Structure and mechanical properties of 3D printed biomimetic multi-tubular carbon fiber composites

-

摘要:

本文基于马蹄、骨骼等自然界生物组织的管状吸能结构启发,设计并制备了一种仿生多重管状结构的碳纤维复合材料。通过3D打印制造出具有多重管状结构的碳纤维复合材料,并引入紫外光固化技术使柔性聚氨酯树脂在管状结构中固化而形成异质界面,显著提升了材料的韧性和抗冲击能力。实验结果表明:该仿生结构材料在静态压缩测试中展现出延长的屈服阶段和优异的变形恢复能力,比强度和能量吸收密度可达130.6 MPa/(g·cm–3)和44.6 J/g,高于传统的蜂窝吸能结构;在三点弯曲试验中表现出更长的塑性变形区域,其断裂韧性为碳纤维板的1.54倍;在冲击测试中,裂纹扩展受限于管的分布,并且通过异质界面破坏显著提高吸收能量,避免材料发生灾难性破坏。该研究为复合材料的抗冲击设计提供了新的仿生策略,尤其在国防、航空航天等需要高韧性、高强度材料的应用领域,具有广泛的应用潜力和前景。

Abstract:Inspired by energy absorbent natural tubular biological structures, a bionic multi-tubular carbon fiber composite was designed. This bionic material was fabricated using 3D printing and UV curing, incorporating heterogeneous interfaces to significantly enhance toughness and impact resistance. Experimental results demonstrate that the bionic structure material exhibits an extended yield phase and exceptional deformation recovery in static compression tests, with the specific energy absorption of 44.6 J/g and specific strength of 130.6 MPa/(g·cm–3). In three-point bending tests, the material shows a prolonged plastic deformation region. The fracture toughness is 1.54 times compared to carbon fiber composite. For impact tests, it effectively absorbs energy with restricted crack propagation, and the destruction of heterogeneous interface. This study provides biomimetic insights for the design of impact-resistant composite materials.

-

钛合金因其比强度高、抗蚀性强、稳定性好等优异的材料特性,在航空航天领域的关键构件中占据着核心地位。然而在复杂的服役环境中,金属结构长期受交变载荷、振动冲击等外部力作用,容易诱发结构裂纹、孔洞和锈蚀等损伤而出现性能退化,因此必须及时对损伤部位进行修复。相较于传统机械修复方式,复合材料贴补修复技术因具有工艺实施性强、密封性能好、无二次损伤等诸多优点更受青睐[1-5]。贴补结构通常情况下被设计为剪切受载,以实现最高的修复强度和耐久性,但对于增压舱、油箱等长期处于高压差环境下的密封结构,修复部位不可避免的出现I型受载情况,因此深入研究航空钛合金损伤构件碳纤维增强树脂基预浸料(CFRP)单面贴补修复界面I型断裂力学特性显得尤为重要。

近年来,国内外研究人员以胶接修补构件的承载强度、疲劳性能、结构刚度等静动态力学性能为修复评估指标,结合数值分析模型对不同贴补修复工艺进行了大量的试验研究,结果表明,胶接结构的修复质量与复合材料补片尺寸、铺层方向、胶接形式等因素有关[6-10]。Hu等[11]通过参数化实验系统分析了补片厚度、固化压力等多个典型单面贴补修复因素对钛合金裂纹修复效率的影响,并基于方差分析法进行参数寻优,验证了参数研究在强度/刚度恢复方面的有效性。毛振刚等[12]通过层合板胶接结构静态拉伸试验对胶接长度和铺层方式进行优化设计,得到了不同搭接方式的最优参数。Shah等[13]则更关注于粘合层的材料特性,通过实验和仿真阐明了胶粘剂厚度对应变能释放速率及失效类型的影响。Tie等[14]通过比较低速冲击试验中试样的冲击力曲线和分层面积,研究不同补片形状和尺寸大小对层合板修复性能的影响,得出半径为2.5倍损伤孔半径的圆形补片能够显著提高修补结构的抗冲击性能。Jefferson Andrew等[15]研究了玻纤/铝合金混合补片修复结构在不同冲击能量下的损伤机制和准静态拉伸响应,突出了补片混合化与铺层配置在构件性能恢复水平方面的重要性。而对于被粘物,Park等[16]研究了高/低周循环加载下,机械打磨、喷砂和剥离喷砂3种表面处理方式对胶接接头疲劳强度和失效模式的影响机制。

上述研究工作从多个维度为航空金属损伤构件的贴补修复和维护作出了巨大贡献,然而在承载性能方面的研究大多只集中在较理想的剪切受载,但实际服役环境下更复杂的受载形式也会干扰整体修复效果。以飞行器上的密闭增压舱为例,由于密封结构内外存在压力差,修复部位在法向拉应力作用下主要表现为I型受载,造成修复界面裂纹尖端的局部应力集中,一旦应力强度随着损伤累积突破临界值,极易诱发细观裂纹的失稳快速扩展,最终造成修复结构的完全失效。而目前针对贴补修复结构I型断裂力学特性的研究尚显匮乏,难以为实际修复工作提供足够的参考价值。

本文以CFRP预浸料补片通过共固化成型修补损伤钛合金构件,采用双悬臂梁(Double cantilever beam,DCB)试验深入研究了补片厚度、铺层方向、表面处理方式等典型因素对修复性能及层间断裂韧性的影响规律,结合修复试样断面特征与微观形貌分析,揭示了纤维桥联作用下钛合金/CFRP贴补修复结构I型静态分层扩展的内在机制,为I型受载条件下钛合金构件损伤CFRP贴补修复工艺的优化设计与应用实践提供参考。

1. 试验材料及方法

1.1 试样规格与材料参数

采用钛合金/CFRP共固化单面贴补修复试样,探究修复界面的I型断裂力学特性,试样规格如图1所示,尺寸参数如表1所示。钛合金试片与CFRP预浸料补片通过结构胶膜进行部分粘接,并在另一端嵌入厚度为0.01 mm的聚四氟乙烯薄膜作为预埋的初始分层,薄膜嵌入的长度为67 mm,包含分层前沿到加载中心线50 mm的初始长度a0及铰链17 mm的附加长度l0。钛合金试片(上海禄浩金属有限公司)的材料为Ti-6 Al-4 V,几何尺寸为150 mm×25 mm×1.5 mm。热固性碳纤维预浸料补片(上海晋飞碳纤科技股份有限公司)有单向和平纹编织两种,均是以725环氧树脂为基体浸渍T700连续纤维制成的,前者的树脂含量约为33%,单层厚度0.19 mm,后者的树脂含量约为40%,单层厚度0.2 mm。尽管平纹编织型补片在相同铺层数量下具有更大的公称厚度,但高树脂含量预浸料会在固化过程中增大流胶引起的厚度缩减,两者的厚度差异进一步减小,因此在本文研究过程中视为同一厚度。胶粘剂(北航材料研究院)采用含支撑载体、中温(120℃)固化的SY-24 C改性环氧树脂结构胶膜,单层厚度0.12 mm。上述材料的主要力学性能参数如表2所示。

![]() 图 1 钛合金/碳纤维增强树脂基(CFRP)预浸料单面贴补修复试样示意图P1—External pressure of member; P2—Internal pressure of member; △P—Difference between internal and external pressure; F—Force; PTFE—PolytetrafluoroethyleneFigure 1. Schematic illustration of titanium alloy/carbon fiber reinforced polymer (CFRP) single-sided patch repaired specimen表 1 钛合金/CFRP单面贴补修复试样几何参数Table 1. Geometric parameters of titanium alloy/CFRP single-sided patch repaired specimen

图 1 钛合金/碳纤维增强树脂基(CFRP)预浸料单面贴补修复试样示意图P1—External pressure of member; P2—Internal pressure of member; △P—Difference between internal and external pressure; F—Force; PTFE—PolytetrafluoroethyleneFigure 1. Schematic illustration of titanium alloy/carbon fiber reinforced polymer (CFRP) single-sided patch repaired specimen表 1 钛合金/CFRP单面贴补修复试样几何参数Table 1. Geometric parameters of titanium alloy/CFRP single-sided patch repaired specimenDescription Value/mm Hinge additional length l0 17 Length of initial crack a0 50 Total length L 150 Specimen width b 25 Ti-alloy thickness t 1.5 Thickness of adhesive film t0 0.12 表 2 结构胶膜、单向(UD)及平纹(PW)编织CFRP力学性能参数Table 2. Mechanical properties of adhesive film, unidirectional (UD) and plain weave (PW) CFRPAdhesive

SY-24 CUD laminate

(T700/725)PW laminate

(T700/725)Property Value Property Value Property Value E/MPa 5750 E1/GPa 119 E1/GPa 66.28 G/MPa 1920 E2/GPa 9 E2/GPa 61.8 σ/MPa 451.6 E3/GPa 9 E3/GPa 10 τ/MPa 36.5 ν12, ν13 0.309 ν12 0.057 GCn/(N·mm−1) 0.48 ν23 0.35 ν13, ν23 0.25 GCs/(N·mm−1) 0.64 G12, G13/GPa 4 G12/GPa 4.52 GCt/(N·mm−1) 0.64 G23/GPa 3.33 G13, G23/GPa 4 Notes: E, G—Elastic modulus in tension and shear; σ, τ—Failure strengths in tension and shear; GCn—Toughness in tension; GCs, GCt—Toughness in shear; Ei (i =1, 2, 3)—Young's modulus (i direction); Gij (i, j =1, 2, 3)—Shear modulus (i-j plane); vij (i, j=1, 2, 3)—Poisson’s ratio (i-j plane). 1.2 试样制备流程与方法

钛合金试片与CFRP预浸料补片的制备工艺对修复试样的力学性能有重要影响,其制备流程包括贴补修复和固化成型两部分。

钛合金/CFRP贴补修复试样的具体贴补流程如图2所示。为了提高胶膜在金属构件表面的粘接性能,试样制备前需要对钛合金试片进行乙醇去污、超声清洗和中温干燥等处理。此外,贴补所需的预浸料补片和结构胶膜均在下料机(纳捷DG2516L20)中预先裁制完成,严格控制了二者的几何尺寸及纤维角度,使用前需提前6 h从低温密封环境中取出进行回温。修复试样粘接时,首先对钛合金试片进行均匀预热,再将胶膜铺贴至待粘接区域,用金属滚轮来回辊压以迅速排出气体,减少粘接界面的空隙率。然后根据表1中的几何参数,在试样另一端平整地嵌入聚四氟乙烯薄膜作为初始分层。最后,将CFRP预浸料补片逐层对齐并覆盖在试样表面,期间需再次加以辊压以提高层间浸润效果。

修复试样在高精度自动热压机(ZG-3 T,正工机电设备科技有限公司,东莞)中完成共固化,全程固化压力设置为(0.3±0.05) MPa,温度曲线如图3(c)所示。SY-24 C胶膜和CFRP预浸料具有相似的固化工艺流程,因此试样材料的选取具有合理性。试样首先以2℃/min的速率从室温升至80℃并保温0.5 h完成初步固化,随后以1.5℃/min的速率升温至125℃并保温2 h,最后自然冷却1 h以释放固化过程中产生的残余热应力。

固化试样在室温下静置24 h后,采用研磨机(MP-1B,蔚仪试验器械制造有限公司)对两侧溢出的预浸料和胶膜进行打磨修整,并通过超声相控阵C扫进行检测,确保嵌入物总长(l0+a0)符合要求,且试样内部不含明显缺陷。

为实现钛合金/CFRP贴补修复试样的I型加载,根据ASTM D5528-13标准[17]采用活动铰链引入拉伸载荷。两者间的粘接区域通过砂纸打磨以增强界面间的机械锚固效应,使用502胶水将铰链对称固定在试样边缘的上下两端。粘接时应保证两侧铰链夹持端位于同一竖直平面,避免在加载过程中引入附加弯矩与剪切应力,导致铰链脱粘。

航空金属损伤构件在实际贴补修复过程中,需要同时兼顾轻量化与高承载性能恢复率的要求。因此,本文详细研究了CFRP补片厚度、铺层方向、钛合金表面处理方法3种典型因素对修复界面I型断裂力学特性的影响规律,相关符号及具体的参数设置如表3所示。金属表面处理主要针对钛合金试片的粘接修复面,其中,机械打磨试样采用400#砂纸沿长度方向往复摩擦直至具有均匀的金属光泽;喷砂试样采用粒径400 μm石英砂,在0.6 MPa的喷砂压力、180 mm的喷砂距离及45°的喷砂角度下制备而成,相关研究中表明TC4钛合金在该喷砂参数下具有最大的粘接强度[18];硫酸阳极化处理工艺中氧化层的厚度设置为3 μm,以改善钛合金粘接面的浸润效果。需要强调的是,补片厚度不包含固化过程中流胶引起的缩减。

表 3 钛合金/CFRP单面贴补修复试样影响因素及参数设置Table 3. Influencing factors and parameter setting of titanium alloy/CFRP single-sided patch repaired specimenRepair factor Factor setting Patch thickness TP/mm 1.14, 1.52, 1.90, 2.28, 2.66 Lay-up direction θP/(°) [0]8, [±45]2 s, [0/90]2 s, [90/0]2 s,

[(0/90)w]8, [0/±45/90]s, [±45/02]sSurface treatment RT Sandpapering, Quartz-blasting,

Sulphuric acid anodizing (SAA),

Untreated1.3 修复试样DCB测试及表征方法

采用双悬臂梁法(DCB)测试钛合金/CFRP贴补修复试样的I型层间力学性能,试验标准参照ASTM D5528-13[17],完整试验平台如图4所示。试验开始前,使用水溶性修正液刷涂试样侧面以提高裂纹与周边区域的对比度,待其干透后以1 mm的间隔划线。DCB测试采用载荷量程为5 kN的高精度拉伸试验机(PT-1179OG,宝大仪器,中国),测力准确度和位移-速度控制精度均在±0.1%以内。为了避免拉伸过程中因夹持面打滑造成试样侧边载荷不对称,装载时要对试验件位姿进行调整,确保试验件对齐居中,同时楔形夹具的夹持长度应大于1/3。

测试过程中,在室温环境(25℃)下以2 mm/min的恒定进给速率施加载荷,并实时采集载荷、位移、时间等参量。同时,在加载过程中采用高光学变焦工业相机(MV-CA050-12UC,Hikrobot)全程动态监测试样分层裂纹的萌生与扩展,如图4(c)所示。以时间为关键参量,建立分层长度与载荷位移的动态关系,并额外记录了裂纹起停扩展阶段对应的载荷、位移及分层长度,作为分析裂纹扩展机制的重要依据。当试样中的CFRP补片与钛合金试片发生完全剥离时,试验机停止加载。

测试完成后,对试样分层扩展断面与横截面进行超声清洗及喷金处理,通过高分辨率相机和扫描电子显微镜(SEM,Hitachi Regulus 8100,日本)识别宏观/微观尺度下的不同断口形貌和失效模式。在此基础上,结合修复试样峰值载荷、断裂韧性等力学响应,作为评估修复效果的主要指标。每种不同修复工艺的试样至少重复实验3次,当测试结果出现显著异常时需重新进行实验,控制上述关键力学参数的变异系数(CV)均小于10%,以确保结论的可靠性及修复工艺的稳定性。需要注意的是,由于试样分层前缘应变能释放率的分布存在不均匀性[19],导致其呈现中间凸起状[20],通过目视确定的分层长度存在一定误差,因此其测量值仅为近似值。

1.4 断裂韧性分析方法

I型裂纹作为最常见的断裂失效类型,通常采用层间断裂韧性来表征其抗分层扩展的能力。在断裂韧性的计算过程中,首先需要准确评定裂纹的分层起始点。ASTM D5528-13[17]中介绍了3种常用评定标准,通常情况下, 非线性偏离点(Non-linear point,NL)以较低的初始断裂韧性作为分层失效标准,为材料修复性能评估提供了更安全的边界条件,因此本文统一采用NL点作为裂纹的分层起始点,并采用修正梁理论(Modified beam theory,MBT)[21]计算试样分层扩展过程中的I型层间断裂韧性GIC,其表达式如下:

GIC=3Pδ2b(a+|Δ|)FN′ (1) 式中:P为施加的外载荷;δ为加载点处的位移;b为试样宽度;a为裂纹分层长度,即试样加载中心线至分层前缘处的距离;Δ为分层长度的修正值,即柔度立方根(C1/3)最小二乘拟合曲线与裂纹长度对应线性图的横轴截距;F和N'为大挠度及加载块法的修正因子,本文取值为1。

2. 实验结果与讨论

2.1 复合材料补片厚度对修复效果的影响

复合材料贴补修复是兼顾航空损伤构件气动外形和综合力学性能的有效手段,但整体修复效果与补片厚度并非呈现简单的正相关,过大的厚度还会导致结构超重及气动性能下降。因此,研究了补片厚度对修复界面I型断裂力学特性的影响规律。

不同厚度补片修复试样的载荷-位移曲线如图5所示,钛合金表面无特殊处理,对应的铺层类型分别为TP=[0]k (k=6, 8, 10, 12, 14)。在曲线上升初期,试样处于线弹性阶段,当分层裂纹抵达嵌入物前沿时,曲线因试样产生的刚度退化出现非线性扰动;随着开口位移的增加,当裂纹尖端应力强度达到临界值时,分层损伤发生失稳扩展,载荷迅速下降,随后再缓慢增长直至下一次失稳扩展。载荷-位移曲线下降段整体呈现出显著的非稳态锯齿形特征,表明裂纹扩展界面存在脆性破坏。由于试样材料特性和几何形状具有相似性,所有修复试样的载荷-位移曲线均表现出类似的演变规律,但所能承受的峰值载荷随厚度的增加而增大。此外,同一厚度试样线性段斜率的差异主要是由于钛合金与碳纤维复合材料间热膨胀系数不同,导致在其界面处产生残余热应力,进而造成修复试样的热变形差异。

试样层间断裂韧性随裂纹扩展长度的变化曲线,即R曲线,如图6所示。所有试样的分层裂纹均出现明显的非稳定扩展[22],主要是由于结构胶膜所带来的起裂韧性与扩展韧性之间的差异。在分层裂纹扩展初期,修复试样的断裂韧性呈现波动上升趋势,最终在分层长度100~115 mm的区间内逐渐趋于平稳。这是由于,在I型静态拉伸试验中,试样总能量释放率主要由基体及纤维桥联断裂能组成[23]。桥联纤维是层间裂纹扩展过程中,在界面效应及粘附力和摩擦力作用下形成的横跨分层断面的交错结构,其作用机制表现在能够改善载荷传递机制以缓解裂纹尖端的应力集中情况,并在纤维滑移、断裂过程耗散大量能量,进而显著提高层间断裂韧性。当桥联纤维的生成与失效断裂达到动态平衡时,即在裂纹分层扩展的后半段中,断裂韧性值逐渐趋于稳定。但随着补片厚度的增加,R曲线的锯齿形波动特征愈发显著,曲线形状表现出对补片厚度的高度依赖性。

不同厚度补片试样平均峰值载荷与稳定断裂韧性的直观对比结果如图7所示。补片面内或轴向弯曲刚度根据经典层合板理论和文献[24]中的公式计算求得,相关表达式如下:

Efx=12D∗11t3 (2) 式中:D∗11为补片等效弯曲刚度矩阵逆矩阵中的第一行/第一列元素;t为CFRP补片厚度;x对应于修复试样的长度方向。

随着补片厚度的增加,试样所能承受的峰值载荷呈上升趋势,且峰值载荷对应的拉伸位移在逐渐减小,说明补片厚度引起的试样轴向弯曲刚度的变化与峰值载荷密切相关,具体表现为:当补片厚度增加时,试样轴向抗弯刚度随试样截面惯性矩和等效弹性模量的提高而显著增大,因此达到临界应变能所需的载荷也相应增大。另外,在1.52~2.66 mm的厚度区间内,试样的稳定断裂韧性值也呈现类似的演变规律,而1.14 mm试样由于厚度缩放至临界值引起的弱刚性响应,导致其在静态拉伸过程中出现大幅弯曲变形,应变能不断积聚,到达峰值GIC=

2840.13 J/mm2时发生裂纹跳跃,断裂韧性迅速下降至1224.81 J/mm2,最终在1503.13 J/mm2上下波动。实验过程中发现,大厚度试样(2.28~2.66 mm)在裂纹扩展过程中出现明显的二次分层现象,即在预制裂纹的界面外出现另一分层,这是由于试样在弯曲载荷作用下发生互反弯曲效应[25],横截面产生拱形翘曲[26],同时拐角刚性约束引起的应力集中较显著,超出了树脂基体及纤维的承载能力。总体而言,补片厚度的增加在一定程度上有助于提高钛合金构件的修复效果,但过大的厚度会导致更多的粘滑行为,实际应用效果需要通过进一步的研究进行量化。为了进一步阐明断裂机制及损伤演化规律,使用高分辨率相机与扫描电子显微镜观察失效试样分层断面的宏观/微观形貌,如图8所示。不同厚度试样的失效模式具有相似性,主要可以归纳为以下3种:胶膜粘附失效、胶膜内聚破坏及CFRP界面破坏。胶膜粘附失效是指胶膜与钛合金结合面因粘附强度不足导致的直接分离破坏,可以在金属侧观察到部分残留的粘接层碎块;胶膜内聚破坏主要为图中白色区域,其损伤机制具体表现为:结构胶膜中的高分子链在拉应力的持续作用下被逐渐拉直,并产生不可逆变形,一旦达到其极限抗拉强度立即发生断裂,并且当分子链在特定方向取向一致时,胶膜会因光学改性而变为白色;胶膜内聚破坏后,分层裂纹继续向断裂韧性弱侧扩展,机械载荷通过桥联纤维有效转移至分层表面[27],导致部分纤维从树脂基体中拔出或断裂,并在基体表面形成空腔,最终引起CFRP层纤维与树脂间的界面破坏。

不同厚度补片修复试样的分层断面中均出现了上述分类中的3种失效模式,如图9所示。可以观察到,所有试样的初始损伤均为胶膜粘附失效与内聚破坏的混合失效模式,说明分层起始点处补片的层间强度大于钛合金/胶膜界面的粘接强度及胶膜自身的内聚强度。这一现象主要归因于胶膜性能及制备工艺,而补片厚度的影响相对有限。随着试样的继续加载,应力会逐渐向补片内部传递。当裂纹发生第一次失稳扩展时,载荷迅速下降,主要失效模式逐渐演化为CFRP界面破坏。为了进一步量化渐进损伤影响机制,分别计算不同试样中各失效模式百分比,如图9(f)所示。随着补片厚度的增加,界面破坏的失效占比增大,纤维桥联作用区域的面积也随之增大,消耗更多断裂能的同时也有利于界面应力的传递,进而提升修复试样的层间断裂韧性。因此,纤维桥联作用的强弱是影响不同厚度补片修复试样稳定断裂韧性的主要原因。

2.2 复合材料铺层方向对修复效果的影响

多向补片因具有更加均衡的力学性能,在实际修复工作中应用广泛,因此本节重点评估了铺层方向对修复试样I型断裂力学特性的影响。考虑到共固化修复试样内部的残余热应力容易引起非对称铺层补片的弯曲变形及分层前缘的三维尺寸效应,因此所有试样均采用对称均衡铺层[28-29]。

不同铺层方向修复试样的载荷-位移曲线如图10所示。曲线整体呈先上升后下降趋势,下降段同样呈现出显著的非稳态锯齿形特征。其中平纹编织试样的锯齿状波动最为明显,且具有最大的峰值载荷。[±45]2 s因缺乏轴向纤维分布导致其弯曲刚度低且弹性耦合作用明显,因此试样层间剥离速度慢,曲线走势较平缓,峰值载荷仅为58.64 N;在此基础上,[0/±45/90]s中嵌入的0°和90°补片可以有效承受中间层两侧的拉压应力,整体承载能力和弯曲刚度提升,曲线线弹性段斜率增大,且峰值载荷约为前者的1.3倍,但稍弱于[0]8试样;而[±45/02]s中尽管增加了0°铺层,但并未改变其初始分层界面的铺层方向,导致两者具有相似的初始损伤机制,峰值载荷没有得到有效提升。[0/90]2 s和[90/0]2 s试样曲线的非线性特征明显,说明初始裂纹扩展的时间早,阻裂能力弱,但堆叠顺序的差异导致前者具有更大的弯曲刚度和峰值载荷。

不同铺层方向试样的断裂韧性曲线如图11所示。除[(0/90)w]8外,其余修复试样的断裂韧性曲线均呈现明显的R曲线行为,但其形状及稳定断裂韧性值受铺层方向影响大。其中,[±45]2 s试样具有最大的断裂韧性,[±45/02]s次之,其相同点在于,两者底部的45°铺层在承受剪切和拉伸载荷时能有效传递和分散应力。而[90/0]2 s和[0/90]2 s试样的层间断裂韧性最小,说明0/90交错铺层的阻裂能力较弱。但二维编织型铺层能够有效弥补这个不足,其具有的均匀且密集的纤维网格能够显著增强界面粘结强度,进而改善试样的层间力学性能。与文献[11]报道的剪切受载相比,编织型补片单面贴补修复结构在I型开裂载荷中的表现更优异。

多向铺层修复试样的宏观失效模式如图12所示,其类型相较于单向铺层试样更具复杂性。[±45]2 s和[±45/02]s试样剥离过程中,剪切应力将其底部的45°铺层沿纤维方向从边缘处撕裂,使其初始损伤特征同时包含图8中的3种失效模式,并且随着裂纹的继续扩展,分层损伤开始在具有不同方向的相邻铺层间迁移,导致裂纹扩展路径长度增加,并呈现出阶梯状的立体传播模式[30],有效分散了裂纹尖端的应力集中区域,进而降低了裂纹在轴向上的扩展速度。同时裂纹迁移会引起基体开裂等额外的能量耗散机制,大幅提高了试样的层间断裂韧性。这是由于修复试样中碳纤维复合材料补片与钛合金试片的刚度差异导致前者出现了更大的弯曲程度,在弹性耦合效应与韧性基体阻碍作用的综合影响下,分层裂纹逐渐向更薄弱的层间界面扩展,即发生裂纹迁移。而[0/±45/90]s、[0/90]2 s及图9中[0]8试样中均未出现类似现象,主要是由于底部铺层与裂纹扩展方向一致,纤维对分层路径的约束作用强,损伤始终位于试样的中间层。这种相关性可以在[90/0]2 s中得到验证,该试样具有和[0/90]2 s同样的铺层方向但不同的堆叠顺序,其底层的横向纤维近乎完整的附着在胶膜表面,裂纹扩展主要发生在次相邻铺层内。但两者还具有另一共同特征,即正交铺层的堆叠会导致纤维间粘附力和摩擦力减弱,进而减小纤维桥联规模,这使它们具有最低的断裂韧性稳定值。[(0/90)w]8平纹编织试样的分层断面中没有出现显著的纤维桥联现象,其失效模式表现为补片的层间脱粘。而其更高的断裂韧性可以归因于织物的固有粗糙度,具体而言,更高的粗糙度有效增加了分离面的面积,进而提升了试样的断裂韧性。

不同铺层方向修复试样分层断面的SEM图像如图13所示。其中,基体开裂、纤维/基体脱粘和桥联纤维断裂是单向预浸料贴补试样的主要微观破坏形式,其对应的断面特征共同表现为纤维/基体脱粘产生的半圆柱形纤维压痕及在剪切载荷作用下,基体材料局部区域形成的特征性锯齿状断面。[±45]2 s和[±45/02]s试样中可以观察到明显的层间裂纹迁移现象,同时伴随着基体面内损伤的形成。这些现象显著增加了裂纹的扩展阻力及所需能量,进而提高了修复试样的层间断裂韧性。[90/0]2 s试样也呈现出相似的损伤特征,但低阻抗脱粘纤维留下的凹槽更清晰圆润,同时还具有最低的层间断裂韧性,原因是裂纹路径增加带来增益性能的同时,纤维桥联作用由于相邻正交铺层纤维与树脂间渗透性不佳而大幅减弱,从而对修复试样断裂韧性造成了超过增益影响的减损。[(0/90)w]8试样的微观破坏形式主要表现为横向纤维与纵向纤维的剥离断裂,其分层断面相比于单向修复试样更粗糙,因此具有最高的层间断裂韧性。有进一步的研究表明,编织型试样的界面脱粘机制高度依赖于交织的纵向纤维对横向纤维的约束程度[31]。

![]() 图 13 不同铺层方向修复试样分层断面的微观形貌:(a) [±45]2 s;(b) [0/90]2 s;(c) [90/0]2 s;(d) [0/±45/90]s;(e) [±45/02]s;(f) [(0/90)w]8Figure 13. Microscopic morphology of delamination sections of repaired specimens with different layup orientations: (a) [±45]2 s; (b) [0/90]2 s; (c) [90/0]2 s; (d) [0/±45/90]s; (e) [±45/02]s; (f) [(0/90)w]8

图 13 不同铺层方向修复试样分层断面的微观形貌:(a) [±45]2 s;(b) [0/90]2 s;(c) [90/0]2 s;(d) [0/±45/90]s;(e) [±45/02]s;(f) [(0/90)w]8Figure 13. Microscopic morphology of delamination sections of repaired specimens with different layup orientations: (a) [±45]2 s; (b) [0/90]2 s; (c) [90/0]2 s; (d) [0/±45/90]s; (e) [±45/02]s; (f) [(0/90)w]82.3 不同金属表面处理方法对修复效果的影响

为了改善钛合金/CFRP界面间的粘接强度和整体修复效果,研究中评估了砂纸打磨、石英喷砂及硫酸阳极化等不同表面处理方法对修复试样层间断裂性能的影响,补片配置统一采用[0]8。

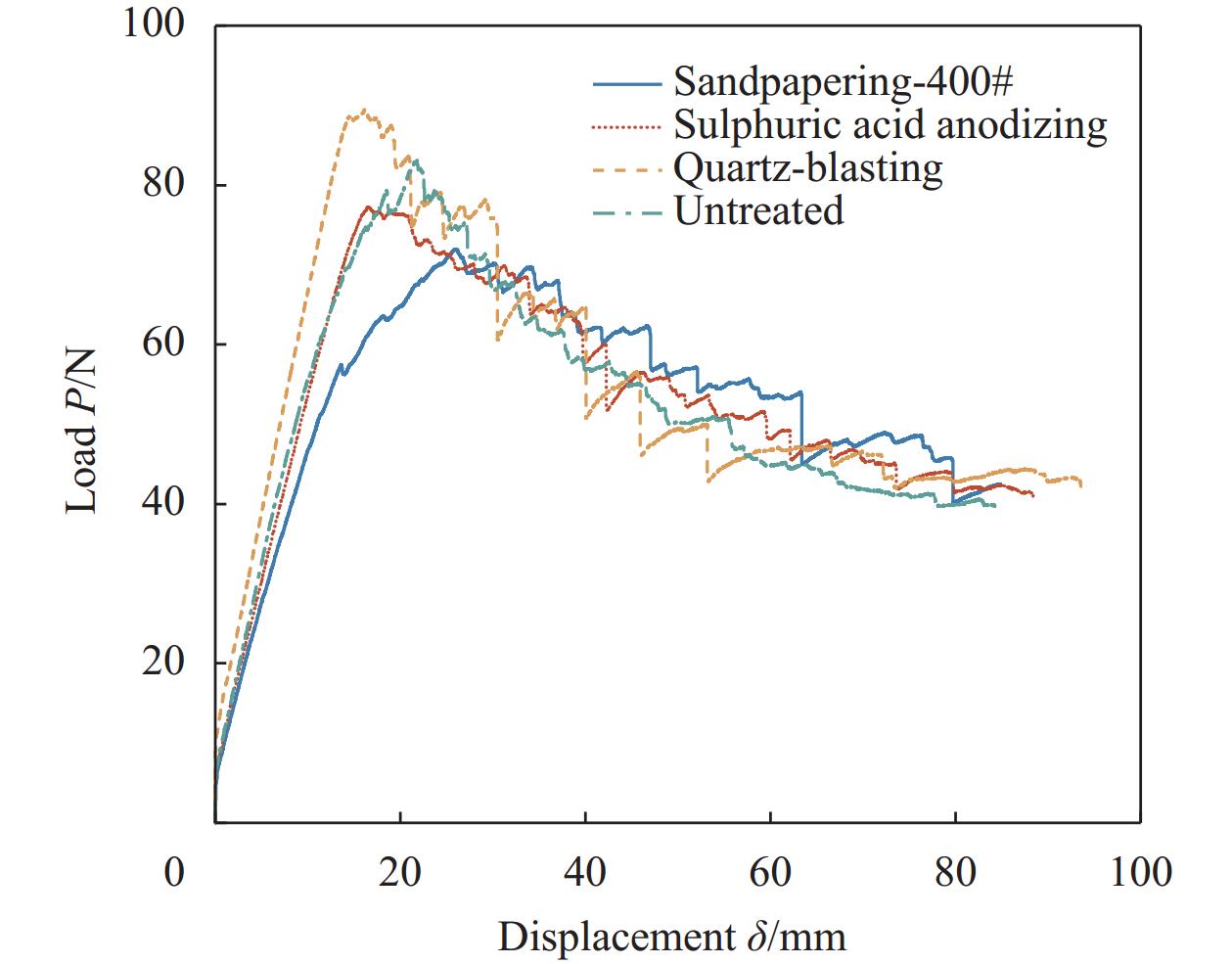

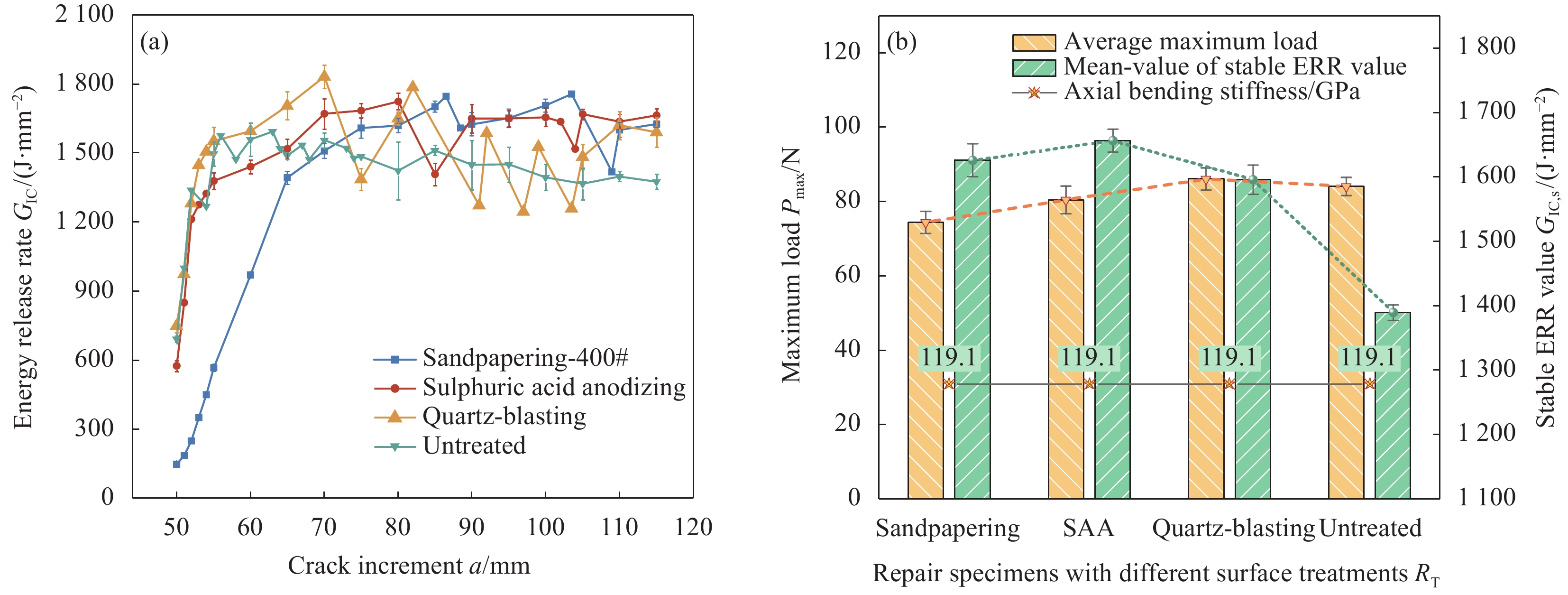

不同表面处理修复试样的载荷-位移曲线如图14所示。整体上看,曲线随位移的增加均呈现先上升后下降的趋势。但经过表面处理的修复试样在载荷下降段表现出更加显著的锯齿形特征,其完全剥离所需的位移也更大,说明试样的抗分层扩展能力明显增强。此外,石英喷砂和硫酸阳极化对修复试样峰值载荷的影响较小,相较于无处理试样的变化分别为2.4%和−4.3%。而400#砂纸打磨试样的峰值载荷则降低了11.4%,且非线性扰动段对应的开口位移较小,说明手动打磨的非均匀性容易导致初始裂纹的萌生时间大幅提前。

不同表面处理方法对钛合金/CFRP贴补修复试样I型断裂韧性的影响如图15所示。可以看出,经过表面处理后,试样的断裂韧性稳定值均显著提高。这是由于处理过程中有效清除了钛合金试片表层的灰尘、油脂等杂质,进而削弱了弱界面层的不利影响,金属粘接修复面的润湿性和吸附性能得到明显改善。其中,硫酸阳极化的增韧效果最为显著,其平均值较石英喷砂和400#砂纸打磨分别提高3.8%和1.9%,而相较于无处理试样更是显著提升了19.2%。

不同表面处理工艺修复试样分层断面的宏观形貌如图16所示。经过界面改性后,钛合金与胶膜粘接界面的相互作用加强,有效改善了界面间的应力分布和能量传递效率。得益于机械互锁与化学键合的协同作用,分层裂纹的扩展路径被牢牢锁定在胶层内部,从而避免了裂纹向钛合金基体的进一步蔓延。因此在砂纸打磨、硫酸阳极化及石英喷砂试样的分层断面中,胶膜内聚破坏的占比显著提高,取代CFRP界面破坏成为I型裂纹扩展的主要失效模式。由于胶层本身具有较强的内聚力和韧性,能够有效地吸收和分散施加在试样的能量,并在裂纹扩展过程中提供更大的阻力,从而增大修复试样的层间断裂韧性。分层断面中零星分布的撕裂纤维束,进一步直观表明了粘接修复面表面处理在增强试样抗分层扩展性能方面的显著效果。

通过SEM和HIROX超景深三维数字显微镜观测4种不同表面处理工艺的钛合金基体粗糙度、表面形貌及其结合界面的微观结构,如图17所示,以进一步精确定征修复试样粘接界面的几何形态并阐明结合机制。钛合金试片经400#砂纸打磨后,表面原有的氧化层及凹凸不平的金属碎块被尽数消除,表面平均粗糙度从3.03 μm降至2.29 μm。同时还出现了更加密集但不均匀的线型凹槽,形成了相对较薄的粘接过渡层,有效改善了粘接界面的耦合效果,进而提高试样的层间抗剥离能力。硫酸阳极化试样在电离过程中,钛合金表面形成了一层致密且均匀的蜂窝状氧化薄膜。尽管平均表面粗糙度降至最低的0.96 μm,但这种特殊的多孔性特征为胶粘剂提供了理想的浸润和吸附条件,使其能够有效渗透到微观孔隙中,通过化学键合作用形成较厚的高活性复合粘接层,显著提升了界面间的载荷传递效率,因此具有最大的层间断裂韧性。与砂纸产生的单向划痕不同,喷砂试样在石英砂砾的高速撞击下,金属表面呈现出形状和大小不一的不规则凹陷。这种粗糙表面具有丰富的机械锚固位点,胶粘剂在固化过程中部分置换出基体孔隙中的空气,形成独特的倒钩结构,钛合金基体与胶膜界面间的过渡带也呈现出不规则的轮廓特征和微观形貌,显著增强了粘接界面的机械锚固效应,从而提高了胶膜的附着力。3种表面处理方法均能起到增韧效果,在航空钛合金构件的实际修复过程中,需根据现场条件与难易程度选择合适的表面处理方法。

![]() 图 17 经处理后的钛合金表面微观形貌:(a)无处理;(b) 400#砂纸打磨;(c)硫酸阳极化;(d)石英喷砂;修复试样粘接界面:(e)无处理;(f) 400#砂纸打磨;(g)硫酸阳极化;(h)石英喷砂Ra—Roughness average; Rz—Maximum height of the profileFigure 17. Microstructure of the Ti-alloy substrate surfaces treated by: (a) Untreated; (b) Sandpapering-400#; (c) Sulphuric acid anodizing; (d) Quartz-blasting; Bonding interfaces in repaired specimens: (e) Untreated; (f) Sandpapering-400#; (g) Sulphuric acid anodizing; (h) Quartz-blasting

图 17 经处理后的钛合金表面微观形貌:(a)无处理;(b) 400#砂纸打磨;(c)硫酸阳极化;(d)石英喷砂;修复试样粘接界面:(e)无处理;(f) 400#砂纸打磨;(g)硫酸阳极化;(h)石英喷砂Ra—Roughness average; Rz—Maximum height of the profileFigure 17. Microstructure of the Ti-alloy substrate surfaces treated by: (a) Untreated; (b) Sandpapering-400#; (c) Sulphuric acid anodizing; (d) Quartz-blasting; Bonding interfaces in repaired specimens: (e) Untreated; (f) Sandpapering-400#; (g) Sulphuric acid anodizing; (h) Quartz-blasting3. 结 论

通过双悬臂梁(DCB)实验和参数化方法,研究了补片厚度、铺层方向、表面处理方式对钛合金单面贴补修复界面I型断裂力学特性的影响,得到了如下主要结论:

(1)不同补片厚度修复试样分层断面的失效破坏特征具有相似性,共包含胶膜粘附失效、胶膜内聚破坏及碳纤维增强树脂基预浸料(CFRP)界面破坏3种类型。当补片铺层方向相同时,修复试样的轴向弯曲刚度随补片厚度的增大而增大,所能承受的峰值载荷呈上升趋势;同时纤维桥联作用的规模也逐渐增大,R曲线表现出更加剧烈的锯齿状波动特征,层间断裂韧性总体稳步增长。但当补片的厚度缩放超过临界值,弱刚性的机械响应会导致试样产生大幅弯曲变形,并在应变能积聚至峰值时发生显著的裂纹跳跃行为;

(2)碳纤维复合材料补片底部铺层的纤维取向对修复试样分层断面的失效模式具有直接影响。随着铺层角度的增大,裂纹的层间迁移行为愈发显著,其复杂的阶梯状扩展路径容易引起基体开裂等额外的能量耗散机制,进而增强修复结构的断裂韧性。其中,0°铺层表现出最强的路径约束作用,45°铺层的层间增韧效果最佳,但会缩短裂纹的起裂时间。当补片具有相同的铺层角度但不同的堆叠顺序时,I型断裂力学性能与轴向弯曲刚度呈正相关。此外,二维编织型补片因织物本身较高的固有粗糙度及交织纤维的约束作用,相较所有单向堆叠补片具有更好的修复效果;

(3)钛合金表面处理能够显著增强粘接界面的机械锚固效应和化学键合作用,有效改善了界面间的应力分布和能量传递效率,使胶膜内聚破坏成为I型裂纹扩展的主要失效模式,钛合金/CFRP贴补修复试样的层间断裂韧性得到明显提升。其中,喷砂和砂纸打磨的层间增韧机制主要归因于粘接界面机械锚固作用的增强,而硫酸阳极化试样独特的多孔氧化膜则有助于形成较厚的高活性复合粘接层,其增韧效果最为显著,断裂韧性稳定值较石英喷砂和400#砂纸打磨分别提高3.8%和1.9%,相比无处理试样则提高了19.2%。但由于相同配置补片的轴向弯曲刚度相同,修复试样峰值载荷的波动幅度较小。

-

图 10 仿生结构材料((a), (b))和碳纤维板((c), (d)) 在15 J冲击后的裂纹及损伤情况;(e)多次冲击测试中仿生结构材料第3次(e)和第5次(f)冲击后的显微图片

Figure 10. Crack formation and damage in the biomimetic structure material ((a), (b)) and carbon fiber plate ((c), (d)) after 15 J impact; Micrographs of bionic structural material after the third (e) and the fifth (f) impact in multiple impact test

S1 压缩-回复实验中碳纤维样品与仿生结构样品在不同压缩程度下的回复率

S1 Recovery rates of carbon fiber samples and biomimetic structure samples under different compression degrees in compression-recovery experiments

Compress Recovery rate/% Carbon fiber sample Biomimetic structure sample 5% 74.8 77.8 15% 39.8 46.0 30% 22.9 29.3 S2 之前报道的生物启发材料的比能量吸收(SEA) 总结

S2 Summary of specific energy absorption (SEA) of previously reported bioinspired materials

Bionic object Materials SEA/(J·mg−1) Ref. Bamboo Polyethylene+Epoxy resin 6.37 [34] Bamboo Bamboo tubes+ Polypropylene+ Polylactide 26 [35] Bone Polyurethane foam+ Carbon blacks 15.7 [36] Bone Aluminium alloy Al-6063-T5 25.26 [37] Mantis shrimp AlSi10Mg 51 [38] Horse hoof Carbon fiber composite+ Polyurethane 44.6 Our work -

[1] GU G X, TAKAFFOLI M, BUEHLER M J. Hierarchically enhanced impact resistance of bioinspired composites[J]. Advanced Materials, 2017, 29(28): 1700060. DOI: 10.1002/adma.201700060

[2] DALILI N, EDRISY A, CARRIVEAU R. A review of surface engineering issues critical to wind turbine performance[J]. Renewable and Sustainable Energy Reviews, 2009, 13(2): 428-438. DOI: 10.1016/j.rser.2007.11.009

[3] 王安妮, 刘晓刚, 岳清瑞. 碳纤维增强树脂基复合材料及其拉索抗低速冲击性能综述[J]. 复合材料学报, 2022, 39(11): 5049-5061. WANG Anni, LIU Xiaogang, YUE Qingrui. Low-velocity impact resistance of carbon fiber reinforced polymer composite and its cables: A review[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5049-5061 (in Chinese).

[4] 张辰, 饶云飞, 李倩倩, 等. 碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能及其模拟[J]. 复合材料学报, 2021, 38(1): 165-176. ZHANG Chen, RAO Yunfei, LI Qianqian, et al. Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites[J]. Acta Materiae Compositae Sinica, 2021, 38(1): 165-176 (in Chinese).

[5] NING F, CONG W, QIU J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering, 2015, 80: 369-378. DOI: 10.1016/j.compositesb.2015.06.013

[6] RITCHIE R O. The conflicts between strength and toughness[J]. Nature Materials, 2011, 10(11): 817. DOI: 10.1038/nmat3115

[7] HUANG W, RESTREPO D, JUNG J, et al. Multiscale toughening mechanisms in biological materials and bioinspired designs[J]. Advanced Materials, 2019, 31: 1901561. DOI: 10.1002/adma.201901561

[8] BARTHELAT F, YIN Z, BUEHLER M J. Structure and mechanics of interfaces in biological materials[J]. Nature Reviews Materials, 2016, 1: 16007. DOI: 10.1038/natrevmats.2016.7

[9] WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials[J]. Nature Materials, 2015, 14: 23-36. DOI: 10.1038/nmat4089

[10] EDER M, AMINI S, FRATZL P. Biological composites—Complex structures for functional diversity[J]. Science, 2018, 362(6414): 543-547. DOI: 10.1126/science.aat8297

[11] CHEN P Y, MCKITTRICK J, MEYERS M A. Biological materials: Functional adaptations and bioinspired designs[J]. Progress in Materials Science, 2012, 57(8): 1492-1704. DOI: 10.1016/j.pmatsci.2012.03.001

[12] MEYERS M A, CHEN P Y, LIN A Y M, et al. Biological materials: Structure and mechanical properties[J]. Progress in Materials Science, 2008, 53(1): 1-206. DOI: 10.1016/j.pmatsci.2007.05.002

[13] NALLA R K, KINNEY J H, RITCHIE R O. Effect of orientation on the in vitro fracture toughness of dentin: The role of toughening mechanisms[J]. Biomaterials, 2003, 24(22): 3955-3968. DOI: 10.1016/S0142-9612(03)00278-3

[14] NALLA R K, KINNEY J H, RITCHIE R O. Mechanistic fracture criteria for the failure of human cortical bone[J]. Nature Materials, 2003, 2: 164. DOI: 10.1038/nmat832

[15] MCKITTRICK J, CHEN P Y, TOMBOLATO L, et al. Energy absorbent natural materials and bioinspired design strategies: A review[J]. Materials Science and Engineering: C, 2010, 30(3): 331-342. DOI: 10.1016/j.msec.2010.01.011

[16] GONG S, NI H, JIANG L, et al. Learning from nature: Constructing high performance graphene-based nanocomposites[J]. Materials Today, 2017, 20(4): 210-219. DOI: 10.1016/j.mattod.2016.11.002

[17] LEE S, NOVITSKAYA E E, REYNANTE B, et al. Impact testing of structural biological materials[J]. Materials Science and Engineering: C, 2011, 31(4): 730-739. DOI: 10.1016/j.msec.2010.10.017

[18] HUANG W. Impact resistant and energy absorbent natural keratin materials: Horns and hooves [D]. San Diego: University of California San Diego, 2018.

[19] 徐菁, 李岩, 付昆昆. 仿羊角管状复合材料结构抗冲击性能[J]. 复合材料学报, 2023, 40(4): 2365-2376. XU Jing, LI Yan, FU Kunkun. Impact resistance of horn-inspired tubular composite structure[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2365-2376 (in Chinese).

[20] GUPTA S, MOINI R. Tough cortical bone-inspired tubular architected cement-based material with disorder[J]. Advanced Materials, 2024, 2313904.

[21] GUSTAFSSON A, WALLIN M, ISAKSSON H. The influence of microstructure on crack propagation in cortical bone at the mesoscale[J]. Journal of Biomechanics, 2020, 112: 110020. DOI: 10.1016/j.jbiomech.2020.110020

[22] ZIMMERMANN E A, LAUNEY M E, BARTH H D, et al. Mixed-mode fracture of human cortical bone[J]. Biomaterials, 2009, 30(29): 5877-5884. DOI: 10.1016/j.biomaterials.2009.06.017

[23] HUANG W, ZAHERI A, JUNG J Y, et al. Hierarchical structure and compressive deformation mechanisms of bighorn sheep (Ovis canadensis) horn[J]. Acta Biomaterialia, 2017, 64: 1-14. DOI: 10.1016/j.actbio.2017.09.043

[24] ZHANG X, ZHANG H. Theoretical and numerical investigation on the crush resistance of rhombic and kagome honeycombs[J]. Composite Structures, 2013, 96: 143-152. DOI: 10.1016/j.compstruct.2012.09.028

[25] ZHANG X, HU H H. Crushing analysis of polygonal columns and angle elements[J]. International Journal of Impact Engineering, 2010, 37: 441-451. DOI: 10.1016/j.ijimpeng.2009.06.009

[26] KIM H S. New extruded multi-cell aluminum profile for maximum crash energy absorption and weight efficiency[J]. Thin-Walled Structures, 2002, 40: 311-327. DOI: 10.1016/S0263-8231(01)00069-6

[27] ZHANG X, ZHANG H. Numerical and theoretical studies on energy absorption of three panel angle elements[J]. International Journal of Impact Engineering, 2012, 46: 23-40. DOI: 10.1016/j.ijimpeng.2012.02.002

[28] LU G, YU T. Energy absorption of structures and materials [M]. Elsevier, 2003.

[29] QIAO J, CHEN C. In-plane crushing of a hierarchical honeycomb[J]. International Journal of Solids and Structures, 2016, 85-86: 57-66. DOI: 10.1016/j.ijsolstr.2016.02.003

[30] SHEN J, XIE Y M, HUANG X, et al. Mechanical properties of Luffa sponge[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2012, 15: 141-152. DOI: 10.1016/j.jmbbm.2012.07.004

[31] XUAN T N, HOU S, LIU T, et al. A potential natural energy absorption material - Coconut mesocarp: Part A: Experimental investigations on mechanical properties[J]. International Journal of Mechanical Sciences, 2016, 115: 564-573.

[32] IDRIS M I, VODENITCHAROVA T, HOFFMAN M. Mechanical behaviour and energy absorption of closed-cell aluminium foam panels in uniaxial compression[J]. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2009, 517: 37-45. DOI: 10.1016/j.msea.2009.03.067

[33] LIU Q, FU J, WANG J, et al. Axial and lateral crushing responses of aluminum honeycombs filled with EPP foam[J]. Composites Part B: Engineering, 2017, 130: 236-247. DOI: 10.1016/j.compositesb.2017.07.041

[34] WEN F F, QIAN Y F, GAO Y, et al. 3D woven tubular composites with bamboo-structures for enhanced energy absorption: Designing, manufacturing and performance analysis[J]. Polymer Composites, 2024, 45(9): 8282-8295. DOI: 10.1002/pc.28340

[35] ZUHRI M, LIAO Y, WANG Q Y, et al. The energy absorbing properties of bamboo-based structures[J]. Journal of Sandwich Structures and Materials, 2019, 21: 1032-1054. DOI: 10.1177/1099636217707171

[36] TAN S, CAI X, LI W, et al. Cancellous bone-like polyurethane foam: A porous material with excellent properties for ultra-high energy absorption[J]. ACS Applied Polymer Materials, 2024, 6(4): 2232-2242. DOI: 10.1021/acsapm.3c02763

[37] NGOC S H, THONG M P, CHEN W, et al . Energy absorption characteristics of bio-inspired hierarchical multi-cell bi-tubular tubes[J]. International Journal of Mechanical Sciences, 2023, 251: 108260. DOI: 10.1016/j.ijmecsci.2023.108260

[38] YANG J, GU D, LIN K, et al. Optimization of bio-inspired bi-directionally corrugated panel impact-resistance structures: Numerical simulation and selective laser melting process[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2019, 91: 59-67. DOI: 10.1016/j.jmbbm.2018.11.026

-

目的

随着科技的不断发展,特别是在高性能复合材料的设计与应用方面,如何在保证材料强度的同时,提升其韧性与抗冲击性能,成为了一个亟待解决的关键问题。近年来,仿生学作为一种设计新型材料的有效手段,得到了广泛关注。本文旨在通过仿生自然界中具有高韧性和抗冲击能力的结构,如马蹄和骨骼等生物组织的管状吸能结构,设计并制备一种具有多重管状结构的碳纤维复合材料,以期在多个力学性能方面取得突破,特别是在静态压缩、三点弯曲和冲击测试中的表现。

方法本文首先基于自然界的管状吸能结构原理,通过3D打印技术制造出具有多重管状结构的碳纤维复合材料。为了进一步提高材料的韧性和抗冲击能力,将柔性聚氨酯树脂引入到管状结构中,紫外固化形成柔性部分,并形成良好异质界面。并通过静态压缩测试、三点弯曲试验以及冲击测试,对所制备的复合材料的力学性能进行了全面评估。

结果实验结果表明,所设计的仿生多重管状结构的碳纤维复合材料在静态压缩测试中展现了显著的优势。其屈服阶段显著延长,且变形恢复能力优异,比强度和能量吸收密度分别达到了130.6 [MPa/(g/cm)]和44.6 J/g,明显优于传统蜂窝吸能结构。这一性能提升可归因于材料中的多重管状结构及其与紫外光固化树脂所形成的异质界面的协同作用。在三点弯曲试验中,材料表现出了更长的塑性变形区域,断裂韧性比碳纤维板高出1.54倍,进一步证明了仿生结构设计在提升韧性方面的有效性。冲击测试中,裂纹的扩展受限于管状结构的分布,并且异质界面破坏显著提高了吸能能力,避免了材料的灾难性破坏。具体而言,通过管状结构的分布和界面优化,材料能够在高能冲击下有效地分散冲击力,显著提升了抗冲击性能。

结论基于马蹄、骨骼等自然界生物组织管状吸能结构的启发,本文设计并制备的仿生多重管状碳纤维复合材料在多个力学性能方面展现了优异的表现,尤其在静态压缩、三点弯曲和冲击测试中的韧性、强度以及能量吸收能力方面,均显著优于传统蜂窝结构材料。这种材料的成功应用为复合材料的抗冲击设计提供了一种新的仿生策略,具有重要的科学价值和工程应用前景,尤其在国防、航空航天等需要高韧性和高强度材料的领域,具有广泛的应用潜力。此外,本文的研究还为今后相关领域的材料设计提供了宝贵的参考和启示。

下载:

下载: