔碳材料用于超级电容器电极材料的研究成果,讨论了植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战,并对植物衍生多孔碳材料的发展前景进行了展望。

Abstract:Supercapacitors represent an energy storage device renowned for its high-power density, rapid charging/discharging rates, long service life, and versatility across diverse applications. The primary factor influencing their performance lies in the electrode materials. Consequently, the development of electrode materials that are conductive, readily available, cost-effective, and environmentally friendly has emerged as a pivotal research focus in the field of supercapacitors. Plant-based porous carbon materials have garnered significant attention due to their adherence to these criteria. This paper categorizes plant-based porous carbons based on their precursor sources, reviews recent research achievements worldwide on their application as electrode materials in supercapacitors, discusses the challenges faced by plant-based porous carbon electrode materials in this domain, and offers an outlook on their promising future.

-

Keywords:

- plant-derived /

- carbon materials /

- supercapacitors /

- electrode materials /

- research progress

-

混凝土是最常用的土木建筑材料,在服役过程中会受到各种复杂环境因素的影响[1],使其内部产生裂纹,承载力下降,而硅酸盐水泥作为混凝土重要的组成部分,在工作时会释放大量的二氧化碳污染环境,同时混凝土自重大,给结构安全带来了潜在威胁。这就要求建构筑物在具有较好承载力的情况下,还具备耐腐蚀、强度高、重量轻和环保的特性。于是各种轻质、环保、高强度的混凝土复合材料发展了起来[2-4]。

玻璃纤维增强塑料管(Glass-Fiber Reinforced Plastic Tube, GFRP Tube)因较好的耐腐蚀性、更高的变形性能和更好的冲击性能在土木结构领域应用越来越广泛。同时钢纤维作为一种高刚度、高抗拉强度的材料,将其适量的添加到混凝土中后,钢纤维可以提供裂纹桥接作用,防止混凝土裂纹的生长和扩展,提高其抗冲击、抗拉、抗压、弯曲强度和延性[5-8]。其次,为克服混凝土自重大和污染环境这些弱点,木材和混凝土材料结合从而形成木-混凝土复合材料,这不仅能减少硅酸盐水泥的用量,降低二氧化碳的排放,还能提高混凝土结构的延性和能量吸收[9],且在保证与原结构同等承载力的情况下减轻结构自重[10-11]。因此,综合GFRP、钢纤维和木材的各个优点,本文设计了GFRP管约束内含木柱的钢纤维混凝土的复合材料,分析其力学性能和在受荷过程中的损伤演化情况,为复合材料的应用提供有力的评价。

随着无损技术的发展,声发射(Acoustic emission, AE)技术在由钢纤维、木材、FRP和混凝土材料的损伤监测中表现出独特的优势。Banjara等[12]通过声发射累积能量、振铃计数和幅值等参数反映了GFRP加固混凝土梁在剪切破坏过程中不同类型裂纹的萌生和扩展。Diakhate等[13]的研究表明,声发射技术结合有限元分析能够清晰监测木材内部裂纹的扩展情况。此外,这些声发射参数还能用于划分混凝土开裂的不同阶段[14]。Ren等[15]研究了钢纤维含量对钢纤维混凝土在劈裂损伤过程中的声发射信号特征的影响,结果显示,声发射计数和能量与混凝土基体开裂及钢纤维含量密切相关。由于钢纤维在混凝土基体中的受力脱粘与拔出过程类似于钢筋混凝土中钢筋的粘结滑移行为,声发射技术在监测钢筋混凝土中钢筋的受力拔出过程中也展现了显著优势。Zhang等[16]利用声发射小波变换研究了冻融环境下钢纤维混凝土的动态劈裂拉伸损伤,发现掺入钢纤维能够有效抑制裂纹扩展。从小波能量分析的角度来看,高频小波能谱系数随着裂纹数量增加而升高,而低频小波能谱系数则相反。邱继生等[17]基于钢纤维煤矸石混凝土在受压过程中释放的声发射能量,定义了损伤变量并建立了损伤演化模型。研究表明,声发射特性参数与钢纤维煤矸石混凝土内部裂纹的形成、扩展和贯通密切相关,而钢纤维含量直接影响声发射信号的强度。Li等[18]通过分形理论分析了钢纤维混凝土的裂纹分形特征,结果显示裂纹分形维数与钢纤维含量呈正相关。较高钢纤维含量的混凝土裂纹群发展得更为广泛且完整,导致混凝土表面更加破碎,砂浆脱落面积更大。因此,钢纤维的掺量对钢纤维复合材料的性能具有至关重要的影响。

本文采用声发射技术对4组不同钢纤维掺量的GFRP管约束内含木柱的钢纤维混凝土复合材料的轴向压缩损伤过程进行了实时监测,分析了其力学性能、声发射信号特征、裂纹扩展特征和内部损伤程度,并在此基础上建立了基于声发射累积事件数和应力的损伤演化模型,为GFRP管约束内含木柱的钢纤维混凝土的损伤评估提供一定依据。

1. 试验概况

1.1 试验材料

以钢纤维体积含量(0%、1%、1.5%和2%)为变量制作了4组尺寸为106 mm× 106 mm× 200 mm的GFRP管约束内含木柱的钢纤维混凝土试件,分别命名为SF-0,SF-1,SF-1.5和SF-2。混凝土采用强度等级为 42.5 MPa 的普通硅酸盐水泥,细骨料为天然河砂(粒径 0.15~2 mm),粗骨料为天然碎石(粒径 5~15 mm),水灰比为0.52。依据国家标准 GB/T

50107 -2010 [19] 制作试件,混凝土材料参数见表1。钢纤维由供应商提供,其尺寸及力学性能参数详见表2。GFRP 管的截面尺寸为 106 mm× 106 mm,高度为 200 mm,壁厚为 3 mm,由瑞康玻璃钢有限公司提供,参数见表3。木材选自中国东北地区的樟子松,尺寸为 60 mm× 200 mm(直径×高度),含水率为 8%~13%,参数如表4所示。表 1 混凝土配合比Table 1. Mix proportion of core concreteSpecimen ID Unit weight/(kg/m3) Water Cement Sand Gravel Plasticizer Steel fiber SF-0 221.3 423.5 810.1 916.5 2.5 (2%) 0 (0%) SF-1 228.7 433.2 811.9 901.4 2.5 (2%) 79.3 (1%) SF-1.5 237.7 445.6 801.3 892.8 2.5 (2%) 115.2 (1.5%) SF-2 245.3 452.2 806.3 880.2 2.5 (2%) 156.8 (2%) Note: Specimen ID "SF-1" indicates that the steel fiber volume content is 1%. 表 2 钢纤维物理力学参数Table 2. Physical and mechanical properties of hooked steel fiber.Dimensions Density/

(kg·m−3)Tensile

strength/

MPaElasticity

modulus/

GPaPoisson

ratio

15 mm × Φ2 mm 7.85 2900 200 0.25 表 3 GFRP管的基本力学性能Table 3. Mechanical Properties of GFRP tubeDirection of fiber molding Elastic modulus/MPa Tensile strength/MPa Compressive strength/MPa Longitudinal direction 14,132 271 120 Lateral direction 9962 180 120 表 4 木材材料性能Table 4. Material properties of woodDensity/

(kg·m−3)Elastic

modulus/MPaTensile

strength/MPaCompressive

strength/MPa0.45 11,000 52 40 1.2 试验制备

为便于试件的制备,设计了若干300 mm× 300 mm× 40 mm定位试件的木板,在木板中心处切割了一个与木材直径相同的圆柱形空心部分用于固定木材,同时在木板相应位置切割了4个与木销尺寸相同的孔洞,试件被放置在定位板中间并对齐,将木销插入孔洞定位试件,见图1(a)~1(c)。参照规范JG/T 472-2015[20],钢纤维以多次少剂量均匀分散加入到混凝土中,将搅拌完成后的钢纤维混凝土倒入模具中并用振动台振实,见图1(d)。24 h后拆除定位板,并使用打磨机平整表面,在标准养护条件下养护28天。养护完后的试样和具体尺寸见图1(e)和1(f).

1.3 试验设备

试验设备由WAW-1000 B微机电液伺服万能试验机、DH3816 N位移采集系统(上海松顿机械设备有限公司)和DS5声发射采集系统(北京软岛时代科技)组成。声发射传感器纵向等距排列在试件两侧,共6个传感器,压力机左右两侧放置LVDT位移传感器用于测定压力机竖向加载位移,具体见图2。测试之前根据ISO 12713:1998[21], ISO 12714:1999[22]和ASTM E976-15 (2021)[23]对AE系统进行调整,为了降低噪音的影响,通道门限值设为20 mV,传感器频率范围为20~400 kHz,前置放大器增益为20~40 dB。

试验加载方式选择轴向位移加载方式,加载速率保持0.2 mm/min,加载过程中同步进行声发射信号采集和DN3816 N静态信号采集,加载装置如图2所示。

2. 力学性能分析

2.1 荷载-位移曲线分析

图3比较了各组试件的轴压荷载位移曲线。可以看出,各组试件荷载位移曲线趋势相似,且均出现了三个典型区域(Region1-Region3),这说明试件内部发生了3处明显的破坏,试件SF-2荷载位移曲线出现了多次连续的抖动,这可能是由钢纤维受力或间断受力引起的。各试件峰值荷载和位移延性系数具体数值如表5所示。试件SF-0、SF-1、SF-1.5和SF-2的峰值荷载分别为328 kN、402 kN、445 kN和404 kN、位移延性系数分别为3.38、3.48、3.54和3.23,与未掺入钢纤维的试件SF-0相比,钢纤维体积掺量为1%、1.5%和2%的试件峰值荷载分别提高了22.6%、35.7%和23.2%,钢纤维体积掺量为1%、1.5%位移延性系数比未掺入钢纤维的试件相比分别提高了2.96%和4.73%,钢纤维体积掺量为2%位移延性系数降低了4.44%。

表 5 不同钢纤维含量混凝土试件峰值荷载和位移延性系数Table 5. Peak load and displacement ductility coefficient of concrete specimens with different steel fiber contentsSpecimen Peak load/kN Δy/mm Δu/mm μ The increase of peak load/% SF-0 328 0.47 1.59 3.38 0 SF-1 402 0.49 1.71 3.48 22.6 SF-1.5 445 0.50 1.77 3.54 35.7 SF-2 404 0.48 1.55 3.23 23.2 Notes: "Δy"—Displacement of concrete specimens under peak load; "Δu"—Displacement when the load drops to 0.75 peak load; "μ"—Displacement ductility coefficient. 通过以上分析可知,1.5%的钢纤维掺量的试件峰值荷载和位移延性系数最高,且提升幅度最大,与其相比,2%的钢纤维掺量的试件力学性能反而降低了。可见,适量钢纤维的掺入可以提高试件的极限承载力和延性,而过量掺入则会适得其反,导致宏观破坏的提前。因为掺入钢纤维能够在混凝土基体中形成不规则但致密的空间结构,强化试件抗压性能,提高结构延性,所以延缓了试件的破坏,但当钢纤维掺量达到一定程度后,如继续提高掺量会使得纤维产生团聚现象,导致纤维难以均匀分布,这将会降低纤维混凝土密实度,导致试件的极限承载力下降,增大试件脆性破坏的可能性。综上所述,钢纤维体积掺量为1.5%时,单轴压缩性能最优。

2.2 破坏形式分析

试件整体和内部混凝土的破坏形式如图4所示,可以看出试件整体的破坏特征均表现为GFRP管边缘断裂,GFRP管中部与混凝土分离、鼓曲。加载过程中均能听到明显的破坏声,相比于试件SF-0,其他3组试件的破坏声音明显减小,且加载过程中还会出现持续低声。各试件具体破坏形式的差异主要体现在内部混凝土,试件SF-0出现3条较宽的裂纹,试件SF-1表现出相同数量的裂纹,但裂纹宽度小于试件SF-0,而试件SF-1.5和SF-2的裂纹数量则明显增加,宽度明显减小。通过分析试件整体和内部混凝土的破坏形式表明,钢纤维的掺入对试件整体的破坏形式影响不大,其差异主要体现在内部混凝土裂纹的数量和尺度,钢纤维的掺入传递了局部应力,降低了损伤程度,减小了试件宏观裂纹的宽度,增加了微裂纹的数量。

3. 声发射信号特征分析

3.1 AE振铃计数特征

声发射特征参数与材料内部损伤密切相关,声发射振铃计数、能量等特征参数能够表征钢纤维混凝土、木材和GFRP复合材料的受力损伤过程。

图5为试件过程中的荷载、振铃计数和累积振铃计数关系图,从图中可看出所有试件的参数变化曲线均表现出相同的趋势,并出现了声发射信号突增的3个特征区域(A,B,C)。因此可将试件的损伤过程用3个标志事件来描述,分别为混凝土开裂、木材开裂和GFRP管断裂。

从图5可知,试件在受压初期产生少量声发射信号,表现为较低的振铃计数。这主要是由于试验机压头与试件接触时的摩擦及对试件原始缺陷的挤压所致。随着初始缺陷被压实,声发射信号逐渐活跃。当荷载加载至A点附近时,振铃计数达到第一个峰值,同时可听见明显的开裂声。其中,试件SF-0的开裂声最为显著,振铃计数峰值也最高(试件 SF-0、SF-1、SF-1.5 和 SF-2 的最大振铃计数值分别为 371×10²、15.8×10²、1.9×10²和16.8×10²)。这表明,钢纤维的加入优化了混凝土内部结构,抑制了微裂纹的产生,从而降低了声发射信号强度。然而,当钢纤维体积掺量达到2%时,振铃计数反而增加,可能是由于钢纤维过量导致的结团现象降低了钢纤维与混凝土的界面粘结力,增加了声发射信号强度。这一规律不仅体现在A点的声发射信号强度变化上,在试件的整个损伤过程中,声发射信号强度的整体变化趋势也类似。此外,通过结合荷载-位移曲线可以推测,A 点所在的绿色区域可能发生了混凝土的初始开裂。

在第一个宏观开裂事件结束后,振铃计数趋于平缓,表明裂纹进入缓慢扩展阶段。直到荷载加载至B点,荷载-位移曲线出现转折点,振铃计数达到第二个峰值。这表明试件内部出现了新的宏观裂纹。然而,与第一个峰值相比,第二个峰值的振铃计数显著降低。这是由于木材作为一种延性材料,其破坏时的声发射信号强度低于脆性较大的素混凝土。由此推测,B点所在的红色区域可能为木材的开裂现象。然而,对于掺入过量钢纤维的试件,这一规律变得不明显。这可能归因于以下两点:其一,钢纤维的过量掺入改变了试件各部分材料的受力特性,导致振铃计数和力学性能的变化;其二,即使试验木材均来自同一批次树木,其天然缺陷仍可能引起力学性能的差异。

随着加载继续进行,GFRP 管开始出现明显的鼓屈现象,但尚未完全开裂。此阶段振铃计数变得密集,但未超过前两个峰值,表明试件内部发生了大量小尺度损伤事件,如钢纤维振动及脱粘现象[24]。这些小裂纹逐渐扩展并合并,最终形成宏观裂纹。当荷载达到 C 点时,可清晰观察到 GFRP 管的断裂,此时振铃计数的第三个峰值产生。在 GFRP 管断裂后,掺入过量钢纤维的试件(如SF-2)还出现了钢纤维断续受力、拔出及脱粘现象,从而产生了振铃计数密集高峰。

通过上述分析可见,钢纤维的掺量对试件内部损伤过程及声发射信号的演化具有显著影响。合理掺量的钢纤维可有效改善材料性能,而过量掺入则可能带来不利影响。

3.2 声发射峰值频率特征

峰值频率是指声发射频域波形中最大振幅对应的频率,是通过对每个声发射信号进行快速傅里叶变换(Fast Fourier transform,FFT)分析所提取到的[25],它可以反应材料损伤过程中裂纹的类型、大小和规模。一般来说,大尺度损伤或大裂纹对应低频信号,小尺度损伤或小裂纹对应高频信号。图6为各组试件峰值频率统计学箱形图,用于描述数据的分散情况,基于峰值频率的范围,将其分为4个峰值频段:低频段(0~100 kHz)、中频段(100~200 kHz)和高频段(200~300 kHz)。

从图中可以看出,各试件的箱形图的四分位间距逐渐变宽,箱体中位数偏向两端,其中试件SF-0的四分位间距最窄,试件SF-1.5的四分位间距最宽,这表明数值总体呈现偏态分布特征,而试件SF-1.5的声发射数据点的分布具有更高的离散程度。随着钢纤维掺入量的增加,箱形图的数据分布逐渐向更高的上四分位点和更长的上盒线移动和转变,即高峰值频段信号逐渐增多,低峰值频段信号分布减少,并逐渐向中高峰值频段过渡,这与Li[26] and Behnia[27]的研究结果相似。根据峰值频率特征研究发现未掺钢纤维的试件为大尺度损伤,掺入不同含量钢纤维试件的为小尺度损伤。这是因为未掺钢纤维的试件局部会产生宏观裂纹导致发生脆性破坏,而掺入不同含量钢纤维试件由于钢纤维传递了局部应力使得混凝土产生了大量的二次裂纹,其产生的声发射高频信号是由钢纤维的变形、摩擦和脱粘所引起的,且掺量越多现象越明显。

3.3 声发射RA-AF值特征

RA-AF(RA=上升时间/幅度,AF=振铃计数/持续时间)组合分析是一种基于日本建筑规范 JCMS-Ⅲ B5706 [28] 的方法,被广泛应用于混凝土内部裂纹类型的识别,其统计分析结果可作为定量判断宏观断裂机制的指标。其中,AF/RA的比值被定义为k当 AF/RA < k时,表现为高RA和低AF的信号被定义为剪切裂纹;而低RA和高AF的信号则对应拉伸裂纹。根据 Li [18]和 Ohno [29]的建议,k值选择80较为合适。

图7 展示了 RA/AF 值随时间变化的三维分布图,采用k值为斜率的分界线划分裂纹类型,并计算了不同裂纹类型的比例以及混凝土的破坏特征。试件 SF-0、SF-1、SF-1.5 和 SF-2的剪切裂纹比例分别为 26.4%、28.4%、31.1%和32.2%。各组试件的 RA和AF 值主要集中在0-5 ms·V-1和0-400 kHz范围内。从图7(a)和7(b)的对比中可以看出,钢纤维的掺入减少了以拉伸裂纹为特征的蓝色数据点数量,促使裂纹类型向以剪切裂纹为特征的数据点偏移。图7(a)~7(c)还表明,数据点在加载早期的分布数量逐渐减少,而整体分布向加载末期偏移。当钢纤维掺量达到2%时,数据点的分布趋于均匀。

以上结果表明,钢纤维的掺入推迟了裂纹的出现时间,提高了剪切裂纹的比例,并使断裂模式逐渐向复合型断裂转变。这种变化与纤维与基体之间的摩擦、脱粘及拔出效应密切相关。当钢纤维的体积掺量达到2%时,剪切裂纹比例的提升趋势有所减缓,这是由于钢纤维过多可能发生团聚,降低基质密度,从而增加拉伸裂纹的比例。在破坏特征方面,未掺钢纤维的试件SF-0和掺1%钢纤维的试件SF-1均产生了3条较宽的主裂纹,此时钢纤维对大裂纹的抑制效果和对剪切裂纹比例的提升尚不显著。而当钢纤维掺量提高至1.5%时,裂纹形式发生明显改变,试件表面产生了5条较窄的主裂纹,同时部分微裂纹向侧面延伸形成剪切裂纹。当掺量达到2%时,裂纹宽度进一步减小,裂纹数量增多,微裂纹向侧面延伸的现象更加明显。

综上所述,RA-AF 值分析的裂纹类型与混凝土实际破坏特征吻合良好。钢纤维的掺入有效减少了试件的宏观裂纹宽度,提高了剪切裂纹比例,显著改善了裂纹分布和破坏模式。

3.4 声发射事件数损伤模型

通过上述分析可以看出,声发射参数与试件的损伤过程密切相关,试件在轴压过程中的损伤程度与裂纹数量和尺度有关,为评估GFRP管约束内含木柱的钢纤维混凝土准脆性材料开裂过程的多尺度性,建立了基于声发射事件数的损伤演化模型:

引入损伤参数D:

D=1−SeS=SdS (1) S=Se+Sd (2) D为试件的损伤参数;Se为当应力为σ时的试件未产生损伤的面积(mm2);Sd为当应力为σ时的试件产生损伤的面积(mm2);S为试件的初始面积(mm2)。损伤参数D越大,表明损伤越严重,D=0表示试件没有发生损伤,D=1表示试件完全破坏。

假定Cm为整个加载过程中的声发射总累积事件数,Cd为单位面积所释放的声发射累积事件数,则有:

Cd=CmS (3) 将应力为σ、损伤面积为Sd时的声发射累积事件数表示为

C=SdCd=SdCmS (4) 将(4)代入(1)得到损伤参数和事件数的关系:

D=CCm (5) 在损伤统计理论中,钢纤维混凝土被认为是由许多具有不同断裂概率的微元组成的复合材料,其在受力过程中的断裂概率函数可以用 Weibull函数来描述[30]。假设应力与声发射事件数之间的关系符合双参数Weibull函数[31],建立单轴压缩荷载过程中概率密度函数和应力之间的关系:

C(σ)=F(σ)=mθ(σθ)m−1exp[−(σθ)m] (6) σ为Weibull分布的随机变量,θ为尺度参数,m为形状参数。

损伤参数D可以表示为

dDdσ=C(σ) (7) 对式(7)进行积分得到应力σ时的Weibull累积分布函数,即损伤演化方程:

D=∫σ0C(σ)dσ=1−exp[−(σθ)m] (8) 将(8)代入(5)得到应力σ时的声发射累积事件数:

C=Cm−Cmexp[−(σθ)m] (9) 利用式(8)、(9)对不同钢纤维掺量下试件的应力和相应的声发射事件数进行拟合,拟合结果如图8所示,Weibull模型损伤参数及损伤演化方程在表6列出,损伤演化曲线如图9所示。由图表可知,Weibull累计分布函数与试验数据的拟合效果良好,拟合度均在0.97以上,钢纤维的掺入增加了声发射事件数,增大了m的数值,值得注意的是,当掺量为1.5%时,m值增加的幅度最大,当掺入为2%时,m值反而减小。

表 6 不同钢纤维含量混凝土试件Weibull损伤模型参数和损伤演化方程Table 6. Weibull model damage parameters and damage evolution equation of concrete specimens with different steel fiber contentsSpecimen θ m R2 D SF-0 19.3407 2.5231 0.99283 1-exp(−(x/ 19.3407 )2.5231 )

1-exp(−(x/24.5143 )3.3861 )

1-exp(−(x/33.1430 )4.4772 )

1-exp(−(x/26.8991 )3.6548 )SF-1 24.5143 3.3861 0.99176 SF-1.5 33.1430 4.4772 0.97917 SF-2 26.8991 3.6548 0.99654 Notes: θ—Scale parameter; m—Shape parameter; R2—Goodness of fit; D—Damage parameter. 一般来说,θ和m的数值与试件的脆性密切相关,m值越大,试件脆性越小,本文表现出同样的特征,钢纤维的掺入增大了m的数值,增加了累积事件数,这说明,钢纤维传递了局部应力,削弱了试件的局部损伤,减小了试件宏观裂纹的数量和宽度,增加了微裂纹的数量,降低了整体损伤程度,使得试件的脆性更小,但过多的掺入钢纤维反而会降低m值,即增大试件的脆性,这与前文的研究结论一致,1.5%钢纤维参量为最优掺量。

4. 结 论

对GFRP管约束内含木柱的钢纤维混凝土试件进行了单轴压缩试验。以不同钢纤维体积掺量(0、1%、1.5%和2%)为变量,基于声发射技术研究了试件的力学性能、损伤特征和裂纹扩展,该研究可为一种耐腐蚀和轻质高强的新型复合材料的应用提供参考价值,主要结论如下:

(1)适量钢纤维的掺入可以提高试件的极限承载力和延性,但过量掺入不仅会适得其反,还会导致宏观破坏的提前,1.5%体积掺量的钢纤维为最适掺量,提高了试件35.7%的极限承载力和4.73%的位移延性系数。

(2)根据AE振铃计数特征,将试件的损伤分别为混凝土开裂、木材开裂和GFRP管断裂过程,且钢纤维的掺入可以降低声发射信号强度。

(3)将试件损伤过程中的声发射峰值频率划分为低频段(0~100 kHz)、中频段(100~200 kHz)和高频段(200~300 kHz),钢纤维的掺入使得峰值频段由低频段逐渐向高频段过度,损伤形式从大尺度损伤逐渐转变为小尺度损伤。

(4)声发射RA-AF分析法的结果表明,钢纤维的掺入增加了裂纹数量和扩展的范围,减小了宏观裂纹的宽度,提高了剪切裂纹的比例。

(5) 建立的基于声发射累积事件数和应力的损伤演化模型可以反映试件损伤演化规律,该模型服从双参数Weibull分布,钢纤维的掺入降低了损伤程度,其参数m值越大,试件脆性越小。

-

表 1 部分植物衍生碳材料的电化学性能

Table 1 Electrochemical properties of some plant-derived carbon materials

Material Activator Specific

Capacitance/(F·g−1)Electrolyte Energy density/

(Wh·kg−1)Power density/

(W·kg−1)Cycling

stabilityReference Shaddock endotheliums KOH 550

(0.2 A·g−1)1 mol·L−1

BMIMBF4/AN46.88 300 93.7% 10000 cycles97 Cashew nut husk KOH 305.2

(1 A·g−1)6 mol·L−1

KOH11.2 400 97.1% 4000 cycles98 Zanthoxylum Leaves ZnCl2 196

(0.5 A·g−1)0.5 mol·L−1

Na2SO418.68 225 92% 20000 cycles99 Pine pollen MgCO3 416.9

(1 A·g−1)6 mol·L−1

KOH34.9 181 97.4% 10000 cycles100 Willow catkin KOH 298

(0.5 A·g−1)6 mol·L−1

KOH21.0 180 99.7% 10000 cycles101 Loofah sponge KOH 309.6

(1 A·g−1)6 mol·L−1

KOH16.1 160 81.3% 10000 cycles102 Bamboo fungi [ZnCO3]2·

[Zn(OH)2]3367

(0.5 A·g−1)6 mol·L−1

KOH24.6 400 95.7% 10000 cycles103 Banana CO2 178.9

(1 A·g−1)6 mol·L−1

KOH3.23 50 67% 10000 cycles104 Eucalyptus bark KOH 483.5

(0.5 A·g−1)1 mol·L−1

Na2SO421.7 168.9 83.1% 10000 cycles105 Lacquer wood H3PO4 354

(0.2 A·g−1)1 mol·L−1

H2SO4/ / 95.3% 10000 cycles106 Notes:BMIMBF4/AN is 1-butyl-3-methylimidazolium tetrafluoroborate/acetonitrile -

[1] KUMAR A, BHATTACHARYA T, HASNAIN S M M, et al. Applications of biomass-derived materials for energy production, conversion, and storage[J]. Materials Science for Energy Technologies, 2020, 3: 905-920. DOI: 10.1016/j.mset.2020.10.012

[2] SHARMA S, CHAND P. Supercapacitor and electrochemical techniques: A brief review[J]. Results in Chemistry, 2023, 5: 100885. DOI: 10.1016/j.rechem.2023.100885

[3] SATPATHY S, DAS S, BHATTACHARYYA B K. How and where to use super-capacitors effectively, an integration of review of past and new characterization works on super-capacitors[J]. Journal of Energy Storage, 2020, 27: 101044. DOI: 10.1016/j.est.2019.101044

[4] WANG J, ZHOU J, ZHAO W. Deep reinforcement learning based energy management strategy for fuel cell/battery/supercapacitor powered electric vehicle[J]. Green Energy and Intelligent Transportation, 2022, 1(2): 100028. DOI: 10.1016/j.geits.2022.100028

[5] WINTER M, BRODD R J. What are batteries, fuel cells, and supercapacitors?[J]. Chemical reviews, 2004, 104(10): 4245-4270. DOI: 10.1021/cr020730k

[6] SALLEH N A, KHEAWHOM S, HAMID N A A, et al. Electrode polymer binders for supercapacitor applications: a review[J]. Journal of Materials Research and Technology, 2023, 23: 3470-3491. DOI: 10.1016/j.jmrt.2023.02.013

[7] SUBRAMANIAN B, VEERAPPAN M, RAJAN K, et al. Fabrication of hierarchical indium vanadate materials for supercapacitor application[J]. Global Challenges, 2020, 4(11): 2000002. DOI: 10.1002/gch2.202000002

[8] SENTHIL C, LEE C W. Biomass-derived biochar materials as sustainable energy sources for electrochemical energy storage devices[J]. Renewable and Sustainable Energy Reviews, 2021, 137: 110464. DOI: 10.1016/j.rser.2020.110464

[9] LI Y, GUPTA R, ZHANG Q, et al. Review of biochar production via crop residue pyrolysis: Development and perspectives[J]. Bioresource Technology, 2023, 369: 128423. DOI: 10.1016/j.biortech.2022.128423

[10] “十四五”能源领域科技创新规划[R]. 中国科技奖励, 2022, 09: 23-42. The 14th five-year plan for scientific and technological innovation in the energy sector[R]. China Awards for Science and Technology, 2022, 09: 23-42.

[11] Supercapacitor Market to Generate Revenue of USD24.37 Billion by 2029 Demand, Trends and Growth Industries from 2022 to 2029[J]. M2 Presswire, 2022.

[12] VAITHYANATHAN V K, GOYETTE B, RAJAGOPAL R. A critical review of the transformation of biomass into commodity chemicals: Prominence of pretreatments[J]. Environmental Challenges, 2023, 11: 100700. DOI: 10.1016/j.envc.2023.100700

[13] ANTAR M, LYU D, NAZARI M, et al. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization[J]. Renewable and Sustainable Energy Reviews, 2021, 139: 110691. DOI: 10.1016/j.rser.2020.110691

[14] KARAM D S, NAGABOVANALLI P, RAJOO K S, et al. An overview on the preparation of rice husk biochar, factors affecting its properties, and its agriculture application[J]. Journal of the Saudi Society of Agricultural Sciences, 2022, 21(3): 149-159. DOI: 10.1016/j.jssas.2021.07.005

[15] 宋晓岚, 段海龙, 王海波, 等. 稻壳基活性炭电极材料制备及其电化学性能研究[J]. 硅酸盐通报, 2017, 36(3): 991-995. SONG Xiaolan, DUAN Hailong, WANG Haibo, et al. Preparation and electrochemical performance of rice husk-based activated carbon electrode[J]. Bulletin of the Chinese Ceramic Society, 017, 36(3): 991-995. (in Chinese)

[16] GAO Y, LI L, JIN Y, et al. Porous carbon made from rice husk as electrode material for electrochemical double layer capacitor[J]. Applied Energy, 2015, 153: 41-47. DOI: 10.1016/j.apenergy.2014.12.070

[17] HE X, LING P, YU M, et al. Rice husk-derived porous carbons with high capacitance by ZnCl2 activation for supercapacitors[J]. Electrochimica Acta, 2013, 105: 635-641. DOI: 10.1016/j.electacta.2013.05.050

[18] LOBATO-PERALTA D R, DUQUE-BRITO E, ORUGBA H O, et al. Sponge-like nanoporous activated carbon from corn husk as a sustainable and highly stable supercapacitor electrode for energy storage[J]. Diamond and Related Materials, 2023, 138: 110176. DOI: 10.1016/j.diamond.2023.110176

[19] 隋光辉, 程岩岩. 以稻壳热解炭制备镧负载多孔炭复合电极材料[J]. 高等学校化学学报, 2024, 45(4): 151-159. SUI Guanhui, CHENG Yanyan. Preparation of lanthanum-loaded porous carbon composite electrode materials from rice husk pyrolytic carbon[J]. Chemical Journal of Chinese Universities, 2024, 45(4): 151-159(in Chinese).

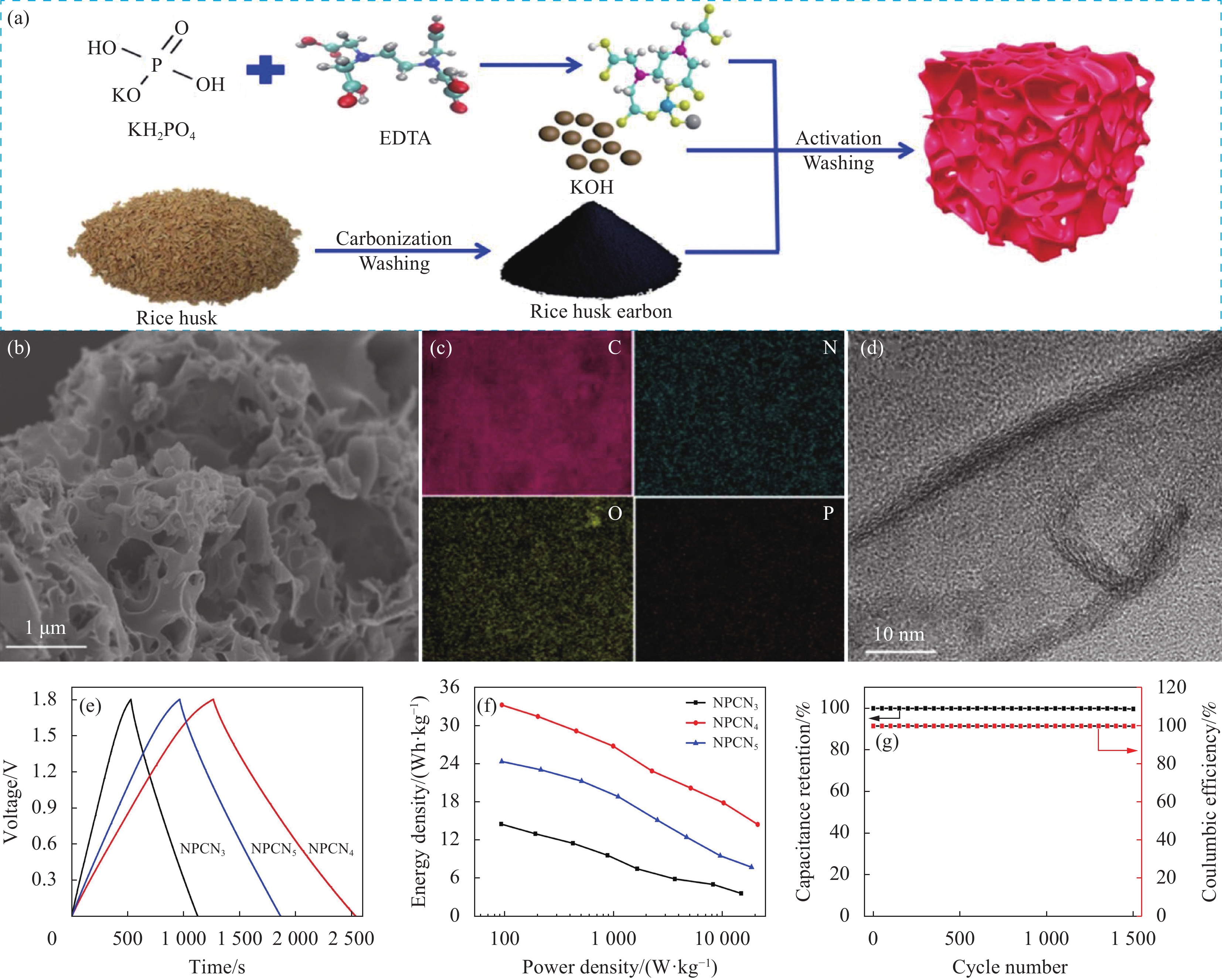

[20] WEI F, GUO Y, WANG S, et al. N, P codoped carbon nanosheets derived from rice husk for supercapacitors with high energy density[J]. Diamond and Related Materials, 2023, 137: 110161. DOI: 10.1016/j.diamond.2023.110161

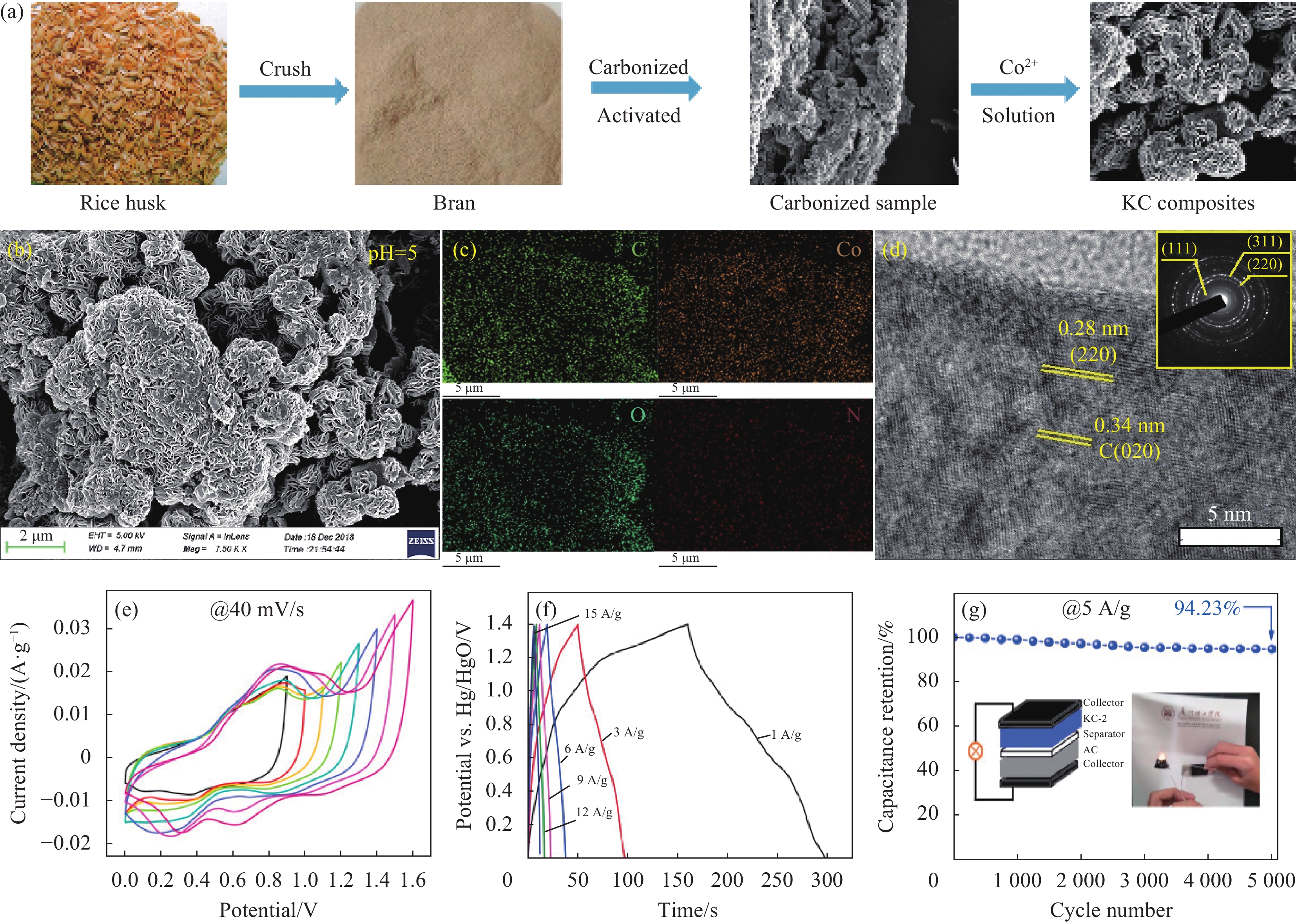

[21] XIAO S, HUANG J, LIN C, et al. Porous carbon derived from rice husks as sustainable bioresources: Insights into the role of micro/mesoporous hierarchy in Co3O4/C composite for asymmetric supercapacitors[J]. Microporous and Mesoporous Materials, 2020, 291: 109709. DOI: 10.1016/j.micromeso.2019.109709

[22] BARBIERI V, GUALTIERI M L, SILIGARDI C. Wheat husk: A renewable resource for bio-based building materials[J]. Construction and Building Materials, 2020, 251: 118909. DOI: 10.1016/j.conbuildmat.2020.118909

[23] BLEDZKI A K, MAMUN A A, Volk J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites[J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(4): 480-488. DOI: 10.1016/j.compositesa.2009.12.004

[24] CUI J, SUN H, LUO Z, et al. Preparation of low surface area SiO2 microsphere from wheat husk ash with a facile precipitation process[J]. Materials Letters, 2015, 156: 42-45. DOI: 10.1016/j.matlet.2015.04.134

[25] 卓祖优, 宋生南, 黄明堦, 等. 草酸钾-尿素协同活化法制备超大比表面积面粉基多级孔炭及其电化学储能应用[J]. 化工进展, 2023, 42(2): 925-933. ZHUO Zuyou, SONG Shengnan, HUANG Mingjie, et al. Preparation of wheat flour-based hierarchical porous carbon with ultra large specific surface area by synergistic activation of potassium oxalate-urea and its electrochemical energy storage performance[J]. Chemical Industry and Engineering Progress, 2023, 42(2): 925-933(in Chinese).

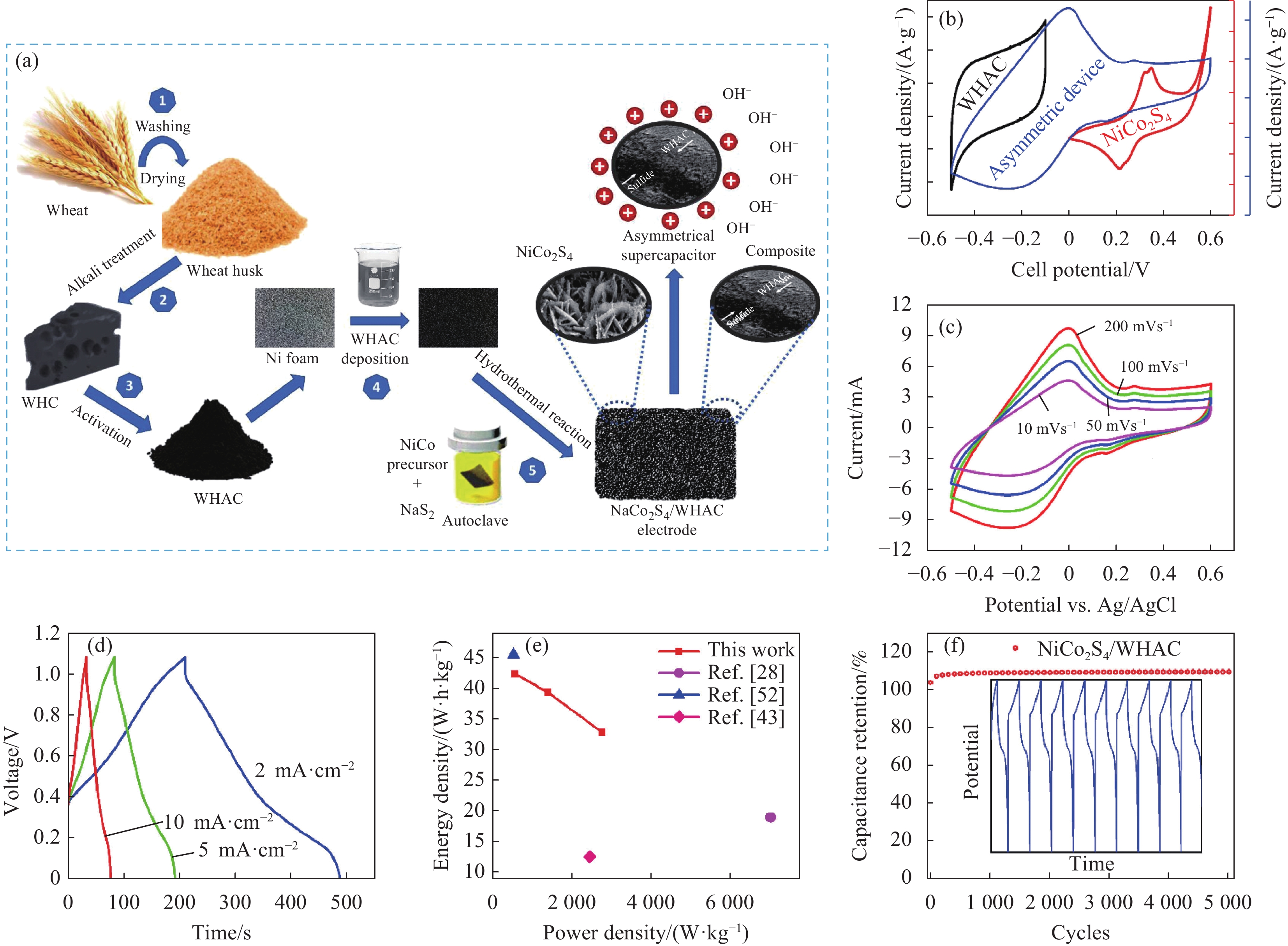

[26] BAIG M M, GUL I H. Conversion of wheat husk to high surface area activated carbon for energy storage in high-performance supercapacitors[J]. Biomass and Bioenergy, 2021, 144: 105909. DOI: 10.1016/j.biombioe.2020.105909

[27] BAIG M M, GUL I H. Transformation of wheat husk to 3D activated carbon/NiCo2S4 frameworks for high-rate asymmetrical supercapacitors[J]. Journal of Energy Storage, 2021, 37: 102477. DOI: 10.1016/j.est.2021.102477

[28] KONG S, JIN B, QUAN X, et al. MnO2 nanosheets decorated porous active carbon derived from wheat bran for high-performance asymmetric supercapacitor[J]. Journal of Electroanalytical Chemistry, 2019, 850: 113412. DOI: 10.1016/j.jelechem.2019.113412

[29] DU W, ZHANG Z, DU L, et al. Designing synthesis of porous biomass carbon from wheat straw and the functionalizing application in flexible, all-solid-state supercapacitors[J]. Journal of Alloys and Compounds, 2019, 797: 1031-1040. DOI: 10.1016/j.jallcom.2019.05.207

[30] ZHANG R, MA S, LI L, et al. Comprehensive utilization of corn starch processing by-products: A review[J]. Grain & Oil Science and Technology, 2021, 4(3): 89-107.

[31] RATNA A S, GHOSH A, MUKHOPADHYAY S. Advances and prospects of corn husk as a sustainable material in composites and other technical applications[J]. Journal of Cleaner Production, 2022, 371: 133563. DOI: 10.1016/j.jclepro.2022.133563

[32] AHMED M J, DANISH M, ANASTOPOULOS I, et al. Recent progress on corn (Zea mays L. )-based materials as raw, chemically modified, carbonaceous, and composite adsorbents for aquatic pollutants: A review[J]. Journal of Analytical and Applied Pyrolysis, 2023, 172: 106004. DOI: 10.1016/j.jaap.2023.106004

[33] LEITE M, FREITAS A, SILVA A S, et al. Maize (Zea mays L. ) and mycotoxins: A review on optimization and validation of analytical methods by liquid chromatography coupled to mass spectrometry[J]. Trends in Food Science & Technology, 2020, 99: 542-565.

[34] 林彦萍, 任源, 王晓娥, 等. 农业生物质废弃物转化功能材料的研究进展[J]. 环境科学, 2024, 45(7): 4332-4351. LIN Yanping, REN Yuan, WANG Xiaoe, et al. Research progress on functional materials for agricultural biomass waste conversion[J]. Environmental Science, 2024, 45(7): 4332-4351(in Chinese).

[35] 韦会鸽, 李桂星, 雷祥楠, 等. 聚苯胺-玉米苞叶纤维复合材料基柔性自支撑电极的制备及其电化学性能[J]. 复合材料学报, 2022, 39(7): 3462-3468. WEI Huige, LI Guixing, LEI Xiangnan, et al. Polyaniline-corn husk fiber composite based flexible self-standing electrode: Preparation and electrochemical properties[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3462-3468(in Chinese).

[36] ZOU Q. Corn-straw-converted activated carbons with tunable porosity and N/O functionalities as high-performance supercapacitors electrode at commercial-level mass loading[J]. Journal of Energy Storage, 2023, 72: 108673. DOI: 10.1016/j.est.2023.108673

[37] 邢宝林, 陈丽薇, 张传祥, 等. 玉米芯活性炭的制备及其电化学性能研究[J]. 材料导报, 2015, 29(6): 45-48+64. DOI: 10.11896/j.issn.1005-023X.2015.06.010 XING Baolin, CHEN Liwei, ZHANG Chuanxiang, et al. Preparation and electrochemical performance of corncob based activated carbon[J]. Materials Reports, 2015, 29(6): 45-48+64(in Chinese). DOI: 10.11896/j.issn.1005-023X.2015.06.010

[38] YU K, ZHU H, QI H, et al. High surface area carbon materials derived from corn stalk core as electrode for supercapacitor[J]. Diamond and Related Materials, 2018, 88: 18-22. DOI: 10.1016/j.diamond.2018.06.018

[39] RANI M U, NANAJI K, RAO T N, et al. Corn husk derived activated carbon with enhanced electrochemical performance for high-voltage supercapacitors[J]. Journal of Power Sources, 2020, 471: 228387. DOI: 10.1016/j.jpowsour.2020.228387

[40] ZHOU J, YUAN S, LU C, et al. Hierarchical porous carbon microtubes derived from corn silks for supercapacitors electrode materials[J]. Journal of Electroanalytical Chemistry, 2020, 878: 114704. DOI: 10.1016/j.jelechem.2020.114704

[41] SUN K, ZHANG Z, PENG H, et al. Hybrid symmetric supercapacitor assembled by renewable corn silks based porous carbon and redox-active electrolytes[J]. Materials Chemistry and Physics, 2018, 218: 229-238. DOI: 10.1016/j.matchemphys.2018.07.052

[42] TANG J, GUO Z, KONG X, et al. Soybean meal-derived heteroatoms-doped porous carbons for supercapacitor electrodes[J]. Materials Chemistry and Physics, 2022, 284: 126055. DOI: 10.1016/j.matchemphys.2022.126055

[43] WANG A, SUN K, XU R, et al. Cleanly synthesizing rotten potato-based activated carbon for supercapacitor by self-catalytic activation[J]. Journal of Cleaner Production, 2021, 283: 125385. DOI: 10.1016/j.jclepro.2020.125385

[44] ZHANG Q, WANG J, DENG M. Preparation of Porous Carbon from Buckwheat Husk and its Electrochemical Properties[J]. International Journal of Electrochemical Science, 2022, 17(11): 221145. DOI: 10.20964/2022.11.32

[45] HU H, WU G. Porous carbon derived from sweet potato biomass as electrode for zinc-ion hybrid supercapacitors[J]. International Journal of Electrochemical Science, 2021, 16(9): 210937. DOI: 10.20964/2021.09.01

[46] ALBATRNI H, QIBLAWEY H, Al-MARRI M J. Walnut shell based adsorbents: A review study on preparation, mechanism, and application[J]. Journal of Water Process Engineering, 2022, 45: 102527. DOI: 10.1016/j.jwpe.2021.102527

[47] 郭晖, 张记升, 朱天星, 等. 利用核桃壳制备高比表面积活性炭电极材料的研究[J]. 材料导报, 2016, 30(2): 24-27+33. GUO Hui, ZHANG Jisheng, ZHU Tianxing, et al. Preparation of high specific surface area activated carbon electrode materials from walnut shell[J]. Materials Reports, 2016, 30(2): 24-27+33(in Chinese).

[48] FU H, CHEN L, GAO H, et al. Walnut shell-derived hierarchical porous carbon with high performances for electrocatalytic hydrogen evolution and symmetry supercapacitors[J]. International Journal of Hydrogen Energy, 2020, 45(1): 443-451. DOI: 10.1016/j.ijhydene.2019.10.159

[49] 张传涛, 邢宝林, 黄光许, 等. 水热炭化-KOH活化制备核桃壳活性炭电极材料的研究[J]. 材料导报, 2018, 32(7): 1088-1093. ZHANG Chuantao, XING Baolin, HUANG Guangxu, et al. Preparation of walnut shell activated carbons via combination of hydrothermal carbonization and KOH activation[J]. Materials Reports, 2018, 32(7): 1088-1093(in Chinese).

[50] XU X, GAO J, TIAN Q, et al. Walnut shell derived porous carbon for a symmetric all-solid-state supercapacitor[J]. Applied Surface Science, 2017, 411: 170-176. DOI: 10.1016/j.apsusc.2017.03.124

[51] CUI S, MCCLEMENTS D J, XU X, et al. Peanut proteins: extraction, modifications, and applications: a comprehensive review[J]. Grain & Oil Science and Technology, 2023, 6(3): 135-147.

[52] 宋晓琪, 雷西萍, 樊凯, 等. 基于生物质衍生炭在超级电容器中的研究进展[J]. 复合材料学报, 2023, 40(3): 1328-1339. SONG Xiaoqi, LEI Xiping, FAN Kai, et al. Research progress of biomass derived carbon in supercapacitors[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1328-1339(in Chinese).

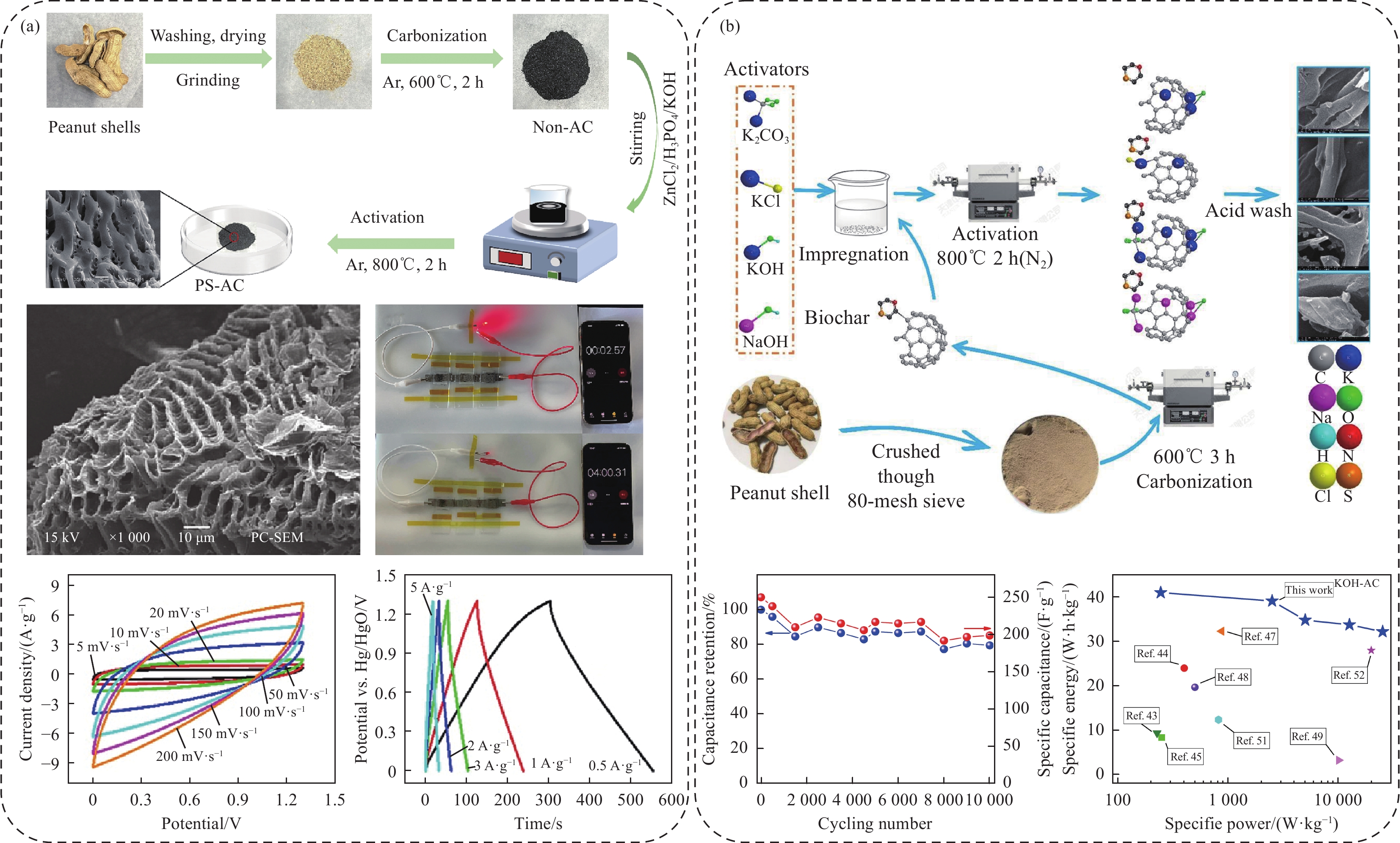

[53] LIANG K, CHEN Y, WANG S, et al. Peanut shell waste derived porous carbon for high-performance supercapacitors[J]. Journal of Energy Storage, 2023, 70: 107947. DOI: 10.1016/j.est.2023.107947

[54] ZHAN Y, ZHOU H, GUO F, et al. Preparation of highly porous activated carbons from peanut shells as low-cost electrode materials for supercapacitors[J]. Journal of Energy Storage, 2021, 34: 102180. DOI: 10.1016/j.est.2020.102180

[55] NGUYEN N T, LE P A, PHUNG V B T. Biomass-derived carbon hooks on Ni foam with free binder for high performance supercapacitor electrode[J]. Chemical Engineering Science, 2021, 229: 116053. DOI: 10.1016/j.ces.2020.116053

[56] JANNAT N, Al-MUFTI R L, HUSSIEN A, et al. Utilisation of nut shell wastes in brick, mortar and concrete: A review[J]. Construction and Building Materials, 2021, 293: 123546. DOI: 10.1016/j.conbuildmat.2021.123546

[57] BORRES M P, SATO S, EBISAWA M. Recent advances in diagnosing and managing nut allergies with focus on hazelnuts, walnuts, and cashew nuts[J]. World Allergy Organization Journal, 2022, 15(4): 100641. DOI: 10.1016/j.waojou.2022.100641

[58] OZPINAR P, DOGAN C, DEMIRAL H, et al. Activated carbons prepared from hazelnut shell waste by phosphoric acid activation for supercapacitor electrode applications and comprehensive electrochemical analysis[J]. Renewable Energy, 2022, 189: 535-548. DOI: 10.1016/j.renene.2022.02.126

[59] LIU Y, LIU P, LI L, et al. Fabrication of biomass-derived activated carbon with interconnected hierarchical architecture via H3PO4-assisted KOH activation for high-performance symmetrical supercapacitors[J]. Journal of Electroanalytical Chemistry, 2021, 903: 115828. DOI: 10.1016/j.jelechem.2021.115828

[60] FARMA R, TANIA Y, APRIYANI I. Conversion of hazelnut seed shell biomass into porous activated carbon with KOH and CO2 activation for supercapacitors[J]. Materials Today: Proceedings, 2023, 87: 51-56. DOI: 10.1016/j.matpr.2023.02.099

[61] XIE Y, ZHANG D, JATI G N P, et al. Effect of structural and compositional alterations on the specific capacitance of hazelnut shell activated carbon[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 625: 126951. DOI: 10.1016/j.colsurfa.2021.126951

[62] QIN L, HOU Z, LU S, et al. Porous carbon derived from pine nut shell prepared by steam activation for supercapacitor electrode material[J]. International Journal of Electrochemical Science, 2019, 14(9): 8907-8918. DOI: 10.20964/2019.09.20

[63] 王芳平, 马婧, 李小亚, 等. 板栗壳生物炭高性能对称性超级电容器电极材料的制备及性能[J]. 化工进展, 2021, 40(8): 4381. WANG Fangping, MA Jing, LI Xiaoya, et al. Preparation and properties of chestnut shell-based biochar electrode material for high-performance symmetrical supercapacitor[J]. Chemical Industry and Engineering Progress, 2021, 40(8): 4381(in Chinese).

[64] MA C, BAI J, DEMIR M, et al. Water chestnut shell-derived N/S-doped porous carbons and their applications in CO2 adsorption and supercapacitor[J]. Fuel, 2022, 326: 125119. DOI: 10.1016/j.fuel.2022.125119

[65] CAI N, CHENG H, JIN H, et al. Porous carbon derived from cashew nut husk biomass waste for high-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2020, 861: 113933. DOI: 10.1016/j.jelechem.2020.113933

[66] HAMID M, AMATURRAHIM S A, DALIMUNTHE I B, et al. Synthesis of magnetic activated carbon-supported cobalt (II) chloride derived from pecan shell (Aleurites moluccana) with co-precipitation method as the electrode in supercapacitors[J]. Materials Science for Energy Technologies, 2023, 6: 429-436. DOI: 10.1016/j.mset.2023.04.004

[67] WU C, ZHANG G, LIU J, et al. A green strategy to prepare nitrogen-oxygen co-doped porous carbons from macadamia nut shells for post-combustion CO2 capture and supercapacitors[J]. Journal of Analytical and Applied Pyrolysis, 2023, 171: 105952. DOI: 10.1016/j.jaap.2023.105952

[68] BHATTACHARJEE C, DUTTA S, SAXENA V K. A review on biosorptive removal of dyes and heavy metals from wastewater using watermelon rind as biosorbent[J]. Environmental Advances, 2020, 2: 100007. DOI: 10.1016/j.envadv.2020.100007

[69] YANG C, LI P, WEI Y, et al. Preparation of nitrogen and phosphorus doped porous carbon from watermelon peel as supercapacitor electrode material[J]. Micromachines, 2023, 14(5): 1003. DOI: 10.3390/mi14051003

[70] OMAR N, ABDULLAH E C, NUMAN A, et al. Facile synthesis of a binary composite from watermelon rind using response surface methodology for supercapacitor electrode material[J]. Journal of Energy Storage, 2022, 49: 104147. DOI: 10.1016/j.est.2022.104147

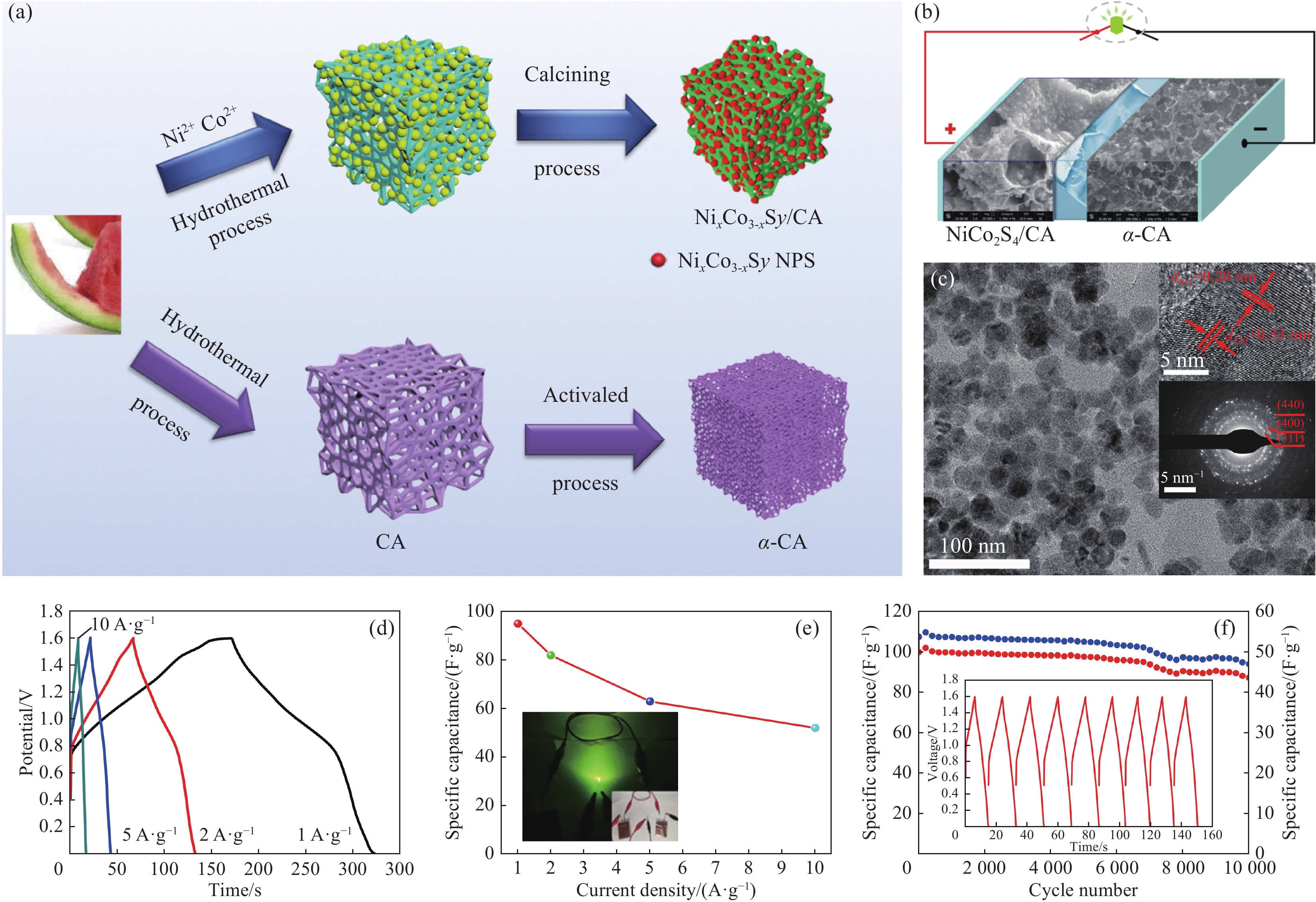

[71] DONG J, LI S, DING Y. Anchoring nickel-cobalt sulfide nanoparticles on carbon aerogel derived from waste watermelon rind for high-performance asymmetric supercapacitors[J]. Journal of Alloys and Compounds, 2020, 845: 155701. DOI: 10.1016/j.jallcom.2020.155701

[72] ABOAGYE D, BANADDA N, KIGGUNDU N, et al. Assessment of orange peel waste availability in Ghana and potential bio-oil yield using fast pyrolysis[J]. Renewable and Sustainable Energy Reviews, 2017, 70: 814-821. DOI: 10.1016/j.rser.2016.11.262

[73] SIDDIQUI S A, PAHMEYER M J, ASSADPOUR E, et al. Extraction and purification of d-limonene from orange peel wastes: Recent advances[J]. Industrial Crops and Products, 2022, 177: 114484. DOI: 10.1016/j.indcrop.2021.114484

[74] XU C, HU Z, WANG X, et al. Facile preparation of hierarchical porous carbon from orange peels for high-performance supercapacitor[J]. International Journal of Electrochemical Science, 2021, 16(3): 210350. DOI: 10.20964/2021.03.07

[75] DING F, LI J, DU H, et al. Highly porous heteroatom doped-carbon derived from orange peel as electrode materials for high-performance supercapacitors[J]. International Journal of Electrochemical Science, 2020, 15(6): 5632-5649. DOI: 10.20964/2020.06.75

[76] SNOOK G A, KAO P, BEST A S. Conducting-polymer-based supercapacitor devices and electrodes[J]. Journal of Power sources, 2011, 196(1): 1-12. DOI: 10.1016/j.jpowsour.2010.06.084

[77] AJAY K M, DINESH M N, BYATARAYAPPA G, et al. Electrochemical investigations on low cost KOH activated carbon derived from orange-peel and polyaniline for hybrid supercapacitors[J]. Inorganic Chemistry Communications, 2021, 127: 108523. DOI: 10.1016/j.inoche.2021.108523

[78] SUN K, WANG H, PENG H, et al. Manganese oxide nanorods supported on orange peel-based carbon nanosheets for high performance supercapacitors[J]. International Journal of Electrochemical Science, 2015, 10(3): 2000-2013. DOI: 10.1016/S1452-3981(23)04823-X

[79] YUMNAM M, MARAK P R, GUPTA A K, et al. Effect of pomelo peel essential oil on the storage stability of a few selected varieties of freshwater fish[J]. Journal of Agriculture and Food Research, 2023, 11: 100472. DOI: 10.1016/j.jafr.2022.100472

[80] 王芳平, 周凯玲, 马婧, 等. 葡萄柚皮多孔碳高性能对称性超级电容器电极材料的制备及性能[J]. 硅酸盐学报, 2021, 49(3): 495-502. WANG Fangping, ZHOU Kailing, MA Jing, et al. Preparation and properties of porous carbon electrode material of grapefruit peel for high performance symmetrical supercapacitor[J]. Journal of the Chinese Ceramic Society, 2021, 49(3): 495-502(in Chinese).

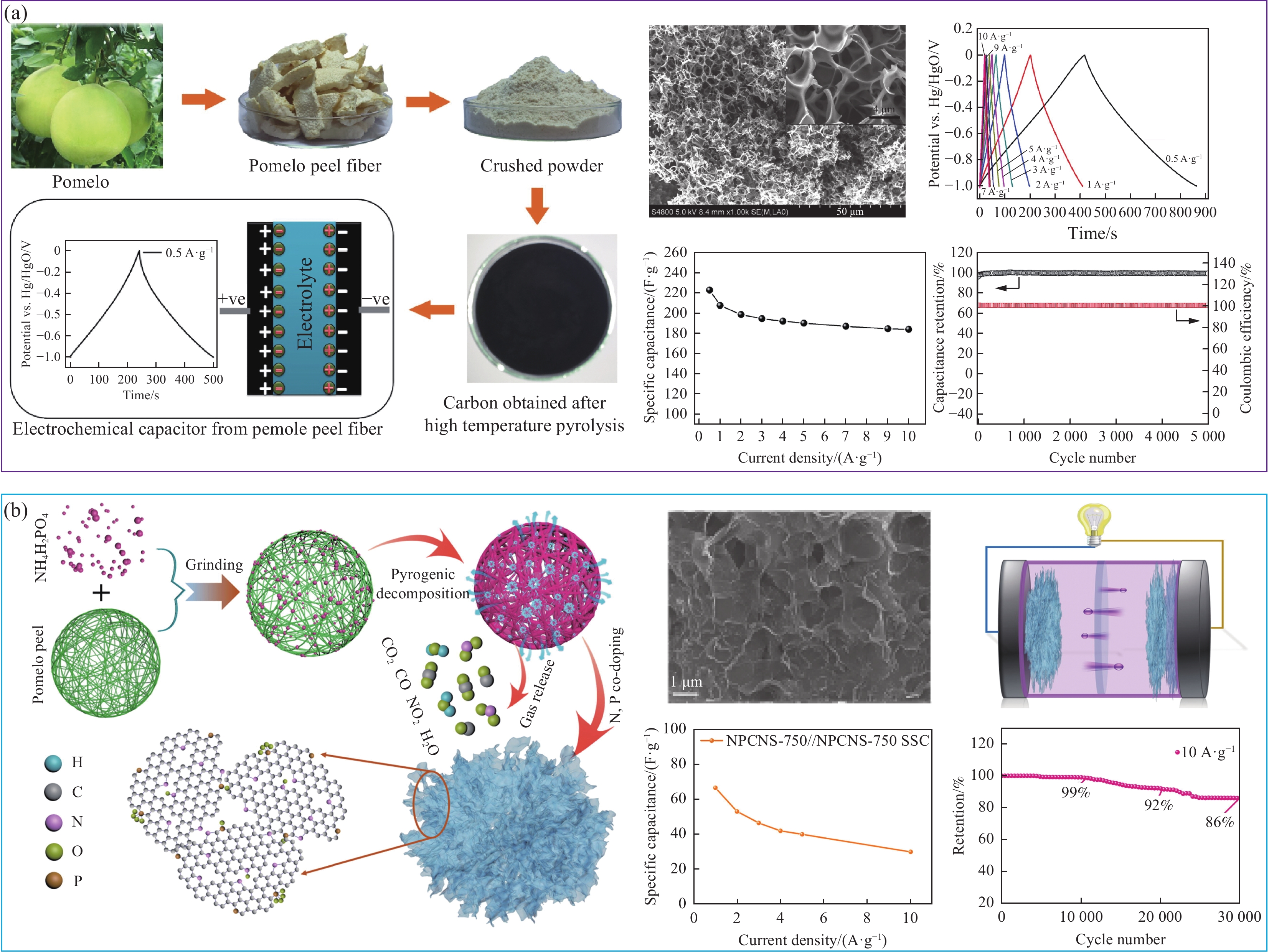

[81] LI J, LIU W, XIAO D, et al. Oxygen-rich hierarchical porous carbon made from pomelo peel fiber as electrode material for supercapacitor[J]. Applied Surface Science, 2017, 416: 918-924. DOI: 10.1016/j.apsusc.2017.04.162

[82] CHEN J, LIN Y, LIU J, et al. Outstanding supercapacitor performance of nitrogen-doped activated carbon derived from shaddock peel[J]. Journal of Energy Storage, 2021, 39: 102640. DOI: 10.1016/j.est.2021.102640

[83] LI G, LI Y, CHEN X, et al. One step synthesis of N, P co-doped hierarchical porous carbon nanosheets derived from pomelo peel for high performance supercapacitors[J]. Journal of Colloid and Interface Science, 2022, 605: 71-81. DOI: 10.1016/j.jcis.2021.07.065

[84] HAN J, PING Y, LI J, et al. One-step nitrogen, boron codoping of porous carbons derived from pomelo peels for supercapacitor electrode materials[J]. Diamond and Related Materials, 2019, 96: 176-181. DOI: 10.1016/j.diamond.2019.05.014

[85] LIU Y, CHANG Z, YAO L, et al. Nitrogen/sulfur dual-doped sponge-like porous carbon materials derived from pomelo peel synthesized at comparatively low temperatures for superior-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2019, 847: 113111. DOI: 10.1016/j.jelechem.2019.04.071

[86] SURYA K, MICHAEL M S. Hierarchical porous activated carbon prepared from biowaste of lemon peel for electrochemical double layer capacitors[J]. Biomass and Bioenergy, 2021, 152: 106175. DOI: 10.1016/j.biombioe.2021.106175

[87] KITENGE V N, TARIMO D J, OYEDOTUN K O, et al. Facile and sustainable technique to produce low-cost high surface area mangosteen shell activated carbon for supercapacitors applications[J]. Journal of Energy Storage, 2022, 56: 105876. DOI: 10.1016/j.est.2022.105876

[88] MOHAMMED A A, CHEN C, ZHU Z. Low-cost, high-performance supercapacitor based on activated carbon electrode materials derived from baobab fruit shells[J]. Journal of Colloid and Interface Science, 2019, 538: 308-319. DOI: 10.1016/j.jcis.2018.11.103

[89] 李涛, 何松, 林晓莹, 等. 农林废弃生物质资源精深加工技术进展[J]. 材料导报, 2021, 35(19): 19001-19014. LI Tao, HE Song, LIN Xiaoying, et al. Recent advances on deep processing technologies for resourcing utilization of agricultural and forestry biomass wastes[J]. Materials Reports, 2021, 35(19): 19001-19014(in Chinese).

[90] IWUOZOR K O, ADENIYI A G, EMENIKE E C, et al. Prospects and challenges of utilizing sugarcane bagasse as a bio-coagulant precursor for water treatment[J]. Biotechnology Reports, 2023, 39: e00805. DOI: 10.1016/j.btre.2023.e00805

[91] IWUOZOR K O, EMENIKE E C, IGHALO J O, et al. A review on the thermochemical conversion of sugarcane bagasse into biochar[J]. Cleaner Materials, 2022, 6: 100162. DOI: 10.1016/j.clema.2022.100162

[92] YADAV N, HASHMI S A. High energy density solid-state supercapacitors based on porous carbon electrodes derived from pre-treated bio-waste precursor sugarcane bagasse[J]. Journal of Energy Storage, 2022, 55: 105421. DOI: 10.1016/j.est.2022.105421

[93] CHEN J, QIU J, WANG B, et al. Polyaniline/sugarcane bagasse derived biocarbon composites with superior performance in supercapacitors[J]. Journal of Electroanalytical Chemistry, 2017, 801: 360-367. DOI: 10.1016/j.jelechem.2017.08.014

[94] TU J, QIAO Z, WANG Y, et al. American ginseng biowaste-derived activated carbon for high-performance supercapacitors[J]. International Journal of Electrochemical Science, 2023, 18(2): 16-24. DOI: 10.1016/j.ijoes.2023.01.011

[95] GOPALAKRISHNAN A, RAJU T D, Badhulika S. Green synthesis of nitrogen, sulfur-co-doped worm-like hierarchical porous carbon derived from ginger for outstanding supercapacitor performance[J]. Carbon, 2020, 168: 209-219. DOI: 10.1016/j.carbon.2020.07.017

[96] NGUYEN T B, YOON B, NGUYEN T D, et al. A facile salt-templating synthesis route of bamboo-derived hierarchical porous carbon for supercapacitor applications[J]. Carbon, 2023, 206: 383-391. DOI: 10.1016/j.carbon.2023.02.060

[97] YANG S, WANG S, LIU X, et al. Biomass derived interconnected hierarchical micro-meso-macro-porous carbon with ultrahigh capacitance for supercapacitors[J]. Carbon, 2019, 147: 540-549. DOI: 10.1016/j.carbon.2019.03.023

[98] CAI N, CHENG H, JIN H, et al. Porous carbon derived from cashew nut husk biomass waste for high-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2020, 861: 113933. DOI: 10.1016/j.jelechem.2020.113933

[99] XU Y, LEI H, QI S, et al. Three-dimensional zanthoxylum Leaves-Derived nitrogen-Doped porous carbon frameworks for aqueous supercapacitor with high specific energy[J]. Journal of Energy Storage, 2020, 32: 101970. DOI: 10.1016/j.est.2020.101970

[100] WAN L, SONG P, LIU J, et al. Facile synthesis of nitrogen self-doped hierarchical porous carbon derived from pine pollen via MgCO3 activation for high-performance supercapacitors[J]. Journal of Power Sources, 2019, 438: 227013. DOI: 10.1016/j.jpowsour.2019.227013

[101] LI Y, WANG G, WEI T, et al. Nitrogen and sulfur co-doped porous carbon nanosheets derived from willow catkin for supercapacitors[J]. Nano Energy, 2016, 19: 165-175. DOI: 10.1016/j.nanoen.2015.10.038

[102] SU X L, CHEN J R, ZHENG G P, et al. Three-dimensional porous activated carbon derived from loofah sponge biomass for supercapacitor applications[J]. Applied Surface Science, 2018, 436: 327-336. DOI: 10.1016/j.apsusc.2017.11.249

[103] ZHAO Y, CHEN P, TAO S, et al. Nitrogen/oxygen co-doped carbon nanofoam derived from bamboo fungi for high-performance supercapacitors[J]. Journal of Power Sources, 2020, 479: 228835. DOI: 10.1016/j.jpowsour.2020.228835

[104] LEI E, LI W, MA C, et al. CO2-activated porous self-templated N-doped carbon aerogel derived from banana for high-performance supercapacitors[J]. Applied Surface Science, 2018, 457: 477-486. DOI: 10.1016/j.apsusc.2018.07.001

[105] LI K, LIU Z, MA X, et al. A combination of heteroatom doping engineering assisted by molten salt and KOH activation to obtain N and O co-doped biomass porous carbon for high performance supercapacitors[J]. Journal of Alloys and Compounds, 2023, 960: 170785. DOI: 10.1016/j.jallcom.2023.170785

[106] HU S C, CHENG J, WANG W P, et al. Structural changes and electrochemical properties of lacquer wood activated carbon prepared by phosphoric acid-chemical activation for supercapacitor applications[J]. Renewable Energy, 2021, 177: 82-94. DOI: 10.1016/j.renene.2021.05.113

-

其他相关附件

-

本文图文摘要

点击下载

-

-

目的

目前在储能领域,植物衍生多孔碳基超级电容器因其优异的性能而备受研究者的青睐。本文通过综述植物衍生多孔碳材料的制备方法、结构特性及其在超级电容器中的应用效果,深入分析其储能机理、性能优化策略及未来发展方向。这不仅有助于推动超级电容器技术的进一步创新,还为实现绿色、高效的能源存储解决方案提供有力支持。此外,通过探讨当前研究中存在的问题与挑战,提出针对性的改进策略和未来发展方向,为进一步提升超级电容器的性能、推动其产业化应用提供理论依据和实践指导。

方法本文按照前驱体的来源对植物衍生多孔碳材料进行了分类,介绍了近年来国内外植物衍生多孔碳材料用于超级电容器电极材料的研究成果,讨论了植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战,并对植物衍生多孔碳材料的发展前景进行了展望。

结果1、粮食作物衍生碳材料:粮食作物作为人类主要的食物来源,种类繁多、种植广泛,产量巨大。将其制成超级电容器电极材料不仅有利于离子与电子的传输,还易于实现杂原子掺杂。但由于粮食作物废弃物种类繁杂,材质不均匀,在实际研究和应用中仍存在一些挑战。将生物质与其他材料复合可制备复合电极材料,但复合材料存在成本高,制备条件难调控的缺点,未来还需进一步研究。2、坚果壳衍生碳材料:坚果壳质地坚硬,固定碳含量高,灰分低,且富含醛基、羟基、羧基等活性基团,是一种生产电极材料的优质资源。目前,坚果壳衍生碳材料主要通过高温活化法制得,常用的活化剂主要为碱、酸、盐类,如KOH、HPO、KCl、ZnCl等,单活化剂制备碳材料方法简便,效果良好可行性高。除单活化剂活化法,还存在双活化剂(HPO与KOH、Zn(NO)与KOH)活化法,双活化剂之间的协同作用可以使制备的碳材料具有更丰富的孔隙分布,不同尺寸孔隙之间的协同作用可使得材料表现出良好的电化学性能。3、果皮衍生碳材料:果皮来源广、品种多、产量大,富含纤维素、果胶,是制备碳电极材料的理想材料。果皮衍生碳材料蕴含独特的三维孔道结构且富含不同杂原子(N、O、P、S、B),电化学性能良好。将果皮衍生碳材料与导电聚合物、过渡金属氧化物复合,电容性能更佳,但制备成本,时间较长,同时材料的循环稳定性能会受到一定影响。

结论本文综述了近年来国内外植物衍生多孔碳在超级电容器中的应用及研究进展,归纳总结了不同类别植物衍生多孔碳材料的制备方法、掺杂方法及电化学性能。尽管通过活化和表面性质调控改性,能提高植物衍生多孔碳材料的电化学性能,但还存在以下不足:离子传输内阻大、孔径分布难调控、制备过程较复杂。尽管植物衍生多孔碳材料在超级电容器中的应用前景广阔,但仍面临一些挑战,如提高能量密度、降低内阻、增强电导率以及实现规模化生产等。未来的研究将聚焦于开发新的制备技术、探索新型生物质原料以及改进现有材料的性能。

-

超级电容器是一种高效能、充放电循环稳定的绿色的能源储存器件,因其比传统的蓄电池具有更长的使用寿命、更优的可逆充放电效能以及更低的循环损耗而受到了全世界的极大关注。影响超级电容器的生产成本和性能的关键因素是电极材料。植物衍生多孔碳作为一种常用的高比表面积材料,由于其成本低、性能稳定,在结构和形貌方面得到了广泛的科学研究。生物质碳是一系列具有复杂结构和丰富形态的碳基材料的总和,由于其良好的电导率、稳定的化学循环和优良的电化学特性等特有性质,在能量储存领域包括超级电容器方面展示出了庞大的潜在应用价值。本文综述了近年来国内外植物衍生多孔碳用于超级电容器电极材料的研究进展,归纳总结了不同类别植物衍生多孔碳材料的孔结构、表面官能团对其电化学性能的影响规律,并对植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战与发展前景进行了展望。

各种植物前驱体用作超级电容器的电极材料

下载:

下载: