Preparation and performance of ultra-low core loss FeSiAl soft magnetic composites

-

摘要:

目前家电、汽车和手机等产品的电子元器件日益呈现小型化、智能化的发展趋势,因此,降低磁粉芯(SMCs)在高频、大功率下应用时的功率损耗是适应其发展的必要措施。将气雾化Fe-9.6 wt%Si-5.4 wt%Al(FeSiAl)磁粉进行磷化绝缘处理,经预热处理、成型和退火热处理,得到了超低损耗FeSiAl复合磁粉芯(SMCs)。分析结果表明,磷化后的FeSiAl磁粉经热处理后,颗粒表面包覆的磷酸盐转变为硅酸盐,且磁粉中晶粒长大,磁粉的矫顽力降低;制得的磁粉芯功率损耗也明显降低,这主要归因于磁滞损耗的显著降低;当磷酸使用量为0.5 wt%时,50 kHz下功率损耗由79.44 mW·cm−3降低至58.56 mW·cm−3。

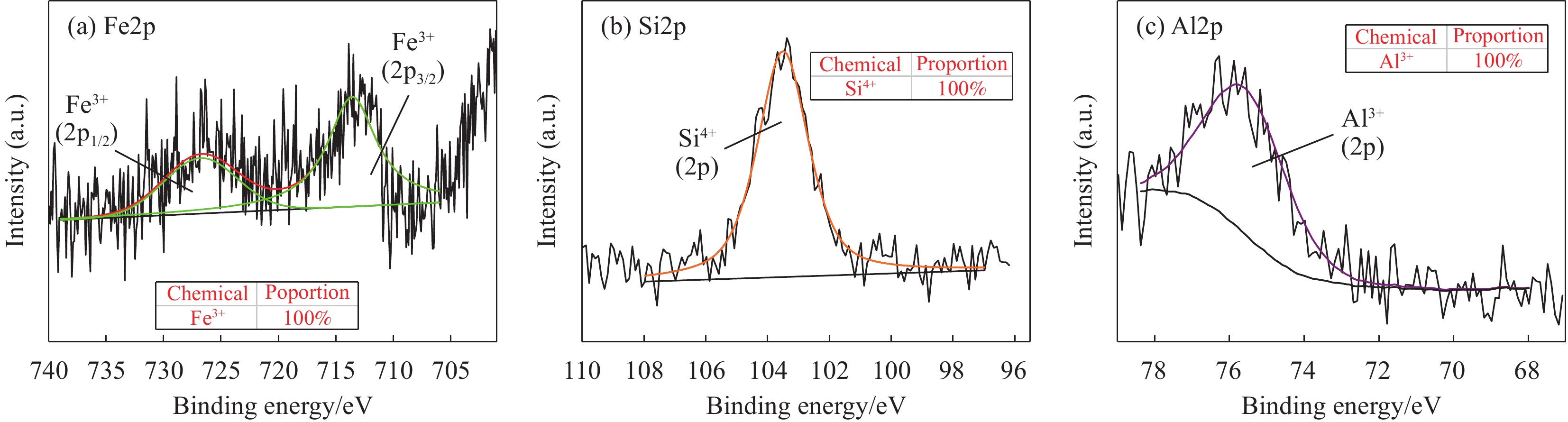

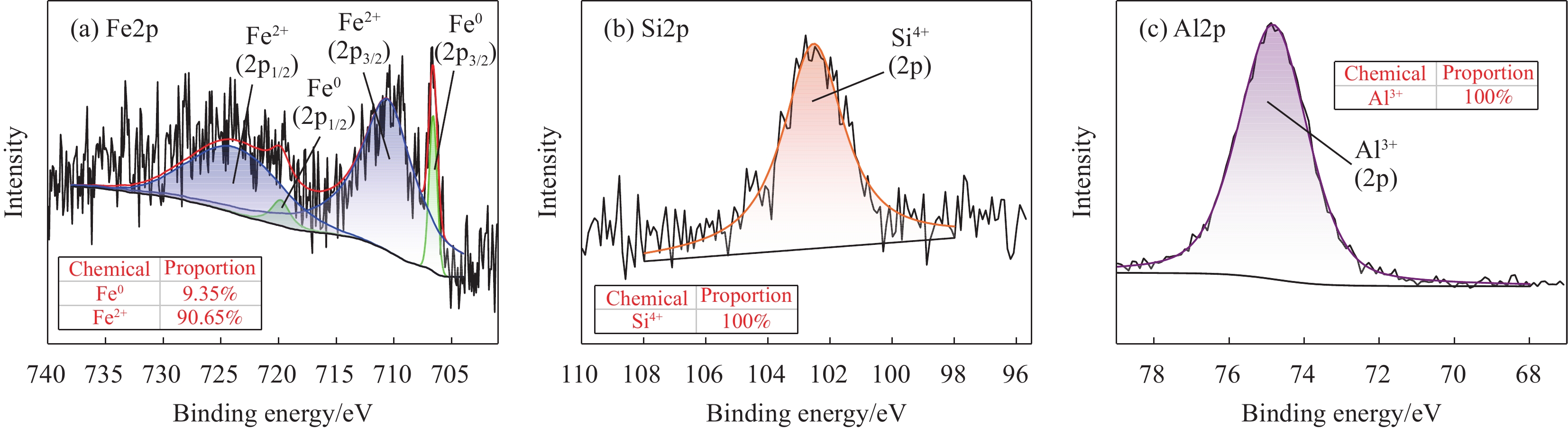

Abstract:Currently, electronic components applied in household electric appliances, cars and mobile phones are increasingly presenting a trend of miniaturization and intelligence. Thus, it is urgent to reduce the core loss of soft magnetic composites (SMCs) apply at high frequency and high power. In this work, gas atomized Fe-9.6wt%Si-5.4wt%Al (FeSiAl) magnetic powder was firstly subjected to a phosphating process for electrical insulation, then the phosphated FeSiAl magnetic powder was heated, formed, and annealed, resulting in FeSiAl SMCs. Analytical results show that the particle surface of the phosphated FeSiAl magnetic powder was transformed from phosphate to silicate after heat treatment, accompanied by an increase in its crystalline size and a decrease in its coercivity. Core loss of the obtained SMCs also decreases apparently, due to the significant decrease in their hysteresis loss. Moreover, when the amount of the phosphoric acid used reaches 0.5 wt%, the core loss decreases from 79.44 mW·cm−3 to 58.56 mW·cm−3 at 50 kHz.

-

Keywords:

- FeSiAl /

- Soft magnetic composites /

- Phosphatiztion /

- Heating treatment /

- Core loss

-

-

表 1 磁粉芯的电阻率、功率损耗、涡流损耗和磁滞损耗

Table 1 Comparison of electrical resistivity, core loss, eddy current loss and hysteresis loss of SMCs

Sample Core loss/(mW·cm−3) Eddy current coefficient Eddy current loss/(mW·cm−3) Hysteresis coefficient Hysteresis loss/(mW·cm−3) Electrical resistivity/(Ω·cm) 0.5 wt%HP/FeSiAl 79.44 1.74×10−6 43.53 7.01×10−3 35.03 25.23×106 0.5 wt%HPT/FeSiAl 58.56 1.63×10−6 40.73 3.23×10−3 16.17 2.48×106 Notes: Bm—Maximum magnetic induction intensity=100 mT; f—Frequency=50 kHz 表 2 本文与此前报道磁粉芯性能对比

Table 2 Comparison of previously reported SMCs properties and this work

Sample Core loss/(mW·cm−3) Permeability Refs f=50 kHz f=100 kHz 0.5 wt%HPT/FeSiAl 58.56 190.1 52.1 (f=100 kHz) This work SiO2@FeSiAl 77.6 216.53 57(f=1 MHz) [18] MoS2/FeSiAl 181 454 90.6(f=1 MHz) [19] 2.25 wt%WS2/FeSiAl 171 431 62~64(f=50 kHz) [20] Commercially SMCs <120 60(f=100 kHz) NCD Co., Ltd. Notes:Bm—Maximum magnetic induction intensity=100 mT; f—Frequency; SiO2@FeSiAl—SiO2 coated spherical-FeSiAl SMC;MoS2/FeSiAl and 2.25 wt%—WS2/FeSiAl MoS2 and 2.25 wt%WS2 coated FeSiAl SMCs respectively;Commercially SMCs—Atomized FeSiAl SMCs produced by Ma’anshan New Conda Magnetic Industrial Co., Ltd. -

[1] ZHONG X, LIU Y, LI J, et al. Structure and magnetic properties of FeSiAl-based soft magnetic composite with AlN and Al2O3 insulating layer prepared by selective nitridation and oxidation[J]. Journal of Magnetism and Magnetic Materials, 2012, 324(17): 2631-2636. DOI: 10.1016/j.jmmm.2012.03.026

[2] SHOKROLLAHI H, JANGHORBAN K. Soft magnetic composite materials (SMCs)[J]. Journal of Materials Processing Technology, 2007, 189(1-3): 1-12. DOI: 10.1016/j.jmatprotec.2007.02.034

[3] NIE W, YU T, WANG Z, et al. High-performance core-shell-type FeSiCr@MnZn soft magnetic composites for high-frequency applications[J]. Journal of Alloys and Compounds, 2021, 864: 158215-158221. DOI: 10.1016/j.jallcom.2020.158215

[4] 许欣蓓, 鲁书潮, 鲍康馨, 等. 气雾化铁硅铝磁粉粒度级配对磁粉芯性能的影响[J]. 磁性材料及器件, 2024: 1-10. XU Xinpei, LU Shuchao, BAO Kangxin, et al. Effect of grading of gas atomized Fe-Si-Al powders on properties of the soft magnetic cores[J]. Journal of Magnetic Materials and Devices, 2024: 1-10. (in Chinese)

[5] 刘国忠, 杨啸峰, 张公平, 等. 金属磁粉芯绝缘包覆研究进展[J]. 磁性材料及器件, 2021, 52(6): 93-100. LIU Guozhong, YANG Xiaofeng, ZHANG Gongping, et al. Research progress in preparation of insulating coatings on metal soft magnetic cores[J]. Journal of Magnetic Materials and Devices, 2021, 52(6): 93-100(in Chinese).

[6] 郭海山, 陈建川, 钟小溪, 等. FeSiAl磁粉芯制备工艺研究进展[J]. 热加工工艺, 2021, 50(24): 17-20. GUO Haishan, CHEN Jianchuan, ZHONG Xiaoxi, et al. Research progress of preparation technology of FeSiAl magnetic particle core[J]. Hot Working Technology, 2021, 50(24): 17-20(in Chinese).

[7] Taghvaei A H, Shokrollahi H, Janghorban K, et al. Eddy current and total power loss separation in the iron–phosphate–polyepoxy soft magnetic composites[J]. Materials & Design, 2009, 30(10): 3989-3995.

[8] 贺泓鑫, 侯海彬, 李奇, 等. 磁粉芯的研究现状及发展趋势[J]. 磁性材料及器件, 2023, 54(6): 95-104. HE Hongxin, HOU Haibin, LI Qi, et al. Research status and development trend of magnetic powder cores[J]. Journal of Magnetic Materials and Devices, 2023, 54(6): 95-104(in Chinese).

[9] 王尧, 朱乾科, 陈哲, 等. 成型压强对FeSiB磁粉芯磁性能的影响[J]. 功能材料, 2020, 51(8): 8165-8169. DOI: 10.3969/j.issn.1001-9731.2020.08.026 WANG Yao, ZHU Qianke, CHEN Zhe, et al. The influence of forming pressure on the magnetic properties of FeSiB magnetic powder cores[J]. Journal of Functional Materials, 2020, 51(8): 8165-8169(in Chinese). DOI: 10.3969/j.issn.1001-9731.2020.08.026

[10] HSING H, CHEN C H, CHEN C C. Magnetic properties of FeSiCr alloy powder coils made by gel casting process[J]. Journal of Materials Science: Materials in Electronics, 2021, 32(11): 14584-14591. DOI: 10.1007/s10854-021-06017-y

[11] LI S, ZHANG M, ZHAN Z, et al. Study on novel Fe-based core-shell structured soft magnetic composites with remarkable magnetic enhancement by in-situ coating nano-ZnFe2O4 layer[J]. Journal of Magnetism and Magnetic Materials, 2020, 500: 166321-166327. DOI: 10.1016/j.jmmm.2019.166321

[12] LUO Z, FAN X, HU W, et al. Properties of Fe2SiO4/SiO2 coated Fe-Si soft magnetic composites prepared by sintering Fe-6.5wt%Si/Fe3O4 composite particles[J]. Journal of Magnetism and Magnetic Materials, 2020, 499: 166278-166284. DOI: 10.1016/j.jmmm.2019.166278

[13] LI W, XIAO S, LI W, et al. Hybrid amorphous soft magnetic composites with ultrafine FeSiBCr and submicron FeBP particles for MHz frequency power applications[J]. Journal of Magnetism and Magnetic Materials, 2022, 555: 169365. DOI: 10.1016/j.jmmm.2022.169365

[14] HUANG H, ZHANG R, SUN H, et al. High density Fe-based soft magnetic composites with nice magnetic properties prepared by warm compaction[J]. Journal of Alloys and Compounds, 2023, 947: 169460-169469. DOI: 10.1016/j.jallcom.2023.169460

[15] SUN K, FENG S, JIANG Q, et al. Intergranular insulating reduced iron powder-carbonyl iron powder/SiO2-Al2O3 soft magnetic composites with high saturation magnetic flux density and low core loss[J]. Journal of Magnetism and Magnetic Materials, 2020, 493: 165705-165711. DOI: 10.1016/j.jmmm.2019.165705

[16] WANG J, LIU X, ZHENG Z, et al. Reduction of core loss for FeSi soft magnetic composites prepared using atomic layer deposition-based coating and high-temperature annealing[J]. Journal of Alloys and Compounds, 2022, 909: 164655-164665. DOI: 10.1016/j.jallcom.2022.164655

[17] HE Y, LI G, YANG S, et al. Improvements of magnetic performances for carbonyl iron soft magnetic composites (CI-SMCs) induced by Mn-based phosphating coating[J]. Journal of Alloys and Compounds, 2023, 958: 170498-170506. DOI: 10.1016/j.jallcom.2023.170498

[18] LI W, LI Wc, WU J, et al. Particles size-dependent magnetic properties of a FeSiAl soft magnetic composite with hybrid insulating coating for MHz applications[J]. Materials Science and Engineering: B, 2023, 291: 116387-116395. DOI: 10.1016/j.mseb.2023.116387

[19] ZHU S, DUAN F, NI J, et al. Soft magnetic composites FeSiAl/MoS2 with high magnetic permeability and low magnetic loss[J]. Journal of Alloys and Compounds, 2022, 926:

[20] ZHU S, DUAN F, FENG S, et al. Efficient inorganic-coated FeSiAl/WS2 soft magnetic composites with low magnetic loss[J]. Journal of Alloys and Compounds, 2023, 936: 168190-168197. DOI: 10.1016/j.jallcom.2022.168190

[21] GUO R, YU G, ZHU M, et al. Regulation of magnetic and electrical performances in core-shell-structured FeSiCr@BaTiO3 soft magnetic composites[J]. Journal of Alloys and Compounds, 2022, 895: 162724-162730. DOI: 10.1016/j.jallcom.2021.162724

[22] WANG J, LI G, HE Y, et al. Improvement in core losses for FeSiAl soft magnetic composites induced by powder annealing treatment[J]. Journal of Materials Research and Technology, 2023, 24: 2500-2513. DOI: 10.1016/j.jmrt.2023.03.168

[23] 唐进军, 何配群. 磷化液中金属离子的分析[J]. 电镀与环保, 2009, 29(1): 49-50. DOI: 10.3969/j.issn.1000-4742.2009.01.016 TANG Jingjun, HE Peiqun. Analysis of metal ions in phosphating solution[J]. Electroplating & Pollution Control, 2009, 29(1): 49-50(in Chinese). DOI: 10.3969/j.issn.1000-4742.2009.01.016

[24] CHEN Z, LIU X, KAN X, et al. Phosphate coatings evolution study and effects of ultrasonic on soft magnetic properties of FeSiAl by aqueous phosphoric acid solution passivation[J]. Journal of Alloys and Compounds, 2019, 783: 434-440. DOI: 10.1016/j.jallcom.2018.12.328

[25] HUANG M, WU C, JIANG Y, et al. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites[J]. Journal of Alloys and Compounds, 2015, 644: 124-130. DOI: 10.1016/j.jallcom.2015.04.201

[26] HU B, WANG X, SHU H, et al. Improved electrochemical properties of BiF3/C cathode via adding amorphous AlPO4 for lithium-ion batteries[J]. Electrochimica Acta, 2013, 102: 8-18. DOI: 10.1016/j.electacta.2013.03.168

[27] LUO Z, FAN X, HU W, et al. Effect of sintering temperature on microstructure and magnetic properties for Fe-Si soft magnetic composites prepared by water oxidation combined with spark plasma sintering[J]. Journal of Magnetism and Magnetic Materials, 2019, 491: 165615-165622. DOI: 10.1016/j.jmmm.2019.165615

[28] ZHOU Q, LI C, LI X, et al. Reaction behavior of ferric oxide in system Fe2O3–SiO2–Al2O3 during reductive sintering process[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 842-848. DOI: 10.1016/S1003-6326(16)64175-4

[29] LUO Z, FAN X, HU W, et al. Enhanced magnetic properties and reduced core loss of intergranular insulating Fe-Si soft magnetic composites with three-shell SiO2-Fe2SiO4-SiO2 insulating layer[J]. Journal of Solid State Chemistry, 2019, 270: 311-316. DOI: 10.1016/j.jssc.2018.11.034

[30] LIU X, MA Y, HE Q, et al. Some IR features of SiO4 and OH in coesite, and its amorphization and dehydration at ambient pressure[J]. Journal of Asian Earth Sciences, 2017, 148: 315-323. DOI: 10.1016/j.jseaes.2017.03.016

[31] MOUNIR F, KARIMA H, KHALED B, et al. Modeling Li-ion conductivity in LiLa(PO3)4 powder[J]. Physica B: Condensed Matter, 2012, 407(13): 2593-2600. DOI: 10.1016/j.physb.2012.03.077

[32] SAITO T, TAKEMOTO S. Core Loss in Fe-Si Powder Cores[J]. Journal of the Magnetics Society of Japan, 2013, 37(3-2): 155-160.

[33] WANG J, QIU Z, XU J, et al. Evolution of coating layers during high-temperature annealing and their effects on magnetic behavior of Fe(Si) soft magnetic composites[J]. Advanced Powder Technology, 2022, 33(12): 103876-103889. DOI: 10.1016/j.apt.2022.103876

-

目的

目前家电、汽车和手机等产品的电子元器件日益呈现小型化、智能化的发展趋势。因此,降低磁粉芯在高频、大功率下应用时的功率损耗是适应其发展的必要措施。行业内广泛采用磷酸有机溶液作为包覆磁粉的方案降低磁粉芯功率损耗,但残存磷酸有恶化磁粉芯磁性能风险,另外有机溶剂用量大、挥发性强且污染较为严重。因此本文采用磷酸水溶液磷化磁粉的方法来获得绝缘层(磷化层),结合热处理的方式去除多余磷酸并进一步降低磁粉芯功率损耗。

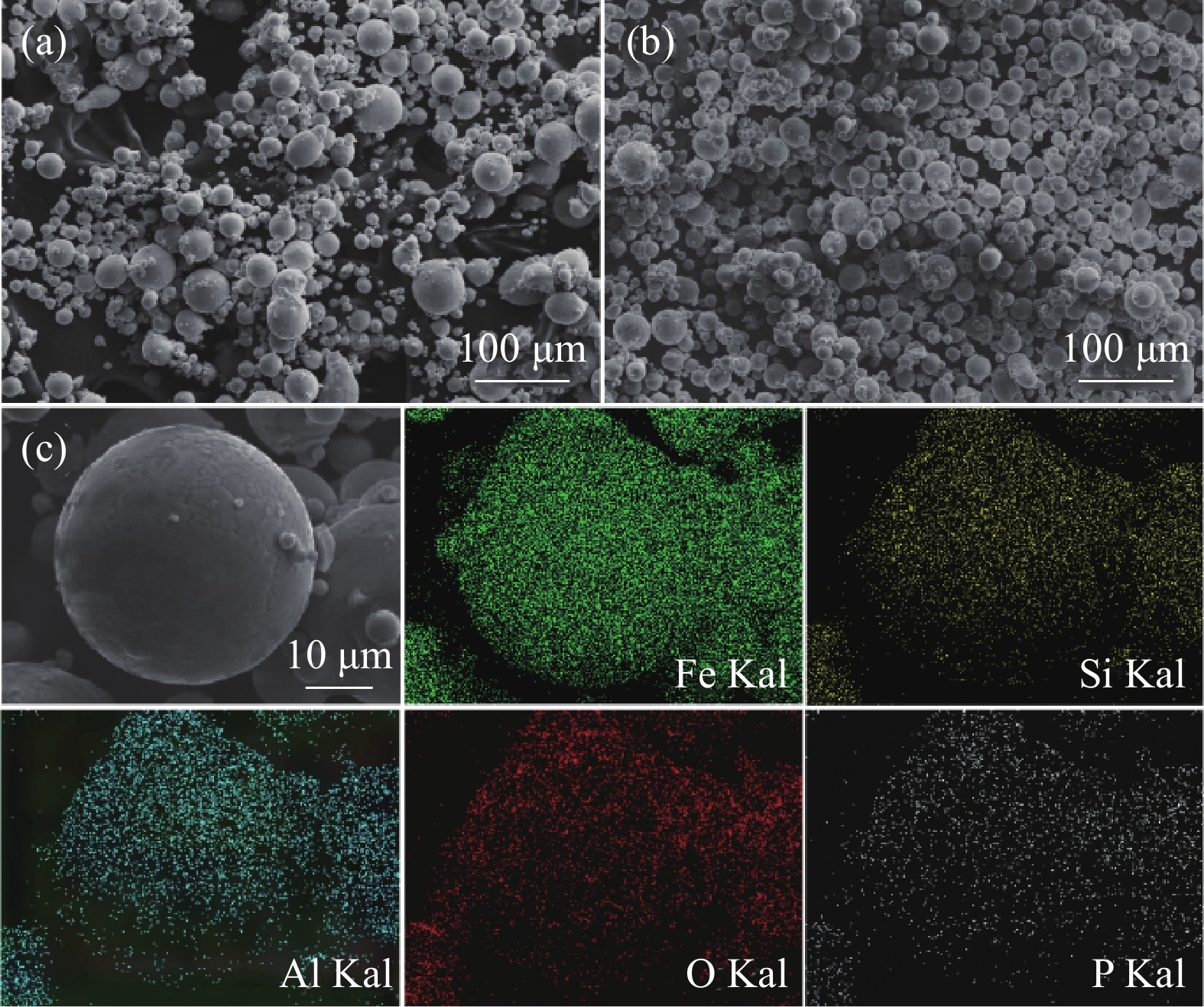

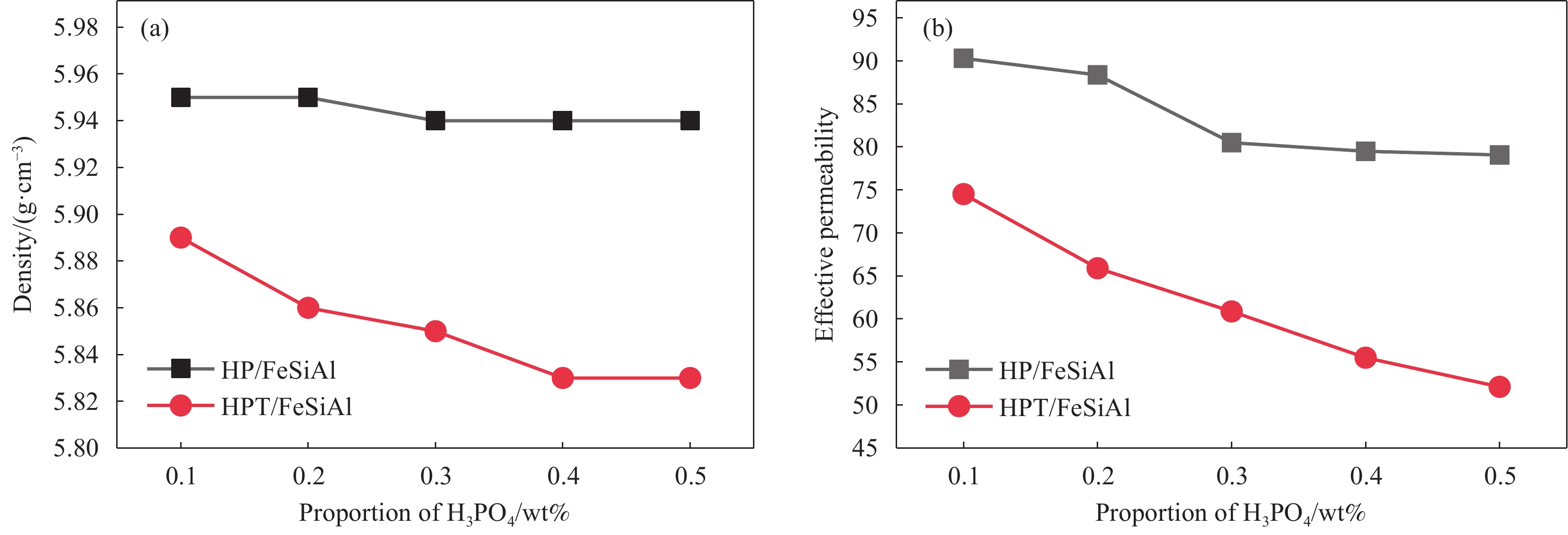

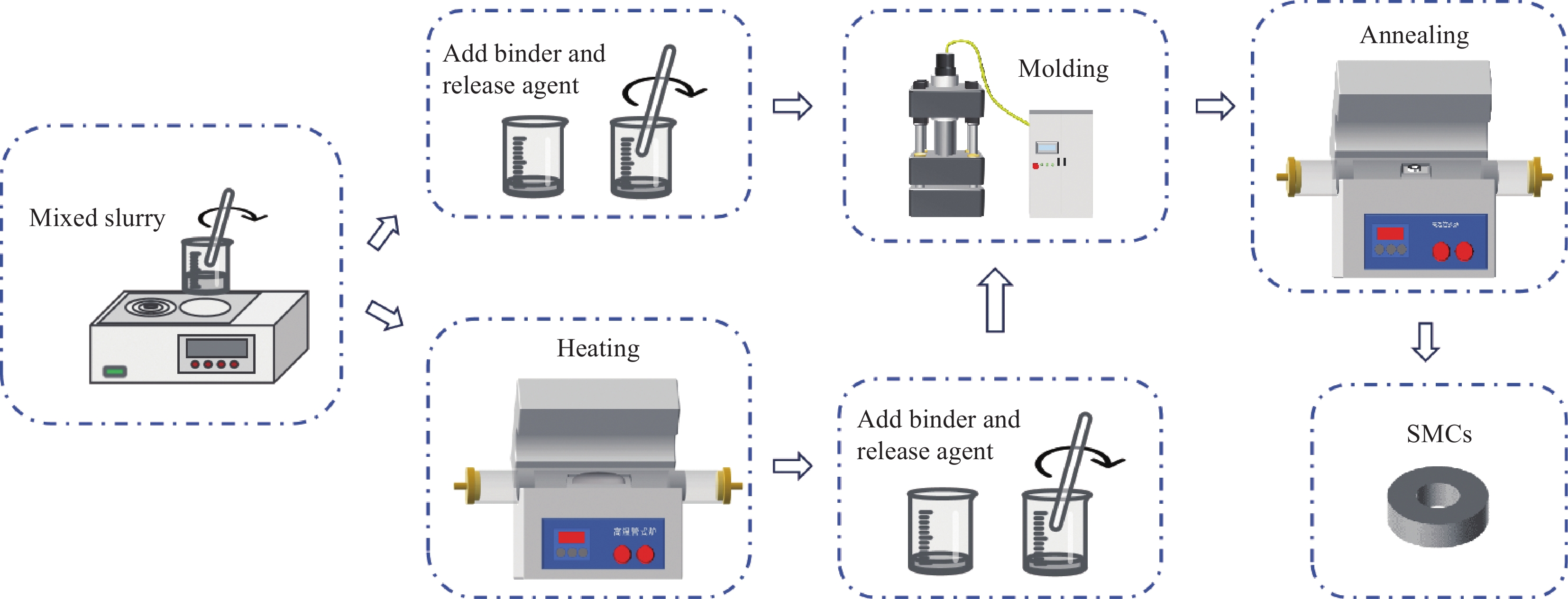

方法称取适量的Fe-9.6 wt%Si-5.4 wt%Al(FeSiAl)磁粉,分别按FeSiAl磁粉重量的0.1 wt%、0.2wt%、0.2wt%、0.4 wt%和0.5 wt%称取磷酸,将称取的磷酸分别溶于10 mL水中,再将FeSiAl磁粉加入到配制得磷酸水溶液中,混合搅拌、加热至干燥,制得5种磷化磁粉样品。磷化包覆的磁粉经过680 ℃、N气氛预热处理1h后添加0.5 wt%硅树脂粘结剂、0.3 wt%硬脂酸锌脱模剂并混合均匀;在2090 MPa下将磁粉压制成环形试样(外径26.92 mm、内径 14.73 mm、高度 11.10 mm)。最后,压制成型的试样在680℃、N气氛下退火1h,得到了超低损耗FeSiAl复合磁粉芯(SMCs)。另设置未经预热处理的磁粉芯作为对照组,按照磷酸加入量从小到大编号为0.1~0.5wt%HP/FeSiAl,同理预热处理样品编号为0.1~0.5wt%HPT/FeSiAl。

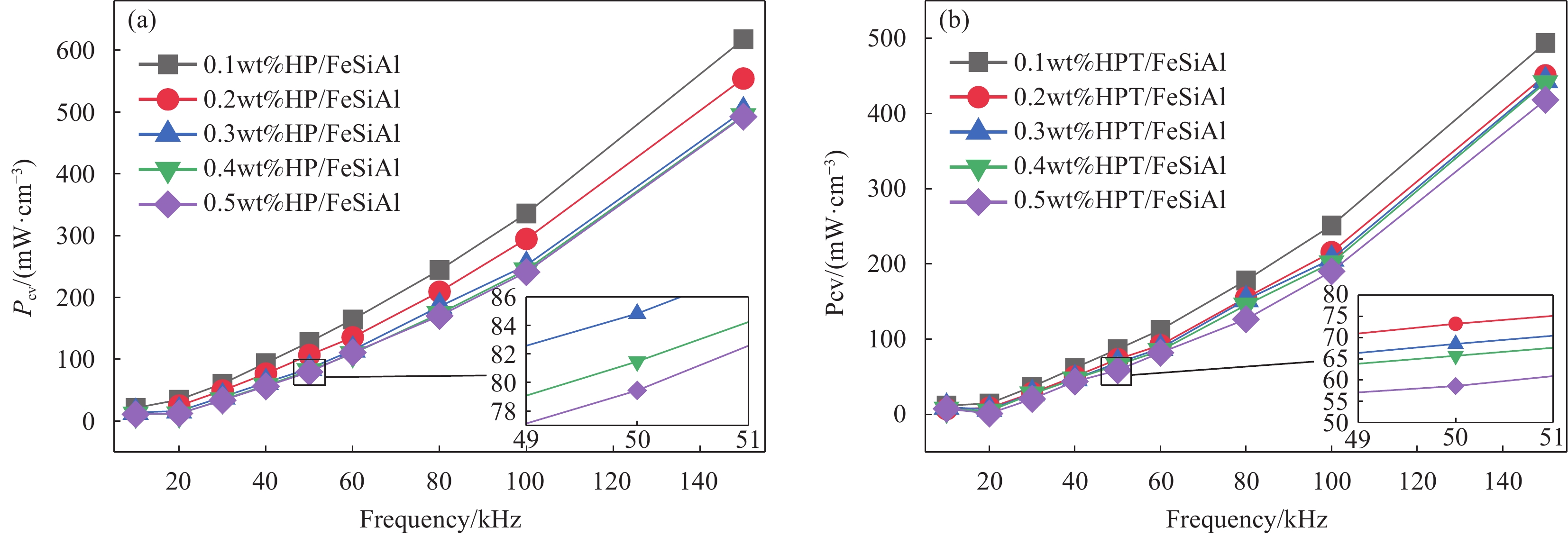

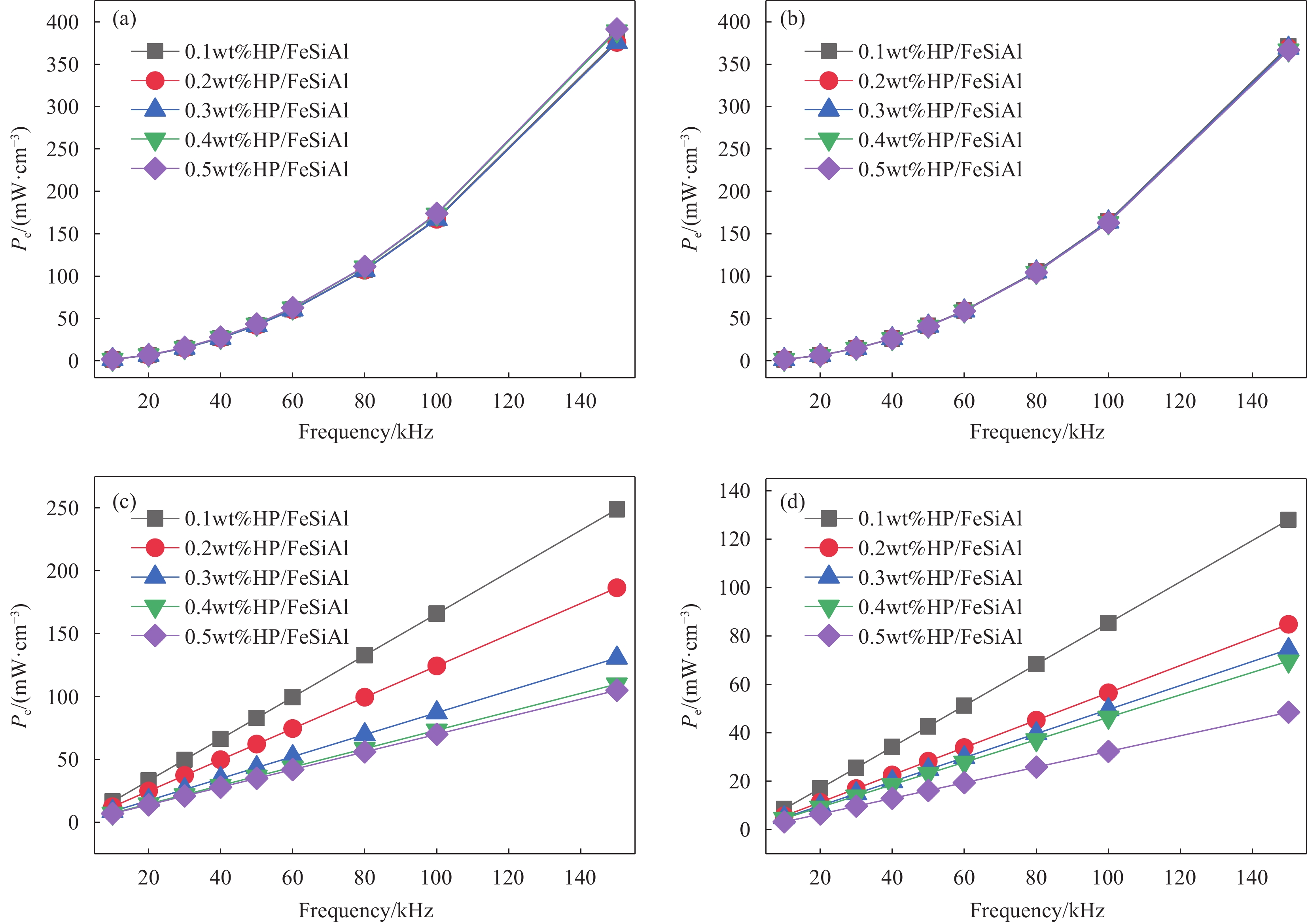

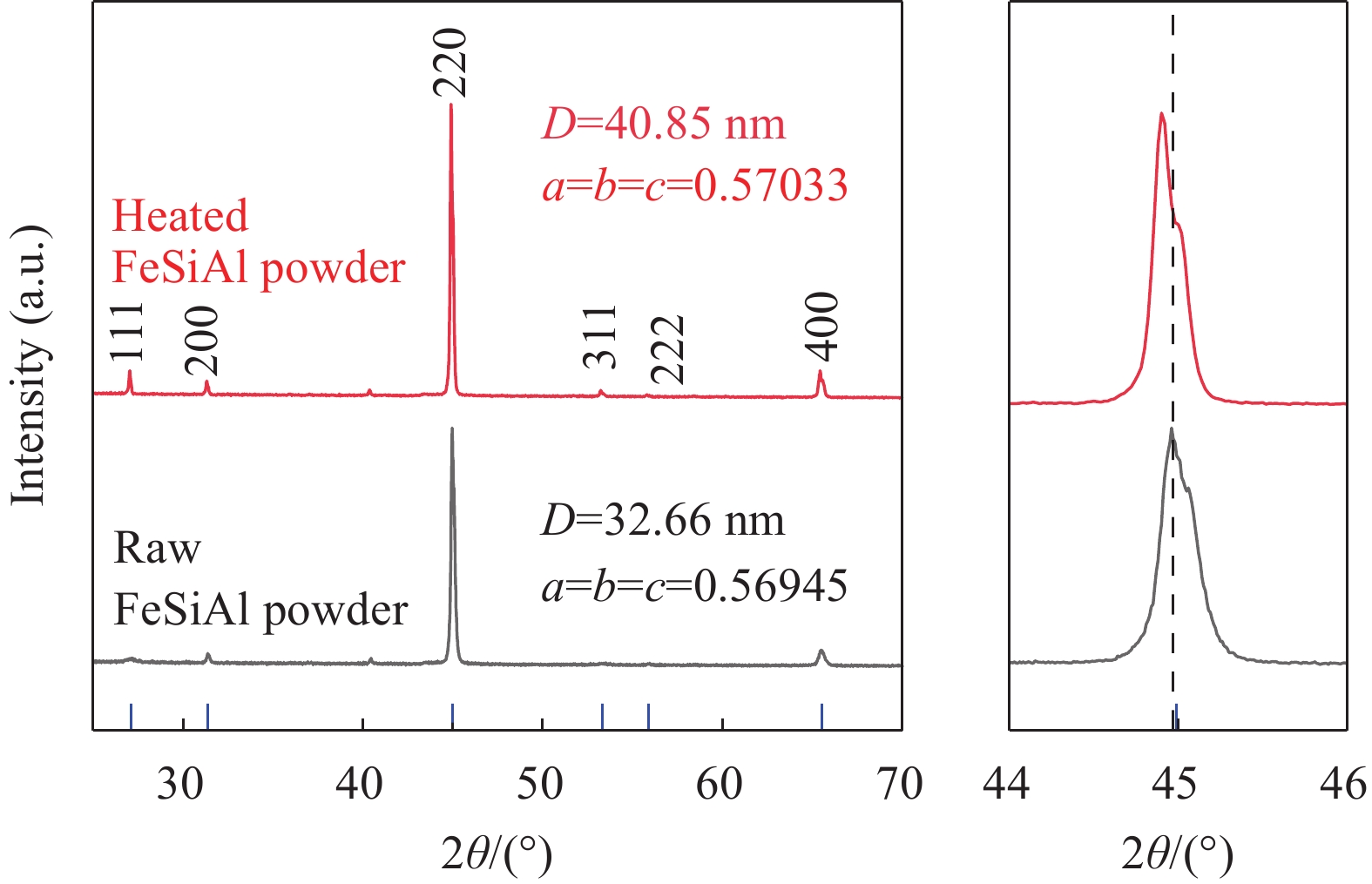

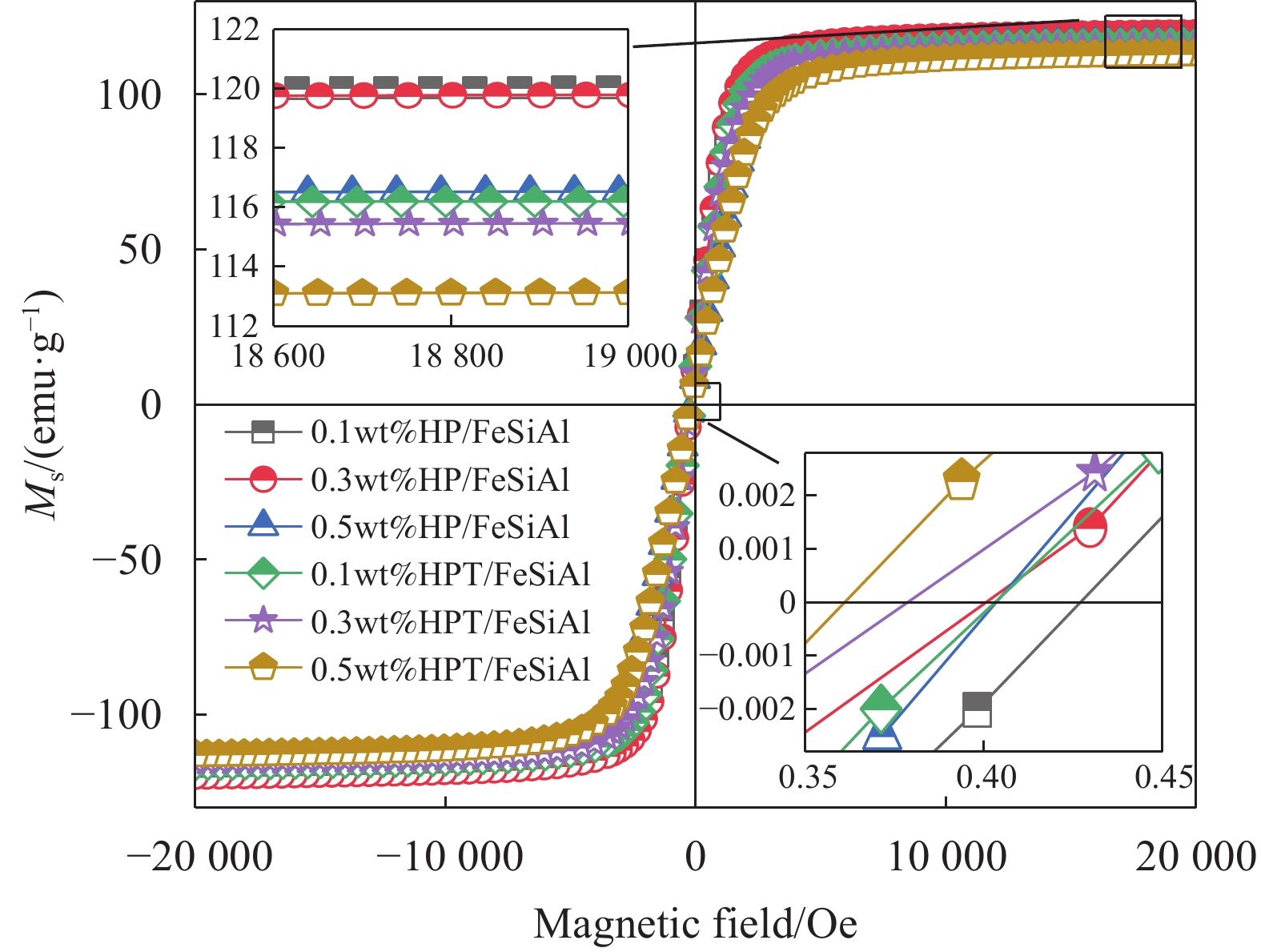

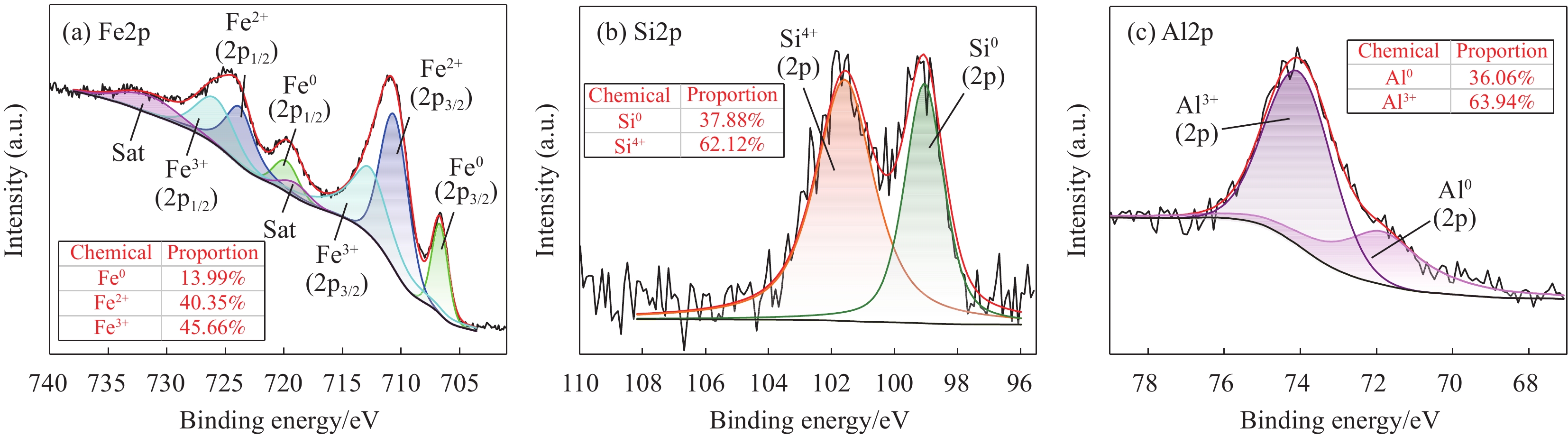

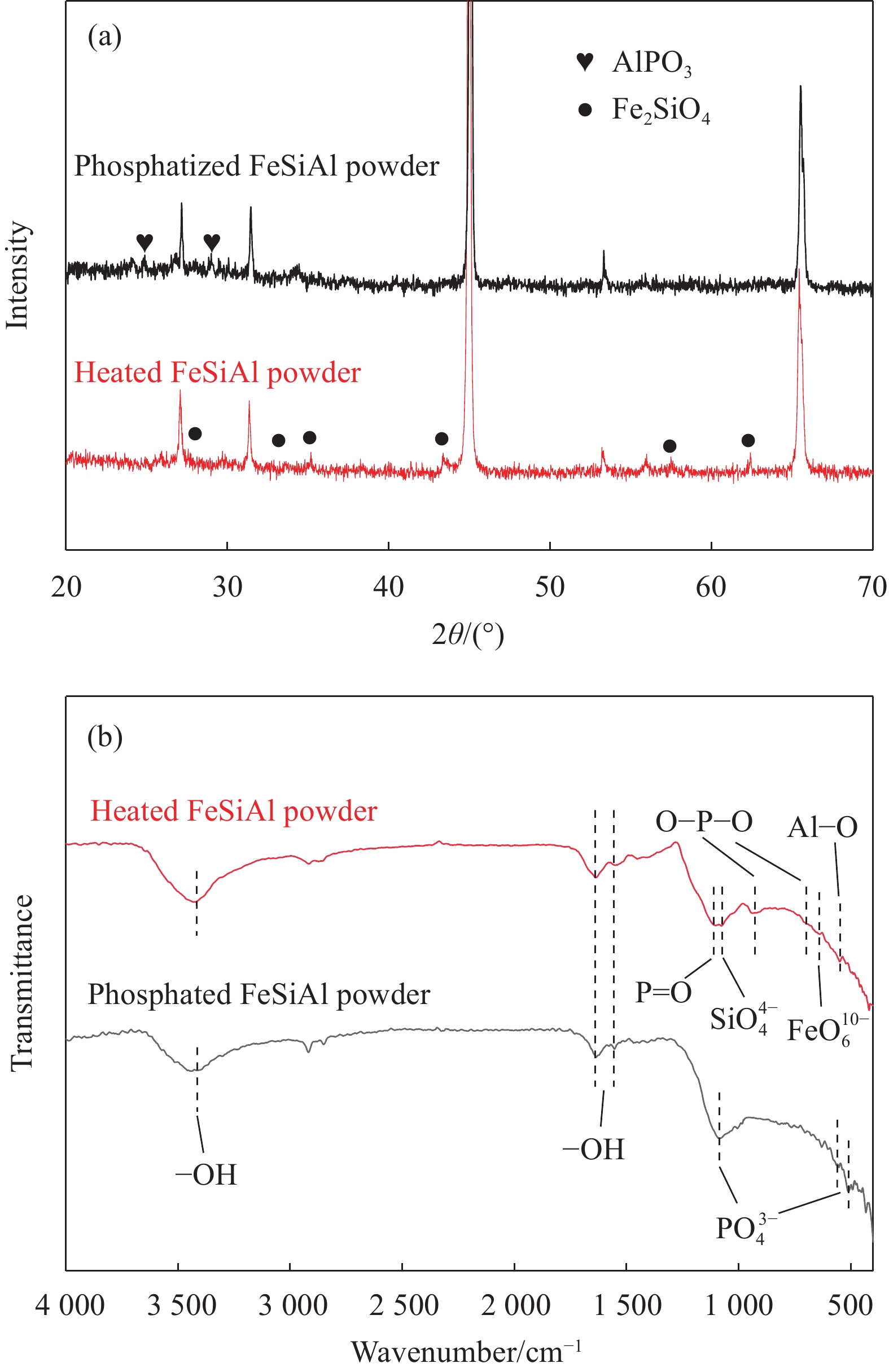

结果①在磷酸的水溶液中气雾化FeSiAl磁粉可成功在表面生成绝缘层,结合XRD、XPS和FTIR分析结果表明:绝缘层主要由磷酸盐组成,经过预热处理后绝缘层以AlO、FeSiO、PO为主。②0.5wt%HPT/FeSiAl相较于0.5wt%HP/FeSiAl磁粉芯密度更低,这是热处理后的磁粉颗粒相结合,压制过程中小颗粒不易滑动填充至气隙中导致。0.5wt%HPT/FeSiAl磁粉芯中气隙的增多使磁粉芯中磁性物质占比降低;对比0.5wt%HP/FeSiAl磁粉芯有效磁导率74.52下降到52.10(100 kHz),另外功率损耗从79.44mW·cm降低至58.56mW·cm(50 mT、100 kHz)。③通过对HPT/FeSiAl和HP/FeSiAl磁粉芯的功率损耗分离并拟合发现预热处理后磁粉芯磁滞损耗降低幅度与功率损耗接近,涡流损耗略有降低。④使用高斯函数拟合XRD分析图谱并根据Debye-Scherrer公式得到磁粉的平均晶粒尺寸,计算结果表明预热处理后的磁粉晶粒尺寸长大,此前报道显示高温热处理的磁粉晶粒尺寸明显增大,晶界减少,从而削弱了对磁畴壁的钉扎效应,磁滞损耗降低。⑤0.5wt% HPT/FeSiAl相较于0.5wt%HP/FeSiAl磁粉芯电阻率由25.23×10 Ω·cm降低至2.48×10 Ω·cm,预热处理过程中产生的单质Fe加之颗粒内晶界减少导致电阻率降低,但电阻率仍保持了较高水平。磁粉芯经过热处理后高电阻率的晶界减少会导致经典涡流损耗上升,但经典涡流损耗占比极小;而占比较大的异常涡流损耗在热处理后降低;因此导致了磁粉芯略微下降。

结论磷酸水溶液磷化FeSiAl磁粉并结合预热处理的方式可获得超低损耗HPT/FeSiAl复合磁粉芯。经预热处理,磁粉表面剩余酸性物质被去除,磁粉芯有效磁导率降低,适用于较低磁导率应用场景;功率损耗显著降低,完全满足商业气雾化FeSiAl磁粉芯标准。

-

金属磁粉芯,因其具有高饱和磁通密度和有效磁导率而广泛应用于电工领域。当今社会家电、汽车、手机等工业品电子元器件的发展呈现出小型化、智能化的趋势,因此减少磁粉芯在高频、大功率应用下的功率损耗是适应电子元器件发展的必要措施。作为磁粉芯生产过程中重要步骤之一,磷化处理过程通常在有机溶剂中进行,有机溶剂易挥发、污染较大,且磷化后残留的酸性物质有腐蚀磁粉的风险。

本文通过对气雾化FeSiAl磁粉进行磷化处理,再对其进行热处理,去除多余酸性物质,制备了具有超低损耗的FeSiAl复合金属磁粉芯(soft magnetic composites, 简写SMCs)。较低含量的磷酸可在FeSiAl磁粉表面形成一层薄而均匀的绝缘层,经过预热处理后,磁粉表面磷酸盐转变为硅酸盐,磁粉颗粒内晶体长大,晶界减少,磁畴壁转动克服能量减少,磁粉矫顽力降低;得到的磁粉芯功率损耗急剧降低,主要归因于磁滞损耗明显降低损;当磷酸加入量为0.5 wt%时,制备的磁粉芯体电阻率为2.48×106 Ω·cm,功率损耗仅为58.56mW·cm-3。

磁粉芯的功率损耗随频率变化图

磷化及预热处理过程磁粉表面反应示意图

下载:

下载: