Preparation and properties of flexible MXene-carbon black/polyimide electromagnetic shielding composite films with harsh environment resistance

-

摘要:

导电聚合物复合材料(CPC)以其价格低廉、重量轻、比强度高、耐腐蚀、屏蔽性能优异等优点,正逐步取代传统的金属基电磁屏蔽材料,但传统聚合物对极端温度、酸性和碱性溶液等恶劣环境的耐受性较差,影响了 CPC 在恶劣环境中的电磁屏蔽性能(EMI SE),难以满足特殊环境等领域的需求。因此,探索制备方法简单、适用于极端环境的柔性多功能电磁屏蔽材料仍然是一项挑战。本文通过刮膜法和热亚胺化工艺,成功制备了具有高电磁屏蔽效能的 MXene-炭黑/聚酰亚胺(MXene-CB/MCP)复合薄膜。由于 MXene 和炭黑(CB)具有良好的导电性以及二者之间的协同效应,厚度为 80 μm的MXene-CB/MCP -35 复合薄膜在 8.2~12.4 GHz 的频率范围内的EMI SE 和电磁屏蔽效能与厚度的比值(EMI SE/t)分别为 24.06 dB 和 300.75 dB/mm。且经过复杂环境处理后,该复合薄膜仍表现出稳定的电磁屏蔽效能。另外复合薄膜都具有优异的力学性能,MXene-CB/MCP -35 复合薄膜的平均拉伸强度仍可达到 100.40 MPa。与此同时,薄膜还具有优异的热稳定性和阻燃性。

Abstract:Conductive polymer composites (CPC) are gradually replacing traditional metal-based electromagnetic shielding materials due to their advantages of low price, light weight, high specific strength, corrosion resistance, and excellent shielding performance, etc. However, the traditional polymers are less resistant to harsh environments, such as extreme temperatures, acidic and alkaline solutions, which affects the electromagnetic shielding performance of CPC in harsh environments (EMI SE) and makes it difficult to satisfy the needs of special environments and other It is difficult to meet the needs of special environments and other fields. Therefore, it is still a challenge to explore flexible multifunctional EM shielding materials with simple preparation methods and suitable for extreme environments. In this paper, MXene-carbon black/polyimide (MXene-CB/MCP) composite films with high electromagnetic shielding efficiency were successfully prepared by the scraping method and thermal imidization process. Due to the good electrical conductivity of MXene and carbon black (CB) and the synergistic effect between them, the EMI SE and the ratio of electromagnetic shielding effectiveness to thickness (EMI SE/t) of the MXene-CB/MCP -35 composite film with a thickness of 80 μm were 24.06 dB and 300.75 dB/mm, respectively, in the frequency range of 8.2-12.4 GHz, and after complex environmental treatment, the composite film was successfully fabricated. The composite films show stable EMI shielding performance even after complex environmental treatment. In addition, the composite films have excellent mechanical properties, with the average tensile strength of the MXene-CB/MCP -35 composite film still reaching 100.40 MPa. The films also have excellent thermal stability and flame retardancy.

-

Keywords:

- Polyimide /

- Carbon black /

- MXene /

- Electromagnetic interference shielding /

- Harsh environment

-

麻纤维具有与玻璃纤维相当的比强度和比刚度,同时成本低、来源广泛、绿色天然无污染,因此由其增强的复合材料有望在汽车、高铁、飞机等运载工具上得到广泛应用[1-4]。由于麻纤维增强复合材料的力学性能对其在运载工具上的应用有很大影响,如何有效地设计和开发麻纤维增强复合材料以达到所需性能已成为当务之急。以往的研究大都通过实验探究麻纤维增强复合材料的性能:Mohammad等[5]通过实验得出黄麻纤维增强复合材料拉伸性能改善的最佳辐射剂量;Akash等[6]的研究获得了剑麻纤维/大麻纤维混杂的增强复合材料最大弯曲和压缩强度下的纤维含量;Jomy等[7]采用实验发现黄麻增强复合材料的耐磨性最佳的黄麻含量。然而实验研究包括了制备和测试等过程,需要花费大量的成本和时间,采用数值仿真分析技术有望弥补实验研究的不足,从而快速有效地设计和预测复合材料性能。

因此,Kern等[8]利用二维代表性体积元(RVE)模型对比了具有和不具有微孔泡沫结构的短切天然麦秸纤维复合材料的力学行为。Sukiman等[9]基于二维RVE研究了随机分布的短纤维复合材料的微观结构,以评估复合材料有效的热和机械性能。但对于不连续天然纤维复合材料,纤维在空间上分布不同,采用2D平面模型计算出的结果会与其整体性能有偏差。Sliseris等[10]在考虑纤维缺陷和纤维束的情况下,采用RSA算法生成了不同纤维取向和不同长径比的亚麻短纤维复合材料微观三维RVE结构模型,并研究了复合材料的损伤机制。然而,相比于玻璃纤维和碳纤维等人造纤维,植物麻纤维具有更复杂的微观结构,有空腔结构的纤维管胞,每个管胞为厚壁中空结构,由初级细胞壁、次级细胞壁、中空空腔组成[11-12]。而现有麻纤维复合材料拉伸性能RVE模型在建模过程中却未充分考虑麻纤维的腔体结构对麻纤维增强树脂基复合材料弹性模量的影响,迫切需要进一步开展基于腔体结构的麻纤维增强复合材料弹性模量预测方法研究,以期更准确地预测和调控麻纤维增强树脂基一大类复合材料的性能。

为此,本文针对植物麻纤维增强复合材料力学性能模拟仿真中,未能充分考虑麻纤维独特的腔体微观结构特征,难以准确预测麻纤维增强复合材料拉伸性能的现状,本文以注塑成型短苎麻纤维增强聚丙烯复合材料为研究对象,综合混合定律和Micro-CT技术,提出了基于麻纤维腔体结构特征的麻纤维等效模型及其弹性模量计算理论公式。在此基础上,探寻一种基于腔体的天然麻纤维增强树脂基复合材料的RVE多尺度模型并预测复合材料弹性模量的理论方法,从微/细观尺度出发,求解其均质化性能,构建多尺度计算联系,并与实验测试结果进行对比以验证RVE多尺度建模的有效性与可靠性。另一方面,采用正交试验和方差分析探讨纤维含量、纤维空腔占比、纤维取向、纤维长径比多参数对麻纤维增强复合材料弹性模量的影响权重顺序,运用多项式拟合法获得了以上述4个参数为自变量的麻纤维增强树脂基复合材料弹性模量预测公式,由于各类植物麻纤维都具有与苎麻纤维类似的腔体结构,本文提出的基于腔体结构的植物麻纤维增强树脂基复合材料弹性模量预测方法可以推及拓展至麻类纤维增强树脂基一大类复合材料,为预测和调控麻纤维增强树脂基一大类复合材料的拉伸模量提供了新方法。

1. 理论与模型

1.1 复合材料内部微观结构

本文采用CT扫描技术(Xradia 515 Versa,ZEISS)对苎麻纤维增强复合材料进行CT扫描。首先将样品固定在夹具中,并放在工作台上。采用60 kV加速电压和5 W的功率以1.99 μm的分辨率对复合材料样品进行扫描,扫描结果如图1所示。

由图1可见,苎麻纤维具有腔体微观结构特征。通过CT扫描自带软件构建复合材料3D图像堆栈,然后导入Avizo软件进行可视化和纤维数据分析。首先在选择的分析区域(图1(b)方框部分)进行双边滤波,得到所选区域放大图像(图1(d)),再对区域进行阈值分割和降噪处理得到图1(e),最终采用Avizo软件计算获得空腔体积比为20vol%。

1.2 麻纤维等效模型及其弹性模量计算

由苎麻纤维的SEM扫描电镜截图(图2)可知[13-14],麻纤维具有独特的腔体结构特征,该微观结构将影响麻纤维增强复合材料的整体力学性能和预测建模的准确性[15-16]。因此,本文在建模的过程中充分考虑麻纤维腔体结构,将含空腔的麻纤维看成具有空腔和纤维两种组分的非均质材料,如图2(c)所示。麻纤维的等效弹性模量可采用均匀化方法中的混合定律[17]求解,求解公式如下:

Eef=vlEl+vfEf (1) vl+vf=1 (2) 式中:Eef、El、Ef分别为含空腔麻纤维等效弹性模量、空腔弹性模量、麻纤维弹性模量;vl、vf分别为空腔体积占比和除空腔部分的纤维体积占比。由于空腔的弹性模量为0 MPa,故公式(1)可简化为

Eef=vfEf (3) 1.3 纤维取向

考虑麻纤维增强复合材料注塑成型过程中形成的纤维取向[18-19],采用Bay和Tucker[20]提出的纤维的取向模型,描述了3种典型纤维取向状态,并给出了纤维取向张量分量的取值,在纤维增强复合材料中,纤维一般假设为不可弯曲的棒状体,用单位矢量p来描述单根纤维的取向,如图3所示,p的表达式如下:

p=(u,v,w)=(sinθcosφ,sinθsinφ,cosθ) (4) 式中:θ表示p与3轴的夹角,范围是(0°,90°);ϕ表示p在1-2平面上的投影与1轴的夹角,范围是(−180°,180°)。

对RVE中的所有纤维,取向也可以用取向概率分布函数ψ(p)来表示,取向在p和p+dp之间的纤维概率为ψ(p)dp,基于概率分布函数ψ(p)定义的二阶取向张量aij为

aij=∫pipjψ(p)dp=∫pipjψ(θ)sinθdθdϕ (5) 对角化后的纤维二阶取向张量可以采用如下形式:

aij=[λ1000λ2000λ3] (6) 其中:λ1+λ2+λ3=1,设λ1=sin2θcos2φ,λ2=sin2θsin2φ,λ3=cos2θ[20]。根据此式画出的纤维取向三角如图4所示,其中三角形的3个端点A(1, 0)、B(0.5, 0.5)、C(0.33, 0.33)对应纤维取向的3个状态:单向分布、平面随机分布和空间随机分布。

CT扫描苎麻纤维取向角度参数如表1所示,在注射成型复合材料的初始填充中,纤维主要位于注射流动平面中,与平面有轻微的偏转角[21],取向张量的分量λ3的中位数为0.01,考虑到研究和建模的便利性,设λ3为0[22],由此可得λ1+λ2=1,实际注射成型样件的纤维取向张量λ1的范围在0.00~1.00之间。

表 1 CT扫描获取苎麻增强复合材料中苎麻纤维取向张量分量值、长度和直径分布参数Table 1. Distribution parameters of orientation tensor components, length and diameters of ramie fibers in the ramie fiber reinforced composite from CT scanningParameter λ1 λ2 λ3 L/μm d/μm Max 1.00 1.00 0.92 505 86 Min 0.00 0.00 0.00 65 3 Mean 0.83 0.14 0.03 122 20 Notes:λ1, λ2, λ3—Fiber orientation tensor components; L—Fiber length; d—Fiber diameter. 1.4 纤维长径比

除了纤维取向,纤维长径比对纤维增强复合材料的性能也有较大的影响,通过Avizo软件分析CT扫描并统计获取苎麻纤维的长度(L)和直径(d)的最大值、最小值和平均值数据如表1所示,苎麻纤维长径比分布图如图5所示。

1.5 RVE多尺度模型

采用Digimat软件构建注塑成型苎麻短纤维增强复合材料的RVE有限元模型,麻类纤维增强复合材料可以采用同样的方式来构建,两种组分的材料力学参数如表2所示,聚丙烯(PP)的弹性模量参数由PP样件的拉伸实验获取。RVE尺寸设置为2L×2L×4d[23],拉伸方向为1方向。

表 2 苎麻纤维与聚丙烯(PP)力学性能参数Table 2. Mechanical properties of ramie fiber and polypropylene (PP) in materialsComponent Elastic modulus/

MPaDensity/

(g·cm−3)Poisson's

ratioRamie fiber 61400 1.550 0.30 Polypropylene (PP) 790 0.904 0.42 建立合适的代表性体积元(RVE)后,对其进行网格划分,网格类型为四面体网格(Conforming(tetra)),网格尺寸设为0.004,边界条件设置为周期性边界条件,然后进行有限元数值计算,用RVE的平均力学性能代表整体结构的性能。

−σ11=1V′∫σ11dV (7) −ε11=1V′∫ε11dV (8) E11=−σ11−ε11 (9) 1.6 仿真试验设计

通过正交试验法研究纤维含量(A)、纤维空腔占比(B)、纤维取向张量分量λ1(C)、纤维长径比(D) 4个因素对麻纤维增强聚丙烯复合材料拉伸弹性模量的影响规律及影响权重。正交设计方案的仿真试验因素和水平如表3所示。

表 3 仿真实验水平和因素Table 3. Simulation experiment levels and factorsLevel Factor A/wt% B/vol% C D 1 5 16 0.4 2 2 10 18 0.6 6 3 15 20 0.8 10 4 20 22 1.0 14 Notes:A—Fiber content; B—Lumen volume fraction; C—Fiber orientation tensor component λ1; D—Fiber aspect ratio. 2. 拉伸性能实验

2.1 麻纤维增强复合材料制备

本文以麻纤维增强聚丙烯复合材料为研究对象,其制备所用主要原材料包括苎麻(工业级,农科院麻类研究所)、氨基硅油微乳液(自制)[24]、聚丙烯(工业级,中石油兰州石化公司)。

麻纤维增强树脂复合材料的制备过程是首先取一定量麻纤维浸入到氨基硅油微乳液中,超声振荡45 min,然后将麻纤维放入干燥箱充分干燥。将充分干燥的麻纤维和聚丙烯粒料在挤出机中充分混合造粒,然后将复合粒子放入注塑机中注塑成型为麻纤维含量为10wt%的麻纤维/聚丙烯复合材料(RFPC)测试标准样件。

2.2 拉伸性能测试

拉伸模量按照GB/T 1447—2005 《纤维增强塑料拉伸性能试验方法》[25]在微型电子万能试验机(WDW3020)上进行测试,拉伸速度为10 mm/min,标距为60 mm,将5组数据获取的平均值作为复合材料的拉伸模量值。

3. 结果与讨论

3.1 仿真模型验证

为验证仿真模型的可靠性,设定仿真模型中的纤维参数与实验测试中的纤维参数相同,即纤维含量为10wt%,纤维长度和直径值选择表1中的平均数(122 μm、20 μm),空腔占比20vol%,建立RVE多尺度模型计算复合材料的拉伸模量,RVE有限元模拟与拉伸实验测试结果的对比如图6所示。由图可知,当λ1为0.2~1.0的范围内时,考虑植物麻纤维腔体结构的拉伸模量值相比于未考虑植物麻纤维腔体结构的拉伸模量值更接近实验值,表明考虑腔体结构的复合材料RVE模型相比未考虑腔体结构的复合材料更精确。为了验证建立模型的有效性,本文采用CT扫描技术测试获取了本文研制的苎麻纤维含量为10wt%的苎麻纤维增强聚丙烯复合材料(RFPC)内苎麻纤维的取向张量分量λ1的均值为0.83。按照拉伸模量测出该材料的弹性模量为

1020 MPa。由图6可知,模拟仿真对应的复合材料当λ1=0.83时,其拉伸模量模拟值为1157 MPa,模拟结果与实验测试的误差为13.4%,该误差满足工程模拟误差≤20%的要求[26],表明所建立的RVE仿真模型具有有效性。3.2 麻纤维参数对复合材料弹性模量的影响分析

3.2.1 正交试验和方差分析

本文将纤维含量(A)、纤维空腔占比(B)、纤维取向张量分量λ1(C)、纤维长径比(D) 4个参数作为仿真实验变量,纤维直径采用CT扫描获取的平均值,采用正交试验设计了正交表L16(44),进行了16次仿真试验,RVE模型如图7所示,正交试验结果如表4所示。

从图8和表5中可以清楚地看出,纤维含量(A)对复合材料的拉伸性能影响最为显著,纤维空腔占比(B)对复合材料拉伸模量的影响最不显著,4个参数对麻纤维复合材料拉伸模量的影响权重大小排序为纤维含量(A)>纤维长径比(D)>取向张量分量(C)>空腔占比(B)。对拉伸模量最大的影响因素是纤维含量,随着纤维含量的增加,复合材料拉伸模量增大。这是由于纤维的刚度高于基体的刚度,因而纤维含量越高,复合材料的弹性模量越大。纤维长径比对复合材料的拉伸模量也有较大的影响,纤维长径比与复合材料的界面多少有关,纤维长径比越大,纤维和基体之间的界面越多,界面可以实现复合材料力的转移和传递,因此纤维长径比越大,组分间的结合强度增加,故其复合材料的弹性模量也相应增加。随着纤维在拉伸方向的取向张量分量值增大,拉伸模量也增大。这是由于纤维取向分量值越接近1,纤维长度方向与受力方向越一致,纤维可以承受的力就越大,因此纤维取向分量值越大,其增强的复合材料的拉伸模量值也越大。空腔占比越大,拉伸模量越小,这是由于随着空腔占比的增加,纤维的刚度下降。

由图8可知,拉伸模量最大时的参数组合为A4B1C4D4,即纤维含量为20wt%,纤维空腔占比为16vol%,纤维取向张量分量λ1为1.0,纤维长径比为14。

3.2.2 多项式拟合

为定量求解纤维增强相参数与复合材料拉伸性能之间的作用规律,本文以xi设定4个麻纤维参数,以x1代表纤维含量、x2代表纤维空腔占比、x3代表纤维取向、x4代表纤维长径比,并以y代表拉伸模量进行拟合,建立纤维参数与拉伸模量之间的函数方程式,具体表示为

表 4 苎麻/聚丙烯复合材料拉伸模量正交试验结果Table 4. Orthogonal experimental results for tensile modulus of ramie fiber reinforced compositesNo. Factor Evaluation metrics A/wt% B/vol% C D Tensile modulus/MPa 1 1 1 1 1 836.1 2 1 2 2 2 955.6 3 1 3 3 3 1084.0 4 1 4 4 4 1234.7 5 2 1 2 3 1185.5 6 2 2 1 4 1131.7 7 2 3 4 1 991.1 8 2 4 3 2 1195.1 9 3 1 3 4 2149.3 10 3 2 4 3 2255.0 11 3 3 1 2 1187.3 12 3 4 2 1 1070.1 13 4 1 4 2 2051.8 14 4 2 3 1 1191.0 15 4 3 2 4 2202.0 16 4 4 1 3 1426.8 表 5 苎麻/聚丙烯复合材料拉伸模量方差分析Table 5. Analysis of variance for tensile modulus of ramie fiber reinforced compositesFactor Df Sum Sq Mean Sq F value P value A 3 1537406 512469 4.127 0.137 B 3 211984 70661 0.569 0.673 C 3 481388 160463 1.292 0.419 D 3 921524 307175 2.474 0.238 Notes:Df—Degree of freedom; Sum Sq—Sum of squares; Mean Sq—Mean of squares. y=β0+4∑i=1βixi+4∑i=1βiixii+3∑i=14∑j=i+1βijxij (10) 利用Matlab对表3中的16组正交实验数据进行多项式拟合,求解出函数方程式的系数值,得出纤维参数与弹性模量之间的函数方程式:

y=−3802.23−59.31x1+503.77x2−64.01x4−1.09x21−10.70x22+257.01x23−0.81x24+0.23x1x2+123.81x1x3+6.03x1x4−102.30x2x3−1.29x2x4+130.67x3x4 (11) 将多项式拟合方程计算出的值与正交实验的仿真模拟值进行对比并计算出两者之间的误差,如表6所示。可以看出拟合结果与模拟结果的误差较小,最大仅为1.67%,说明本文拟合求解所得的函数方程式(11)具有较高的准确性,可用于分析纤维参数与拉伸模量的影响规律,预测并获知拉伸模量最大时的麻纤维参数组合。

表 6 苎麻/聚丙烯复合材料拉伸模量正交实验结果与拟合结果误差Table 6. Errors between orthogonal experimental results and fitting results for tensile modulus of ramie fiber reinforced compositesNo. Factor Tensile modulus/MPa x1/wt% x2/vol% x3 x4 Fitting value Simulation value Error/% 1 5 16 0.4 2 841.1 836.1 0.59 2 5 18 0.6 6 955.0 955.6 −0.06 3 5 20 0.8 10 1084.6 1084.0 0.05 4 5 22 1.0 14 1229.7 1234.7 −0.40 5 10 16 0.6 10 1167.7 1185.5 −1.50 6 10 18 0.4 14 1135.3 1131.7 0.32 7 10 20 1.0 2 987.5 991.1 −0.36 8 10 22 0.8 6 1212.9 1195.1 1.49 9 15 16 0.8 14 2167.1 2149.3 0.83 10 15 18 1.0 10 2258.6 2255.0 0.16 11 15 20 0.4 6 1183.7 1187.3 −0.30 12 15 22 0.6 2 1052.3 1070.1 −1.67 13 20 16 1.0 6 2039.3 2051.8 −0.61 14 20 18 0.8 2 1207.1 1191.0 1.35 15 20 20 0.6 14 2185.9 2202.0 −0.73 16 20 22 0.4 10 1439.3 1426.8 0.88 Notes:x1—Fiber content; x2—Lumen volume fraction; x3—Fiber orientation tensor component λ1;x4—Fiber aspect ratio. 3.2.3 单一麻纤维参数对拉伸模量的主效应作用规律

通过前面的分析得出纤维含量x1和纤维长径比x4为影响复合材料拉伸模量的显著因素,这里利用降维处理的方法从麻纤维参数中分离出单一参数进行主效应分析,取x2=20、x3=0.8、x4=6代入公式(11)获得8,显著因素x1(纤维含量)为自变量的复合材料拉伸模量公式(12),同理,取x1=10、x2=20、x3=0.8的值代入公式(11)获得以显著因素x4(纤维长径比)为自变量的复合材料拉伸模量公式(13)。纤维含量x1和纤维长径比x4与拉伸模量的函数图像如图9所示。

y1=−1.09x21+80.52x1+580.05 (12) y2=−0.81x24+75.03x4+855.24 (13) 由图9(a)可知,纤维含量在5wt%~20wt%时,复合材料拉伸弹性模量随着纤维含量的增加而增大。纤维含量为5wt%时,拉伸弹性模量最小为955.4 MPa;纤维含量为20wt%时,拉伸弹性模量最大为

1754.4 MPa。纤维含量越高,复合材料弹性模量越大,这是由于纤维的刚度高于基体的刚度,因此纤维含量越高,复合材料的弹性模量越大。由图9(b)可知,纤维长径比在2~14时,复合材料拉伸模量随着纤维长径比的增加而增加,当纤维长径比为2时,拉伸弹性模量最小为1002.0 MPa;当纤维长径比达到14时,拉伸弹性模量达到了最大的1746.8 MPa。3.2.4 麻纤维双参数对拉伸模量的协同作用规律

从图10可以看到纤维含量、纤维空腔占比、纤维取向、纤维长径比之间两两协同作用对麻纤维增强复合材料弹性模量的影响。图10(a)为纤维含量与纤维空腔占比对拉伸模量的影响规律,随着纤维含量的增大,拉伸模量增加;空腔占比对拉伸模量的影响不大。从等高线图可以看到,最大的拉伸模量出现在纤维含量和空腔占比分别为20wt%和19.5vol%时。图10(b)为纤维含量与纤维取向对拉伸模量的影响规律,当纤维取向张量分量λ1在0.4~0.5之间时,复合材料拉伸模量随着纤维含量的增加变化不大,当纤维取向张量分量λ1大于0.5时,复合材料拉伸模量随着纤维含量的增加而增加,λ1越大,拉伸模量随纤维含量增加而增加的幅度越大。从等高线图可以看到,最大的拉伸模量出现在纤维含量和纤维取向张量分量λ1分别为20wt%和1.0时。图10(c)为纤维含量与纤维长径比对拉伸模量的影响规律,纤维长径比在2~4之间时,复合材料拉伸模量随纤维含量的增加变化不显著,随着纤维长径比的增加,复合材料拉伸模量随纤维含量的增加而显著增加。从等高线图可以看到,最佳的纤维含量和长径比的组合为20wt%和14。

![]() 图 10 纤维参数协同作用对苎麻/聚丙烯复合材料拉伸模量的影响:(a)空腔占比和纤维含量;(b)纤维取向和纤维含量;(c)纤维长径比和纤维含量;(d)纤维取向和空腔占比;(e)空腔占比和纤维长径比;(f)纤维长径比和纤维取向Figure 10. Synergistic effects of fiber parameters on tensile modulus of ramie fiber reinforced composites: (a) Lumen volume fraction and fiber content; (b) Fiber orientation and fiber content; (c) Fiber aspect ratio and fiber content; (d) Fiber orientation and lumen volume fraction; (e) Lumen volume fraction and fiber aspect ratio; (f) Fiber aspect ratio and fiber orientation

图 10 纤维参数协同作用对苎麻/聚丙烯复合材料拉伸模量的影响:(a)空腔占比和纤维含量;(b)纤维取向和纤维含量;(c)纤维长径比和纤维含量;(d)纤维取向和空腔占比;(e)空腔占比和纤维长径比;(f)纤维长径比和纤维取向Figure 10. Synergistic effects of fiber parameters on tensile modulus of ramie fiber reinforced composites: (a) Lumen volume fraction and fiber content; (b) Fiber orientation and fiber content; (c) Fiber aspect ratio and fiber content; (d) Fiber orientation and lumen volume fraction; (e) Lumen volume fraction and fiber aspect ratio; (f) Fiber aspect ratio and fiber orientation图10(d)是纤维空腔占比与纤维取向张量分量对拉伸模量的影响规律,从图上可知空腔占比对复合材料的拉伸模量影响不大;随着纤维取向张量分量的增大,复合材料拉伸模量也随之增加。从等高线图可以看到,最佳的纤维空腔占比和纤维取向张量分量的组合为18.5vol%和1.0。图10(e)为纤维空腔占比与纤维长径比对拉伸模量的影响规律,从图上可知空腔占比对复合材料的拉伸模量影响不大;随着纤维长径比的增大,复合材料拉伸模量也随之增加。从等高线图可以看到,最佳的纤维空腔占比和纤维长径比分量的组合为18.9vol%和14。图10(f)为纤维取向张量分量与纤维长径比对拉伸模量的影响规律,从图上可知,随着纤维取向张量分量和纤维长径比的增大,复合材料拉伸模量也随之增加。从等高线图可以看到,最佳的纤维取向张量分量与纤维长径比的组合为1.0和14。

综上所述,纤维含量越高,复合材料弹性模量越大,这是由于纤维的刚度高于基体的刚度,因此纤维含量越高,复合材料的弹性模量越大。纤维空腔越大,纤维的刚度相应减小,使复合材料的模量减小。纤维取向张量分量值越接近1,说明纤维长度方向与受力方向越一致,纤维可以承受的力就越大,因此其相应方向的弹性模量值也越大。纤维长径比与复合材料的界面多少有关,纤维长径比越大,纤维和基体之间的界面越多,界面可以实现复合材料力的转移和传递,因此纤维长径比越大,复合材料的弹性模量也相应的增加。

4. 结 论

本文针对麻纤维腔体结构的微观结构特征,开展了含腔体麻纤维的均匀化等效模型理论研究,以苎麻纤维增强聚丙烯复合材料为研究对象,构建了基于腔体特征的麻纤维增强树脂基复合材料代表性体积元(RVE)多尺度模型,并开展了不同纤维参数下的复合材料弹性模量预测研究。

(1)本文应用混合定律将含空腔特质麻纤维均匀化为等效固体材料,并计算其等效弹性模量。基于此,采用有限元分析法构建了腔体特征麻纤维增强树脂基复合材料RVE数值仿真模型,并通过与拉伸实验结果的对比验证了数值建模的有效性。

(2)采用正交试验法探讨了麻纤维多参数(纤维含量、纤维空腔占比、纤维取向、纤维长径比)对麻纤维增强复合材弹性模量的影响,并分析明确了影响麻纤维复合材料弹性模量的麻纤维参数的权重顺序为纤维含量>纤维长径比>纤维取向张量分量值>纤维空腔体积比。获得了弹性模量最大时的麻纤维参数组合为A4B1C4D4,即纤维含量为20wt%,纤维空腔占比为16vol%,纤维取向张量分量λ1为1.0,纤维长径比为14。

(3)采用多项式拟合法获得了定量预测求解麻纤维增强树脂基复合材料弹性模量的计算公式,研究明确了麻纤维参数中纤维含量和纤维取向为主效应参数,并系统分析了4个麻纤维参数的协同效应,为指导麻纤维增强复合材料微细观结构设计、降低实验测试成本、设计和调控力学性能提供了理论依据。

总之,本文提出的基于腔体结构的植物麻纤维增强树脂基复合材料弹性模量预测方法,可望为更准确地预测和调控麻纤维增强树脂基复合材料这一大类复合材料的性能提供新理论和新方法。

-

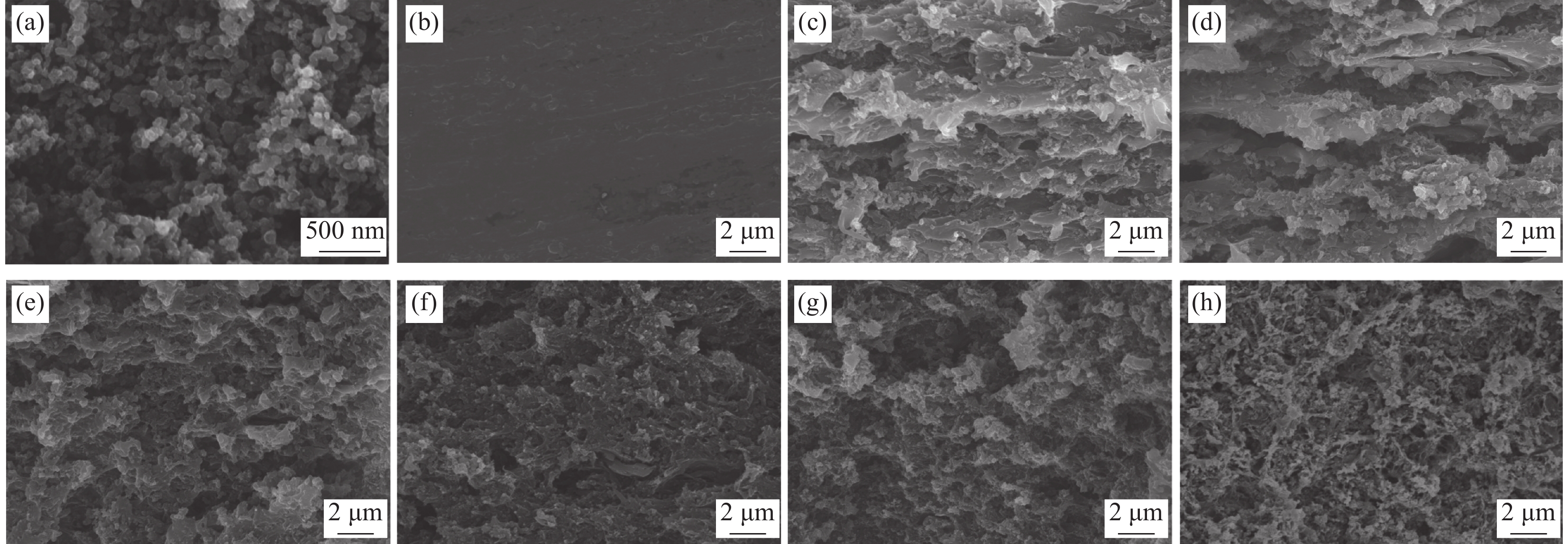

图 5 (a)炭黑颗粒,(b) PI 薄膜,(c) MXene-CB/MCP -10 复合薄膜,(d) MXene-CB/MCP -15 复合薄膜,(e) MXene-CB/MCP -20 复合薄膜,(f) MXene-CB/MCP -25 复合薄膜,(g) MXene-CB/MCP -30 复合薄膜,(h) MXene-CB/MCP -35 复合薄膜经过拉伸断裂的截面 SEM 图

Figure 5. (a) SEM images of carbon black particles, (b) PI film, (c) MXene-CB/MCP -10 composite film, (d) MXene-CB/MCP -15 composite film, (e) MXene-CB/MCP -20 composite film, (f) MXene-CB/MCP -25 composite film, (g) MXene-CB/MCP -30 composite film, and (h) MXene-CB/MCP -35 composite film after pulling.

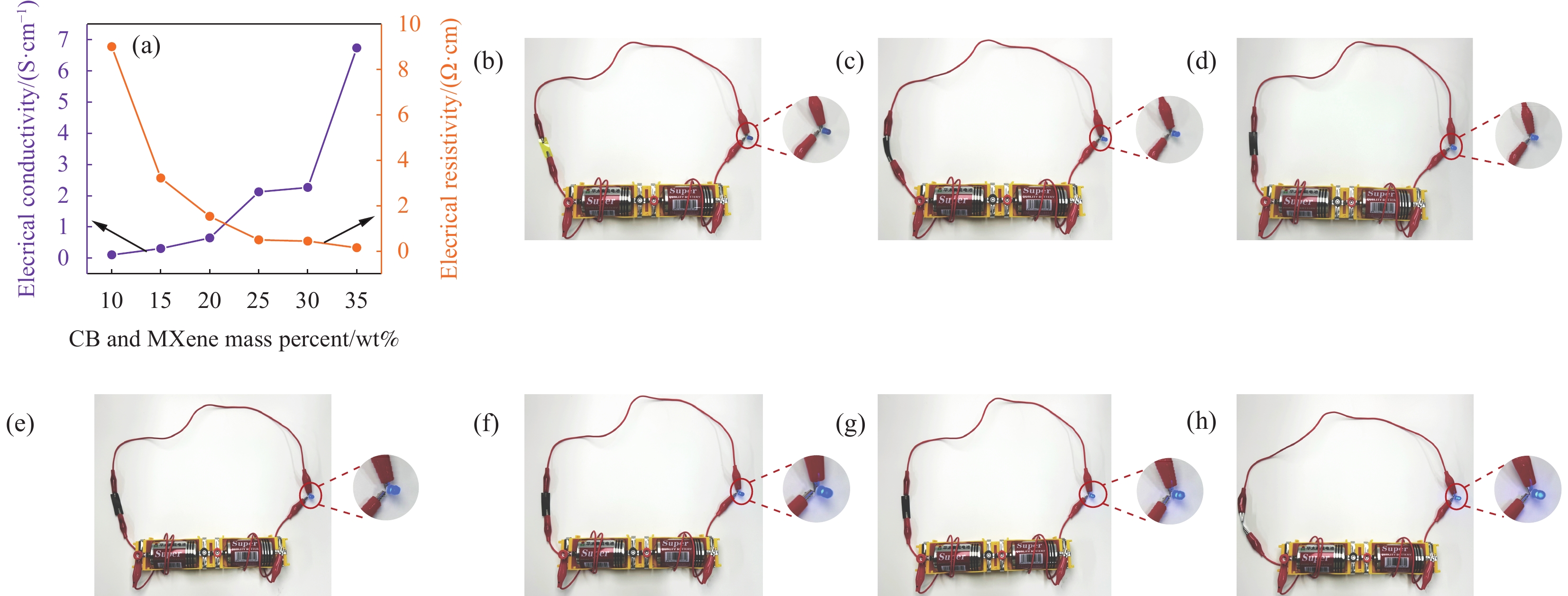

图 6 (a) MXene-CB/MCP 复合薄膜的电导率曲线图。(b) PI 薄膜,(c) MXene-CB/MCP -10 复合薄膜,(d) MXene-CB/MCP -15 复合薄膜,(e) MXene-CB/MCP -20 复合薄膜,(f) MXene-CB/MCP -25 复合薄膜,(g) MXene-CB/MCP -30 复合薄膜,(h) MXene-CB/MCP -35 复合薄膜连接在电路两端灯泡的亮度示意图

Figure 6. (a) Conductivity profiles of MXene-CB/MCP composite films. (b) PI film, (c) MXene-CB/MCP -10 composite film, (d) MXene-CB/MCP -15 composite film, (e) MXene-CB/MCP -20 composite film, (f) MXene-CB/MCP -25 composite film, (g) MXene-CB/MCP -30 composite film, (h) MXene-CB/MCP -35 composite film schematic diagram of the brightness of a light bulb connected to both ends of a circuit

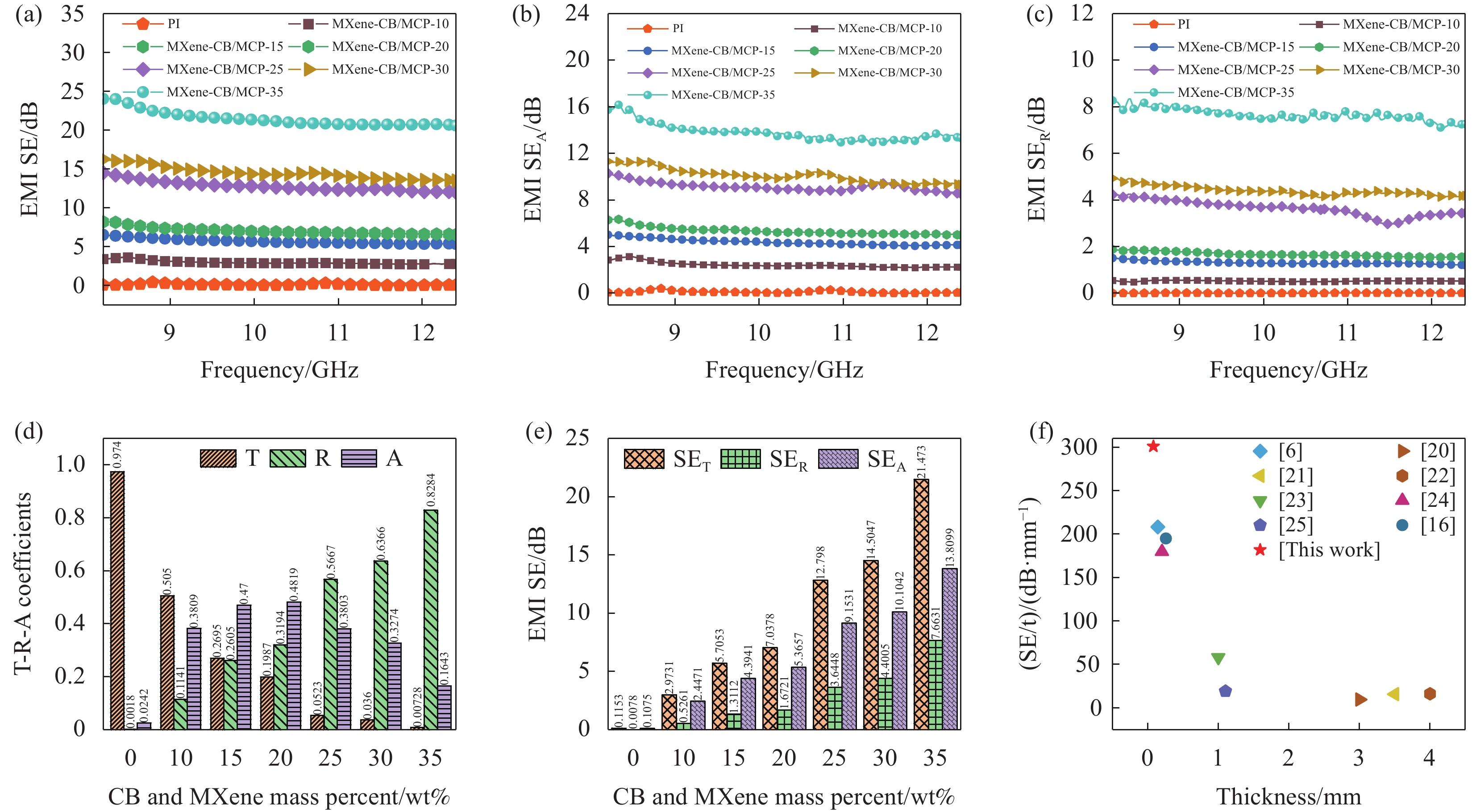

图 7 (a) X波段不同 MXene-CB/MCP 膜的 EMI SE,(b)不同 MXene-CB/MCP 膜在 X 波段的 EMI SEA,(c)不同 MXene-CB/MCP 膜在 X 波段的 EMI SER,(d)不同 MXene-CB/MCP 膜的 T−R−A 系数,(e)不同 MXene-CB/MCP 膜的平均 SER、SET、SEA和(f)SE/t 与先前报告比较

Figure 7. (a) EMISE of different MXene-CB/MCP membranes in X-band, (b) EMISEA of different MXene-CB/MCP membranes in X-band, (c) EMISER of different MXene-CB/MCP membranes in X-band, (d) T-R-A coefficient of different MXene-CB/MCP membranes, (e) Average SER, SET, SEA of different MXene-CB/MCP membranes and (f) SE/t compared with previous reports

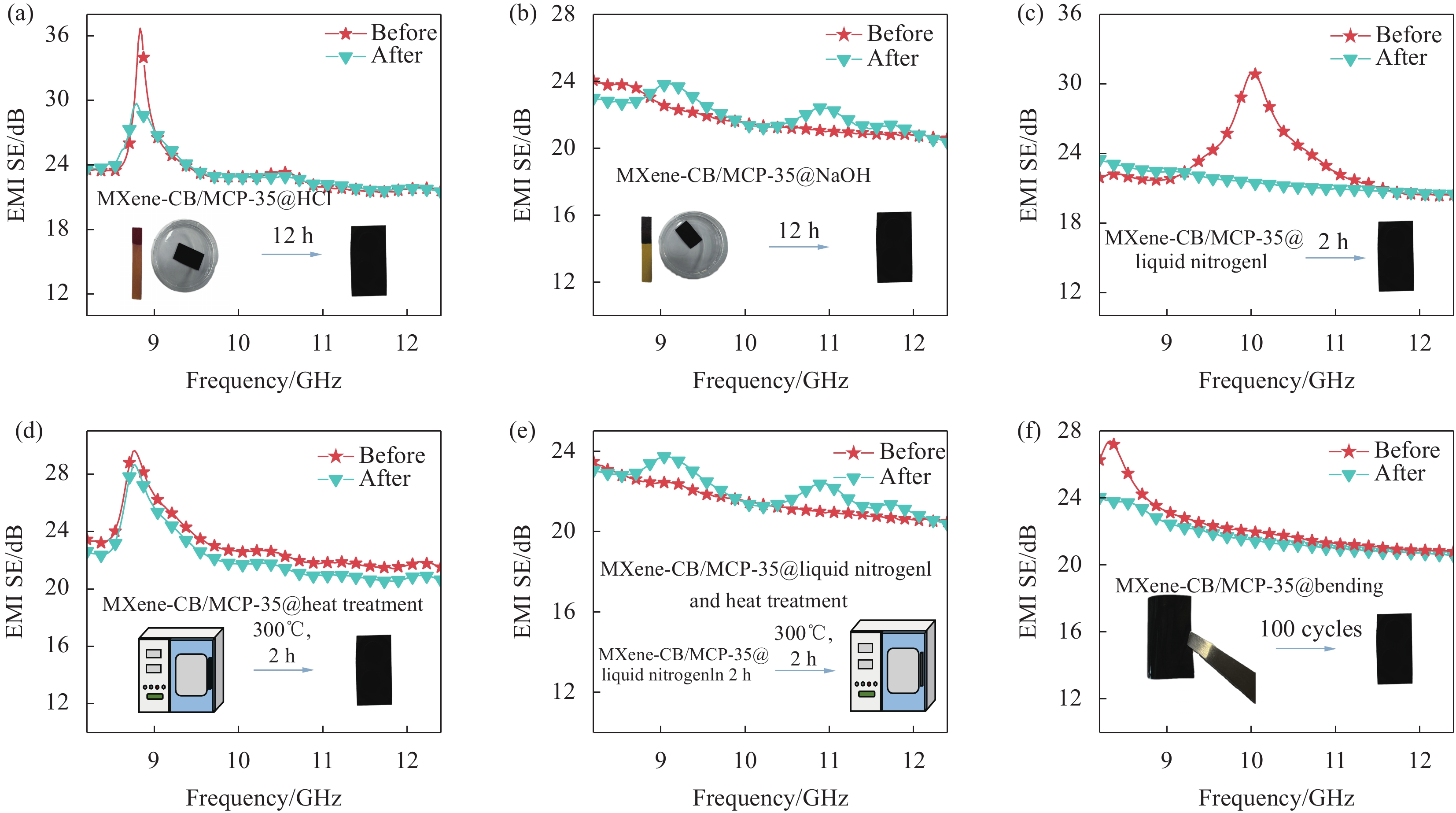

图 9 (a) MXene-CB/MCP-35 复合薄膜在 HCl 中浸泡 12 h,(b)在 NaOH 中浸泡 12 h,(c)在液氮(−196℃)中浸泡 2 h,(d)在 300℃ 下处理 2 h,(e)在液氮(−196℃)中浸泡 2 h 后在 300℃ 下处理 2 h,以及(f)重复弯曲 100 次前后的电磁屏蔽性能

Figure 9. Electromagnetic shielding properties of MXene-CB/MCP-35 composite film before and after immersion (a) in HCl for 12 h, (b) in NaOH for 12 h, (c) in liquid nitrogen (−196℃) for 2 h, (d) treated at 300℃ for 2 h, and (e) in liquid nitrogen (−196℃) for 2 h followed by treatment at 300℃ for 2 h, as well as (f) before and after 100 repetitions of bending

表 1 MXene-炭黑/聚酰亚胺(MXene-CB/MCP)薄膜成分用量

Table 1 Composition of MXene-carbon black/polyimide (MXene-CB/MCP) Films

Sample name ODA/g BPDA/g MXene/g CB/g DMAc/g PI 1.2 1.8 0 0 17.00 MXene-CB/MCP -10 1.2 1.8 0.0667 0.2667 18.89 MXene-CB/MCP -15 1.2 1.8 0.1059 0.4235 20.00 MXene-CB/MCP -20 1.2 1.8 0.1500 0.600 21.25 MXene-CB/MCP -25 1.2 1.8 0.200 0.800 22.67 MXene-CB/MCP -30 1.2 1.8 0.2571 1.0286 24.29 MXene-CB/MCP -35 1.2 1.8 0.3231 1.2923 26.15 Notes: polyimide (PI); MXene-carbon black/polyimide (MXene-CB/MCP); 表 2 MXene-CB/MCP 复合薄膜的拉伸强度和断裂伸长率

Table 2 Tensile strength and elongation at break of MXene-CB/MCP composite films

Sample name Average tensile strength/MPa Average elongation at break/% PI 162.03 12.90 MXene-CB/MCP -10 155.57 9.71 MXene-CB/MCP -15 146.19 7.80 MXene-CB/MCP -20 141.43 5.74 MXene-CB/MCP -25 138.60 4.83 MXene-CB/MCP -30 108.11 3.14 MXene-CB/MCP -35 100.40 3.07 表 3 MXene-CB/MCP 膜的EMI SE/t 与以往报道文献对比

Table 3 EMI SE/t of MXene-CB/MCP film vs. previously reported literature

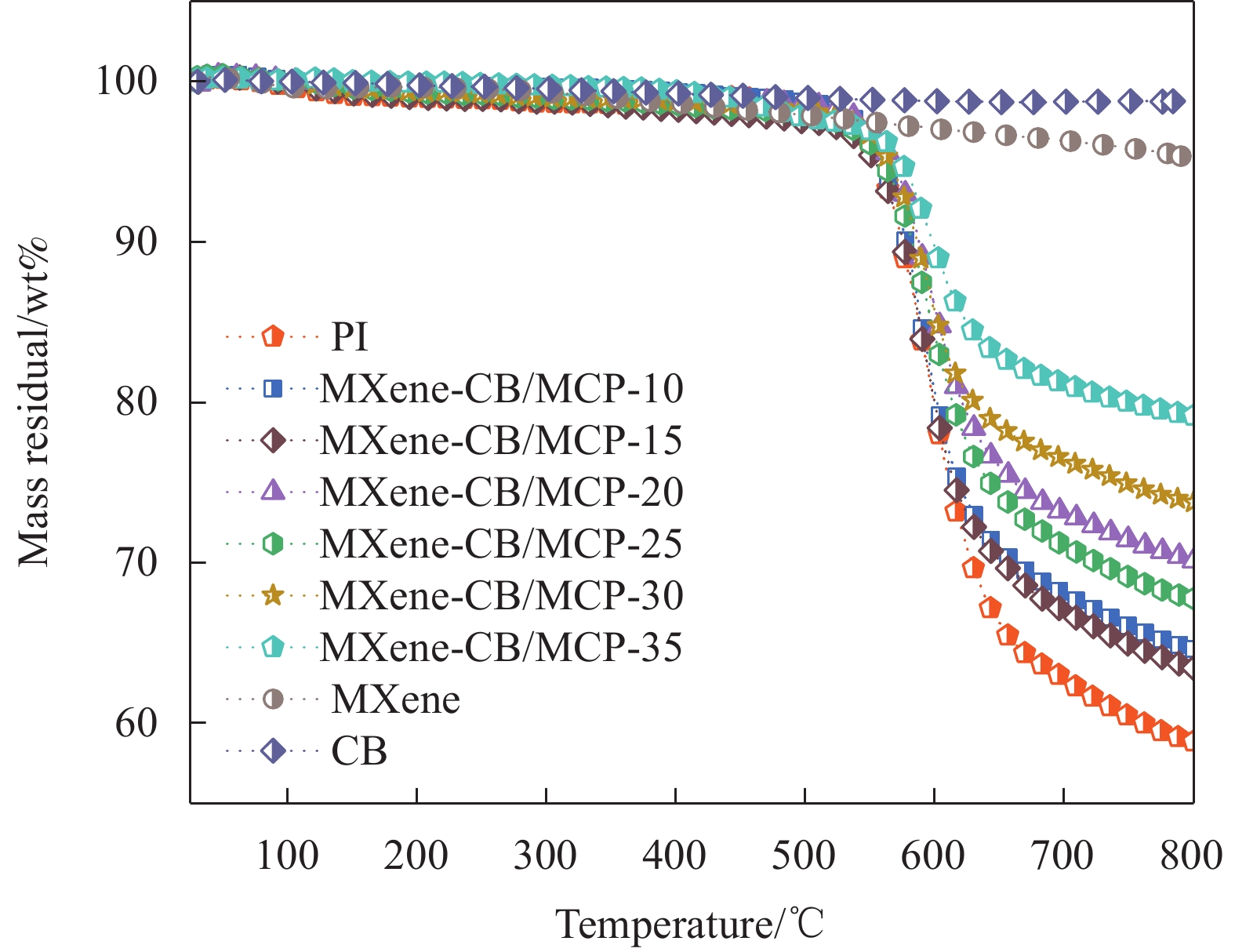

Polymer Conductive filler Filler content Thicknesses/mm EMISE/dB SE/t(dB/mm) Ref. PI MXene 25 wt% 0.14 29.12 208.00 [26] paraffin PNT/GOEDA-Fc-EDA-GO-7:1 50 wt% 3.00 28.73 9.58 [30] CE GNSs/CINAP 5 wt%/20 wt% 3.50 55.00 15.71 [31] Ti3C2Tx MXene PPy 9 wt% 4.00 64.50 16.13 [32] SiO2 nano powder 80 wt% U- Ti3C2Tx MXeneNS 80 wt% 1.00 58.10 58.10 [33] PVDF RGO/BaCo2Fe16O27 (10 wt%)/10 wt% 0.20 35.94 179.70 [34] - NS-rGO:NiO - 1.10 21.00 19.09 [35] PI MXene 49.1 wt% 0.256 49.90 194.9 [9] PI CB/MXene 35 wt% 0.08 21.47 268.41 本文 Notes: polyimide (PI); Polypyrrole nanotube (PNT); ferrocene (Fc); cyanate resin (CE); graphene nanosheets (GNSs); carbonyl iron–nickel alloy powder (CINAP) 表 4 MXene-CB/MCP 复合薄膜的热性能

Table 4 Thermal properties of MXene-CB/MCP composite films

Sample name T5%/℃ T10%/℃ Rw/% PI 556.013 574.393 58.84129 MXene-CB/MCP -10 553.84 575.365 63.42869 MXene-CB/MCP -15 559.67 577.59 64.61333 MXene-CB/MCP -20 560.008 582.415 67.74976 MXene-CB/MCP -25 567.228 587.557 70.14916 MXene-CB/MCP -30 565.11 586.254 73.75634 MXene-CB/MCP -35 573.99 598.253 79.17731 MXene - - 95.3546 CB - - 98.7653 Notes: T5% and T10% are the temperatures corresponding to the first 5% weight loss and the first 10% weight loss; RW is the final carbon residue. 表 5 MXene-CB/MCP复合薄膜的LOI

Table 5 LOI of MXene-CB/MCP composite films

Sample name LOI/% PI 37.1 MXene-CB/MCP -20 44.3 MXene-CB/MCP -35 45.0 -

[1] NI L, LUO Y, WANG G, et al. Fabrication of flexible polyimide/rGO composite foams and their derived carbon foams for thermal insulation and EMI shielding applications. Polymer[J]. 2023, 284: 126296.

[2] JIA X, SHEN B, ZHANG L, et al. Construction of compressible Polymer/MXene composite foams for high-performance absorption-dominated electromagnetic shielding with ultra-low reflectivity[J]. Carbon, 2021, 173: 932-940. DOI: 10.1016/j.carbon.2020.11.036

[3] 黄星, 任家飞, 李齐方, 等 聚合物基柔性透明电磁屏蔽复合材料研究进展[J]. 复合材料学报, 2023, 40 (06): 3153-3166. HUANG X, REN J F, Li Q F, et al. Advances in polymer-based flexible and transparent electromagnetic shielding composites[J]. Acta Materiae Compositae Sinica, 2023, 40 (06): 3153-3166. (in Chinese)

[4] 张梦辉, 马忠雷, 马建中, 等 聚合物基电磁屏蔽复合材料的结构设计与性能研究进展[J]. 复合材料学报, 2021, 38 (05): 1358-1370. ZHANG M H, MA Z L, MA J Z, et al. Advances in structural design and performance of polymer-based electromagnetic shielding composites[J]. Acta Materiae Compositae Sinica, 2021, 38 (05): 1358-1370. (in Chinese)

[5] JIA X, LI Y, SHEN B, et al. Evaluation, fabrication and dynamic performance regulation of green EMI-shielding materials with low reflectivity: A review[J]. Composites Part B: Engineering, 2022, 233: 109652. DOI: 10.1016/j.compositesb.2022.109652

[6] MA M, LIAO X, CHU Q, et al. Construction of gradient conductivity cellulose nanofiber/MXene composites with efficient electromagnetic interference shielding and excellent mechanical properties[J]. Composites Science and Technology, 2022, 226: 109540. DOI: 10.1016/j.compscitech.2022.109540

[7] ZHANG Y, GU J, A Perspective for Developing Polymer-Based Electromagnetic Interference Shielding Composites[J]. Nano-Micro Letters, 2022, 14 (1): 89.

[8] MA S, JIA T, WANG C, et al. Anisotropic MWCNT/polyimide aerogels with multifunctional EMI shielding and strain sensing capabilities[J]. Composites Part A: Applied Science and Manufacturing, 2022, 163 107208.

[9] SUN K, WANG F, YANG W, et al. Flexible Conductive Polyimide Fiber/MXene Composite Film for Electromagnetic Interference Shielding and Joule Heating with Excellent Harsh Environment Tolerance[J]. ACS Applied Materials & Interfaces, 2021, 13(42): 50368-50380.

[10] ALTAN A, NAMVARI M, et al. Multifunctional, flexible, and mechanically robust polyimide-MXene nanocomposites: a review[J]. 2D Materials, 2023, 10(4): 042001. DOI: 10.1088/2053-1583/acf327

[11] ZHANG Y, RUAN K, ZHOU K, et al. Controlled Distributed Ti3C2Tx Hollow Microspheres on Thermally Conductive Polyimide Composite Films for Excellent Electromagnetic Interference Shielding[J]. Advanced Materials, 2023, 35(16): 2211642. DOI: 10.1002/adma.202211642

[12] CHENG Y, LI X Y, QIN Y X, et al. Hierarchically porous polyimide/ Ti3C2Tx film with stable electromagnetic interference shielding after resisting harsh conditions[J]. Science Advances, 2021, 7(39): eabj1663 DOI: 10.1126/sciadv.abj1663

[13] 储娜, 骆春佳, 晁敏, 等 多功能MXene-CCNT/聚酰亚胺电磁屏蔽薄膜的制备与性能[J]. 复合材料学报, 2024, 41 (08): 4146-4159. CHU N, LUO C J, CHAO M, et al. Preparation and properties of multifunctional MXene-CCNT/polyimide electromagnetic shielding films[J]. Acta Materiae Compositae Sinica, 2024, 41 (08): 4146-4159. (in Chinese).

[14] ZHANG S, WU J, LIANG W, et al. Flexible and multifunctional polyimide-based composite films by self-reducing reaction for electromagnetic interference shielding in extreme environments[J]. Carbon, 2023, 212: 118103. DOI: 10.1016/j.carbon.2023.118103

[15] JOSHI A, DATAR S, Carbon nanostructure composite for electromagnetic interference shielding[J]. Pramana, 2015, 84 (6): 1099-1116.

[16] SOARES B G, TOUCHALEAUME F, CALHEIROS L F, et al. Effect of double percolation on the electrical properties and electromagnetic interference shielding effectiveness of carbon-black-loaded polystyrene/ethylene vinyl acetate copolymer blends[J]. Journal of Applied Polymer Science, 2016, 133(7): 43013. DOI: 10.1002/app.43013

[17] YANG H, GONG J, WEN X, et al. Effect of carbon black on improving thermal stability, flame retardancy and electrical conductivity of polypropylene/carbon fiber composites[J]. Composites Science and Technology, 2015, 113: 31-37. DOI: 10.1016/j.compscitech.2015.03.013

[18] MONDAL S, GANGULY S, RAHAMAN M, et al. A strategy to achieve enhanced electromagnetic interference shielding at low concentration with a new generation of conductive carbon black in a chlorinated polyethylene elastomeric matrix[J]. Physical Chemistry Chemical Physics, 2016, 18(35): 24591-24599. DOI: 10.1039/C6CP04274K

[19] KIM J, KIM G, KIM S Y, et al. Fabrication of highly flexible electromagnetic interference shielding polyimide carbon black composite using hot-pressing method[J]. Composites Part B: Engineering, 2021, 221: 109010. DOI: 10.1016/j.compositesb.2021.109010

[20] 中国国家标准化管理委员. 塑料薄膜拉伸性能试验方法: GB/T 13022-1991[S]. 北京: 中国标准出版社 1991. Standardization Administration of the People’s Republic of China. Test method for tensile properties of plastic films: GB/T 13022-1991[S]. Beijing: China Stand-ards Press, 1991(in Chinese).

[21] 中国国家标准化管理委员. 塑料用氧指数测定燃烧行为第1部分: GB/T 2406.1-2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People’s Republic of China. Plastics - Determination of combustion behaviour by oxygen index-Part 1: GB/T 2406.1- 2008[S]. Beijing: China Stand-ards Press, 2008. (in Chinese)

[22] XIANG Z, SHI Y, ZHU X, et al. Flexible and Waterproof 2D/1D/0D Construction of MXene-Based Nanocomposites for Electromagnetic Wave Absorption, EMI Shielding, and Photothermal Conversion[J]. Nano-Micro Letters, 2021, 13(1): 150. DOI: 10.1007/s40820-021-00673-9

[23] LIMBU T B, CHITARA B, GARCIA CERVANTES M Y, et al. Unravelling the Thickness Dependence and Mechanism of Surface-Enhanced Raman Scattering on Ti3C2TX MXene Nanosheets[J]. The Journal of Physical Chemistry C, 2020, 124(32): 17772-17782. DOI: 10.1021/acs.jpcc.0c05143

[24] 张艳, 马忠雷, 李桢, 等 轻质高强MXene/细菌纤维素复合气凝胶的制备及其电磁屏蔽性能[J]. 复合材料学报, 2023, 40 (11): 6407-6415. ZHANG Y, MA Z L, LI Z, et al. Preparation of lightweight and high-strength MXene/bacterial cellulose composite aerogels and their electromagnetic shielding properties[J]. Acta Materiae Compositae Sinica, 2023, 40 (11): 6407-6415. (in Chinese)

[25] MAO X, GUO W, LI C, et al. Preparation and characterization of PI/PVDF composite films with excellent dielectric property[J]. Journal of Materials Science: Materials in Electronics, 2017, 28(5): 4088-4094. DOI: 10.1007/s10854-016-6027-7

[26] CHU N, LUO C J, CHEN X, et al. Ti3C2Tx MXene/polyimide composites film with excellent mechanical properties and electromagnetic interference shielding properties[J]. Journal of Alloys and Compounds, 2023, 955: 170241. DOI: 10.1016/j.jallcom.2023.170241

[27] 万长鑫. 碳基填料改性聚酰亚胺复合材料压塑热成型及摩擦学性能研究[D]. 科学研究总院, 2023. WAN C X, Research on Hot Compression Molding and Tribological Properties of Carbon-based Fillers Modified Polyimide Composites[D]. China Academy of Machinery Science and Technology, 2023. (in Chinese)

[28] WANG L, MA Z, ZHANG Y, et al. Polymer-based EMI shielding composites with 3D conductive networks: A mini-review[J]. SusMat, 2021, 1(3): 413-431. DOI: 10.1002/sus2.21

[29] LIU R, MIAO M, LI Y, et al. Ultrathin Biomimetic Polymeric Ti3C2Tx MXene Composite Films for Electromagnetic Interference Shielding[J]. ACS Applied Materials & Interfaces, 2018, 10(51): 44787-44795.

[30] LIN T F, YU H J, WANG Y, et al. Polypyrrole nanotube/ferrocene-modified graphene oxide composites: From fabrication to EMI shielding application[J]. Journal of Materials Science, 2021, 56(32): 18093-18115. DOI: 10.1007/s10853-021-06406-y

[31] RRN F, SONG D, LI Z, et al. Synergistic effect of graphene nanosheets and carbonyl iron–nickel alloy hybrid filler on electromagnetic interference shielding and thermal conductivity of cyanate ester composites[J]. Journal of Materials Chemistry C, 2018, 6(6): 1476-1486. DOI: 10.1039/C7TC05213H

[32] YANG S, YANG R, LIN Z, et al. Ultrathin, flexible, and high-strength polypyrrole/Ti3C2Tx film for wide-band gigahertz and terahertz electromagnetic interference shielding[J]. Journal of Materials Chemistry A, 2022, 10(44): 23570-23579. DOI: 10.1039/D2TA06805B

[33] HE P, WANG X X, CAI Y Z, et al. Tailoring Ti3C2Tx nanosheets to tune local conductive network as an environmentally friendly material for highly efficient electromagnetic interference shielding[J]. Nanoscale, 2019, 11(13): 6080-6088. DOI: 10.1039/C8NR10489A

[34] ANAND S, PAULINE S, Electromagnetic Interference Shielding Properties of BaCo2Fe16O27 Nanoplatelets and RGO Reinforced PVDF Polymer Composite Flexible Films[J]. Advanced Materials Interfaces, 2021, 8 (3): 2001810.

[35] KUMAR R, MACEDO W C J, SINGH R K, et al. Nitrogen–Sulfur Co-Doped Reduced Graphene Oxide-Nickel Oxide Nanoparticle Composites for Electromagnetic Interference Shielding[J]. ACS Applied Nano Materials, 2019, 2(7): 4626-4636. DOI: 10.1021/acsanm.9b01002

[36] CAO W, MA C, TAN S, et al. Ultrathin and Flexible CNTs/MXene/Cellulose Nanofibrils Composite Paper for Electromagnetic Interference Shielding[J]. Nano-Micro Letters, 2019, 11(1): 72. DOI: 10.1007/s40820-019-0304-y

[37] LI Q, YANG W, SUN K, et al. Superhydrophobic flexible conductive PFDT/CB/MXene@Paper for high-efficiency EMI shielding and Joule heating applications[J]. Journal of Materials Chemistry C, 2022, 10(39): 14560-14568. DOI: 10.1039/D2TC02727E

[38] ZHANG L, HUANG Y, DONG H, et al. Flame-retardant shape memory polyurethane/MXene paper and the application for early fire alarm sensor[J]. Composites Part B: Engineering, 2021, 223: 109149. DOI: 10.1016/j.compositesb.2021.109149

[39] ARABY S, PHILIPS B, MENG Q, et al. Recent advances in carbon-based nanomaterials for flame retardant polymers and composites[J]. Composites Part B: Engineering, 2021, 212: 108675. DOI: 10.1016/j.compositesb.2021.108675

-

目的

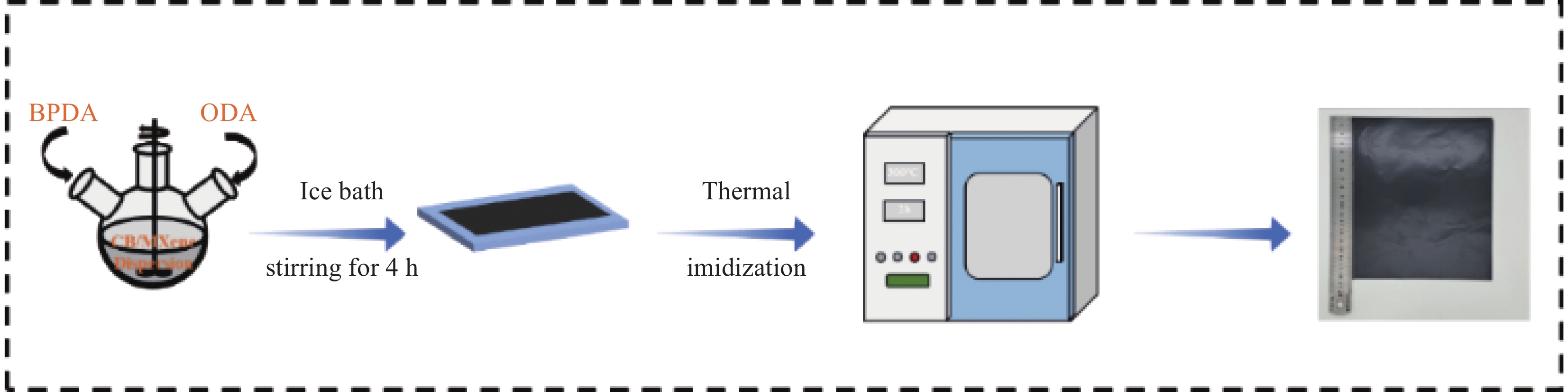

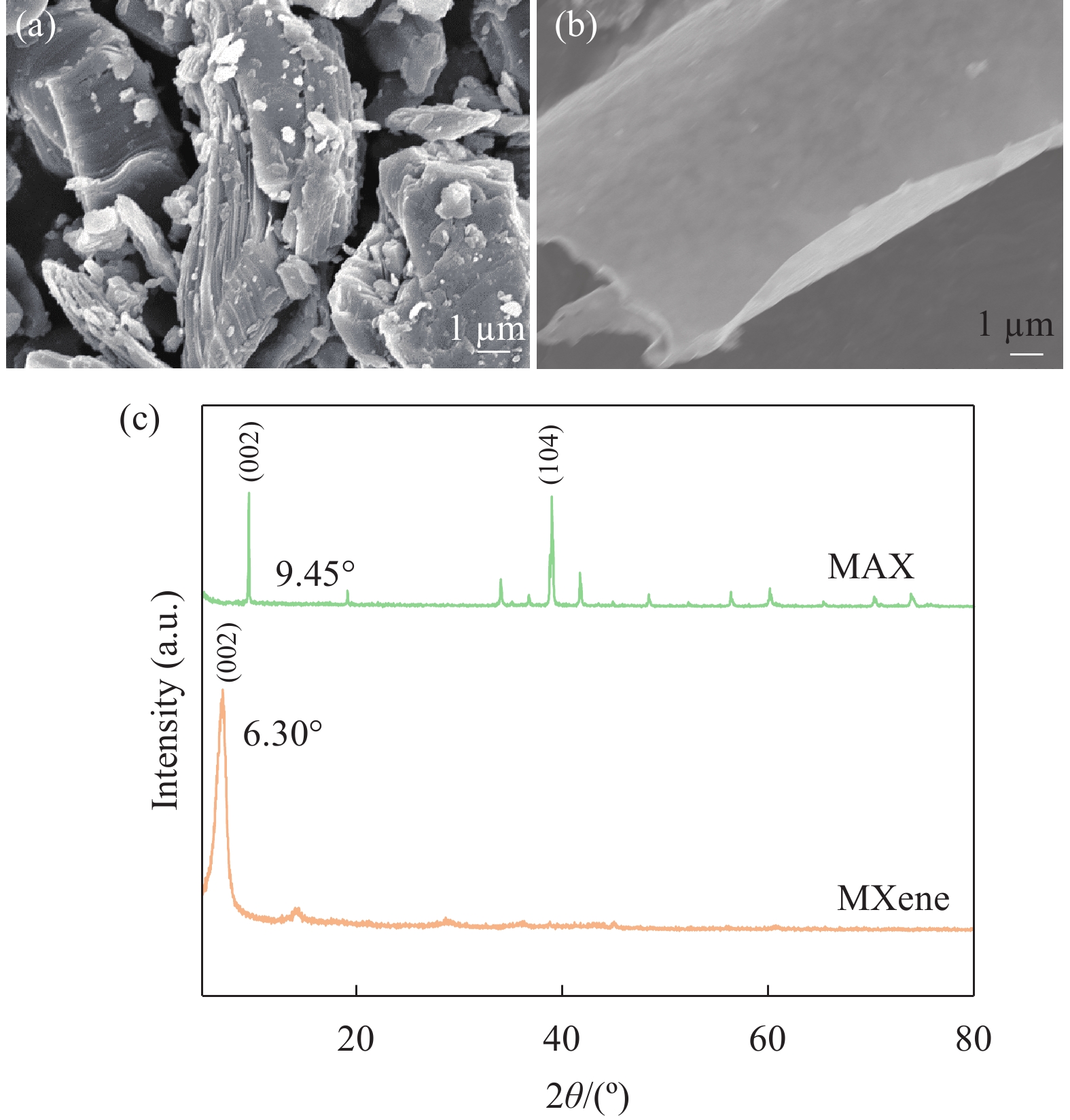

航空航天武器装备、无线基站和 5G 通信技术的快速发展,不可避免地带来电磁辐射和电磁干扰等问题。通过使用电磁干扰(EMI)屏蔽材料可以有效阻挡日益严重的 EMI 污染的扩散,避免电磁辐射带来的问题。导电聚合物复合材料(CPC)以其价格低廉、重量轻、比强度高、耐腐蚀、易于加工、屏蔽性能优异等优点,正逐步取代传统的金属基电磁屏蔽材料。然而,传统的聚合物在面对极端的温度、酸性和碱性溶液等恶劣条件时,其耐受能力相对较弱,这可能会对 CPC 在这些环境中的电磁屏蔽性能(EMI SE)的稳定性产生不良影响。所以本文将具有优异的力学性能、热稳定性和耐候性的 PI 作为聚合物基体。具有良好的导电性以及成本低廉的 CB 作为主要的导电填料,辅以二维填料 MXene 纳米片来构筑导电网络为进一步降低电阻率。最后通过刮膜法和热亚胺化工艺成功制备了 MXene-CB/PI复合薄膜。

方法通过原位聚合和刮膜法制备具有恶劣环境耐受性的柔性MXene-炭黑/聚酰亚胺(MXene-CB/MCP)复合薄膜,详细研究薄膜的微观结构、力学性能、热稳定性、阻燃性能和电磁屏蔽效能,并探索薄膜在不同的恶劣环境处理后的电磁屏蔽效能。

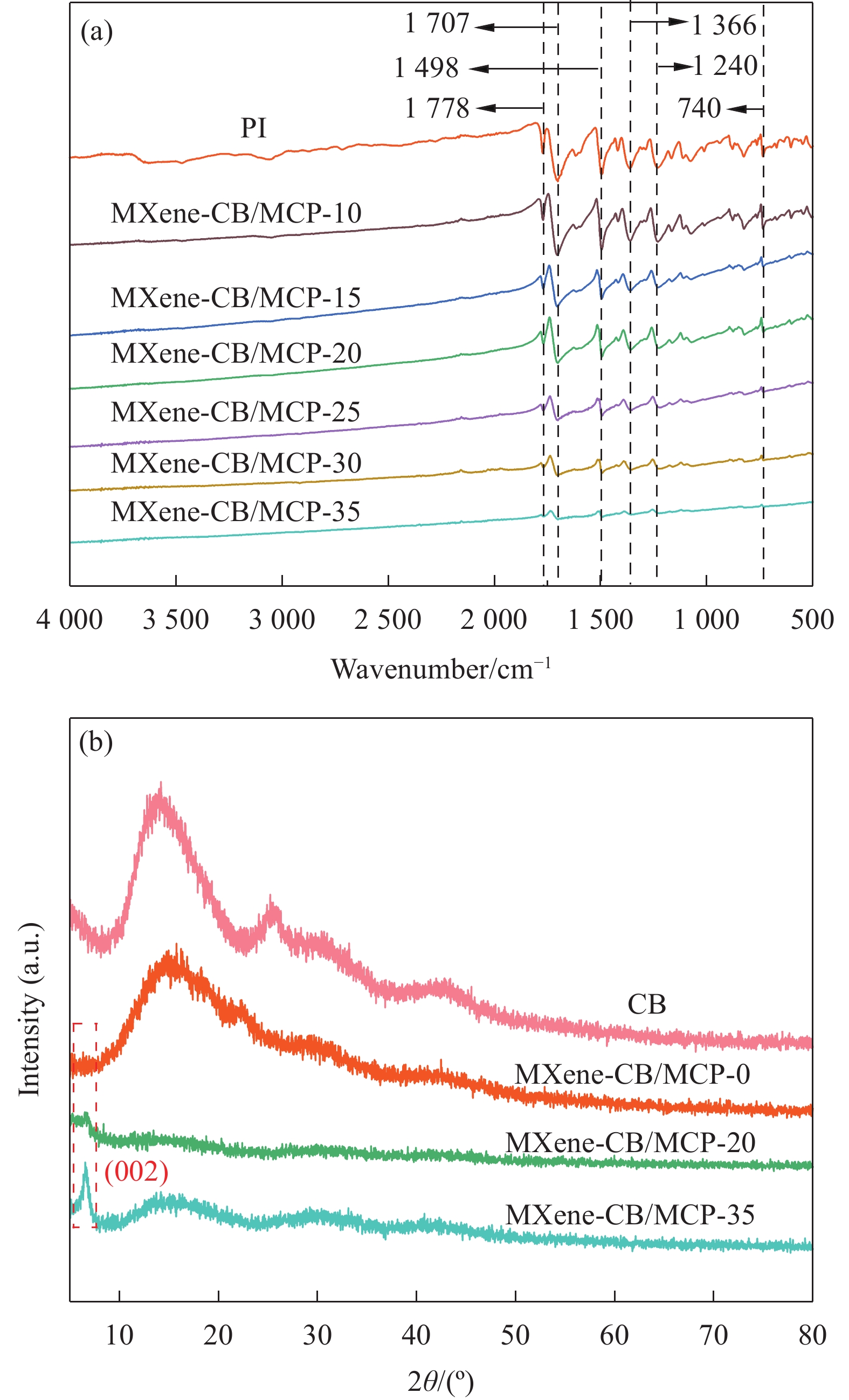

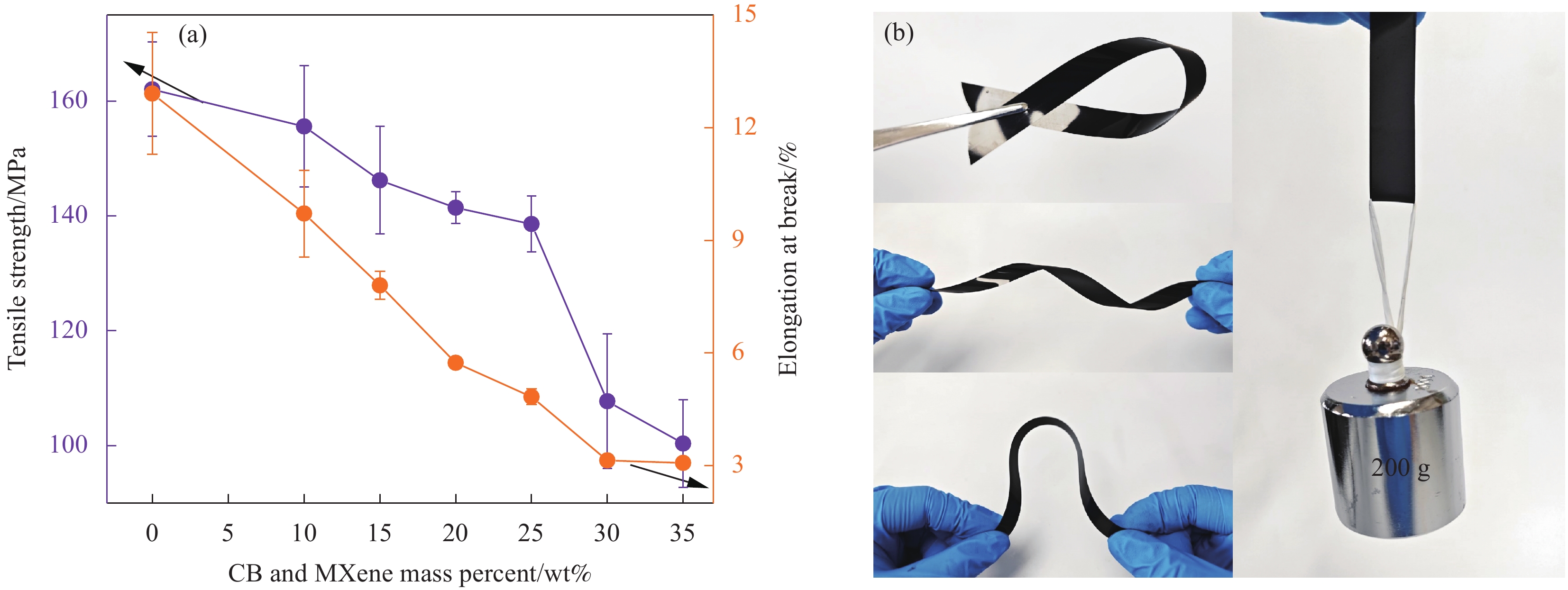

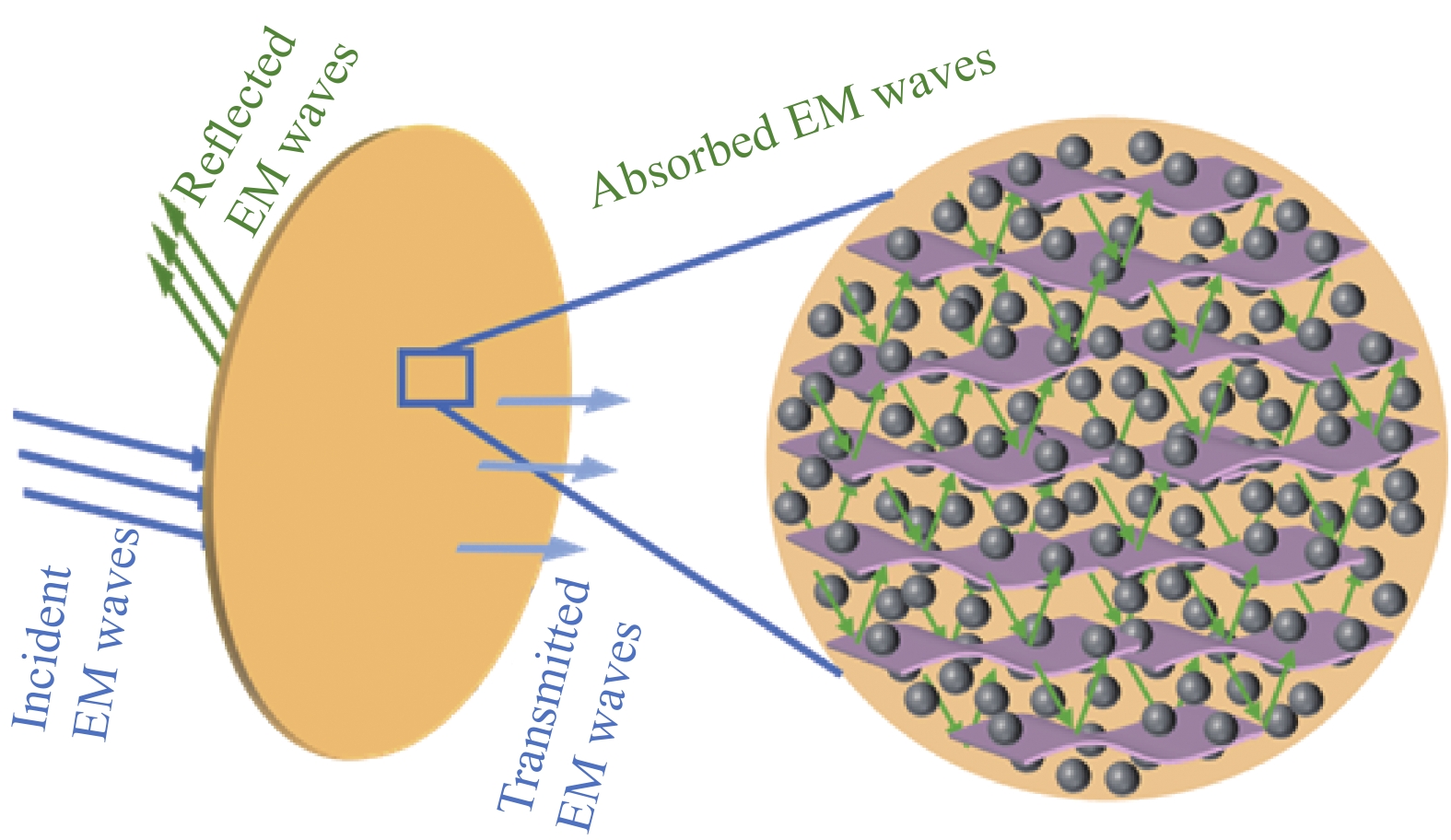

结果1. FTIR 和 XRD 结果表明 MXene 和 CB 的成功引入,MXene-CB/MCP 复合薄膜成功制备。2. MXene-CB/MCP -35 复合薄膜具有优异的力学性能,平均拉伸强度可达 100.40 MPa。3. 随着 MXene 和 CB 含量的增加,导电网络进一步完整,MXene-CB/MCP 复合薄膜的电导率升高,电阻率降低。MXene-CB/MCP-35 复合薄膜的电导率增加至 6.74 S/cm,相较于 MXene-CB/MCP-10 复合薄膜提高了 6027 %。4.所有的薄膜均在 520 ℃ 以上才开始出现明显的失重,表明所有的复合薄膜均具有优异的热稳定性。引入了具有良好热稳定性的 MXene 和 CB,使得 MXene-CB/MCP-35 复合薄膜在 800℃ 时的碳残留量明显高于其他薄膜。5. MXene 和 CB 含量增加,在复合材料中形成的导电网络越完整,对电磁波的吸收衰减越好。MXene-CB/MCP-35 复合薄膜的 EMI SE 值最佳,为 24.06 dB,相较于 MXene-CB/MCP-10 复合薄膜(3.64 dB)提高了 560.99 %,屏蔽效率为 99.61 %。且经过不同环境处理前后薄膜的平均 EMI SE 几乎不变,具有很好的环境稳定性。6. 查阅文献分析 MXene-CB/MCP 复合薄膜电磁屏蔽机理,当电磁波撞击到 MXene-CB/MCP 复合薄膜表面时,会发生电磁波的反射、吸收和透射。通常情况下,当电磁波入射到 MXene-CB/MCP 复合薄膜表面时,由于导电层的高导电率,从而导致阻抗失配,一部分电磁波立即被反射回去,其余部分电磁波继续向内传播,在薄膜内部通过与 MXene 和 CB 的自由电子相互作用产生的传导损耗,从而导致电磁波能量大幅下降。而随着导电填料含量的增加,强化的导电网络会逐渐提高电子传导能力,进一步促进了 MXene-CB/MCP 复合薄膜对电磁波的损耗。MXene/PI、CB/MXene 和 CB/PI 界面的不对称电荷分布引起的界面极化损耗以及缺陷和终端功能基团对电磁波产生的偶极极化损耗被吸收到薄膜内部。此外,电磁波还会在薄膜内部的界面之间发生多重反射,未被耗散的电磁波则会透过屏蔽材料成为透射波。

结论通过简单的刮膜和热酰亚胺化的方法合成了具有稳定的电磁屏蔽效能、优异的热稳定性、阻燃性和良好的力学性能的 MXene-炭黑/聚酰亚胺(MXene-CB/MCP)复合薄膜。由于 MXene 和 CB 之间的协同作用,厚度为 80 μm 的 MXene-CB/MCP -35 复合薄膜在 8.2~12.4 GHz 的频率范围内表现出 24.06 dB 的EMI SE和 300.75 dB/mm的SE/t,且屏蔽效率可达到 99.61 %,并且该复合薄膜经过极端环境处理后仍表现出稳定电磁屏蔽效能。

-

航空航天武器装备、无线基站和 5G 通信技术的快速发展,促使电子设备和元器件向高频率、大功率、高密度、高集成度方向升级,不可避免地带来电磁辐射和电磁干扰等问题。

本文通过简单的刮膜法和热亚胺化工艺合成了具有一定电磁屏蔽效能的 MXene-炭黑/聚酰亚胺(MXene-CB/MCP)复合薄膜。由于 MXene 和炭黑(CB)之间的协同作用,厚度为 80 μm 的 MXene-CB/MCP -35 复合薄膜在 8.2~12.4 GHz 的频率范围内表现出 24.06 dB 的 EMI SE 和 300.75 dB/mm 的 SE/t。并且该复合薄膜经过极端环境处理后仍表现出稳定电磁屏蔽效能。同时,MXene-CB/MCP -35 复合薄膜仍具有良好的力学性能,平均拉伸强度可达到 100.40 MPa。复合薄膜还具有优异的热稳定性和阻燃性,MXene-CB/MCP -35 在酒精灯下燃烧 1 分钟,只发生略微变化,极限氧指数达到 45 %。因此,MXene-CB/MCP 复合薄膜能满足复杂环境的实际需求,在电磁屏蔽多功能材料领域具有广阔的发展前景,对于航空航天、可穿戴电子设备和人工智能等相关领域的材料设计和拓展具有一定的理论意义和实际应用价值。

(a)X 波段不同 MXene-CB/MCP 膜的 EMI SE,(b)不同 MXene-CB/MCP 膜在 X 波段的 EMI SEA,(c)不同 MXene-CB/MCP 膜在 X 波段的 EMI SER,(d)不同 MXene-CB/MCP 膜的 T−R−A 系数,(e)不同 MXene-CB/MCP 膜的平均 SER、SET、SEA 和(f) SE/t 与先前报告比较

(a)MXene-CB/MCP -35 薄膜在在 HCl 中浸泡 12 h,(b)在 NaOH 中浸泡 12 h,(c)在液氮(-196 ℃)中浸泡 2 h,(d)在 300 ℃ 下处理 2 h,(e)在液氮(-196 ℃)中浸泡 2 h 后在 300 ℃ 下处理 2 h,以及(f)重复弯曲 100 次前后的电磁屏蔽性能

下载:

下载: