Progress in preparation and research of VO2-based composite structure films for smart windows

-

摘要:

二氧化钒(VO2)在68℃附近发生绝缘体-金属相转变,同时伴随着近红外光透射率突变,因此在智能节能窗领域具有巨大的应用潜力。近年来,关于 VO2的制备方法、相变机制及改善光学性能方面取得了显著进展。然而,在实际应用中,VO2仍面临一系列挑战,包括本征相变温度较高、可见光透过率(Tlum)较低、太阳能调节效率(∆Tsol)不佳、耐候性差及颜色舒适度较差(呈现棕黄色)。针对这些问题,国内外的研究者进行了大量研究,发现复合结构对改善VO2性能具有显著作用,对推进其实际应用具有重要意义。然而,目前关于VO2基复合结构的综述相对较少。本文概括了VO2基复合结构的制备方法及在智能窗领域的性能研究进展,并对VO2基复合结构薄膜未来发展前景进行了展望。

Abstract:Vanadium dioxide (VO2) exhibits an insulator-metal phase transition near 68℃, coupled with a sudden alteration in near-infrared light transmittance, rendering it highly promising for intelligent energy-saving windows. Despite extensive research in recent years on preparation methods, phase transition mechanisms, and enhancement of dimming capabilities for VO2, practical applications face numerous challenges. These include its high intrinsic phase transition temperature, low visible light transmittance (Tlum), inefficient regulation of solar energy (∆Tsol), poor weather resistance, and limited color comfort (brownish-yellow hue). Addressing these challenges, researchers worldwide have conducted extensive investigations, with composite structures emerging as a promising avenue for enhancing the overall performance of VO2 and advancing its practical applications. However, there remains a paucity of comprehensive reviews on VO2-based composite structures. This paper provides a synthesis and discussion of the preparation methods and performance research progress in the field of smart windows of VO2-based composite structures, while also exploring the future prospects of VO2-based composite structures.

-

Keywords:

- vanadium dioxide /

- thermochromism /

- smart windows /

- energy conservation /

- composite structure

-

防火技术的进步对工业工程和建筑行业的发展具有重要意义[1-4]。在火灾下,火源温度可以迅速传递到整个钢结构,钢材的强度和刚度随着温度上升而降低,在600℃以上可能导致结构失稳和倒塌,造成巨大经济损失和人员伤亡[5-7]。膨胀型钢结构防火涂料作为一种膨胀阻燃、装饰性好的防火材料,在遇到火源时迅速膨胀形成焦炭层,对基材提供有效防护[8]。目前广泛采用的膨胀阻燃体系(IFR)是酸源(如聚磷酸铵(APP))、碳源(如季戊四醇(PER))、气源(如三聚氰胺(MEL))的组合物[9]。然而,该膨胀型防火涂料主要由有机树脂和阻燃剂构成,一般在800℃以上难以长时间稳定存在,遇火逐渐分解,失去防护效果。研究表明,添加无机填料可以填补涂层空隙,有利于致密膨胀炭层的形成,抑制热量传递,增强涂层的耐火极限和隔热性能[10]。

粉煤灰(FA)是火电厂燃煤后产生的废弃物,每年全球大约生产500万吨,而仅有16%被回收利用,这导致大量FA被浪费,且带来处理问题[11]。在“双碳”政策的引领下,资源的再利用和循环利用被重视,FA在防火阻燃材料中的应用越来越广泛。如Batistella等[12]考察了FA在聚乳酸阻燃体系中的增效作用,结果显示其可取代25%的聚磷酸铵并降低了聚乳酸阻燃体系的燃烧热值。Kim等[11]制备了碳化处理的FA,通过气化火焰实验得出,有效增强有机硅复合材料的防火性能和力学性能。Zhou等[13]制备了焦磷酸哌嗪/氢氧化镁/粉煤灰空心球复合材料,并将其掺杂于聚氨酯泡沫中,燃烧等级测试结果显示其有效提升了聚氨酯泡沫的阻燃性能。然而,其在防火阻燃体系(特别是膨胀型防火涂料)中的分散性、相容性是影响防火涂层隔热性能的关键因素。

壳聚糖(CS)作为一种来源于甲壳类动物外壳的天然高分子,在生物医药、食品添加剂、涂层材料等领域得到广泛应用,这归因于其优异的生物相容性和独特的化学修饰功能。Yu等[14]通过制备CS/聚磷酸三聚氰胺/钼磷铵共混的多功能阻燃涂料,CS的添加在涂料中成功形成密集交联的网络结构,提高了聚合物涂层的相容性。常娟等[15]通过CS改性硫铁矿(FeS)制备了FeS/CS基气凝胶复合材料,结果显示CS对FeS分散性有良好的促进作用。范佳璇等[16]制备了CS/植酸静电纺涂层阻燃棉织物,结果显示CS可以增强涂层的阻燃性能,主要归因于在燃烧过程中CS可以参与成炭和阻燃。王娜等[17]进一步总结了CS基阻燃剂的制备及其在防火涂层中应用,结果表明相比纯环氧防火涂层,CS基阻燃剂防火涂料在500℃下残炭量提高47%,氧指数值可达25.5%。

本实验以FA和CS为原料,制备了FA-CS复合阻燃填料,并将其引入水性膨胀型防火涂料体系中,以强化涂层的耐火极限和隔热性能。通过FTIR和SEM表征复合阻燃填料的成分组成和微观形貌,表明FA-CS复合阻燃填料的成功制备。SEM观察了涂层膨胀层表面形貌,结果显示相比其他涂层,FA-CS/水性膨胀体系(WIS)涂层具有更致密光滑的表面,通过大板实验可以看出,FA-CS复合阻燃填料有效提升了膨胀涂层的耐火性能。资源再利用为水性膨胀型防火涂料的原料来源和性能提升提供了新思路。

1. 实验部分

1.1 原材料

冰醋酸,AR,采购于国药集团化学试剂有限公司;壳聚糖(CS),采购于上海麦克林生化科技有限公司;粉煤灰(FA)由湖南兰驰粉体输送设备有限公司提供;多聚磷酸铵(APP)、季戊四醇(PER)和三聚氰胺(MEL)购于天津奥洛奇化工科技有限公司;水性丙烯酸乳液(WA)由武汉市瑞元诚新材料有限公司提供。

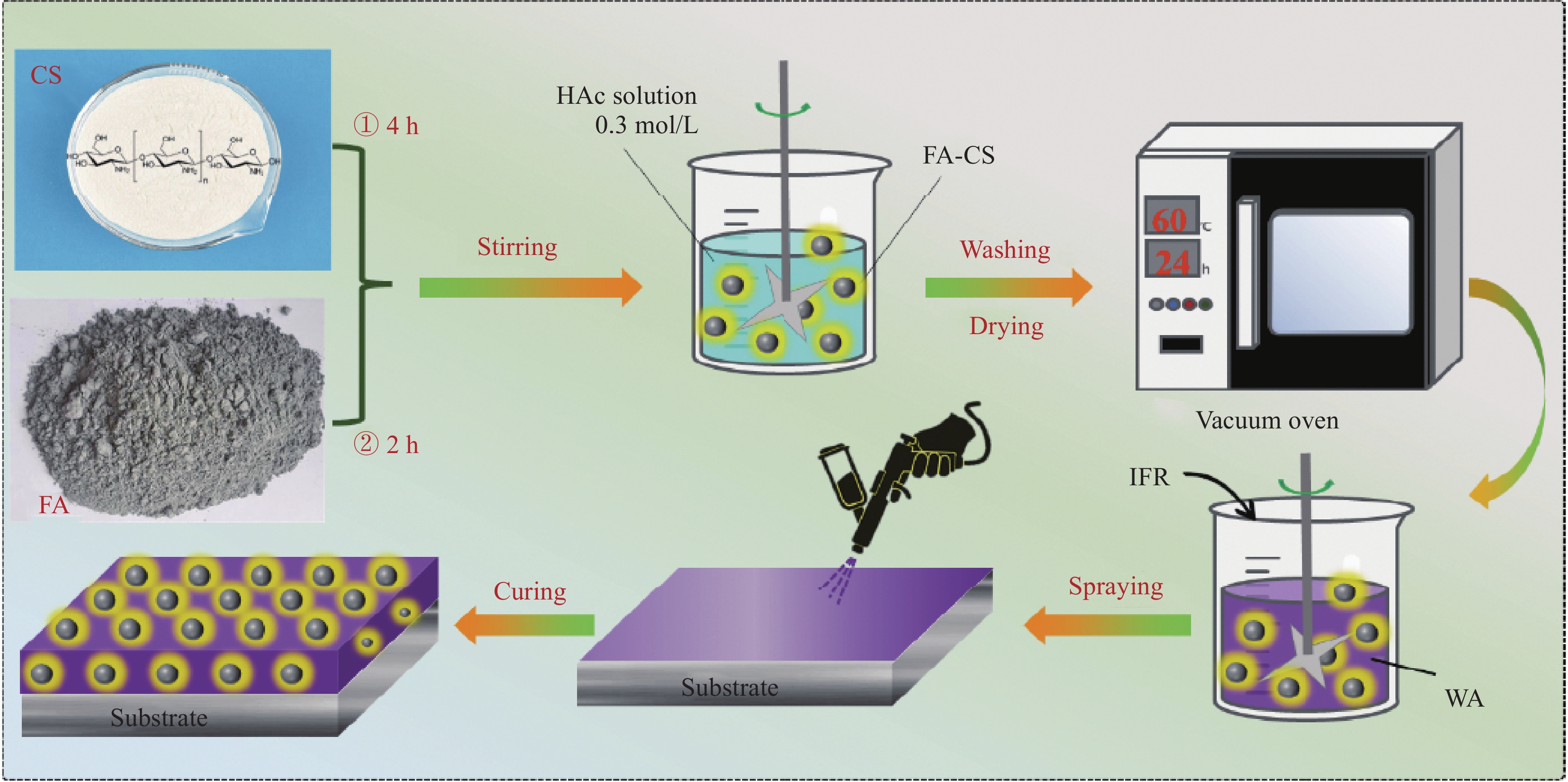

1.2 FA-CS改性水性膨胀型防火涂层的制备

取冰醋酸3.45 mL,配制0.3 mol/L的冰醋酸溶液200 mL于烧杯,将2 g CS添加于烧杯中,在

2000 r/min下搅拌4 h,使CS充分溶解。再将4 g FA添加于持续搅拌的溶液中,将搅拌速率调整为2500 r/min,混合搅拌2 h,对混合液进行离心,并用去离子水洗涤3次,在60℃的烘箱(DZ-1BC1V,泰斯特)中持续干燥24 h,获得FA-CS复合阻燃填料。取40 g水性丙烯酸乳液于烧杯中,将52 g膨胀阻燃体系(APP∶PER∶MEL质量比为2∶1∶1)添加于烧杯中,在

1000 r/min的速率下分散搅拌40 min,得到水性膨胀体系(WIS)。然后将制备的FA-CS复合阻燃填料5 g分散在混合液中,在3000 r/min搅拌20 min,在搅拌过程中补充3 g水,得到较均一的水性膨胀型防火涂料。将涂料采用喷涂的方式涂装于Q235基材表面,每次涂装厚度为600 μm,固化1 d,反复涂装,至涂层厚度(3.0±0.1) mm,室温下养护7 d,得到FA-CS改性的水性膨胀型防火涂层(FA-CS/WIS)。为了进行比较,采用类似的技术制备了FA和CS基复合涂层,分别命为FA/WIS和CS/WIS。水性膨胀型防火涂层的制备路线如图1所示,组成比例见表1。表 1 水性膨胀型防火涂层的组成比例(wt%)Table 1. Composition ratio of water-based intumescent flame-retardant coatings (wt%)Coating WA APP PER MEL FA CS FA-CS H2O WIS 45 26 13 13 – – – 3 FA/WIS 40 26 13 13 5 – – 3 CS/WIS 40 26 13 13 – 5 – 3 FA-CS/WIS 40 26 13 13 – – 5 3 Notes: APP—Ammonium polyphosphate; PER—Pentaerythritol; MEL—Melamine; WIS—Waterborne intumescent system. 1.3 表征

采用傅里叶变换红外光谱仪(FTIR,Nicolet iS10,Thermofisher Scienticfic)对FA-CS复合阻燃填料进行官能团表征,测试的波长范围为500~

4000 cm−1。通过电子扫描显微镜(SEM,JSM-6510LV,JEOL)观察了FA-CS复合阻燃填料的表面形貌并分析其元素组成。运用X射线衍射仪(XRD,SmartLab SE,Rigaku)对FA、CS和FA-CS的组织结构进行了对比分析,其扫描速率20°/min,2θ的测试范围为5°~90°。采用SEM进一步观察水性膨胀型防火涂层的表面状态和微观形貌,观察防火涂层膨胀后的微观组织和致密程度。采用高精度多通道热电偶测温仪(TA612C,TASI)对基材的背面温度进行了记录。1.4 水性膨胀型防火涂层耐火性能

大板实验是将涂层涂敷于钢板观察涂层燃烧过程中涂层形态变化和背面温度变化研究涂层材料耐火极限和隔热性能的重要方法。使用煤气喷枪为火源,燃烧过程中喷嘴与涂层之间的距离固定为80 mm,使外焰燃烧涂层,外焰温度维持在

(1000 ±50)℃。测量钢板的厚度为d0,涂覆水性膨胀型防火涂层后的干燥涂层样板厚度为d1,燃烧60 min后涂层膨胀后的涂层样板厚度为d2,结果精确到0.1 mm。通过记录背面温度的实时数据,绘制背面温度随时间的变化曲线。涂层的膨胀倍率由下式计算:Em=d2−d0d1−d0×100% (1) 2. 结果与讨论

2.1 FA-CS复合阻燃填料的表征

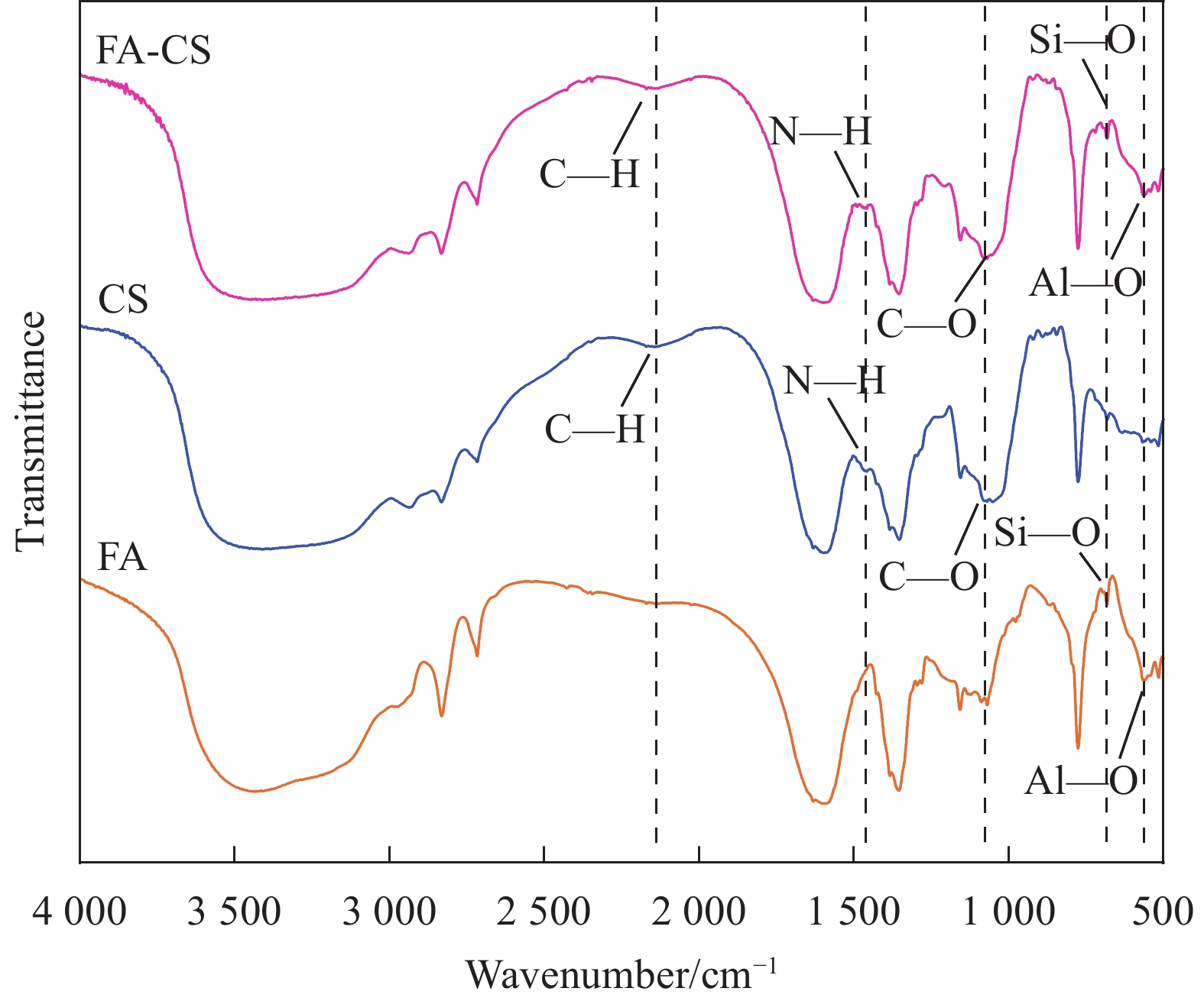

采用FTIR对FA、CS和FA-CS复合阻燃填料的官能团进行了表征,如图2所示。798 cm−1处的吸收峰归结于FA中Si—O键的拉伸振动,684 cm−1处的吸收峰对应于Si—O键的弯曲振动,520 cm−1处的吸收峰是由Al—O弯曲振动引起的[18]。CS在

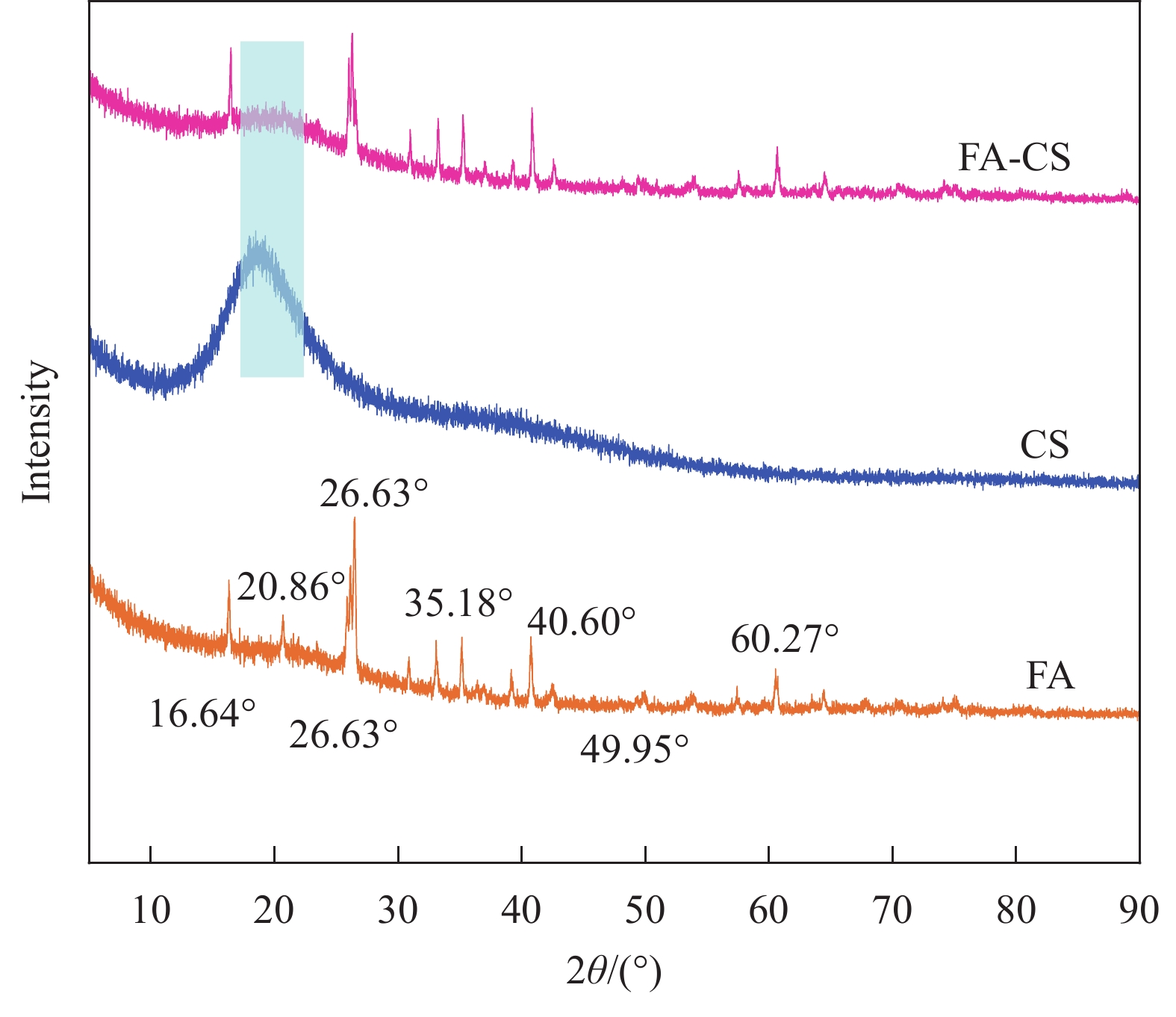

3433 、2140 、1426 和1083 cm−1处的特征峰分别归因于O—H拉伸振动、C—H拉伸振动、N—H弯曲振动和C—O拉伸振动[19]。FA-CS的特征峰与FA和CS完全对应,这表明FA-CS复合材料的成功制备。采用XRD对FA、CS和FA-CS复合阻燃填料的结构进行了表征,如图3所示。FA的晶体结构与石英和莫来石晶相的标准PDF卡一致(JCPDS 46-1045为二氧化硅,JCPDS 15-0776为硅铝氧化物),其中20.86°、26.63°、35.18°、40.60°和60.27°分别对应二氧化硅的(100)、(101)、(110)、(111)和(121)晶面的衍射峰,其主要晶相为石英相;16.64°、26.63°和49.95°分别对应硅酸铝莫来石的衍射峰[20]。CS的唯一衍射峰出现在2θ=18.98°处,对应于CS的特征峰,归因于分子间相互作用而排列的聚合物链为无定型结构[21]。在FA-CS复合材料中,可以清晰地观察到FA的强烈衍射峰和CS的微弱衍射峰(图中阴影部位标记),这表明两者良好复合及晶体和非晶体衍射峰的强度存在差异性。

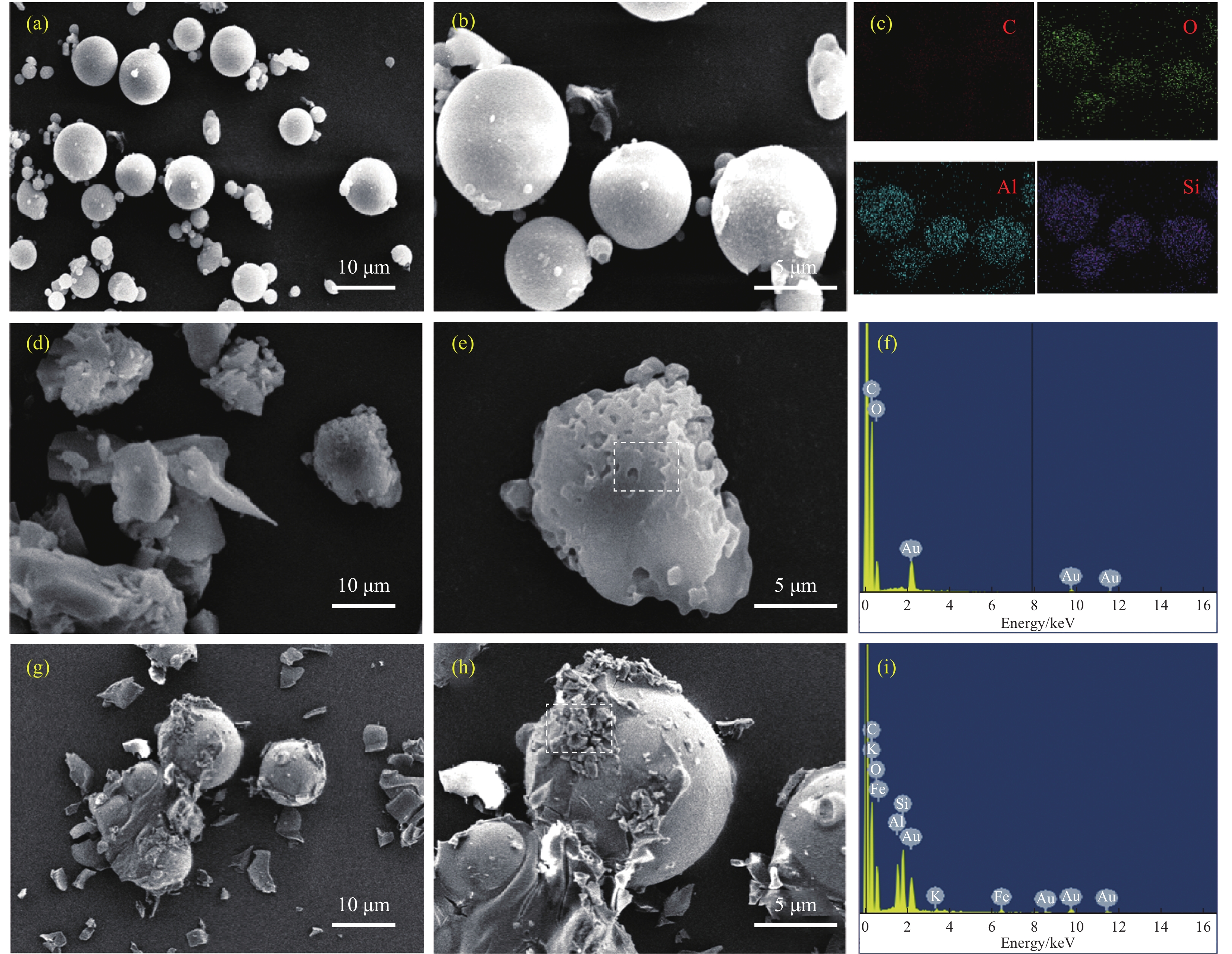

采用SEM对FA、CS和FA-CS复合阻燃填料的微观形貌和元素组成表征分析,如图4所示。图4(a)、图4(b)显示了FA的微观形貌,可以看出,FA呈现球状,微球直径大约5 μm,图4(c)显示了其元素组成,主要有O、Si、Al等元素,C元素几乎没有。图4(d)~4(f)显示了CS的微观状态和元素组成,CS主要表现为无规则形状,所含元素主要为C和O。图4(g)~4(i)对FA-CS复合阻燃填料进行了观察,可以看出,FA微球表面被CS附着,这有利于改善FA在乳液中的相容性。EDS元素分析可以看出复合填料包含了FA和CS的元素,证明复合材料的成功制备。

![]() 图 4 ((a)~(c)) FA的SEM图像及其放大图和Mapping图;((d)~(f)) CS的SEM图像及其放大图和EDS图;((g)~(i)) FA-CS复合阻燃填料的SEM图像及其放大图和EDS图Figure 4. ((a)-(c)) SEM images of FA, its magnification and mapping; ((d)-(f)) SEM images of CS, its magnification and EDS; ((g)-(i)) SEM images of FA-CS composite flame-retardant filler, its magnification and EDS

图 4 ((a)~(c)) FA的SEM图像及其放大图和Mapping图;((d)~(f)) CS的SEM图像及其放大图和EDS图;((g)~(i)) FA-CS复合阻燃填料的SEM图像及其放大图和EDS图Figure 4. ((a)-(c)) SEM images of FA, its magnification and mapping; ((d)-(f)) SEM images of CS, its magnification and EDS; ((g)-(i)) SEM images of FA-CS composite flame-retardant filler, its magnification and EDS2.2 涂层表面分析

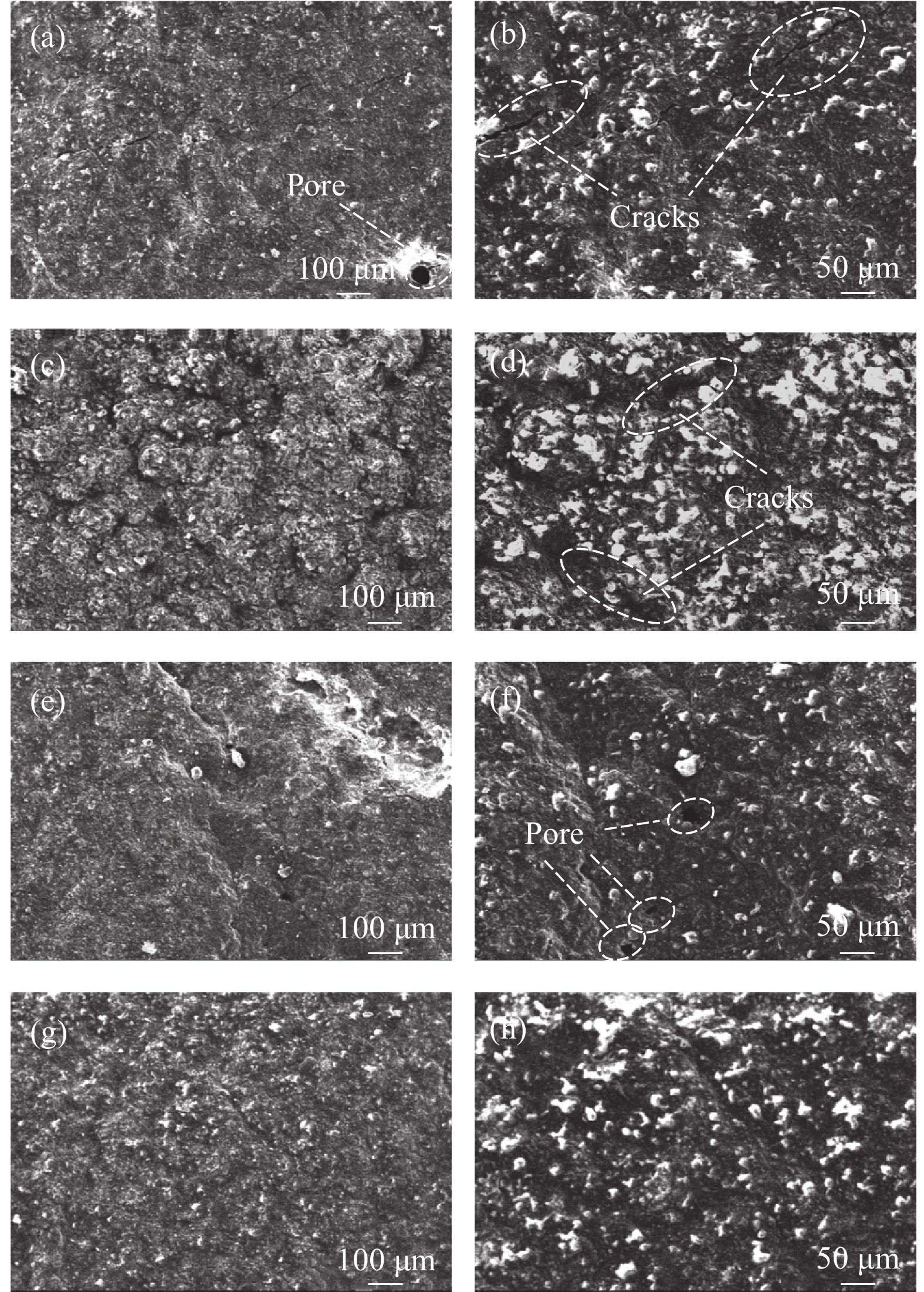

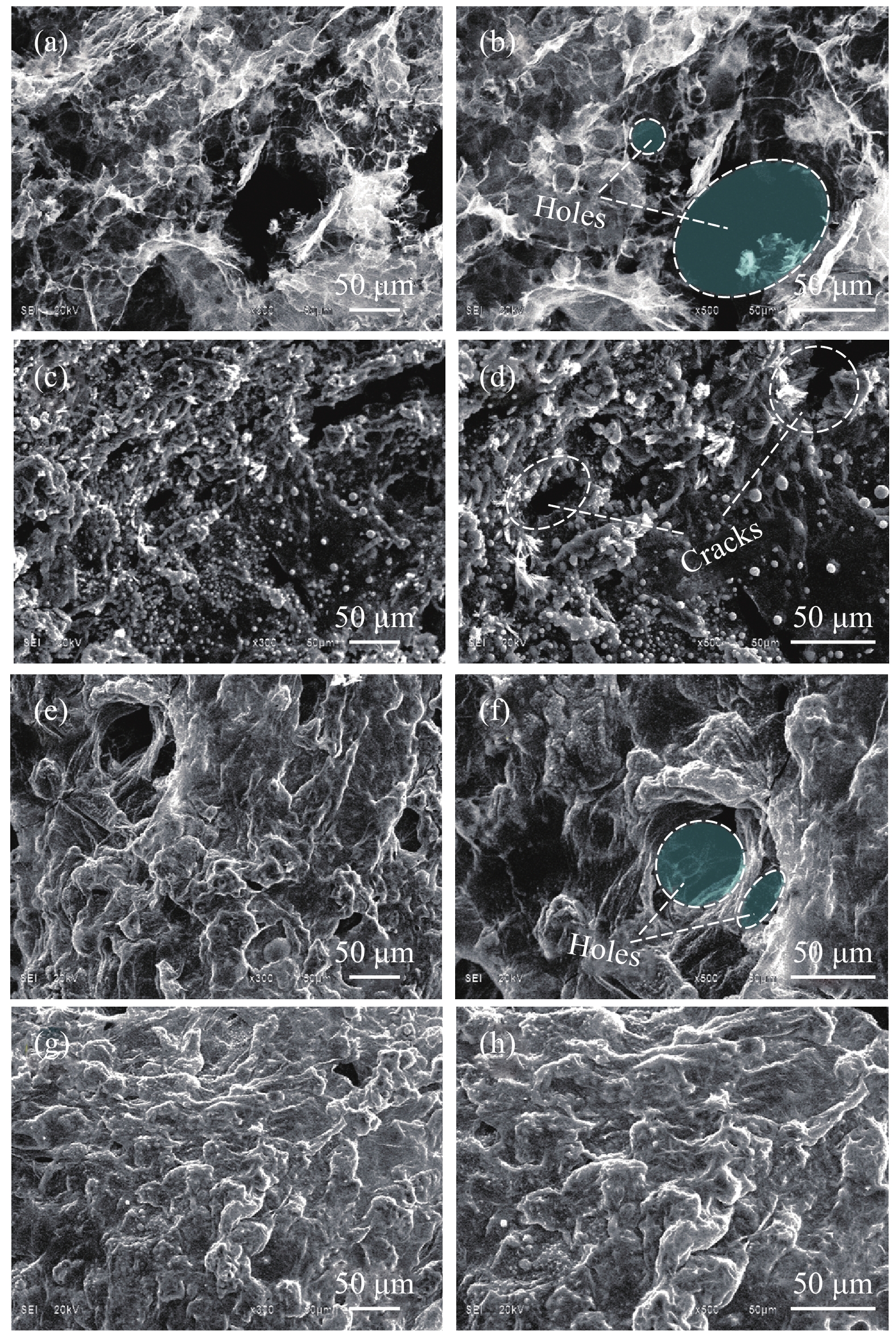

采用SEM对固化的WIS、FA/WIS、CS/WIS、FA-CS/WIS涂层进行了观察,如图5所示。从图5(a)、图5(b)可以看出,WIS涂层的表面较光滑,但存在明显的裂纹和孔隙,这为火焰冲刷提供了通道,不利于阻隔热量的侵入和渗透。FA/WIS涂层表面粗糙不平(图5(c)、图5(d)),存在凹陷和裂纹,这难以阻止热量向涂层内部传递,抑制基材温度的上升。如图5(e)、图5(f)所示,CS/WIS涂层相比FA/WIS的表面更加光滑,这主要归因于CS具有优异的相容性,改善了树脂与阻燃填料间的界面,减少了涂层裂纹的产生,但是无法避免涂层中仍然存在许多孔隙,这主要归因于CS通常以聚合物链存在,难以提高填补空隙能力[22]。相比之下,FA-CS/WIS表面则未出现明显的裂纹和孔隙(图5(g)、图5(h)),这归结于CS对FA相容性的提升,改善了FA在WIS中的分散性和成膜性能,同时FA填补了涂层中的孔隙,获得表面致密光滑的防火涂层,可有效抑制和阻隔涂层热量、火焰的冲刷,为延长涂层的耐火极限和提升阻燃能力提供了良好的保障。

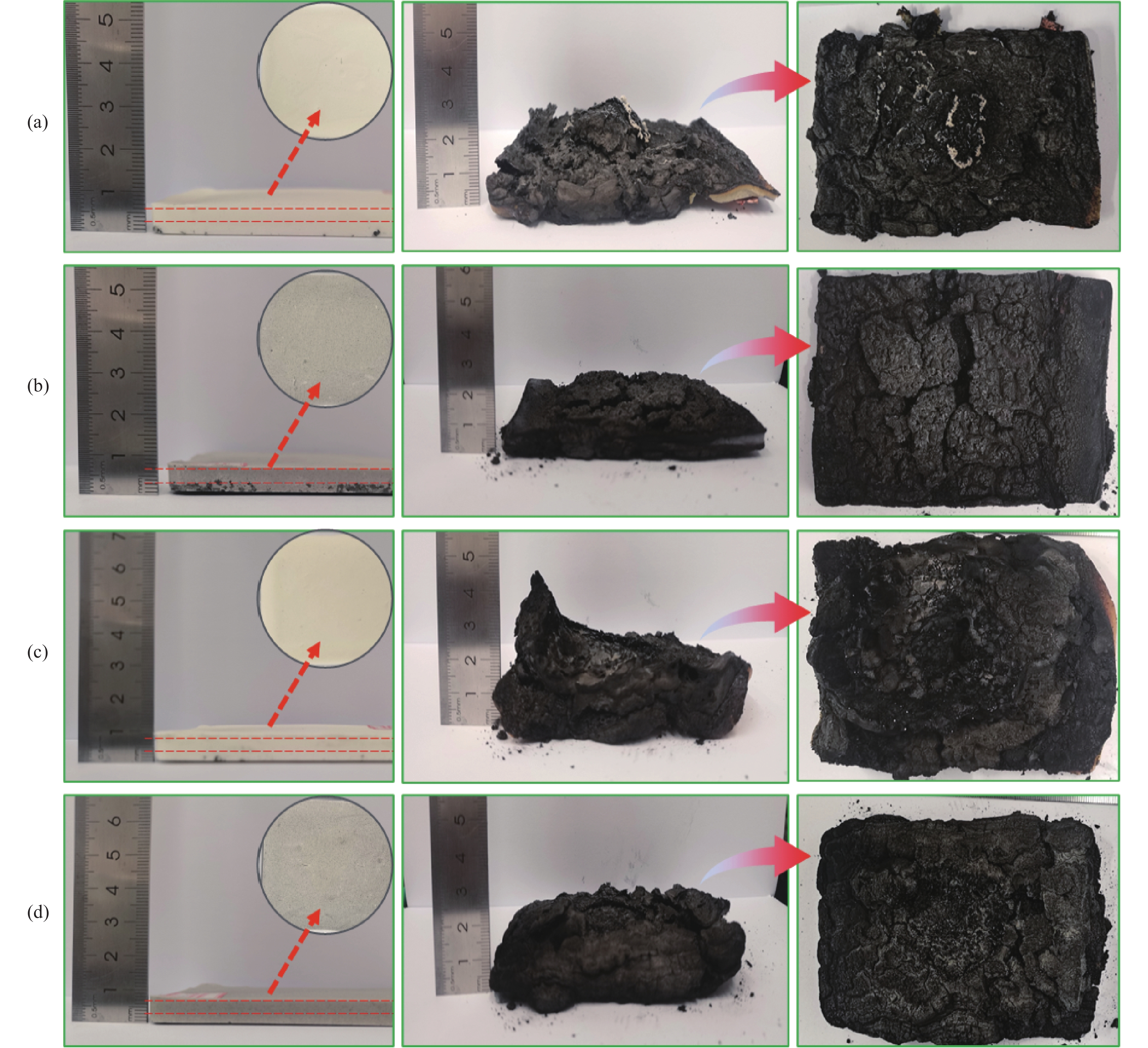

2.3 水性膨胀型防火涂层耐火性能研究

通过大板实验对各水性膨胀型防火涂层的耐火性能进行考察,WIS、FA/WIS、CS/WIS、FA-CS/WIS燃烧前后的截面、表面照片如图6所示。从图6(a)可以观察出,WIS涂层燃烧前的样品厚度为6.0 mm,其中钢板为3.0 mm,涂层表面较光滑,涂层在煤气喷枪火焰中燃烧35 min的过程中,涂层快速膨胀,膨胀高度为28.0 mm,涂层出现了大量裂纹,这为火焰和热量快速渗入基材提供了路径通道。如图6(b)所示,FA/WIS涂层在火焰中燃烧60 min,涂层样片的厚度由6.2 mm膨胀到了27.5 mm,这表明FA的添加使涂层的膨胀性能有所降低,但FA作为具有优异耐温性能的无机填料,可以延长涂层的耐火时间,初始涂层WIS只能耐火35 min,而FA/WIS的耐温时间提升到了60 min。但是从表面状态可以观察出,FA的存在让涂层在后期产生了裂纹。CS/WIS涂层则表现出完全不同的现象,CS/WIS涂层在燃烧过程中从6.1 mm膨胀到45.3 mm,其膨胀倍率约为13.6倍,表现出极高的膨胀性能(图6(c))。这归因于添加的CS中大量的羟基基团参与了成炭反应,为涂层提供了更高的膨胀倍率,这为涂层良好的阻隔热量提供了基础。然而,CS作为高分子,在火焰的长期灼烧下,燃烧60 min后,涂层中间出现了空洞,这表明膨胀层逐渐炭化分解[23],膨胀层在变薄,这导致基材将进一步受到火焰和热量的渗透。相比之下,将CS和FA复合的阻燃填料添加到阻燃体系中得到的FA-CS/WIS涂层(图6(d))则表现出更好的耐温性能和较优的膨胀性能,其膨胀高度为33.5 mm (膨胀倍率为10.2倍),膨胀层的表面状态也更加完整致密,这归因于两者的协同作用。

此外,在燃烧过程中,各涂层钢板的背面温度变化如图7所示。对于涂覆WIS涂层的钢板,其背面温度普遍高于其他涂层,在燃烧25 min后其背面温度迅速上升,在35 min时涂层的背面温度上升至496℃,难以抵抗火焰的长期烧蚀,这与涂层的膨胀体系不耐温而快速分解有关系。FA/WIS涂层的耐温性能优于WIS涂层,这主要归因于FA微球对火焰和热量有一定的阻隔作用,但是涂层的膨胀性能有所抑制。从图中可以看出,相比于WIS和FA/WIS涂层,CS/WIS涂层在前期具有优异的耐温性能,这归因于CS参与了成炭反应,促进了炭化层的生成,增加了涂层的膨胀倍率。但随着时间的延长,膨胀层逐渐分解,涂层的耐温性能下降,在燃烧40 min后,背面温度快速上升。相比之下,FA-CS/WIS涂层则表现出更加优异的耐温性能,在燃烧60 min后,涂层的背面温度仅为279℃,低于其他涂层,这归结于FA的隔热性能和CS对涂层膨胀性能的提升。

2.4 膨胀炭化层分析

不同涂层燃烧后膨胀层的SEM图像如图8所示。从图8(a)、图8(b)中可以看出,WIS涂层的膨胀层出现了大面积的孔洞,这主要归结于WIS涂层由丙烯酸乳液和三元阻燃体系组成,在高温下快速分解消失,形成了让火焰和热量快速侵入通道,难以抑制火焰的长时间渗透。图8(c)、图8(d)为FA/WIS涂层的膨胀层微观形貌,可以观察到,膨胀层内部有大量的FA微球存在,这些微球为基材和涂层提供了良好的热量阻隔作用,抑制了部分火焰和热量对涂层的灼烧,但是仍然产生了大量的裂纹,这归结于涂层中不耐燃易分解的成分在火焰下的消失[24-25]。CS/WIS涂层在长期燃烧后,涂层也出现了孔洞(图8(e)、图8(f)),但相比WIS涂层的孔洞有所改善,这归结于CS的添加增强了涂层膨胀层的成炭反应,抑制了部分热量传递于内部涂层和基材,为延长耐火极限提供可能。相比之下,FA-CS/WIS涂层在FA和CS的协同作用下,膨胀层具有较致密的表面,未出现大面积的孔洞和裂纹(图8(g)、图8(h)),这主要由于FA为涂层和基材提供了优异的隔热性能,CS增加了涂层的膨胀性能,从而大大减缓了热量向涂层内部渗透作用,改善膨胀层致密性,延长了涂层在火焰下的耐火能力。

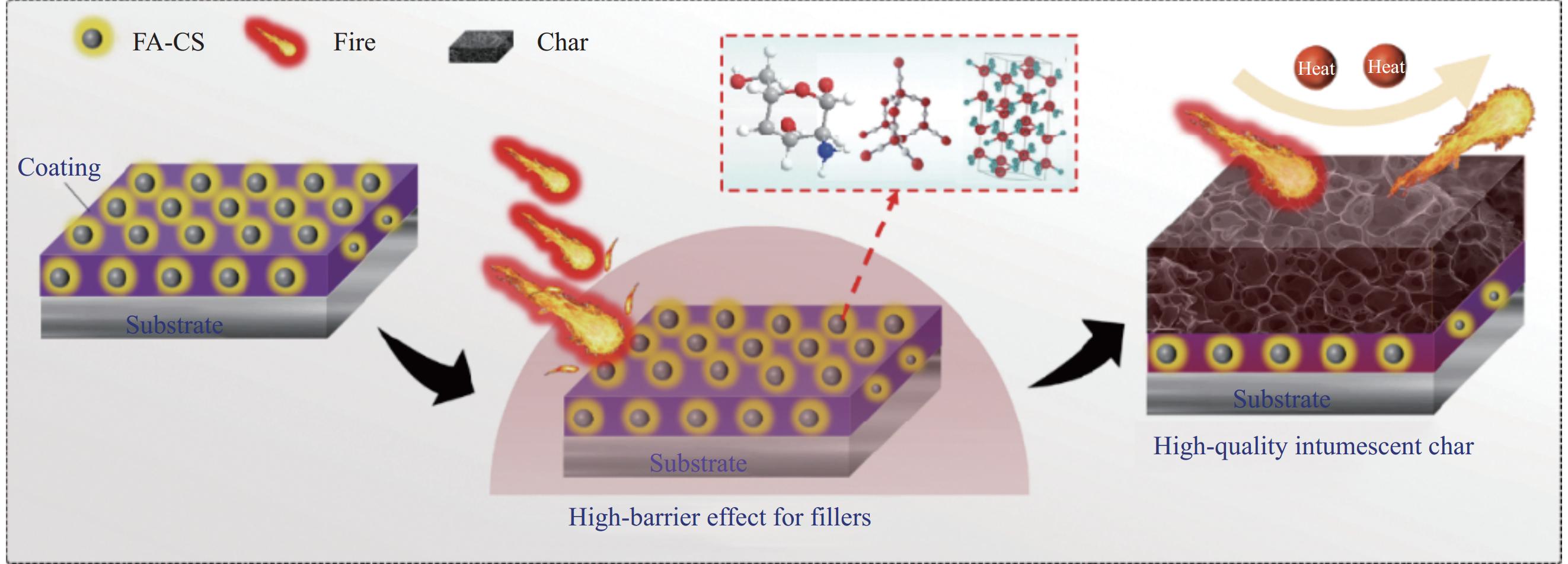

2.5 FA-CS/WIS涂层的防火隔热机制

FA-CS/WIS涂层的防火隔热机制如图9所示。在燃烧初期,FA-CS复合填料填补了涂层网络结构中的孔隙,减少了外部热量向涂层内部的扩散路径,对火焰和热量的侵入有良好的阻隔作用[26]。CS在涂层中增加了FA在WIS中的相容性,为其形成致密的涂层表面奠定了基础。随着温度上升,体系中的聚磷酸铵、三聚氰胺和季戊四醇组成的三元阻燃体系开始发生酸化、气化等反应,逐渐形成膨胀层。CS与季戊四醇和环糊精一样具有多羟基结构,在燃烧过程中促进焦炭的形成[27]。因此,CS在高温火焰下燃烧脱水分解并逐步炭化,参与膨胀层的成炭反应,促进了膨胀倍率的提升[28]。此外,具有优异耐热性能的FA则在燃烧后的残炭中首先作为耐温材料,抑制涂层在火焰下的分解和破坏,其次作为微球可以填补膨胀层的孔隙,形成了高质量的膨胀炭化层,阻隔热量和火焰的渗透,提升膨胀层的热稳定性和耐火时间。总之,FA和CS的协同作用,有效地提高了WIS涂层的隔热和保温效果,使FA-CS/WIS涂层对基材耐火能力的提升明显优于其他涂层。

3. 结 论

(1)以粉煤灰(FA)、壳聚糖(CS)等废弃物为原料制备了FA-CS复合材料,并将其添加于水性丙烯酸乳液中,辅以膨胀阻燃体系,发展了一种水性膨胀型防火涂料,涂层的膨胀倍率高(10.2倍),其涂覆的钢板在燃烧 60 min 时背面温度为279℃。

(2)通过SEM对涂层及膨胀层表面形貌进行观察,发现水性膨胀体系(WIS)、FA/WIS、CS/WIS涂层表面存在大量孔隙和裂纹。而FA-CS/WIS涂层具有更致密光滑的表面,有效阻隔热量传递和火焰冲刷,提升了涂层耐火性能。

(3) FA-CS/WIS涂层具有优异的隔热耐火性能,这主要归结于:CS改善了FA在WIS中的分散性和成膜性能,同时FA填补了涂层中的孔隙;FA具有良好的隔热性能,为涂层提供了物理屏障;在火焰冲刷涂层过程中,CS参与成炭反应,提升了涂层的膨胀倍率,增强了涂层的膨胀和防火性能。

-

图 2 ((a), (b)) VO2纳米颗粒[18-19];((c), (d))无机壳层结构[24];((e), (f))有机壳层结构[32];((g), (h))无机-有机壳层结构[33]

DA—Dopamine; PDA—Polydopamine; PET—Polyethylene terephthalate; PVB—Polyvinyl butyral

Figure 2. ((a), (b)) Nanocomposite particle[18-19]; ((c), (d)) Inorganic shell structure[24]; ((e), (f)) Organic shell structure[32]; ((g), (h)) Inorganic-organic shell structure[33]

图 4 (a) SiO2@TiO2@VO2三层空心纳米球结构[48];(b) VO2@SiO2双层空心核壳结构[49];(c) VO2-Mg1.5VO4多孔结构[50]

VS1-VS4—VO2@SiO2 bivalve particles prepared by reaction of vanadium dioxide precursor solution at 60℃ for 1-4 h

Figure 4. (a) SiO2@TiO2@VO2 three-layer hollow nanospheres[48]; (b) VO2@SiO2 double layer hollow core-shell structure[49]; (c) VO2-Mg1.5VO4 porous structure[50]

图 5 (a) Cr2O3-VO2缓冲层结构[70];(b) VO2-TiO2减反射结构[74];(c) 空心SiO2-VO2-FSiO2-聚合物多功能结构[80];(d) VO2-HfO2多功能结构[81]

Figure 5. (a) Cr2O3-VO2 buffer layer structure[70]; (b) VO2-TiO2 antireflection structure[74]; (c) Hollow SiO2-VO2-FSiO2-polymer multi-function structure[80]; (d) VO2-HfO2 multi-function structure[81]

表 1 VO2核壳结构复合薄膜的光学性能

Table 1 Optical properties of VO2 core-shell composite thin films

Structure Tlum/% ∆Tsol/% Tc/℃ Ref. VO2@SiO2 38.0 18.9 — Du et al[30] VO2@ZnO 51.0 19.1 — Chen et al[27] VO2@SiO2 50.6 14.7 25.2 Zhu et al[34] VO2@TiO2 59.3 6.2 — Li et al[28] VO2@PDA 56.3 14.5 33.8 Guo et al[32] VO2@PMMA — 17.5 57 Hu et al[35] VO2@Polymer — 20.34 — Zhao et al[36] VO2@MgF2@PDA — 25.0 — Zhao et al[33] Notes:Tlum—Luminous transmittance; ∆Tsol—Modulation of solar energy; Tc—Transition temperature; A@B—Core(A)@shell(B) structure; PMMA—Polymethyl methacrylate. 表 2 不同基质材料VO2基复合薄膜的光学性能

Table 2 Optical properties of VO2-based composite films of different matrix materials

Structure Tlum/% ∆Tsol/% Ref. VO2-hydrogel 62.6 34.7 Zhou et al[40] VO2-Ni-Cl-IL 66.85 23.77 Zhu et al[41] VO2-{[(C2H5)2NH2]2NiBr4@SiO2} 52.9 25.7 Zhao et al[51] VO2-spiropyran 48.58 23.58 Zhao et al[45] VO2@SiO2 61.8 12.6 Qu et al[49] SiO2@TiO2@VO2 73.9 12.0 Yao et al[48] VO2-[1, 4-bis (benzoxazol-2-yl) naphthalene] 73.0 9.0 Qin et al[52] VO2-PDA 56.23 7.64 Wang et al[53] Notes: A-B is the mixture of A and B; Ni-Cl-IL is the ionic liquid-nickel-chlorine complexes. 表 3 VO2多层结构复合薄膜的光学性能

Table 3 Optical properties of VO2 multilayer composite films

Structure Tlum/% ∆Tsol/% Ref. Double-layer ZnO-VO2 46.4 6.0 Gagaoudakis et al[82] VO2-TiO2 61.5 15.1 Chen et al[61] TiO2-VO2 50.49 20.11 Wu et al[74] TiO2-VO2 47.3 8.8 Ji et al[83] VO2-HfO2 55.8 15.9 Chang et al[81] VO2-C₈H20O₄Si 52.7 16.4 Liu et al[84] TiO2-VO2 49.0 7.0 Jin et al[72] Three-layer SiNx-VO2-SiNx 40.4 14.5 Long et al[85] Cr2O3-VO2-SiO2 50.0 16.1 Chang et al[86] TiO2-VO2-TiO2 57.6 2.9 Jin et al[69] Multi-layer VO2-fluorescent brightener-organic polymer 78.87 7.34 Gao et al[87] SiNx-NiCrOx-SiNx-VOx-SiNx-NiCrOx-SiNx 40.5 18.4 Zhan et al[88] TiO2-VO2-TiO2-VO2-TiO2 45 12.1 Mlyuka et al[89] HSi-VO2-FSi-P 54.0 16.4 Yao et al[80] Notes: A-B is the multi-layer structure of the lower layer (A) and the upper layer (B); HSi is the antireflective hollow SiO2 layer; FSi is the protective fluorosilane SiO2 layer; P is the antifogging cross-linked poly(vinyl alcohol) and poly(acrylic acid)layer. -

[1] WARWICK M E A, BINIONS R. Advances in thermochromic vanadium dioxide films[J]. Journal of Materials Chemistry A, 2014, 2(10): 3275-3292. DOI: 10.1039/C3TA14124A

[2] MANJAKKAL L, PEREIRA L, BARIMAH E K, et al. Multifunctional flexible and stretchable electrochromic energy storage devices[J]. Progress in Materials Science, 2024, 142: 101244.

[3] MA D, YANG T, FENG X, et al. Quadruple control electrochromic devices utilizing Ce4W9O33 electrodes for visible and near-infrared transmission intelligent modulation[J]. Advanced Science, 2024, 11(14): 2307223.

[4] WANG J, WANG Z, ZHANG M, et al. A semi-solid, polychromatic dual-band electrochromic smart window: Visualizing sunlight and solar heat transmission[J]. Chemical Engineering Journal, 2024, 484: 149628.

[5] ZHANG Z, MO H, LI R, et al. The counterbalancing role of oxygen vacancy between the electrochromic properties and the trapping effect passivation for amorphous tungsten oxide films[J]. Small Science, 2024, 4(3): 2300219.

[6] ZHAO X, SUN J, GUO Z, et al. One-step hydrothermal synthesis of monoclinic vanadium dioxide nanoparticles with low phase transition temperature[J]. Chemical Engineering Journal, 2022, 446: 137308. DOI: 10.1016/j.cej.2022.137308

[7] ZHANG Z, ZHANG L, ZHOU Y, et al. Thermochromic energy efficient windows: Fundamentals, recent advances, and perspectives[J]. Chemical Reviews, 2023, 123(11): 7025-7080. DOI: 10.1021/acs.chemrev.2c00762

[8] LA M, ZHOU H, LI N, et al. Improved performance of Mg-Y alloy thin film switchable mirrors after coating with a superhydrophobic surface[J]. Applied Surface Science, 2017, 403: 23-28. DOI: 10.1016/j.apsusc.2017.01.106

[9] WITTWER V, DATZ M, ELL J, et al. Gasochromic windows[J]. Solar Energy Materials and Solar Cells, 2004, 84(1-4): 305-314. DOI: 10.1016/j.solmat.2004.01.040

[10] LI N, LI Y, LI W, et al. One-step hydrothermal synthesis of TiO2@MoO3 core-shell nanomaterial: Microstructure, growth mechanism, and improved photochromic property[J]. The Journal of Physical Chemistry C, 2016, 120(6): 3341-3349. DOI: 10.1021/acs.jpcc.5b10752

[11] LI N, LI Y, ZHOU Y, et al. Interfacial-charge-transfer-induced photochromism of MoO3@TiO2 crystalline-core amorphous-shell nanorods[J]. Solar Energy Materials and Solar Cells, 2017, 160: 116-125. DOI: 10.1016/j.solmat.2016.10.016

[12] WANG S, FAN W, LIU Z, et al. Advances on tungsten oxide based photochromic materials: Strategies to improve their photochromic properties[J]. Journal of Materials Chemistry C, 2018, 6(2): 191-212. DOI: 10.1039/C7TC04189F

[13] GU J, WEI H, ZHAO T, et al. Unprecedented spatial manipulation and transformation of dynamic thermal radiation based on vanadium dioxide[J]. ACS Applied Materials & Interfaces, 2024, 16: 10352-10360.

[14] WEI H, YAN X, GU J, et al. A universal approach to fabricating infrared-shielding smart coatings based on vanadium dioxide[J]. Solar Energy Materials and Solar Cells, 2022, 241: 111728. DOI: 10.1016/j.solmat.2022.111728

[15] WANG S, LIU M, KONG L, et al. Recent progress in VO2 smart coatings: Strategies to improve the thermochromic properties[J]. Progress in Materials Science, 2016, 81: 1-54. DOI: 10.1016/j.pmatsci.2016.03.001

[16] GOODENOUGH J B. The two components of the crystallographic transition in VO2[J]. Journal of Solid State Chemistry, 1971, 3(4): 490-500. DOI: 10.1016/0022-4596(71)90091-0

[17] CHANG T, CAO X, LONG Y, et al. How to properly evaluate and compare the thermochromic performance of VO2-based smart coatings[J]. Journal of Materials Chemistry A, 2019, 7(42): 24164-24172. DOI: 10.1039/C9TA06681K

[18] POPURI S R, MICLAU M, ARTEMENKO A, et al. Rapid hydrothermal synthesis of VO2(B) and its conversion to thermochromic VO2(M1)[J]. Inorganic Chemistry, 2013, 52(9): 4780-4785.

[19] WANG C, XU H, WANG C, et al. Preparation of VO2(M) nanoparticles with exemplary optical performance from VO2(B) nanobelts by ball milling[J]. Journal of Alloys and Compounds, 2021, 877: 159888.

[20] 钟莉, 李明, 李广海. D相二氧化钒纳米星粉体及其制备方法: 中国专利, CN104402050B [P]. 2016-02-10. ZHONG Li, LI Ming, LI Guanghai. D-phase vanadium dioxide nano-star powder and preparation method: Chinese patent, CN 104402050B[P]. 2016-02-10(in Chinese).

[21] 李登兵, 李明, 潘静, 等. 单分散的M相二氧化钒纳米颗粒的制备方法: 中国专利, CN104071843A [P]. 2014-10-01. LI Dengbing, LI Ming, PAN Jing, et al. Preparation method of monodisperse M phase vanadium dioxide nanoparticles: Chinese patent, CN104071843A[P]. 2014-10-01(in Chinese).

[22] CAO C, GAO Y, LUO H. Pure single-crystal rutile vanadium dioxide powders: Synthesis, mechanism and phase-transformation property[J]. The Journal of Physical Chemistry C, 2008, 112(48): 18810-18814. DOI: 10.1021/jp8073688

[23] ALIE D, GEDVILAS L, WANG Z, et al. Direct synthesis of thermochromic VO2 through hydrothermal reaction[J]. Journal of Solid State Chemistry, 2014, 212: 237-241. DOI: 10.1016/j.jssc.2013.10.023

[24] LI Y, JI S, GAO Y, et al. Core-shell VO2@TiO2 nanorods that combine thermochromic and photocatalytic properties for application as energy-saving smart coatings[J]. Scientific Reports, 2013, 3(1): 1370. DOI: 10.1038/srep01370

[25] ZHOU Y, JI S, LI Y, et al. Microemulsion-based synthesis of V1− xW xO2@SiO2 core-shell structures for smart window applications[J]. Journal of Materials Chemistry C, 2014, 2(19): 3812-3819. DOI: 10.1039/C3TC32282C

[26] LI W, JI S, QIAN K, et al. Preparation and characterization of VO2(M)-SnO2 thermochromic films for application as energy-saving smart coatings[J]. Journal of Colloid and Interface Science, 2015, 456: 166-173. DOI: 10.1016/j.jcis.2015.06.013

[27] CHEN Y, ZENG X, ZHU J, et al. High performance and enhanced durability of thermochromic films using VO2@ZnO core-shell nanoparticles[J]. ACS Applied Materials & Interfaces, 2017, 9(33): 27784-27791.

[28] LI Y, JI S, GAO Y, et al. Modification of mott phase transition characteristics in VO2@TiO2 core/shell nanostructures by misfit-strained heteroepitaxy[J]. ACS Applied Materials & Interfaces, 2013, 5(14): 6603-6614.

[29] XIE Y M, ZHAO X P, MOFID S A, et al. Influence of shell materials on the optical performance of VO2 core-shell nanoparticle-based thermochromic films[J]. Materials Today Nano, 2021, 13: 100102. DOI: 10.1016/j.mtnano.2020.100102

[30] DU Z, LI M, ZOU F, et al. VO2@SiO2 nanoparticle-based films with localized surface plasmon resonance for smart windows[J]. ACS Applied Nano Materials, 2022, 5: 12972-12979. DOI: 10.1021/acsanm.2c02788

[31] CHEN Y, SHAO Z, YANG Y, et al. Electrons-donating derived dual-resistant crust of VO2 nano-particles via ascorbic acid treatment for highly stable smart windows applications[J]. ACS Applied Materials & Interfaces, 2019, 11(44): 41229-41237.

[32] GUO X, XU H, MA X, et al. Photothermal polydopamine coated VO2 nanoparticle thin film with enhanced optical property and stability[J]. Vacuum, 2022, 196: 110776. DOI: 10.1016/j.vacuum.2021.110776

[33] ZHAO S, TAO Y, CHEN Y, et al. Room-temperature synthesis of inorganic-organic hybrid coated VO2 nanoparticles for enhanced durability and flexible temperature-responsive near-infrared modulator application[J]. ACS Applied Materials & Interfaces, 2019, 11(10): 10254-10261.

[34] ZHU J, ZHOU Y, WANG B, et al. Vanadium dioxide nanoparticle-based thermochromic smart coating: High luminous transmittance, excellent solar regulation efficiency, and near room temperature phase transition[J]. ACS Applied Materials & Interfaces, 2015, 7(50): 27796-27803.

[35] 呼啸, 李文婷, 付勍玮, 等. VO2@PMMA 微胶囊的原位制备及其热致变色涂层性能[J]. 复合材料学报, 2023, 40(8): 4587-4600. HU Xiao, LI Wenting, FU Qingwei, et al. In situ preparation of VO2@PMMA microcapsule and thermochromic properties of its coating[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4587-4600(in Chinese).

[36] ZHAO X, SUN J, MA J, et al. Combining reversible addition-fragmentation chain transfer polymerization and thiolene click reaction for application of core-shell structured VO2@polymer nanoparticles to smart window[J]. Sustainable Materials and Technologies, 2022, 32: e00420. DOI: 10.1016/j.susmat.2022.e00420

[37] LAAKSONEN K, LI S Y, PUISTO S R, et al. Nanoparticles of TiO2 and VO2 in dielectric media: Conditions for low optical scattering, and comparison between effective medium and four-flux theories[J]. Solar Energy Materials and Solar Cells, 2014, 130: 132-137. DOI: 10.1016/j.solmat.2014.06.036

[38] LI S Y, NIKLASSON G A, GRANQVIST C G. Nanothermochromics: Calculations for VO2 nanoparticles in dielectric hosts show much improved luminous transmittance and solar energy transmittance modulation[J]. Journal of Applied Physics, 2010, 108(6): 063525. DOI: 10.1063/1.3487980

[39] ZHOU Y, HUANG A, LI Y, et al. Surface plasmon resonance induced excellent solar control for VO2@SiO2 nanorods-based thermochromic foils[J]. Nanoscale, 2013, 5(19): 9208-9213. DOI: 10.1039/c3nr02221h

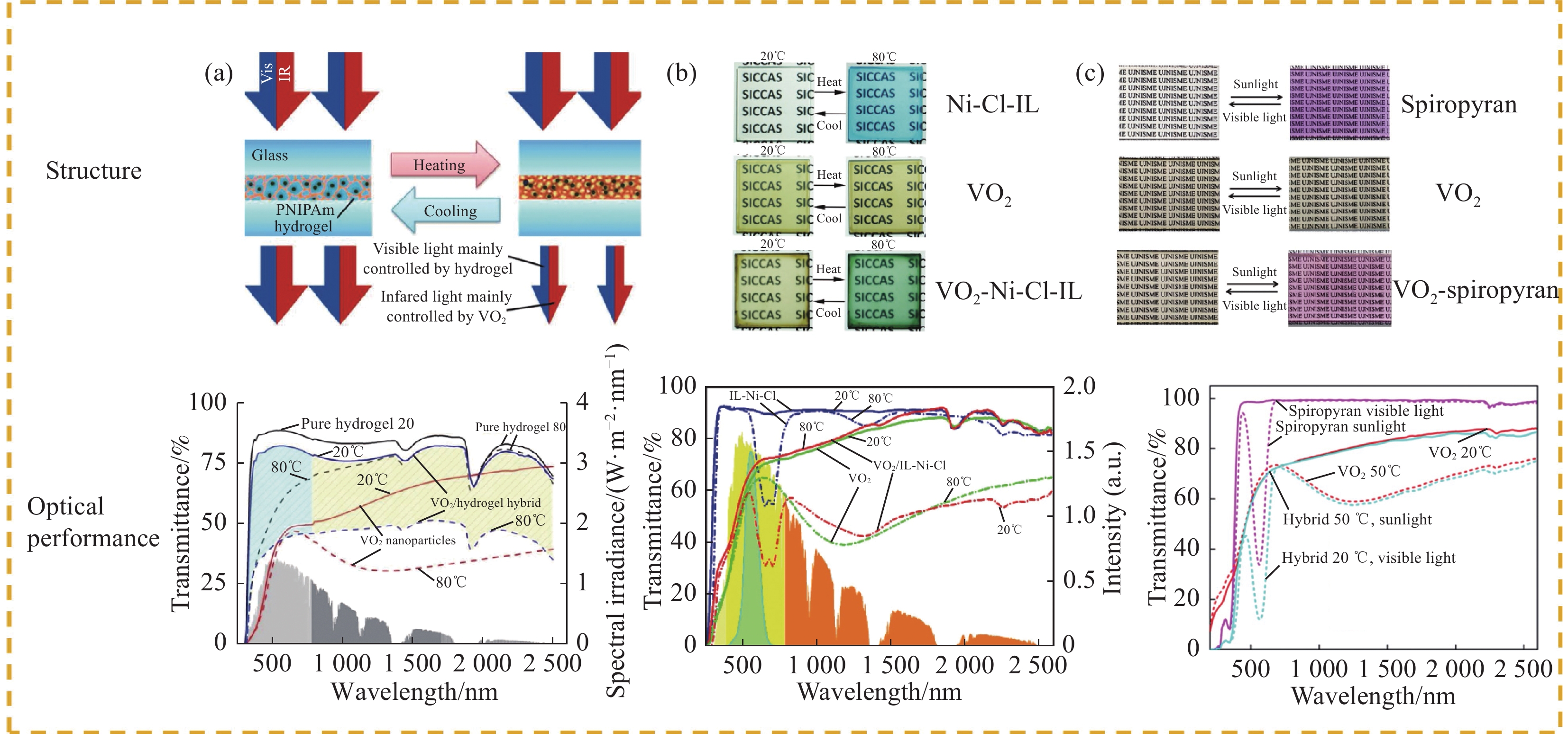

[40] ZHOU Y, CAI Y, HU X, et al. VO2/hydrogel hybrid nanothermochromic material with ultra-high solar modulation and luminous transmission[J]. Journal of Materials Chemistry A, 2015, 3(3): 1121-1126. DOI: 10.1039/C4TA05035E

[41] ZHU J, HUANG A, MA H, et al. Composite film of vanadium dioxide nanoparticles and Ionic liquid-nickel-chlorine complexes with excellent visible thermochromic performance[J]. ACS Applied Materials & Interfaces, 2016, 8(43): 29742-29748.

[42] CHEN Y, ZHU J, MA H, et al. VO2/nickel-bromine-ionic liquid composite film for thermochromic application[J]. Solar Energy Materials and Solar Cells, 2019, 196: 124-130. DOI: 10.1016/j.solmat.2019.03.047

[43] ZHU J, HUANG A, MA H, et al. Solar-thermochromism of a hybrid film of VO2 nanoparticles and Co II-Br-TMP complexes[J]. RSC Advances, 2016, 6(71): 67396-67399. DOI: 10.1039/C6RA14232J

[44] XU F, CAO X, ZHU J, et al. Broadband thermochromic VO2-based composite film with ultra-high solar modulation ability[J]. Materials Letters, 2018, 222: 62-65. DOI: 10.1016/j.matlet.2018.03.176

[45] ZHAO X, HU X, SUN J, et al. VO2-based composite films with exemplary thermochromic and photochromic performance[J]. Journal of Applied Physics, 2020, 128(18): 185107. DOI: 10.1063/5.0015382

[46] CAO X, WANG N, LAW J Y, et al. Nanoporous thermochromic VO2 (M) thin films: Controlled porosity, largely enhanced luminous transmittance and solar modulating ability[J]. Langmuir, 2014, 30(6): 1710-1715. DOI: 10.1021/la404666n

[47] LONG S, CAO X, HUANG R, et al. Self-template synthesis of nanoporous VO2-based films: Localized surface plasmon resonance and enhanced optical performance for solar glazing application[J]. ACS Applied Materials & Interfaces, 2019, 11(25): 22692-22702.

[48] YAO L, QU Z, PANG Z, et al. Three-layered hollow nanospheres based coatings with ultrahigh-performance of energy-saving, antireflection, and self-cleaning for smart windows[J]. Small, 2018, 14(34): 1801661. DOI: 10.1002/smll.201801661

[49] QU Z, YAO L, LI J, et al. Bifunctional template-induced VO2@SiO2 dual-shelled hollow nanosphere-based coatings for smart windows[J]. ACS Applied Materials & Interfaces, 2019, 11(17): 15960-15968.

[50] XU H, GUO X, WANG S, et al. Double in-situ synthesis of highly dispersed VO2-Mg1.5VO4 porous film with excellent optical performance and durability for advanced smart windows[J]. Applied Surface Science, 2023, 622: 156851. DOI: 10.1016/j.apsusc.2023.156851

[51] ZHAO X, YAO W, SUN J, et al. Thermochromic composite film of VO2 nanoparticles and [(C2H5)2NH2]2NiBr4@SiO2 nanospheres for smart window applications[J]. Chemical Engineering Journal, 2023, 460: 141715. DOI: 10.1016/j.cej.2023.141715

[52] 秦成远, 高迎, 王程, 等. 二氧化钒-1, 4-双 (苯并噁唑-2-基) 萘复合薄膜及其热致变色和发光性能[J]. 复合材料学报, 2021, 38(10): 3412-3423. QIN Chengyuan, GAO Ying, WANG Cheng, et al. Vanadium dioxide-1, 4-bis (benzoxazol-2-yl) naphthalene composite films and their thermochromic and photoluminescent property[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3412-3423(in Chinese).

[53] 王彬彬, 高阳, 杨帅军, 等. 二氧化钒-聚二乙炔热致变色复合薄膜及其调光性能[J]. 复合材料学报, 2023, 40(6): 3417-3427. WANG Binbin, GAO Yang, YANG Shuaijun, et al. Vanadium dioxide-polydiacetylene thermochromic composite films and their solar regulation properties[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3417-3427(in Chinese).

[54] GUZMAN G, MORINEAU R, LIVAGE J. Synthesis of vanadium dioxide thin films from vanadium alkoxides[J]. Materials Research Bulletin, 1994, 29(5): 509-515. DOI: 10.1016/0025-5408(94)90039-6

[55] FITZGERALD J V. Anelasticity of glass: II, internal friction and sodium ion diffusion in tank plate glass, a typical soda-lime-silica glass[J]. Journal of the American Ceramic Society, 1951, 34(11): 339-342. DOI: 10.1111/j.1151-2916.1951.tb13481.x

[56] KOO H, YOU H, KO K E, et al. Thermochromic properties of VO2 thin film on SiNx buffered glass substrate[J]. Applied Surface Science, 2013, 277: 237-241. DOI: 10.1016/j.apsusc.2013.04.031

[57] NAGASHIMA K, YANAGIDA T, TANAKA H, et al. Interface effect on metal-insulator transition of strained vanadium dioxide ultrathin films[J]. Journal of Applied Physics, 2007, 101(2): 026103. DOI: 10.1063/1.2424321

[58] ZHANG Z, GAO Y, LUO H, et al. Solution-based fabrication of vanadium dioxide on F: SnO2 substrates with largely enhanced thermochromism and low-emissivity for energy-saving applications[J]. Energy & Environmental Science, 2011, 4(10): 4290-4297.

[59] KANG L, GAO Y, LUO H, et al. Thermochromic properties and low emissivity of ZnO: Al/VO2 double-layered films with a lowered phase transition temperature[J]. Solar Energy Materials and Solar Cells, 2011, 95(12): 3189-3194. DOI: 10.1016/j.solmat.2011.06.047

[60] KANG L, GAO Y, CHEN Z, et al. Pt/VO2 double-layered films combining thermochromic properties with low emissivity[J]. Solar Energy Materials and Solar Cells, 2010, 94(12): 2078-2084. DOI: 10.1016/j.solmat.2010.06.023

[61] CHEN Z, GAO Y, KANG L, et al. VO2-based double-layered films for smart windows: Optical design, all-solution preparation and improved properties[J]. Solar Energy Materials and Solar Cells, 2011, 95(9): 2677-2684. DOI: 10.1016/j.solmat.2011.05.041

[62] ZHU M, QI H, WANG B, et al. Thermochromism of vanadium dioxide films controlled by the thickness of ZnO buffer layer under low substrate temperature[J]. Journal of Alloys and Compounds, 2018, 740: 844-851. DOI: 10.1016/j.jallcom.2018.01.066

[63] GU J, WEI H, REN F, et al. VO2-based infrared radiation regulator with excellent dynamic thermal management performance[J]. ACS Applied Materials & Interfaces, 2022, 14(2): 2683-2690.

[64] REN F, WEI H, GU J, et al. In situ preparation of VO2 films with controlled ionized flux density in hipims and their regulation of thermal radiance[J]. ACS Applied Electronic Materials, 2020, 2(7): 2203-2210. DOI: 10.1021/acsaelm.0c00383

[65] KOO H, XU L, KO K E, et al. Effect of oxide buffer layer on the thermochromic properties of VO2 thin films[J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3967-3973. DOI: 10.1007/s11665-013-0696-7

[66] LONG S, CAO X, SUN G, et al. Effects of V2O3 buffer layers on sputtered VO2 smart windows: Improved thermochromic properties, tunable width of hysteresis loops and enhanced durability[J]. Applied Surface Science, 2018, 441: 764-772. DOI: 10.1016/j.apsusc.2018.02.083

[67] XU G, JIN P, TAZAWA M, et al. Optimization of antireflection coating for VO2-based energy efficient window[J]. Solar Energy Materials and Solar Cells, 2004, 83(1): 29-37. DOI: 10.1016/j.solmat.2004.02.014

[68] KOO H, SHIN D, BAE S H, et al. The effect of CeO2 antireflection layer on the optical properties of thermochromic VO2 film for smart window system[J]. Journal of Materials Engineering and Performance, 2014, 23: 402-407. DOI: 10.1007/s11665-013-0740-7

[69] JIN P, XU G, TAZAWA M, et al. Design, formation and characterization of a novel multifunctional window with VO2 and TiO2 coatings[J]. Applied Physics A: Materials Science & Processing, 2003, 77: 455-459.

[70] CHANG T, CAO X, LI N, et al. Facile and low-temperature fabrication of thermochromic Cr2O3/VO2 smart coatings: Enhanced solar modulation ability, high luminous transmittance and UV-shielding function[J]. ACS Applied Materials & Interfaces, 2017, 9(31): 26029-26037.

[71] LEE M H, CHO J S. Better thermochromic glazing of windows with anti-reflection coating[J]. Thin Solid Films, 2000, 365(1): 5-6. DOI: 10.1016/S0040-6090(99)01112-8

[72] JIN P, XU G, TAZAWA M, et al. A VO2-based multifunctional window with highly improved luminous transmittance: Surfaces, interfaces, and films[J]. Japanese Journal of Applied Physics, 2002, 41(3): L278-L280.

[73] SAITZEK S, GUINNETON F, SAUQUES L, et al. Thermochromic CeO2-VO2 bilayers: Role of ceria coating in optical switching properties[J]. Optical Materials, 2007, 30(3): 407-415. DOI: 10.1016/j.optmat.2006.11.067

[74] WU W, WANG C, CHEN C, et al. Design of antireflection and enhanced thermochromic properties of TiO2/VO2 thin films[J]. Advanced Materials Interfaces, 2023, 10(15): 2202506. DOI: 10.1002/admi.202202506

[75] DOU S, WANG Y, ZHANG X, et al. Facile preparation of double-sided VO2 (M) films with micro-structure and enhanced thermochromic performances[J]. Solar Energy Materials and Solar Cells, 2017, 160: 164-173. DOI: 10.1016/j.solmat.2016.10.025

[76] DOU S, ZHAO J, ZHANG W, et al. A universal approach to achieve high luminous transmittance and solar modulating ability simultaneously for vanadium dioxide smart coatings via double-sided localized surface plasmon resonances[J]. ACS Applied Materials & Interfaces, 2020, 12(6): 7302-7309.

[77] XU F, CAO X, SHAO Z, et al. Highly enhanced thermochromic performance of VO2 film using "movable" antireflective coatings[J]. ACS Applied Materials & Interfaces, 2019, 11(5): 4712-4718.

[78] POWELL M J, QUESADA-CABRERA R, TAYLOR A, et al. Intelligent multifunctional VO2/SiO2/TiO2 coatings for self-cleaning, energy-saving window panels[J]. Chemistry of Materials, 2016, 28(5): 1369-1376. DOI: 10.1021/acs.chemmater.5b04419

[79] ZHENG J, BAO S, JIN P. TiO2(R)/VO2(M)/TiO2(A) multilayer film as smart window: Combination of energy-saving, antifogging and self-cleaning functions[J]. Nano Energy, 2015, 11: 136-145. DOI: 10.1016/j.nanoen.2014.09.023

[80] YAO L, QU Z, SUN R, et al. Long-lived multilayer coatings for smart windows: Integration of energy-saving, antifogging, and self-healing functions[J]. ACS Applied Energy Materials, 2019, 2(10): 7467-7473. DOI: 10.1021/acsaem.9b01382

[81] CHANG T, CAO X, LI N, et al. Mitigating deterioration of vanadium dioxide thermochromic films by interfacial encapsulation[J]. Matter, 2019, 1(3): 734-744. DOI: 10.1016/j.matt.2019.04.004

[82] GAGAOUDAKIS E, APERATHITIS E, MICHAIL G, et al. Low-temperature RF sputtered VO2 thin films as thermochromic coatings for smart glazing systems[J]. Solar Energy, 2018, 165: 115-121. DOI: 10.1016/j.solener.2018.03.010

[83] JI Y, MATTSSON A, NIKLASSON G A, et al. Synergistic TiO2/VO2 window coating with thermochromism, enhanced luminous transmittance, and photocatalytic activity[J]. Joule, 2019, 3(10): 2457-2471. DOI: 10.1016/j.joule.2019.06.024

[84] LIU C, WANG S, ZHOU Y, et al. Index-tunable anti-reflection coatings: Maximizing solar modulation ability for vanadium dioxide-based smart thermochromic glazing[J]. Journal of Alloys and Compounds, 2018, 731: 1197-1207. DOI: 10.1016/j.jallcom.2017.10.045

[85] LONG S, CAO X, LI N, et al. Application-oriented VO2 thermochromic coatings with composite structures: Optimized optical performance and robust fatigue properties[J]. Solar Energy Materials and Solar Cells, 2019, 190: 138-148.

[86] CHANG T, CAO X, DEDON L R, et al. Optical design and stability study for ultrahigh-performance and long-lived vanadium dioxide-based thermochromic coatings[J]. Nano Energy, 2018, 44: 256-264. DOI: 10.1016/j.nanoen.2017.11.061

[87] 高迎, 秦成远, 聂永, 等. 二氧化钒-荧光增白剂-有机聚合物三层多功能复合薄膜[J]. 复合材料学报, 2022, 39(8): 3828-3844. GAO Ying, QIN Chengyuan, NIE Yong, et al. Three-layer multifunctional vanadium dioxide-fluorescent brightener-organic polymer composite films[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3828-3844(in Chinese).

[88] ZHAN Y, LU Y, XIAO X, et al. Tuning thermochromic performance of VO x-based multilayer films by controlling annealing pressure[J]. Ceramics International, 2020, 46(2): 2079-2085. DOI: 10.1016/j.ceramint.2019.09.188

[89] MLYUKA N R, NIKLASSON G A, GRANQVIST C G. Thermochromic multilayer films of VO2 and TiO2 with enhanced transmittance[J]. Solar Energy Materials and Solar Cells, 2009, 93(9): 1685-1687. DOI: 10.1016/j.solmat.2009.03.021

-

目的

近年来,关于VO的制备方法、相变机制以及改善热致变色性能的研究取得了显著进展。然而,在实际应用中,VO仍面临一系列挑战,包括较高的本征相变温度()、较低的可见光透过率()、不尽人意的太阳能调制能力()、较差的耐候性以及不美观的棕黄色外观。针对这些问题,国内外研究者开展了大量研究,发现复合结构能够显著改善VO的性能。然而,目前关于VO基复合结构薄膜的综述相对较少。因此,迫切需要对这一领域的最新研究进展进行全面综述。

方法本文综述了VO基复合结构薄膜的制备方法及性能提升策略的研究进展,并最后对智能窗用VO基复合结构薄膜未来的发展方向进行了展望。①本文阐述了VO基智能窗的性能评价指标;②总结了VO纳米颗粒基复合结构的制备方法及其性能提升策略,包括核壳结构和基质材料,核壳结构涵盖无机、有机及无机-有机外壳材料,基质材料则包括变色基质及具有不同微纳结构的基质;③总结了多层结构的制备方法及其性能提升策略,包括缓冲层、减反射层和多功能层;④展望了智能窗用VO基复合结构薄膜的发展前景。

结果通过调节壳层结构、改变VO纳米颗粒的分散基质以及设计多层结构等方式,可以制备具有优异热致变色性能的VO基复合薄膜。①通过将VO纳米颗粒与无机或有机材料形成核壳结构,复合薄膜可获得卓越的热致变色性能和稳定性;②选择有机热致变色材料作为基质的复合薄膜展现了丰富的颜色,而以多孔材料作为基质的复合薄膜则具备减反射效果和高度分散性的VO纳米颗粒,表现出优异的光学性能;③多层结构的设计不仅有助于改善复合薄膜的光学性能,还能赋予其自清洁和防雾等附加功能。

结论随着能源日益枯竭和环境污染问题的日益严峻,迫切需求采取节能减排措施。热致变色智能窗可根据环境温度的变化自动调整太阳光透过率,无能源消耗,因此成为当前研究的焦点。VO基热致变色智能窗的主要研究方向是光学性能和环境耐久性。然而,为了满足实际应用的需求,需要确保各项指标达到应用标准。复合结构在同时改善VO光学性能和稳定性方面优势显著,但现有的VO复合结构较为简单,限制了其综合性能的提升。因此,有必要探索新的制备方法以丰富复合结构,进一步改善VO的综合性能,促进其在智能窗等节能领域的实际应用。

-

近年来,关于VO2 制备方法、相变机制以及改善热致变色性能的研究取得了显著进展。然而,在实际应用中,VO2仍面临一系列挑战,包括本征相变温度较高、可见光透过率(Tlum)较低、太阳能调节效率(∆Tsol)不够高、耐候性不佳,以及呈现棕黄色的颜色舒适度较差。针对这些问题,国内外的研究者进行了大量研究,发现复合结构可以显著改善VO2的性能,因此迫切需要对这一领域的最新研究进展进行综述。围绕“智能窗用二氧化钒基复合结构薄膜的制备及研究进展”这一主题,本文涵盖四部分内容:(1)阐述了二氧化钒基智能窗的性能评价指标;(2)总结了二氧化钒纳米颗粒基复合结构的制备方法及其性能提升策略,其中包括核壳结构和二氧化钒纳米颗粒基质材料;(3)总结了多层结构的制备方法及其性能提升策略,其中包括缓冲层,减反射层和多功能层;(4)对智能窗用二氧化钒基复合结构薄膜的发展前景进行了展望。

下载:

下载: