Experimental study on mechanical properties of silica fume modified steel fibre reinforced geopolymer recycled aggregate concrete

-

摘要:

钢纤维增强地聚物再生混凝土(SFRGRAC)具有碳排放量低、节约天然矿物资源以及延性韧性好等优点,具有广泛应用前景。为改善SFRGRAC力学性能,本文以硅灰为增强材料,通过立方体抗压、劈裂抗拉、抗折和弹性模量试验,研究硅灰掺量、钢纤维体积掺量和再生骨料取代率等因素对SFRGRAC力学性能的影响规律,并基于SEM和低场核磁共振测试结果揭示硅灰的改性机制。结果表明:掺入硅灰可延长SFRGRAC的凝结时间,当硅灰掺量为15wt%时,初凝和终凝时间分别提高了29.68%和22.98%;由于硅灰与碱激发溶液快速发生发应,加快了水化反应的速度,SFRGRAC 3 d抗压强度和劈裂抗拉强度可达到28 d强度的85%以上;随着钢纤维体积掺量从0vol%增至1.5vol%,其抗压强度可提高17.44%,随着再生骨料取代率从0%增至50%,其强度降低了9.79%。掺入10wt%硅灰,总孔隙率降低了23.79%,能显著提高其抗压、劈裂抗拉和抗折强度,但当硅灰掺量为15wt%时,因过量硅灰降低了基体的碱度,导致地聚物水化反应不完全,使其力学性能表现出下降趋势。研究成果为再生混凝土相关规范的修订和完善提供参考依据。

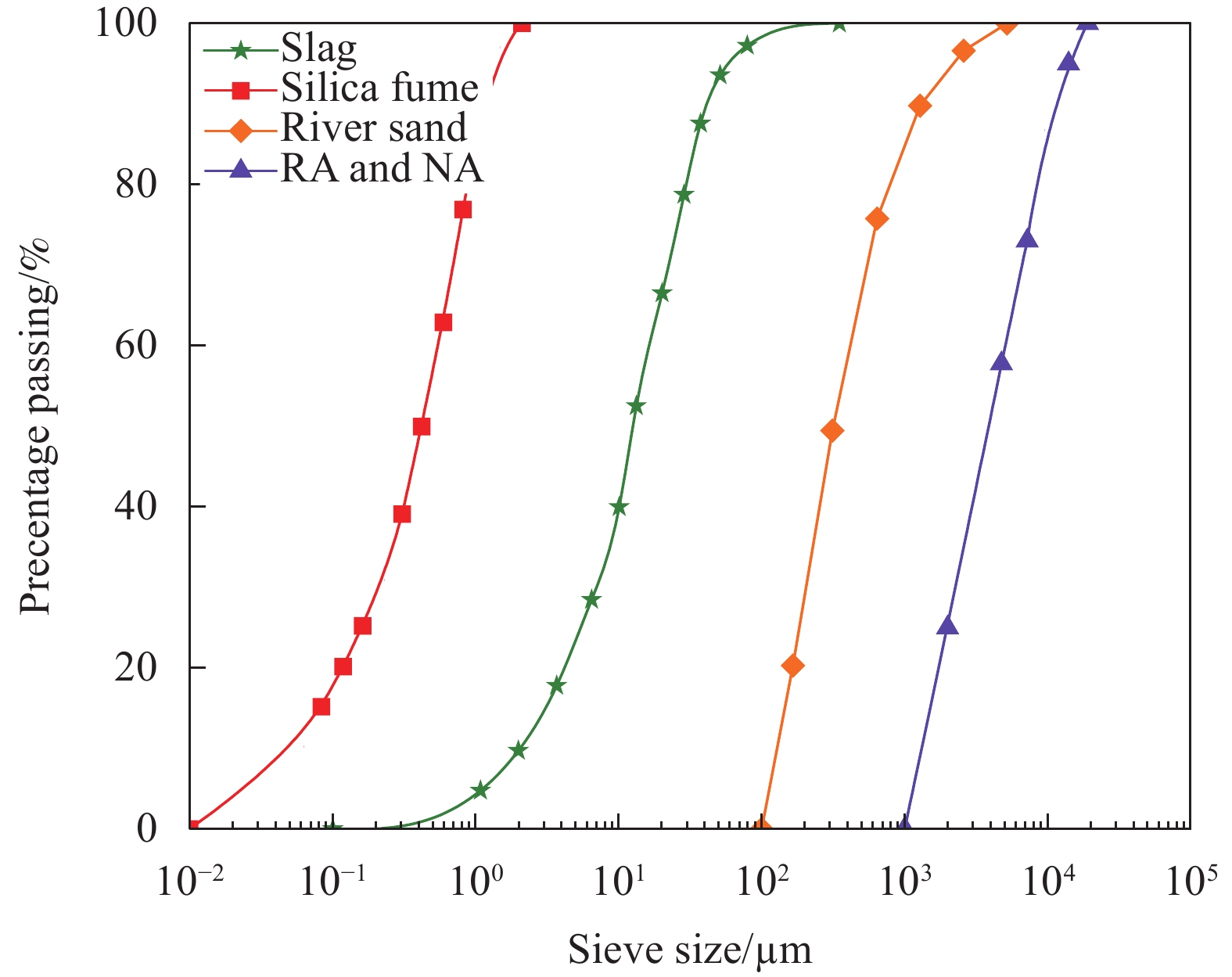

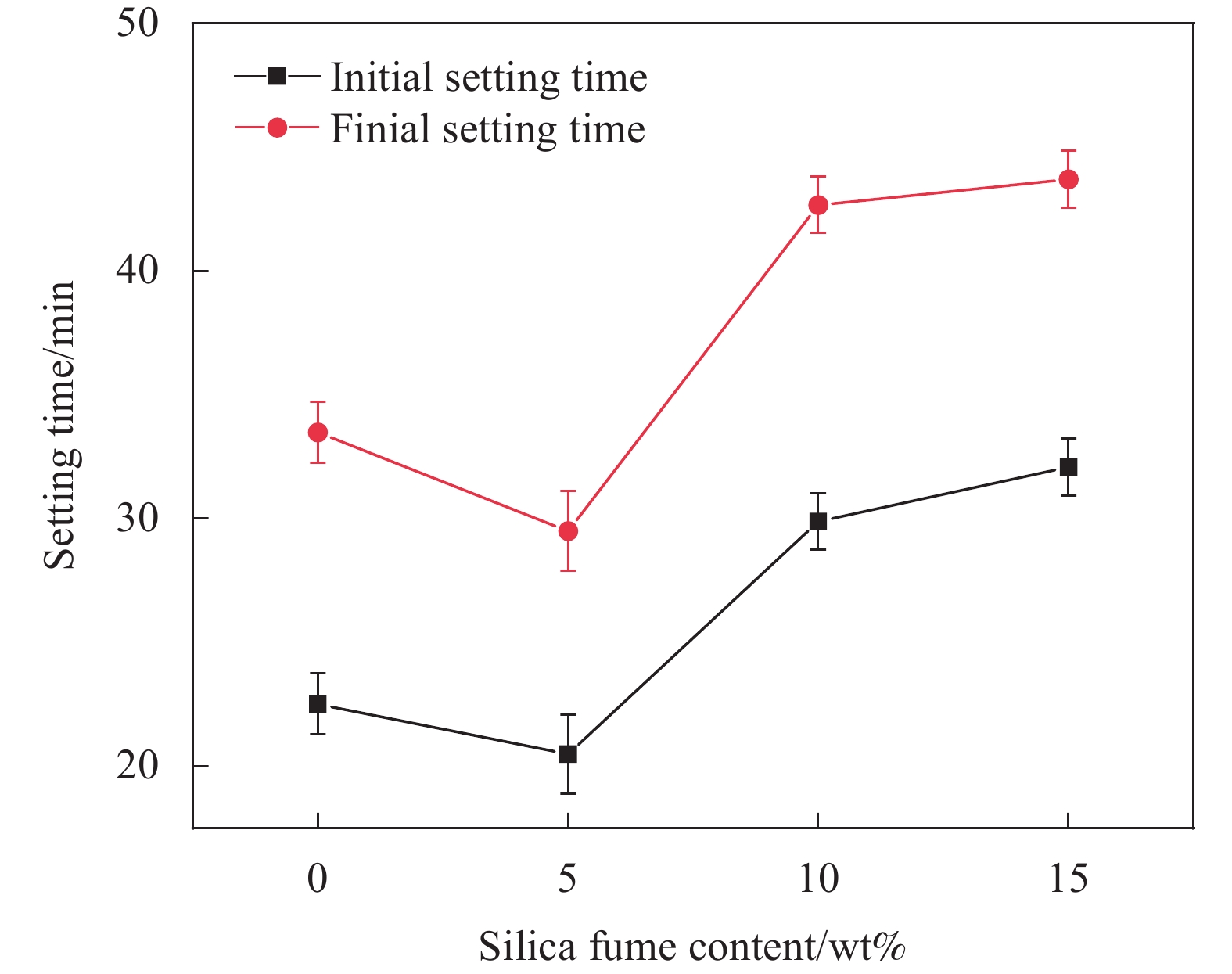

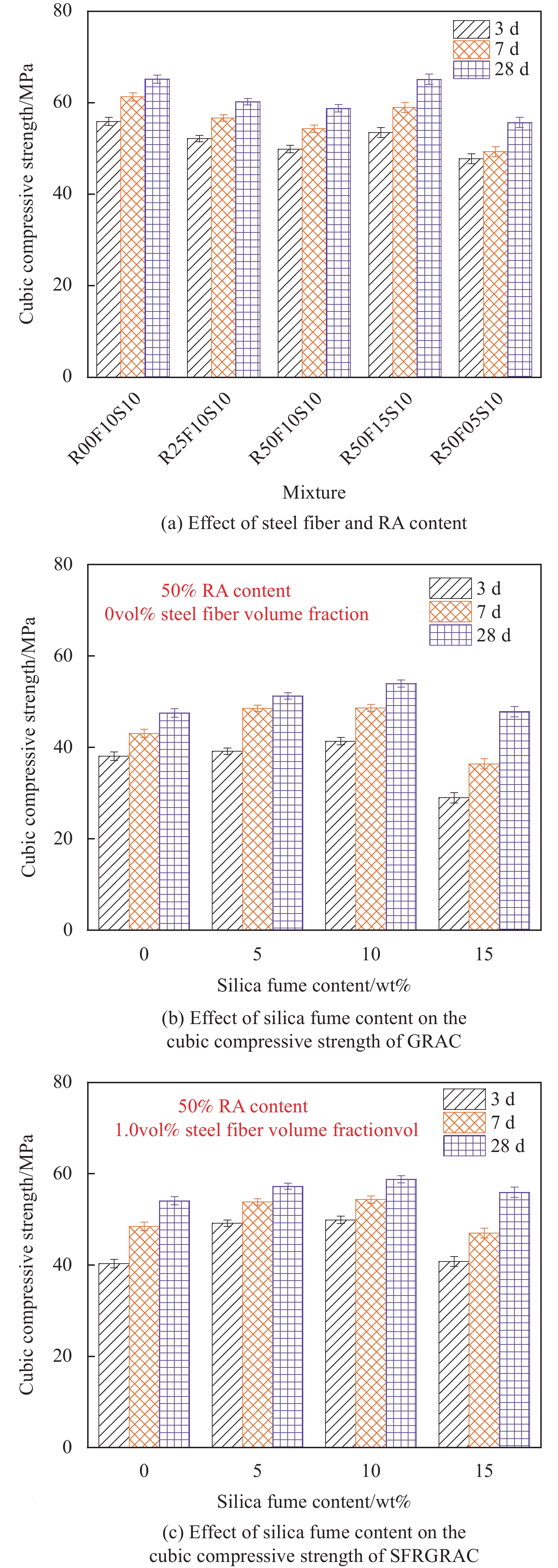

Abstract:Steel fiber reinforced geopolymer recycled concrete (SFRGRAC) presents several benefits, including reduced carbon emissions, conservation of natural minerals, and enhanced ductility and toughness, rendering it a promising material for broad applications. This study aims to augment the mechanical characteristics of SFRGRAC by incorporating silica fume as a reinforcing agent. It examines the influence of silica fume content, steel fiber volume fraction, and recycled aggregate substitution ratio on mechanical performance of SFRGRAC through cube compression, split tensile strength, flexural strength, and modulus of elasticity test. Additionally, the study elucidates the modification mechanism of silica fume via SEM and low field NMR test. The findings indicate that silica fume addition extends the setting time of SFRGRAC, with 15wt% content of silica fume leading to a 29.68% increase in initial setting time and a 22.98% increase in final setting time. The accelerated hydration reaction, prompted by the prompt pozzolanic reaction between silica fume and the alkali activator, results in the SFRGRAC achieving over 85% of its 28 d compressive and tensile strengths within 3 d. The compressive strength improves by 17.44% as steel fiber volume fraction increases from 0vol% to 1.5vol%, whereas a 50% substitution of recycled aggregate causes a 9.79% reduction in strength than 0% substitution rate. A 10wt% silica fume content diminishes total porosity by 37.38%, substantially enhancing compressive, tensile, and flexural strengths. When the silica fume content reaches 15wt%, the excessive silica fume reduces the alkalinity of matrix, resulting in an incomplete hydration reaction of the geopolymer. Consequently, this causes a decline in its mechanical properties. These findings offer valuable insights for the revision and enhancement of specifications related to recycled concrete.

-

近年来,柔性压力传感器凭借其轻量、柔韧、生物相容等特点在生物医疗[1]、电子皮肤[2]、人机交互[3]、柔性机器人[4]等领域具有广泛的应用前景。根据传感原理,柔性压力传感器主要分为电阻式[5]、电容式[6]、压电式[7]、摩擦电式[8]4种。而柔性电容式压力传感器因其结构简单、信号稳定,且能与静态力测量兼容及低功耗优点,得到了研究人员的广泛关注[9]。但在电容式柔性压力传感器的性能优化研究中存在一个共性问题,即高灵敏度与宽检测范围之间的制约,如何解决两者之间的矛盾仍是亟需解决的瓶颈问题。

目前,研究人员在介电层结构方面主要通过设计介电层的表面微结构或介电层体相多孔结构,来提高柔性电容压力传感器的灵敏度和检测范围。一般,在介电层表面设计金字塔形[10]、半球形[11]、荷叶表面乳突[12]等微纳结构。但制作这些微纳结构一般需要光刻[13]、3D打印[14]和仿生模板复刻[15]等技术,存在工艺复杂、成本高、耗时长等缺陷。并且由于表面微纳结构在压力作用下的变形易快速达到饱和状态,只能提高一部分检测量程。而介电层的体相多孔结构,由于本身就存在孔隙,在压力作用下先后发生孔隙减小、孔壁接触和孔壁进一步挤压过程,延缓了形变达到饱和状态的过程,从而提高了检测量程。因此相较于表面微纳结构,多孔结构在传感器的设计中存在显著优势。而在介电层材料方面,研究人员主要提出在介电层中添加高介电常数、低介电损耗填料的方法,以形成复合介电层,提高介电层的有效介电常数,从而提高灵敏度和检测范围。通常,可以分为导电填料(炭黑(CB)[16]、碳纳米管(CNTs)[17]、石墨烯(GO)[18]等),压电填料(聚偏氟乙烯(PVDF)[19]、钛酸钡(BTO)[20]等)和磁性填料(金属镍(Ni)[21]等)。

本文针对高灵敏度、宽检测范围和制作成本不能兼顾的问题,利用模板组装法制备出了一种多孔结构的电容式柔性压力传感器。首先,在基底材料上选择了具有价格低廉、质量轻、弹性好、孔隙率高、比表面积大等特点的聚氨酯(PU)海绵。其次,在填料的选择上,分别选择了导电填料炭黑(Carbon black,CB)和压电填料钛酸钡(BaTiO3,BTO),由于CB不仅具有良好的附着能力,还可以改善压力下介电常数的变化,从而提高传感器的性能[22]。而选择BTO,则是因其具有高介电常数和低介电损耗特性。两者都可以利用范德华力和静电引力附着在PU骨架上。最后,利用PU海绵现有的多孔结构作为模板,采用超声浸渍涂覆的方法将CB和BTO附着在海绵骨架上,从而制备出高的有效介电常数及低介电损耗的CB-BTO/PU海绵体。并以此为介电层组装成电容式柔性压力传感器。同时,还对该压力传感器进行了性能测试和应用范围的研究,解决了在大量程范围压力信号检测中测量量程与灵敏度之间的矛盾。

1. 实验材料及方法

1.1 CB-BTO/PU海绵柔性电容式压力传感器的制备

前处理:将聚氨酯海绵(PU,大城好五金店,优质高密度)剪切成10 mm×10 mm×3 mm的立方体,用无水乙醇(Ethanol absolute,太仓新太酒精)与去离子水(浙江南岱实业)交替清洗2次,每次10 min,以除去PU海绵表面的杂质,并在恒温培养箱中干燥1 h,以待后用。

CB-BTO/PU海绵柔性电容式压力传感器的制备过程:将炭黑(CB,美国CABOT,粉末,~15 nm)与钛酸钡(BTO,麦克林,99.9%metals basis,粉末,~100 nm)按照质量比为2.5∶100、5∶100、7.5∶100、10∶100分别加入一定量无水乙醇中,用磁力搅拌器(ZNCL-BS,山东元创仪器)进行搅拌,30 min后搅拌停止,分别往各悬浮液中加入前处理后的PU海绵,随后在超声波细胞破碎仪(LC-JY98-IIIDN,上海力辰邦西仪器科技)中进行超声分散,超声过程中产生的局部高温和超声波,其一可大幅度地减弱CB和BTO纳米颗粒之间的作用力,防止纳米颗粒团聚;其二是让悬浮液中的纳米颗粒不断地无规则运动,均匀地分散在PU海绵内部。超声1 h后,将附着有CB与BTO的PU海绵放入80℃的恒温培养箱(XMTA-600,余姚市科洋仪表)中干燥1 h,随后将干燥完成的PU海绵进行机械压缩20 min,以达到海绵的老化处理和将附着不牢的纳米颗粒去除,当压缩过程中海绵不再脱落纳米颗粒和用纸擦拭海绵表面不再出现灰色污渍时,证明得到结构稳定的CB-BTO/PU海绵三维复合材料。最后在CB-BTO/PU海绵三维复合材料的两端贴附铜箔电极,并用聚对苯二甲酸乙二醇酯(Polyethlene terephthalate,PET)薄膜封装得到CB-BTO/PU海绵柔性电容式压力传感器。具体制备流程如图1所示。

1.2 表征方法

采用扫描电子显微镜(SEM,日立SU8020)对CB-BTO/PU复合材料的形貌进行表征。用能谱分析仪(EDS,美国edax)探究CB-BTO/PU复合材料中的碳(C)、钛(Ti)和钡(Ba)元素的分布。将CB-BTO/PU海绵固定在样品台上,然后放入真空镀膜仪内喷金,喷金结束后将样品置于SEM扫描电镜下,观察海绵断面形貌。电子加速电压为5.0 kV,工作距离为13.6 mm,上下探头同时成像;然后用扫描电镜上配置的EDS对海绵上的元素成分和含量进行观察分析。

压力传感器的传感性能测试主要通过万能试验机(ZQ-950B,东莞市智取精密仪器)、LCR测试仪(TH2830,上海双旭电子)等完成。将传感器放置到万能试验机的下端压头平台上,通过控制上端压头的位移,以10 mm/min的恒定速度将0~300 kPa压力施加于传感器表面上;将传感器电极板引出的导线连接LCR测试仪(工作电压1 V),使用远端接口模式连接到PC,实时测量传感器的电容信号。

2. 结果与讨论

2.1 CB-BTO/PU海绵传感器的表征与分析

图2(a)为PU海绵浸渍前后实物图,浸渍前PU海绵骨架清晰,孔隙分布均匀;浸渍后PU海绵由淡黄色转为黑灰色,这是CB与BTO有效沉积的结果。将制备的CB-BTO/PU海绵完全压缩,当撤去外力之后,仍能恢复到初始状态,展现了该材料具有很好的柔韧性和弹性,如图2(b)、图2(c)所示。图2(d)~图2(f)为CB-BTO/PU海绵骨架的断面SEM图像。可以看出,PU海绵骨架结构明显,孔隙清晰,且随着图像的放大,能看到CB与BTO(呈颗粒状,少量团聚)均匀地附着在PU海绵骨架上。从EDS能谱分析表明,Ba (图2(g))、Ti (图2(h))、C (图2(i))3种元素在PU海绵均匀分布,再一次验证了CB与BTO在PU海绵骨架上分布均匀。

![]() 图 2 CB-BTO/PU海绵的形貌与结构表征:(a)浸渍前后PU海绵实物图;((b), (c)) PU海绵压缩的初始状态和压缩状态图;((d)~(f)) PU海绵断面SEM图像;((g)~(i)) Ba元素、Ti元素、C元素的EDS分布图Figure 2. Morphology and structure characterization of CB-BTO/PU sponge: (a) Physical diagram of PU sponge before and after impregnation; ((b), (c)) Initial compression state and compression state diagrams of PU sponge respectively; ((d)-(f)) SEM images of PU sponge sections; ((g)-(i)) EDS distribution diagrams of Ba element, Ti element and C element respectively

图 2 CB-BTO/PU海绵的形貌与结构表征:(a)浸渍前后PU海绵实物图;((b), (c)) PU海绵压缩的初始状态和压缩状态图;((d)~(f)) PU海绵断面SEM图像;((g)~(i)) Ba元素、Ti元素、C元素的EDS分布图Figure 2. Morphology and structure characterization of CB-BTO/PU sponge: (a) Physical diagram of PU sponge before and after impregnation; ((b), (c)) Initial compression state and compression state diagrams of PU sponge respectively; ((d)-(f)) SEM images of PU sponge sections; ((g)-(i)) EDS distribution diagrams of Ba element, Ti element and C element respectively2.2 CB-BTO/PU海绵传感器的传感机制与性能分析

CB-BTO/PU 海绵压力传感器可视为平行板电容器[23],在外界压力作用下,平行板电容器的两极板之间的相对距离和介电层的相对介电常数都发生了改变,从而引起了电容的变化。传感器的电容的计算公式为

C=ε0εrAd (1) 其中:C是电容器的电容;ε0是真空介电常数;εr是介电层的相对介电常数;A是上下电极板的有效重叠表面积;d是上下两电极之间的距离。

CB-BTO/PU 海绵压力传感器的传感机制为:在没有外界压力作用的初始状态下,PU海绵骨架表面附着CB和BTO,空气充满了骨架空隙,介电层具有较低的相对介电常数εr。而当受到外界压力作用以后,介电层被压缩,上下两电极之间的距离d减小,并且PU海绵微孔开始闭合,介电层中的空气被排出,εr增加,导致电容C随着压力的增加而不断增大。

对于CB-BTO/PU 海绵介电层来说,可以根据一般的Lichtenecker 混合规则[24],求出有效的相对介电常数。有效相对介电常数的计算公式为

lnεr=Vairlnεair+VCBlnεCB+VBTOlnεBTO+VPUlnεPU (2) 其中:Vair、VCB、VBTO与VPU分别为复合材料中空气、炭黑、钛酸钡与聚氨酯海绵所占的体积比;εair、εCB、εBTO与εPU分别为空气、炭黑、钛酸钡与聚氨酯海绵的介电常数。

由上式可知,当介电层受力被压缩时,空气被逐渐排出,其他三相所占的体积比逐渐增大,介电层的相对介电常数也逐渐增大,因此电容传感器的电容才能逐渐增大。

通过制备CB与BTO不同质量比的CB-BTO/PU 海绵传感器,进行传感性能测试分析,从而对传感器进行工艺参数优化。

不同配比的传感器性能也不尽相同,而质量比为mCB:mBTO=5:100的CB-BTO/PU海绵传感性能是最好的,如图3所示。从图上可知,随着CB的含量增大,传感器的灵敏度逐渐增大然后逐渐减小并趋于一致。笔者认为,一方面,CB表面具有大量的羟基、羰基、酸基和吸附水分子等官能团[25],而PU海绵中除了氨基甲酸酯官能团外,还可含有醚、酯、脲、缩二脲、脲基甲酸酯等基团[26]。这些官能团可以使CB和BTO附着在PU海绵上,并且随着CB的含量增加,附着在PU海绵上的CB与BTO也越来越多,而CB作为导电填料既可以强化BTO在PU海绵上的附着能力,还能在PU海绵上形成零星微电容,提高复合材料的介电常数,进而提高器件性能。但当CB含量超过某阈值后,虽然能让更多的BTO附着在PU海绵上,但CB附着在PU海绵上的含量也会逐渐增大,随着外界压力的作用下,CB之间相互接近逐渐形成渗流和遂穿,从而形成部分导电通路降低电容,这与田玉玉等[22]分析的导电填料在介电层中的作用结果一致。另一方面,PU海绵的空隙是有限的,而随着填料的增加,附着在PU海绵上的填料逐渐变缓,并趋于一致。上述原因解释了为什么会出现随着CB含量的增加,传感器的灵敏度会先增加后减小并趋于一致的结果。

灵敏度是评价压力传感器对压力变化敏感程度的重要性能指标,电容式压力传感器的灵敏度公式为

S=(C−C0)/C0ΔP=ΔC/C0ΔP (3) 其中: ΔC是施加压力后的电容变化量;C0是不施加压力时的初始电容值;ΔP是压力变化量;ΔC/C0为电容信号的相对变化量;C是压缩过程中传感器的实时电容。

通过上述不同配比的介电层组装的传感器的压力-电容响应曲线,可以看出,CB与BTO质量比为5∶100的海绵介电层的传感器灵敏度是最高。从图4 可以看出,CB-BTO/PU 海绵压力传感器在较小的压力范围内(0~10 kPa)的灵敏度平均为

0.6311 kPa−1,而随着压力的不断增加,在10~140 kPa范围内传感器的平均灵敏度有所增加,达到了0.7911 kPa−1。在这两个压力范围内灵敏度快速增加的原因是,越来越大的压力,使介电层不断压缩,两电极板的相对距离逐渐变小,而海绵介电层中的空气也逐渐排出,使介电层的相对介电常数迅速变大,这两方面都能增大电容的变化量,因此灵敏度在这两个压力范围内快速提升。在较大的压力范围内(140~300 kPa)的平均灵敏度为0.1395 kPa−1,相较于前两个压力范围的灵敏度,较大的压力范围内(140~300 kPa)的灵敏度有所降低,但也达到了0.1395 kPa−1,这是由于随着压力的增大,介电层的变化趋于饱和,灵敏度也随之下降。线性度值越小,表明拟合的曲线与实测的曲线之间的偏差越小[27]。如图4所示,对压力传感器进行了线性度分析,结果表明,在0~10 kPa、10~140 kPa、140~300 kPa这3个压力范围内的线性度分别为5.3%、1.4%、0.8%。该结果也从侧面证明了传感器在3个压力范围的灵敏度拟合更加可靠和准确。

综上所述,从灵敏度与线性度可以得出,CB-BTO/PU 海绵压力传感器在宽的压力范围内能保持高的灵敏度,具备良好的传感性能。

此外,与近年来相关领域文献中报道的柔性电容式压力传感器性能比较如表1所示[26, 28-30]。

表 1 CB-BTO/PU传感器与文献报道性能比较Table 1. Performance comparison between CB-BTO/PU sensor and literature reportMaterials Sensitivity Detection range/kPa Ref. TiO2@PU 0.93 kPa−1 (0-0.37 kPa)

0.079 kPa−1 (0.37-2.83 kPa)

0.02 kPa−1 (2.83-10 kPa)0-10 [26] CCTO@PU 0.73 kPa−1 (0-1.6 kPa)

0.135 kPa−1 (1.6-22.8 kPa)

0.026 kPa−1 (22.8-100 kPa)0-100 [28]

GO/CNTs@TPU0.05777 kPa−1 (0-5 kPa)

0.33213 kPa−1 (5-60 kPa)0-60 [29]

GNPs/MWCNTs/SR/PS0.062 kPa−1 (0-0.3 kPa)

0.033 kPa−1 (0.3-4.5 kPa)0-4.5 [30] CB-BTO/PU 0.6311 kPa−1 (0-10 kPa)0.7911 kPa−1 (10-140 kPa)0.1395 kPa−1 (140-300 kPa)0-300 This work Notes: CCTO—Calcium copper titanate; GO—Graphene oxide; CNTs—Carbon nanotube; TPU—Thermoplastic polyurethane; GNPs—Graphene nanosheets; MWCNTs—Carboxyl-functionalized multiwalled carbon nanotubes; SR—Silicone rubber; PS—Commercial polyurethane sponge. 对于传感器性能而言,传感器的响应时间/恢复时间、最小压力检测极限、稳定性和耐久性等性能指标也是评估传感器的重要参数。如图5(a)所示,通过在传感器加/卸载100 g砝码测量传感器的响应与恢复时间。结果表明,响应时间与恢复时间分别为0.375 s、0.125 s,响应时间略长是由于PU海绵被快速压缩形变后在短时间内仍然会持续形变才能到达最终的稳定状态,而当卸载砝码时海绵却能快速恢复原状,因此恢复时间较短。但响应时间和恢复时间都接近于人体对压力的响应时间400 ms[31],因此该传感器在人体运动监测具备一定的可行性。如图5(b)所示,为了检测传感器的最小压力测量极限,将一颗质量为0.25 g (~24.5 Pa)的小磁子放置在传感器表面,通过观察加载和卸载前后的电容变化,检测出传感器的最低压力极限。根据Zang等[32]对压力范围的分类方法,该传感器的最低检测限处于微压范围内(1 Pa~1 kPa),表明了传感器在微小压力检测方面具有潜在的应用价值。稳定性是评估压力传感器维持稳定工作的重要参数。如图5(c)所示,为了评估该传感器的输出可靠性、稳定性和重复性,分别在不同的压力下对传感器进行了响应特性测试,电容变化随着压力的增加而增加,且能在压力撤销以后恢复到初始值,这说明了该传感器具有良好的分辨率及测压的应用潜力。此外,还对传感器进行了在200 kPa压力下的

2500 次循环响应恢复测试。如图5(d)所示,在上千次的测试中,传感器的电容变化率幅值无明显变化,电容变化率曲线波形保持了良好的一致,证明了该传感器具有良好的重复性和稳定性。还与近年来相关领域文献中报道的柔性传感器耐久性进行了比较,如表2所示[33-35]。2.3 CB-BTO/PU 海绵压力传感器的应用研究

通过上述对传感器的一系列力学传感性能检测,验证了基于CB-BTO/PU海绵柔性电容式传感器具有高灵敏度、宽检测范围等较优异的传感性能。在此基础上,对传感器的应用方面进行了拓展。首先,是对传感器在小压力范围内的应用,将传感器安装在鼠标上如图6(a)所示,通过对鼠标的单击快慢和双击时的力度变化,输出不同的电容信号。结果显示,对鼠标的单击力度的不相同,所输出的信号峰值也不相同,并且随着对鼠标的单击速度加快,所得到的电容信号也会越来越密集;而双击鼠标时,则会得到连续输出的信号。

![]() 图 6 CB-BTO/PU海绵压力传感器在各种变形信号监测中的应用:(a)手指点击鼠标上传感器的响应(0~5 kPa);(b)指关节弯曲的传感器响应(0~7 kPa);(c)抓取不同质量玻璃杯的传感器响应(0~40 kPa);(d)足底压力和步态监测的传感器响应(0~110 kPa)Figure 6. Application of CB-BTO/PU sponge pressure sensor in monitoring various deformation signals: (a) Response of sensor when finger clicks the mouse (0-5 kPa); (b) Sensor response of knuckle bending (0-7 kPa); (c) Sensor responses for grabbing glasses with different qualities (0-40 kPa); (d) Sensor response of plantar pressure and gait monitoring (0-110 kPa)

图 6 CB-BTO/PU海绵压力传感器在各种变形信号监测中的应用:(a)手指点击鼠标上传感器的响应(0~5 kPa);(b)指关节弯曲的传感器响应(0~7 kPa);(c)抓取不同质量玻璃杯的传感器响应(0~40 kPa);(d)足底压力和步态监测的传感器响应(0~110 kPa)Figure 6. Application of CB-BTO/PU sponge pressure sensor in monitoring various deformation signals: (a) Response of sensor when finger clicks the mouse (0-5 kPa); (b) Sensor response of knuckle bending (0-7 kPa); (c) Sensor responses for grabbing glasses with different qualities (0-40 kPa); (d) Sensor response of plantar pressure and gait monitoring (0-110 kPa)该传感器还可以监测人体的小规模活动,如图6(b)所示,将传感器安装在手指的关节处,监测手指关节在不同弯曲角度时的电容相对变化值。当手指关节的弯曲角度变大时,对传感器的压缩形变也越来越大,而传感器所输出的电容信号值也不断变大,因此通过传感器的电容相对变化,可以精确地区分手指的弯曲程度。

除了传感器在上述小压力范围内的应用以外,该传感器还能应用于较大的压力场景,如图6(c)所示,通过拿起和放下侧面安装有传感器的玻璃杯(重600 g),传感器的电容幅值也会产生相应的变化,而随着玻璃杯中水的质量不断增加(50 g、100 g、150 g、200 g、250 g、300 g),其电容的相对变化也不断变大,并且当玻璃杯被拿起和放下时,传感器都能产生稳定的信号。在图6(d)中,将传感器连接到鞋底,用于检测足底压力和步态监测。当落脚时,传感器被压缩,电容值立即增大;而当抬脚时,传感器被释放恢复原状,电容值立即恢复初始值,表明了该传感器具有良好的稳定性及快速响应的特性。

以上的4种不同压力范围的应用检测无不都验证了该传感器在人机交互、电子皮肤、运动监测等领域应用的巨大潜力。

3. 结 论

本工作利用模板组装的方法制备了炭黑(CB)-钛酸钡(BTO)/聚氨酯(PU)海绵型电容式柔性压力传感器。得出以下结论:

(1)通过对制备的CB-BTO/PU海绵骨架进行SEM、EDS表征,结果表明CB与BTO均匀地浸渍涂覆在PU海绵骨架上。从而使该传感器的介电层融合了PU海绵的低弹性模量和CB-BTO的高介电常数等特性,显著地增强了电容变化,使传感器拥有了良好的传感性能;

(2)通过控制CB和BTO的质量比可改善海绵介电层的传感性能,最佳的配比为mCB:mBTO=5:100。该配比所制备的电容传感器,兼具了高灵敏度与宽的检测范围,在0~10 kPa、10~140 kPa与140~300 kPa的灵敏度分别为

0.6311 kPa−1、0.7911 kPa−1与0.1395 kPa−1。同时,传感器还展示出较快的响应与恢复时间(<0.375 s)及低的检测限(~0.25 g),并且还具有良好的分辨率和长久的使用寿命(>2500 次);(3)本工作被成功地验证可用于在人机交互、电子皮肤、运动监测等领域的巨大潜力,并为低成本、大规模商业化制备柔性压力传感器提供了可能。

-

表 1 胶凝材料主要化学成分

Table 1 Chemical composition of cementitious materials

Binder Compositions/wt% Specific surface

area/(cm2·g−1)Density/

(kg·m−3)CaO SiO2 Al2O3 Fe2O3 MgO SO3 K2O Na2O MnO TiO2 Slag 36.82 26.75 19.66 0.32 11.1 2.65 0.29 0.84 0.37 0.94 428 2.9 Silica fume 0.12 96.65 0.31 0.07 0.11 1.21 0.22 0.67 0.17 0.83 200000 2.1 表 2 钢纤维增强地聚物再生混凝土(SFRGRAC)设计配合比

Table 2 Designed mix proportions of steel fiber reinforced geopolymer recycled aggregate concrete (SFRGRAC)

No. Specimen Proportions/(kg·m−3) Slag Sand NA RA Silica fume Steel fiber Water Sodium

silicateSodium

hydroxidePlastisizer 1 R50F00S00 417 724 724 543 0 0 61.08 161.75 3.59 3.3 2 R50F00S05 396.15 724 724 543 20.85 0 66.77 168.68 12.08 3.3 3 R50F00S10 375.3 724 724 543 41.7 0 72.47 159.80 11.45 3.3 4 R50F00S15 354.45 724 724 543 62.55 0 78.17 150.93 10.81 3.3 5 R50F10S00 417 724 724 543 0 78.5 61.08 161.75 3.59 3.3 6 R50F05S10 375.3 724 724 543 41.7 39.25 72.47 159.8 11.45 3.3 7 R50F10S05 396.15 724 724 543 20.85 78.5 66.77 168.68 12.08 3.3 8 R50F10S10 375 724 724 543 41.7 78.5 72.47 159.8 11.45 3.3 9 R50F10S15 354.45 724 724 271.5 62.55 78.5 78.17 150.93 10.81 3.3 10 R25F10S10 375.3 724 724 271.5 41.7 78.5 72.47 159.8 11.45 3.3 11 R00F10S10 375.3 724 818 0 41.7 78.5 72.47 159.8 11.45 3.3 12 R50F15S10 375.3 724 626 543 41.7 117.75 72.47 159.8 11.45 3.3 Notes: R—Addition of recycled aggregate; F—Volume fraction of steel fiber; S—Addition of silica fume. R50F10S10 represents the 50% recycled aggregate content, 1.0vol% steel fiber volume fraction and 10wt% silica fume content. 表 3 SFRGRAC强度和弹性模量测试结果

Table 3 Test results of machine strength and elastic modulus of SFRGRAC

Specimen Compressive strength/MPa Splitting tensile strength/MPa Flexural strength/MPa Modulus of elasticity/GPa 3 d 7 d 28 d 3 d 7 d 28 d 28 d 28 d R50F00S00 38.07 43.05 47.51 3.39 3.71 4.16 3.79 13.02 R50F00S05 39.15 48.53 51.24 3.72 4.10 4.41 4.18 13.35 R50F00S10 41.36 48.60 53.96 3.91 4.27 4.32 4.26 14.75 R50F00S15 28.95 36.39 47.80 2.66 3.10 3.19 3.64 11.29 R50F10S00 40.30 48.44 54.05 3.98 4.42 4.91 4.30 13.85 R50F05S10 47.78 49.31 55.68 4.57 5.26 5.80 4.48 18.48 R50F10S05 49.15 53.75 57.25 5.54 5.91 6.26 4.83 16.43 R50F10S10 49.85 54.30 58.76 5.61 6.15 6.61 5.18 22.51 R50F10S15 40.75 46.93 55.91 5.00 5.51 6.16 4.06 14.22 R25F10S10 52.15 56.62 60.21 5.64 6.56 6.88 5.32 24.37 R00F10S10 55.91 61.27 65.14 6.16 7.01 7.24 5.68 27.52 R50F15S10 53.49 58.95 65.39 5.75 6.46 6.68 5.34 24.35 表 4 混凝土基质中孔隙率的总体积分数

Table 4 Total volume fraction of porosity in the concrete matrix

Specimen Curing age/d Small pores (<4 μm) Medium pores (4~6 μm) Large pores (≥10 μm) Total R50F10S00 3 3.15 0.29 0.61 4.05 28 2.31 0.08 0.94 3.32 R50F10S05 3 3.06 0.12 0.72 3.91 28 2.11 0.06 0.61 2.78 R50F10S10 3 3.13 0.061 0.86 4.06 28 2.07 0.08 0.37 2.53 R50F10S15 3 4.01 0.38 0.80 5.19 28 2.71 0.12 0.88 3.71 -

[1] SABAU M, BOMPA D, SILVA L, et al. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content[J]. Geoscience Frontiers, 2021, 12(6): 101235. DOI: 10.1016/j.gsf.2021.101235

[2] 李佳彬, 肖建庄, 孙振平. 再生粗骨料特性及其对再生混凝土性能的影响[J]. 建筑材料学报, 2004(4): 390-395. DOI: 10.3969/j.issn.1007-9629.2004.04.006 LI Jiabin, XIAO Jianzhuang, SUN Zhenping. Properties of recycled coarse aggregate and its influence on recycled concrete[J]. Journal of Building Materials, 2004(4): 390-395(in Chinese). DOI: 10.3969/j.issn.1007-9629.2004.04.006

[3] XIE J H, CHEN W, WANG J J, et al. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete[J]. Construction and Building Materials, 2019, 226: 345-359. DOI: 10.1016/j.conbuildmat.2019.07.311

[4] 丁兆洋, 周静海, 苏群, 等. 地聚物再生骨料混凝土的力学性能研究[J]. 沈阳建筑大学学报(自然科学版), 2021, 37(1): 138-146. DING Zhaoyang, ZHOU Jinghai, SU Qun, et al. Mechanical properties of geopolymer recycled aggregate concrete[J]. Journal of Shenyang Jianzhu University (Natural Science), 2021, 37(1): 138-146(in Chinese).

[5] 龙涛, 石宵爽, 王清远, 等. 粉煤灰基地聚物再生混凝土的力学性能和微观结构[J]. 四川大学学报(工程科学版), 2013, 45(S1): 43-47. LONG Tao, SHI Xiaoshuang, WANG Qingyuan, et al. Mechanical properties and microstructure of fly ash based geopolymeric polymer recycled concrete[J]. Advanced Engineering Sciences, 2013, 45(S1): 43-47(in Chinese).

[6] ZHANG P, WANG J, LI Q F, et al. Mechanical and fracture properties of steel fiber-reinforced geopolymer concrete[J]. Science and Engineering of Composite Materials, 2021, 28(1): 299-313. DOI: 10.1515/secm-2021-0030

[7] ZHENG J H, QI L, ZHENG Y Q, et al. Mechanical properties and compressive constitutive model of steel fiber-reinforced geopolymer concrete[J]. Journal of Building Engineering, 2023, 80: 108161. DOI: 10.1016/j.jobe.2023.108161

[8] ZHAO Q H, WANG Y Q, XIE M, et al. Experimental study on mechanical behavior of steel fiber reinforced geopolymeric recycled aggregate concrete[J]. Construction and Building Materials, 2022, 356: 129267. DOI: 10.1016/j.conbuildmat.2022.129267

[9] XU Z, HUANG Z P, LIU C J, et al. Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete[J]. Reviews on Advanced Materials Science, 2021, 60(1): 578-590. DOI: 10.1515/rams-2021-0050

[10] OKOYE F, DURGAPRASAD J, SINGH N. Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete[J]. Ceramics International, 2016, 42(2): 3000-3006. DOI: 10.1016/j.ceramint.2015.10.084

[11] LIU Y W, SHI C J, ZHANG Z H, et al. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume[J]. Cement and Concrete Composites, 2020, 112: 103665. DOI: 10.1016/j.cemconcomp.2020.103665

[12] LI B, GAO A X, LI Y, et al. Effect of silica fume content on the mechanical strengths, compressive stress-strain behavior and microstructures of geopolymeric recycled aggregate concrete[J]. Construction and Building Materials, 2023, 384: 131417. DOI: 10.1016/j.conbuildmat.2023.131417

[13] 马维, 何兆益. 碱激发矿渣粉煤灰地质聚合物力学性能改性及其混凝土性能[J]. 矿产综合利用, 2024, 45(4): 182-189. MA Wei, HE Zhaoyi. Mechanical properties modification of alkali-activated slag fly ash based geopolymer and its concrete properties[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(4): 182-189(in Chinese).

[14] 夏冬桃, 吴晨, 崔凯, 等. 粉煤灰和硅灰取代率对碱矿渣混凝土力学性能影响分析[J]. 西南交通大学学报, 2024, 59(5): 1113-1122. XIA Dongtao, WU Chen, CUI Kai, et al. Effect of fly ash and silica fume contents on the mechanical properties of alkali-activated slag-based concrete[J]. Journal of Southwest Jiaotong University, 2024, 59(5): 1113-1122(in Chinese).

[15] 中国国家标准化管理委员会. 普通混凝土配合比设计规程: JGJ 55—2011[S]. 北京: 中国建筑工业出版社, 2011. Standardization Administration of the People's Republic of China. Specification for mix proportion design of ordinary concrete: JGJ 55—2011[S]. Beijing: China Architecture & Building Press, 2011(in Chinese).

[16] 中国国家标准化管理委员会. 再生混凝土结构技术标准: JGJ/T 443—2018[S]. 北京: 中国建筑工业出版社, 2018. Standardization Administration of the People's Republic of China. Technical standard for recycled concrete structures: JGJT 443—2018[S]. Beijing: China Architecture & Building Press, 2018(in Chinese).

[17] LI B, WU C, WANG S N, et al. Monotonic and cyclic compressive behavior of ultra-high performance concrete with coarse aggregate: Experimental investigation and constitutive model[J]. Journal of Building Engineering, 2023, 68: 106002. DOI: 10.1016/j.jobe.2023.106002

[18] LI B, WANG C L, YU S T, et al. Effect of recycled aggregate and steel fiber contents on the mechanical properties and sustainability aspects of alkali-activated slag-based concrete[J]. Structures, 2023, 66: 105939.

[19] 中国国家标准化管理委员会. 混凝土物理力 学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国标准出版社, 2019. Standardization Administration of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Standards Press, 2019(in Chinese).

[20] 中国国家标准化管理委员会. 普通混凝土拌和性能标准: GB/T 50080—2016[S]. 北京: 中国建筑工业出版社, 2016. Standardization Administration of the People's Republic of China. Standard for test method of performance on ordinary fresh concrete: GB/T 50080—2016[S]. Beijing: China Architecture & Building Press, 2016(in Chinese).

[21] WAN Q, ZHANG Y M, ZHANG R B. The effect of pore behavior and gel structure on the mechanical property at different initial water content[J]. Construction and Building Materials, 2021, 309: 125146. DOI: 10.1016/j.conbuildmat.2021.125146

[22] BAI W F, LU X F, GUAN J F, et al. Experimental study on uniaxial compression mechanical properties of recycled concrete with silica fume considering the effect of curing age[J]. Construction and Building Materials, 2022, 350: 128758. DOI: 10.1016/j.conbuildmat.2022.128758

[23] SASANIPOUR H, ASLANI F, TAHERINEZHAD J. Effect of silica fume on durability of self-compacting concrete made with waste recycled concrete aggregates[J]. Construction and Building Materials, 2019, 227: 116598. DOI: 10.1016/j.conbuildmat.2019.07.324

[24] 张雄, 张恒, 张晓乐, 等. 硅灰调控混凝土力学性能的关键界面参数研究. 建筑材料学报[J]. 2019, 22(4): 626-631. ZHANG Xiong, ZHANG Heng, ZHANG Xiaole, et al. Key interface parameters for the control of silica fume on mechanical properties of concrete[J]. Journal of Building Materials, 2019, 22(4): 626-631(in Chinese).

[25] 黄华, 郭梦雪, 张伟, 等. 粉煤灰-矿渣基地聚物混凝土力 学性能与微观结构[J]. 哈尔滨工业大学学报, 2022, 54(3): 74-84. DOI: 10.11918/202104058 HUANG Hua, GUO Mengxue, ZHANG Wei, et al. Mechanical property and microstructure of geopolymer concrete based on fly ash and slag[J]. Journal of Harbin Institute of Technology, 2022, 54(3): 74-84(in Chinese). DOI: 10.11918/202104058

[26] ZHU L, NING Q, HAN W, et al. Compressive strength and microstructural analysis of recycled coarse aggregate concrete treated with silica fume[J]. Construction and Building Materials, 2022, 334: 127453.

[27] 吴中伟. 混凝土科学技术近期发展方向的探讨[J]. 硅酸盐学报, 1979(3): 262-270. WU Zhongwei. An approach to the recent trends of concrete science and technology[J]. Journal of the Chinese Ceramic Society, 1979(3): 262-270(in Chinese).

-

期刊类型引用(1)

1. 曾鹏程,肖书平,杨柳,谈灵操,徐百平. 较宽压强响应范围和较高灵敏度的聚丙烯基电容式压力传感器的研制. 机电工程技术. 2025(03): 58-63 .  百度学术

百度学术

其他类型引用(3)

-

其他相关附件

-

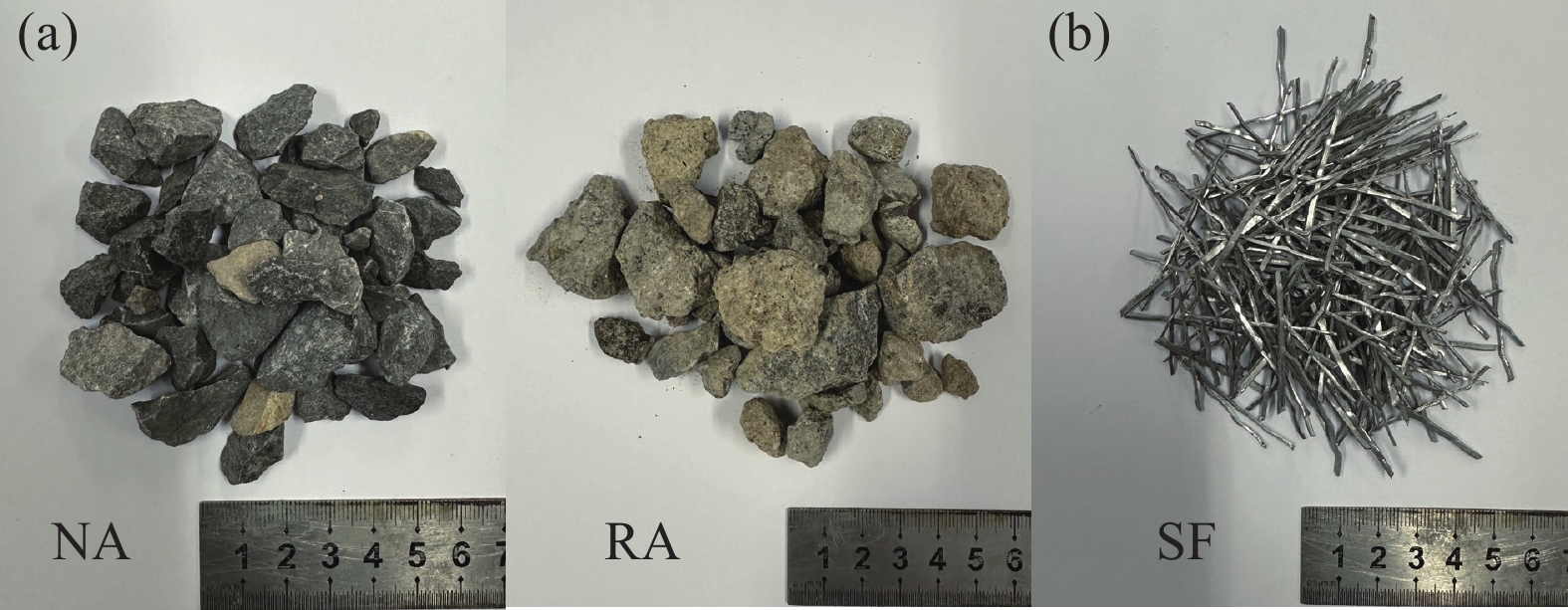

目的

硅灰具有良好的填充和火山灰效应,能够有效弥补钢纤维和再生骨料间的界面薄弱区。目前,硅灰对地聚物混凝土力学性能的影响已取得了一些进展,但硅灰改性SFRGRAC的研究还鲜见报道,硅灰取代率和钢纤维体积掺量对SFRGRAC力学性能影响规律并未达成一致,硅灰对SFRGRAC的改性机理也尚不明确。因此,探究硅灰对SFRGRAC的增强机理具有重要意义。

方法采用试验研究和理论分析相结合的方法,以硅灰改性SFRGRAC机理研究为主线,通过立方体抗压、劈裂抗拉、抗折和弹性模量试验,研究硅灰取代率、钢纤维体积掺量和再生骨料取代率等因素对SFRGRAC力学性能的影响规律,并基于SEM扫描电镜和低场核磁共振测试结果揭示硅灰的改性机制。

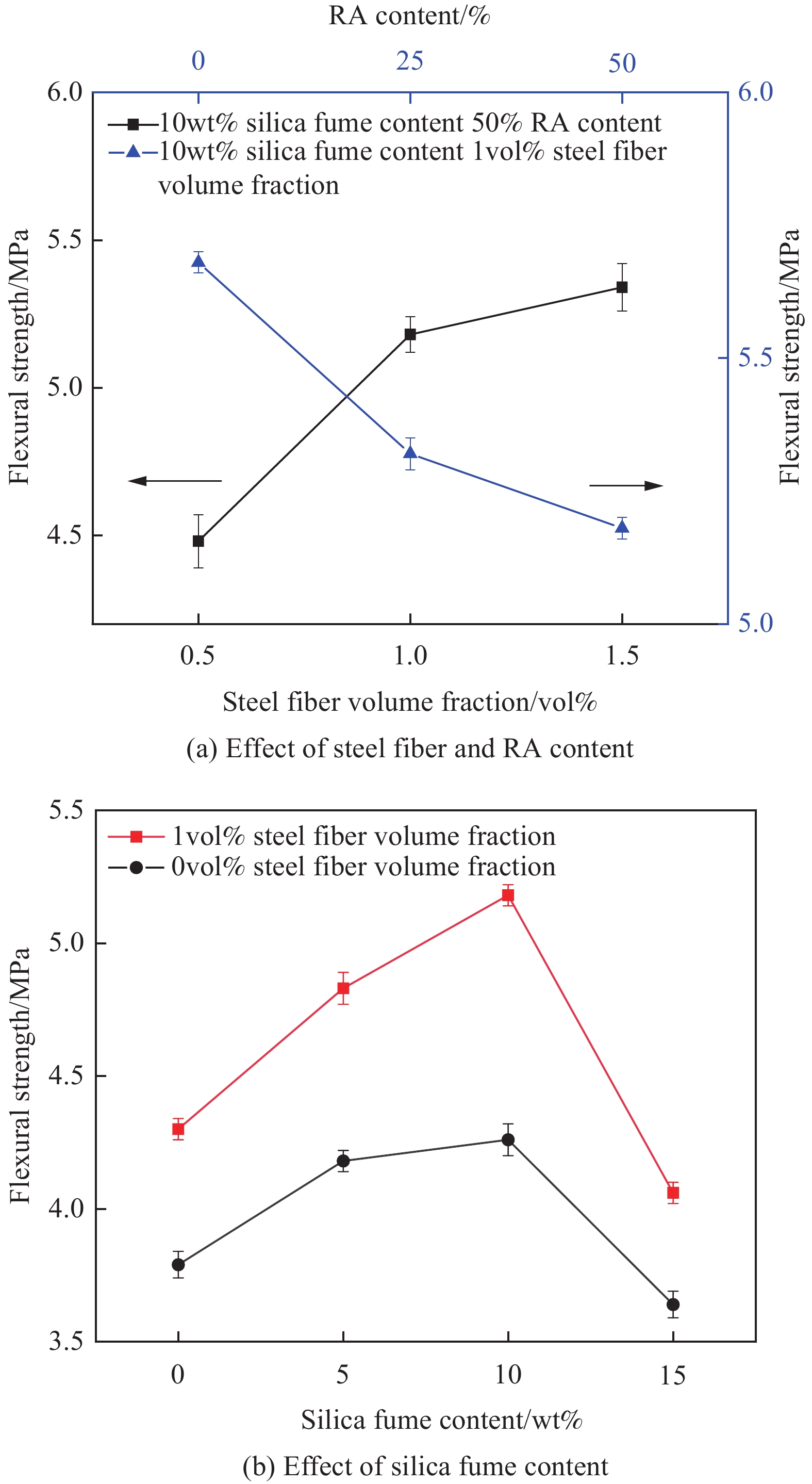

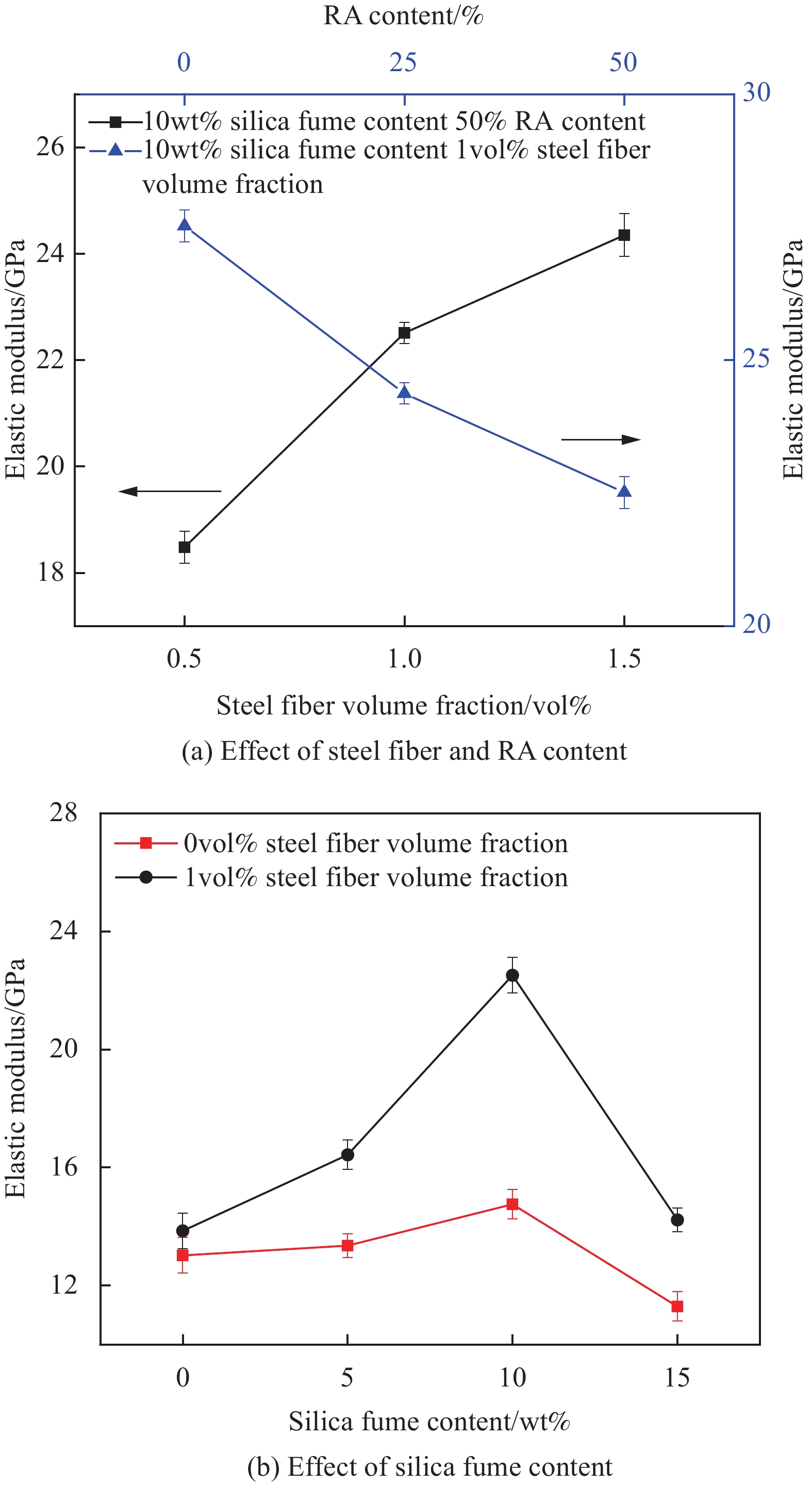

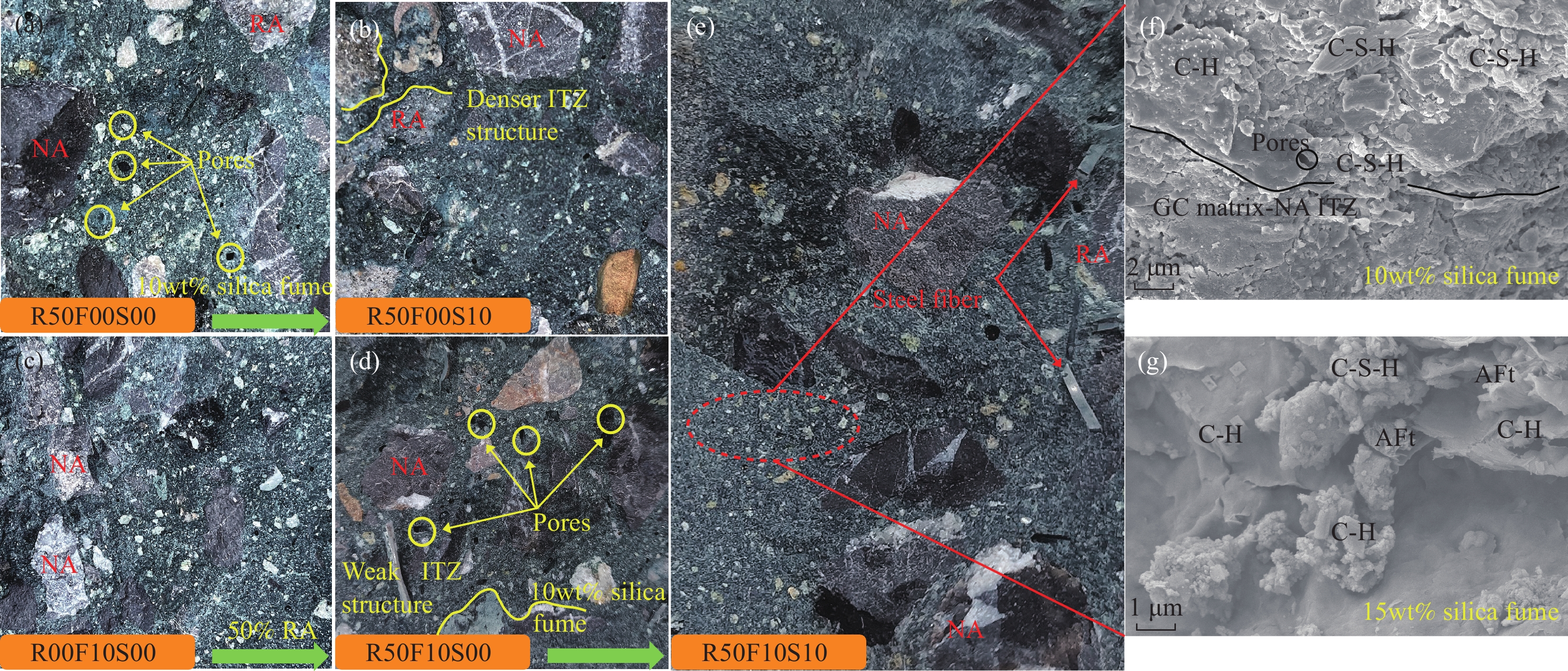

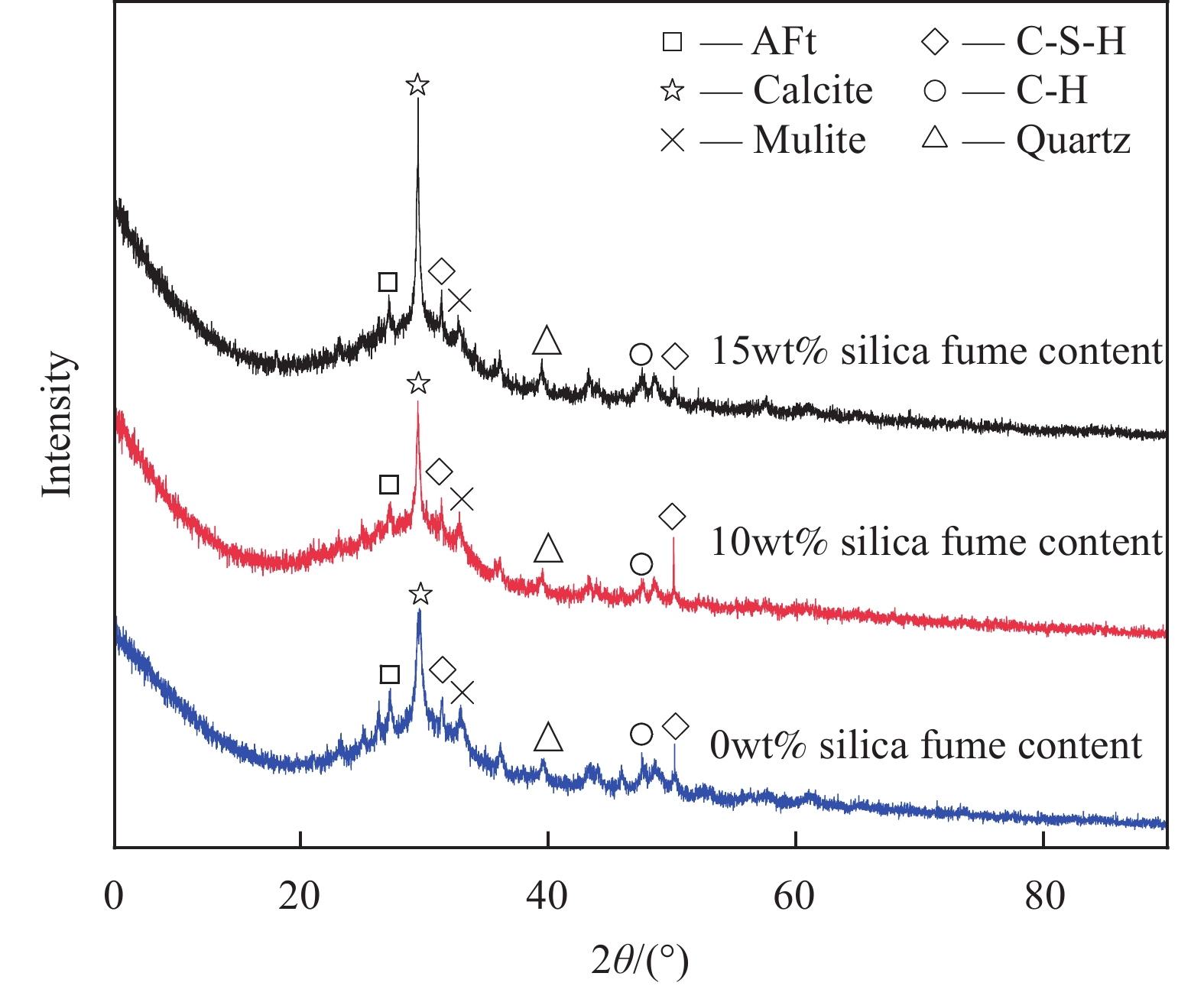

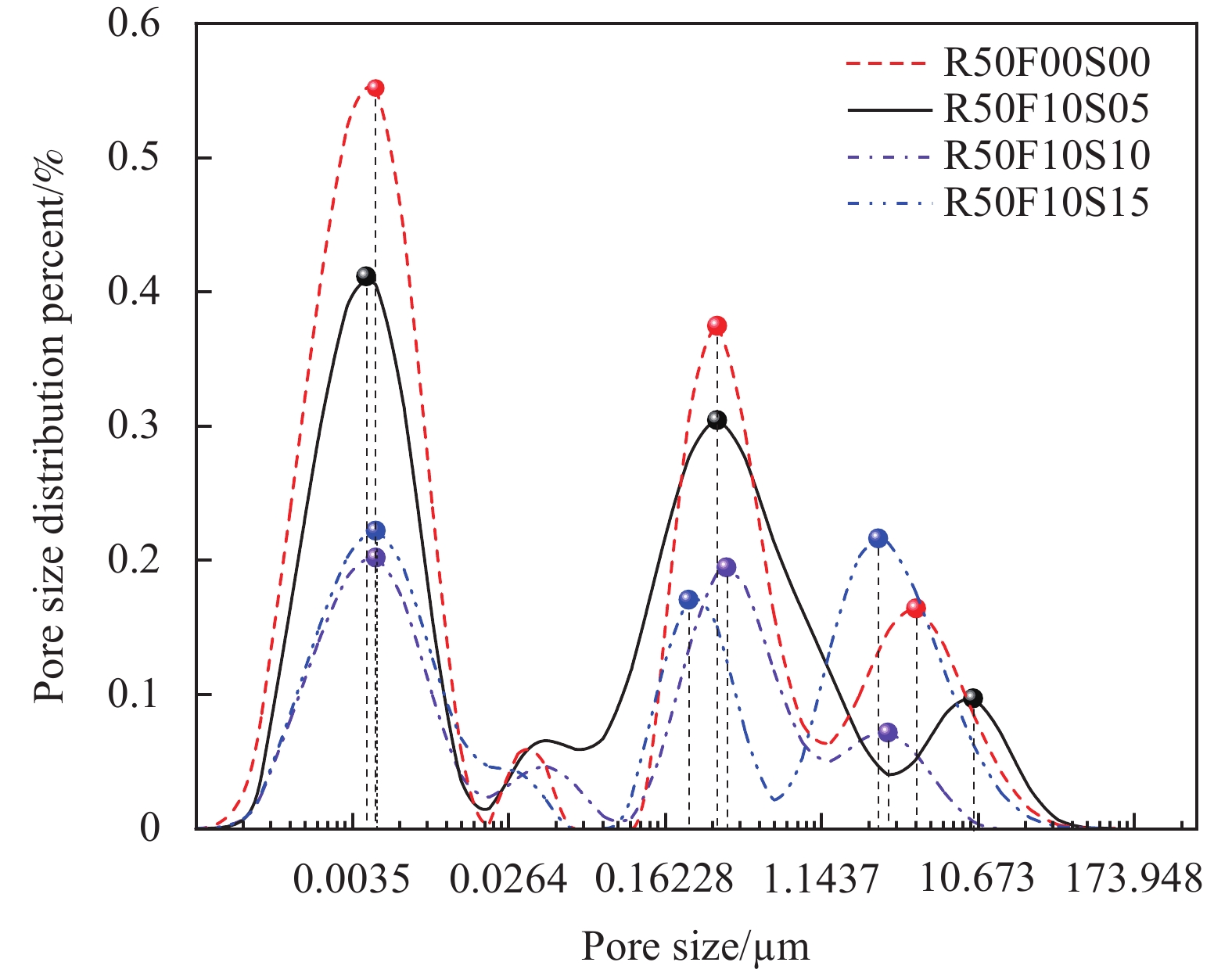

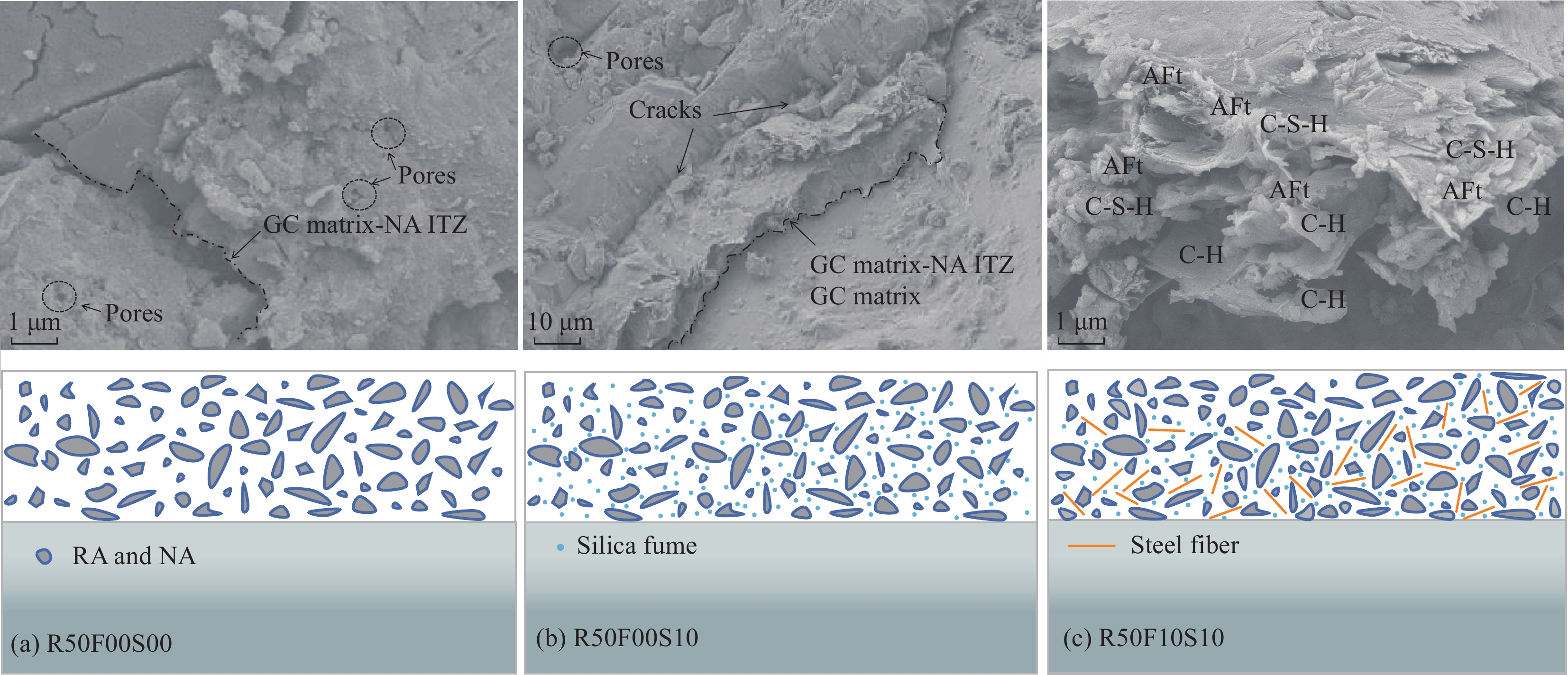

结果通过对SFRGRAC力学性能及微观结构分析,研究结果表明:(1)硅灰对SFRGRAC的改性效果优于GRAC。添加5%~15%硅灰后,GRAC的强度提升幅度为7%左右,而SFRGRAC强度提高幅度可到到20%以上;掺入10%硅灰后,随着钢纤维体积掺量由0.5%增至1.5%,SFRGRAC的立方体抗压、劈裂抗拉、抗折强度和弹性模量分别增加了17.44%、15.17%、19.19%和31.76%;(2)加入硅灰可有效弥补由再生骨料的弱界面对GRAC强度的负面影响。硅灰掺量为10%时,SFRGRAC立方体抗压、劈裂抗拉、抗折强度和弹性模量分别比未掺硅灰试件增加了8.89%、34.62%、20.47%和62.53%;(3)硅灰的填充和火山灰效应有效改善了SFRGRAC的微观结构。掺入10%硅灰时降低了浆体中C-H含量并提高了C-S-H含量,密实了混凝土基体和骨料基体ITZ的微观结构。然而,当硅灰掺量增至15%时,由于胶凝材料水化不足,.导致方解石体积增大及C-S-H凝胶体积减少,从而减弱了SFRGRAC基体的密实程度。硅灰掺量由0%增至10%和15%,凝结时间平均提高了34.35%和42.38%;(4)硅灰的加入能有效降低SFRGRAC的孔隙率。添加10%硅灰后,SFRGRAC总孔隙率降低23.79%,而硅灰掺量为15%时,试件总孔隙率降低幅度明显减小。试件抗压、劈拉和抗折强度和弹性模量均随着孔隙率增大而线性降低。

结论掺入钢纤维能够显著提高GRAC的强度。硅灰与SFRGRAC能产生良好的耦合效应,使其微观结构更加致密,进而提升SFRGRAC力学性能。目前,本文研究主要集中在硅灰改性SFRGRAC力学性能研究,而地聚物水化反应机理较为复杂,本文只分析了水化产物、微观形貌和孔结构,而碱矿渣体系的水化过程的相关分析较为浅薄,可以考虑借助水化热试验和TGA热重分析试验对碱矿渣体系的水化反应过程进行系统研究。同时,为硅灰改性SFRGRAC的推广应用,建议对其耐久性能(如抗氯离子渗透、抗硫酸盐腐蚀、耐高/温性能等)进行系统研究。

-

钢纤维增强地聚物再生混凝土(Steel fiber reinforced geopolymer recycled concrete,简称SFRGRAC)具有碳排放低、高早期强度和高韧性等优点,具有广泛的应用前景。但掺入钢纤维易在混凝土内部形成弱界面,影响了SFRGRAC力学性能和微观结构。因此,本文以硅灰为增强材料对SFRGRAC的力学性能进行改善。

本文主要研究了硅灰取代率、钢纤维体积掺量和再生骨料取代率对SFRGRAC强度和弹性模量的影响规律,并基于微观试验测试结果,揭示硅灰对SFRGRAC的改性机理。研究发现:钢纤维体积掺量由0.5%增至1.5%,SFRGRAC的立方体抗压、劈裂抗拉、抗折强度和弹性模量分别增加了17.44%、15.17%、19.19%和31.76%;掺入10%硅灰有效改善SFRGRAC的微观结构,使得SFRGRAC强度平均提高了20%以上,但当硅灰掺量为15%时,由于胶凝材料未能充分水化,减弱了SFRGRAC的基体致密程度和力学性能;掺入硅灰使SFRGRAC总孔隙率降低了35%以上。

SFRGRAC劈裂抗拉强度和孔隙率分布图 (a)硅灰取代率对SFRGRAC劈裂抗拉强度影响(b)硅灰掺量对SFRGRAC总孔隙率的影响

下载:

下载: