Simulation and experimental study of CFRP micro cutting considering voids defects

-

摘要: 碳纤维增强树脂基复合材料(CFRP)在航空航天等领域应用广泛。在CFRP制造过程中难以避免会产生孔隙等缺陷,对后续的切削加工造成一定影响。在考虑了CFRP成型过程形成的孔隙缺陷基础上,运用有限元仿真模拟方法,从纤维-树脂-界面尺度建立了含孔隙缺陷的CFRP微观切削仿真模型,研究了不同孔隙率条件下不同纤维排布方向的CFRP微观切削行为,并通过实验验证了仿真模型的正确性。研究结果表明:孔隙的存在会增加刀具的“空切”现象,从而对CFRP切削过程的切削力、材料破坏及亚表面损伤、材料能量等产生影响。随孔隙率的增加,切削力呈下降趋势,孔隙边缘的纤维产生整体断裂的倾向增加;孔隙对0°、45°和135°纤维排布方向的CFRP切削加工的面下损伤影响不大,在纤维排布方向为90°条件下,孔隙率高于3vol%时对加工表面的面下损伤具有较大影响;在材料内部能量耗散方面,“顺切”(纤维方向角小于90°)时的总耗散能低于“逆切”,随孔隙率增加,总耗散能降低。Abstract: Carbon fiber-reinforced plastic (CFRP) composites have been widely used in aerospace and other most advanced fields. It is difficult to avoid voids and other defects in the manufacturing process of CFRP, which will have a certain impact on the subsequent machining. Based on the consideration of the voids defects in the process of CFRP forming, a CFRP micro cutting simulation model with void defects was established from the fiber-resin-interface scale by using the finite element simulation method. The micro cutting behavior of CFRP with different fiber orientations under different void content conditions was studied, and the correctness of the simulation model was verified by experiments. The results show that the existence of voids will increase the ‘virtual cutting’ phenomenon of the tool, which will have an impact on the cutting force, material damage, sub-surface damage and material energy in the cutting process of CFRP. The cutting force decreases with the increase of void content, and the tendency of fibers at the edge of voids to produce overall fracture will increase. The voids have little effect on the damage under the machined surface of CFRP with 0°, 45° and 135° fiber orientations. The void content higher than 3vol% has a great effect on the damage under the machined surface when the fiber orientation is 90°. In terms of energy dissipation inside the material, the total dissipated energy in ‘forward cut’ (fiber orientation angle less than 90°) is lower than ‘reverse cut’, furthermore, the total dissipated energy decreases with the increase of void content.

-

Keywords:

- CFRP /

- void /

- cutting /

- material damage /

- finite element simulation

-

通过结构减重来提高飞行器的飞行速度和续航历程,是航空航天领域一直以来的追求目标。以树脂为基体、碳纤维为增强相的碳纤维增强树脂基复合材料(CFRP)因具有轻质、高强、耐疲劳、抗腐蚀等诸多优异性能,在航空航天领域得到广泛应用,其使用比例成为衡量航空航天结构先进性的重要标志[1-3]。

固化成型和切削加工是CFRP结构件的两个主要制造工序。CFRP的固化主要指经一定的温度制度和压力制度,在模具约束下实现特定几何结构的整体成型。对于成型后的构件,往往还需进行切削加工工序,以满足CFRP构件与其他金属或非金属构件的装配需求[4]。在CFRP固化过程中,易产生孔隙、分层等成型缺陷。其中,以孔隙缺陷最为常见,这类缺陷往往难以完全根除[5-7]。孔隙含量通常用孔隙率来描述,孔隙率的大小会直接影响CFRP的力学性能[8]。在实际应用中,一些重要的应用领域要求孔隙率必须严格限制在1vol%以内[9-10]。而在有些应用领域,孔隙率高达5vol%却仍属可接受范围[11]。然而,在对含孔隙CFRP构件进行切削加工时,孔隙对切削加工过程造成的影响还未引起足够的重视。

目前针对CFRP切削加工的研究,相关文献从材料的损伤行为[12-13]、去除机制[14]等方面已开展了大量有益的探索。但现有研究几乎均假定加工对象CFRP是较理想的质量状态,没有考虑固化后孔隙缺陷带来的“遗传效应”。虽然文献[15]考虑了固化过程的分层缺陷对切削加工的影响,但对于航空航天结构件来说,分层缺陷一般为毫米-厘米量级,其控制要求极其严格。因而与孔隙缺陷相比,分层缺陷对CFRP切削加工的影响不具有普遍性。

CFRP固化过程所形成的孔隙缺陷往往随机分布于材料内部,通过实验很难观测其对CFRP切削的影响,采用建立考虑孔隙缺陷的微观切削模型是较有效的手段。对于CFRP微观切削的建模研究虽陆续已有报道,但尚缺乏考虑孔隙缺陷对切削过程的材料变形、损伤及加工表面形成和演变等影响的相关研究。本文旨在通过建立考虑孔隙缺陷的CFRP微观切削仿真模型,来揭示CFRP固化孔隙缺陷的“遗传效应”对其切削加工的影响。采用热压成型工艺制备了不同孔隙含量的CFRP层合板,开展了不同孔隙率、典型纤维铺层方向的CFRP切削实验,采集了相应的切削力,通过SEM对CFRP微观形貌进行了表征,用以对模型进行验证和评价。

1. 理论模型

CFRP是一种包含了树脂、纤维、树脂-纤维界面的多相复合材料,为研究含孔隙缺陷CFRP微观切削过程的材料变形、损伤行为,对各组成相进行单独本构建模并采用单独的失效准则。

1.1 树脂本构模型及失效准则

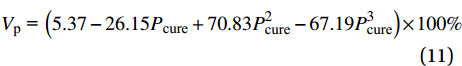

在本文中,将树脂看作是具有各向同性的弹性和非线性塑性材料[16]。在切削载荷作用下,树脂经历从弹塑性变形到损伤失效3个响应阶段。其中,A-B段为弹性变形阶段,B-C段为塑性变形阶段,C-D段为损伤刚度衰减阶段,如图1所示。考虑损伤的树脂本构和失效模型如下式:

σm = (1−dm)Emεm (1) 其中:

σm 和εm 分别表示树脂的瞬时应力和应变;Em 表示树脂未发生损伤时的刚度;dm 表示树脂的损伤变量。图1中

σy0m 和¯εpl0 分别是损伤起始点的屈服应力和等效塑性应变,¯εplm 为树脂损伤变量达到最大值1时的等效塑性应变,此时树脂发生完全破坏。树脂的损伤变量dm 包含基体开裂和剥离等多种破坏形式引起的强度下降,一般认为损伤变量dm 符合Weibull分布函数:dm=1−exp[−1ne(Emεmσy0m)n] (2) 其中:n为损伤变量的形状参数,取值0.33[17];e为欧拉常数 。

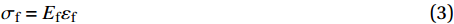

1.2 纤维本构及失效模型

将纤维看作脆性材料,根据固体力学理论,纤维在沿长度方向具有横观各向同性[18]。在承受外界载荷作用而发生脆性断裂的过程中,纤维的刚度虽然发生衰减,但刚度衰减时间较短,其刚度衰减系数很快达到最大值1。因此,可忽略纤维刚度衰减的影响。其本构关系可表示为

σf=Efεf (3) 其中,

σf 、εf 和Ef 分别表示纤维的应力、应变和弹性模量。采用最大主应力失效准则来判定纤维在外界载荷作用下的失效行为[19]。即在外载荷作用下,纤维所承受的最大主应力达到纤维的拉伸强度极限或压缩强度极限时,便会发生脆性断裂而失效,此时失效因子

If 值为1。相关表达关系如下:If=max (4) 其中:P、Q、R分别对应纤维材料主方向i取沿纤维轴向的X方向和垂直于纤维轴向的Y (Z) 方向时对应的值;

{\sigma _i} 为相应不同方向的应力;Xt (Yt)为纤维抗拉强度;Xc (Yc)为纤维抗压强度。由于纤维具有横观各向同性,因此纤维Z方向和Y方向的失效强度阈值相等。1.3 树脂-纤维界面本构及失效准则

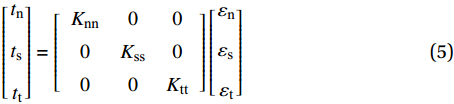

基于牵引-分离法则来建立纤维-树脂界面的内聚力模型,其本构模型[20]可表示为

\left[ \begin{gathered} {t_{\text{n}}} \\ {t_{\text{s}}} \\ {t_{\text{t}}} \end{gathered} \right] = \left[ {\begin{array}{*{20}{c}} {{K_{{\text{nn}}}}}&0&0 \\ 0&{{K_{{\text{ss}}}}}&0 \\ 0&0&{{K_{{\text{tt}}}}} \end{array}} \right]\left[ \begin{gathered} {\varepsilon _{\text{n}}} \\ {\varepsilon _{\text{s}}} \\ {\varepsilon _{\text{t}}} \end{gathered} \right] (5) 其中:

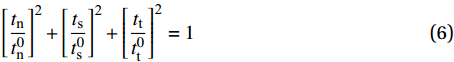

{t_{\text{n}}} 和{\varepsilon _{\text{n}}} 分别表示法向应力和应变;{t_{{\text{s}}({\text{t}})}} 和{\varepsilon _{{\text{s}}({\text{t}})}} 分别表示剪切方向的应力和应变;Knn为界面法向刚度;Kss和Ktt为界面切向刚度。当界面的正应力或剪切力达到界面强度极限时,纤维与树脂开始分离。采用名义应力二次方准则预测界面的损伤起始行为[14],如下式所示:

{\left[ {\frac{{{t_{\text{n}}}}}{{t_{\text{n}}^0}}} \right]^{\text{2}}} + {\left[ {\frac{{{t_{\text{s}}}}}{{t_{\text{s}}^0}}} \right]^{\text{2}}} + {\left[ {\frac{{{t_{\text{t}}}}}{{t_{\text{t}}^0}}} \right]^{\text{2}}} = 1 (6) 其中:

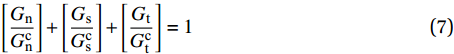

t_{\text{n}}^0 表示界面损伤起始时的法向应力;t_{\text{s}}^0 和t_{\text{t}}^0 表示界面损伤起始时的剪切应力。随切削载荷增加,裂纹开始扩展,纤维-树脂界面逐渐张开,界面内聚力单元的刚度开始衰减直至完全开裂和剥离。此时,作用于界面上的切削载荷消失。采用基于能量的界面损伤扩展失效准则[21],其表达式为

\left[ {\frac{{{G_{\text{n}}}}}{{G_{\text{n}}^{\text{c}}}}} \right] + \left[ {\frac{{{G_{\text{s}}}}}{{G_{\text{s}}^{\text{c}}}}} \right] + \left[ {\frac{{{G_{\text{t}}}}}{{G_{\text{t}}^{\text{c}}}}} \right] = 1 (7) 其中:

{G_{\text{n}}} 和G_{\text{n}}^{\text{c}} 分别表示法向瞬时断裂能及其临界断裂能;{G_{{\text{s}}({\text{t}})}} 和G_{{\text{s}}({\text{t}})}^{\text{c}} 分别表示剪切方向的瞬时断裂能及其临界断裂能。1.4 刀-工接触模型

刀具前刀面与工件材料的接触摩擦服从库伦摩擦定律,接触面上的接触应力可表示为

{\tau _{\text{s}}} = \left\{ \begin{gathered} \tau {\text{ }}\quad\left( {\tau \leqslant \mu {\sigma _{\text{c}}}} \right) \\ \mu {\sigma _{\text{c}}}\quad\left( {\tau > \mu {\sigma _{\text{c}}}} \right) \\ \end{gathered} \right. (8) 其中:

{\sigma _{\text{c}}} 为刀-工接触区域的名义应力;{\tau _{\text{s}}} 为刀-工接触区域的摩擦应力;τ为切削材料的剪切应力;\mu 为摩擦系数,其值设定为0.3[21]。2. 有限元建模

2.1 含孔隙缺陷的CFRP微观几何模型

由于实际应用中要求CFRP的孔隙含量不得超过5vol%。因此,分别设定0vol%(无孔隙)、1vol%、3vol%、5vol% 4种不同的孔隙体积含量进行研究。根据目前已有对孔隙形态特征的研究[22],低孔隙率(1vol%以内)时,孔隙截面形状多接近圆形,高孔隙率(3vol%~5vol%)时,孔隙截面形状多呈扁平状。孔隙平均长度随孔隙率的增加而增加,但保持在110 μm以内。综合以上因素,为避免单个孔隙的形状、尺寸和分布对切削情况造成干扰,同时为提高计算效率但又不影响结果分析,在构建有限元仿真几何模型时,特进行以下假设和简化:(1) 孔隙缺陷形状各异,在几何模型中将孔隙截面形状均按四周为圆形边缘的三角形或扁平状四边形设定;(2) 为使设置的孔隙长度都在统计结果范围内,将孔隙长度统一设置成77 μm (几何模型高度的一半);(3) 纤维均匀分布于树脂基体内部且孔隙周围纤维的位置一致,避免纤维分布对结果产生影响;(4) 为使孔隙均位于刀具切削路径上,切削深度设置在距离孔隙表面的35 μm处。

在进行含不同孔隙率的CFRP微观几何建模时,采用对代表性体积单元(RVE)进行空间阵列的方式首先完成整个CFRP微观几何体的三维建模。然后,根据下式在三维几何体上挖去相应的孔隙含量所占据的空间,来代替孔隙含量:

{V_{\text{p}}} = \frac{{S {{h}}}}{{{V_{{\text{model}}}}}} (9) 其中:

{V_{\text{p}}} 为体积孔隙率;S为孔隙截面积;h为单孔隙长度;Vmodel为CFRP微观几何体的体积。其中,孔隙含量不高于1vol%时,孔隙截面形状按四周为圆形边缘的三角形进行设置,孔隙含量超过1vol%时孔隙截面形状按四周为圆形边缘的三角形和扁平状四边形共同设定。CFRP的微观几何模型如图2(a)所示。

![]() 图 2 含孔隙碳纤维增强树脂基复合材料 (CFRP)的微观切削建模Figure 2. Micro cutting modeling of carbon fiber-reinforced plastic (CFRP) with voidsθ—Fiber orientation angle; α—Rake angle; γ—Clearance angle; Vp—Volumetric voids; U—Translational degrees of freedom; UR—Rotational degrees of freedom; RVE—Representative volume element; ap—Depth of cut

图 2 含孔隙碳纤维增强树脂基复合材料 (CFRP)的微观切削建模Figure 2. Micro cutting modeling of carbon fiber-reinforced plastic (CFRP) with voidsθ—Fiber orientation angle; α—Rake angle; γ—Clearance angle; Vp—Volumetric voids; U—Translational degrees of freedom; UR—Rotational degrees of freedom; RVE—Representative volume element; ap—Depth of cut2.2 CFRP微观切削有限元建模

在获得不同孔隙含量的CFRP几何模型基础上,采用ABAQUS/EXPLICIT有限元仿真软件,建立考虑孔隙缺陷的CFRP微观切削有限元仿真模型。CFRP工件的几何尺寸为0.144 mm × 0.144 mm × 0.050 mm,纤维体积分数为60vol%,单根纤维直径为7 μm。树脂-纤维界面采用零厚度内聚力单元。对CFRP几何体的底面和侧面进行面固定铰接约束,在其厚度方向设置平行约束,单根纤维与基体间均分别设置面约束。

切削建模时采用正交切削方式,刀具设定为刚体。为避免计算运行初期报错,在刀尖与工件之间设定0.5 μm接触间隙。采用统一的八节点减缩积分线性单元(C3D8R)进阶算法对CFRP工件和刀具分别进行扫掠式网格划分,工件和刀具的单元网格尺寸均为1.5 μm。对参与切削的刀具刃口区域进行网格细化,细化网格尺寸为1 μm。

此外,考虑到实际应用中CFRP工件中的材料铺层方向的非单一性,本文针对不同孔隙含量的CFRP材料,分别设置了0°、45°、90°和135° 4种典型的纤维排布方向。所建立的CFRP微观切削有限元模型如图2(b)所示,相关的材料性能参数和切削工艺参数分别如表1和表2所示。

Material Parameter Value Carbon fiber Elastic modulus/GPa E1=231, E2=E3=15 Poisson’s ratio {{v}_{12}} ={{v}_{13}} =0.2, {{v}_{23}} =0.25 Shear modulus/GPa G12=G13=15, G23=7 Tensile strength/GPa Xt=4.62, Yt=1.5 Compressive strength/GPa Xc=3.96, Yc=3.34 Resin Elastic modulus/GPa E=3.35 Poisson’s ratio {{v}} =0.35 Yield strength/MPa σy=120 Fracture energy/(N·mm−1) Gf=0.01 Interface Normal strength/MPa σmax=50 Shear strength/MPa τmax=75 Elastic stiffness/(N·mm−3) K=100000 Fracture energy/(N·mm−1) GI=0.002 表 2 有限元模型(FEM)切削工艺参数Table 2. Cutting process parameters used in the finite element model (FEM)Parameter Value Rake angle of tool/(°) 15 Clearance angle of tool/(°) 10 Edge radius of tool/μm 5 Depth of cutting/μm 35 Cutting speed/(mm·s−1) 300 3. 结果和讨论

3.1 考虑孔隙缺陷的CFRP切削力

图3为不同纤维方向下含不同孔隙率的CFRP切削力时变曲线。当纤维方向角为0°时,相对于其他纤维排布方向,初始切削力较大,如图3(a)所示。在刀具与材料接触初始阶段,最大切削力随着孔隙率增大而减小。当进入稳定切削阶段,孔隙率在0vol%~3vol%时的平均切削力相差较小。但孔隙率为5vol%时,平均切削力有所减小,此时切削力产生局部突变现象。当纤维方向角为45°时,相对于0°纤维排布方向,总体上切削力呈下降趋势。在此条件下,孔隙率在0vol%~1vol%时平均切削力相近,而当孔隙率为3vol%~5vol%时平均切削力出现明显降低,如图3(b)所示。当纤维方向角为90°时,整体上相对于其他纤维排布方向,切削力相对较大。此时,在稳定切削阶段的切削力随孔隙率增大而降低。当孔隙率为0vol%~1vol%时切削力相对稳定,而当孔隙率在3vol%~5vol%时,相应的切削力则表现出较大的波动,如图3(c)。当纤维方向角为135°时,在较低孔隙率下(0vol%~1vol%)和较高孔隙率下(3vol%~5vol%),切削力整体变化幅度均相对较小,如图3(d)所示。但相对于较低孔隙率,较高孔隙率下的切削力降低的趋势明显增加。

造成上述现象的原因:一方面是纤维方向角不同,导致材料断裂和破坏的方式产生差异;另一方面,CFRP中孔隙含量不同,促使不同纤维方向角下材料的断裂行为差异进一步扩大。尤其在高孔隙率条件下,这种现象更加明显。

图4提取了不同孔隙率下、大孔隙边缘同一位置(图2(a))的最大应力值。可以发现,当纤维方向角为0°和45°时,孔隙边缘的最大应力变化幅度均相对较小,下降的幅值在30%以内。但在90°和135°的纤维方向角时,高孔隙率下(3vol%~5vol%)的最大应力下降幅度明显增大。尤其当纤维方向角为90°时,相对于无孔隙的最大应力下降了60.02%。该结果表明,孔隙的存在使周围材料对待切削纤维的约束作用减弱,并进一步诱发切削力的下降。

3.2 考虑孔隙缺陷的CFRP微观切削材料断裂与损伤

图5为不同纤维排布方向、不同孔隙含量下CFRP微观切削的材料断裂仿真结果。纤维方向角为0°时的仿真结果如图5(a)所示,可以看到,当刀具开始接触工件材料时,受刀具前刀面的推挤作用,工件上方整块材料被逐渐掀起,伴随一定长度的纤维断裂并最终形成块状切屑。同时,与刃口直接相对的纤维因受轴向压缩载荷而产生径向弯曲折断。随孔隙率增大,孔隙附近的材料对纤维的约束减弱,从而使纤维先产生一定的弯曲变形后再发生折断。但是,当孔隙含量较高时(如5vol%的孔隙率),与刃口相对的纤维并未发生径向折断,而是随前刀面的推挤作用直接被掀起而形成块状切屑。这是由于高孔隙率下纤维周围的约束几乎完全消失,当刃口切过时产生一定的“空切”效应,因而此时纤维表现为直接掀起变形,并最终在与孔隙相邻的纤维根部产生弯曲断裂。图5(b)为纤维方向角为45°时的切削情况。可知,与刃口接触的纤维一部分沿纤维径向被直接切断,一部分受前刀面和周围材料挤压作用产生挤压断裂,并沿纤维轴线方向脱离加工表面。当材料中不存在孔隙时,加工表面形成较规则的锯齿状碎屑。而当材料中存在一定孔隙时,同样由于靠近刃口的纤维周围的约束弱化,使纤维受前刀面挤压作用减小,在低孔隙率下(低于3vol%)纤维主要发生切削断裂。随孔隙率增加,孔隙周围的纤维发生切削断裂的倾向增加,在高孔隙率条件下(高于3vol%)纤维的弯曲断裂趋势减小。

纤维方向角为90°时的仿真结果如图5(c)所示。在刃口前刀面附近的纤维,其断裂形式主要是径向挤压断裂,与刃口后刀面相邻的纤维,其断裂形式主要是轴向挤压断裂。同时可以观察到,随着孔隙率的增加,与刃口靠近的后刀面所对应加工表面的面下纤维发生轴向挤压断裂的长度增加。当孔隙率为5vol%时,孔隙周围的纤维呈现近乎整体沿孔隙边缘的弯曲折断。这是由于在较高孔隙率、纤维方向角为90°条件下,被切削纤维后方完全失去了周围材料的约束作用,导致纤维的过度“空切”而形成大范围纤维折断。

当纤维方向角为135°时,材料为逆向切削,刀具前刀面首先与材料接触,纤维的初始断裂点位于刀尖斜下方。随着前刀面的推挤作用,与前刀面相对的纤维根部存在沿纤维轴向并向下开裂的趋势。从图5(d)的仿真结果中可以看出,在此纤维方向角下,孔隙率的大小对纤维的断裂损伤影响并不明显。但对于靠近孔隙边缘的纤维,随孔隙率的增加,纤维呈较整齐的断裂方式,其弯曲断裂延伸至孔隙而终止,断屑长度随之增加。

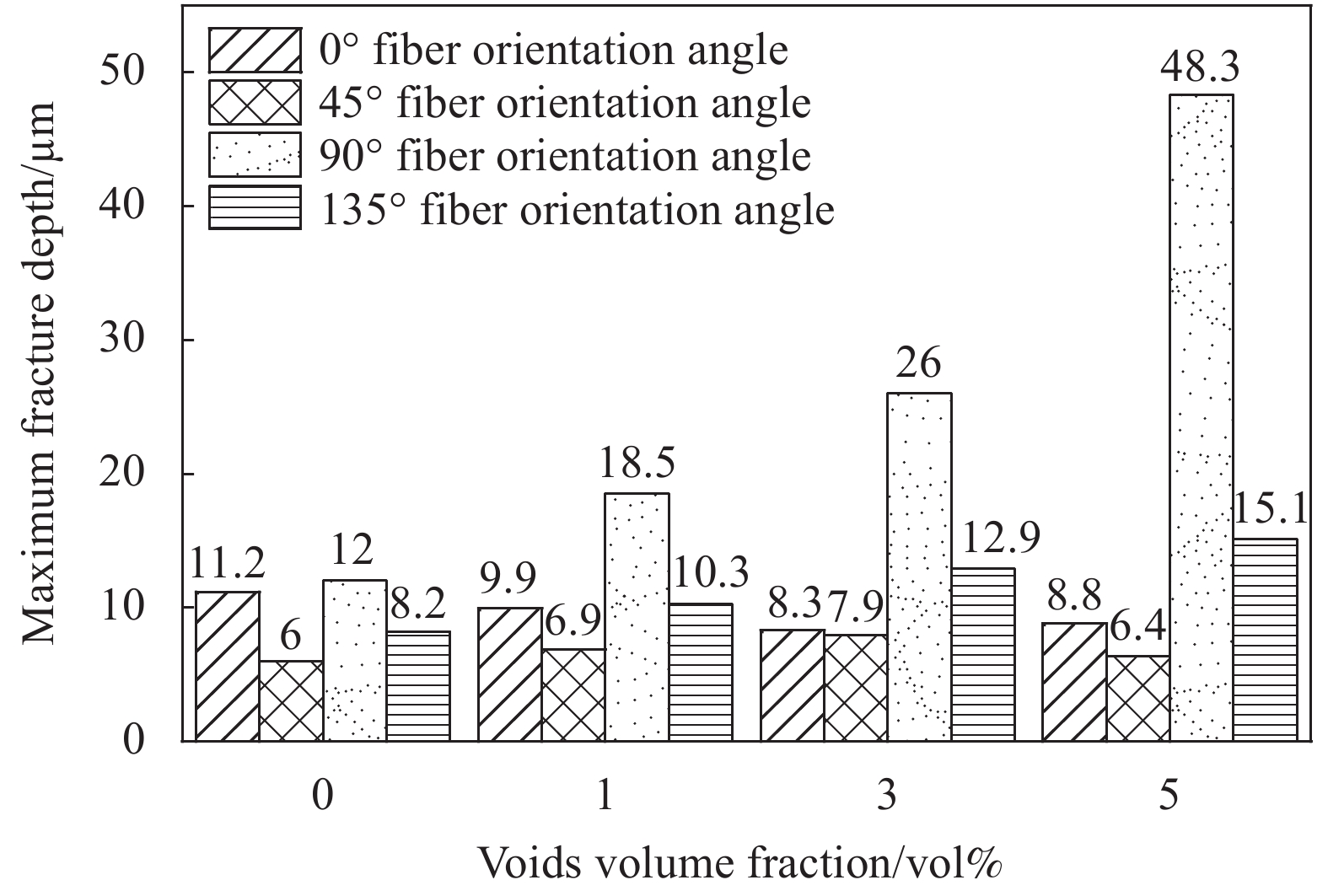

进一步地,本研究提取了不同纤维方向角、不同孔隙含量条件下的加工表面及面下损伤情况,如图6所示。其中,孔隙位于与加工表面相邻的材料内部。从仿真结果可以看出,纤维方向角为0°、45°时,加工表面受孔隙含量的影响较低,面下损伤深度相对较小。其中,纤维方向角为0°时加工表面的形成主要源于表层纤维的剥离作用,切屑形态为相对规则的长条状切屑;纤维方向角为45°时形成相对较小的颗粒状碎屑。而当纤维方向角为90°和135°时,加工表面存在明显的纤维断裂和切屑残留。其中,纤维方向角为90°时对应的切屑长度随孔隙含量的增加而明显增加,同时加工表面的面下损伤深度受孔隙率的影响最大;而当纤维方向角为135°时,受纤维弯曲断裂和拔出的影响,加工表面的面下出现纤维断裂形成的“V”形凹槽。

图7为不同纤维排布方向条件下,含不同孔隙率切削时的面下最大损伤深度。孔隙率由0vol%增加到5vol%,90°纤维方向角对应的面下损伤深度增加了302.5%,135°时的损伤深度增幅为84.2%。而对于纤维方向角为0°和45°时,相应的面下损伤深度变化较不明显。这是由于,一方面孔隙率越高,纤维周围的支撑和约束作用越低;另一方面,当纤维方向角为90°时,此时纤维与刀具的初始接触仅限于刀具部分,纤维末端缺乏前刀面的支撑作用。从而导致纤维一旦承受刀具刃口的切削挤压作用,便会沿孔隙边缘末端发生整体弯曲折断,形成较大的面下损伤。而纤维方向角为135°时,由于纤维最先与前刀面接触,使待切削纤维在末端存在支点约束,因而面下损伤虽随孔隙率增加而增加,但增幅不大,这也与文献[25]的实验研究结果相符。

3.3 考虑孔隙缺陷的CFRP微观切削能量分析

当材料中含有孔隙缺陷时,伴随着孔隙含量的变化,材料的切削过程必然存在切削能量的波动。Mcgregor等[26]通过数值模拟研究了轴向冲击下编织复合材料的能量吸收特性,定量分析了不同损伤机制下的能量吸收情况。Williams等[27]提供了一个切削能量平衡模型,该模型涉及在切削弹塑性材料过程中的外部功、断裂能、摩擦能和塑性耗散能。鉴于此,本文基于有限元模拟仿真,进一步分析了CFRP正交切削过程中的能量耗散变化,定量给出了不同孔隙含量下不同纤维取向的能量耗散规律。在材料的切削加工过程中,总的耗散能主要包括材料的摩擦耗散能EFD、断裂损伤耗散能EDMD、塑性耗散能EPD,其关系如下式所示:

{E_{{\text{Total}}}} = {E_{{\text{FD}}}} + {E_{{\text{DMD}}}} + {E_{{\text{PD}}}} (10) 根据式(10)绘制不同孔隙含量下的CFRP切削能量耗散曲线(切削深度为35 μm),如图8所示。可以看出,随纤维方向角增加,相同孔隙率的总耗散能和各项分耗散能均相应增加。这是由于,对于CFRP的正交切削加工,纤维方向角由0°向135°转变是一个由“顺切”向“逆切”逐步过渡的过程,刀具克服工件材料的阻力做功越来越大,从而导致相应的能量耗散量增加。总体上,随孔隙率的增加,总耗散能及材料的摩擦耗散能和塑性耗散能减少,但材料的断裂耗散能受孔隙率的影响较小。其原因是:一方面材料的断裂能的消耗主要与材料自身的力学性能特性有关;另一方面,由于孔隙的存在,实际上是减小了刀具与材料的摩擦接触面积,及材料参与塑性变形的数量。随孔隙率由0vol%增加到5vol%,不同纤维方向角所对应的总耗散能分别降低了22.30% (0°)、52.46% (45°)、26.55% (90°)和28.24% (135°)。另外,从图中还可以看出,当材料中一旦出现较大孔隙时(如孔隙率高于1vol%),其切削过程的总耗散能呈现近乎线性的下降趋势。因此从能量的角度进一步揭示了CFRP切削过程受自身孔隙率的影响关系。

4. 考虑孔隙缺陷的CFRP切削实验验证

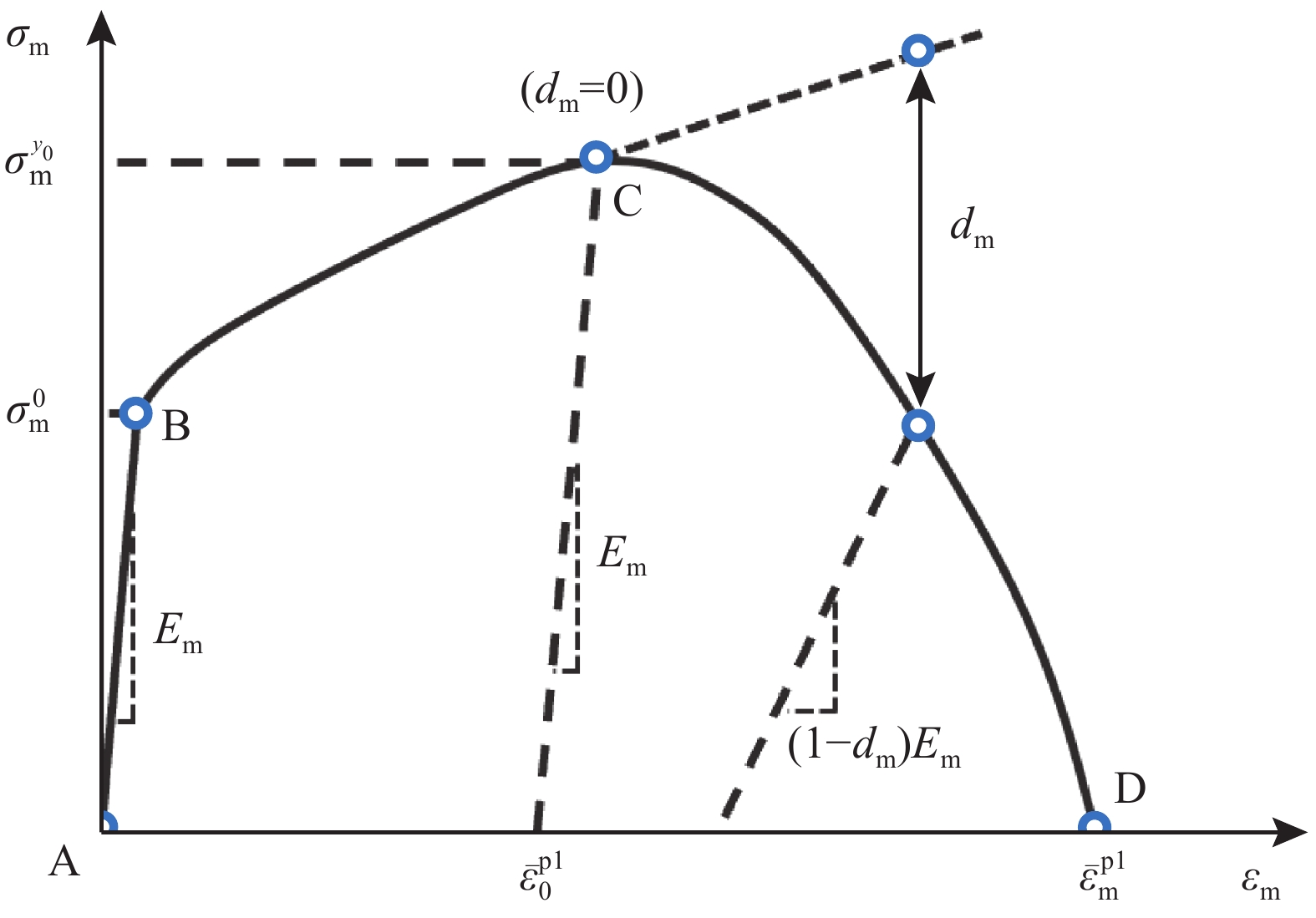

已有研究[5]表明,CFRP固化过程的孔隙率与固化压力存在如下式所示关系:

{V_{{\text{p}}}}{\text{ = }}\left( {5.37 - 26.15{P_{{\text{cure}}}} + 70.83P_{{\text{cure}}}^2 - 67.19P_{{\text{cure}}}^3} \right)\times 100{{\% }} (11) 其中:

{V_{{\text{p}}}} 为孔隙率;{P_{{\text{cure}}}} 为固化压力。因此,基于热压成型工艺,通过控制固化压力的方法来控制孔隙率,分别制备了孔隙率近似为0vol%、1vol%、3vol%、5vol%的CFRP单向层合板,用于与仿真模型中的孔隙率设置相匹配,其微观结构如图9所示。由于固化压力的作用,孔隙一般沿纤维间或层间扩展,并形成截面为扁圆或带有圆形边缘的不规则孔隙,这与仿真模型中的孔隙假设相符。

针对不同孔隙含量的层合板,分别进行了0°、45°、90°和135°纤维排布方向的切削实验。为避免孔隙大小、分布造成的干扰,在切削时尽量选择含较大孔隙的区域进行切削。实验中刀具的切削速度、进给率均与仿真的参量相同,分别为300 mm/s和150 mm/min,材料的切削深度为0.1 mm。加工机床采用长征四坐标立式加工中心(KVC800/1)。采用测力仪(Kistler-9253B)对切削力进行采集,并与仿真模型中的切深进行等效计算,以获得与仿真模型相同切深的切削力。利用SEM(日立高新技术公司,SU1510)对加工后的CFRP层压板的加工表面进行观测和对比分析。

选取90°纤维排布方向为典型代表,该条件下不同孔隙含量的CFRP最大切削力的实验和仿真结果如图10所示。可以看出,最大误差为9.6%,出现在孔隙率为1vol%时。造成相关误差的主要原因是:(1) 在仿真中,材料一旦到达损伤极限相应单元网格便会自动删除,而实验中断裂的纤维还会部分残留在已加工表面,对实验结果产生一定干扰;(2) 仿真中设置的孔隙形态与实际的孔隙形态还存在一定的差异。但总体上,切削力的仿真结果与实验结果吻合性较好。

图11和图12分别为不含孔隙和含孔隙条件下获得的CFRP切削加工表面形貌。可以看出,无论是不含孔隙还是含孔隙情况下,仿真结果与实验观测的加工表面形貌特征吻合性较好,从而进一步验证了仿真模型的正确性。此外,从含孔隙切削加工后的实验结果可以观察到,孔隙边缘的纤维由于缺乏足够的约束和支撑作用,在刀具刃口或前刀面的切削和推挤作用下,产生向孔隙内侧的弯曲断裂,并形成断裂切屑而残留在孔隙内部,这也与有限元仿真模拟结果相一致。

5. 结 论

采用有限元建模仿真的方法,在考虑了孔隙缺陷的基础上,建立了含孔隙缺陷的碳纤维增强树脂复合材料(CFRP)不同纤维方向角的微观切削仿真模型,揭示了含孔隙缺陷对材料切削损伤的影响规律,并通过实验验证了模型的正确性。相关结论如下:

(1) 在较低孔隙率条件下(低于3vol%),CFRP的切削力变化较平稳,而当孔隙率高于3vol%时,CFRP的切削力存在明显的波动,整体呈现较大的下降趋势。

(2) 孔隙的存在使CFRP切削时存在“空切”现象,导致孔隙边缘的纤维产生整体断裂的倾向增加。

(3) 孔隙对0°、45°和135°纤维方向角的CFRP加工面下损伤影响不大。而对于90°纤维方向角,当孔隙率高于3vol%时,加工表面的面下损伤影响最大,相对于无孔隙时,孔隙率为5vol%时的面下损伤深度增加了302.5%。

(4) 纤维方向角对CFRP切削过程的总耗散能影响明显,“顺切”时的总耗散能低于“逆切”时。随孔隙率增加,总耗散能降低,孔隙率高于1vol%时,总耗散能近乎呈线性下降趋势。

-

图 1 树脂本构模型[16]

Figure 1. Constitutive model of resin[16]

Em—Elastic modulus; dm—Stiffness degradation factor; σm—Stress of matrix; εm—Strain of matrix; {\sigma }_{\mathrm{m}}^{0} —Starting point of plastic stage; \sigma _{\rm{m}}^{{{{y}}_{\rm{0}}}} —Yield stress at damage initiation point; {{\bar\varepsilon }}_{0}^{\mathrm{p}\mathrm{l}} —Failure initiation strain; {{\bar\varepsilon }}_{\mathrm{m}}^{\mathrm{p}\mathrm{l}} —Complete failure strain

图 2 含孔隙碳纤维增强树脂基复合材料 (CFRP)的微观切削建模

Figure 2. Micro cutting modeling of carbon fiber-reinforced plastic (CFRP) with voids

θ—Fiber orientation angle; α—Rake angle; γ—Clearance angle; Vp—Volumetric voids; U—Translational degrees of freedom; UR—Rotational degrees of freedom; RVE—Representative volume element; ap—Depth of cut

Material Parameter Value Carbon fiber Elastic modulus/GPa E1=231, E2=E3=15 Poisson’s ratio {{v}_{12}} ={{v}_{13}} =0.2, {{v}_{23}} =0.25 Shear modulus/GPa G12=G13=15, G23=7 Tensile strength/GPa Xt=4.62, Yt=1.5 Compressive strength/GPa Xc=3.96, Yc=3.34 Resin Elastic modulus/GPa E=3.35 Poisson’s ratio {{v}} =0.35 Yield strength/MPa σy=120 Fracture energy/(N·mm−1) Gf=0.01 Interface Normal strength/MPa σmax=50 Shear strength/MPa τmax=75 Elastic stiffness/(N·mm−3) K=100000 Fracture energy/(N·mm−1) GI=0.002 表 2 有限元模型(FEM)切削工艺参数

Table 2 Cutting process parameters used in the finite element model (FEM)

Parameter Value Rake angle of tool/(°) 15 Clearance angle of tool/(°) 10 Edge radius of tool/μm 5 Depth of cutting/μm 35 Cutting speed/(mm·s−1) 300 -

[1] 邢丽英, 包建文, 礼嵩明, 等. 先进树脂基复合材料发展现状和面临的挑战[J]. 复合材料学报, 2016, 33(7):1327-1338. DOI: 10.13801/j.cnki.fhclxb.20160323.003 XING Liying, BAO Jianwen, LI Songming, et al. Development status and facing challenge of advanced polymer matrix composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1327-1338(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20160323.003

[2] HEGDE S, SATISH SHENOY B, CHETHAN K N. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance[J]. Materials Today: Proceedings,2019,19:658-662. DOI: 10.1016/j.matpr.2019.07.749

[3] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):12. DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):12(in Chinese).

[4] GEIER N, DAVIM J P, SZALAY T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review[J]. Composites Part A: Applied Science and Manufacturing,2019,125:105552. DOI: 10.1016/j.compositesa.2019.105552

[5] LI S J, ZHAN L H, CHEN R, et al. The influence of cure pressure on microstructure, temperature field and mechanical properties of advanced polymer-matrix composite laminates[J]. Fibers and Polymers,2014,15(11):2404-2409. DOI: 10.1007/s12221-014-2404-0

[6] FARHANG L, FERNLUND G. Void and porosity characterization of uncured and partially cured prepregs[J]. Journal of Composite Materials,2016,50(7):937-948. DOI: 10.1177/0021998315583924

[7] GU Y Z, LI M, ZHANG Z G, et al. Void formation model and measuring method of void formation condition during hot pressing process[J]. Polymer Composites,2010,31(9):1562-1571. DOI: 10.1002/pc.20944

[8] CARRERA E, PETROLO M, NAGARAJ M H, et al. Evaluation of the influence of voids on 3D representative volume elements of fiber-reinforced polymer composites using CUF micromechanics[J]. Composite Structures,2020,254:112833. DOI: 10.1016/j.compstruct.2020.112833

[9] 李树健, 湛利华, 周源琦, 等. 基于图像处理的碳纤维增强树脂基复合材料固化压力-缺陷-力学性能建模与评估[J]. 复合材料学报, 2018, 35(12):3368-3376. DOI: 10.13801/j.cnki.fhclxb.20180317.001 LI Shujian, ZHAN Lihua, ZHOU Yuanqi, et al. Modeling and evaluation of curing pressurer-defects-mechanical properties of carbon fiber composites based on image processing[J]. Acta Materiae Compositae Sinica,2018,35(12):3368-3376(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20180317.001

[10] ZHANG D, HEIDER D, GILLESPIE J W. Determination of void statistics and statistical representative volume elements in carbon fiber-reinforced thermoplastic prepregs[J]. Journal of Thermoplastic Composite Materials,2017,30(8):1103-1119. DOI: 10.1177/0892705715618002

[11] 任明法, 常鑫. 基于两尺度代表体元的含孔隙复合材料单层板弹性常数预测[J]. 复合材料学报, 2016, 33(5):1111-1118. DOI: 10.13801/j.cnki.fhclxb.20160121.004 REN Mingfa, CHANG Xin. Prediction for elastic coefficients of composite single layer laminate containing voids based on two-scale representative volume elements[J]. Acta Materiae Compositae Sinica,2016,33(5):1111-1118(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20160121.004

[12] WANG D Y, HE X D, XU Z H, et al. Study on damage evaluation and machinability of UD-CFRP for the orthogonal cutting operation using scanning acoustic microscopy and the finite element method[J]. Materials,2017,10(2):204. DOI: 10.3390/ma10020204

[13] LI H N, WANG J P, WU C Q, et al. Damage behaviors of unidirectional CFRP in orthogonal cutting: A comparison between single- and multiple-pass strategies[J]. Composites Part B: Engineering,2020,185:107774. DOI: 10.1016/j.compositesb.2020.107774

[14] 高汉卿, 贾振元, 王福吉, 等. 基于细观仿真建模的CFRP细观破坏[J]. 复合材料学报, 2016, 33(4):758-767. DOI: 10.13801/j.cnki.fhclxb.20150907.003 GAO Hanqing, JIA Zhenyuan, WANG Fuji, et al. Mesoscopic failure of CFRP based on mesoscopic simulation modeling[J]. Acta Materiae Compositae Sinica,2016,33(4):758-767(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20150907.003

[15] 王福吉, 胡海波, 张博宇, 等. 复合材料成型分层缺陷在钻削横刃挤压阶段的扩展行为[J]. 机械工程学报, 2019, 55(11):197-204. DOI: 10.3901/JME.2019.11.197 WANG Fuji, HU Haibo, ZHANG Boyu, et al. The expansion behavior of composite delamination defect during the chisel edge extrusion stage[J]. Journal of Mechanical Engineering,2019,55(11):197-204(in Chinese). DOI: 10.3901/JME.2019.11.197

[16] ZHANG S, LI Y, LUO M, et al. Modelling of nonlinear and dual-modulus characteristics and macro-orthogonal cutting simulation of unidirectional carbon/carbon composites[J]. Composite Structures,2022,280:114928. DOI: 10.1016/j.compstruct.2021.114928

[17] 郭芳芳, 肖建章. 基于三相微观结构的纤维复合材料切削仿真研究[J]. 工具技术, 2017, 51(6):26-30. DOI: 10.3969/j.issn.1000-7008.2017.06.005 GUO Fangfang, XIAO Jianzhang. Study on cutting simulation of fiber reinforced composite materials based on three phase microstructure[J]. Tool Engineering,2017,51(6):26-30(in Chinese). DOI: 10.3969/j.issn.1000-7008.2017.06.005

[18] ZENIA S, BEN AYED L, NOUARI M, et al. Numerical analysis of the interaction between the cutting forces, induced cutting damage, and machining parameters of CFRP composites[J]. The International Journal of Advanced Manufacturing Technology,2015,78(1-4):465-480. DOI: 10.1007/s00170-014-6600-2

[19] LI C P, ZHAO Y F, QIU X Y, et al. Interface mechanical damage mechanism in machining carbon fiber-reinforced plastic/Ti stacks based on a three-dimensional microscopic oblique cutting model[J]. Composite Structures,2022,279:114737. DOI: 10.1016/j.compstruct.2021.114737

[20] CHEN R, LI S J, LI P N, et al. Effect of fiber orientation angles on the material removal behavior of CFRP during cutting process by multi-scale characterization[J]. The International Journal of Advanced Manufacturing Technology,2020,106(11-12):5017-5031. DOI: 10.1007/s00170-020-04968-w

[21] ISBILIR O, GHASSEMIEH E. Finite element analysis of drilling of carbon fibre reinforced composites[J]. Applied Composite Materials,2012,19(3-4):637-656. DOI: 10.1007/s10443-011-9224-9

[22] 华志恒, 周晓军, 刘继忠. 碳纤维复合材料(CFRP)孔隙的形态特征[J]. 复合材料学报, 2005, 22(6):103-107. DOI: 10.3321/j.issn:1000-3851.2005.06.018 HUA Zhiheng, ZHOU Xiaojun, LIU Jizhong. Morphology of pores in carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2005,22(6):103-107(in Chinese). DOI: 10.3321/j.issn:1000-3851.2005.06.018

[23] CAMANHO P P, ARTEIRO A. Analysis models for polymer composites across different length cales[M]. Cham: Springer International Publishing, 2016: 199-279.

[24] YAN X Y, REINER J, BACCA M, et al. A study of energy dissipating mechanisms in orthogonal cutting of UD-CFRP composites[J]. Composite Structures,2019,220:460-472. DOI: 10.1016/j.compstruct.2019.03.090

[25] 秦旭达, 朱圣富, 李士鹏, 等. 不同纤维方向角时碳纤维增强树脂基复合材料切削力建模[J]. 宇航材料工艺, 2020, 50(6):31-40. QIN Xuda, ZHU Shengfu, LI Shipeng, et al. Modeling of cutting force for carbon fiber reinforced plastic with different fiber orientation angle[J]. Aerospace Materials & Technology,2020,50(6):31-40(in Chinese).

[26] MCGREGOR C, VAZIRI R, XIAO X. Finite element modelling of the progressive crushing of braided composite tubes under axial impact[J]. International Journal of Impact Engineering,2010,37(6):662-672. DOI: 10.1016/j.ijimpeng.2009.09.005

[27] WILLIAMS J G, PATEL Y. Fundamentals of cutting[J]. Interface Focus,2016,6(3):20150108. DOI: 10.1098/rsfs.2015.0108

-

期刊类型引用(3)

1. 周兰,王云龙,安国升,朱瑞彪,李光奇,马蓉. 基于斜角切削的CFRP螺旋铣孔微观仿真分析. 航空制造技术. 2024(21): 14-26 .  百度学术

百度学术

2. 周强,陈燕,王晓宇,张川川,陈雪梅,刘元吉,陈清良,勾江洋. 平纹编织结构CFRP正交切削切屑形成及表面损伤. 复合材料学报. 2023(09): 5371-5385 .  本站查看

本站查看

3. 郭南,陈燕,钱宁,孟祥军,晏超仁,刘元吉,勾江洋. CFRP切削加工力热特性建模预测研究进展. 航空制造技术. 2022(22): 44-59 .  百度学术

百度学术

其他类型引用(2)

-

下载:

下载: