Review on recent advances in nanocellulose aerogels for oil-water separation

-

摘要:

石油泄漏事件频繁发生,对环境和人类健康造成了极大的危害,因此亟需对含油废水进行有效的处理。目前的吸油材料存在局限性,如吸附量小、成本高和对环境有害等,而纳米纤维素气凝胶由于具有高孔隙度、高比表面积和低密度等特点,经疏水改性后能够吸附大量的油,在油水分离中有着显著优势。本文综述了纳米纤维素气凝胶的制备和疏水改性方法;介绍了纳米纤维素气凝胶结构特点及对其吸附性能的影响,综述了近年来纳米纤维素气凝胶在油和有机溶剂的吸附及油水混合物分离中的应用;最后提出了纳米纤维素气凝胶的发展现状及对未来的展望。

Abstract:The frequent occurrence of oil spills has caused great threat to environment and human health, so it is urgent to treat oily wastewater effectively. Current oil absorbing materials have limitations, such as low absorption capacity, high cost and environmental harm. Nanocellulose aerogel can absorb a large amount of oil because of its high porosity, high specific surface area and low density. After hydrophobic modification, nanocellulose aerogel has a significant advantage in oil-water separation. The preparation and hydrophobic modification of nanocellulose aerogel are reviewed in this paper. The structural characteristics of nanocellulose aerogel and their influence on absorption performance were introduced. The application of nanocellulose aerogel in adsorption of oil and organic solvent and separation of oil-water mixture in recent years were reviewed. Finally, the development status and future prospects of nanocellulose aerogel are presented.

-

Keywords:

- aerogels /

- nanocellulose /

- absorption /

- hydrophobicity /

- oil absorption /

- oil-water separation

-

随着现代无废城市及城镇化进程的发展与推进,废旧建筑物的改造与拆除和新建筑工程的建成,都会产生大量的建筑垃圾,而且目前建筑垃圾主要还是采用随意堆放的方式,占用了大量的土地资源;另外,由于目前建筑工程用砂石骨料等原材料过度开采及大量使用,引起了建筑原材料资源的匮乏等问题。因此,建筑垃圾的回收与循环利用技术在当今建筑工程中变得尤为重要。其中,若将建筑垃圾中的废弃混凝土破碎变成级配符合要求的再生粗骨料(RCA)替代天然砂石骨料使用,可有效缓解建筑垃圾超荷及自然资源匮乏的问题。因此,发展再生混凝土(RAC)技术及推广应用对目前国家倡导的“双碳”行动具有重要意义。但是,由于RCA破碎过程中造成的损伤及骨料本身的缺陷,相较于天然粗骨料(NCA)而言,RCA具有孔隙率和吸水率大、压碎指标及Ca(OH)2晶体含量高等特点,对所制备的RAC力学及耐久性能影响显著[1-3]。

纳米材料作为一种新型的、高效的无机材料,如纳米SiO2 (NS)、纳米CaCO3 (NC)等,因其粒径小、比表面积大、表面吸附力强和表面能大等特性。若将纳米材料掺入到水泥基材料中,可发挥其较高的火山灰活性、晶核及填充效应,能够有效改善水泥基材料内部结构。当前,针对纳米材料单掺入水泥基复合材料中应用研究较多,如胡建城等[4]研究NS对水泥-粉煤灰体系泡沫混凝土抗压强度的影响规律,研究发现:掺入NS的混凝土28 d抗压强度显著提高。Ghafari等[5]研究发现:NS改性混凝土内部界面过渡区(ITZ)更致密,主要由于 NS的高火山灰活性,与水化产物Ca(OH)2(CH)生成更多水化硅酸钙(C-S-H)凝胶产物,使混凝土内部相连通的孔隙减少,有效提升了混凝土耐久性。Sivasankaran等[6]研究发现掺入过量的NS反而会降低混凝土内部结构致密性,主要是由于NS的团聚效应导致其分布不均无法改善内部孔隙结构,未能充分发挥其纳米材料特性。

然而,目前大部分研究主要针对NS单掺改性混凝土,而针对NC改性水泥基材料的相关研究相对较少。NC是一种新型超细固体粉末颗粒,具有量子尺寸、表面和宏观量子效应,且是目前最廉价的纳米材料之一,价格也仅仅是NS的1/10。NC掺入可有效促进其水化反应使内部结构变得更加致密,从而提升水泥基材料性能。王冲等[7]研究了NC对水泥砂浆标准养护3 d和28 d后的力学性能影响,当NC掺入量为1.5%时,水泥砂浆的3 d和28 d抗压强度和抗折强度较对照组明显提高,当NC掺量为2.5%时,水泥砂浆的抗压强度和抗折强度较NC掺入量为1.5%时又有所下降,由此得出水泥砂浆的抗压和抗折强度随NC掺量的增加呈现先增高后降低的趋势。卫益辰[8]对掺入NC和聚丙烯纤维的RAC力学性能和微观结构进行了研究,分析表明:聚丙烯纤维再生混凝土标准养护28 d后的抗压强度随着NC掺量的增加而降低,劈裂抗拉强度及抗折强度与抗压强度变化规律相同,但比抗压强度变化更加显著;进一步也发现,掺入NC后聚丙烯纤维再生混凝土的ITZ处生成了更多的水化产物,显著提高了再生混凝土内部结构的致密性。Shaikh等[9]开展了NC对混凝土吸水率的影响研究,结果表明:NC掺入可减少混凝土内部孔隙和微裂缝,有效降低混凝土吸水率。

NS和NC的单独掺入,可改善RAC各项性能,但为了考虑成本费用的性价比,已有文献针对NS和NC复掺改性混凝土性能进行了试验研究,Yue等[10]研究了NS和微碳酸钙(MC)复掺改性RAC对界面过渡区力学性能的影响,发现掺2%NS-1%MC的RAC在90 d时抗压强度分别比对照组(0%NS-0%MC)和掺2%NS的RAC高19.46%和14.26%,通过纳米压痕测试,RAC-2%NS-1%MC内新砂浆的平均弹性模量为23.57 GPa,高于对照混凝土内新砂浆的平均弹性模量16.23 GPa。随着时间的推移,MC掺入可有效克服NS改性效果逐渐减小的劣势。苏鑫[11]开展了NS和NC对混凝土力学性能和耐久性能的研究,当复掺NS和NC时,随着纳米材料的增加,混凝土的抗压、劈裂抗拉强度及抗氯离子渗透性能都会呈现出先升高后降低的趋势,发现NS掺入对混凝土性能的影响要大于NC的作用。

综上所述,NS和NC的纳米效应能促进水化作用,使混凝土内部ITZ结构更加致密,从而提高RAC力学及耐久性能[12]。目前研究针对NS和NC的单掺提升普通混凝土性能的研究较多,而二者协同改性效果及机制尚不清晰,且二者掺量比例多少效果最佳也未知。因此,为了进一步明确RAC性能提升的纳米复掺改性机制,并考虑NC掺量超过某一阈值是否会对RAC性能产生消极作用,本文选用NC掺量为0%、1%、3%和5%,而已有研究表明NS改性RAC最佳掺量为3%,故本文其产量仅选用0%、1%、2%和3%。基于此,开展不同掺量的NS与NC单/复掺改性全再生粗骨料混凝土(FRAC)力学及吸水性能的试验研究,分析纳米材料掺量对其强度及吸水率的影响规律,最后在微观尺度上表征纳米材料单/复掺对其微观形貌的改性效果。

1. 试 验

1.1 原材料及配合比

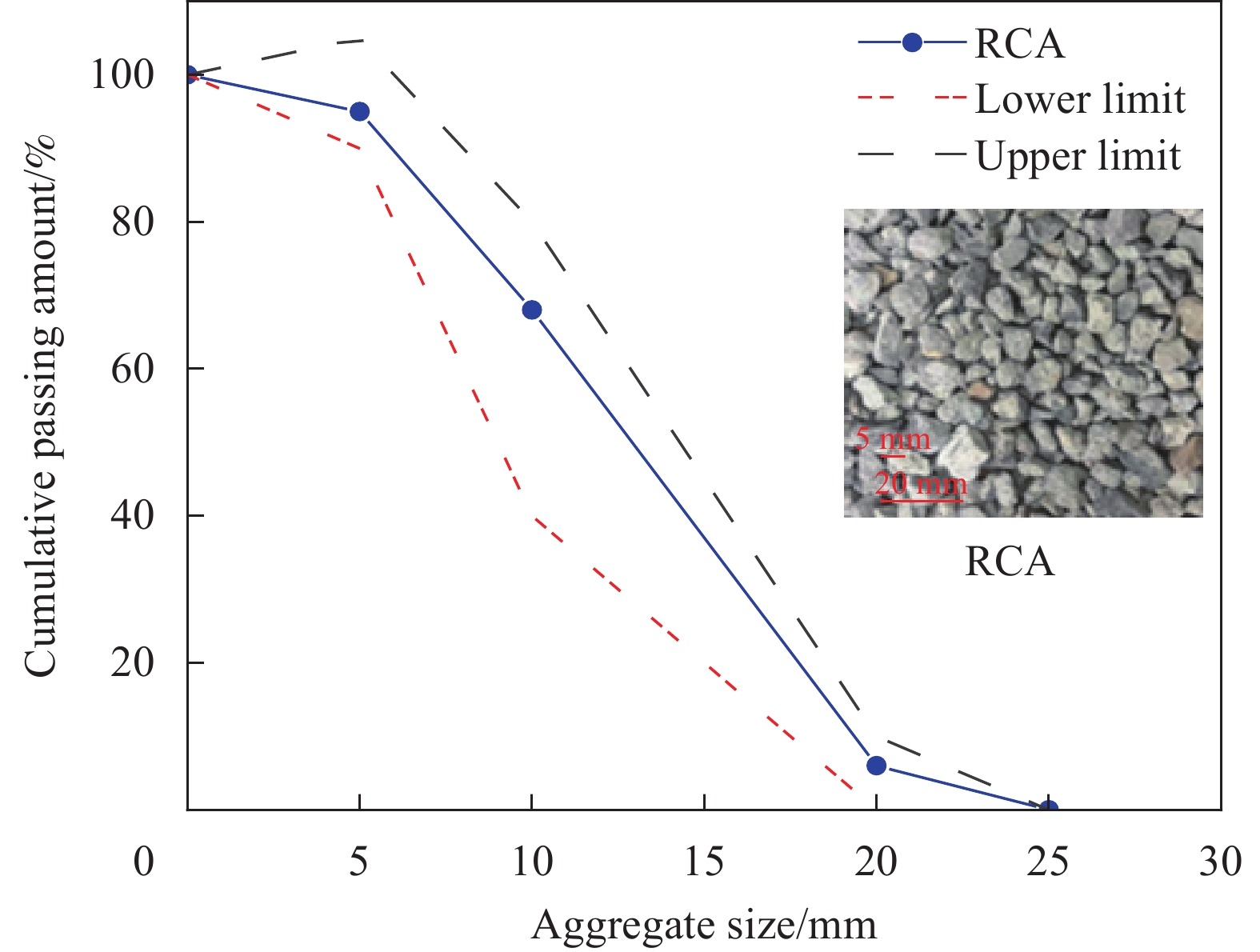

再生混凝土所使用的胶凝材料选用国家标准《通用硅酸盐水泥》(GB 175—2023)[13]中的P·O 42.5普通硅酸盐水泥(C),细骨料选用为级配良好的青岛大沽河天然河砂(S),最大粒径为5 mm,细度模数为2.7,级配符合要求;再生粗骨料(RCA)由C30级现场浇筑混凝土构件经颚式破碎机破碎2~3次获得,根据《建筑用卵石、碎石》(GB/T 14685—2022)[14]测试了再生粗骨料的颗粒级配(图1)和物理性能指标(表1);试验所需的纳米材料,采用微量分散剂的商用NS溶液;选用宜城市晶纳环保科技有限公司生产的NC分散溶液。通过由日本电子株式会社生产的型号JEM-2100F透射电子显微镜对NS和NC溶液进行分散性能的测试(图2),NS溶液粒径在10~20 nm之间,NC溶液粒径在40~50 nm,表明NS微粒和NC微粒具有良好的分散性和稳定性,其物理性能参数指标见表2。为了提高新拌再生混凝土的流动性,选用了江苏苏博特新材料有限公司生产的聚羧酸高效减水剂(SP),本试验所用的水均为实验室的普通自来水(W)。

表 1 再生粗骨料的物理性能指标Table 1. Physical properties index of recycled coarse aggregateType Water

absorption/

%Moisture

content/

%Crush

index/

%Apparent

density/

(kg·m−3)RCA 5.2 4.0 19.12 2706.2 表 2 NS和NC分散剂溶液的物理性质Table 2. Physical properties of NS and NC dispersant solutionType Appearance Granular size/nm Mass concentration/% pH NS Clear liquid 155 30 9.0-11.0 NC Clear liquid 402 20 9.5-10.5 本试验全再生混凝土(FRAC)配合比如表3所示,采用有效水灰比为0.4,RCA取代率为100% (R100);向RAC中加入占胶凝材料含量 0%、1%、2%和3%的NS及0%、1%、3%和5%的NC,分别用S和C表示,例如:S3C1表示为向RAC内掺入3%的NS和1%的NC;NS和NC分别为分散溶液,由于自身溶液内含有一定水分,因此在计算实际用水量时要减去NS和NC用量内的水分;相对于普通混凝土(NAC)不同,在RAC拌合过程中还需要加入附加用水量(AW)[15],主要是由于RCA的吸水率要远高于天然粗骨料(NCA),会影响RAC实际水灰比,进而影响RAC的水化程度及其各项性能。

表 3 全再生混凝土(FRAC)配合比(单位:kg/m3)Table 3. Mix proportion of fully recycle aggregate concrete (FRAC) (Unit: kg/m3)Group C W AW S RCA SP NS NC S0C0 380 152 26 627 1269 2.28 0 0 S1C0 380 152 26 627 1269 2.28 12.7 0 S2C0 380 152 26 627 1269 2.28 25.3 0 S3C0 380 152 26 627 1269 2.28 38 0 S0C1 380 152 26 627 1269 2.28 0 19 S0C3 380 152 26 627 1269 2.28 0 57 S0C5 380 152 26 627 1269 2.28 0 95 S1C1 380 152 26 627 1269 2.28 12.7 19 S1C3 380 152 26 627 1269 2.28 12.7 57 S1C5 380 152 26 627 1269 2.28 12.7 95 S2C1 380 152 26 627 1269 2.28 25.3 19 S2C3 380 152 26 627 1269 2.28 25.3 57 S2C5 380 152 26 627 1269 2.28 25.3 95 S3C1 380 152 26 627 1269 2.28 38 19 S3C3 380 152 26 627 1269 2.28 38 57 S3C5 380 152 26 627 1269 2.28 38 95 Notes: C represents cement; W and AW mean water content and additional water content in the recycled aggregate concrete (RAC) mix; S means the used sand; SP means polycarboxylate superplasticizer. 再生混凝土拌合物制备采取多次搅拌法,先倒入RCA,并加入预先计算好的附加用水量,搅拌1 min,继而加入水泥、河砂、所需用水量和SP,搅拌2 min,使水泥的水化反应更加充分,以提高混凝土内部结构的致密性[16];最后依次加入NS、NC分散溶液,二者间隔1 min,目的是让NS充分发挥火山灰和填充等作用,加入NC后继而搅拌2 min,最后装入尺寸为100 mm×100 mm×100 mm的立方体模具内,浇筑完成后用保鲜膜覆盖试件,放置在温度为20℃室内养护24 h,然后拆模并放置在温度(20±2)℃和相对湿度95%的标准养护室养护至28 d。

1.2 力学性能测试

依据国家标准《混凝土物理力学性能试验方法标准》(GB/T 50081—2019)[17],采用济南纳斯诺工业测试系统有限公司生产的YAW-3000D液压式万能试验机对28 d养护完成后的试件进行抗压强度和劈裂抗拉强度测试,加荷速度分别保持在0.5 MPa/s和0.05 MPa/s。劈裂抗拉强度试验应保持试件中心与下承压板中心对齐。每个配合比选取3个试件测试的算术平均值作为该组试件的强度值。

1.3 毛细吸水试验

基于传统的测重法开展了RAC吸水性能试验。依据ASTM C1585—04[18]规范标准,在试件养护完成后,将试件放于105℃的由绍兴苏珀仪器设备有限公司生产的101-1B烘干箱直至达到恒重。取出试件,冷却至室温,将试块侧面用自黏贴锡纸包住,以保证混凝土内水分的一维传输行为。试验开始前,将试块放在三角垫条上,使水面高出试件底面3~5 mm (图3)。利用昆山优科维特有限公司生产的精度为0.01 g、型号为HZ-20003的电子称记录试件吸水前的质量,吸水开始后每隔一定时间记录一次吸水质量,具体时间间隔分别为1 min、5 min、10 min、20 min、30 min、1~6 h (每隔1 h测一次)、1~8 d (每隔1 d 测一次)。

1.4 微观结构表征

1.4.1 SEM测试

为了研究NS和NC单/复掺后对FRAC内部微观结构的影响,表征了不同纳米材料单/复掺量下试件内部微观形貌。选取S0C0、S3C0、S0C3、S3C1、S1C3和S3C3试样,试件尺寸为10 mm×10 mm×10 mm,采用日本电子有限公司(JEOL)生产的JSM-7610 SEM设备,设定工作电压为15 kV,采用放大倍数为

5000 ×,然后对RAC样品进行微观结构的观察。1.4.2 XRD 测试

试件养护28 d后利用力学性能测试试块取中间部位10 g 左右浸泡在无水乙醇中48 h终止水化,然后放入由常州苏瑞仪器有限公司生产的XA-3型高速粉碎机中进行研磨成粉末,用筛径74 μm的筛进行筛分,筛分完成放入烘箱中烘干至恒重,使用布鲁克D8 advance型X射线多晶衍射仪进行粉 末样品的试验分析。

1.4.3 MIP测试

为表征改性后的FRAC内部孔隙结构,采用压汞法(MIP)进行表征。利用Micro Active Auto Pore V 9600型压汞仪,基于Wittman假设,通过外加压力与压入气孔中汞的表面张力,得到孔径的分布状态。对 S0C0、S3C0、S0C3和S3C3这4种不同纳米材料掺量的试块进行中心取样,尺寸大小为 10 mm×10 mm×10 mm,放于105℃的烘箱中至达到恒重。假设接触角为130°,在0.69 kPa至420 MPa的压力下进行汞的压入和挤出,每种压力水平的平衡时间为10 s。因此,最大和最小应力条件下将分别对应于从5 nm至

100000 nm的圆柱形孔隙尺寸。1.4.4 显微硬度测试

采用显微硬度测试技术表征NS和NC改性后FRAC的多重界面性能变化,对骨料、旧砂浆和二者之间的ITZ进行维氏硬度进行定量评测,显微硬度测试设备型号为YZHV-1 ZP,双光通道,最小检测分辨率为0.01 μm。样品准备为:用切割机在试块中心处切割厚度为10 mm的片状样品,保持样品两个面平行;符合标准的样品放置于异丙醇中浸泡24 h,终止水化;接着依次将74 μm、37 μm、15 μm、11 μm、9 μm 的砂纸固定于金相研磨抛光机上对片状样品进行逐级研磨,每级砂纸研磨时间为10~15 min,选用无水乙醇为润滑剂;分别使用粒度为2.5 μm和1 μm金刚石喷雾抛光剂对样品切片进行抛光,每一粒度的抛光时间为8~10 min;抛光完成后使用超声波清洗机清除样品表面的残留物,最后将样品切片置于50℃的烘箱中烘干至恒重,烘干结束后放于干燥皿中备用。

2. 结果分析与讨论

2.1 FRAC抗压强度

混凝土经过NS和NC改性后会有效改善内部微观结构,进而体现出在掺入适量的纳米材料后,混凝土的力学性能有所提高[19-21],提高混凝土构件的承载能力。相比普通混凝土,RAC本身内部缺陷更明显,改善效果更显著。纳米SiO2/CaCO3复掺改性FRAC的28 d抗压强度结果如图4所示。可以发现,单掺NS/NC后的再生混凝土抗压强度较对照组均有一定程度的提高;对于单掺NS的FRAC,S1C0、S2C0和S3C0试件抗压强度分别较S0C0提高了8.4%、12.4%和17.6%,即抗压强度随着NS掺量的增加而升高;当单掺NC组,S0C1、S0C3和S0C5试件抗压强度较S0C0分别提高了9.2%、16.6%和11.2%,即在NC掺量0%~5%范围内,抗压强度随着NC掺量的增加呈现出先升高后降低的趋势,NC掺量为3%时抗压强度最高,但降低后的抗压强度也仍高于S0C0组试件。

当FRAC复掺纳米材料时,针对S1C0而言,掺入一定量的NC后,会对FRAC抗压强度有明显的改善,S1C1、S1C3和S1C5的抗压强度分别较S1C0提高了3.7%、8%和7.1%;同理,S2C0组与此相似,S2C1、S2C3和S2C5分别提高了0.9%、6.2%和5.1%;FRAC经NS一定量改性后,随着NC掺量的增加,抗压强度呈现先升高后降低的趋势,而S2C1、S2C3和S2C5的抗压强度分别高于相对应的S1C1、S1C3和S1C5,也进一步证实了随着NS增加到适当的掺量,会增大FRAC抗压强度。当NC掺量一定时,再生混凝土抗压强度随NS掺量的增加而升高,主要是由于NS具有较强的火山灰活性,与水泥的水化产物CH发生反应,生成的C-S-H改善RAC内部结构缺陷,使其内部结构变得更加致密均匀[22]。然而,随着NC掺量增加而升高的现象,是由于NC在水化的过程中与水泥中的铝酸三钙(C3A)和铁铝酸四钙(C4AF)发生反应,生成的水化碳铝酸钙提高混凝土强度[11]。另外,无论是NS还是NC,由于纳米材料粒径微小,因其本身就具备有填充作用,可减少FRAC内部孔隙和微裂缝,使ITZ更致密。对于后期降低的现象主要是由于掺入过量NC会生成过量的低碳型水化碳铝酸钙产生团聚现象所致;而当NC掺量过大,在FRAC碱性环境中易发生团聚现象而不能发挥纳米粒子的特殊优势,在FRAC内部产生更多薄弱的ITZ,导致孔隙和微裂缝的增加,从而降低改性效果[23]。此外,由于S3C0的抗压强度值为47.4 MPa,S1C3的抗压强度值为47.2 MPa,发现当复掺比例为1%NS和3%NC时,达到3%NS单掺的效果。综合来看,当选用S3C3时为最佳掺量组,改善FRAC抗压强度效果最为明显。

2.2 FRAC劈裂抗拉强度

同抗压强度研究结果相似,NS和NC单/复掺改性后的再生混凝土试件28 d的劈裂抗拉强度如图5所示;单掺NS和NC及复掺改性后的FRAC劈裂抗拉强度都比S0C0有一定程度的提高。当NS掺量一定时,随着NC掺量的增加,FRAC劈裂抗拉强度大致呈现先升高后降低的趋势,而当NC掺量一定时,随着NS掺量的增加,FRAC的劈裂抗拉强度呈现逐渐升高的趋势。S0C1、S0C3和S0C5较S0C0劈裂抗拉强度分别提高了15.6%、25%和18.8%,而S2C1、S2C3和S2C5劈裂抗拉强度分别较S0C0提高了2.9%、13.5%和12.2%,S3C0和S1C3的劈裂抗拉强度值分别为3.85 MPa和4.1 MPa,二者强度值接近,也进一步说明当复掺比例为1%NS和3%NC时,可达到3%NS单掺的效果。综合来看,复掺纳米材料对FRAC劈裂抗拉强度改善效果较好,且最佳掺量的试件组为S3C3。

2.3 FRAC的毛细吸水性能分析

2.3.1 毛细吸水质量

NS和NC单/复掺改性条件下FRAC的毛细吸水质量如图6所示,其中S代表为NS的掺量。无论是NS和NC的单掺还是复掺,都会减少FRAC的毛细吸水质量。由图6(a)、图6(b)可知,S0C0的毛细吸水质量最多,由于掺入了100%的RCA代替NCA;掺入纳米材料后,有效减少了孔隙和微裂缝的数量,NS与CH发生二次水化反应生成C-S-H,且NS由于本身细小粒径,发挥了其物理填充效应;另外,适量的NC掺入可促进水泥水化作用,与C3A和C4AF反应生成水化碳铝酸钙,进而形成RAC内部较均匀且致密的水化基体结构,改善内部孔隙结构,细化并降低有害孔含量,降低了RAC毛细吸水质量。

如图6(b)~图6(d)所示,当掺入过量的NC反而会导致吸水量升高;S0C3、S1C3、S2C3和S3C3在吸水8 d后,吸水质量分别增加了107.61 g、100.36 g、98.92 g和93.66 g,而S0C5、S1C5、S2C5和S3C5吸水质量分别增加了136.28 g、108.56 g、 105.36 g和108.57 g,但均远低于S0C0组8 d后的吸水质量。随着NC掺量的增加,FRAC的吸水质量呈现先降低后升高的趋势。这是由于当FRAC内NS一定量时,掺入过量的NC后,发生反应会生成过量的低碳型水化碳铝酸钙,其团聚后会降低强度,且过量掺杂会导致孔隙和微裂纹增加,从而导致FRAC毛细吸水质量增加。当NC掺量一定时,FRAC毛细吸水质量随着NS掺量增加而呈现降低趋势,NS掺量越大,降低趋势越平缓。单掺纳米材料时,S3C0和S0C3吸水质量减少的最明显,而纳米材料复掺中S3C3的毛细吸水质量减小最明显,说明纳米材料复掺后各自发挥在FRAC中的填充作用[10],使内部的微裂缝和孔隙得到有效填充,同时也提高了FRAC耐久性能。

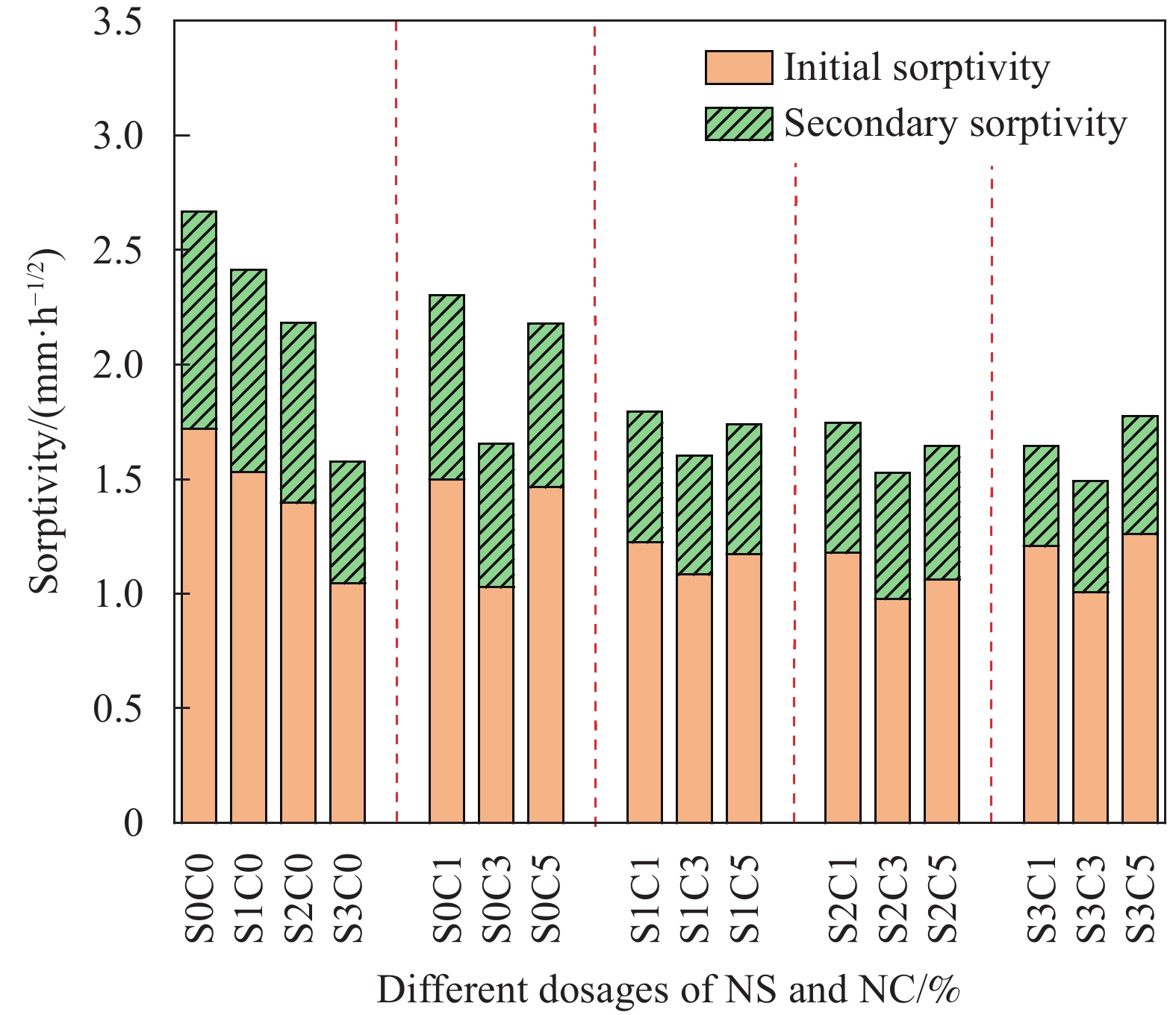

2.3.2 吸水率

为了评价混凝土吸水性能,通常用吸水率Sw来表征,也可间接反映并量化纳米材料复掺对全再生混凝土性能的改性效果。吸水率Sw (m/h0.5)为自变量时间的平方根与因变量毛细吸水质量之间的吸水曲线的斜率。由于FRAC与水接触瞬间,表层的微裂缝及孔隙瞬间被水填充,因此,混凝土在t时刻的一维累积毛细吸水质量i (mm)可用下式所示:

i=ΔmρwAc=Sw√t+b (1) 式中:

Δ m为毛细吸水质量(g);ρw为水的密度(g/mm3);Ac为试件与水接触的截面积(mm2);b为拟合曲线的纵轴截距。利用式(1)对FRAC的毛细吸水质量曲线进行拟合,以吸水时间t=24 h为分界点,分别确定出FRAC的初期吸水率Sini与后期吸水率Ssec,图7为NS及NC改性后FRAC的初期率和后期吸水率变化规律。每组试件的后期吸水率均低于初期吸水率,原因可能是由于试件的表面毛细孔的表面张力增加了初期吸水率,而对后期吸收阶段试件内部孔隙的填充速度相对较慢。烘干后,FRAC内的孔隙压力较低,在接触水后,内部微裂缝及孔隙迅速吸水,微裂缝和孔隙越多,导致前期的吸水率越高;对于S0C0~S3C0这4组试件,随着NS掺量的增加,FRAC内部结构被填充越致密,NS与CH的二次水化产生的C-S-H有效改善FRAC内部微结构,可供水分流经的通道越来越少,近而前期吸水率逐渐降低;而S0C1~S0C3试件,初期吸水率先降低后升高,是由于当掺入过量的NC后,其团聚后会导致FRAC内部水分传输通道变多,加快了FRAC初期吸水率。2.4 FRAC的微观结构分析

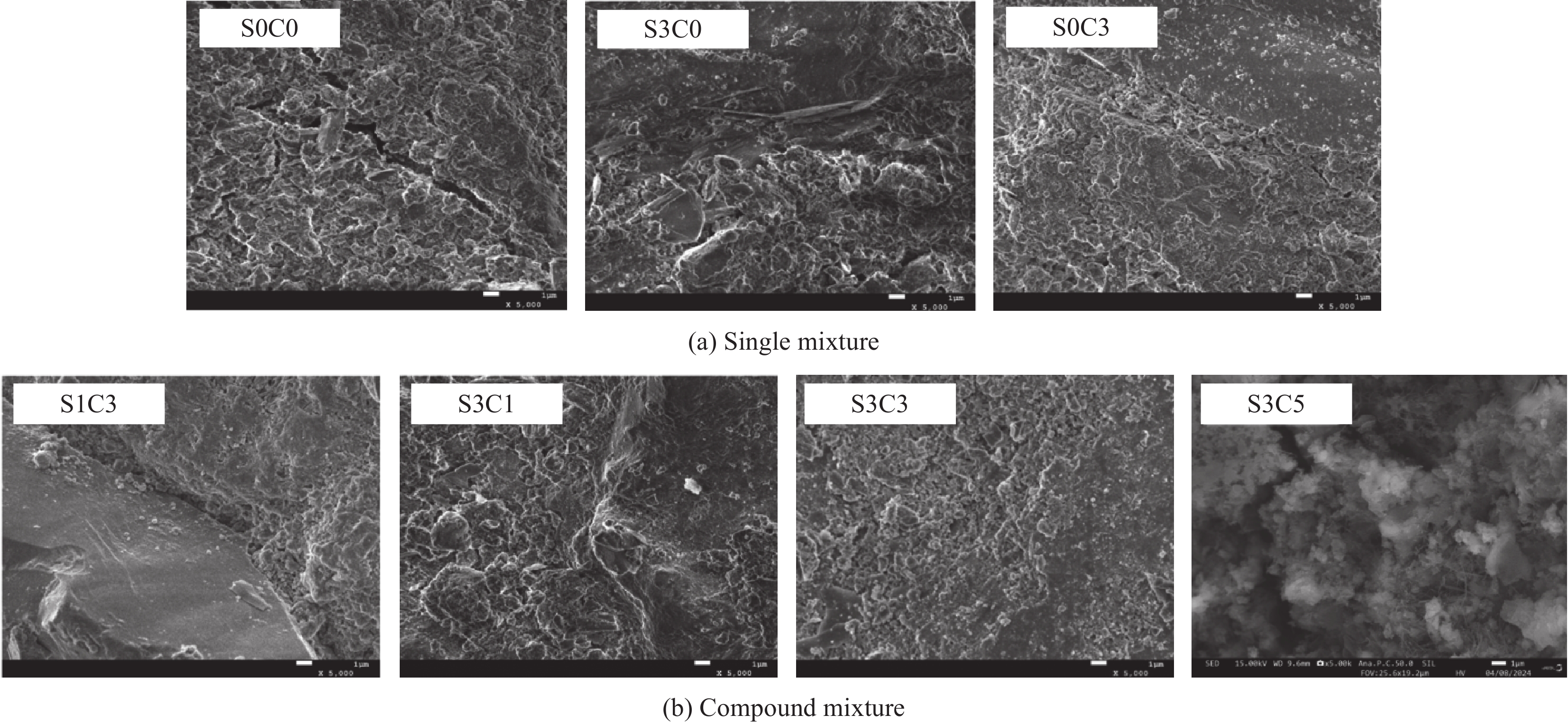

2.4.1 SEM微观形貌

纳米材料有效改善FRAC内部结构,大大减少微裂缝和孔隙数量,ITZ附近变得更加致密[24-26]。对单/复掺纳米材料改性后FRAC的扫描电镜试验分析,如图8所示。未进行纳米材料改性的S0C0为对照组,可以观察到试件内的水化产物较少,且内部有较多的微裂缝和孔隙,ITZ周围存在明显裂纹;单掺NS和NC的S3C0和S0C3试件,可明显观察裂缝和孔隙都变得很少,而内部结构中ITZ周围变得较致密,一方面是NS与CH的二次水化产物C-S-H和NC促进水泥水化作用,参与水化反应生成了水化碳铝酸钙,对ITZ及内部缺陷进行填充;另一方面是由于NS和NC的粒径极小,可以直接发挥物理填充效应,对FRAC内部结构有明显的改善作用。如图8(b)所示,对于复掺纳米材料改性后FRAC微观形貌,从S1C3和S3C1的SEM图像可观察,试块内部的水化产物比单掺时更多,微裂缝和孔隙都也减少许多,而S3C3组中微裂缝和孔隙更少,且内部结构中ITZ周围变得致密,这是由于除了纳米材料的填充效应外,NS和NC还具有协同效应,可以更好地改善再生混凝土的微观结构。通过S3C5的SEM可以明显观测到纳米粒子发生团聚现象,且微裂缝有所加宽。这是由于过量NC和NS的掺入,会在FRAC内产生团聚现象,团聚后的FRAC内部产生更多薄弱的ITZ,导致孔隙和微裂缝的增加,降低FRAC改性效果。

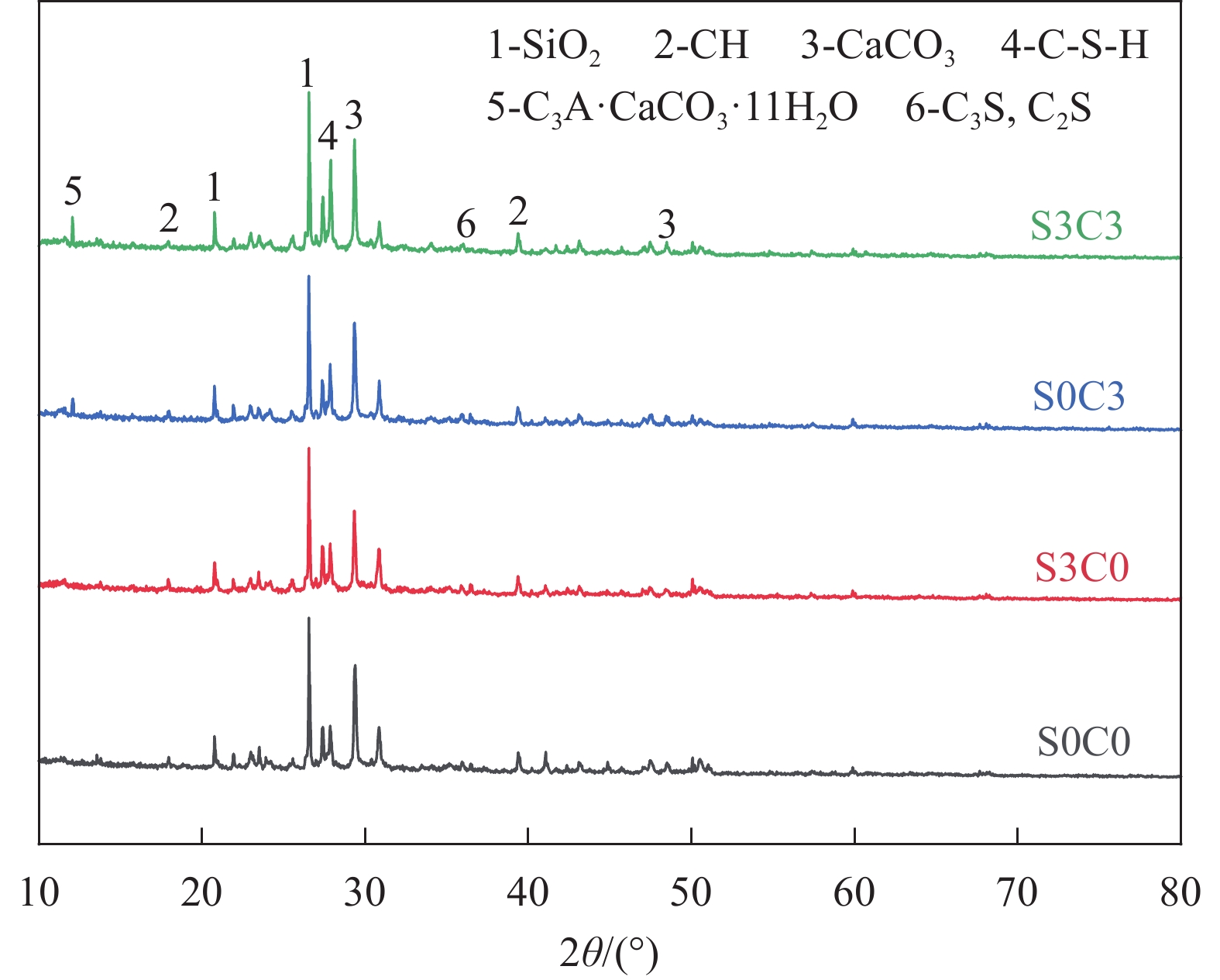

2.4.2 XRD物相分析

通过X射线多晶衍射仪对FRAC的S0C0、S3C0、S0C3和S3C3的水化产物进行表征分析,如图9所示。从XRD图谱可知,水化产物主要成分为二氧化硅(SiO2)、CH、硅酸三钙(C3S)、硅酸二钙(C2S)、碳酸钙(CaCO3)、水化硅酸钙(C-S-H)和水化碳铝酸钙(C3A·CaCO3·11H2O)。在4种试样中,C3S和C2S含量都相对较低,说明FRAC水化过程较完全;C-S-H在S3C3试样中峰值最高,且CH此时峰值较小;在S0C3和S3C3试样中得到C3A·CaCO3·11H2O,且在S3C3试样中峰值最高,表明了由于NS具有良好的成核效应和火山灰活性,加速消耗了FRAC中的CH含量生成更多的C-S-H,使FRAC内部空间排列更加致密均匀;而NC可以促进水泥水化作用,生成新的水化产物C3A·CaCO3·11H2O,改善内部孔隙结构,减少有害孔,且NC具有较高的表面能,能够使混凝土浆体中的Ca2+和OH–吸附到其表面,进而降低CH 的含量。

2.4.3 MIP分析

为了进一步分析纳米材料对FRAC内部孔隙结构的影响,分别对S0C0、S3C0、S0C3和S3C3 4种试块开展了不同纳米掺量改性的FRAC内部孔隙率、平均孔径及孔径分布的影响分析,总体发现,NS和NC的掺入可有效改善FRAC内部孔结构。从图10(a)可以看出,未经NS/NC改性后的S0C0组FRAC孔隙率最高,平均孔径最大,这是由于RCA在形成过程中,经过机械的破碎、研磨等工序,导致本身具有孔隙率高和压碎指标大等缺陷,又因RCA表面带有旧砂浆,导致ITZ结构更加复杂且增加了孔隙率。S3C0、S0C3和S3C3组的孔隙率和平均孔径相对于S0C0分别降低了25.45%、30.2%及72.3%,27.9%、25.2%和33.6%,S3C0和S0C3均高于S0C0,但S3C3组改性效果最为明显,表明单掺NS和NC可以改性FRAC内部孔隙结构,但二者复掺改性效果明显优于NS和NC的单掺;通过图10(a)的孔径分布影响曲线可知,随着纳米材料NS和NC的掺入,FRAC内部最可几孔径在减小,且S3C3复掺后减小最明显,S3C0最可几孔径小于S0C3组,表明同质量分数掺入情况下,NS改性效果优于NC。综上可知,NS和NC一方面因纳米材料比表面能大,发挥着火山灰效应和成核效应,促进FRAC的二次水化作用,消耗更多的CH含量,产生更多能使FRAC内部均匀致密的C-S-H和C3A·CaCO3·11H2O;另一方面,由于NS和NC粒径极小,发挥其填充效应,减少FRAC内部有害孔数量;然而,NS和NC的复掺改性,二者体现出协同改性的作用,进一步改善FRAC内部孔结构。

2.4.4 显微硬度分析

图11为NS和NC单/复掺改性FRAC样品显微硬度测试结果。选取S0C0、S3C0、S0C3和S3C3这4组试件,通过显微硬度测试技术测定了经NS和NC单/复掺改性作用后FRAC中RCA、旧砂浆及ITZ的维氏显微硬度变化。从图中可以发现,FRAC中RCA的显微硬度值约为300 MPa左右,远超于旧砂浆和ITZ的显微硬度值;旧砂浆基体是一个复杂集合体,包含着细骨料、孔隙及裂纹、多种水化产物及未发生水化反应的水泥颗粒,导致其内部质地不均,因此显微硬度值会有一定小范围的波动;而ITZ的显微硬度值波动范围较大,因其内部结构疏松多孔导致性能较薄弱。另外,S0C0组ITZ的显微硬度值为78.6~121.2 MPa,差值为42.6 MPa,ITZ宽度约为71 μm;单掺3%NS后,S3C0组ITZ的显微硬度值在98.8~134.6 MPa之间,差值为35.8 MPa,ITZ宽度约为61 μm;单掺3%NC后,S0C3组ITZ的显微硬度值在95.9~129.7 MPa之间,差值为33.8 MPa,ITZ宽度约为66 μm;而在纳米材料复掺作用下,S3C3组ITZ的显微硬度值在109.3~141.2 MPa之间,差值为31.9 MPa,ITZ宽度约为50 μm。对比可知,单掺NS和NC的ITZ维氏硬度得到一定提升,复掺后的S3C3组优于单掺改性。产生这种现象的原因是S3C3内的NS和NC在二次水化过程中各自发挥着自身优势,表明其具有协同改性作用;此外,又因NS和NC粒径极小,发挥填充作用,使FRAC的ITZ显微硬度提升,ITZ宽度减小。

3. 结 论

(1)与未改性的全再生粗骨料混凝土(FRAC)相比,纳米SiO2 (NS)和纳米碳酸钙(NC)的掺入可有效改善FRAC内部微观结构,提升混凝土强度。纳米SiO2 (NS)和纳米碳酸钙(NC)单/复掺对FRAC的抗压、劈裂抗拉强度均有所提高,但随着NC掺量的增加会呈现先升高后降低的趋势,这是由于过量的NC会在FRAC内部发生团聚作用,对FRAC的强度产生负增长,生成过量的低碳型水化碳铝酸钙,会导致孔隙和裂痕增加,从而降低改性效果。当复掺比例为1%NS和3%NC时,可达到3%NS单掺的效果。

(2) FRAC内部微观结构改性效果可间接通过毛细吸水性能评价。与对照组比较,NS和NC单/复掺改性后的FRAC,毛细吸水质量及毛细吸水率都会有所降低,纳米材料的二次水化作用及物理填充效应会使FRAC内部结构更加致密,细化孔隙结构,从而使水分子的传输通道曲折且不连续。经比较,S3C3组改性效果最佳,8 d共累计吸水量为93.66 g。

(3)根据单/复掺NS和NC的微观形貌可知,试件内部的孔隙和微裂缝数量大大减少,单掺NC效果要优于单掺NS,但过量的NC也会产生负面影响,本实验中NC掺量控制在3%以内性能改性效果较优;复掺后的改性效果相较于单掺更明显,NS和NC的相互协同作用会将FRAC内界面过渡区(ITZ)结构更加致密,二者的最佳复掺量均为3%。

-

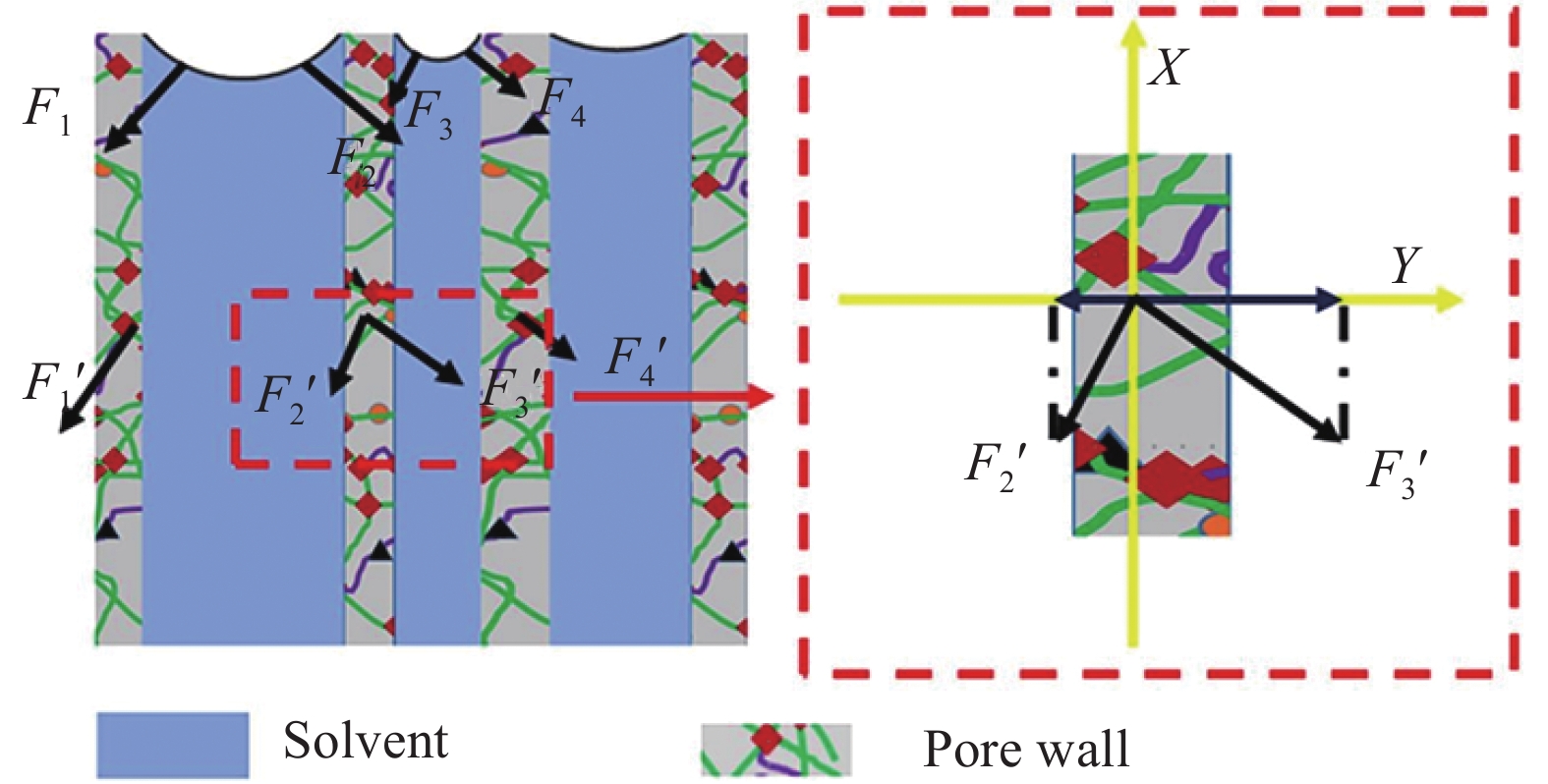

图 2 干燥过程孔壁应力分析[36]

F1, F2, F3, F4—Capillary pressure, resulting from the evaporation of solvent at the gas-liquid interface will transmit to the pore walls; F1′, F2′, F3′, F4′—Resultant forces on the pore walls in the horizontal direction caused by capillary pressure

Figure 2. Stress analysis of pore wall during drying process[36]

图 3 (a) 化学气相沉积法(CVD)改性细菌纳米纤维素(BNC)气凝胶示意图[39];(b)改性前后细菌纳米纤维(BNC)气凝胶的疏水性及相应水接触角[39];(c)不同甲基三甲氧基硅烷(MTMS)添加量改性纤维素纳米纤维(CNF)气凝胶(TCNF-Si)的水接触角[40]

BC—Bacterial cellulose

Figure 3. (a) Illustration for the chemical vapor deposition (CVD) process of bacterial nanocellulose (BNC) aerogel[39]; (b) Hydrophobicity and corresponding water contact angle of bacterial nanocellulose (BNC) aerogel before and after modification[39]; (c) Water contact angle of cellulose nanofibers (CNF) aerogels (TCNF-Si) at different methyltrimethoxy-silane (MTMS) supplemental levels[40]

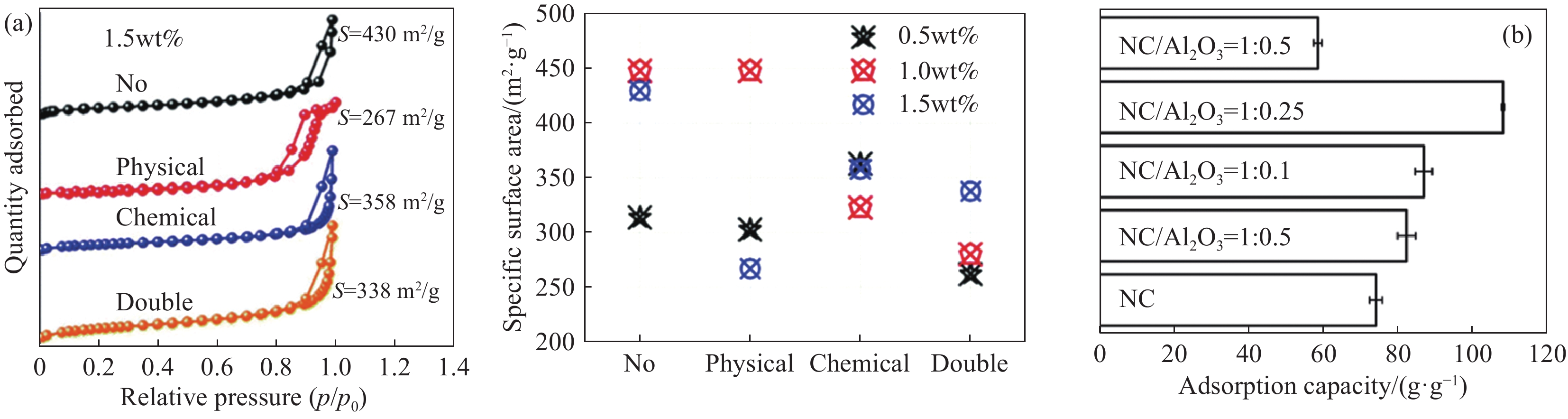

图 4 (a)不同交联方式和不同前驱体浓度下纳米纤维素气凝胶的比表面积[46];(b)不同纳米纤维素(NC)/Al2O3质量比气凝胶对噻吩的吸附能力[49]

S—Specific surface area

Figure 4. (a) Specific surface area of nanocellulose aerogel under different crosslinking methods and different precursor concentrations[46]; (b) Adsorption capacity of aerogel for thiophene at different mass ratios of nanocellulose (NC) to Al2O3[49]

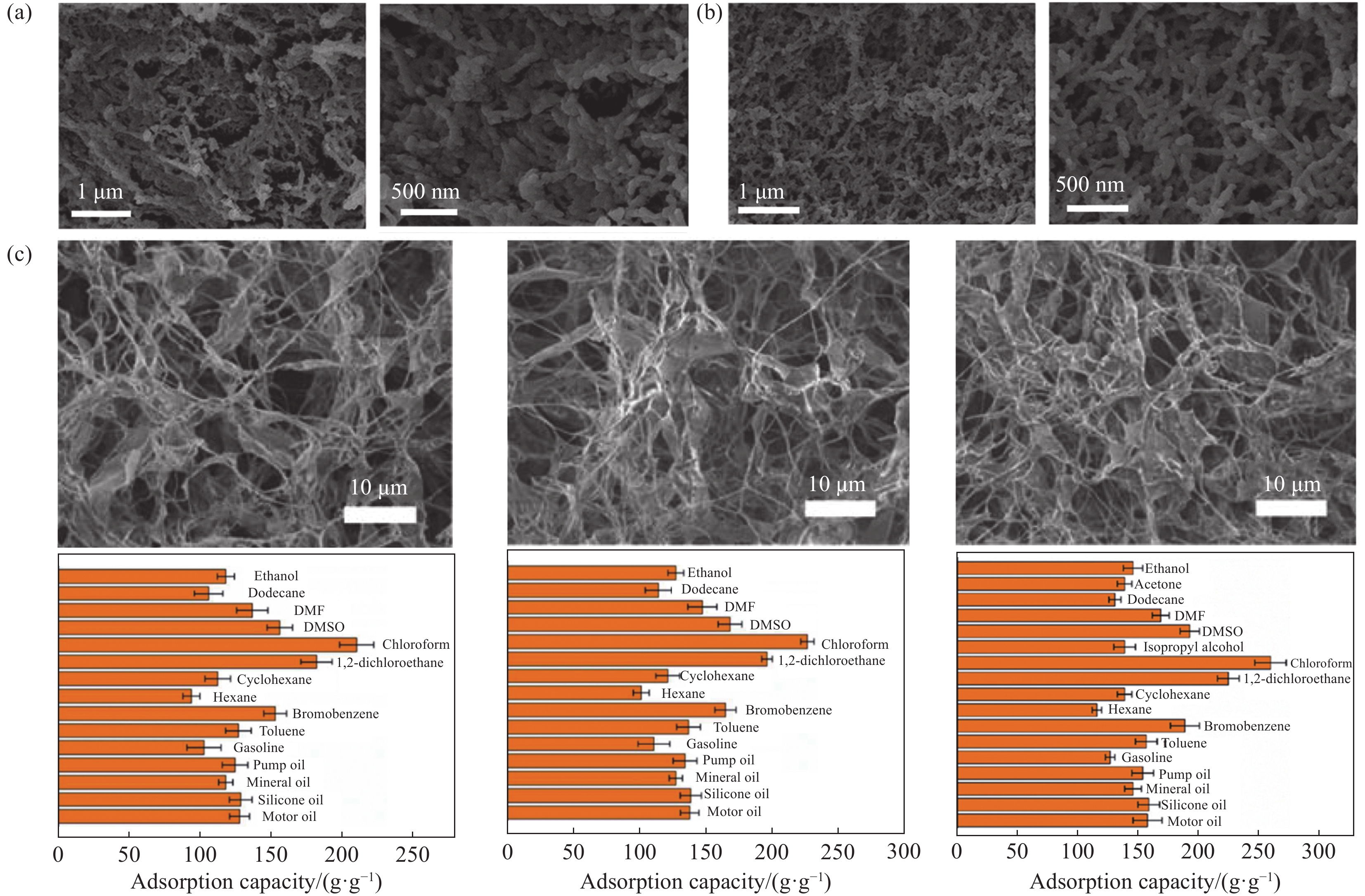

图 5 (a)通过冷冻干燥制备气凝胶的SEM图像[50];(b)通过超临界CO2干燥制备气凝胶的SEM图像[50];(c)不同甲基三乙氧基硅烷(MTES)含量下气凝胶的孔隙结构及对应吸附能力[50]

DMF—Dimethylformamide; DMSO—Dimethyl sulfoxide

Figure 5. (a) SEM images of the aerogels obtained by freeze drying[50]; (b) SEM images of typical aerogels obtained by supercritical CO2 drying[50]; (c) Pore structure and adsorption capacity of aerogel with different methyl triethoxysilane (MTES) contents[50]

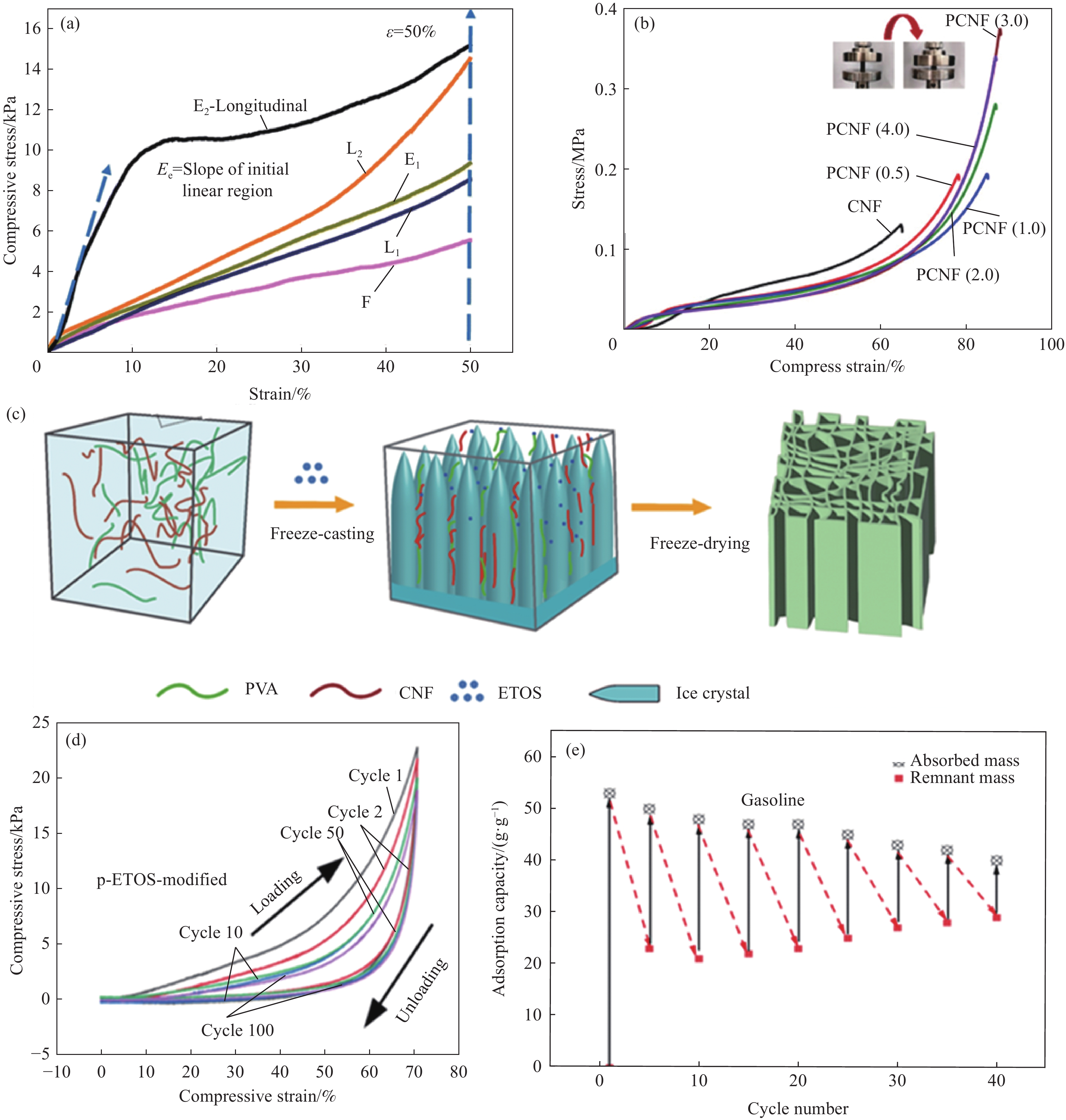

图 6 (a)不同干燥方法下气凝胶的应力-应变曲线[52];(b)不同聚多巴胺(PDA)含量下CNF气凝胶的应力-应变曲线[53];(c) CNF/聚乙烯醇(PVA)/四乙氧基硅烷(ETOS)定向冷冻干燥过程[54];(d) 100次压缩-卸载循环下气凝胶的应力-应变曲线[54];(e) 40次吸附-解吸循环下气凝胶的吸附能力[54]

F—Freezing in a refrigerator; L1—Non-directional freezing in liquid nitrogen; L2—Directional freezing in liquid nitrogen; E1—Non-directional freezing in ethanol; E2—Directional freezing in ethanol; ε—Compressive strain; Ee—Linear elastic region; CNF—Cellulose nanofibers; PCNF—polydopamine (PDA)/CNF composite aerogel, the number represents the PDA concentration

Figure 6. (a) Stress-strain curves of aerogel under different drying methods[52]; (b) Stress-strain curves of CNF aerogel with different polydopamine (PDA) contents[53]; (c) Directional freeze drying process of CNF/polyvinyl alcohol (PVA)/tetraethoxysilane aerogel (ETOS)[54]; (d) Stress-strain curves of aerogel under 100 compression-unload cycles[54]; (e) Adsorption capacity of aerogel after 40 adsorption and desorption cycles[54]

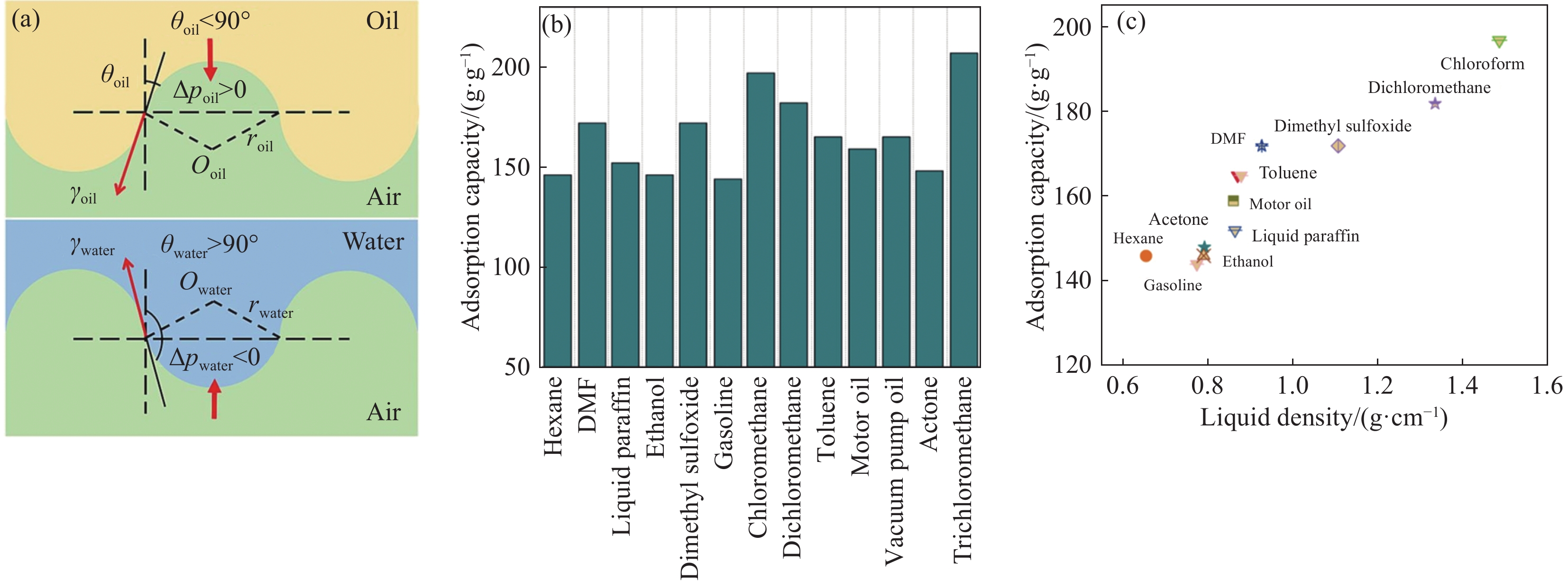

图 7 (a) 气凝胶油水分离机制[56];(b) CNC/壳聚糖(CS)复合气凝胶对油和有机溶剂的吸附能力[58];(c) CNC/CS复合气凝胶吸附能力与溶剂密度关系[58]

Δp—Intrusion pressure; γ, r, θ—Surface tension of the liquid, liquid meniscus radius and liquid contact angle, respectively; O—Center of the circle

Figure 7. (a) Oil-water separation mechanism of aerogel[56]; (b) The ability of CNC/Chitosan (CS) composite aerogel to adsorb oils and organic solvents[58];(c) Relationship between adsorption capacity of CNC/CS composite aerogel and solvent density[58]

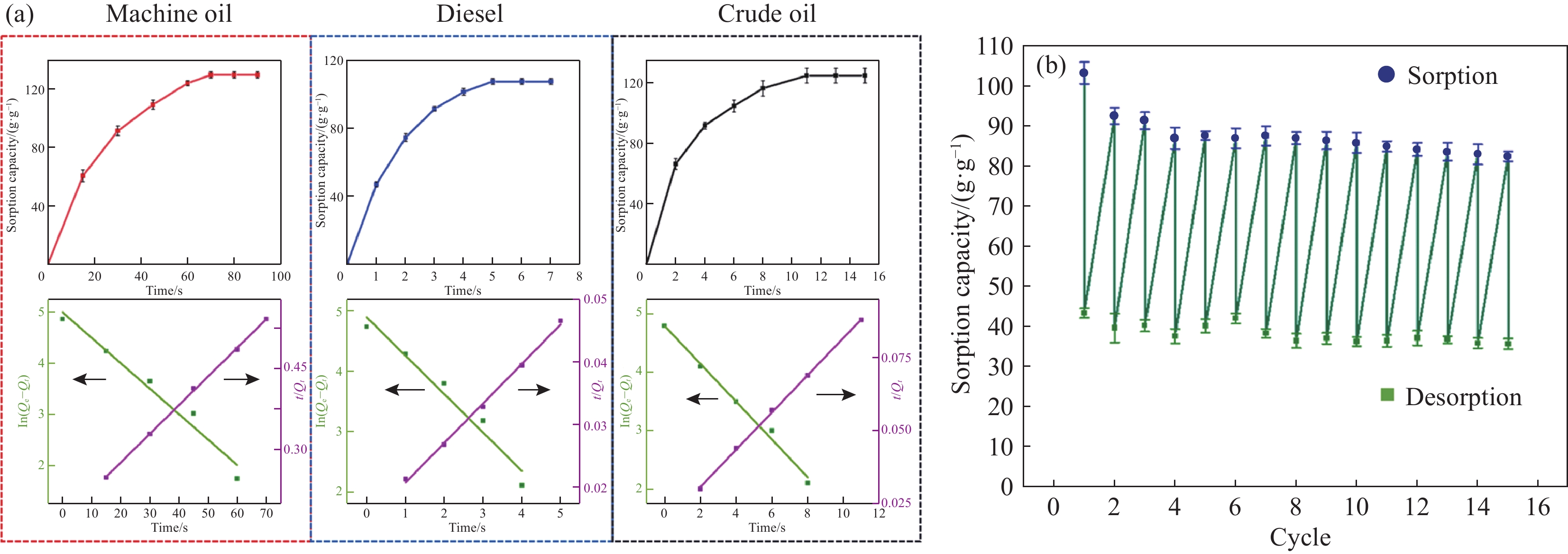

图 8 (a) CNF/富含果胶的小叶(PML)气凝胶对机油、柴油和原油的吸附容量-时间曲线及伪一阶模型和伪二阶模型[60]; (b) CNF/PML气凝胶对柴油的循环吸附测试[60]

Qe—Equilibrium adsorption amount; Qt—Amount of adsorption at time t

Figure 8. (a) Adsorption capacity-time curves of CNF/pectin rich lobule (PML) aerogel on machine oil, diesel and crude oil: Pseudo-first-order model and pseudo-second-order model[60]; (b) Cyclic adsorption test of CNF/PML aerogel on diesel oil[60]

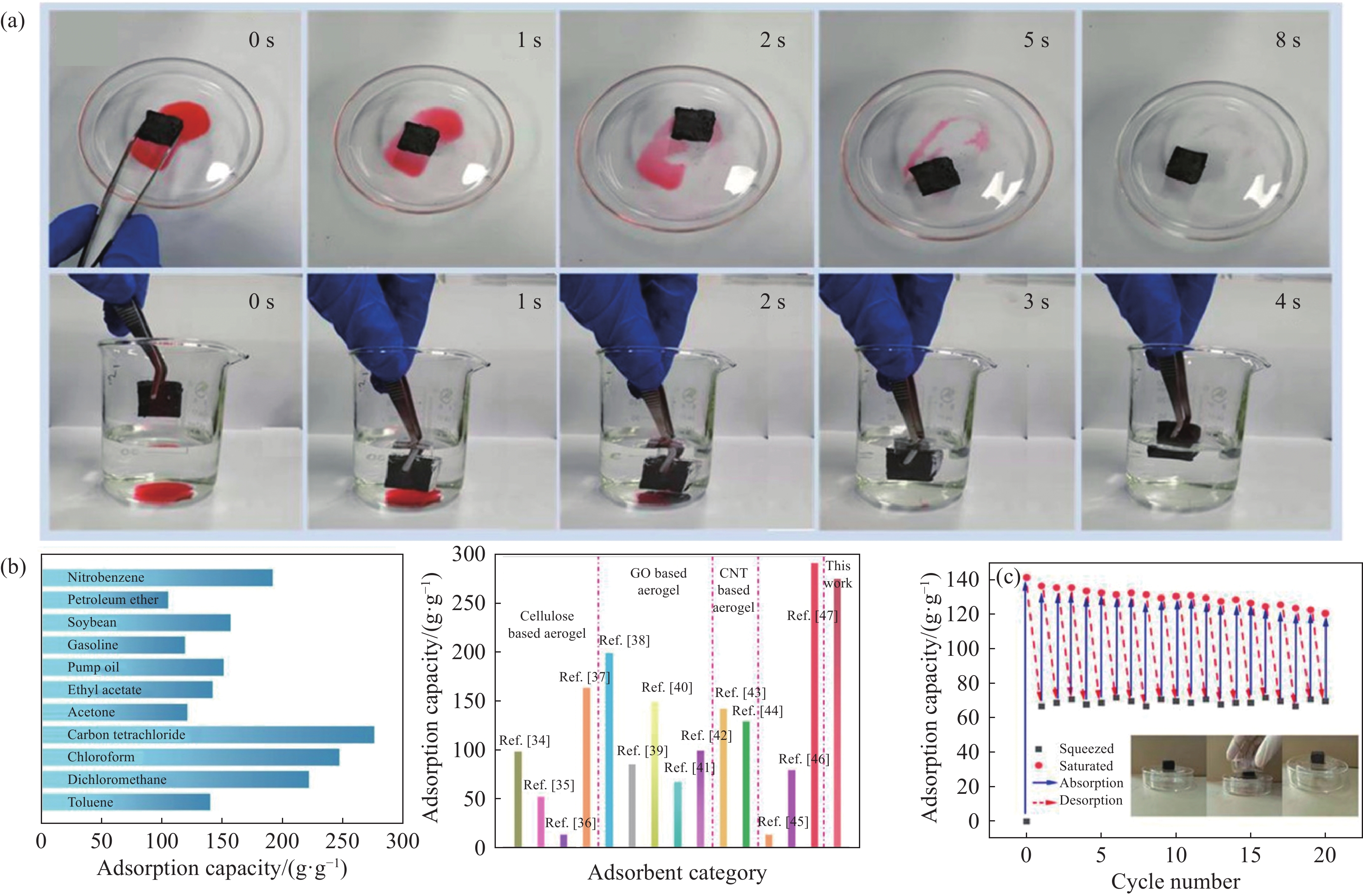

图 9 (a) CNC/石墨烯(GO)复合气凝胶快速吸附乙酸乙酯和四氯甲烷[64];(b) CNC/GO复合气凝胶对各种油和有机溶剂的吸附能力[64];(c) CNC/GO复合气凝胶的重复使用性能[64]

CNT—Carbon nanotube

Figure 9. (a) CNC/graphene (GO) composite aerogel quickly adsorbed ethyl acetate and tetrachloromethane[64]; (b) Ability of CNC/GO composite aerogel to adsorb oils and organic solvents[64]; (c) Reusable performance of CNC/GO composite aerogel[64]

图 10 (a) 气凝胶厚度与通量的关系[67];(b) 泵驱动下的连续油水分离过程[68];(c) CNF/聚二甲基硅氧烷(PDMS)气凝胶对正己烷、甲苯和甲基环己烷的分离通量[68];(d)纯气凝胶(A0)和复合气凝胶(AM4)分离乳液过程及分离前后液滴尺寸[70];(e) 气凝胶分离乳液机制 [70];(f)气凝胶初始分离通量、总分离量和分离效率[70];(g) 气凝胶对4种油包水乳液的分离效率[71]

Figure 10. (a) Relationship between aerogel thickness and flux[67]; (b) A continuous oil-water separation process driven by a pump[68]; (c) Separation fluxes of CNF/polydimethylsiloxane (PDMS) aerogel for n-hexane, toluene and methylcyclohexane[68]; (d) Pure aerogel (A0) and composite aerogel (AM4) separation emulsion process and droplet size before and after separation[70]; (e) Mechanism of aerogels separating emulsion[70]; (f) Initial separation flux, total separation amount and separation efficiency of aerogel[70]; (g) Separation efficiency of aerogel for four water-in-oil emulsions[71]

图 11 (a)纤维素纳米纤维(CNF)/石墨烯(GO)/聚乙烯醇(PVA)气凝胶在10次吸附-燃烧循环下对乙醇的吸附能力[75];(b) 纤维素纳米晶体(CNC)/赤泥(RM)气凝胶可燃性测试照片[76]

Figure 11. (a) Adsorption capacity of cellulose nanofiber (CNF)/graphene (GO)/polyvinyl alcohol (PVA) aerogel for ethanol under 10 sorption-combustion cycles[75]; (b) Digital photographs of cellulose nanocrystals (CNC)/Red Mud (RM) aerogel for flammability tests[76]

表 1 不同原料和干燥方法下纳米纤维素气凝胶的基本性能

Table 1 Basic properties of nanocellulose aerogels under different raw materials and drying methods

Material Content/wt% Density/(mg·cm−3) Porosity/% Specific surface area/(m2·g−1) Drying Ref. BNC 1 90 93.6 660 Supercritical drying [31] CNF 0.5 9.42 99.26 362.7 Freezing drying [33] CNF 1.5 58.82 – 22.4 Atmospheric pressure drying [36] BNC 0.4 46 97.7 – Freezing drying [41] CNC 0.5 5.6 99.6 – Freezing drying [42] CNC 2 21.7 98.6 250 Freezing drying [42] CNF 0.5 4 99.8 42 Freezing drying [43] CNF 0.6 8 99.5 30 Freezing drying [44] CNF 2 23 99 90 Freezing drying [45] Notes: BNC—Bacterial nanocellulose; CNF—Cellulose nanofiber; CNC—Cellulose nanocrystal. 表 2 不同纳米纤维素复合气凝胶的性能及油水分离性能比较

Table 2 Comparison of the properties and oil-water separation performances of different nanocellulose composite aerogel

Materials Density/

(mg·cm−3)Oil types Maximum

absorption

capacity/(g·g−1)WCA/(°) Porosity/% Specific surface

area/(m2·g−1)Reusability/

timesMaximum oil

flux/(L·m−2·h−1)Ref. CNF/CS 8.4 Trichloromethane 253 148 96 – 50 – [58] CNF/PML 5.1 Tetrachloromethane 160 129 – 9.8 15 – [60] CNC/RGO 4.98 Tetrachloromethane 276 – 99.6 272.2 10 – [64] CNF/PEI/EGDE 53.8 Tetrachloromethane 28.03 130 95.73 – 10 5400 [67] CNF/PDMS 22.7 Toluene 48 163.5 98.4 – 20 145 [68] CNF/SiO2 6.43 – 168.4 129 99.6 108.6 20 1910 [70] CNF/TA/ICO 24 Dichloromethane 113.8 134.8 98.32 – – 4783.8 [71] BNC/PMSQ 5.74 Trichloromethane 203 168 99.59 – 10 473.8 [72] CNF/SA 24.2 Silicone oil 88.91 144.5 97.85 149.64 20 – [73] CNF/CS/ZIF-8 15.87 Trichloromethane 74.55 132.6 99.01 5.51 20 13167.5 [74] Notes: CS—Chitosan; PML—Premna microphylla leaves; RGO—Reduced graphene oxide; PEI—Polyethyleneimine; EGDE—Ethylene glycol diglycidyl ether; PDMS—Polydimethylsiloxane; TA—Tannic acid; ICO—Castor oil; PMSQ—Polymethylsilsesquioxane; SA—Sodium alginate; WCA—Water contact angle; ZIF-8—Zeolitic imidazolate framework-8. -

[1] JERNELOV A. How to defend against future oil spills[J]. Nature, 2010, 466(7303): 182-183. DOI: 10.1038/466182a

[2] LI X, DONG G Q, LIU Z W, et al. Polyimide aerogel fibers with superior flame resistance, strength, hydrophobicity, and flexibility made via a universal sol-gel confined transition strategy[J]. ACS Nano, 2021, 15(3): 4759-4768. DOI: 10.1021/acsnano.0c09391

[3] QIN H F, ZHANG Y F, JIANG J G, et al. Multifunctional superelastic cellulose nanofibrils aerogel by dual ice-templating assembly[J]. Advanced Functional Materials, 2021, 31(46): 2106269. DOI: 10.1002/adfm.202106269

[4] LI Z, JIANG F, JIANG G J, et al. C-shaped porous polypropylene fibers for rapid oil absorption and effective on-line oil spillage monitoring[J]. Journal of Hazardous Materials, 2023, 452: 131332. DOI: 10.1016/j.jhazmat.2023.131332

[5] PAVÍA-SANDERS A, ZHANG S Y, FLORES J A, et al. Robust magnetic/polymer hybrid nanoparticles designed for crude oil entrapment and recovery in aqueous environments[J]. ACS Nano, 2013, 7(9): 7552-7561. DOI: 10.1021/nn401541e

[6] WALLACE R L, GILBERT S, REYNOLDS J E. Improving the integration of restoration and conservation in marine and coastal ecosystems: Lessons from the deepwater horizon disaster[J]. Bioscience, 2019, 69(11): 920-927. DOI: 10.1093/biosci/biz103

[7] PING Z X, SUN Q Y, YI J Q, et al. Formulating multiphase medium anti-wetting states in an air-water-oil system: Engineering defects for interface chemical evolutions[J]. ACS Applied Materials & Interfaces, 2021, 13(41): 49556-49566.

[8] DA C G F, DOS S N E V, MARSAIOLI A J. Petroleum degradation by aerobic microbiota from the Pampo Sul oil Field, Campos Basin, Brazil[J]. Organic Geochemistry, 2008, 39(8): 1204-1209. DOI: 10.1016/j.orggeochem.2008.04.010

[9] YI A N, ZHANG H M. Oil spill collection boom of ship based on negative pressure principle[C]//IOP. 5th International Conference on Advances in Energy Resources and Environment Engineering (ICAESEE). Chongqing, China: IOP Conference Series-Earth and Environmental Science, 2020: 052106.

[10] 李晓玲. 船舶污水的处理现状[J]. 皮革制作与环保科技, 2021, 2(19): 93-94. LI Xiaoling. Status quo of marine sewage treatment[J]. Leather Making and Environmental Protection Technology, 2021, 2(19): 93-94(in Chinese).

[11] HUANG Q X, MAO F Y, HAN X, et al. Migration of emulsified water droplets in petroleum sludge during centrifugation[J]. Energy & Fuels, 2014, 28(8): 4918-4924.

[12] 赵云峰. 一种废水处理的新工艺: CN102161906A[P]. 2011-08-24. ZHAO Yunfeng. A new technology for wastewater treatment: CN102161906A[P]. 2011-08-24(in Chinese).

[13] 徐诗琪, 周洲, 汤睿, 等. 高疏水纳米纤维素-壳聚糖/膨润土气凝胶的构建及其高效油水分离的应用[J]. 复合材料学报, 2024, 41(3): 1347-1355. XU Shiqi, ZHOU Zhou, TANG Rui, et al. Construction of highly hydrophobic nanocellulose-chitosan/bentonite aerogel and its application of efficient oil-water separation[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1347-1355(in Chinese).

[14] ALAZAB A A, SALEH T A. Underwater superoleophobic cellulose/acrylamide-modified magnetic polyurethane foam for efficient oil/water separation[J]. Materials Chemistry and Physics, 2023, 302: 127609. DOI: 10.1016/j.matchemphys.2023.127609

[15] 王琛, 张峰. 集中燃烧式原位热脱附技术装备研发与中试应用[J]. 节能与环保, 2022(12): 54-56. WANG Chen, ZHANG Feng. Development and pilot application of centralized combustion in situ thermal desorption technology equipment[J]. Energy Conservation and Environmental Protection, 2022(12): 54-56(in Chinese).

[16] TCHAMANGO S R, NGAYO K W, BELIBI P D B, et al. Treatment of a dairy effluent by classical electrocoagulation and indirect electrocoagulation with aluminum electrodes[J]. Separation Science and Technology, 2021, 56(6): 1128-1139. DOI: 10.1080/01496395.2020.1748889

[17] PATOWARY R, DEVI A, MUKHERJEE A K. Advanced bioremediation by an amalgamation of nanotechnology and modern artificial intelligence for efficient restoration of crude petroleum oil-contaminated sites: A prospective study[J]. Environmental Science and Pollution Research, 2023, 30(30): 74459-74484. DOI: 10.1007/s11356-023-27698-4

[18] WANG C Y, LI X, GUO J, et al. Biodegradation of marine oil spill residues using aboriginal bacterial consortium based on Penglai 19-3 oil spill accident, China[J]. Ecotoxicology and Environmental Safety, 2018, 159: 20-27. DOI: 10.1016/j.ecoenv.2018.04.059

[19] XU C J, GAO M Y, YU X X, et al. Fibrous aerogels with tunable superwettability for high-performance solar-driven interfacial evaporation[J]. Nano-Micro Letters, 2023, 15(1): 64. DOI: 10.1007/s40820-023-01034-4

[20] WU S Y, XIANG Y J, CAI Y Q, et al. Superhydrophobic magnetic Fe3O4 polyurethane sponges for oil-water separation and oil-spill recovery[J]. Journal of Environmental Sciences, 2024, 139: 160-169. DOI: 10.1016/j.jes.2023.05.024

[21] 王百祥, 张惠宁, 彭耀清, 等. 气相吸附制备仿生超疏水棉织物及其油水分离性能[J]. 化工进展, 2023, 42(12): 6490-6497. WANG Baixiang, ZHANG Huining, PENG Yaoqing, et al. Preparation of biomimetic superhydrophobic cotton fabric by gas phase adsorption and its oil-water separation performance[J]. Chemical Industry Progress, 2023, 42(12): 6490-6497(in Chinese).

[22] JI N Y, CHEN H, YU M M, et al. Synthesis of high oil-absorption resins of poly(methyl methacrylate-butyl methacrylate) by suspended emulsion polymerization[J]. Polymers for Advanced Technologies, 2011, 22(12): 1898-1904. DOI: 10.1002/pat.1689

[23] KISTLER S S. Coherent expanded aerogels and jellies[J]. Nature, 1931, 127: 741.

[24] WU L Q, YANG M, YAO L F, et al. Polyaminophosphoric acid-modified ion-imprinted chitosan aerogel with enhanced antimicrobial activity for selective La(III) recovery and oil/water separation[J]. ACS Applied Materials & Interfaces, 2022, 14(48): 53947-53959.

[25] GALLEGOS-CERDA S D, HERNÁNDEZ-VARELA J D, PÉREZ J J C, et al. Development of a low-cost photocatalytic aerogel based on cellulose, carbon nanotubes, and TiO2 nanoparticles for the degradation of organic dyes[J]. Carbohydrate Polymers, 2024, 324: 121476. DOI: 10.1016/j.carbpol.2023.121476

[26] 任培永, 陈淼, 赵科, 等. 超蓬松掺杂石墨烯气凝胶复合材料的制备及其吸波性能[J]. 复合材料学报, 2024, 41(10): 5375-5388. REN Peiyong, CHEN Miao, ZHAO Ke, et al. Preparation and wave-absorbing properties of ultra-fluffy doped graphene aerogel composites[J]. Acta Materiae Compositae Sinica, 2024, 41(10): 5375-5388(in Chinese).

[27] CHEN S W, HU Y H, GAO D F, et al. Superelastic bio-based polyimide aerogel with excellent oil/water separation performance and effective visible light photocatalytic activity[J]. Journal of Cleaner Production, 2023, 428: 139521. DOI: 10.1016/j.jclepro.2023.139521

[28] SHAO H L, ZHAO S, FEI Z F, et al. Unidirectional infiltrated PI/SiO2 composite aerogels with a confined reinforcing strategy for integrated thermal and acoustic insulation[J]. Composites Part B: Engineering, 2023, 266: 111002. DOI: 10.1016/j.compositesb.2023.111002

[29] HE Z W, WU H Q, SHI Z, et al. Mussel-inspired durable TiO2/PDA-based superhydrophobic paper with excellent self-cleaning, high chemical stability, and efficient oil/water separation properties[J]. Langmuir, 2022, 38(19): 6086-6098. DOI: 10.1021/acs.langmuir.2c00429

[30] BUCHTOVÁ N, BUDTOVA T. Cellulose aero-, cryo- and xerogels: Towards understanding of morphology control[J]. Cellulose, 2016, 23: 258-295.

[31] ZHANG J Y, CHENG Y H, TEBYETEKERWA M, et al. "Stiff-Soft" binary synergistic aerogels with superflexibility and high thermal insulation performance[J]. Advanced Functional Materials, 2019, 29(15): 1806407. DOI: 10.1002/adfm.201806407

[32] 林旭, 麦学妍, 王钧, 等. 各向异性纤维素纳米纤维/芳纶纳米纤维复合泡沫的制备与性能[J]. 复合材料学报, 2024, 41(6): 3037-3046. LIN Xu, MAI Xueyan, WANG Jun, et al. Preparation and properties of anisotropic cellulose nanofiber/aramid nanofiber composite foam[J]. Acta Materiae Compositae Sinica, 2024, 41(6): 3037-3046(in Chinese).

[33] ZHANG M L, JIANG S, LI M M, et al. Superior stable, hydrophobic and multifunctional nanocellulose hybrid aerogel via rapid UV induced in-situ polymerization[J]. Carbohydrate Polymers, 2022, 288: 119370. DOI: 10.1016/j.carbpol.2022.119370

[34] CIFTCI D, UBEYITOGULLARI A, HUERTA R R, et al. Lupin hull cellulose nanofiber aerogel preparation by supercritical CO2 and freeze drying[J]. The Journal of Supercritical Fluids, 2017, 127: 137-145. DOI: 10.1016/j.supflu.2017.04.002

[35] SLOSARCZYK A. Carbon fiber-silica aerogel composite with enhanced structural and mechanical properties based on water glass and ambient pressure drying[J]. Nanomaterials, 2021, 11(2): 258. DOI: 10.3390/nano11020258

[36] LI Y Z, GRISHKEWICH N, LIU L L, et al. Construction of functional cellulose aerogels via atmospheric drying chemically cross-linked and solvent exchanged cellulose nanofibrils[J]. Chemical Engineering Journal, 2019, 366: 531-538. DOI: 10.1016/j.cej.2019.02.111

[37] PENG X W, WU K Z, HU Y J, et al. A mechanically strong and sensitive CNT/rGO-CNF carbon aerogel for piezoresistive sensors[J]. Journal of Materials Chemistry A, 2018, 6(46): 23550-23559. DOI: 10.1039/C8TA09322A

[38] CHATTERJEE S, KE W T, LIAO Y C. Elastic nanocellulose/graphene aerogel with excellent shape retention and oil absorption selectivity[J]. Journal of the Taiwan Institute of Chemical Engineers, 2020, 111: 261-269. DOI: 10.1016/j.jtice.2020.04.020

[39] KE W K, GE F, SHI X L, et al. Superelastic and superflexible cellulose aerogels for thermal insulation and oil/water separation[J]. International Journal of Biological Macromolecules, 2024, 260: 129245. DOI: 10.1016/j.ijbiomac.2024.129245

[40] LIU T, CAI C C, MA R J, et al. Super-hydrophobic cellulose nanofiber air filter with highly efficient filtration and humidity resistance[J]. ACS Applied Materials & Interfaces, 2021, 13(20): 24032-24041.

[41] ZHANG X, ZHAO X Y, XUE T T, et al. Bidirectional anisotropic polyimide/bacterial cellulose aerogels by freeze-drying for super-thermal insulation[J]. Chemical Engineering Journal, 2020, 385: 123963. DOI: 10.1016/j.cej.2019.123963

[42] YANG X, CRANSTON E D . Chemically cross-linked cellulose nanocrystal aerogels with shape recovery and superabsorbent properties[J]. Chemistry of Materials, 2014, 26(20): 6016-6025. DOI: 10.1021/cm502873c

[43] CERVIN N T, AULIN C, LARSSON P T, et al. Ultra porous nanocellulose aerogels as separation medium for mixtures of oil/water liquids[J]. Cellulose, 2012, 19: 401-410. DOI: 10.1007/s10570-011-9629-5

[44] JIANG F, HSIEH Y L. Super water absorbing and shape memory nanocellulose aerogels from TEMPO-oxidized cellulose nanofibrils via cyclic freezing–thawing[J]. Journal of Materials Chemistry A, 2014, 2: 350-359. DOI: 10.1039/C3TA13629A

[45] JIMENEZ-SAELICES C, SEANTIER B, CATHALA B, et al. Spray freeze-dried nanofibrillated cellulose aerogels with thermal superinsulating properties[J]. Carbohydrate Polymers, 2017, 157: 105-113. DOI: 10.1016/j.carbpol.2016.09.068

[46] WU T T, ZENG Z H, SIQUEIRA G, et al. Dual-porous cellulose nanofibril aerogels via modular drying and cross-linking[J]. Nanoscale, 2020, 12: 7383-7394. DOI: 10.1039/D0NR00860E

[47] SEHAQUI H, ZHOU Q, BERGLUND L. High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC)[J]. Composites Science and Technology, 2011, 13(71): 1593-1599.

[48] ZU G Q, SHEN J, ZOU L P, et al. Nanocellulose-derived highly porous carbon aerogels for supercapacitors[J]. Carbon, 2016, 99: 203-211. DOI: 10.1016/j.carbon.2015.11.079

[49] ZHOU X M, FU Q G, LIU H, et al. Solvent-free nanoalumina loaded nanocellulose aerogel for efficient oil and organic solvent adsorption[J]. Journal of Colloid and Interface Science, 2021, 581: 299-306. DOI: 10.1016/j.jcis.2020.07.099

[50] ZHOU S K, LIU P P, WANG M, et al. Sustainable, reusable, and superhydrophobic aerogels from microfibrillated cellulose for highly effective oil/water separation[J]. ACS Sustainable Chemistry and Engineering, 2016, 4(12): 6409-6416. DOI: 10.1021/acssuschemeng.6b01075

[51] WANG J, ZHENG Y, WANG A. Coated kapok fiber for removal of spilled oil[J]. Marine Pollution Bulletin, 2013, 69(1-2): 91-96. DOI: 10.1016/j.marpolbul.2013.01.007

[52] CHEN Y M, ZHOU L J, CHEN L, et al. Anisotropic nanocellulose aerogels with ordered structures fabricated by directional freeze-drying for fast liquid transport[J]. Cellulose, 2019, 26(11): 6653-6667. DOI: 10.1007/s10570-019-02557-z

[53] HUO Y, LIU Y Y, YANG J, et al. Polydopamine-modified cellulose nanofibril composite aerogel: An effective dye adsorbent[J]. Langmuir, 2022, 38(14): 4164-4174. DOI: 10.1021/acs.langmuir.1c02483

[54] CHEN B Y, ZHANG H, LI L J, et al. Preparation of a PVA/CNF/ETOS elastic aerogel by directional freezing and its application in oil-water separation[J]. ACS Applied Polymer Materials, 2023, 5(5): 3554-3563. DOI: 10.1021/acsapm.3c00188

[55] DU X S, QIU J H, DENG S, et al. Alkylated nanofibrillated cellulose/carbon nanotubes aerogels supported form-stable phase change composites with improved n-alkanes loading capacity and thermal conductivity[J]. ACS Applied Materials & Interfaces, 2020, 12(5): 5695-5703.

[56] FAN B J, BAO X M, PAN S S, et al. High capillary effect and solar dual-drive nanofibrillated cellulose aerogels for efficient crude oil spill cleanup[J]. Chemical Engineering Journal, 2024, 480: 148149. DOI: 10.1016/j.cej.2023.148149

[57] FAN B J, PAN S S, BAO X M, et al. Highly elastic photothermal nanofibrillated cellulose aerogels for solar-assisted efficient cleanup of viscous oil spill[J]. International Journal of Biological Macromolecules, 2023, 256(Pt 1): 128327.

[58] ZHANG M L, JIANG S, HAN F Y, et al. Anisotropic cellulose nanofiber/chitosan aerogel with thermal management and oil absorption properties[J]. Carbohydrate Polymers, 2021, 264: 118033. DOI: 10.1016/j.carbpol.2021.118033

[59] LAITINEN O, SUOPAJÄRVI T, ÖSTERBERG M, et al. Hydrophobic superabsorbing aerogels from choline chloride-based deep eutectic solvent pretreated and silylated cellulose nanofibrils for selective oil removal[J]. ACS Applied Materials & Interfaces, 2017, 9(29): 25029-25037.

[60] YE R C, LI H S, LONG J Y, et al. Bio-aerogels derived from corn stalk and premna microphylla leaves as eco-friendly sorbents for oily water treatment: The role of microstructure in adsorption performance[J]. Journal of Cleaner Production, 2023, 403: 136720.

[61] LI X C, YANG Z H, PENG Y, et al. Self-powered aligned porous superhydrophobic sponge for selective and efficient absorption of highly viscous spilled oil[J]. Journal of Hazardous Materials, 2022, 435: 129018. DOI: 10.1016/j.jhazmat.2022.129018

[62] ZHANG J C, GUO W J, SHEN S Y, et al. High-compressive, elastic, and wearable cellulose nanofiber-based carbon aerogels for efficient electromagnetic interference shielding[J]. ACS Applied Materials & Interfaces, 2024, 16(13): 16612-16621.

[63] CHEN W, ZHANG Q, UETANI K, et al. Sustainable carbon aerogels derived from nanofibrillated cellulose as high-performance absorption materials[J]. Adcanced Materials Interfaces, 2016, 3(10): 1600004. DOI: 10.1002/admi.201600004

[64] DONG J R, ZENG J S, WANG B, et al. Mechanically flexible carbon aerogel with wavy layers and springboard elastic supporting structure for selective oil/organic solvent recovery[J]. ACS Applied Materials & Interfaces, 2021, 13(13): 15910-15924.

[65] ZHAN W, YU S, GAO L, et al. Bioinspired assembly of carbon nanotube into graphene aerogel with "Cabbagelike" hierarchical porous structure for highly efficient organic pollutants cleanup[J]. ACS Applied Materials & Interfaces, 2018, 10(1): 1093-1103.

[66] YIN X Y, WU J C, ZHAO H Y, et al. A microgel-structured cellulose nanofibril coating with robust antifouling performance for highly efficient oil/water and immiscible organic solvent separation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 20(647): 128875.

[67] FAN B J, WU L L, MING A X, et al. Highly compressible and hydrophobic nanofibrillated cellulose aerogels for cyclic oil/water separation[J]. International Journal of Biological Macromolecules, 2023, 3(242): 125066.

[68] QIAO A H, HUANG R L, PENKOVA A, et al. Superhydrophobic, elastic and anisotropic cellulose nanofiber aerogels for highly effective oil/water separation[J]. Separation and Purification Technology, 2022, 295: 121266. DOI: 10.1016/j.seppur.2022.121266

[69] TIAN N, WU S H, HAN G T, et al. Biomass-derived oriented neurovascular network-like superhydrophobic aerogel as robust and recyclable oil droplets captor for versatile oil/water separation[J]. Journal of Hazardous Materials, 2022, 424: 127393. DOI: 10.1016/j.jhazmat.2021.127393

[70] ZHOU S K, YOU T T, ZHANG X M, et al. Superhydrophobic cellulose nanofiber-assembled aerogels for highly efficient water-in-oil emulsions separation[J]. Applied Nano Materials, 2018, 1(5): 2095-2103. DOI: 10.1021/acsanm.8b00079

[71] SHANG Q Q, CHENG J W, HU L H, et al. Bio-inspired castor oil modified cellulose aerogels for oil recovery and emulsion separation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 636: 128043. DOI: 10.1016/j.colsurfa.2021.128043

[72] ZHANG J Y, CHENG Y H, XU C J, et al. Hierarchical interface engineering for advanced nanocellulosic hybrid aerogels with high compressibility and multifunctionality[J]. Advanced Functional Materials, 2021, 31(19): 2009349. DOI: 10.1002/adfm.202009349

[73] LIU Q Y, LIU Y Q, FENG Q, et al. Preparation of antifouling and highly hydrophobic cellulose nanofibers/alginate aerogels by bidirectional freeze-drying for water-oil separation in the ocean environment[J]. Journal of Hazardous Materials, 2023, 441: 129965. DOI: 10.1016/j.jhazmat.2022.129965

[74] SI R R, LUO H G, ZHANG T, et al. High hydrophobic ZIF-8@cellulose nanofibers/chitosan double network aerogel for oil adsorbent and oil/water separation [J]. International Journal of Biological Macromolecules, 2023, 238: 124008.

[75] ZHOU L J, XU Z Y. Ultralight, highly compressible, hydrophobic and anisotropic lamellar carbon aerogels from graphene/polyvinyl alcohol/cellulose nanofiber aerogel as oil removing absorbents[J]. Journal of Hazardous Materials, 2020, 388: 121804. DOI: 10.1016/j.jhazmat.2019.121804

[76] ZHU G, XU H, DUFRESNE A, et al. High-adsorption, self-extinguishing, thermal, and acoustic-resistance aerogels based on organic and inorganic waste valorization from cellulose nanocrystals and red mud[J]. ACS Sustainable Chemistry & Engineering, 2018, 6: 7168-7180. DOI: 10.1021/acssuschemeng.8b01244

[77] GU H B, ZHOU X M, LYU S Y, et al. Magnetic nanocellulose-magnetite aerogel for easy oil adsorption[J]. Journal of Colloid and Interface Science, 2020, 560: 849-856. DOI: 10.1016/j.jcis.2019.10.084

[78] XU Z Y, JIANG X D, ZHOU H, et al. Preparation of magnetic hydrophobic polyvinyl alcohol (PVA)–cellulose nanofiber (CNF) aerogels as effective oil absorbents[J]. Cellulose, 2018, 25(2): 1217-1227. DOI: 10.1007/s10570-017-1619-9

[79] TANG R, JIANG L Y, YAN J Y, et al. Preparation of magnetic hydrophobic polyvinyl alcohol (PVA)–cellulose nanofiber (CNF) aerogels as effective oil absorbents[J]. Separation and Purification Technology, 2024, 339: 126580. DOI: 10.1016/j.seppur.2024.126580

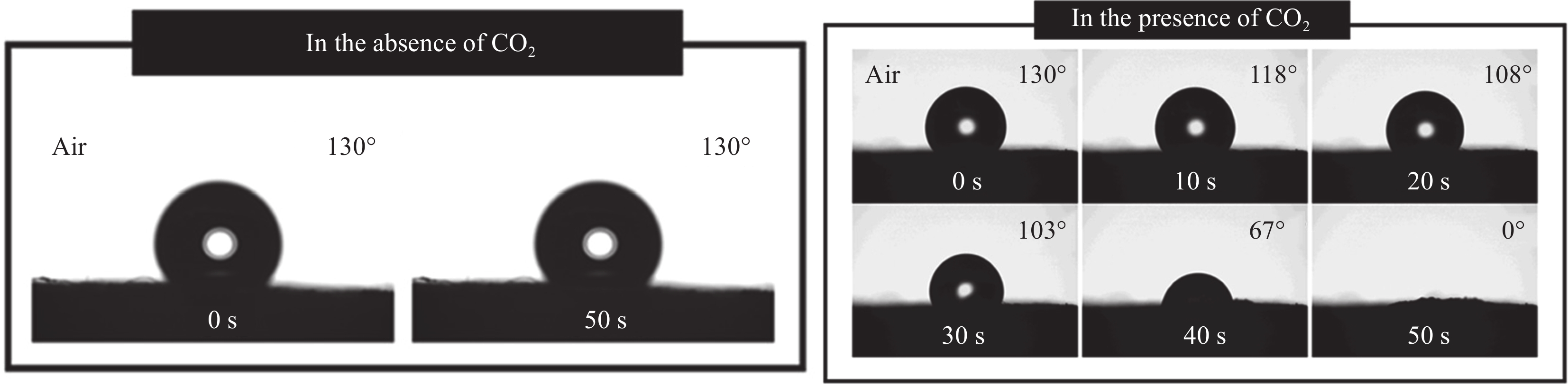

[80] LI Y Z, ZHU L Q, GRISHKEWICH N, et al. CO2-responsive cellulose nanofibers aerogels for switchable oil-water separation[J]. ACS Applied Materials & Interfaces, 2019, 11(9): 9367-9373.

[81] FAN B, PAN S, BAO X, et al. Highly elastic photothermal nanofibrillated cellulose aerogels for solar-assisted efficient cleanup of viscous oil spill[J]. International Journal of Biological Macromolecules, 2023, 256(Pt 1): 128327.

[82] WANG S X, ZENG J S, LI P F, et al. Rechargeable nanofibrillated cellulose aerogel with excellent biocidal properties for efficient oil/water separation[J]. Separation and Purification Technology, 2022, 301: 121955. DOI: 10.1016/j.seppur.2022.121955

-

目的

随着海上石油运输频率和海上油田数量的增加,石油泄漏事件频繁发生。大量的石油泄露对环境以及人类健康造成了极大的危害。与常规吸附材料相比纳米纤维素气凝胶具有高孔隙度、高比表面积和低密度等特点。同时,纳米纤维素具有高比表面积和长径比,其表面丰富的羟基功能基团易于表面修饰或与特定的功能材料复合制备出适用于油水分离领域的气凝胶。本文系统地综述了目前国内外应用于油水分离的纳米纤维素气凝胶研究进展情况。

方法通过归纳整理近年来国内相关文献,对目前用于油水分离的纳米纤维素气凝胶的研究现状进行了简述。总结了纳米纤维素气凝胶的制备和改性方法,并分析了不同制备和改性方法的优缺点;总结了纳米纤维素气凝胶的结构特点以及结构对其性能的影响;综述了纳米纤维素气凝胶在油和有机溶剂的吸附以及油水混合物分离中的应用。最后提出了纳米纤维素气凝胶存在的科学问题以及未来发展建议。

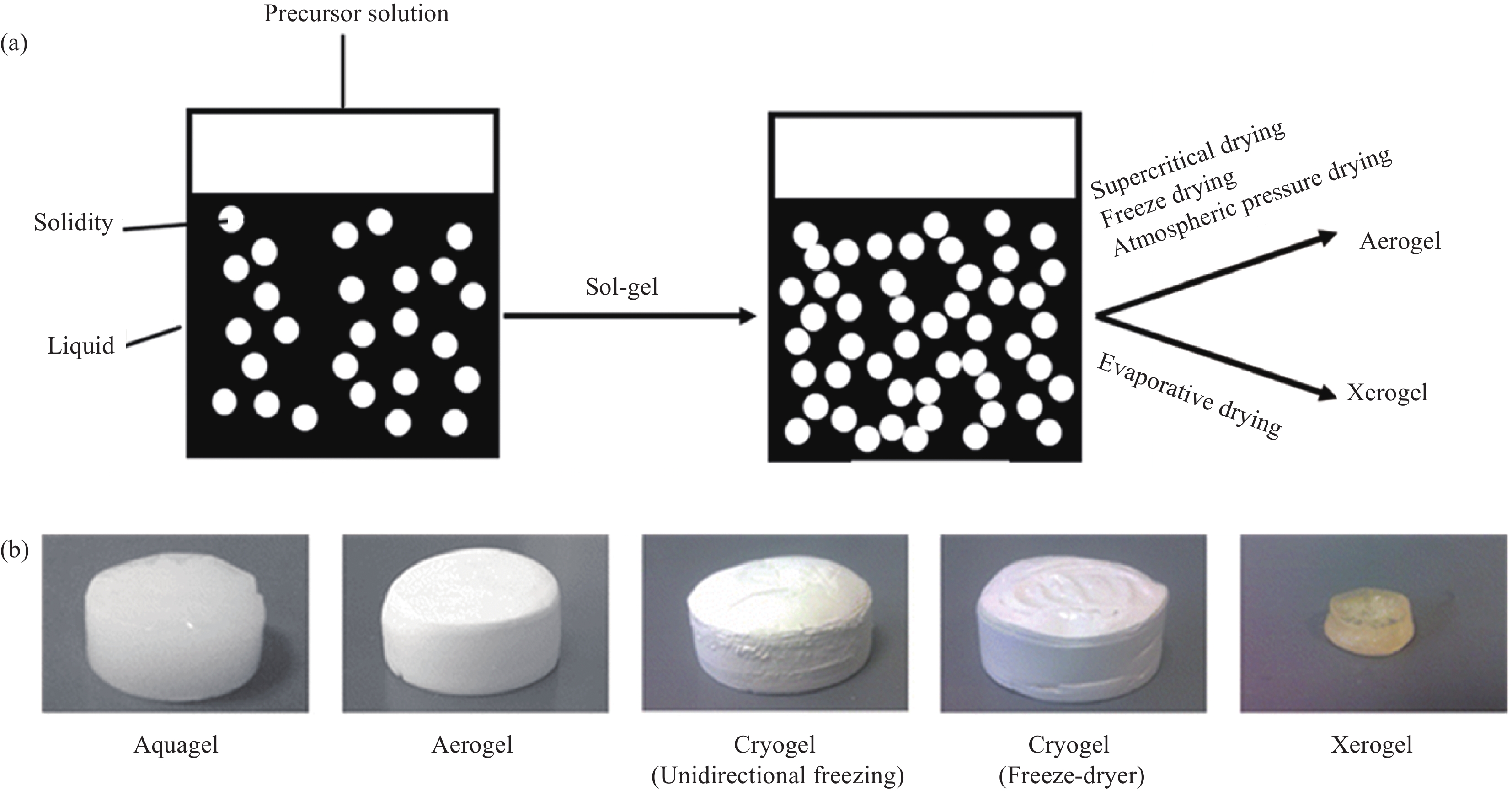

结果从现有研究可以看出,目前制备纳米纤维素气凝胶的步骤主要为将纳米纤维素前驱体转化为高度交联的凝胶后通过超临界干燥、冷冻干燥或常压干燥的方法制备成气凝胶。纳米纤维素具有易于修饰的特点,可通过浸涂法、化学气相沉积法和酸水解硅烷改性法对其进行疏水改性。纳米纤维素气凝胶可作为吸附剂吸附水面或水底的油,也可作为过滤材料分离油水混合物或者乳液,在油水分离领域中具有广泛的应用。除此之外,纳米纤维素气凝胶还可兼具其他性能,如阻燃性、磁性、智能响应性能、光热和抗菌性能等,拓宽了纳米纤维素气凝胶的应用范围。

结论纳米纤维素气凝胶独特的结构和优异的性能,使得其在油水分离领域已经取得一些进展。但仍有一些科学问题有待解决,如(1)纳米纤维素气凝胶的吸附机理有待进一步研究。(2)缺乏对纳米纤维素气凝胶结构和性能之间关系的系统性研究。此外,对优化纳米纤维素气凝胶的实际应用提出了三点建议(1)可将廉价的生物废弃物作为原材料提取纳米纤维素,改进纳米纤维素的制备和与处理工艺。(2)提升纳米纤维素气凝胶长期耐久性和抗污染能力。(3)开发功能性纳米纤维素气凝胶,拓宽其应用范围。

下载:

下载: